Steel-plastics composite pressure pipe and its production method

A steel-plastic composite and pressure pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve problems such as loss of protective effect of plastic layer, low-price oxidation of steel pipe surface, influence of pipe body pressure bearing capacity, etc. To achieve the effect of good economic benefits, low price and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

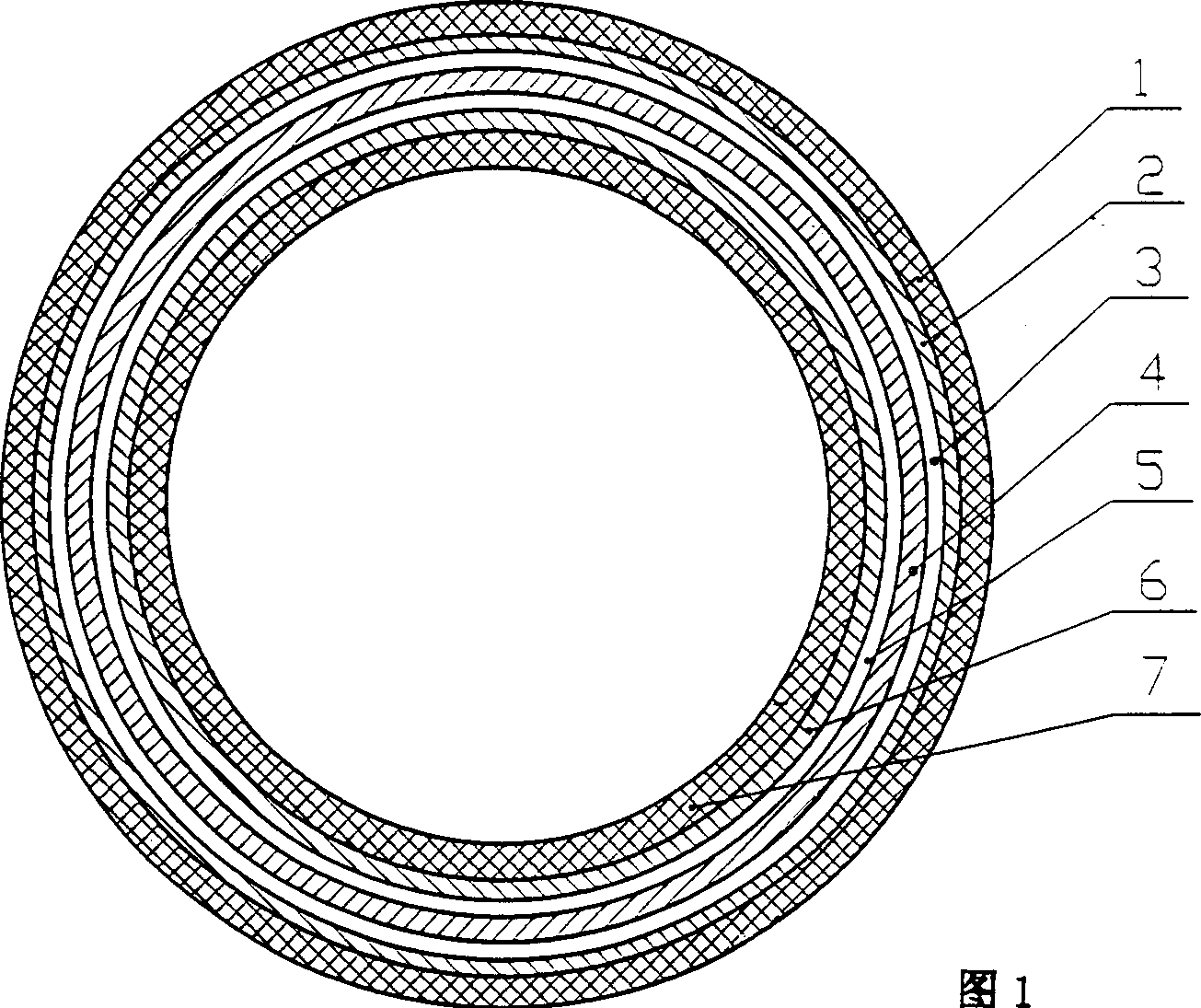

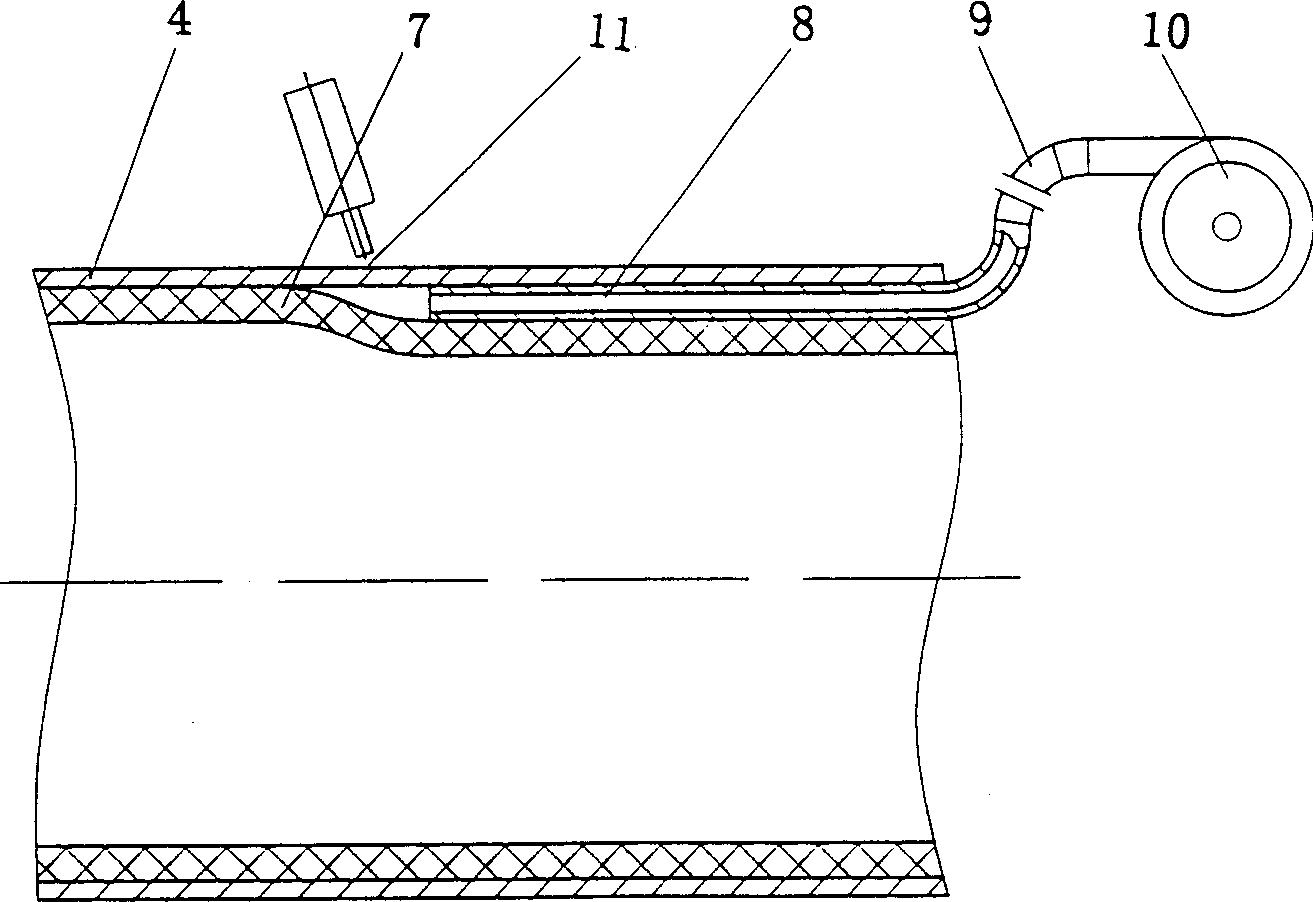

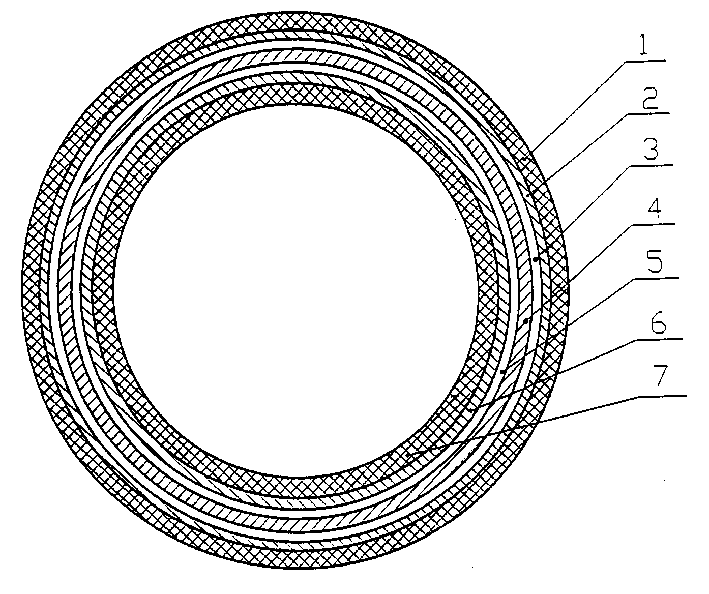

[0035] Referring to Fig. 1, the steel-plastic composite pressure pipe of the present invention comprises an outer plastic layer 1, an outer rubber layer 2, an inner rubber layer 6 and an inner plastic layer 7, and both sides are coated with Galvanized or aluminized steel strip of zinc or aluminum4. In this way, the steel-plastic composite pressure pipe of the present invention has seven layers, namely, the outer plastic layer 1, the outer rubber layer 2, the outer zinc layer or aluminum layer 3, the steel strip layer 4, the inner zinc layer or aluminum layer 5, the inner Adhesive layer 6 and inner plastic layer 7. Due to the steel layer 4, the pressure resistance is high, and because the steel layer 4 has an inner zinc layer or aluminum layer 5 and an outer zinc layer or aluminum layer 4, it has an excellent anti-corrosion effect in a weak oxidizing atmosphere.

[0036] The galvanized or aluminized steel strip 4 can be made from a galvanized or aluminized steel sheet purchase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com