Anti-deformation double-layer composite floor

A composite, anti-deformation technology, applied to floors, flat products, and other household appliances, can solve the problems of glue opening and deformation, damage to the ecological environment, and high production costs, so as to reduce usage, protect the ecological environment, and increase The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

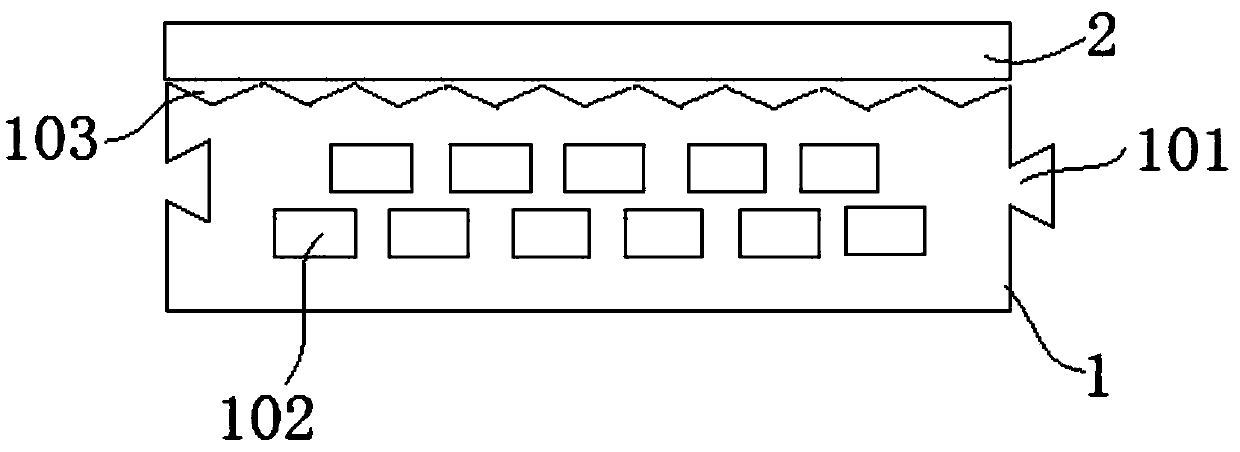

[0039] combine figure 1, the anti-deformation double-layer composite floor of this embodiment is formed by bonding the panel 2 of the upper layer and the substrate 1 of the lower layer. The panel 2 is a solid wood board, and the substrate 1 is a PVC stone-plastic board. The upper surface of the panel 2 is covered with a paint layer, and the paint layer plays the role of protection and decoration. The thickness of the substrate 1 is greater than that of the panel 2 . The upper surface of the substrate 1 is provided with a substrate glue storage tank 103 along the length direction. The substrate glue storage groove 103 is a groove with a V-shaped cross section. The substrate glue storage grooves 103 are adjacently arranged continuously along the width direction of the substrate 1. The two edges along the length direction of the substrate 1 are symmetrically provided with mutually inserted notches and convex structures 101, and the two edges of the substrate 1 along the width d...

Embodiment 2

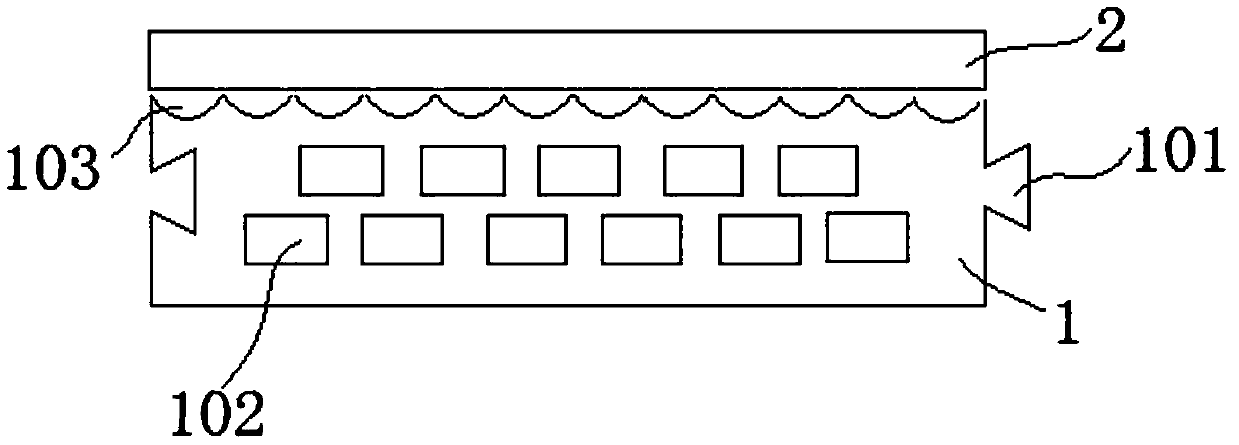

[0048] combine figure 2 , the anti-deformation double-layer composite floor of this embodiment is formed by bonding the panel 2 of the upper layer and the substrate 1 of the lower layer. The panel 2 is a solid wood board, and the substrate 1 is a PVC stone-plastic board. The upper surface of the panel 2 is covered with a painted layer. The thickness of the substrate 1 is greater than that of the panel 2 . The upper surface of the substrate 1 is provided with a substrate glue storage tank 103 along the length direction. The substrate glue storage groove 103 is a groove with an arc-shaped cross section. The substrate glue storage grooves 103 are adjacently arranged continuously along the width direction of the substrate 1. The two edges along the length direction of the substrate 1 are symmetrically provided with mutually inserted notches and convex structures 101, and the two edges of the substrate 1 along the width direction are also symmetrically provided with mutually ins...

Embodiment 3

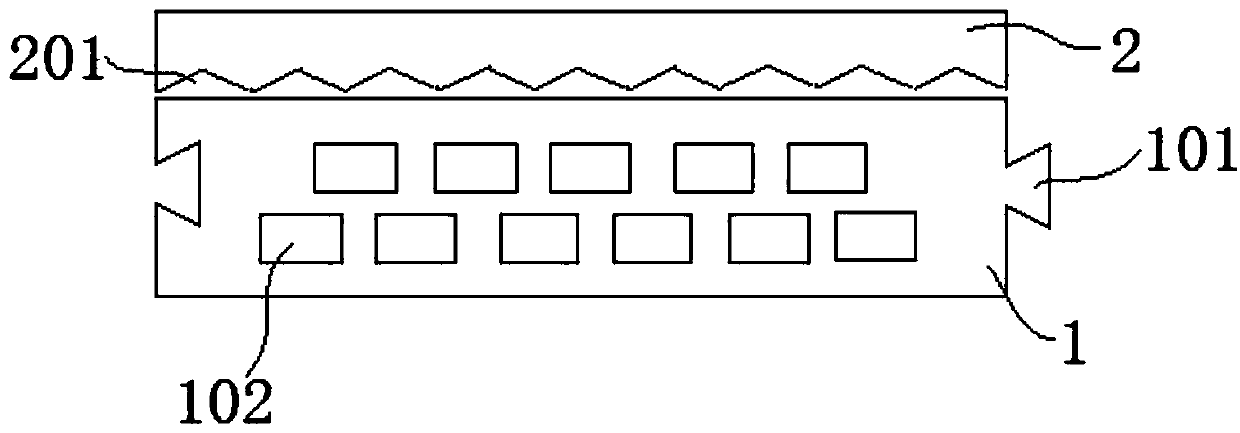

[0050] combine image 3 , the anti-deformation double-layer composite floor of this embodiment is formed by bonding the panel 2 of the upper layer and the substrate 1 of the lower layer. The panel 2 is a solid wood board, and the substrate 1 is a PVC stone-plastic board. The upper surface of the panel 2 is covered with a painted layer. The thickness of the substrate 1 is greater than that of the panel 2 . The lower surface of the panel 2 is provided with a panel glue storage tank 201 along the length direction. The panel glue storage tank 201 is a groove with a V-shaped cross section. The two edges along the length direction of the substrate 1 are symmetrically provided with mutually inserted notches and convex structures 101, and the two edges of the substrate 1 along the width direction are also symmetrically provided with mutually inserted concave and convex structures 101. The recess and protrusion structure 101 in the embodiment is a dovetail groove and a trapezoidal b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com