A kind of flame-retardant steel cord conveyor belt core glue and preparation method thereof

A technology for steel cord cores and conveyor belts, applied in adhesives, epoxy resin glue, chloroprene adhesives, etc., which can solve the problems of poor dynamic fatigue resistance, easy aging and reduction, and decreased bonding strength of core rubber and steel cords , to achieve good physical and mechanical properties, prolong service life and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

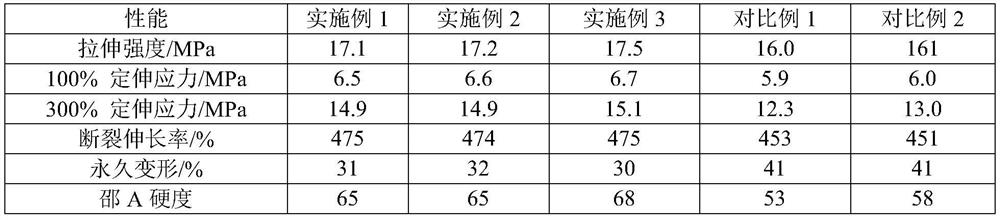

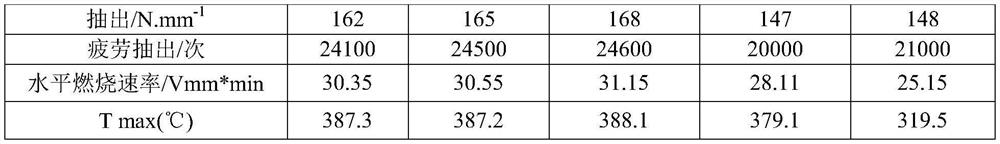

Examples

Embodiment 1

[0028] A flame-retardant steel cord conveyor belt core rubber, which is composed of the following raw materials in parts by weight: 80 parts of neoprene rubber, 30 parts of silicone rubber, 8 parts of polyfluorosiloxane-polyvinyl fluoride block copolymer, polysilicon boron 6 parts of oxane, 10 parts of flame retardant, 25 parts of reinforcing agent coumarone resin, 25 parts of modified kaolin filler, 3 parts of sulfur, 0.5 parts of accelerator CZ, 15 parts of chlorinated paraffin, 1 part of anti-aging agent NBC , 5 parts of epoxy resin adhesive and 1 part of silane coupling agent.

[0029] The preparation process of the polysiloxane is as follows: Weigh 100 parts by weight of ethoxylated silicone oil, add it to a flask, add 25 parts by weight of boric acid, stir at 60°C until the boric acid dissolves, stop stirring, and heat up to 120°C. Ethanol was distilled off and kept warm for 2 hours.

[0030] The synthesis of polyfluorosiloxane-polyvinyl fluoride block copolymer compris...

Embodiment 2

[0039] A flame-retardant steel cord conveyor belt core rubber, which is composed of the following raw materials in parts by weight: 100 parts of neoprene rubber, 40 parts of silicone rubber, 10 parts of polyfluorosiloxane-polyvinyl fluoride block copolymer, polysilicon boron 10 parts of oxane, 20 parts of flame retardant, 35 parts of reinforcing agent coumarone resin, 35 parts of filler modified kaolin, 5 parts of sulfur, 2.5 parts of accelerator CZ, 25 parts of chlorinated paraffin, 4 parts of anti-aging agent NBC parts, 15 parts of epoxy resin adhesive and 3 parts of silane coupling agent.

[0040] The preparation process of the polysiloxane and the synthesis of the polyfluorosiloxane-polyvinyl fluoride block copolymer are shown in Example 1.

[0041] For the preparation method of the core rubber of the flame-retardant steel cord conveyor belt, see Example 1.

Embodiment 3

[0043] A flame-retardant steel cord conveyor belt core rubber, which is composed of the following raw materials in parts by weight: 90 parts of neoprene rubber, 35 parts of silicone rubber, 9 parts of polyfluorosiloxane-polyvinyl fluoride block copolymer, polysilicon boron 8 parts of oxane, 15 parts of flame retardant, 30 parts of reinforcing agent coumarone resin, 30 parts of filler modified kaolin, 4 parts of sulfur, 1.5 parts of accelerator CZ, 20 parts of chlorinated paraffin, anti-aging agent NBC2. 5 parts, 10 parts of epoxy resin adhesive and 2 parts of silane coupling agent.

[0044] The preparation process of the polysiloxane and the synthesis of the polyfluorosiloxane-polyvinyl fluoride block copolymer are shown in Example 1.

[0045] See Example 1 for the preparation method of the core rubber of the flame-retardant steel cord conveyor belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com