Patents

Literature

118results about How to "Avoid fault" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

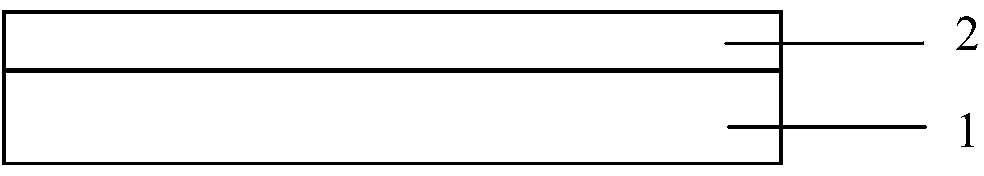

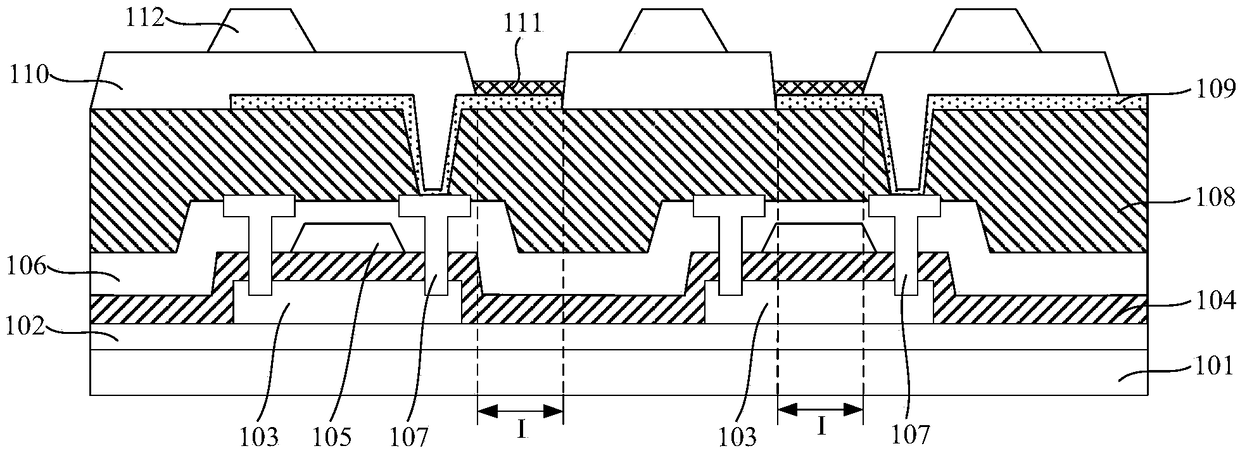

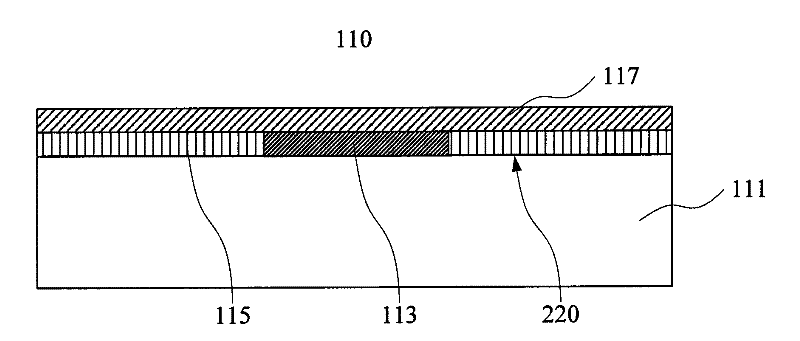

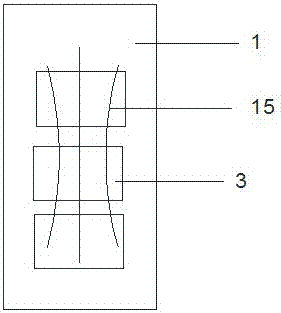

TFT array substrate and preparation method thereof and display device

ActiveCN103646924AAvoid faultInhibited DiffusionTransistorSemiconductor/solid-state device detailsComposite filmDisplay device

The invention relates to the technical field of display and discloses a TFT (thin film transistor) array substrate and a preparation method thereof and a display device which includes the TFT array substrate. A grid is formed in a grid groove of a first insulating layer so that the grid is surrounded by the first insulating layer. The graphic grid does not have any gradient. The first insulating layer separates the grid from the outside so that fault of the grid insulating layer can be prevented and thus copper diffusion in the TFT array substrate can be blocked effectively. Furthermore, the upper surface and / or lower surface of a composite copper metal or a composite thin-film layer including the copper metal are / is completely covered with a metal block layer so that a role of blocking of the copper diffusion is well played. At the same time, more importantly, etching of the copper is not needed so that cost is reduced and yield is improved.

Owner:BOE TECH GRP CO LTD

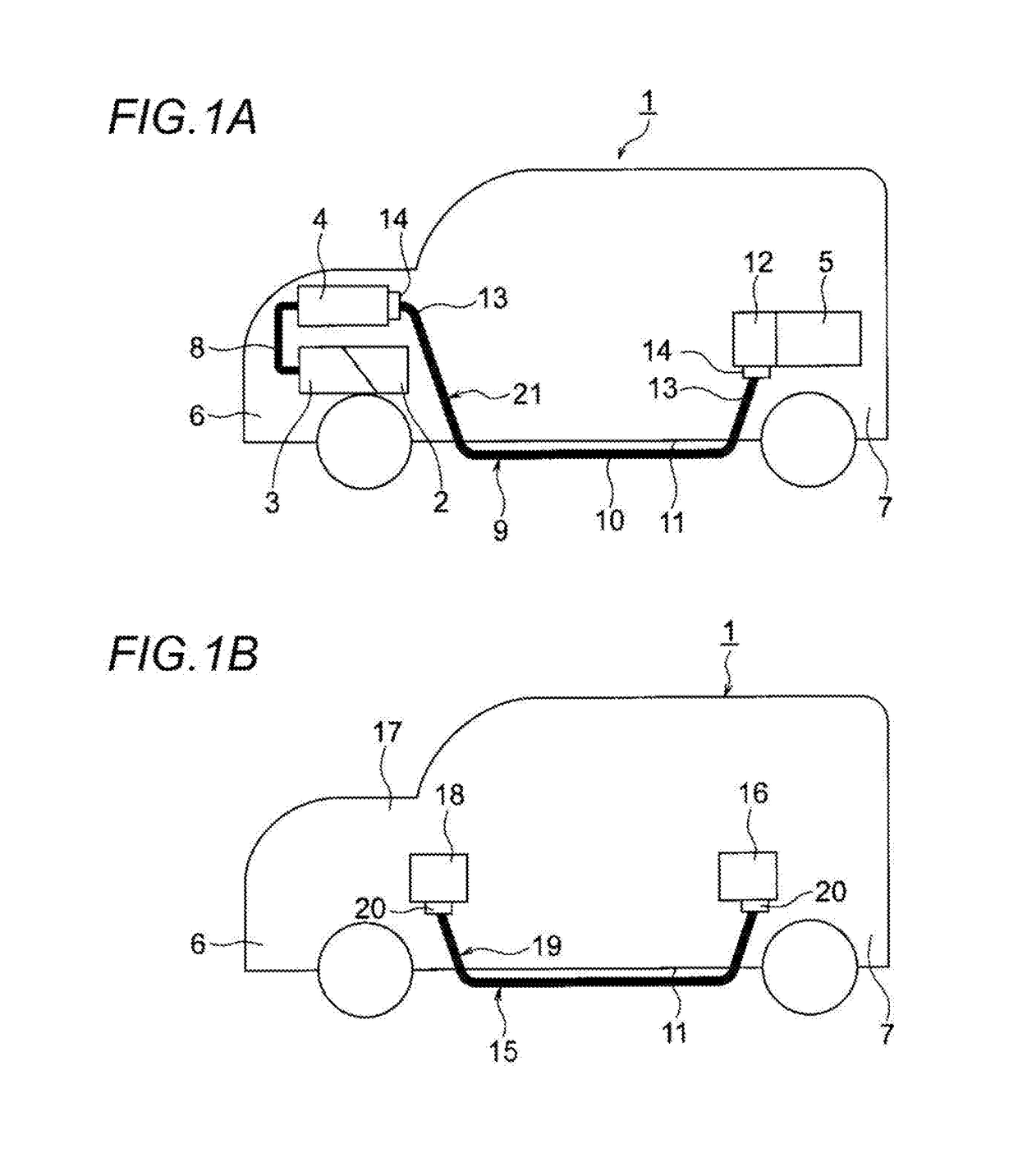

Unmanned aircraft-based continuous shooting method and unmanned aircraft

ActiveCN105511488AAvoid faultAvoid chasmPosition/course control in three dimensionsUnmanned spacecraftAerospace engineering

The embodiment of the invention provides an unmanned aircraft-based continuous shooting method and an unmanned aircraft. The method comprises the steps of acquiring the flight state information of a second unmanned aircraft during the flight and one or more frames of photographed candidate image data when a first unmanned aircraft receives a replacement instruction; enabling the flight according to the flight state information; when the first unmanned aircraft flies to be within a certain range from the second unmanned aircraft, the first unmanned aircraft photographs one or more frames of feature image data according to the flight state information; judging whether the one or more frames of feature image data are matched with the one or more frames of candidate image data or not; if yes, enabling the continuous shooting operation of the first unmanned aircraft. Two video files, obtained before and after the interruption of the continuous shooting process, can be linked up based on the matched frame candidate image data and the feature image data, so that the fault phenomena is avoided.

Owner:BEIJING QIHOO TECH CO LTD

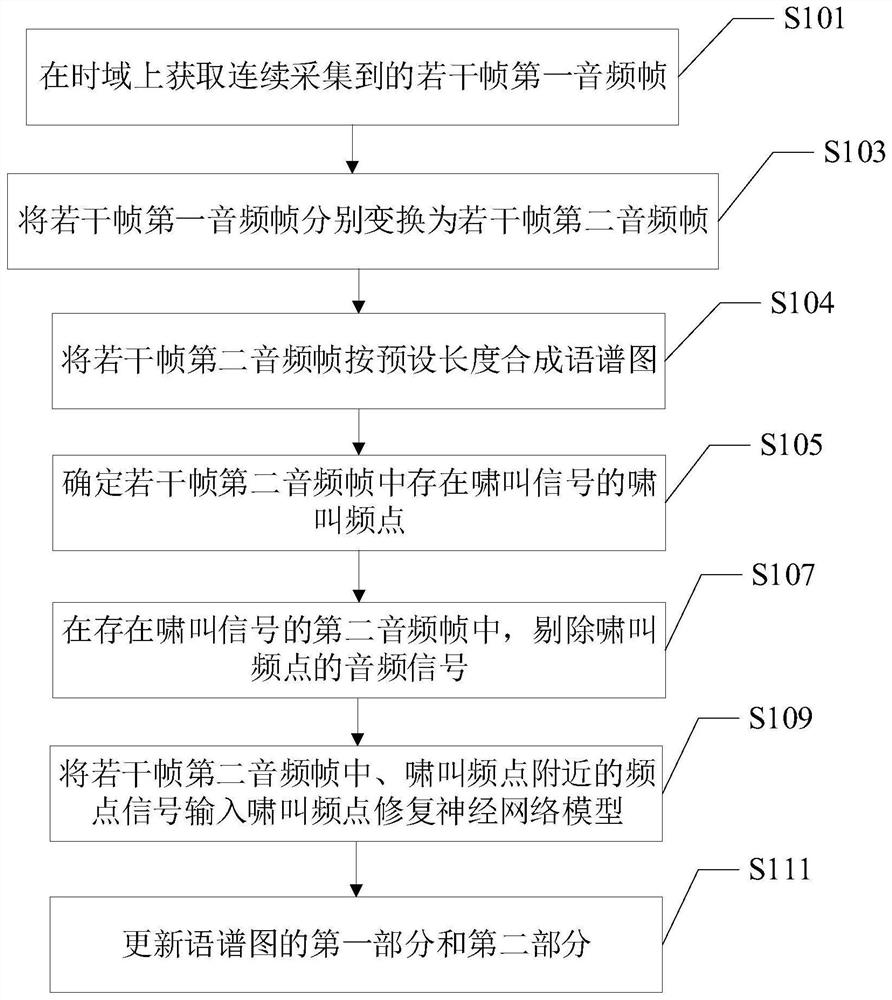

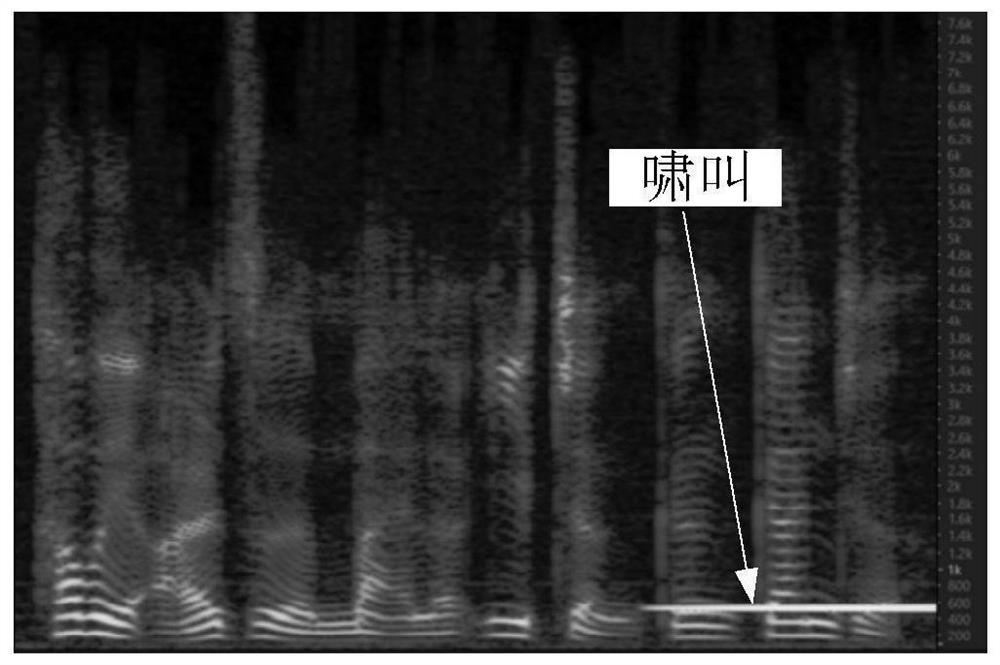

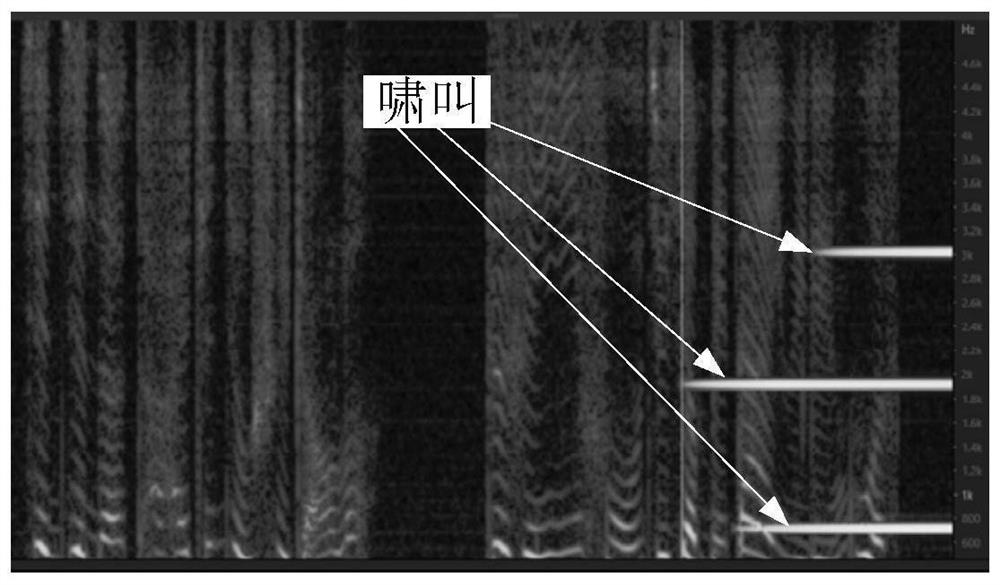

Audio howling suppression method, device and system and neural network training method

PendingCN111883163AEnhanced inhibitory effectSimplified suppressionSpeech analysisHigh level techniquesDistortionEngineering

The invention discloses an audio howling suppression method, device and system and a neural network training method, and the method comprises the steps: obtaining a plurality of continuously collectedfirst audio frames in a time domain; converting the plurality of first audio frames into a plurality of second audio frames respectively, wherein the second audio frames are audio signals in a frequency domain, and each of the plurality of second audio frames comprises a plurality of frequency points; determining howling frequency points with howling signals in the plurality of second audio frames, wherein the howling signals are continuous, single-frequency and high-energy signals; in the second audio frame with the howling signal, removing the audio signal of the howling frequency point; inputting the frequency point signal near the howling frequency point in the plurality of second audio frames into the howling frequency point restoration neural network model, and outputting the restored howling frequency point replacement audio signal to replace the audio signal at the howling frequency point position. Howling signals are suppressed relatively easily and simply, fault of audio signals is avoided, and distortion of the audio signals is reduced.

Owner:ZHUHAI JIELI TECH

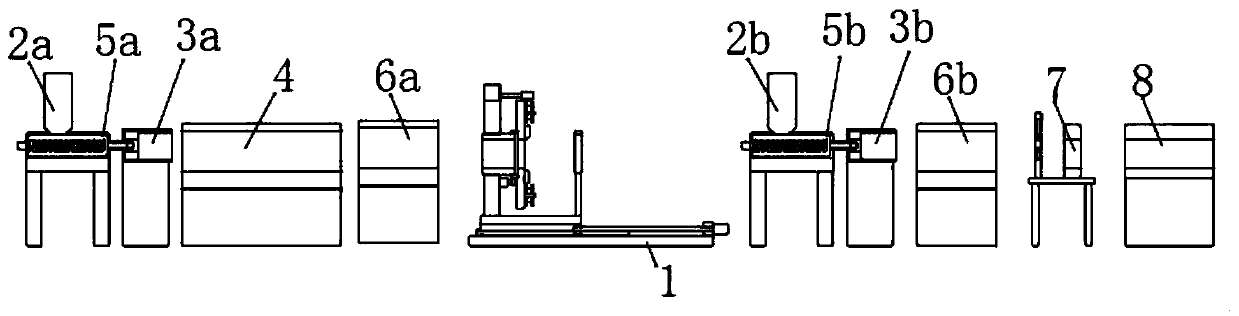

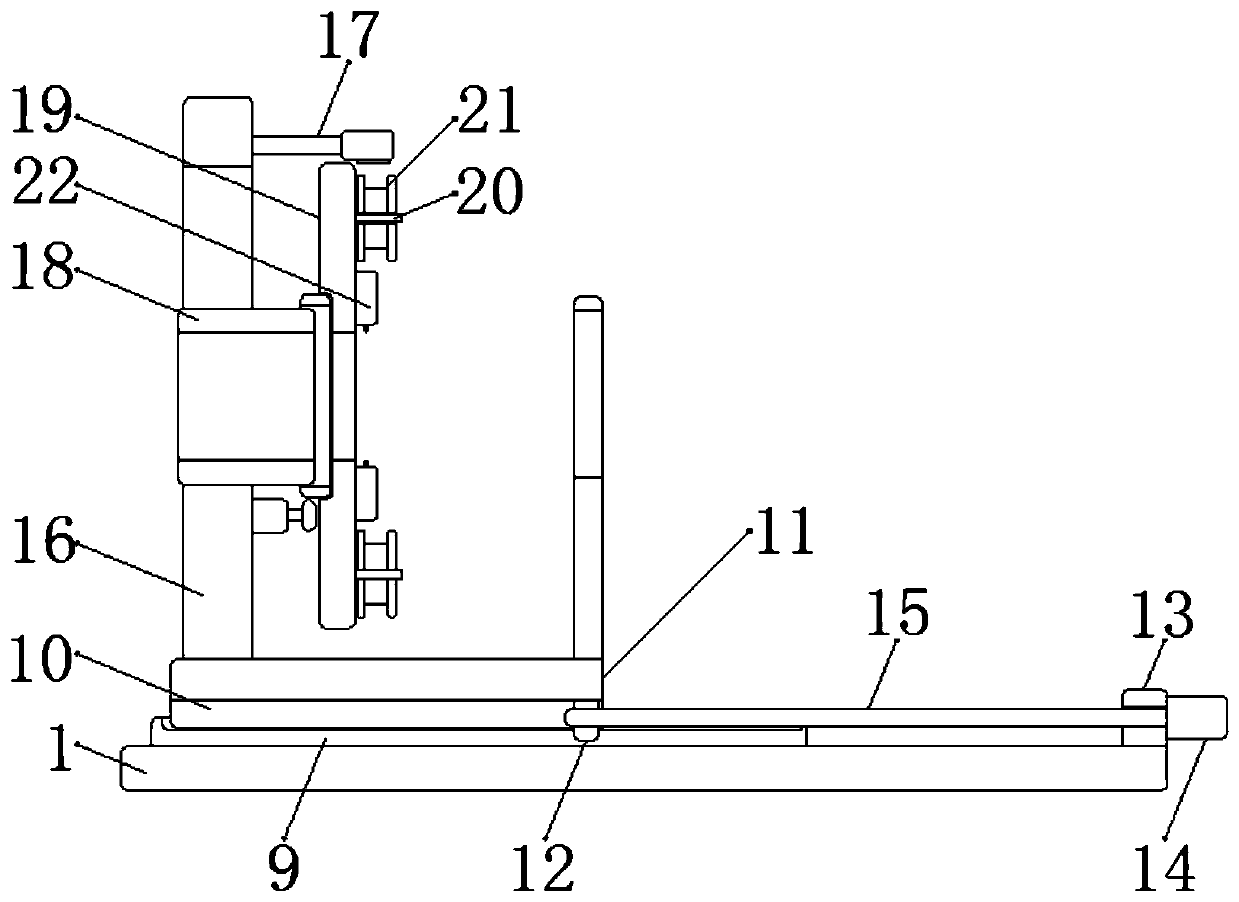

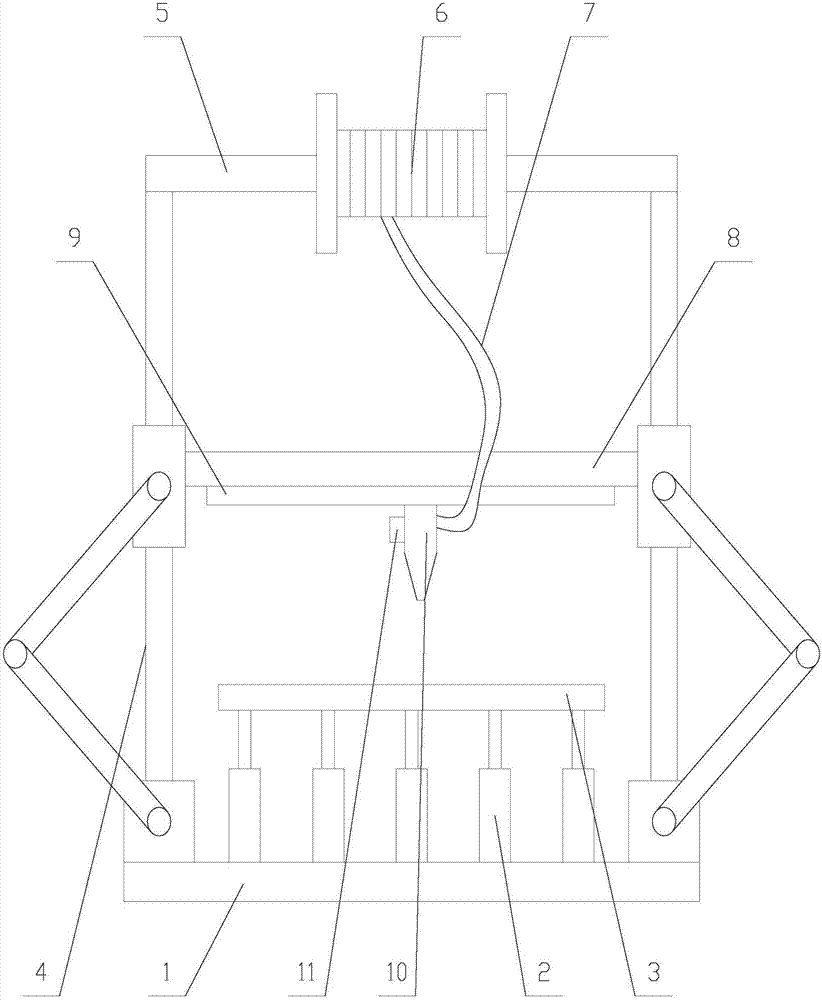

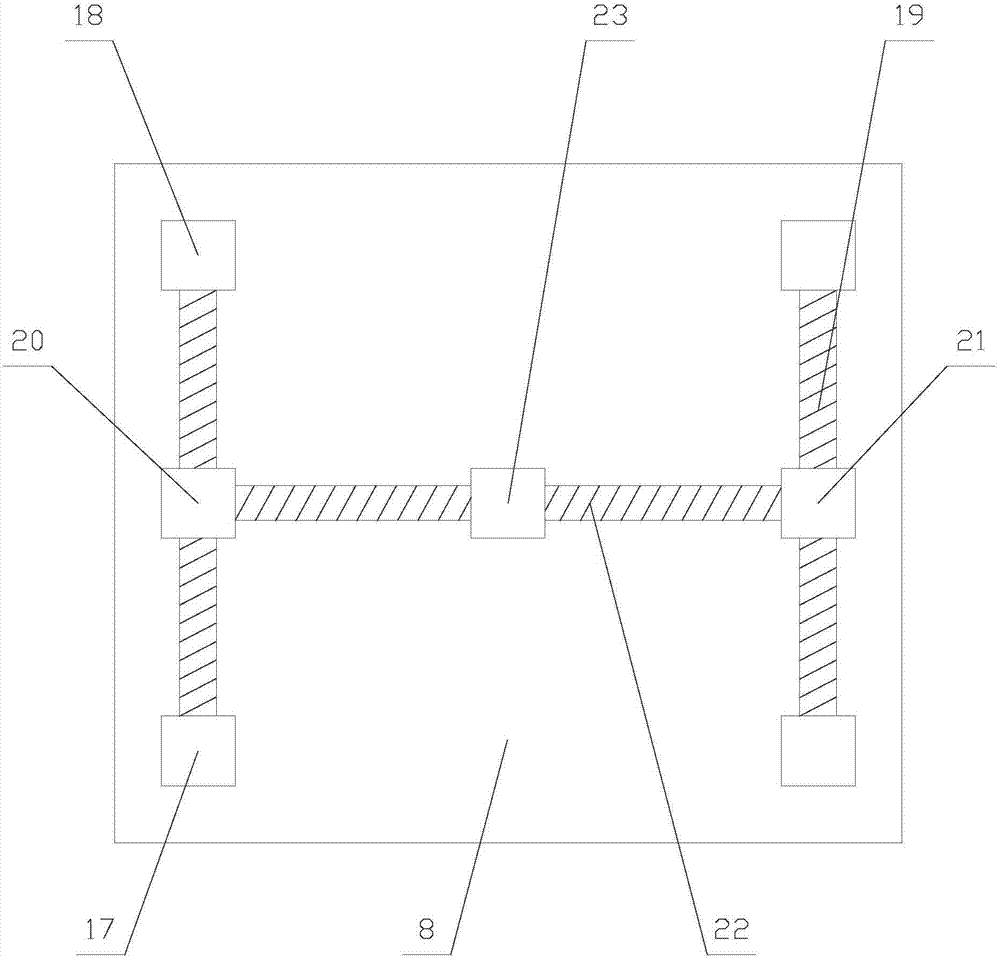

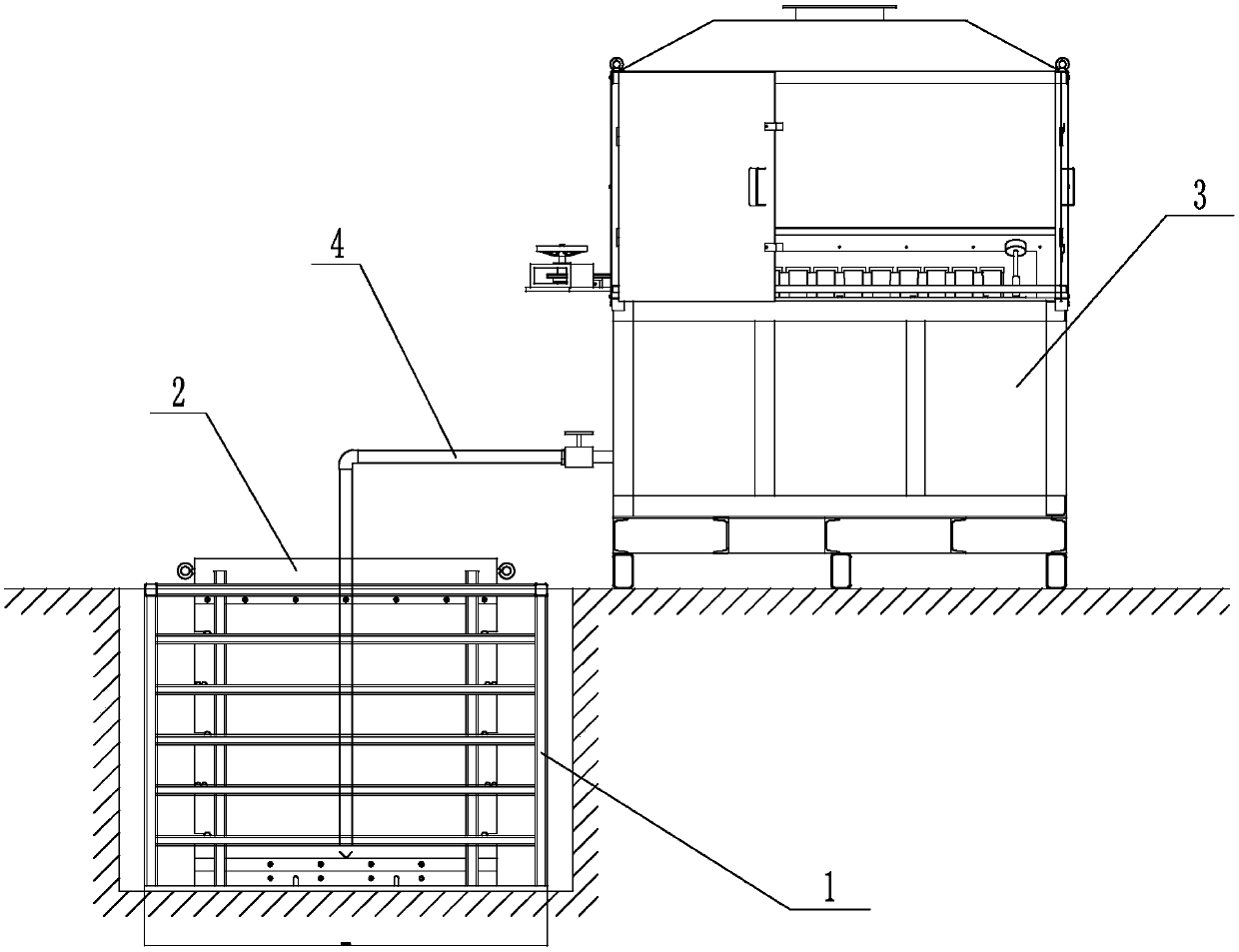

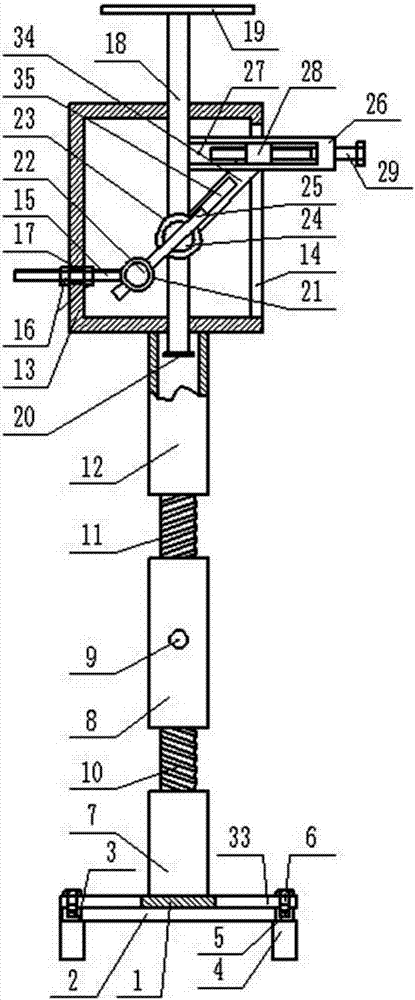

Uninterrupted steel wire winding device for production of PE reinforced composite pipe

The invention relates to the field of plastic processing, and discloses an uninterrupted steel wire winding device for production of a PE reinforced composite pipe. The uninterrupted steel wire winding device comprises a base, two sliding rails are welded to the top of the base, sliding blocks are slidably connected into the two sliding rails correspondingly, a sliding trolley is welded between the two sliding blocks, a traction block is welded to the bottom of the sliding trolley, a screw hole corresponding to a lead screw is formed in the right side of the traction block, a fixing block is welded to the right side of the top of the base, and a motor is mounted on the right side of the fixing block. According to the uninterrupted steel wire winding device for production of the PE reinforced composite pipe, uninterrupted winding is achieved, in this way, a fault of a steel wire wound around the PE pipe is prevented, the production efficiency of the PE pipe is improved, the scrap rate is decreased, and the production cost is saved.

Owner:JIANGSU COCON TECH

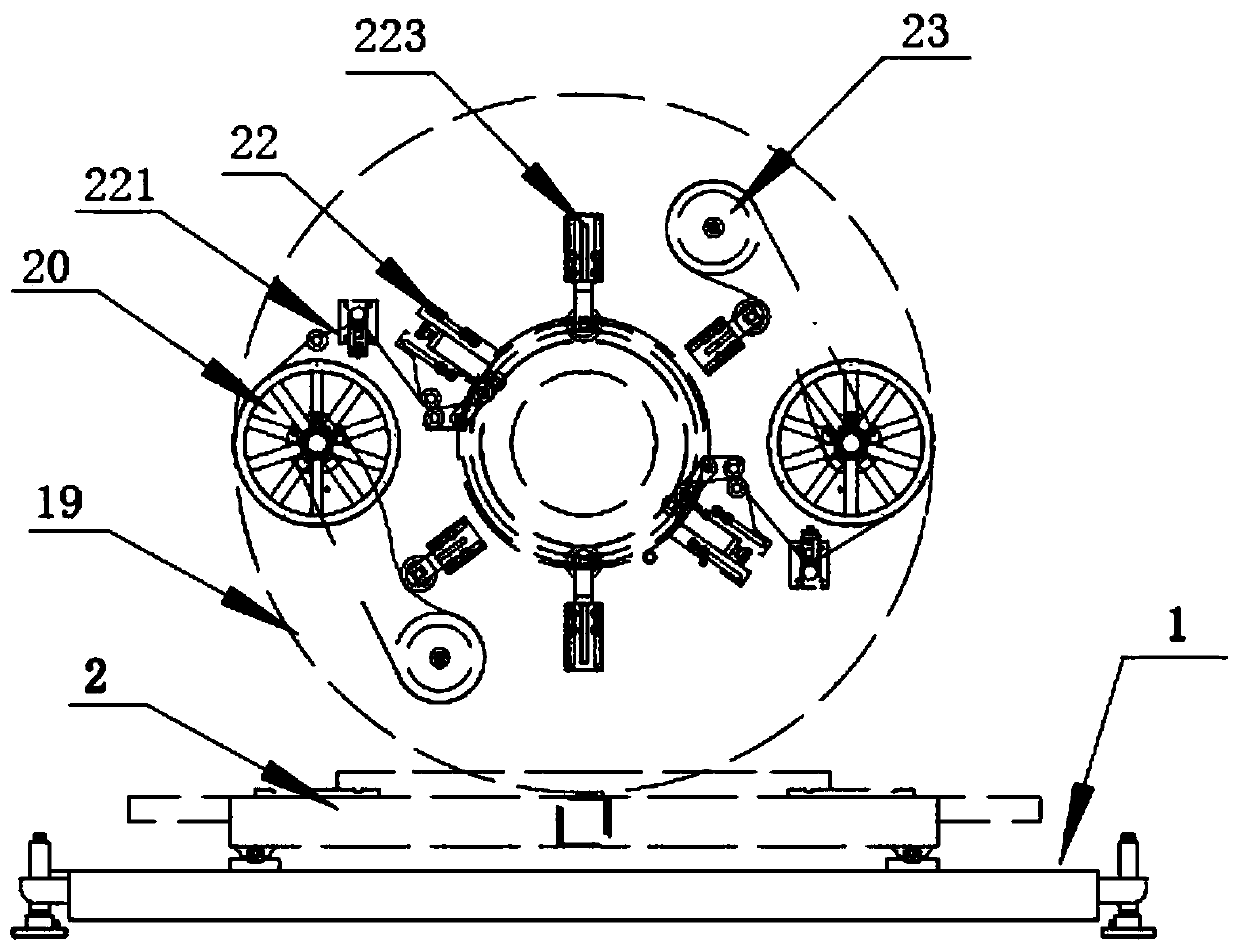

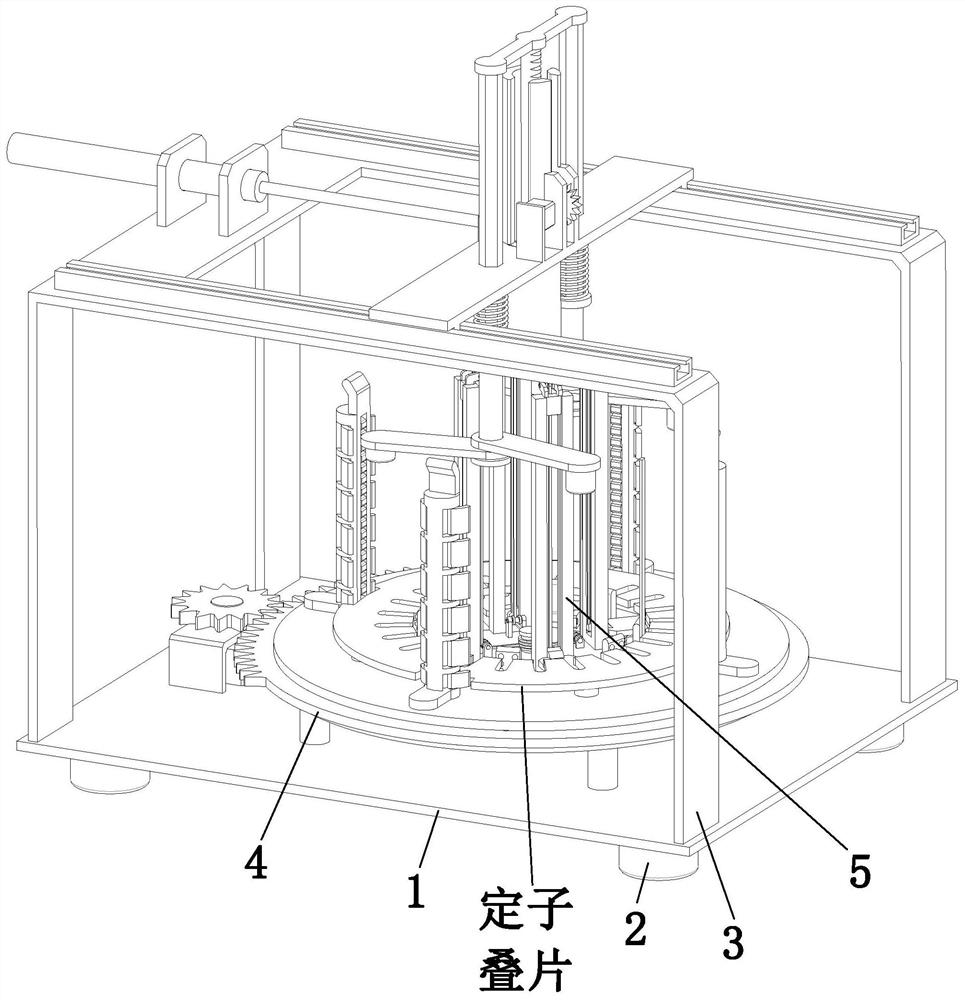

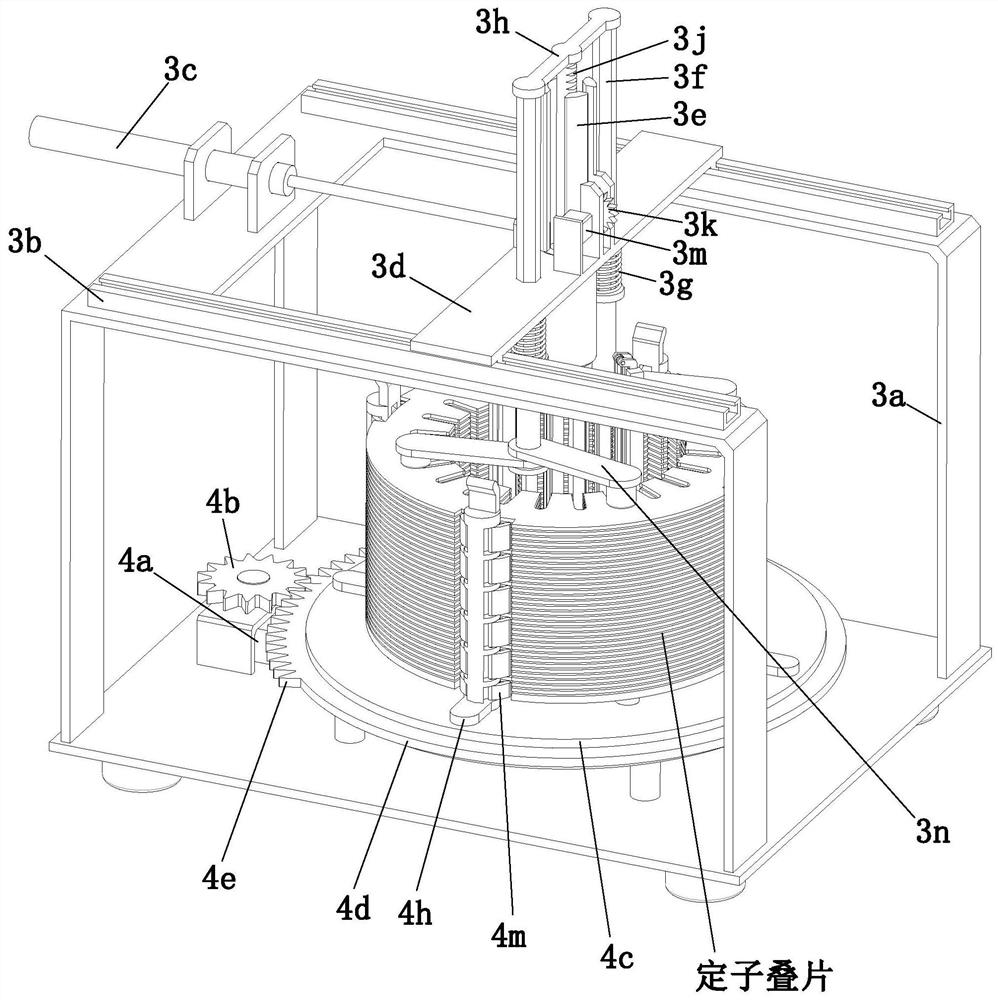

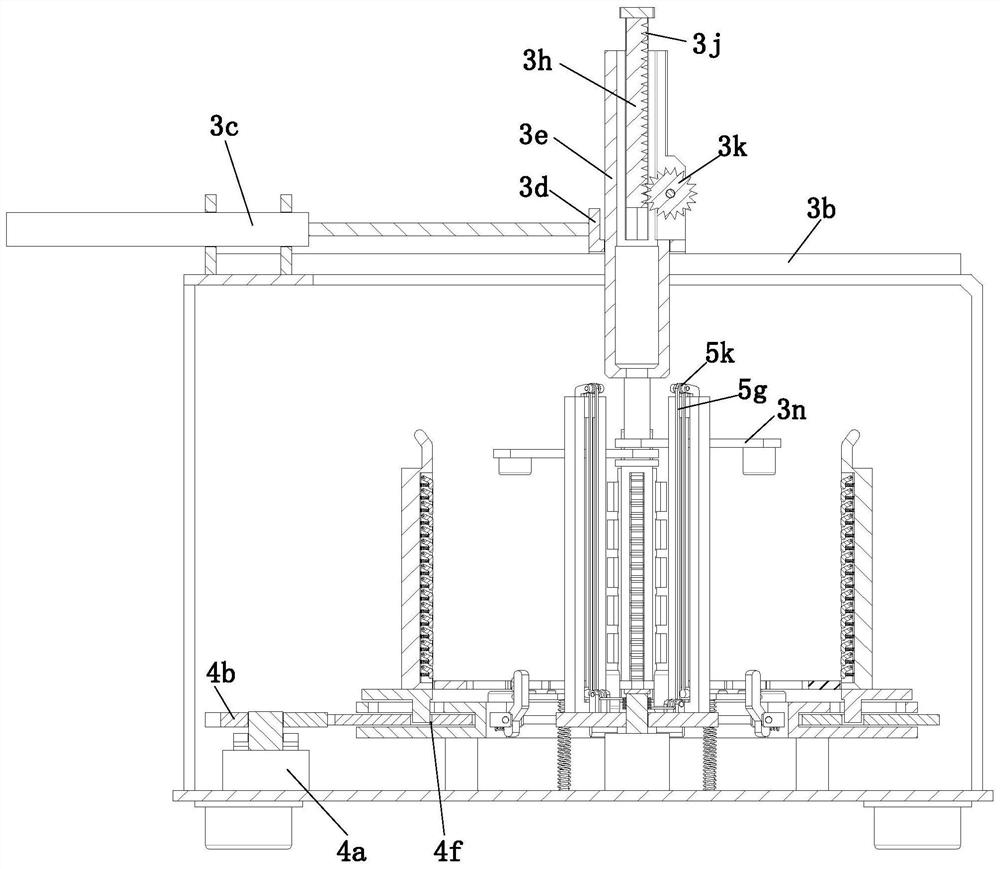

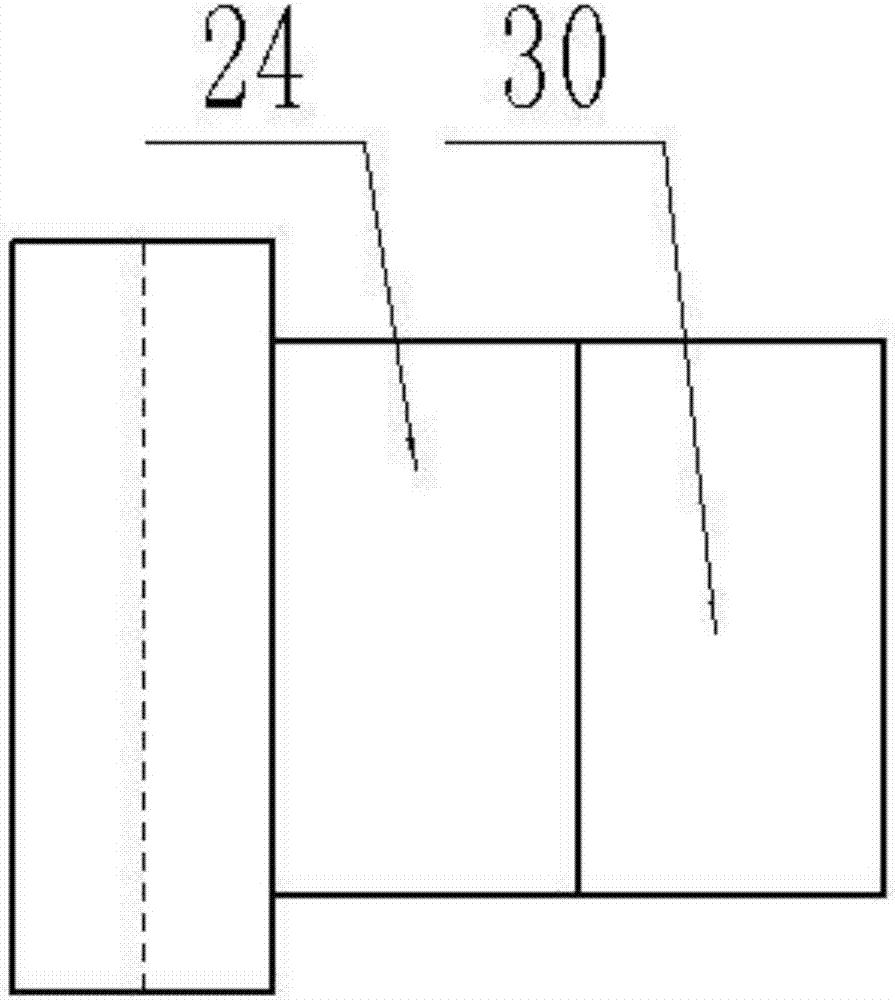

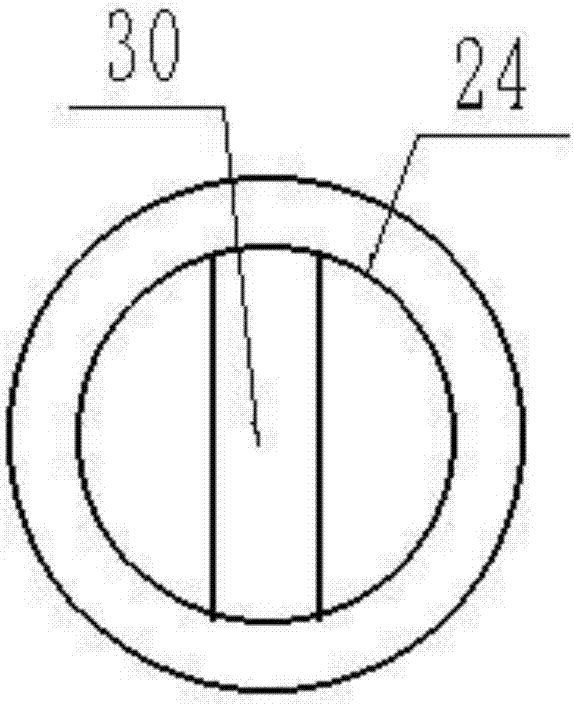

Motor stator punching sheet processing system

ActiveCN113098210AAvoid Rotation SkewImprove accuracyMetal-working feeding devicesManufacturing stator/rotor bodiesPunchingElectric machine

The invention provides a motor stator punching sheet processing system. The system comprises a mounting bottom plate, supporting legs, a positioning mechanism, an assembling mechanism and a supporting mechanism,solves the problem that the inner side and the outer side of a positioning punching sheet are difficult to support and abut synchronously during the lamination operation of the motor stator punching sheet, so that the concentricity of the positioning punching sheet is ensured, but the stator punching sheets which are stacked one by one are difficult to clamp and limit, avoids situations that the stator punching sheets are prevented from rotating and deflecting, the stacked positioning punching sheets are difficult to uniformly and repeatedly extrude, gaps between the motor stator punching sheet laminations are eliminated, and the motor stator punching sheet laminations are difficult to integrally move upwards, and avoids the problems of separation, fault and the like of the motor stator punching sheet lamination in the taking-out process.

Owner:佛山市顺德区致翔金属制品有限公司

Polymer with penetration network structure and used for grouting material, and preparation method thereof

The invention discloses a preparation method for a polymer with a penetration network structure and used for a grouting material. The preparation method comprises the following steps: (1) subjecting diisocyanate and vegetable oil based polyol to a contact reaction so as to obtain a vegetable oil based polyurethane prepolymer; and (2) adding hydrogenated silicon nitrile rubber particles, epoxy resin, a curing agent, a diluent and a curing adjusting additive into the vegetable oil based polyurethane prepolymer obtained in the step (1), carrying out uniform mixing in an inert atmosphere environment, and carrying out vacuum degassing and curing so as to obtain a vegetable oil based polyurethane / epoxy resin polymer with the penetration network structure. The method provided by the invention reinforces the vegetable oil based polyurethane, toughens the epoxy resin, improves the physical and chemical properties of the polymer with the penetration network structure, and is specifically applicable to application in grouting and leaking stoppage in a complicated geological-condition structure.

Owner:CHINA PETROLEUM & CHEM CORP +1

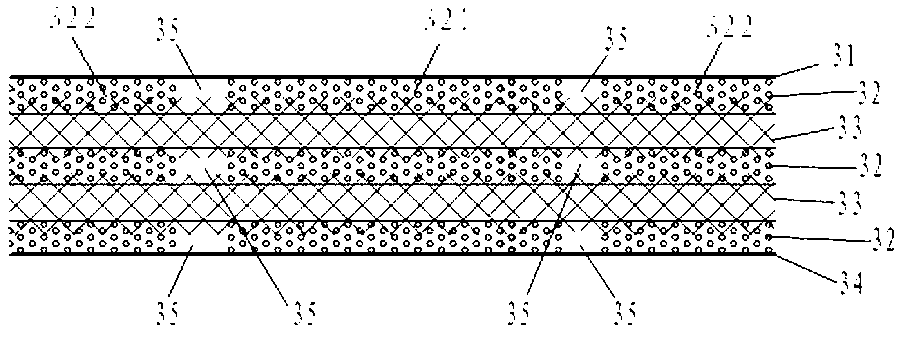

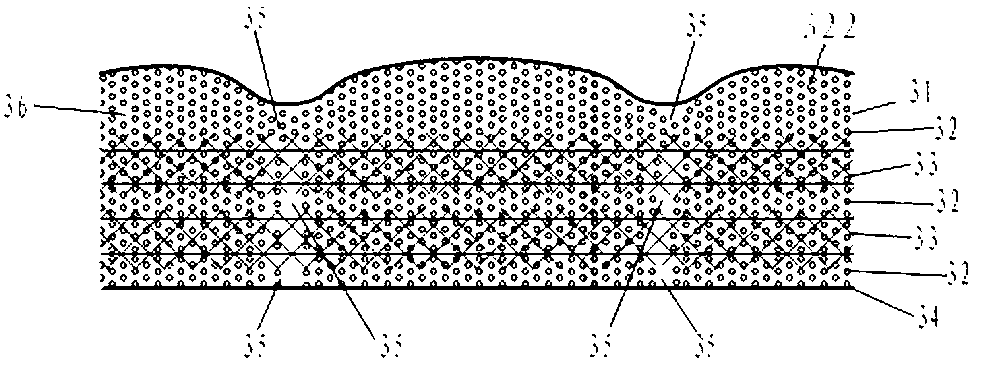

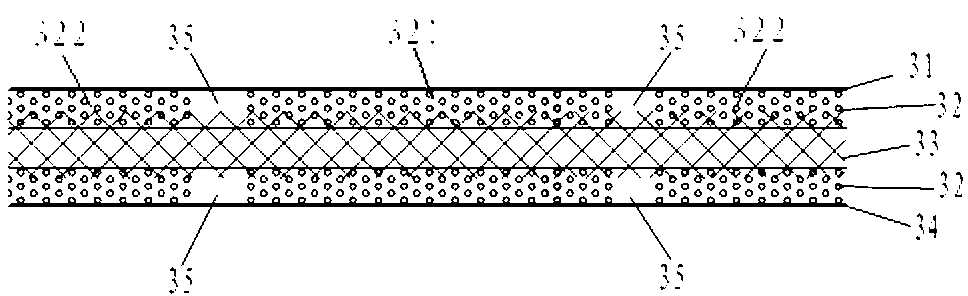

Comb-shaped multi-layered absorption core body and processing method thereof

The invention provides a comb-shaped multi-layered absorption core body and a processing method thereof. The core body comprises an ultra-thin multi-layered absorption core body and a comb-teeth shaped structure in the core body, each absorption body layer consists of a plurality of absorption body strips which are longitudinally arranged and combined onto a fiber structure layer, intervals are arranged among the absorption body strips, the intervals form a longitudinal comb shaped structure on the absorption core body, the innovative multi-layered core body structure is subjected to special manufacture and processing, and a comb-shaped sandwich absorption unit is obtained. After the multi-layered absorption core body is applied to a paper diaper, the paper diaper is enabled to be lighter and thinner, after the paper diaper absorbs liquid, a U-shaped three-dimensional structure is formed, the close-fitting effect is better, urine is prevented from transversely dispersing towards two sides, the urine is better guided, the urine is enabled to move towards a longitudinal direction and to be absorbed, the possibility of side leakage is reduced, the urine is prevented from seeping from two sides of a leg part, by longitudinally dispersing liquid, the absorption body is fully utilized, the replacement of paper diapers is reduced, and the absorption core body is economic, green and environment-friendly.

Owner:百润(中国)有限公司

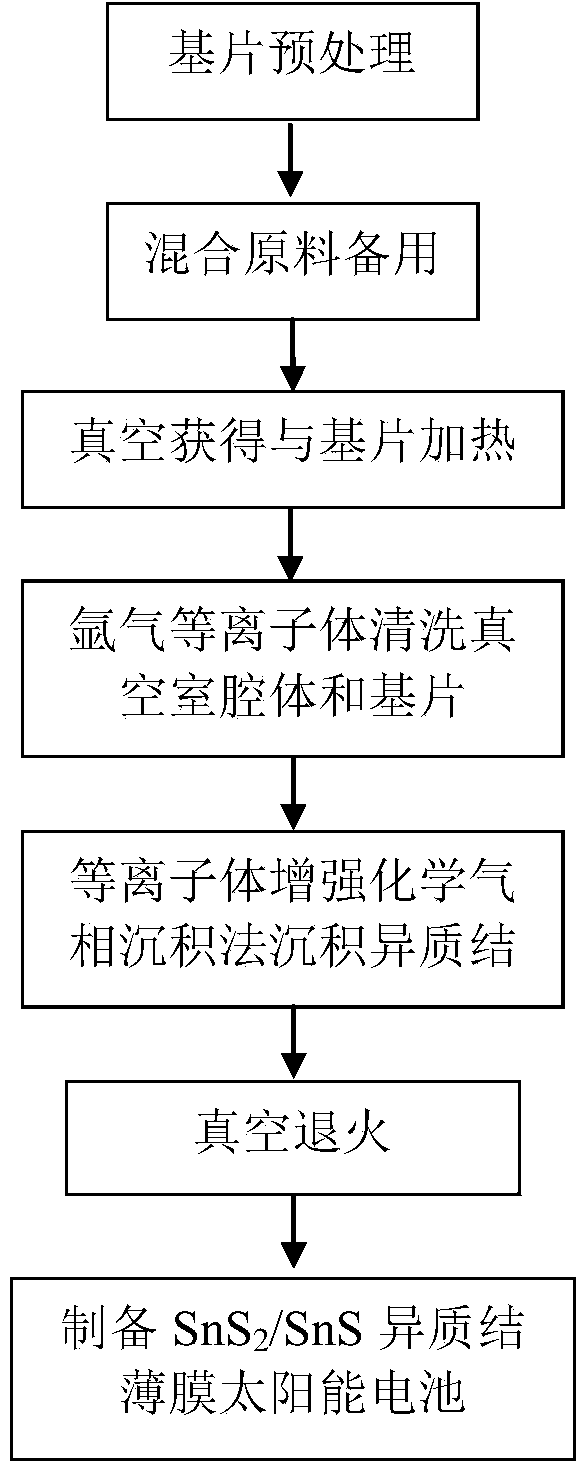

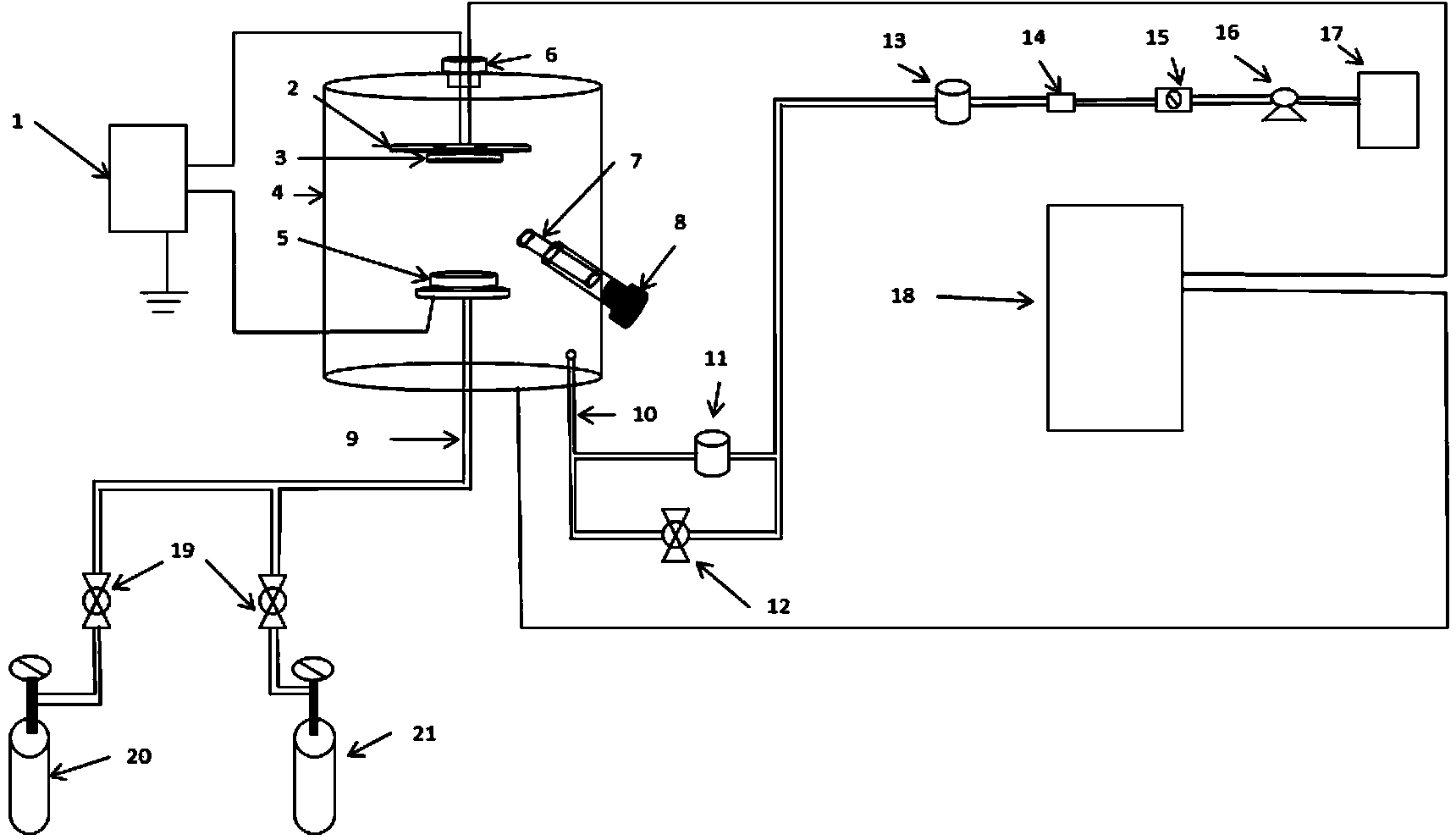

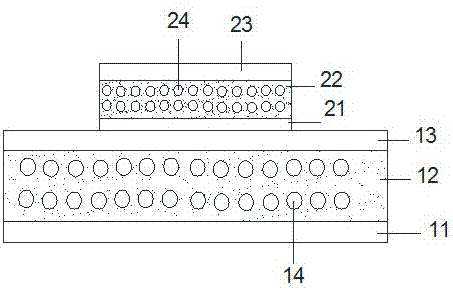

Method for manufacturing SnS2/SnS heterojunction thin-film solar cell at a time

InactiveCN104167469AAvoid makingSimple methodFinal product manufactureChemical vapor deposition coatingHeterojunctionElectrical battery

The invention discloses a method for manufacturing a SnS2 / SnS heterojunction thin-film solar cell at a time. The method includes the following steps: preprocessing a substrate, preparing mixed raw materials for use, conducting vacuum obtaining and substrate heating, cleaning a cavity and the substrate through argon plasma, depositing a heterojunction with a plasma enhanced chemical vapor deposition method, conducting vacuum annealing and cooling, and manufacturing the SnS2 / SnS heterojunction thin-film solar cell. According to the method, due to the fact that the proportion of the mixed raw materials is set, and the relation between a heating temperature value T of a reaction source and a reaction deposition time value t is set, SnS2 thin film and SnS thin film which are excellent in quality can be successively deposited in the one-time experiment process, the core part, namely the p-n junction, of the solar cell is directly manufactured at a time accordingly, the manufacturing period of the SnS2 / SnS heterojunction thin-film solar cell is greatly shortened, and the manufacturing cost of the SnS2 / SnS heterojunction thin-film solar cell is greatly reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

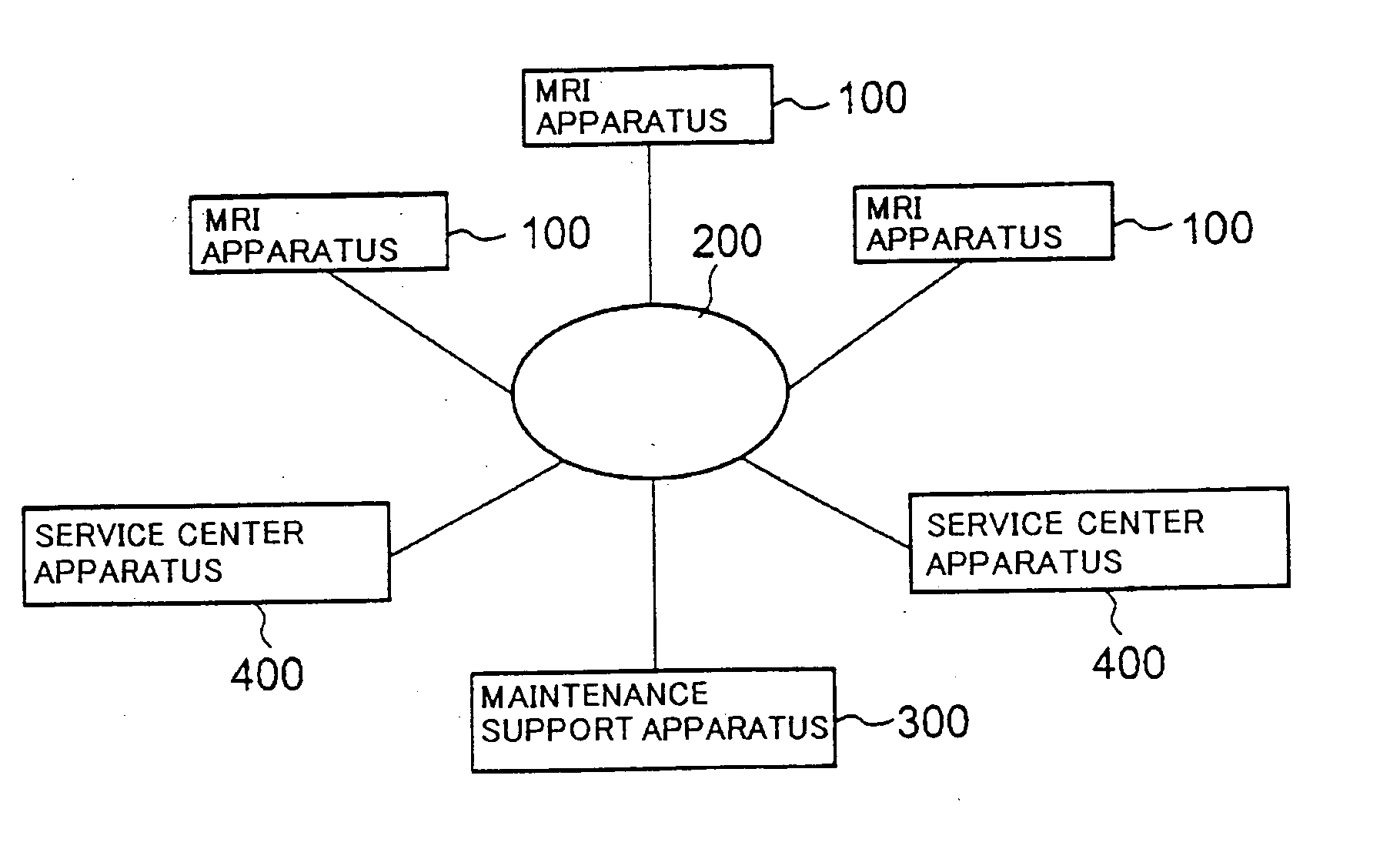

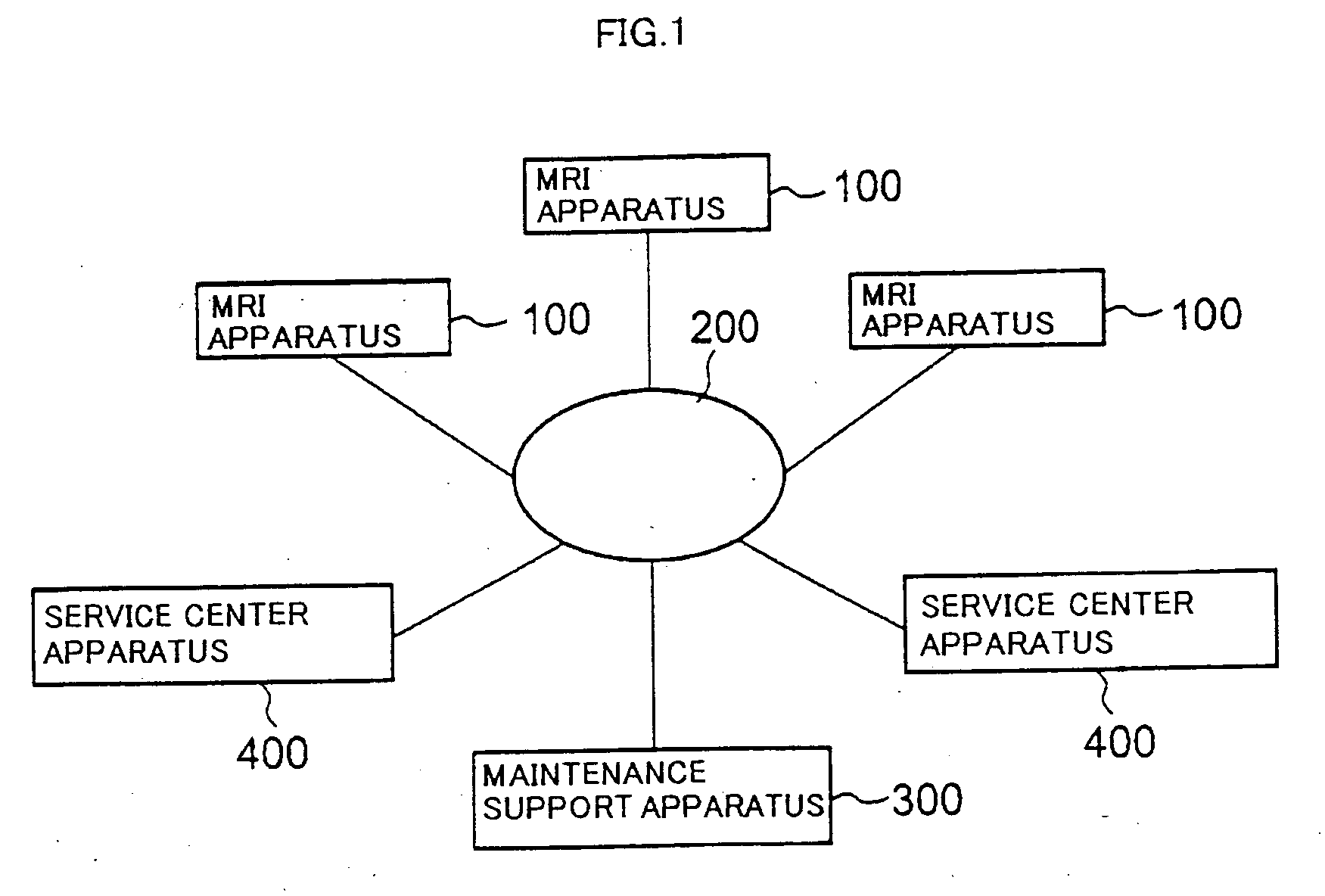

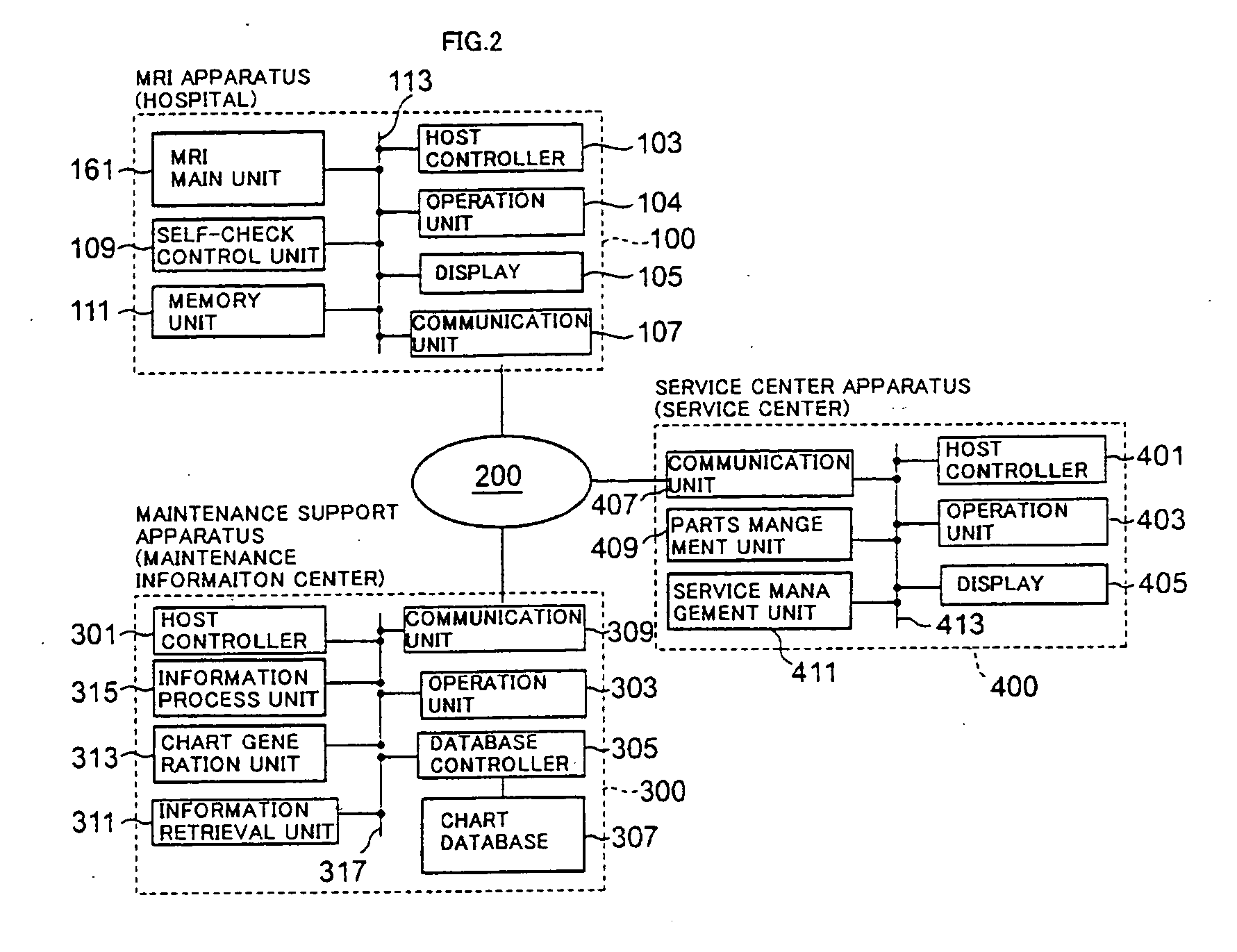

System, method and apparatus for MRI maintenance and support

InactiveUS20050234330A1Avoid faultSpeed up dispatchLocal control/monitoringTelemedicineUpgradeSoftware

An MRI apparatus consolidates and stores maintenance and / or performance data automatically measured by a measurement unit and data manually input via an input device. The automatically measured data may include an adjustment value, a state value or an error record. The manually input data may include a software and / or hardware upgrade record, a customized situation record, a network connection record, a repair record, a check record, a maintenance record or an installation record, for example. Both types of data can be obtained swiftly and faults or malfunctions can be recovered from quickly or even prevented in advance. The stored data may be communicated among a plurality of MRI apparatuses, a service center apparatus and a maintenance support apparatus via a communications network.

Owner:TOSHIBA MEDICAL SYST CORP

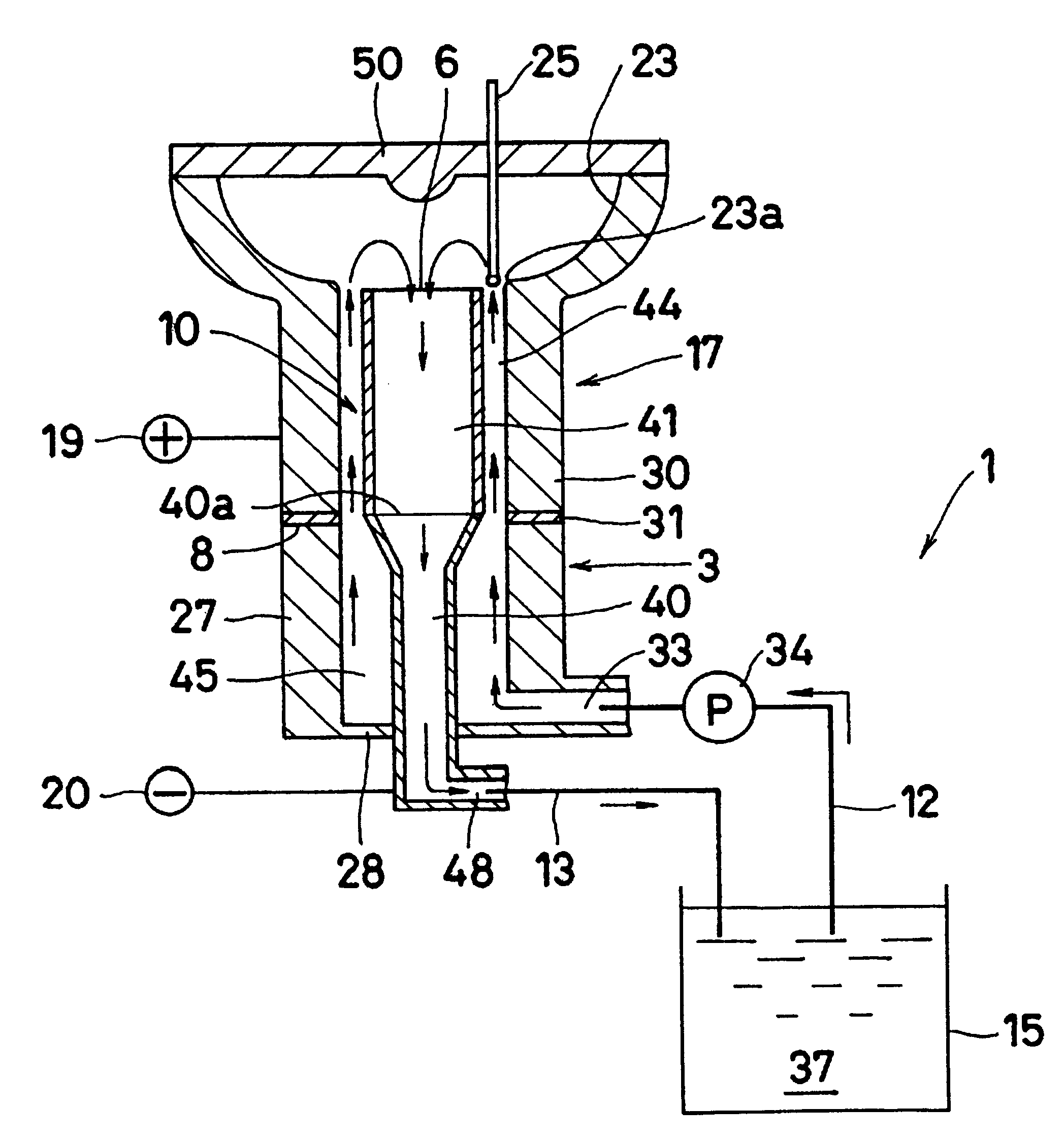

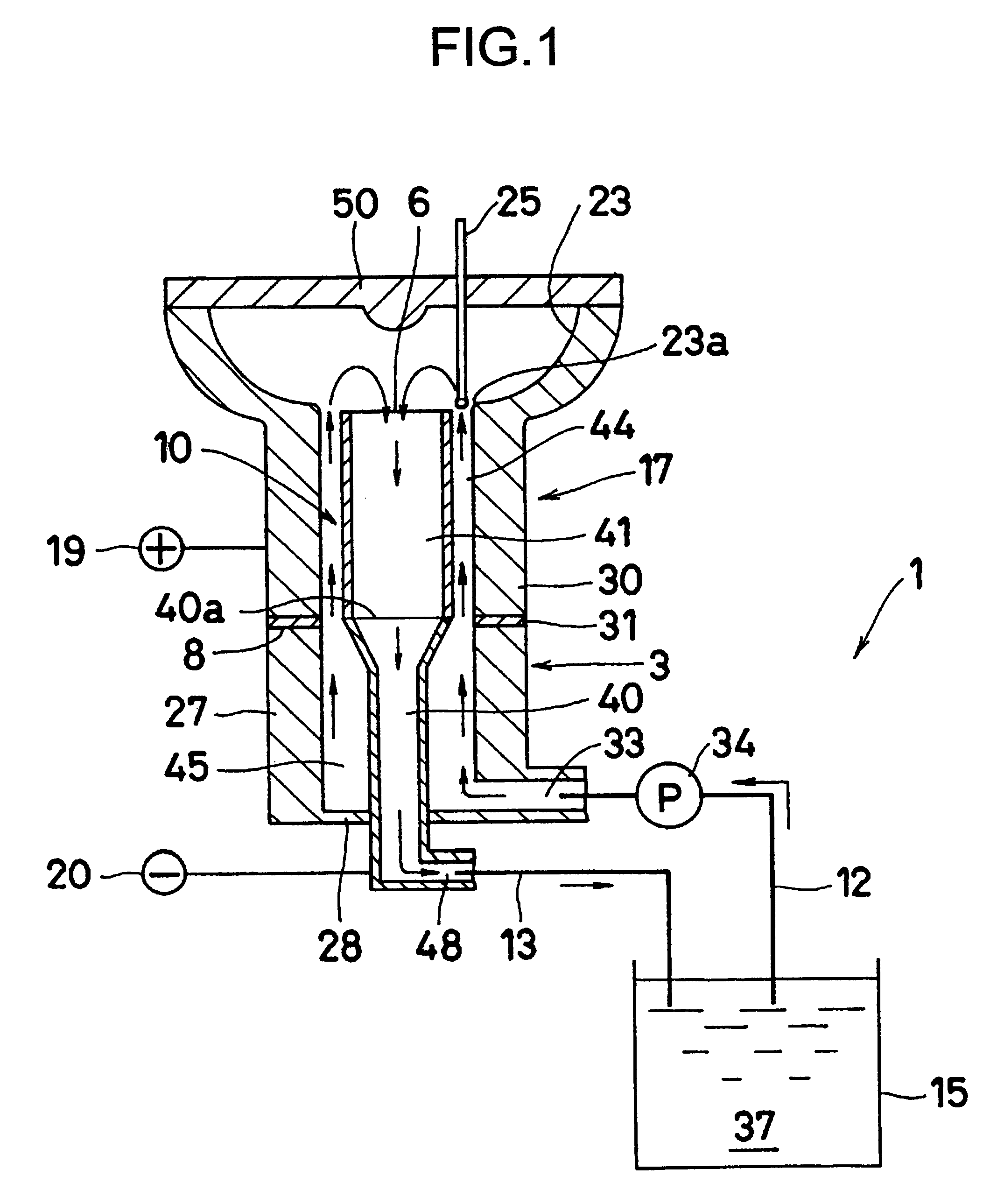

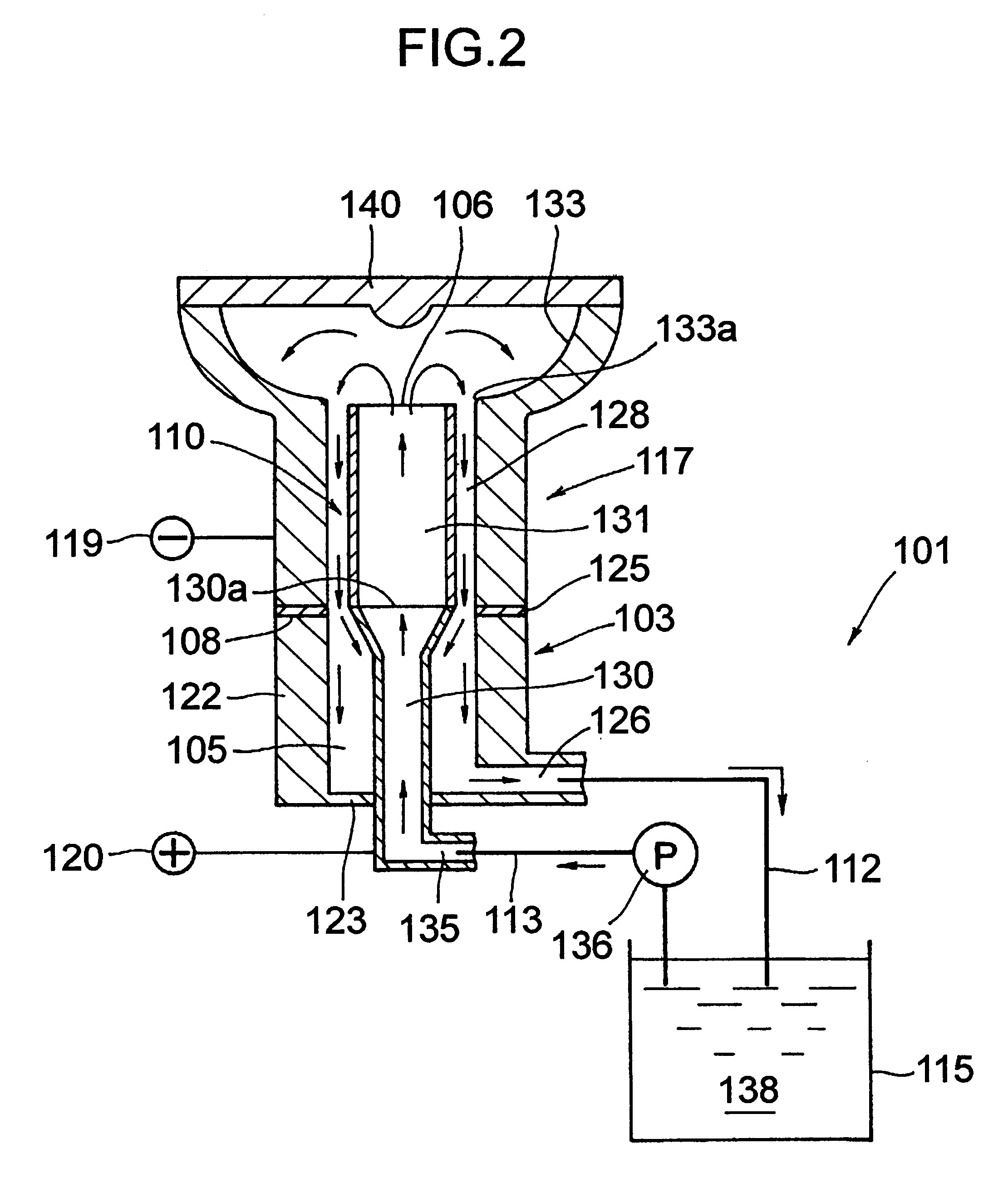

Plating pretreatment apparatus and plating treatment apparatus

InactiveUS6383348B2Improve adhesionPoor adhesionCellsElectrical-based auxillary apparatusEngineeringLiquid tank

The present invention provides a plating pretreatment apparatus that includes a cylindrical cathode disposed in a hollow portion of a fixing jig. A cylindrical object to be treated is installed on the fixing jig so that the cathode is also arranged therein. A lower portion of the cathode has a smaller diameter than an upper portion thereof. The invention also provides a plating treatment apparatus that includes an outlet jig having a hollow portion for installing a cylindrical object to be treated on a top face thereof, a cylindrical anode disposed therein so that a top end thereof projects from the top face of the outlet jig, and a plating liquid tank connected to the anode and the outlet jig. A lower portion of the anode has a smaller diameter than an upper portion thereof.

Owner:SUZUKI MOTOR CORP

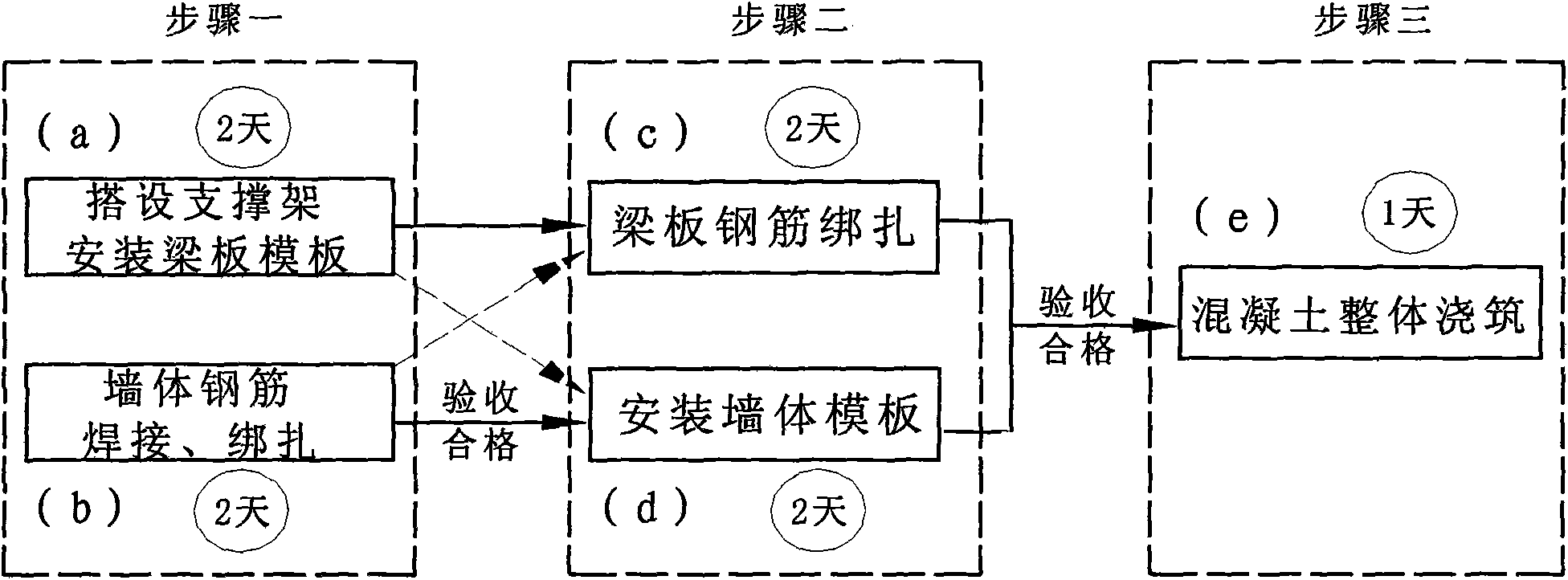

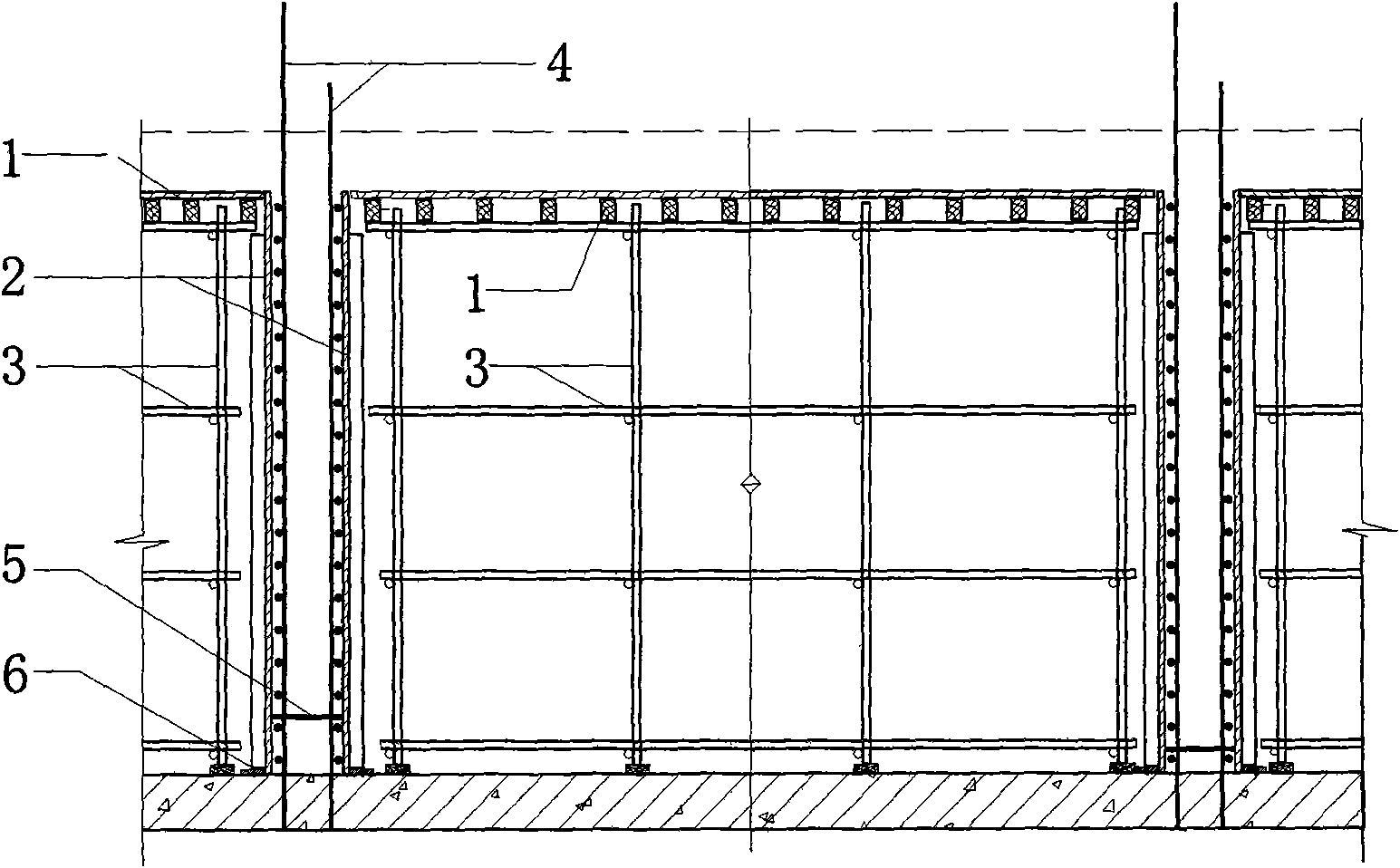

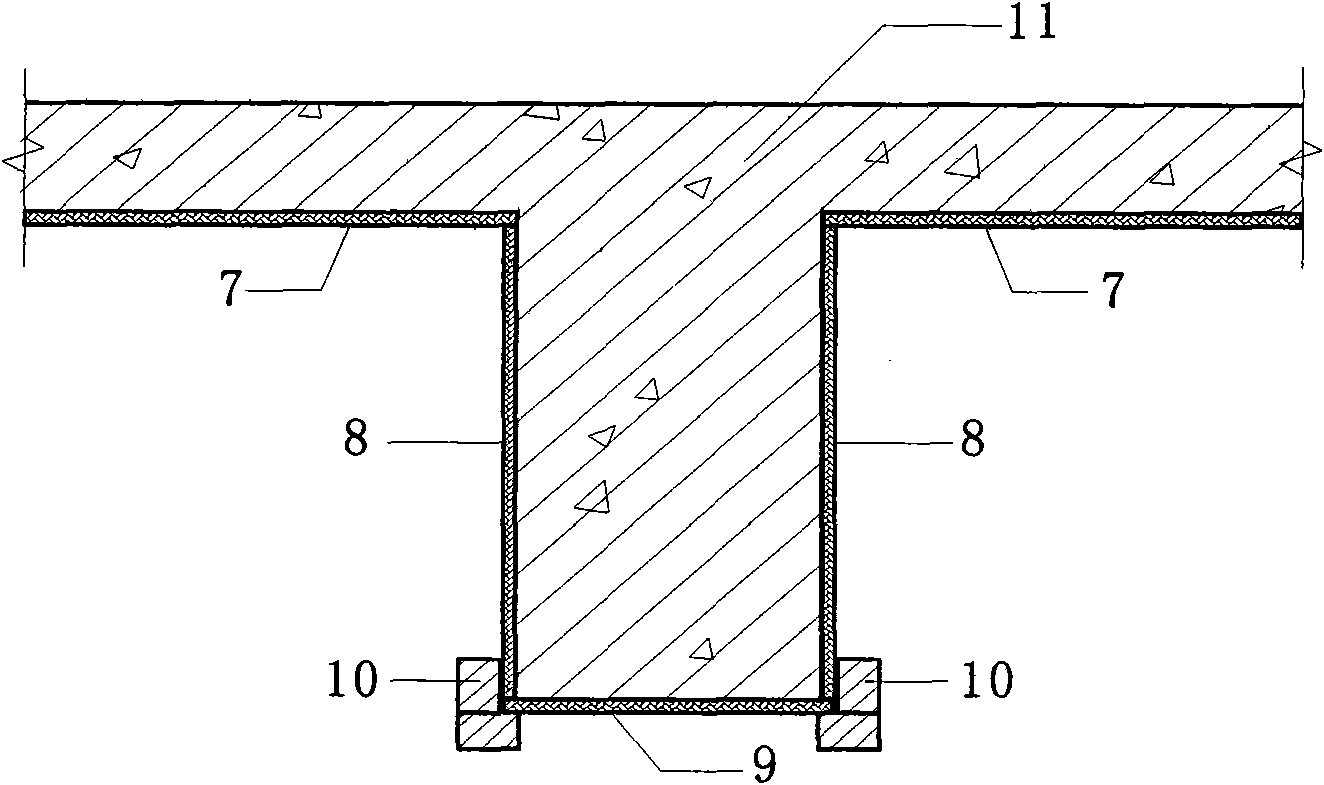

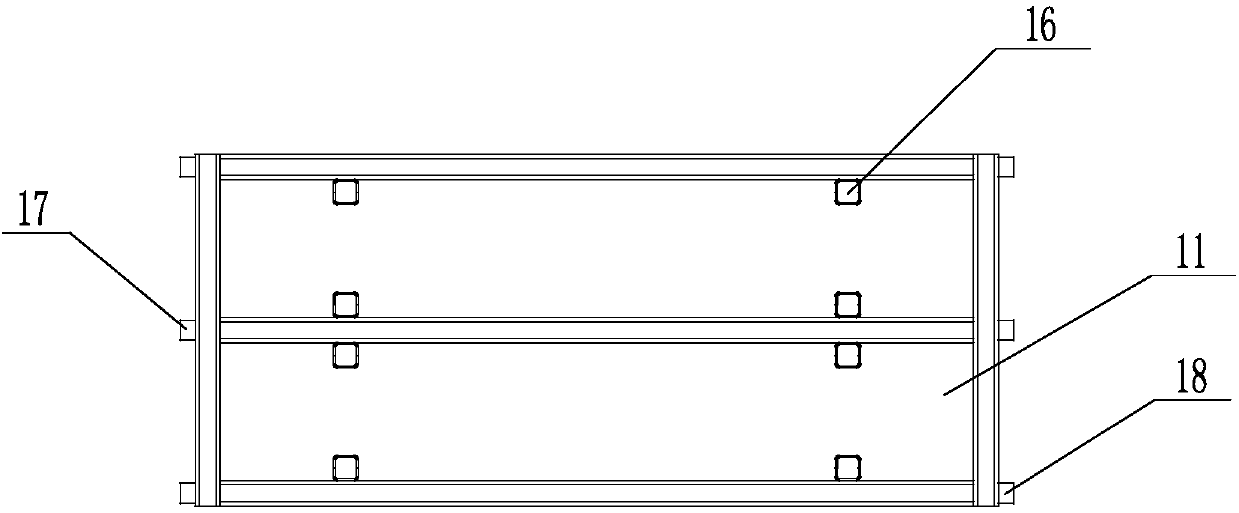

Inverted construction method for template engineering of cast-in-place shear wall structure system

The invention relates to an inverted construction method for template engineering of a cast-in-place shear wall structure system, which specifically comprises the following operation steps: step one, synchronously carrying out (a) a process of setting up a support frame and mounting a beam plate template and (b) a process of welding and binding wall steel bars; step two, (c) a process of binding beam plate steel bars and (d) a process of mounting a wall template; and step three, (e) a process of integrally casting wall panel concrete. The method is suitable for the industrial and civil engineering adopting a shear wall, in particular a short-pier shear wall structure system, is also suitable for scattered-split support templates or steel frame combined templates, and is further suitable for all steel supports adopted by the beam plate template; the work efficiency is remarkably improved, and the construction period of a main body structure is shortened by about 40 percent compared with the prior construction method; the engineering quality is ensured, namely the root of the wall is ensured to be clean, the dislocation and slag inclusion are prevented, the quality of a joint of the beam plate and the wall is ensured, and the verticality of the wall is ensured; the construction safety is ensured; and the construction period is saved by about 40 percent.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP

Intelligent 3D printing device capable of achieving smooth printing and free of faults

ActiveCN106938536AAvoid cloggingPrint smoothly3D object support structuresManufacturing data aquisition/processingDrive wheelSprayer

The invention relates to an intelligent 3D printing device capable of achieving smooth printing and free of faults. The intelligent 3D printing device comprises a printing sprayer and a plurality of supporting units. Each supporting unit comprises a casing pipe, a supporting rod, a buffer board, a spring and a pressure sensor. A material spraying mechanism, a material pipe, a heating ring and a throat pipe are arranged inside the printing sprayer. The material spraying mechanism comprises a slide bar and material spraying units arranged at the two sides of the slide bar. Each material spraying unit comprises a fourth driving motor, a driving wheel and a plurality of driving teeth. Bar-shaped teeth are arranged at the two sides of the slide bar. According to the intelligent 3D printing device capable of achieving smooth printing and free of faults, the pressure sensors in all the supporting units are used for detecting whether a printed sample moves or not, the printing sprayer is moved to a correct position through a camera and a plane moving mechanism and then printing continues, so that the fault problem happening in the printing process is avoided; and moreover, a liquefied material in the throat pipe can flow out of the printing sprayer through the material spraying mechanism, and therefore printing smoothness is guaranteed, nozzle blocking is avoided, and practicability of the printing device is improved.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

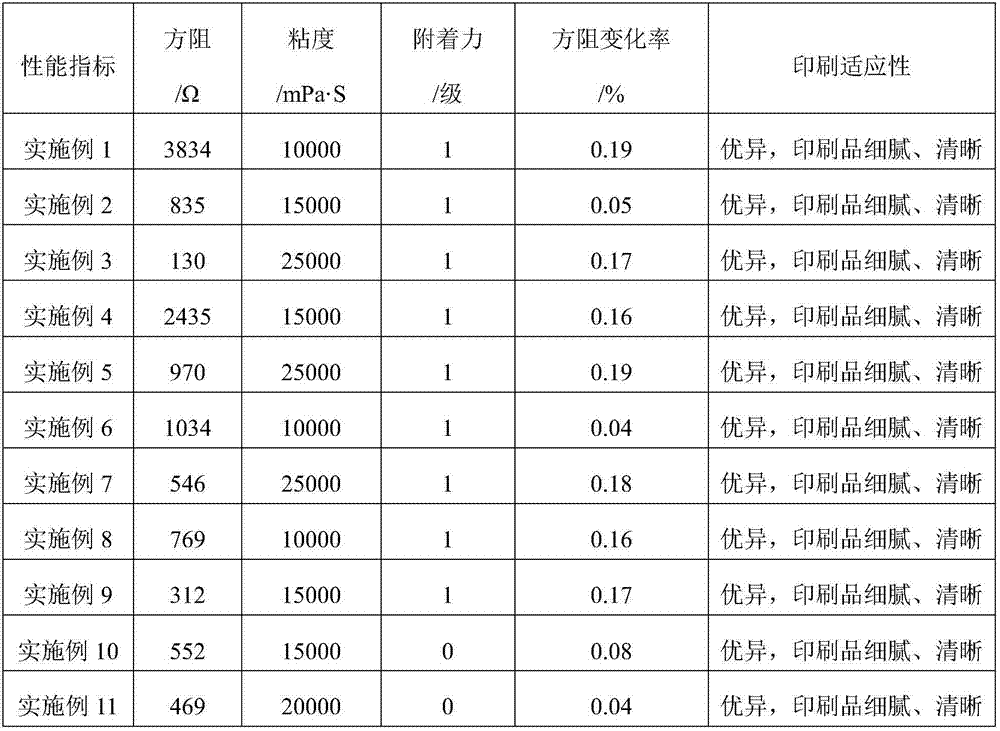

Aqueous graphene conductive ink

InactiveCN107083114AImprove conductivityImprove long-term stabilityInksHeating element materialsGrapheneResin adhesive

The invention discloses an aqueous graphene conductive ink, and belongs to the conductive ink field. The aqueous graphene conductive ink is prepared from, by mass, 0.09-6.40% of graphene, 8.10-63.36% of water, 3.00-24.00% of abrasive mediums, 1.50-24.00% of conductive particles, 3.00-8.00% of second assistants, 10.00-50.00% of resin adhesives and 5.00-20.00% of first assistants, wherein the first assistants comprises dispersing agents and defoamers, and the aqueous graphene conductive ink has a pH value of 8-10, a viscosity value of 3000-30000 mPa.S and a sheet resistance value of 100-5000 Omega. The aqueous graphene conductive ink has the advantages of a good conductivity and long-term stability.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

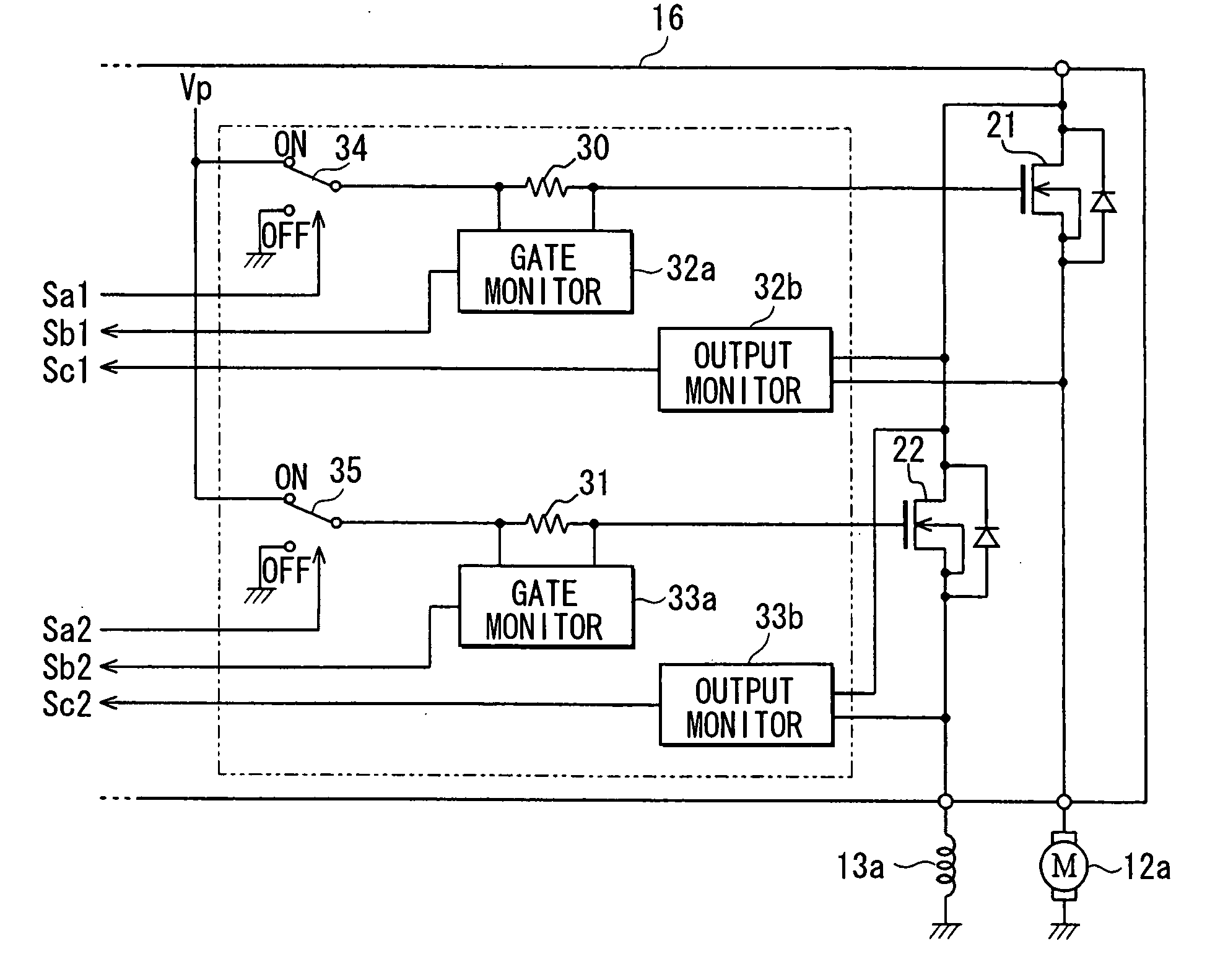

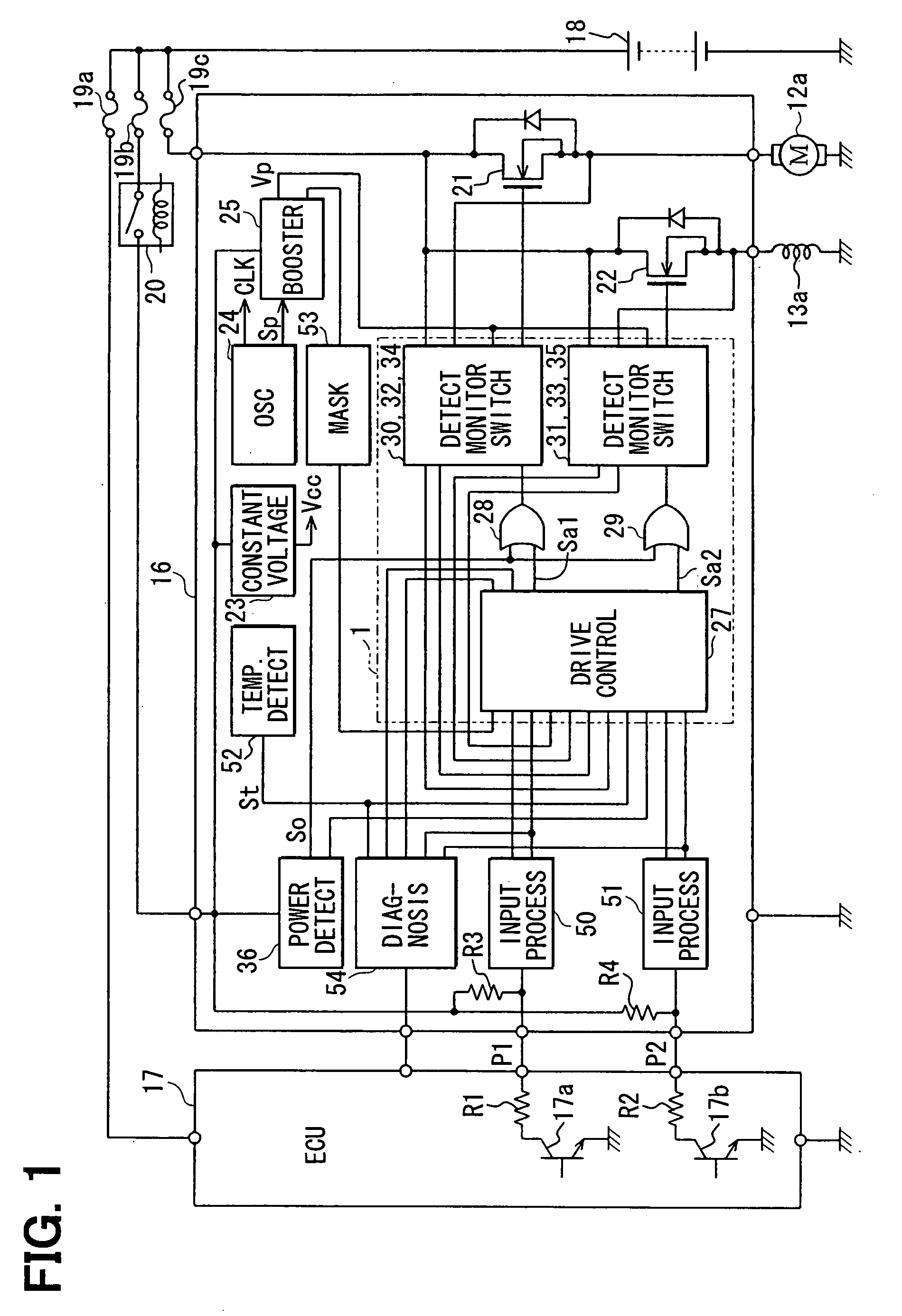

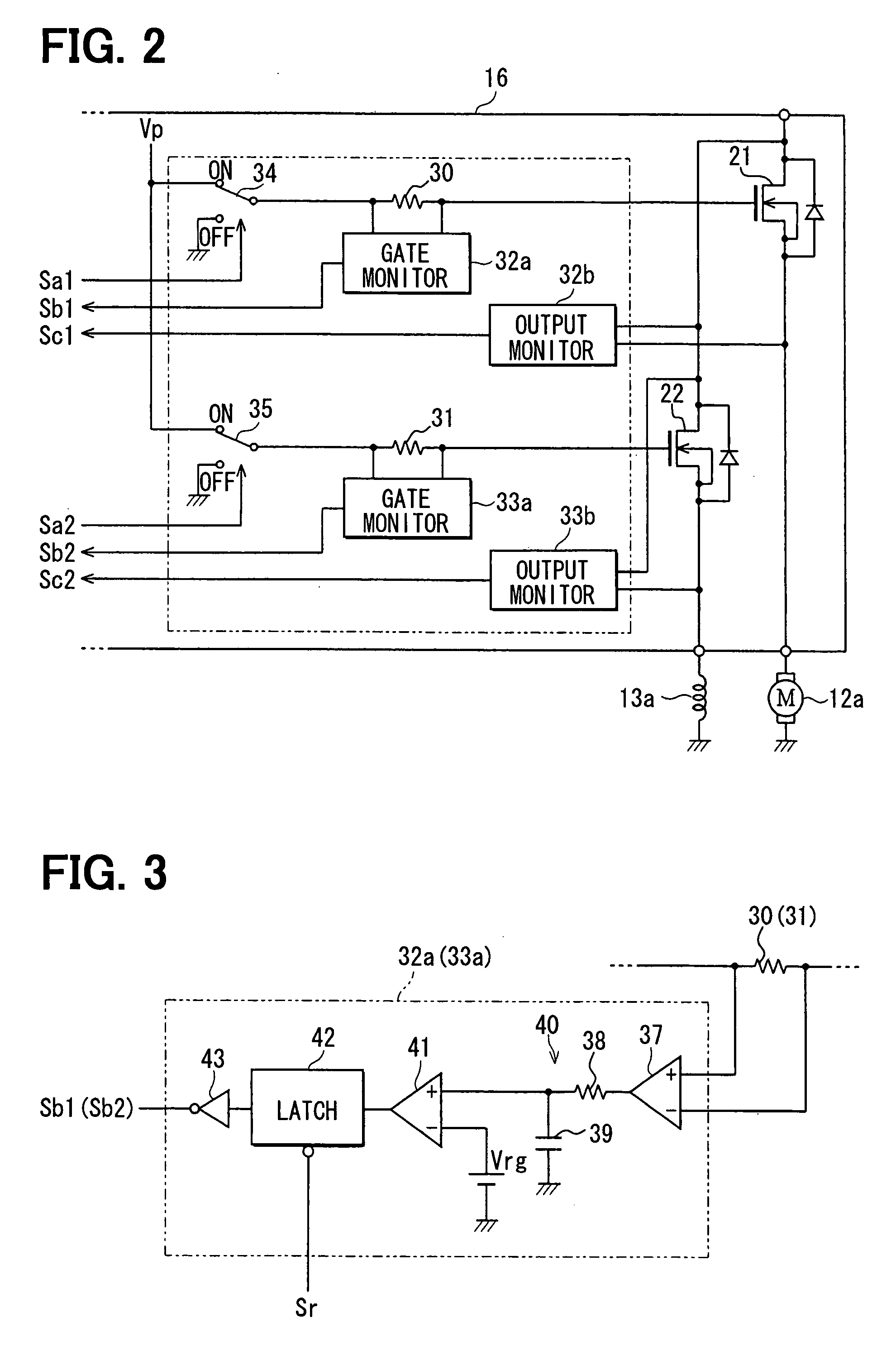

Driving circuit

InactiveUS20070285863A1Avoid faultFaults can be preventedElectrical controlExhaust apparatusMOSFETGate current

When a driving signal changes from L level to H level, a switching-circuit is turned on. Then, a gate current flows from a booster circuit to MOSFET through the switching circuit and a resistor. A gate monitor circuit outputs a drive abnormality detection signal of L level when the gate current exceeds a predetermined threshold value. A switching circuit and MOSFET are also similarly driven by a driving signal, and a gate monitor circuit also similarly outputs a drive abnormality detection signal of the L level. When the drive abnormality detection signal changes to the L level, the driving signals are brought to the L level, and the MOSFETs are separated from the booster circuit.

Owner:DENSO CORP

Preparation method of high-density granulated nickel-cobalt-manganese hydroxide

ActiveCN108264096AGood dispersionLow ammonia usageCell electrodesNickel compoundsManganeseSurface-active agents

The invention relates to a method for continuously preparing high-density granulated nickel-cobalt-manganese hydroxide. Technological parameters are optimized, proper conditions such as liquid feedingtime, ammonia content, temperature, pH (potential of hydrogen) and stirring speed are selected, liquid is continuously fed, deposition is performed, and overflowing liquid is filtered, washed and dried to prepare the nickel-cobalt-manganese hydroxide which is spherical or near-spherical single particles. D50 is 3.0-5.0 micrometers, apparent density (AD) is higher than or equal to 1.2g / cm<3>, tapdensity (TD) is higher than or equal to 1.8g / cm<3>, S<=1200ppm, and Na<=200ppm. According to the method, surface active agents and dispersing agents are not added in the preparation process, crystal nucleuses do not need to be manufactured in advance, production efficiency and product consistency are improved, and the prepared product is good in crystallization property and low in impurity content.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

Wear-resisting antiskid plastic track and preparation method

InactiveCN107090131AGood anti-slip and wear-resistant effectExtended service lifeNon-macromolecular adhesive additivesPaving gutters/kerbsAdhesiveToughness

The invention discloses a wear-resisting antiskid plastic track and a preparation method. The wear-resisting antiskid plastic track sequentially comprises an antiskid wear-resisting layer, a toughness reinforcing layer, a substrate layer and a cement powder stable layer from top to bottom, wherein a figure structure is arranged on the upper surface of the antiskid wear-resisting layer, and the antiskid wear-resisting layer and the toughness reinforcing layer are connected through an adhesive. The preparation method comprises the steps: firstly preparing the antiskid wear-resisting layer, the toughness reinforcing layer and the adhesive respectively; then laying the cement powder stable layer on a soil base layer, laying a self-adhesion SBS modified asphalt layer on the cement powder stable layer, then laying the toughness reinforcing layer on the surface of the asphalt layer, then coating the adhesive on the upper surface of the toughness reinforcing layer and adhering the antiskid wear-resisting layer to obtain the wear-resisting antiskid plastic track. The plastic track not only has better antiskid and wear-resisting performance, but also has better adhering firmness among all the layers; furthermore, the plastic track cannot release toxic gas, is safe and free of pollution and has better practical value.

Owner:合肥市晨雷思建筑材料科技有限公司

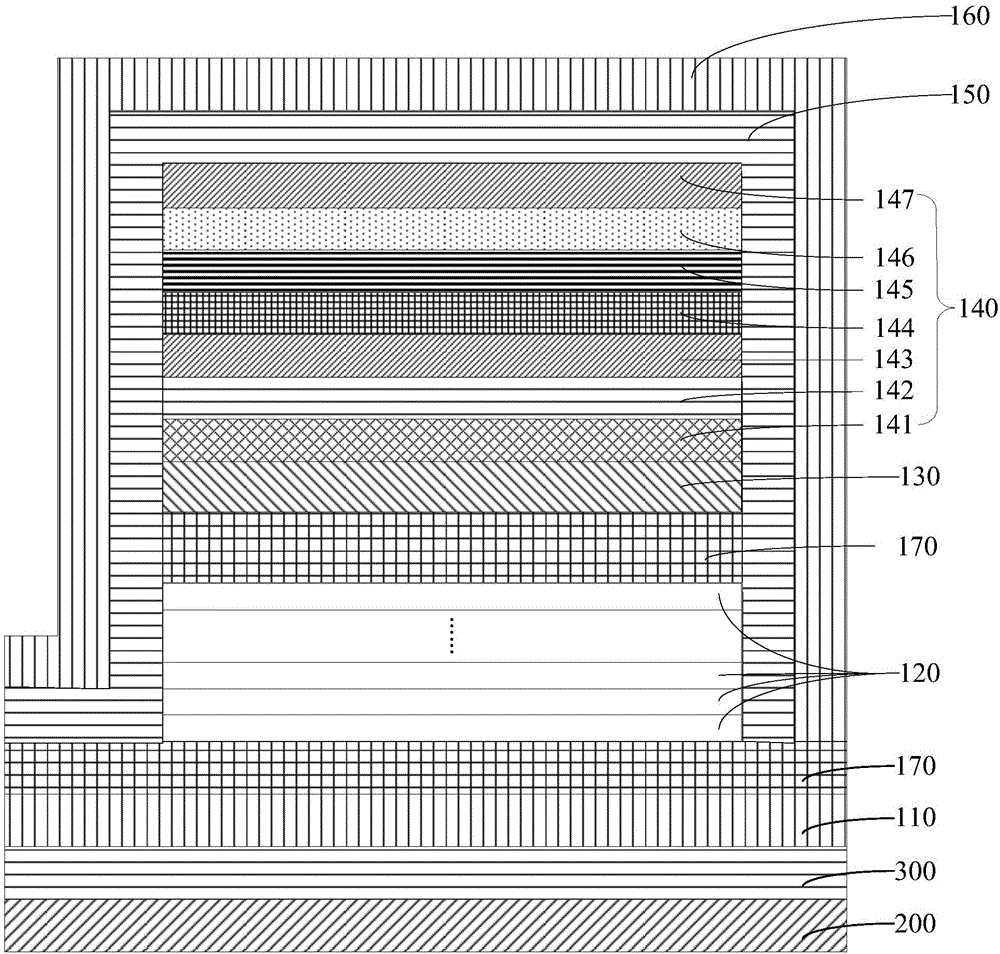

Display panel and preparation method thereof and display device

ActiveCN109390380AAvoid crackingReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The embodiment of the invention discloses a display panel and a preparation method thereof and a display device. The display panel comprises: a planarization layer covering the surface of a device layer, wherein the planarization layer comprises a plurality of pixel regions and a non-pixel region and the planarization layer is provided with a connecting hole exposing an output end; a first anode layer on the bottom and sidewall of the connecting hole and on the upper surface of a part of the planarization layer, the first anode layer spanning the pixel regions and the non-pixel region, and thefirst anode layer being electrically connected to the output end; a pixel defining layer covering the first anode layer of the non-pixel region, the pixel defining layer having a defining hole exposing an upper surface of the first anode layer of the pixel regions; a second anode layer positioned on the upper surface of the first anode layer of the pixel regions in the defining hole. The invention reduces the risk of anode cracking by setting an anode with a special structure, thereby improving the display performance of the display panel.

Owner:YUNGU GUAN TECH CO LTD

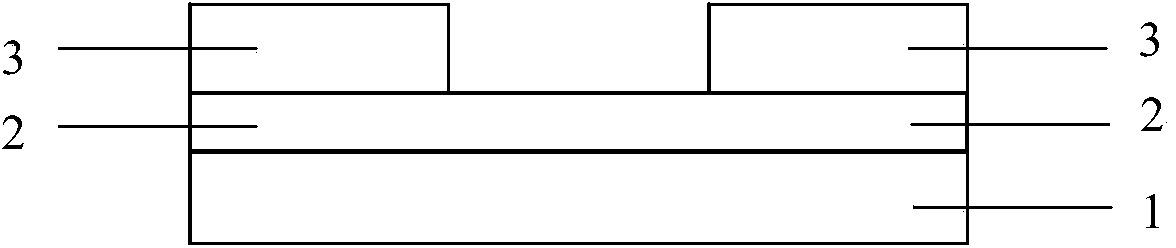

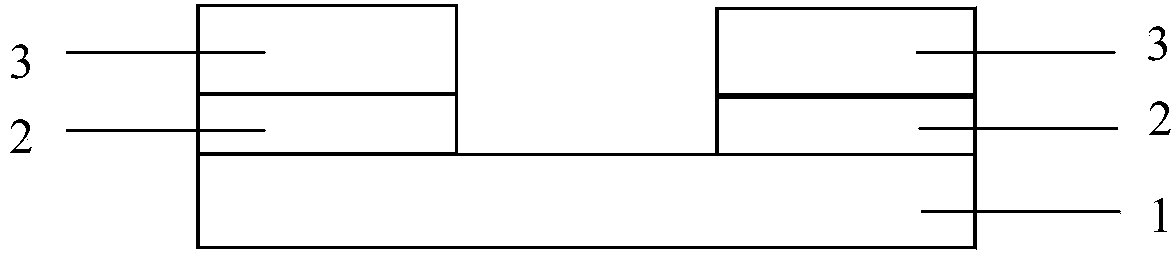

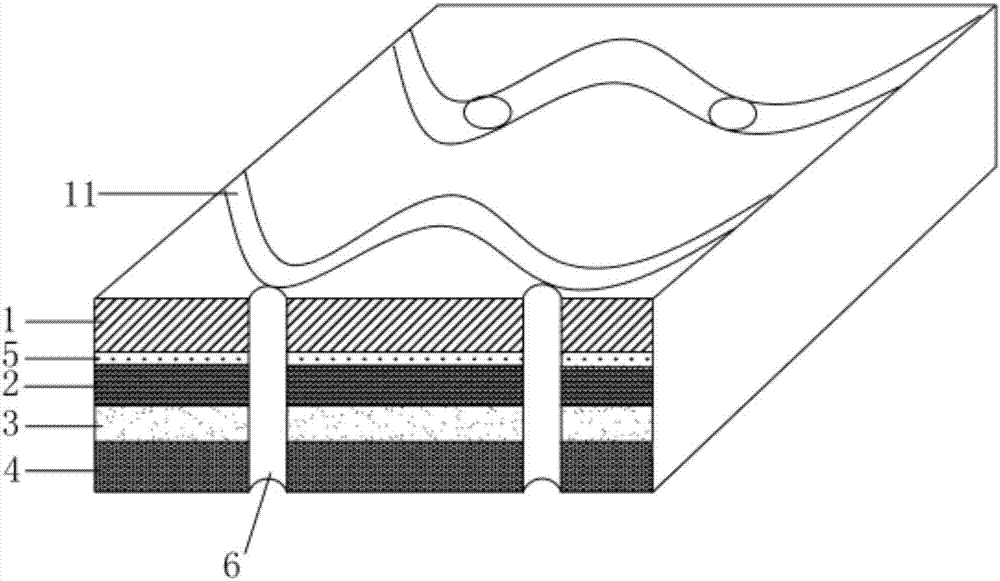

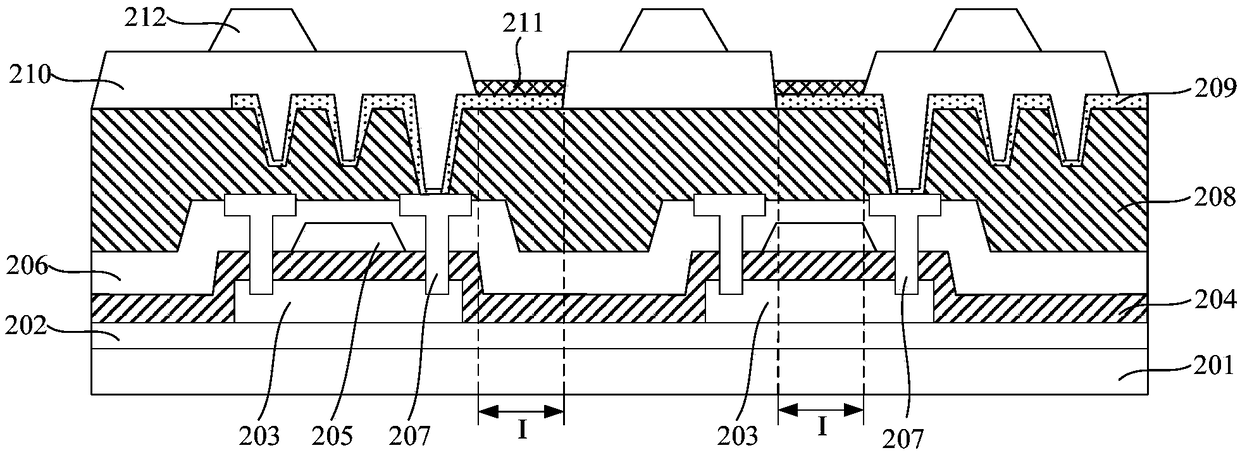

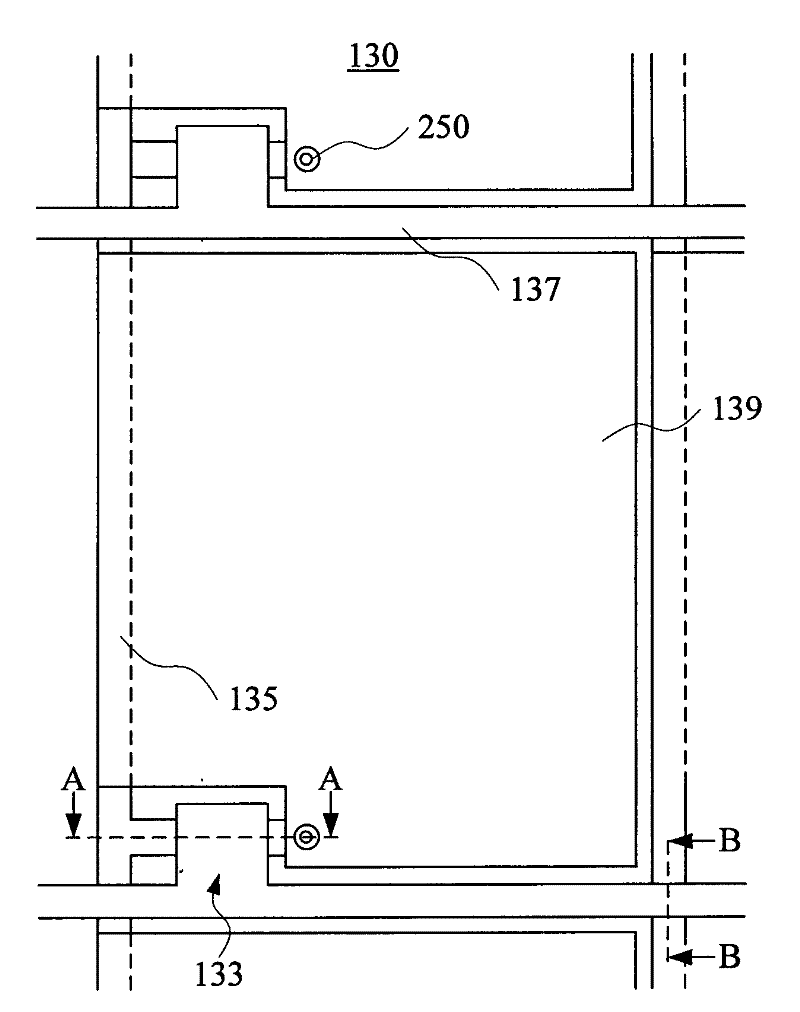

Array baseplate and manufacturing method thereof as well as display panel using same

InactiveCN102315214APrevent display defectsAvoid faultSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransistor

The invention relates to the technical field of flat-plate display, in particular to an array baseplate, which comprises a second transparent substrate, a plurality of thin-film transistors and a plurality of data wires, wherein the second transparent substrate is provided with a third surface for forming a plurality of receiving spaces, and the thin-film transistors and the data wires are formed on the second transparent substrate; and each thin-film transistor comprises a source electrode and a drain electrode, and the source electrodes of the thin-film transistors positioned on the same column are connected with a same data wire and are received in the receiving spaces together with the drain electrodes of the thin-film transistors. In addition, the invention also provides a manufacturing method of the array baseplate and a display panel using the array baseplate.

Owner:SHENZHEN LAIBAO HI TECH

High absorptivity diaper core

InactiveCN106963562AImprove breathabilityImprove absorption and utilizationAbsorbent padsBandagesEngineeringPolymer

The invention discloses a high absorptivity diaper core. The core comprises a lower core, the lower core comprises first wood pulp dust-free paper, first fluffy cotton and first hydrophilic non-woven fabric which are pressed from top to bottom and formed, a first polymer layer is arranged in the first fluffy cotton in a clipped mode, the first polymer layer comprises first polymer water absorbent beads distributed evenly, the upper surface of the first hydrophilic non-woven fabric is provided with an upper core, the surface area of the upper core is 1 / 7 -2 / 3 of the surface area of the lower core, an adhesion layer is connected between the first hydrophilic non-woven fabric and the upper core, the upper core is adhered to the lower core, the upper core is smaller than the lower core, and therefore the thickness of the middle area of a diaper is increased, absorption quantity demanded of the middle portion of the core can be ensured, the thickness of the lower core can be reduced at the same time, the periphery of which the usage rate is low is light and thin, the permeability of the core is improved, and the usage amount of row materials of the core is saved, the middle portion of the core is centralized at the same time, and the absorption and utilization rate of the core can be improved.

Owner:广东恒一实业有限公司

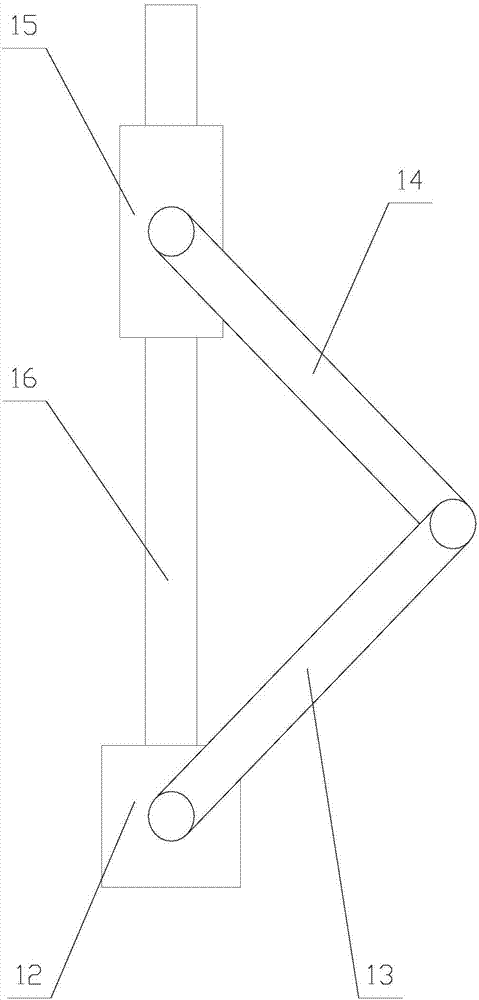

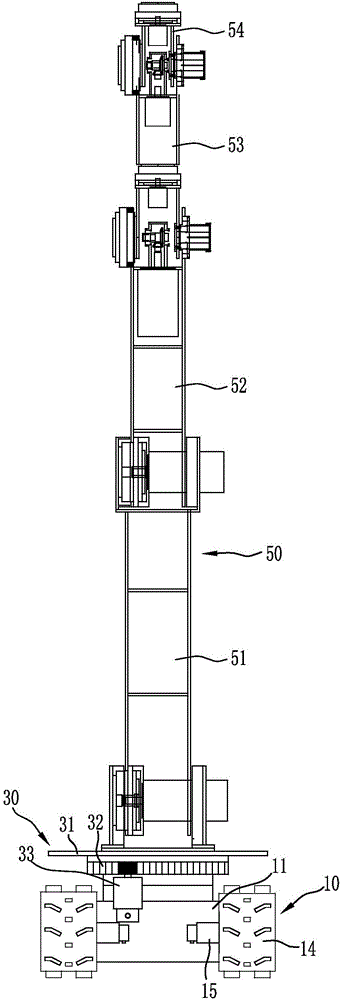

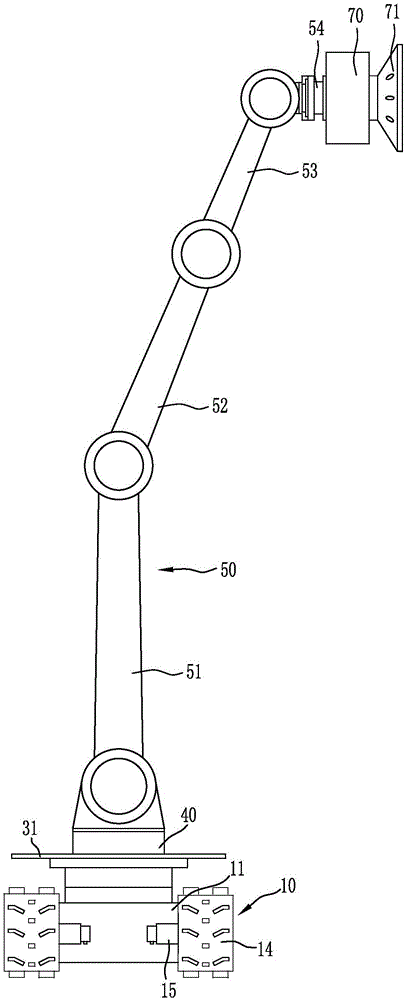

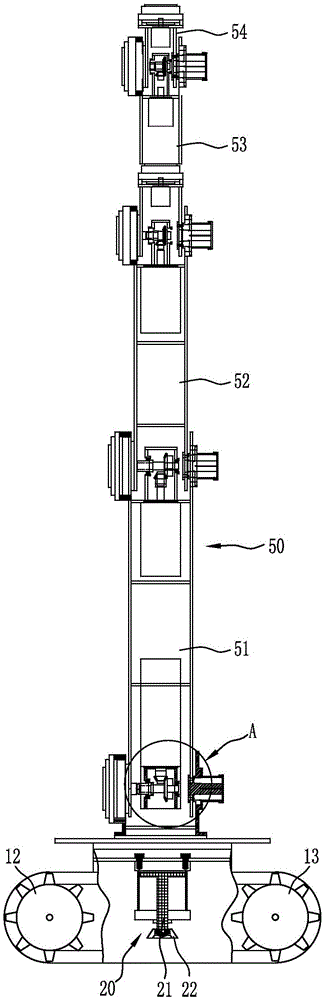

Intelligent robot for architectural ornament

InactiveCN106737560AAchieve stabilityFollow upProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses an intelligent robot for architectural ornament. The intelligent robot comprises a crawler walking mechanism, an origin rotating mechanism, a rotary turntable mechanism, an extension and retraction adjustment mechanical arm and a construction mechanism, wherein the origin rotating mechanism comprises a base plate lifting device mounted on a base plate, the base plate lifting device comprises a liftable rotary device, and a supporting device supported on the ground is mounted at the lower end of the rotary device; the rotary turntable mechanism comprises a rotary turntable rotationally mounted on the base plate, a rotary driving mechanism is arranged between the rotary turntable and the base plate, and a mechanical arm support base is mounted on the rotary turntable; the extension and retraction adjustment mechanical arm is fixedly mounted on the mechanical arm support base; and the construction mechanism is detachably mounted at the tail end of the extension and retraction adjustment mechanical arm. The intelligent robot is more compact in structural design and flexible and convenient in construction, and can realize various operations such as high-quality continuous spraying.

Owner:蒋学凯

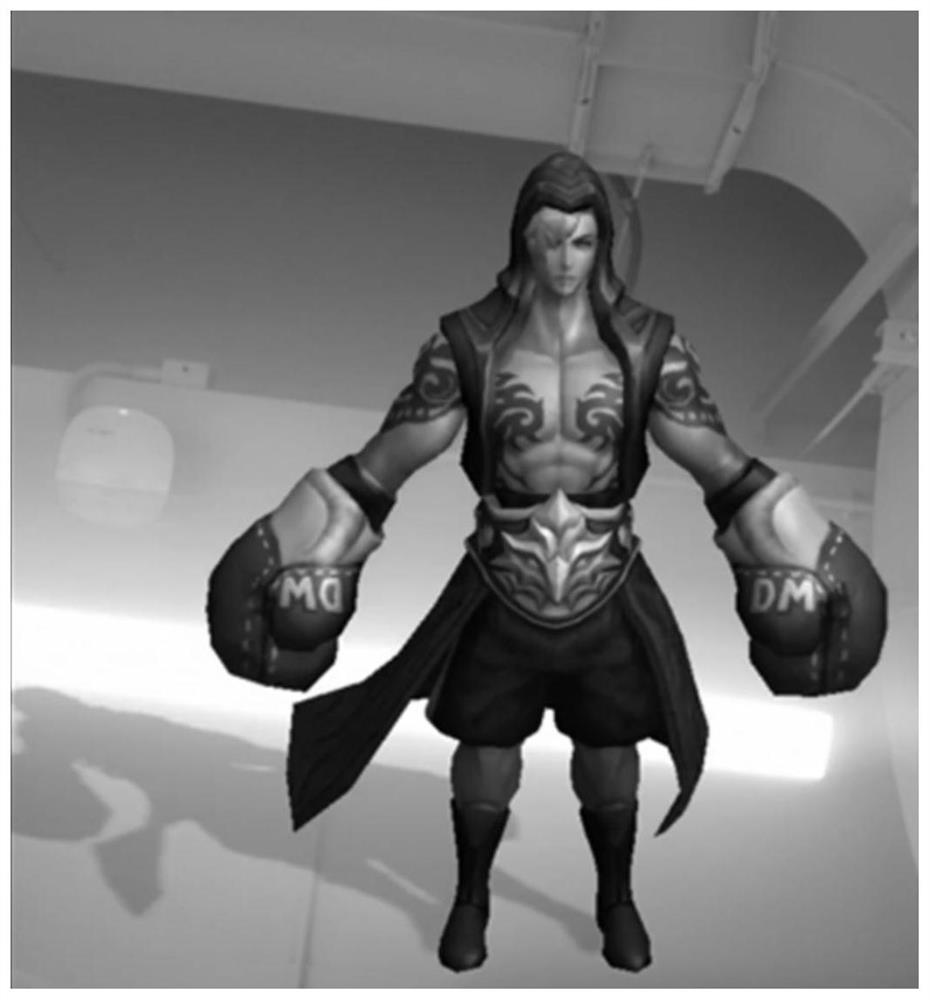

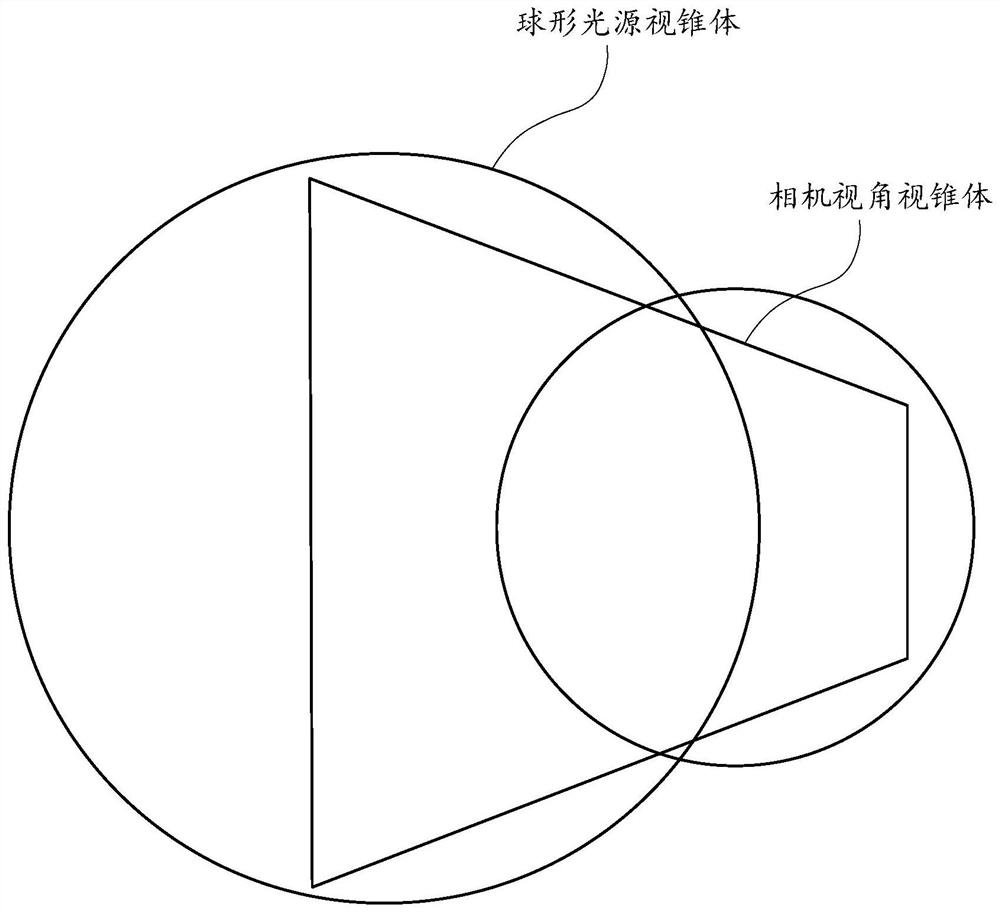

Image rendering method and device, electronic equipment and storage medium

PendingCN112215936AImprove performanceAvoid faultSelective content distribution3D-image renderingGeneration processImaging processing

The invention provides an image rendering method and device, electronic equipment and a storage medium, and relates to the technical field of image processing. The method aims at a virtual object in atarget image to generate a target shadow map corresponding to the virtual object according to a target projection matrix by calculating the target projection matrix of the virtual object under a spherical light source view cone, and therefore the target shadow map is rendered to a target image; thus, in the projection generation process, the same shadow map can be located in the same view frustum, so that a fault is prevented from occurring between every two adjacent view frustums, and the rendering effect of the shadow map is improved.

Owner:GUANGZHOU HUYA TECH CO LTD

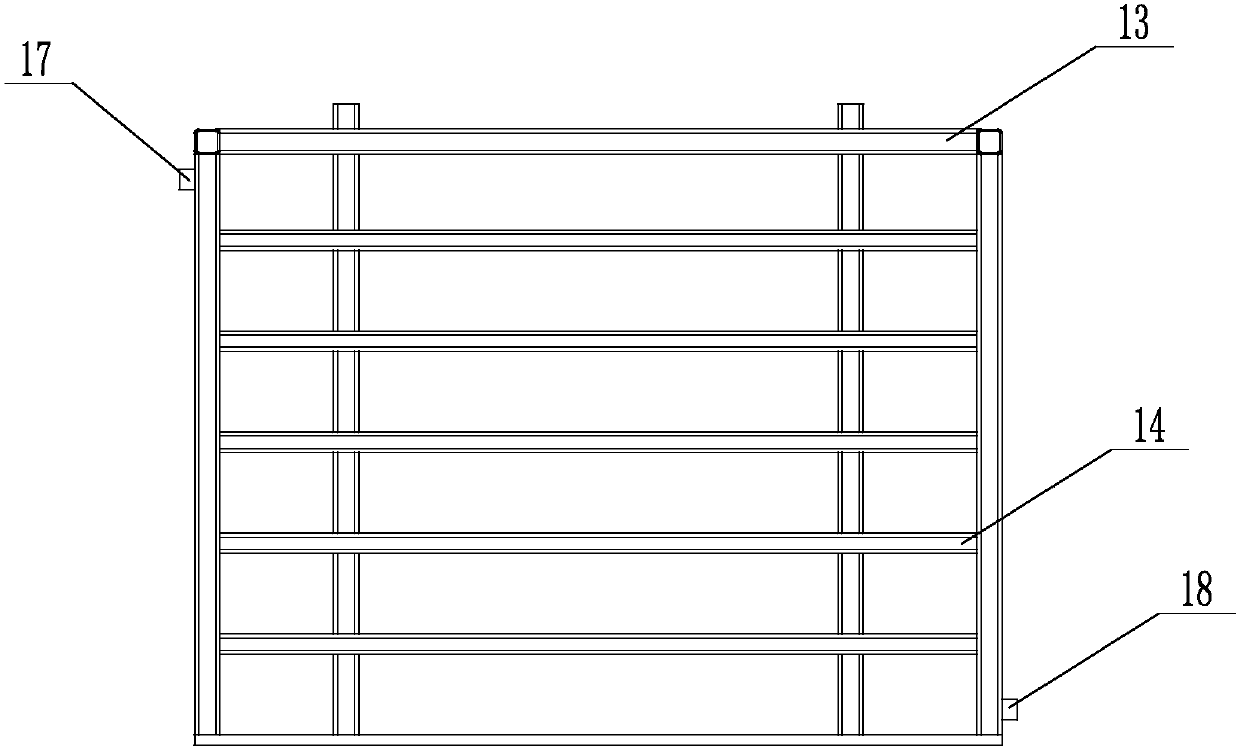

Automatic shielding lead plate pouring device and shielding lead plate production technique

The invention relates to an automatic shielding lead plate casting device and a shielding lead plate production process, belonging to the field of lead shielding product manufacturing, including a support frame body, a mobile vertical mold and a casting lead pot, the mobile vertical mold is installed on the inside of the support frame body, and the lead casting The pot is connected to one end of the pouring lead pipe, and the other end of the lead pouring pipe stretches into the inside of the movable vertical formwork. The invention has a reasonable structural design, can realize one-time continuous casting in a sealed environment, avoids problems such as faults and slag inclusions, can ensure the quality of the shielding lead plate, can realize efficient and safe production, reduces the labor intensity of the staff, and improves the The production efficiency of the shielding lead plate has strong practicability.

Owner:山东沃顿核辐射环境安全装备有限公司

A construction method for greening slope protection in saline-alkali land planted with Zhuge vegetable

ActiveCN108323380BReduce reversion phenomenonAvoid clogged voidsBiocideMagnesium fertilisersVegetationOrychophragmus

The invention discloses a construction method of planting orychophragmus violaceus in a saline-alkali land greening protection slope, and relates to the technical field of greening protection slopes.The method comprises the following steps: (1) cleaning of a slope surface; (2) soil amelioration; (3) preparation of greening concrete; (4) pouring; (5) pretreatment of a sowing slope surface; (6) sowing of the orychophragmus violaceus; and (7) maintenance. The method provided by the invention reduces an efflorescence phenomenon in the saline-alkali land poured greening protection slope, and solves the problems that vegetation of the saline-alkali land protection slope is single and has a low survival rate.

Owner:科利尔环保科技有限责任公司

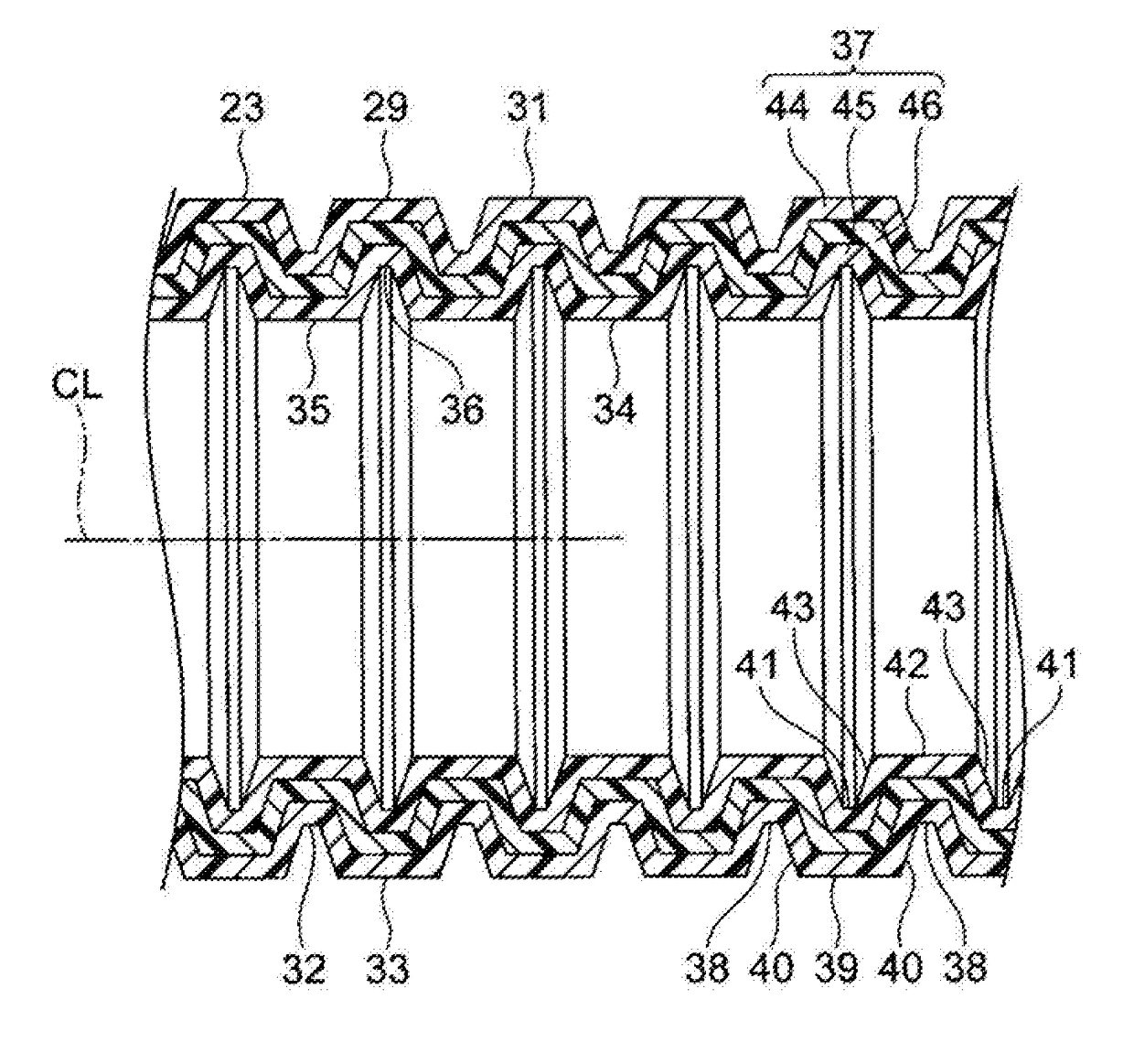

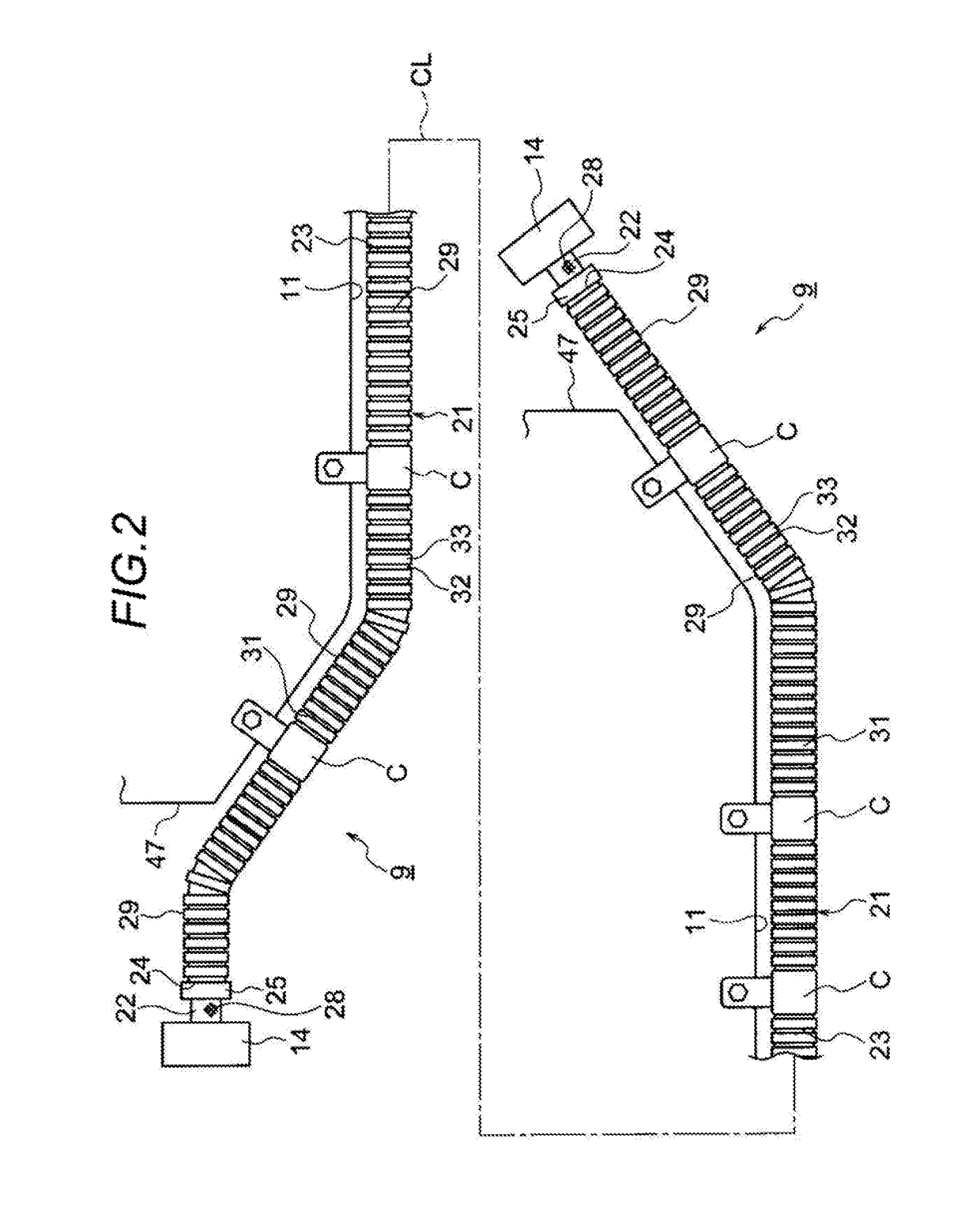

Exterior member and wire harness

ActiveUS20180248346A1Not easy to damageAvoid disconnectionElectrical apparatusElectric/fluid circuitEngineeringCable harness

An exterior member for a wire harness which is formed in a tube shape so as to accommodate and protect one or a plurality of conduction paths, the exterior member includes an outer layer structure part that has an outer surface and that is an outermost layer, an inner layer structure part that has an inner surface and that is an innermost layer, and an intermediate layer structure part that is one or a plurality of layers between the outer layer structure part and the inner layer structure part.

Owner:YAZAKI CORP +1

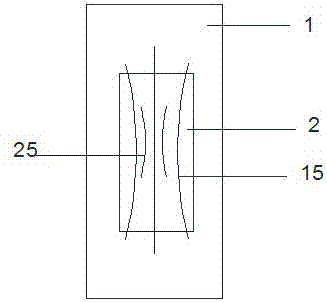

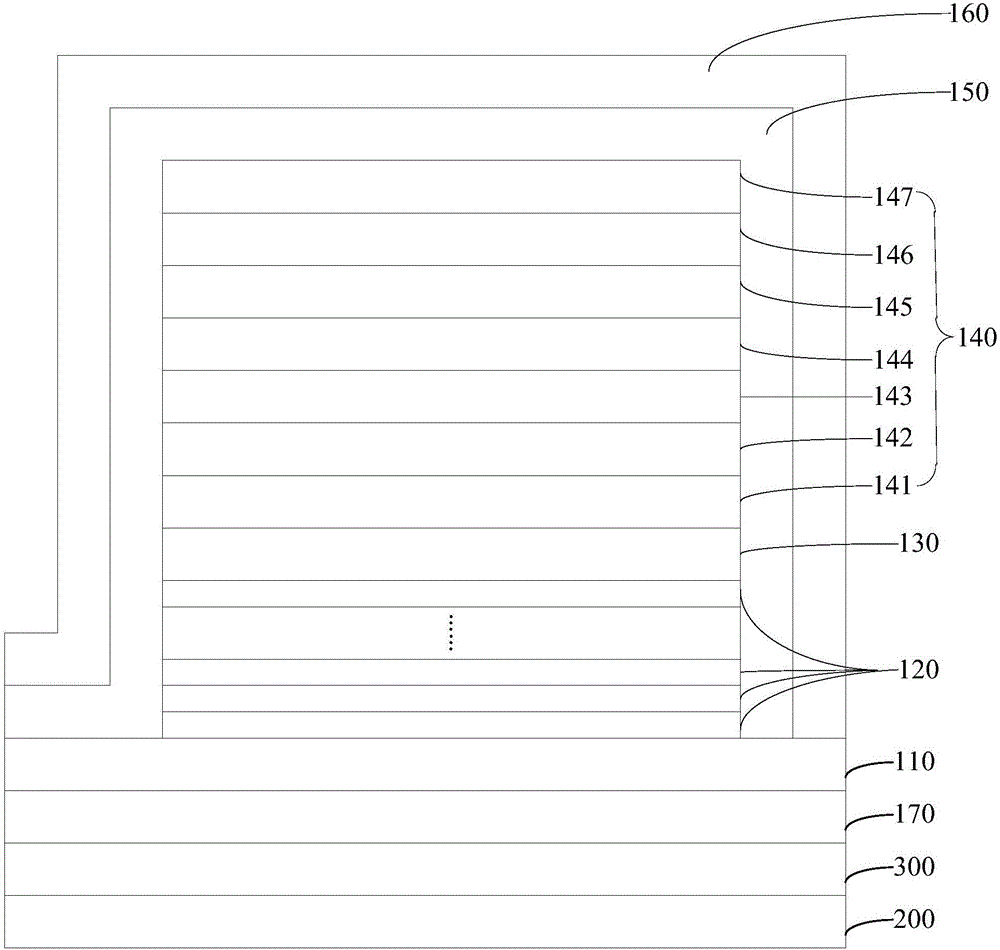

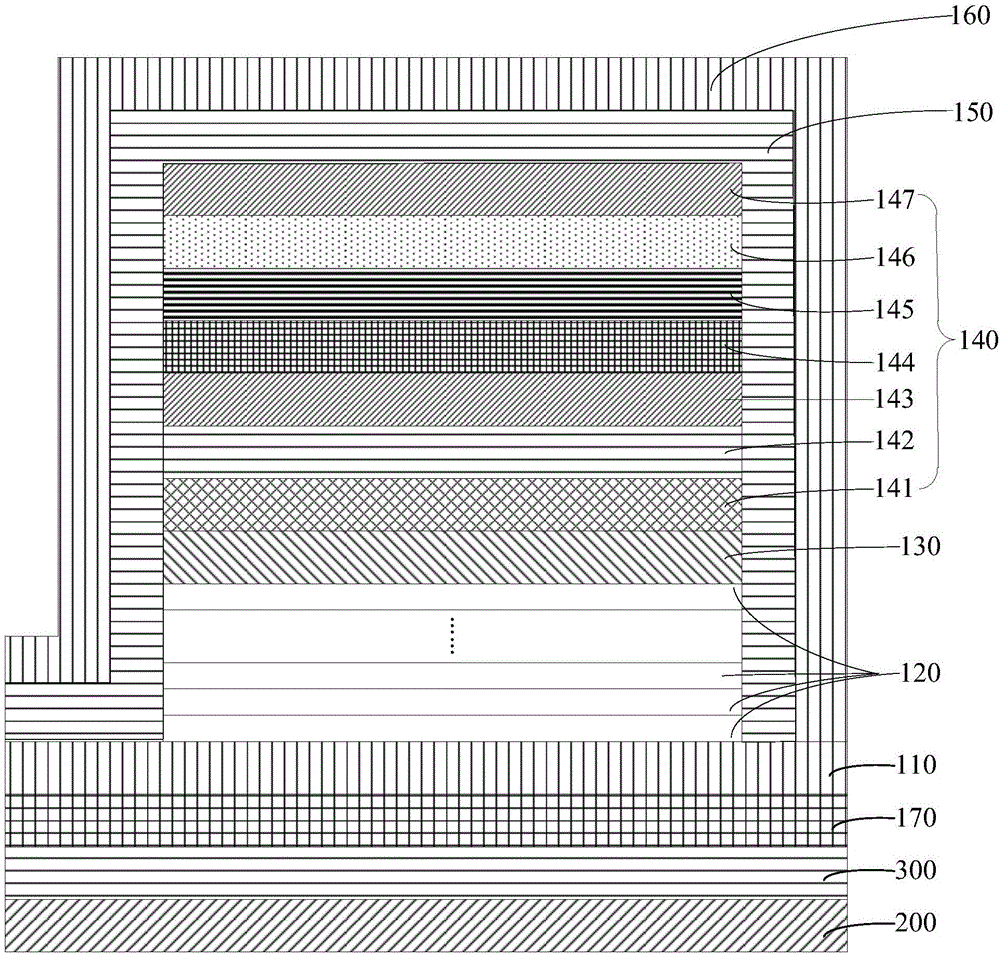

Display device and preparation method thereof and electronic equipment

InactiveCN106024832AGuaranteed display effectAvoid faultSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsOptoelectronics

The invention discloses a display device, which comprises a substrate layer, a TFT layer, an anode layer, an OLED layer, a cathode layer, a packaging layer and a protective film, wherein the TFT layer is formed on the substrate layer; the anode layer is formed on the TFT layer; the OLED layer is formed on the anode layer; the cathode layer is formed on the OLED layer and the substrate layer which is not covered by the OLED layer; the packaging layer is formed on the cathode layer and the substrate layer which is not covered by the cathode layer; the packaging layer, the cathode layer and the substrate layer form a coating space; the protective film is formed on at least one of the following positions: the surface, departing from the TFT layer, of the substrate layer, the part between the TFT layer and the anode layer, the part between the anode layer and the OLED layer, the part between the OLED layer and the cathode layer, the part between the cathode layer and the packaging layer, and the surface, departing from the cathode layer, of the packaging layer; and the protective film is suitable for deforming along with bending of the display device. By the display device, the problem that the overall display effect of a screen body of a traditional display device is uneven is effectively solved. The invention further discloses a preparation method of the display device and electronic equipment.

Owner:刘华英

Slurry conveying device, hole blocking device and hole blocking robot

InactiveCN110778121APrecise deliveryAvoid enteringBuilding repairsBuilding material handlingEngineeringMachine

The invention provides a slurry conveying device, a hole blocking device and a hole blocking robot, and relates to the field of building machines. The slurry conveying device comprises a pumping mechanism and a conveying pipe. The pumping mechanism pumps slurry to a grouting mechanism through the conveying pipe, a first valve is arranged between the conveying pipe and the pumping mechanism, and asecond valve is arranged between the conveying pipe and the grouting mechanism. According to the slurry conveying device, slurry precise conveying can be achieved. The hole blocking device comprises the slurry conveying device, and precise conveying of slurry can be achieved. The hole blocking robot comprises the hole blocking device, and precise conveying of the slurry can be achieved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

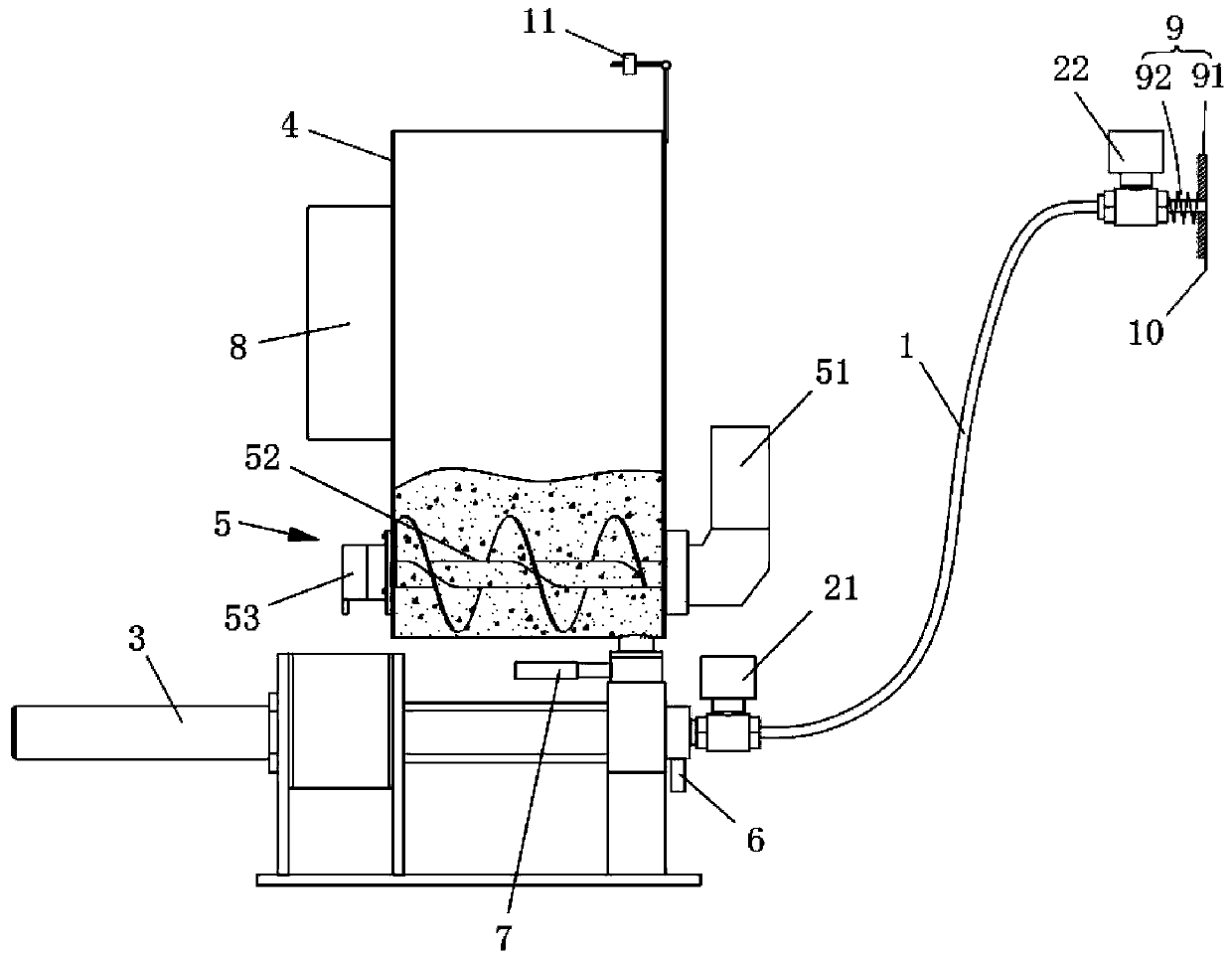

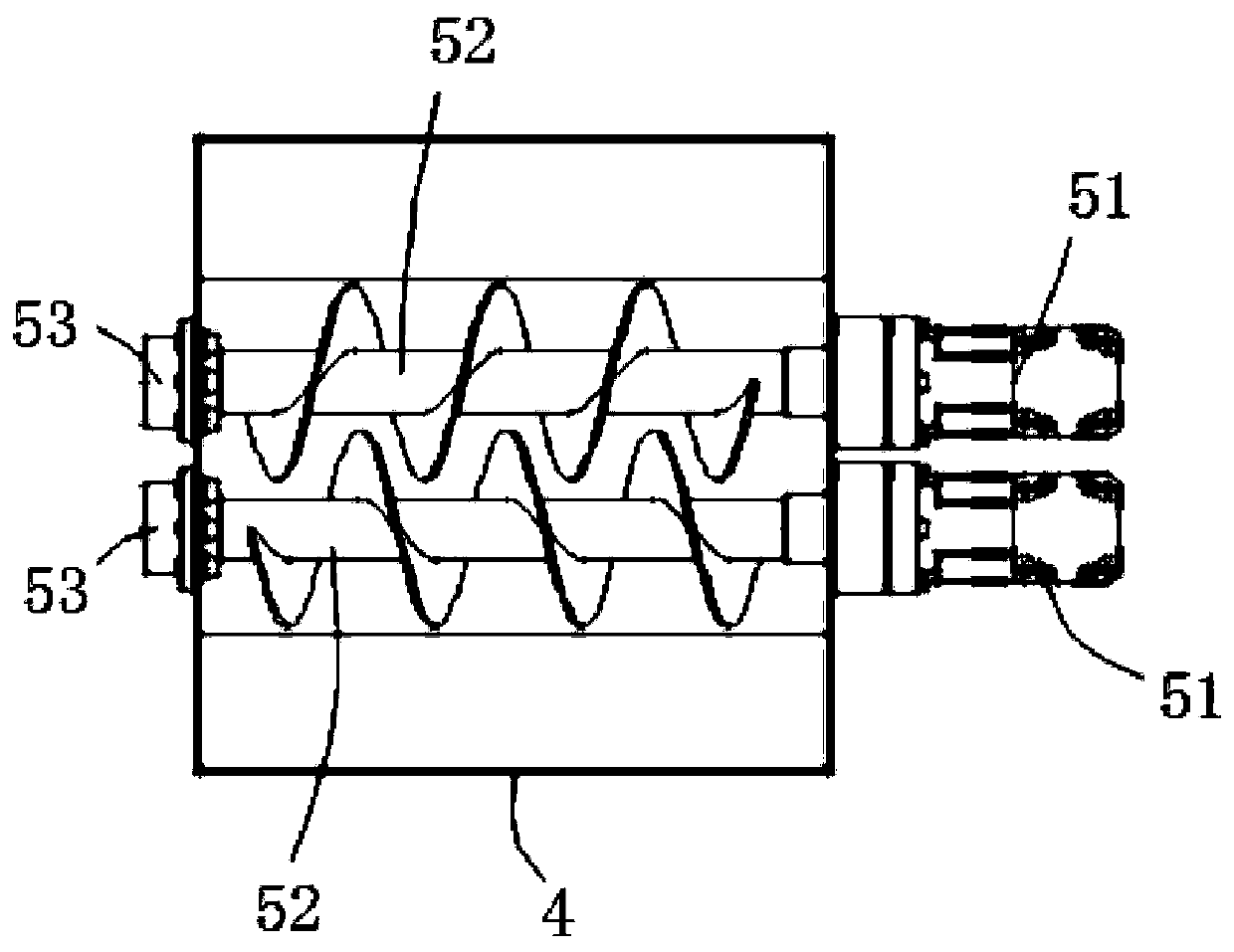

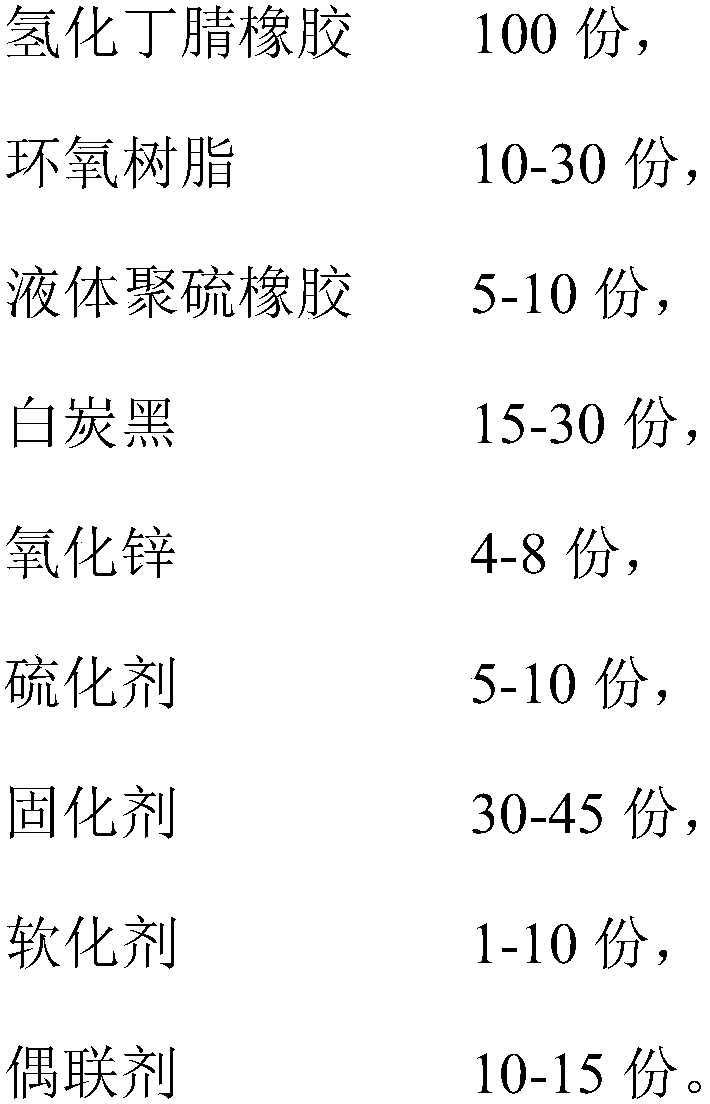

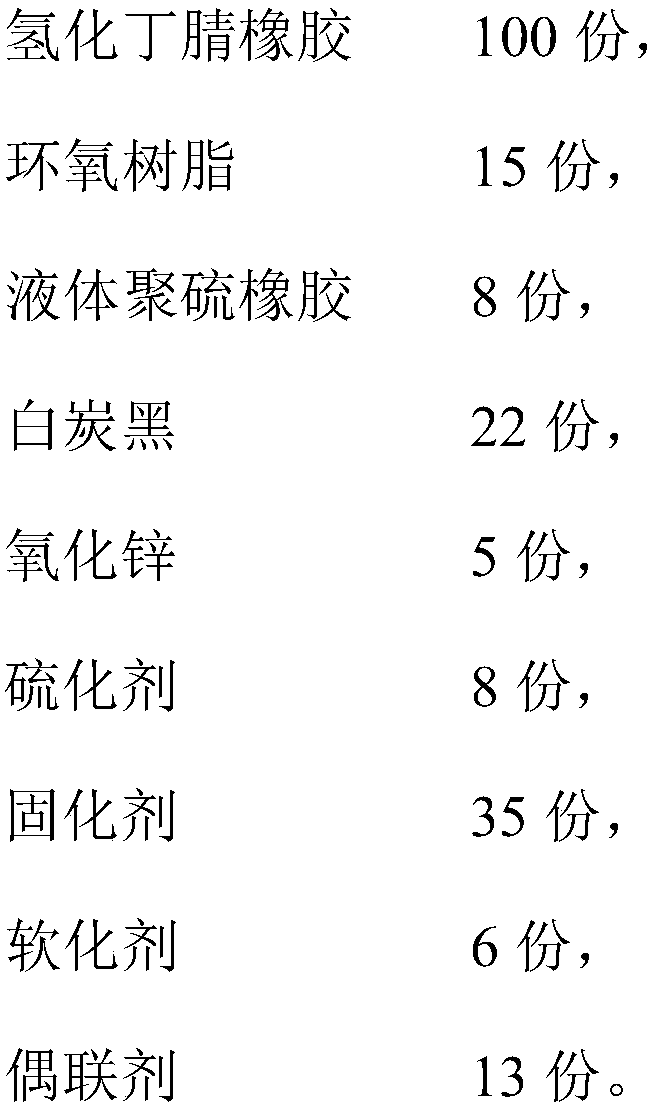

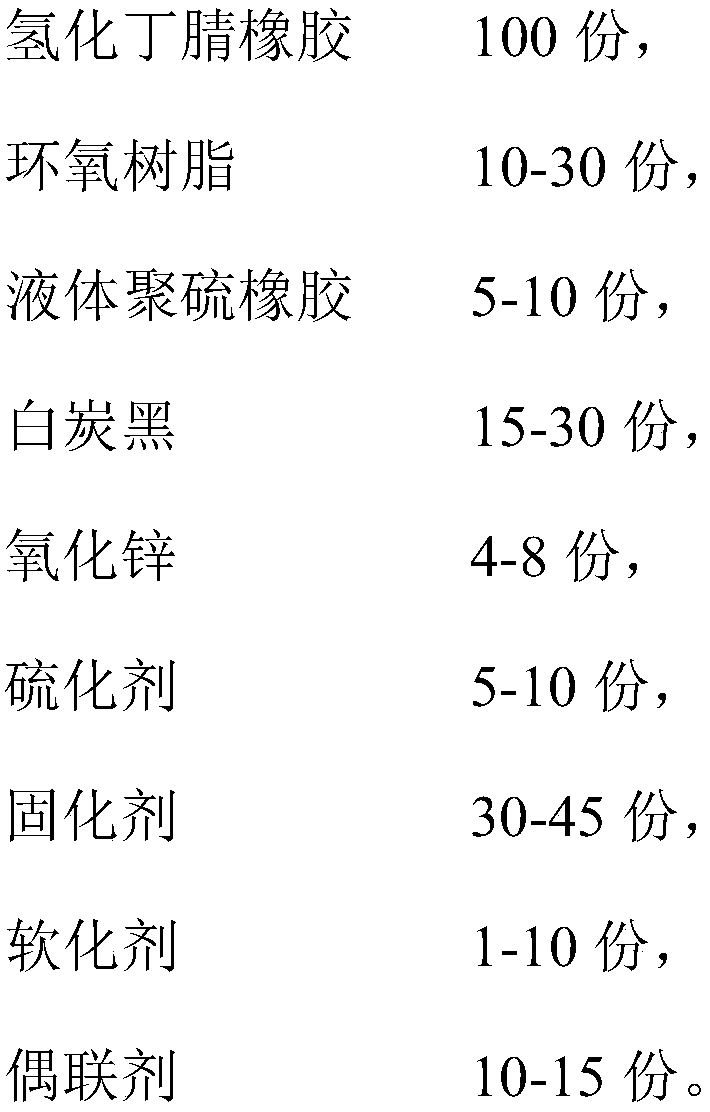

Rubber for sealing metal and preparation method thereof

The invention discloses rubber for sealing metal and a preparation method thereof. The rubber is prepared from the following raw materials in parts by weight: 100 parts of hydrogenated butadiene-acrylonitrile rubber, 10-30 parts of epoxy resin, 5-10 parts of liquid polysulfide rubber, 15-30 parts of white carbon black, 4-8 parts of zinc oxide, 5-10 parts of a vulcanizing agent, 30-45 parts of a curing agent, 1-10 parts of softener and 10-15 parts of a coupling agent. The method comprises the following steps: (1) premixing; (2) mixing; and (3) vulcanizing.The rubber prepared by the method can be used for effectively adsorbing metal when being applied to a metal device, preventing the metal device from loosening or falling and ensuring the sealing property, is convenient to take and replace,and forms a magnet-like effect with metal.

Owner:KACO WUXI

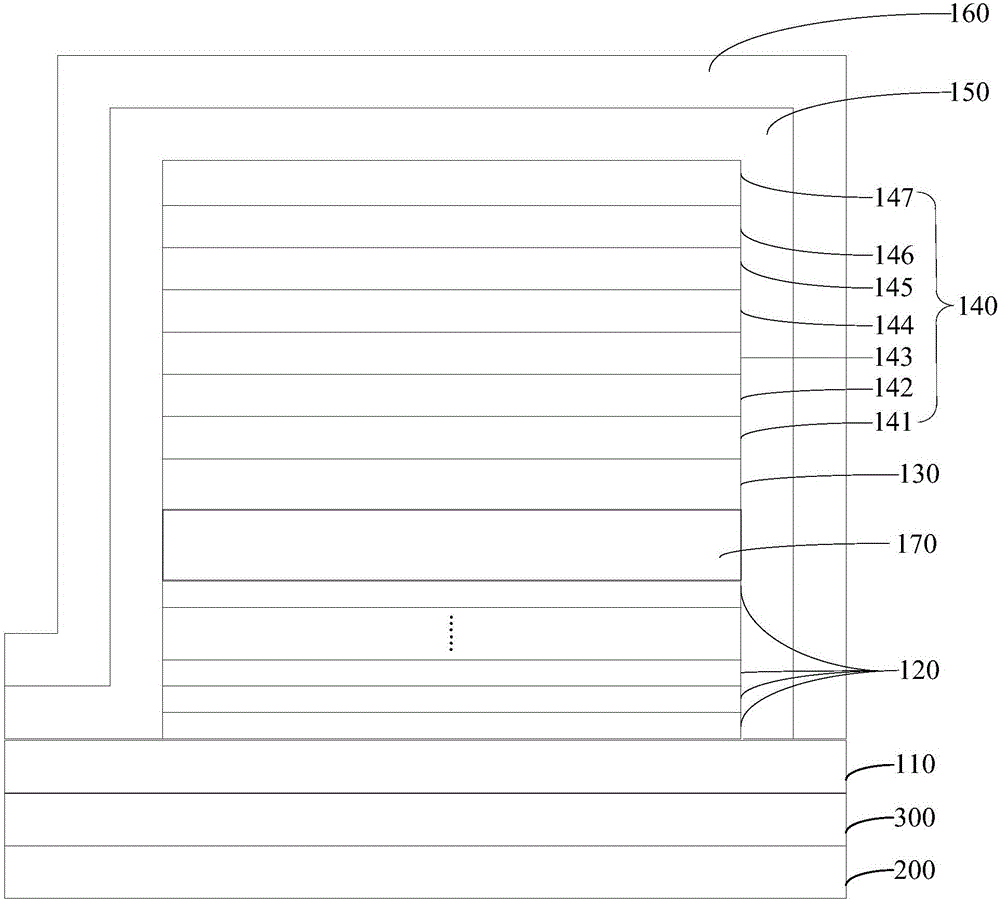

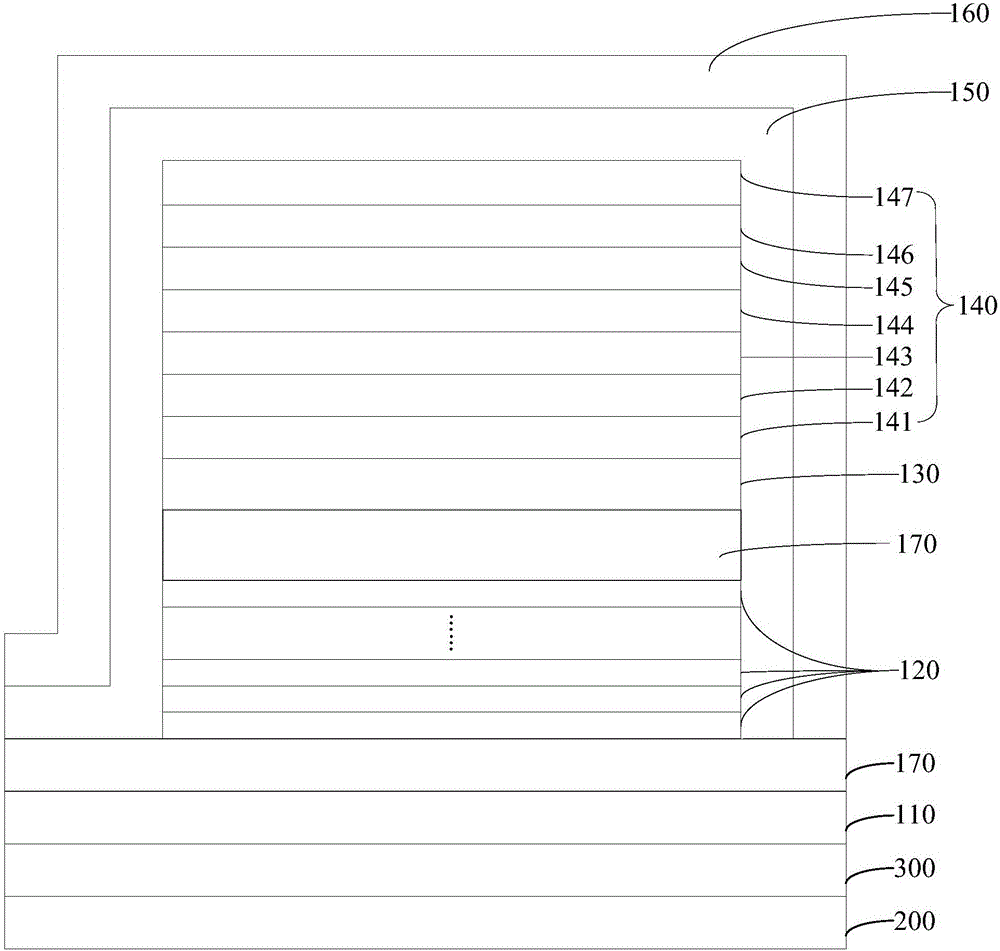

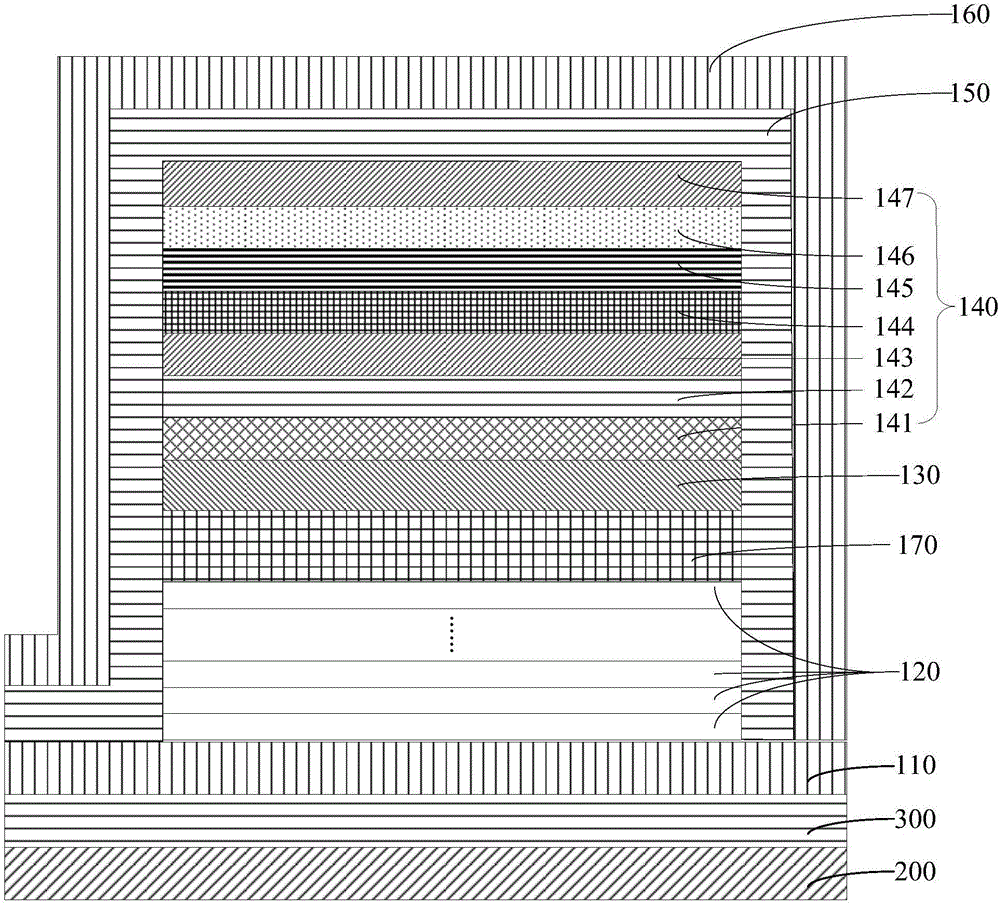

Flexible display apparatus and preparation method therefor, and electronic equipment

ActiveCN105810715AGuaranteed display effectAvoid faultSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The invention discloses a flexible display apparatus and a preparation method therefor, and electronic equipment. The flexible display apparatus comprises a substrate layer, a TFT layer formed on the substrate layer, a positive electrode layer formed on the TFT layer, an OLED layer formed on the positive electrode layer, a negative electrode layer formed on the OLED layer and the substrate layer which is not covered with the OLED layer, and a packaging layer formed on the negative electrode layer and the substrate layer which is not covered with the negative electrode layer, wherein a packaging space is formed by the packaging layer, the negative electrode layer and the substrate layer; the flexible display apparatus also comprises a protective film which is bent and deformed along with the flexible display apparatus; and the protective film is formed in at least one position as follows: the surface, deviating from the TFT layer, of the substrate layer, the position between the TFT layer and the positive electrode layer, the position between the positive electrode layer and the OLED layer, the position between the OLED layer and the negative electrode layer, the position between the negative electrode layer and the packaging layer, and the surface, deviating from the negative electrode layer, of the packaging layer. The problem of uneven display effect of the screen of the conventional flexible display apparatus is effectively solved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

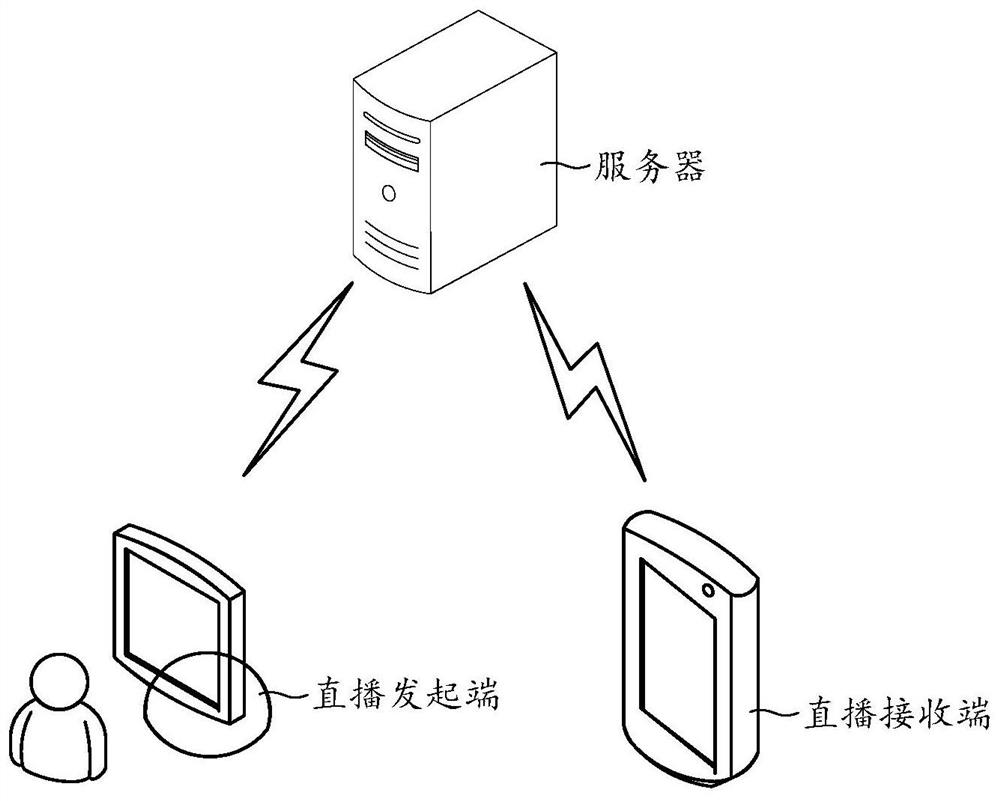

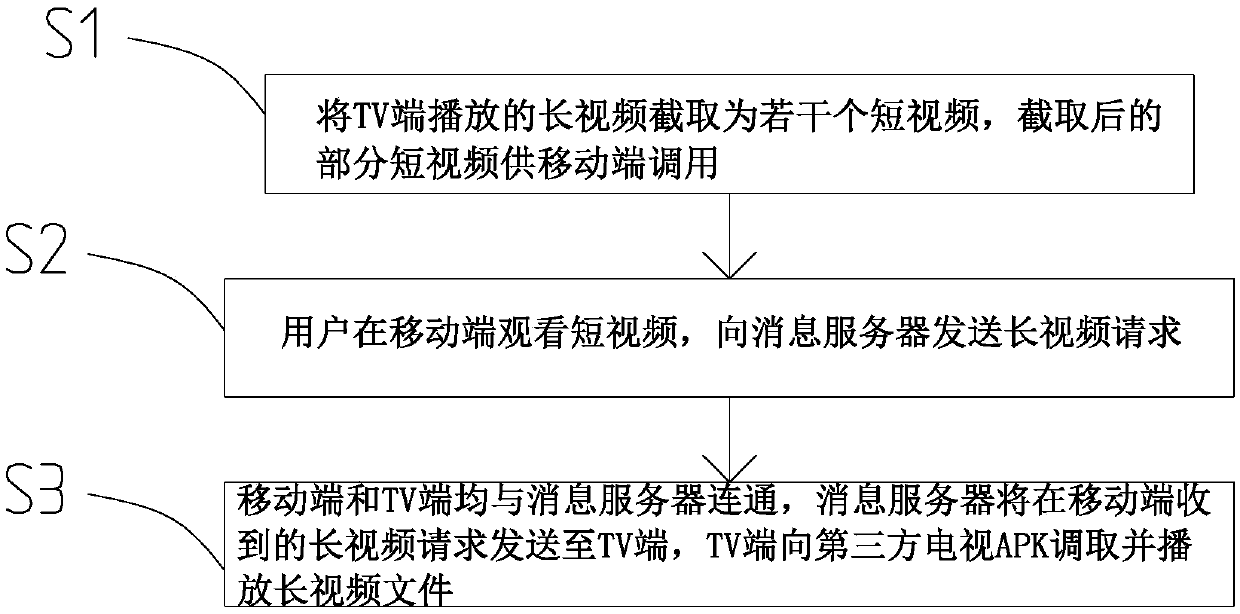

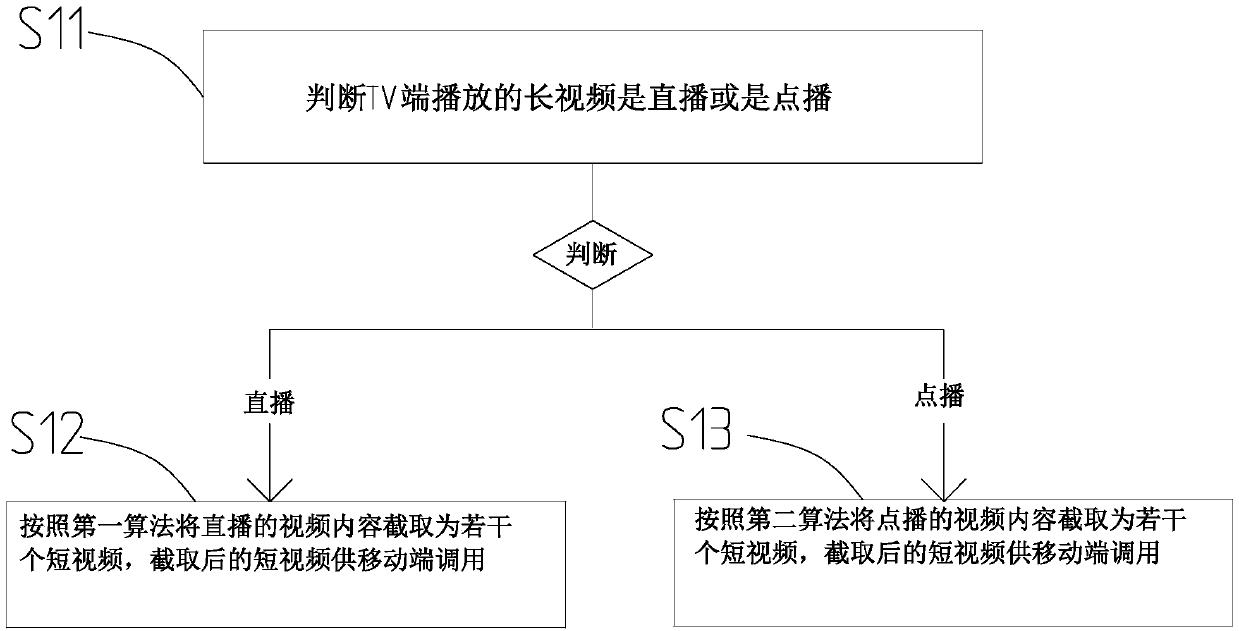

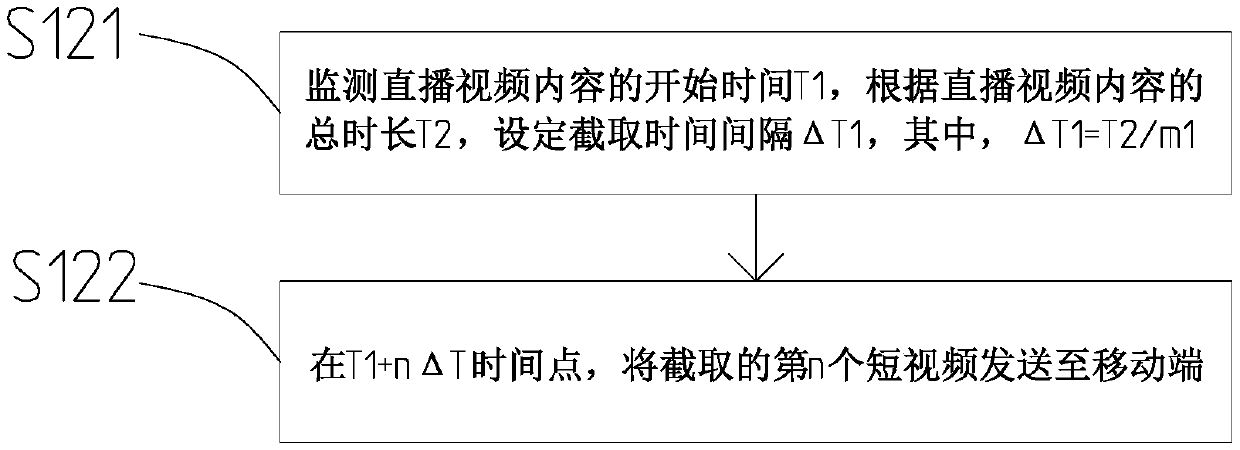

Cross-screen viewing method for guiding long video by short video

InactiveCN110418147AImprove experienceAvoid faultSelective content distributionThird partyComputer science

Owner:彩云之端文化传媒(北京)有限公司

Building support and method of using same

The invention relates to the field of buildings, in particular to a building support and a method of using the same; the building support comprises a bottom plate, a stabilizing device is arranged on the bottom plate, a first adjusting device is arranged on the upper end face of the bottom plate, and a second adjusting device is arranged on an upper support barrel of the first adjusting device. The building support is convenient to operate, the height of the building support can be adjusted from different positions, the building support is applicable to more complex supporting environments, is more convenient to detach, has fine adjustment function, and can provide precise supporting for formworks, preventing breakage occurring to the joints of two formworks.

Owner:济宁弗森机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com