Energy-saving wood board conveying device

A technology of transportation device and plank, which is applied in the direction of vehicles used to carry long goods, which can solve the problems of laborious pulling of planks, poor energy saving, complicated operation, etc., and achieve the effect of easy unloading and avoiding the effect of too small stress area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

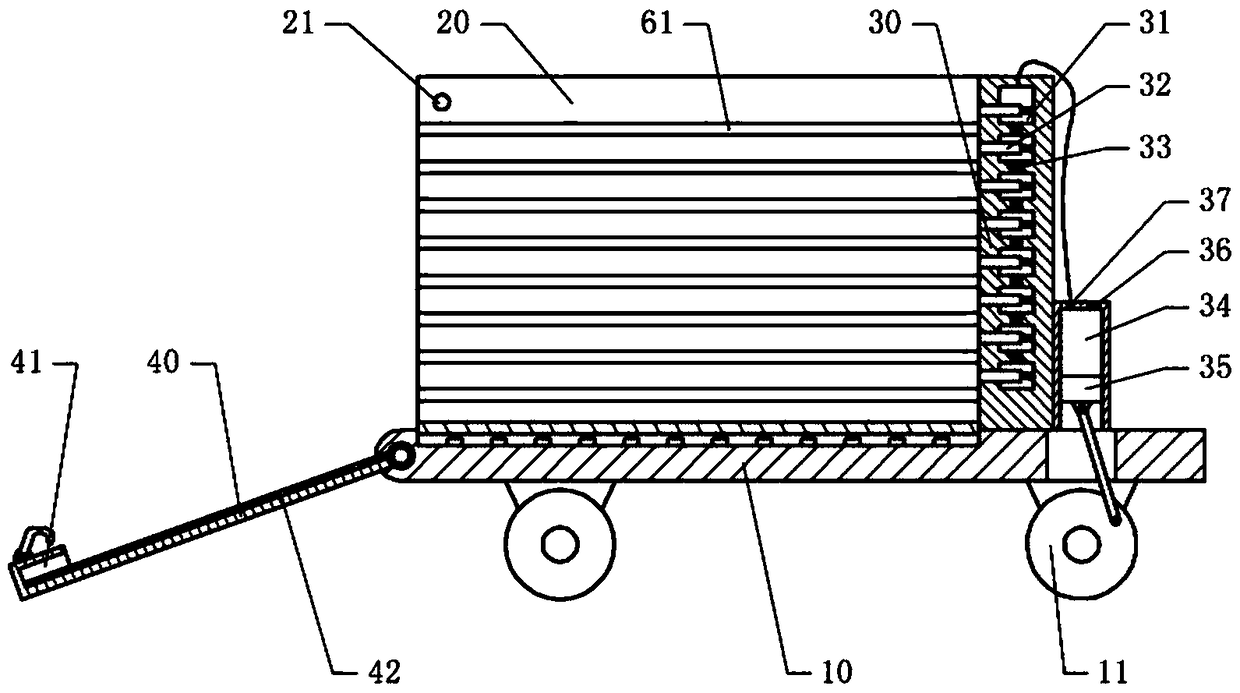

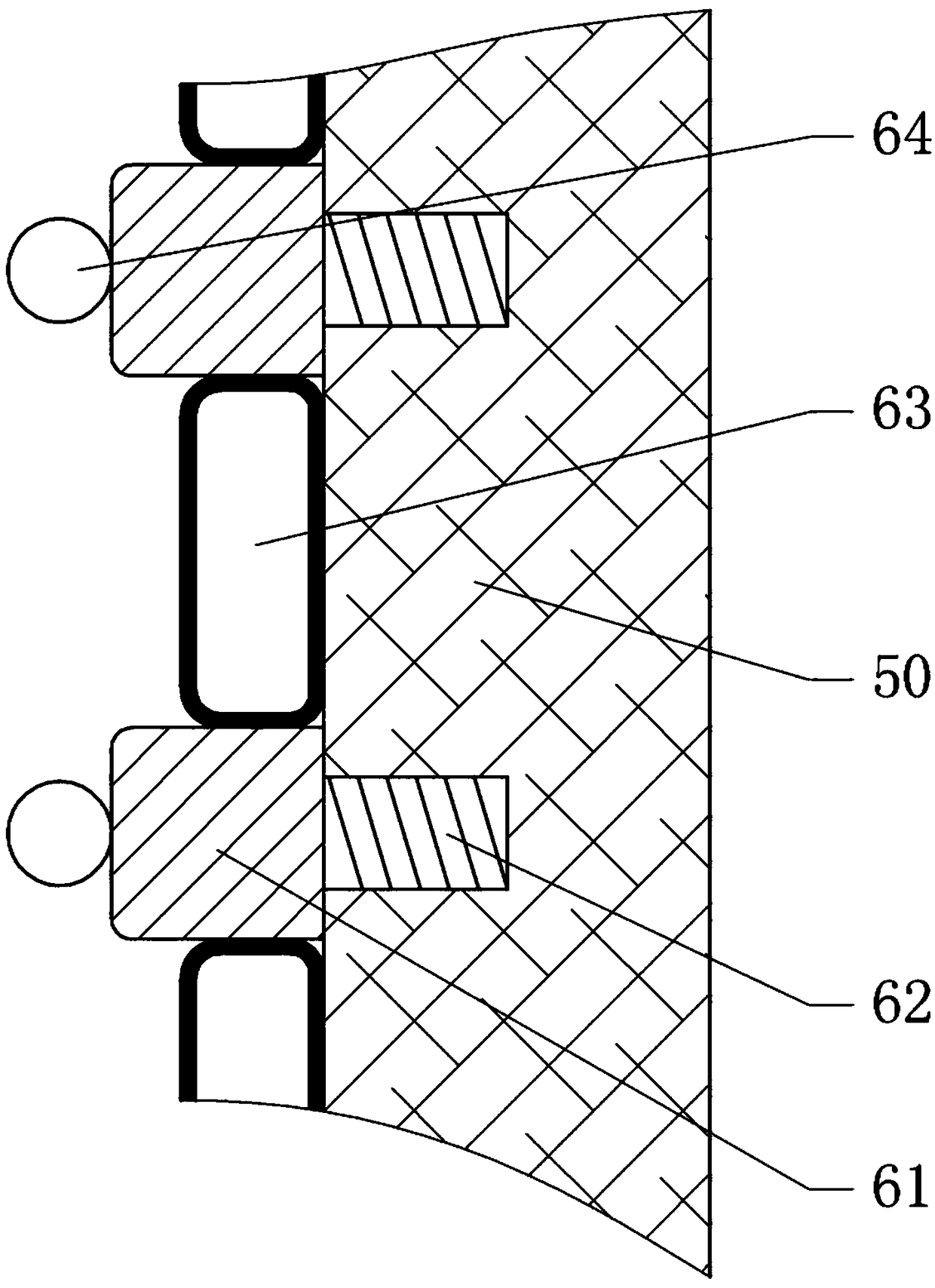

[0022] The reference signs in the drawings of the description include: bottom plate 10, transport wheel 11, left side wall 20, cross bar 21, front side wall 30, air chamber unit 31, push rod 32, one-way valve 33, cylinder body 34, piston 35. Air intake check valve 36, air outlet check valve 37, rear side plate 40, collecting tank 41, groove 42, right side wall 50, rib 61, electromagnet 62, air bag 63, steel ball 64.

[0023] The embodiment is basically as figure 1 , figure 2 Shown:

[0024] The energy-saving plank transport device of this embodiment comprises a plank transport box, a rotating shaft fixed at the bottom of the plank transport box and transport wheels 11 rotatably connected to both ends of the shaft; the front end of the plank transport box is provided with a connecting portion for connecting the plank transport box On the trailer, so that the wooden tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com