Compound supporting device for tunnel micro-step construction

A composite support and micro-step technology, applied in tunnels, shaft equipment, installation of bolts, etc., can solve problems such as excessive tension and accidents, and achieve the effect of good fixation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

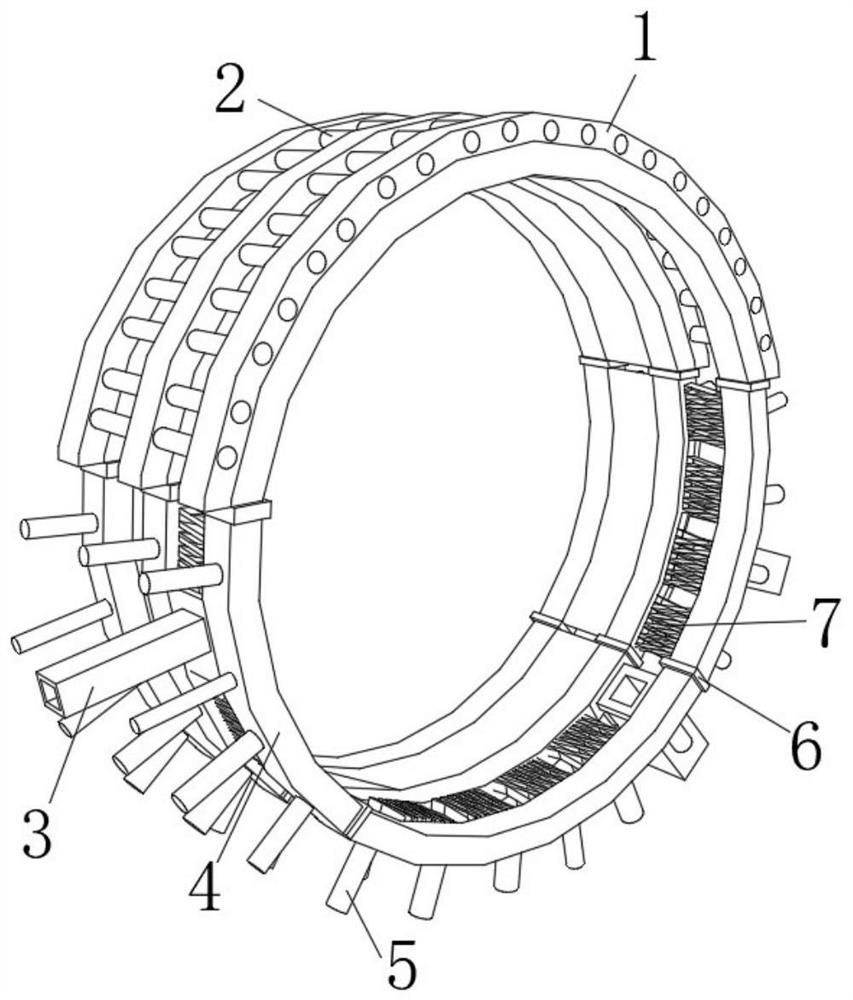

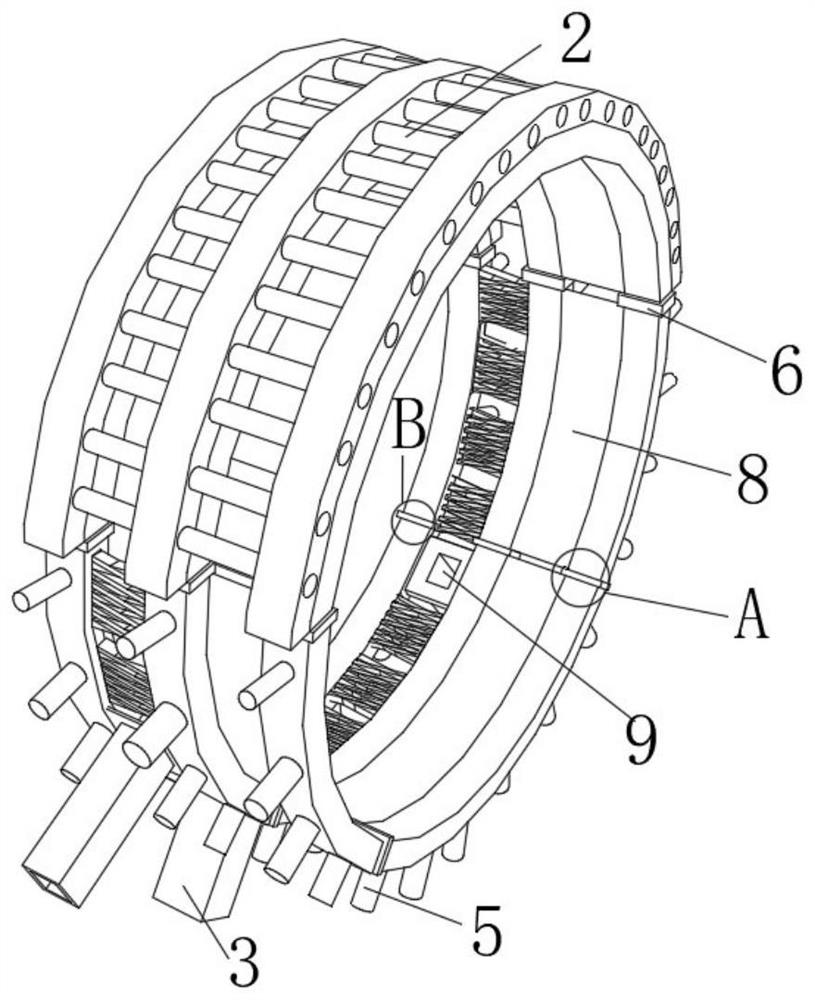

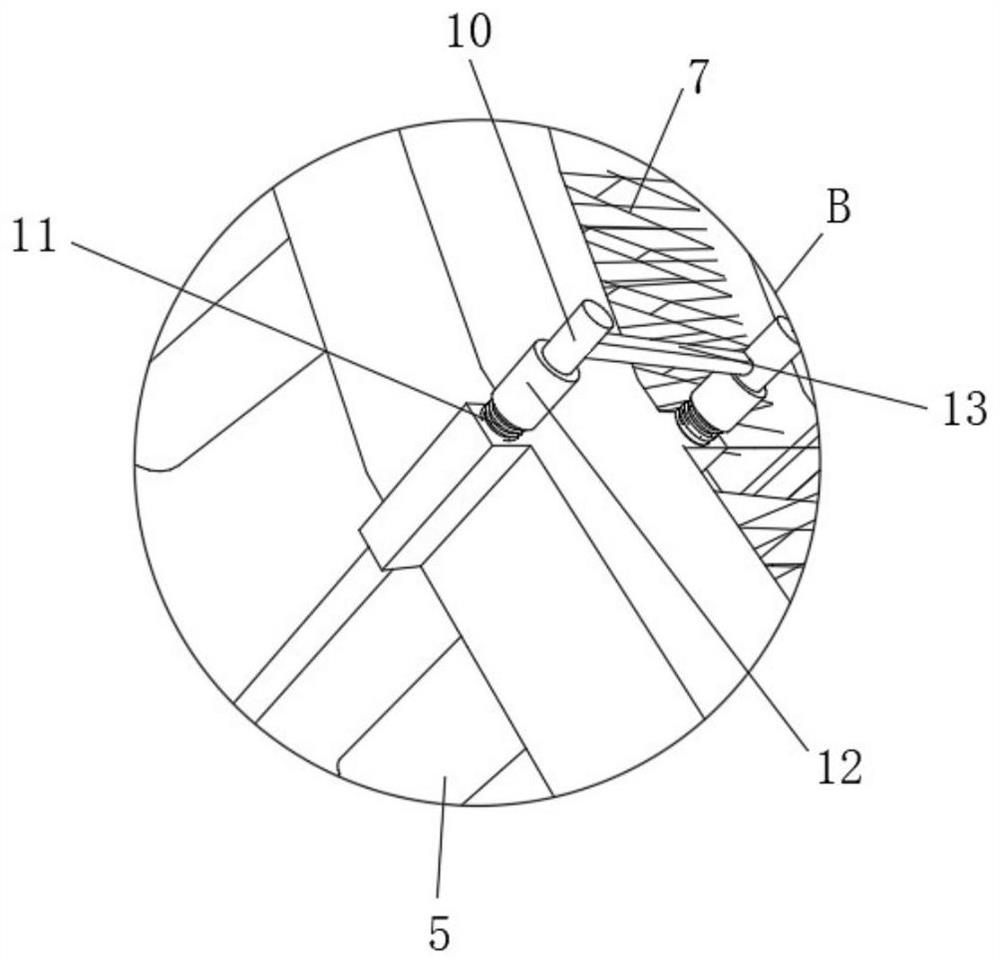

[0025] like Figure 1 to Figure 4 As shown, a composite support device for tunnel micro-step construction, it includes several pipe shed pipes 2, several fixed frames 1 and several steel arch frames 4, the pipe shed pipes 2 are evenly arranged in a semi-circular shape and inserted into the In the rock of the mountain; the fixed frame 1 is a semi-annular body, which is set at a certain distance along the length direction of the pipe shed pipe 2 and is socketed on the pipe shed pipe 2; the steel arch frame 4 is connected in sections to form a semi-annular body, and The length direction of the shed pipe 2 is arranged at regular intervals, and is docked with the fixed frame 1 at the corresponding position. On the same transverse plane perpendicular to the pipe shed pipe 2, the steel arch frame 4 and the fixed frame 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com