TFT array substrate and preparation method thereof and display device

A thin film transistor and array substrate technology, applied in the display field, can solve the problems of difficulty, poor copper etching ability, and high etching solution development cost, and achieve the effects of improving yield, blocking copper diffusion, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a method for preparing the thin film transistor array substrate provided by the above technical solution, comprising the following steps:

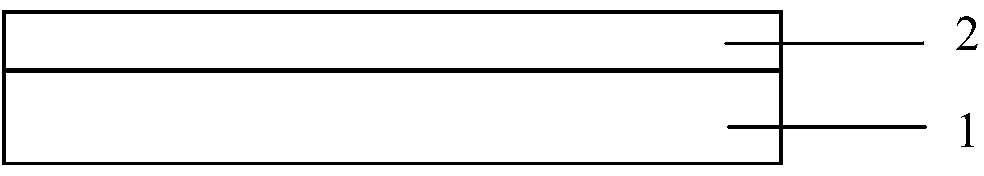

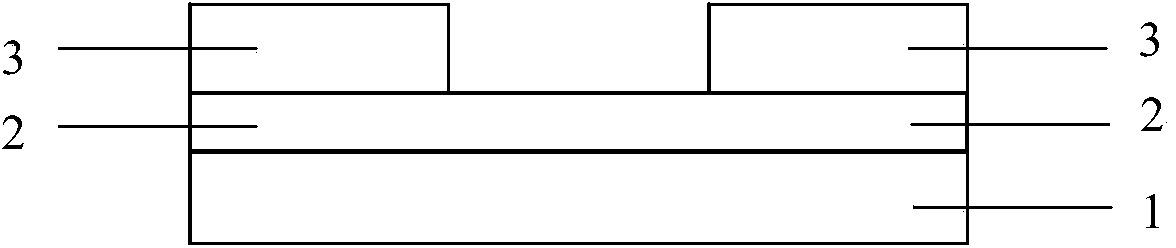

[0065] A first insulating layer 2 is formed on the substrate 1, and a first photoresist layer 3 is formed on the first insulating layer 2, and a gate recess is formed on the first insulating layer 2 formed with the first photoresist layer 3. a groove, the gate groove is surrounded by a first insulating layer;

[0066] forming a gate layer on a substrate 1 having gate grooves;

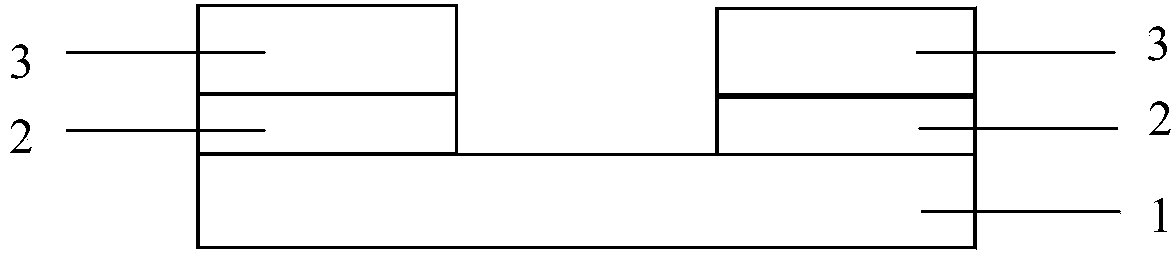

[0067] The first photoresist layer 3 on the substrate on which the gate layer is formed and the gate layer above the first photoresist layer 3 are peeled off to form a gate 4 surrounded by the first insulating layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com