Synthesized easily guiding mould worktable

A workbench and mold technology, which is applied to workbenches, manufacturing tools, workshop equipment, etc., can solve the problems of heavy molds, waste of time, waste of manpower, etc., and achieve the effect of good conductivity, convenient use, and easy access to molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

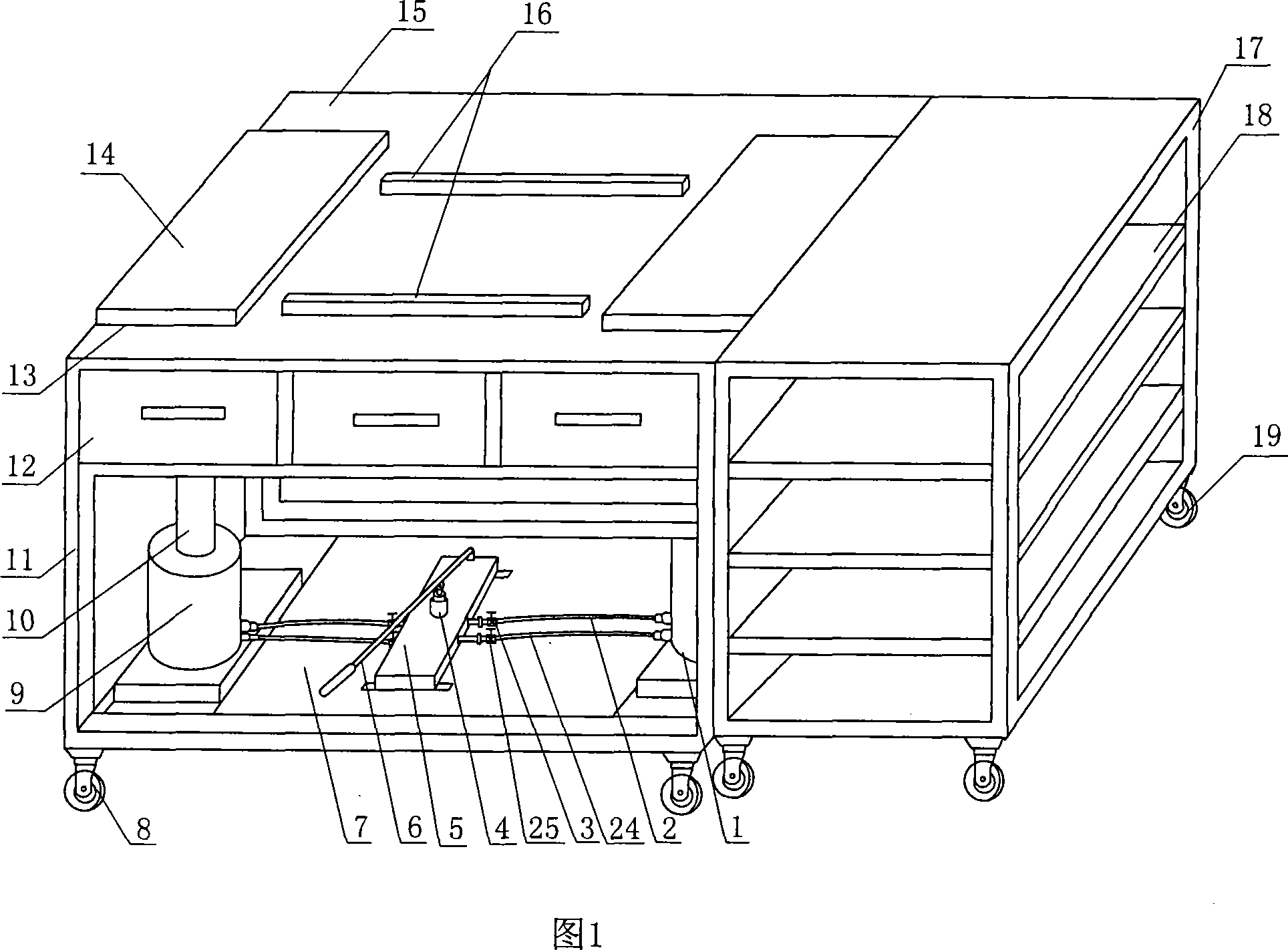

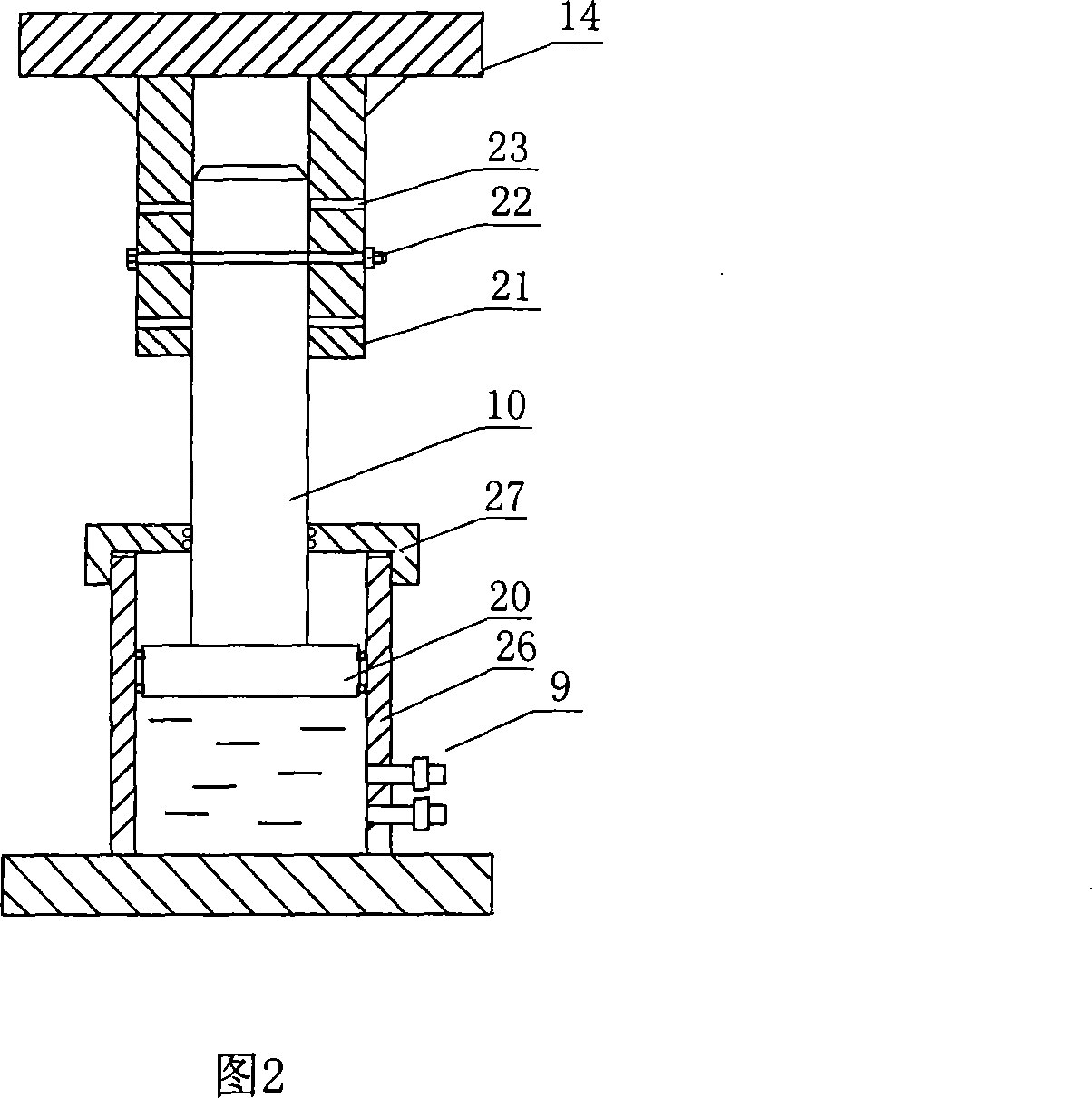

[0013] With reference to accompanying drawing 1,2, comprehensive easy-to-guide mold workbench structure is made up of operating platform, two hydraulic lifters 1,9, two parallel guide rails 16, mold storage frame. The operating table includes an operating table frame 11 , an operating table top 15 , a tool drawer 12 , and universal wheels 8 . Operating table frame 11 top is equipped with operating table top 15, and two parallel guide rails 16 are housed on operating table top 15, and tool drawer 12 is housed on operating table top 15 bottom operating table frames, is used for storing tools, gloves, release agent etc. Universal wheels 8 are installed at the bottom of the console frame 11, which can easily move the console. On both sides of the operating platform 15, there are lifting ports 13 for the hydraulic workbench. Two hydraulic lifters 1,9 are respectively installed on the operation platform 11 both sides, are fixed on the operation platform base 7. The hydraulic lifte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com