Integrated device and process for solar cell film coating and light injection

A technology for solar cells and integrated equipment, applied in the field of solar cells, can solve problems such as the decrease in the bonding strength between silver wires and silicon chips, the adverse effects of cell yields, and the increase in battery manufacturing costs, and solve the problems of reduced bonding strength, Easy optimization of curing conditions and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

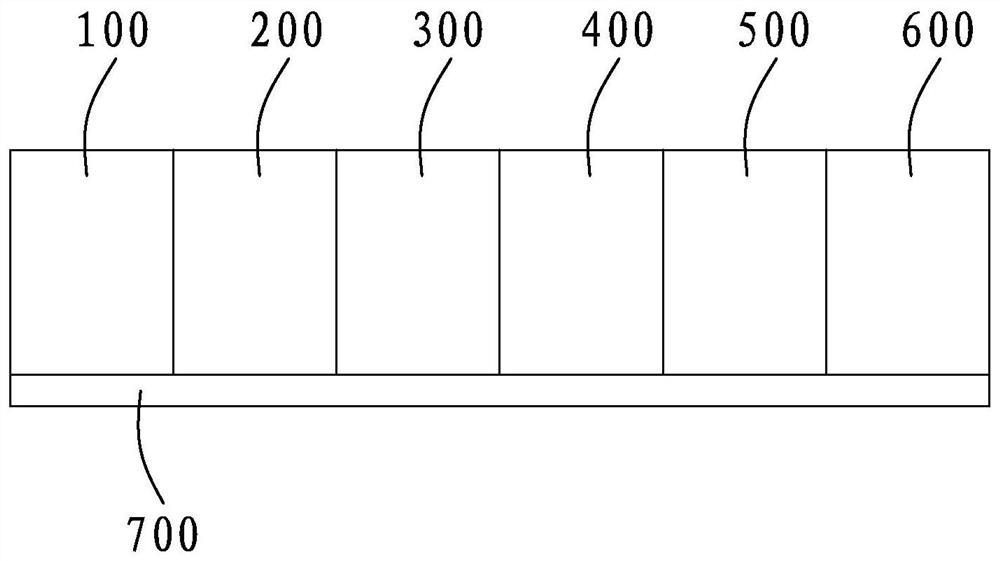

[0036] refer to figure 1 , the present invention provides an integrated device for solar cell film coating and light injection, including a TCO coating chamber 300 and a light injection annealing chamber 400 arranged in sequence, corresponding to the chain transmission of the TCO coating chamber 300 and the light injection annealing chamber 400 The conveying mechanism, and the carrier plate used for carrying silicon wafers that are arranged on the conveying mechanism in a flat manner; the feed end of the TCO coating chamber 300 is also provided with a loading vacuum chamber 200, and the discharge end of the light injection annealing chamber 400 is also provided with There is an unloading vacuum chamber 500; the feeding end of the loading vacuum chamber 200 is also provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com