Comb-shaped multi-layered absorption core body and processing method thereof

A technology of absorbent core and processing method, applied in the direction of absorbent pads, etc., can solve the problems of poor vertical diffusion, non-fitting diapers, and easy side leakage, etc., to reduce the possibility of side leakage, reduce the heavy feeling, and prevent seepage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

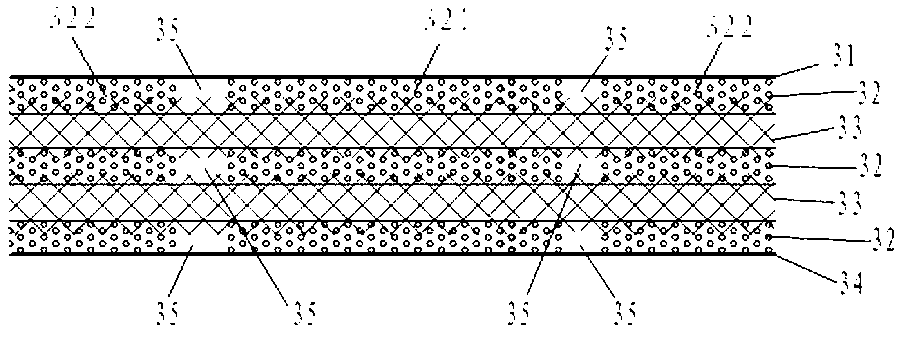

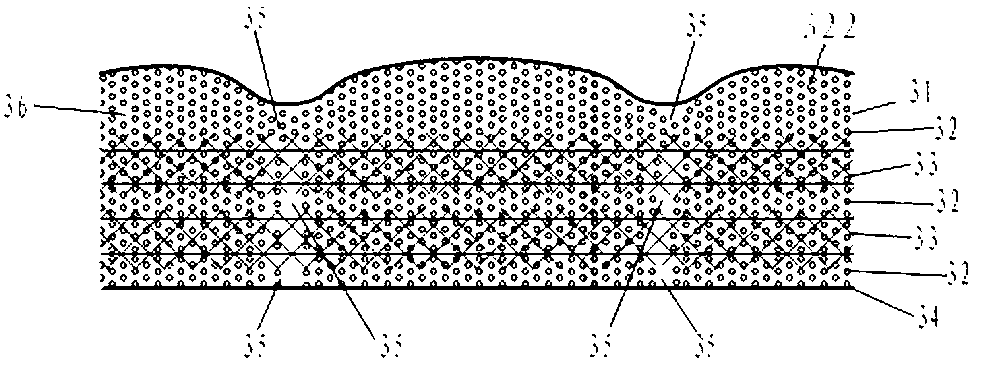

[0024] Embodiment 1: as figure 1 As shown, a comb-shaped multi-layer absorbent core, the absorbent core is a 7-layer core structure connected layer by layer, which successively includes a dust-free paper surface layer 31, a three-layer absorber layer 32 and a dust-free paper bottom layer 34 , the absorber layer 32 is formed by pressing the absorber, and a fiber structure layer 33 is sandwiched between two adjacent absorber layers 32, and the absorber layer 32 is implanted in the part of the absorber next to the fiber structure layer 33 In the holes of the fibrous structure layer 33, the absorber layer 32 and the fibrous structure layer 33 are combined into one, and the uppermost and lowermost absorber layers 32 are attached to the upper and lower dust-free paper surface layers 31 and dust-free paper respectively. Ground floor 34 on.

[0025] Specifically, the dust-free paper surface layer 31 as the first layer is attached to the absorber layer 32 as the second layer, and the ...

Embodiment 2

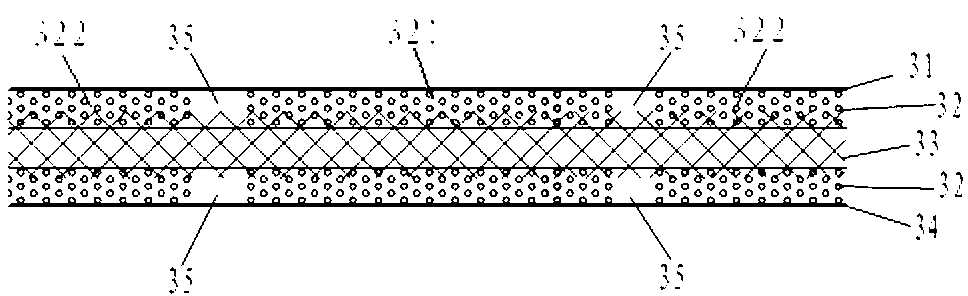

[0032] Embodiment 2: as image 3 and Figure 4 As shown, a comb-shaped multi-layer absorbent core, the absorbent core is a five-layer core structure connected layer by layer, which sequentially includes a dust-free paper surface layer 31, two absorbent layers 32 and a dust-free paper bottom layer 34 The absorber layer 32 is formed by pressing the absorber, and a fiber structure layer 33 is interposed between the two absorber layers 32. The structure, position and connection relationship between the components of the absorber core are the same as in Example 1. , the difference is that there are only two layers of absorbent body layer 32 and one layer of fiber structure layer 33, that is, there is only one sandwich absorbent unit. The absorbent core of the 5-layer structure is combined layer by layer and connected layer by layer. The 5-layer core structure includes a dust-free paper surface layer 31, two absorbent layers 32 and a dust-free paper bottom layer 34. The two absorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com