Flexible display apparatus and preparation method therefor, and electronic equipment

A technology for flexible display devices and electronic equipment, which is applied to circuits, electrical components, and electrical solid devices, and can solve problems such as screen faults or layers, and overall uneven display effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

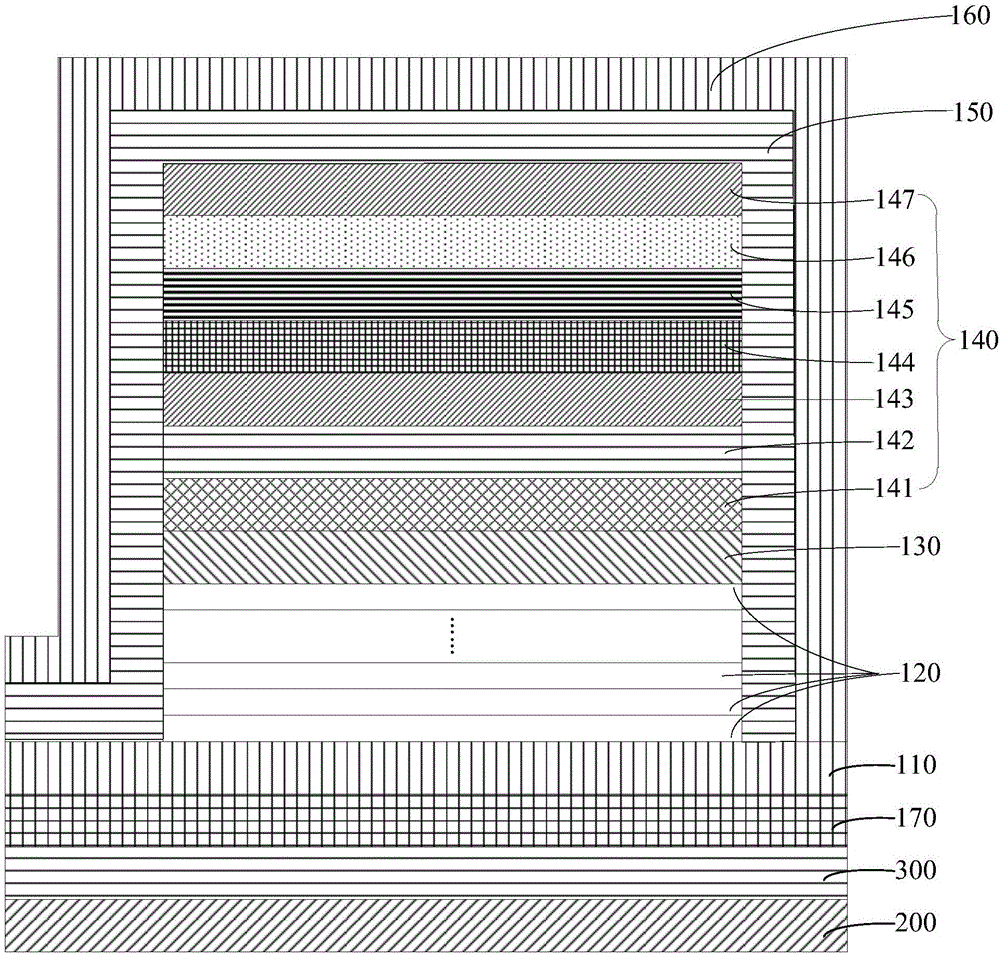

[0080] As a specific embodiment of the flexible display device manufacturing method of the present invention, it includes the following steps:

[0081] First, through step S100, a PI layer is prepared on the surface of the pretreated substrate. Wherein, the substrate may be a glass substrate. At the same time, the pretreatment of the substrate is specifically cleaning the substrate, which may specifically be cleaned by ultrasonic waves. In addition, when the PI layer is prepared on the surface of the cleaned substrate, it can be prepared by a spin coating process. Then, through step S200, a substrate layer is formed on the surface of the PI layer. Wherein, the preparation of the substrate layer may adopt a CVD (Chemical Vapor Deposition, chemical vapor deposition) process. Furthermore, in step S300, a TFT layer is formed on the surface of the substrate layer. Wherein, the preparation of the TFT layer can adopt CVD process, sputter deposition (Sputter) process, yellow light...

Embodiment 1

[0089] This embodiment is a preparation process when the protective film is formed on the periphery of the flexible display device through the preparation process. specific:

[0090] First, the glass substrate is cleaned and pretreated. Then, a PI layer was prepared and formed on the glass substrate by a spin-coating process. Then prepare and form a protective film on the PI layer. Furthermore, a BL layer is formed on the protective film by using a CVD process. Further, the TFT structural part and the anode part are sequentially prepared on the surface of the BL layer. Among them, the preparation process of the TFT structure part and the anode part is mainly CVD / Sputter, yellow light, etching, etc.

[0091] Further, the OLED layer is prepared. Specifically, firstly, a hole injection layer (HIL) is prepared on the surface of the anode layer. Wherein, the hole injection layer is made of an organic material, which is made by evaporation, and the hole injection layer is the ...

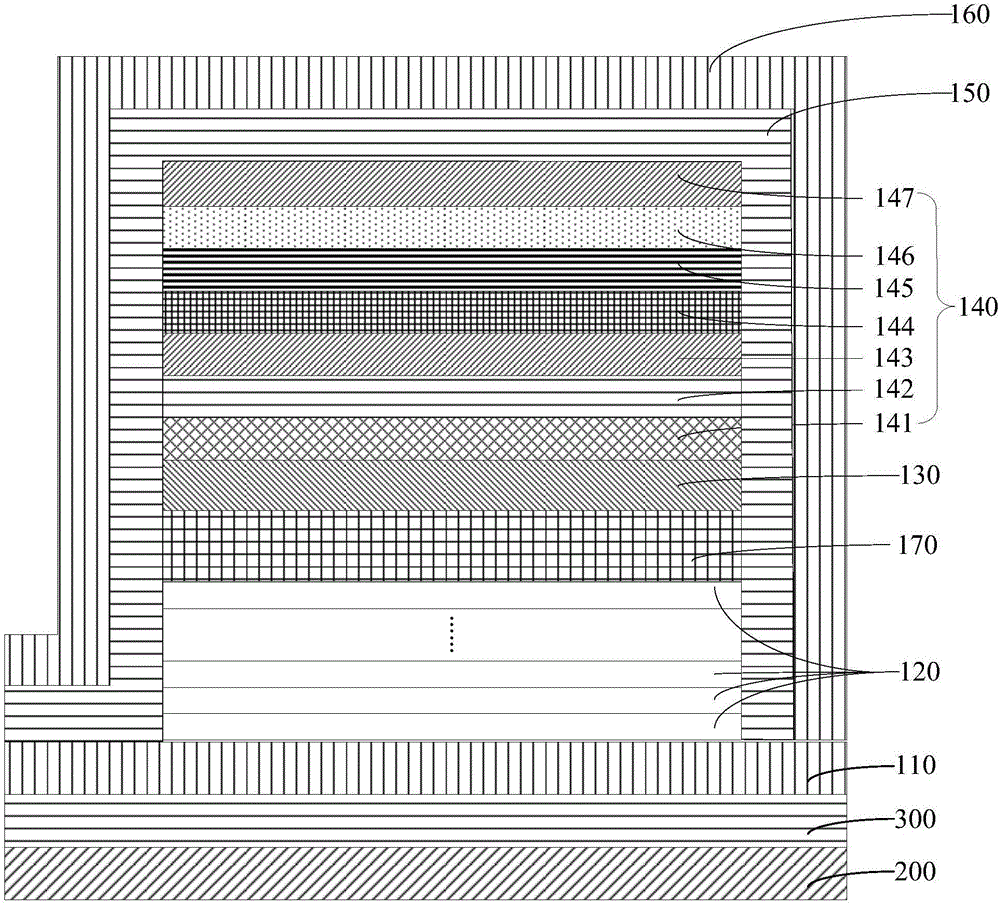

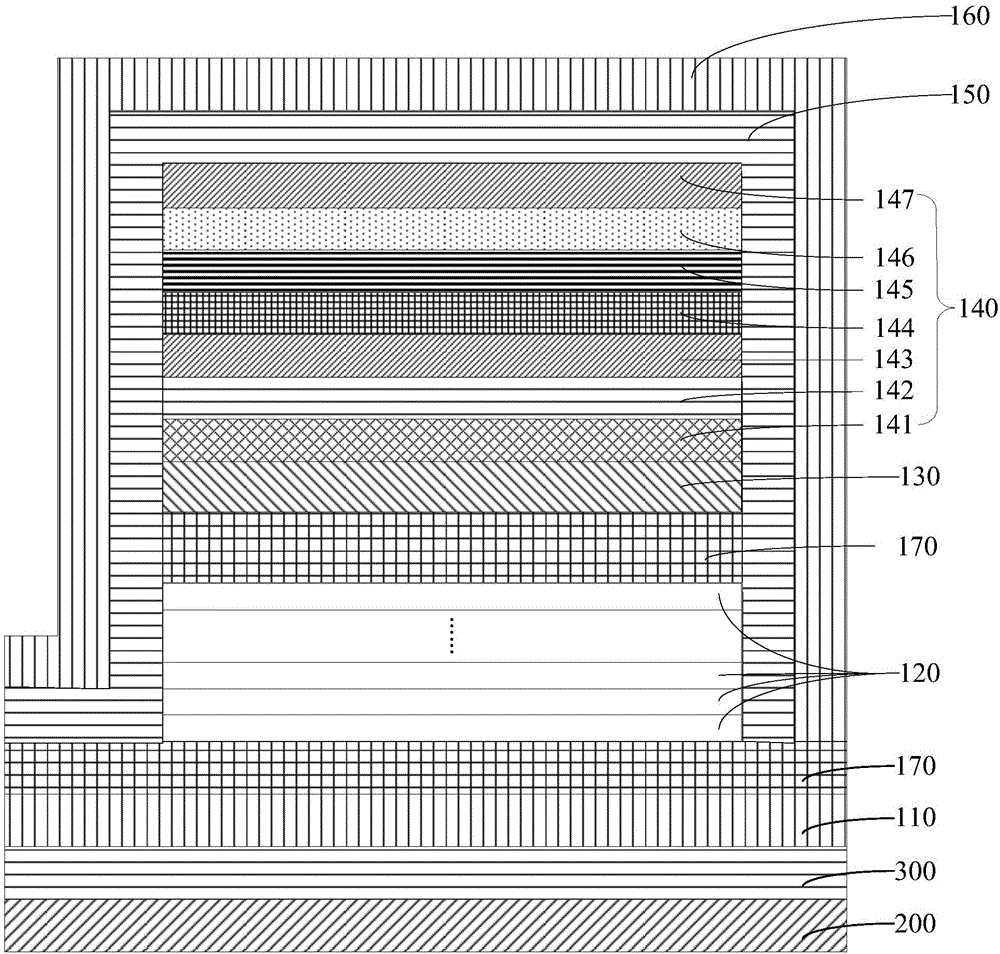

Embodiment 2

[0094] This embodiment is a preparation process when the protective film is formed on the periphery of the flexible display device by bonding.

[0095] specific:

[0096] First, the glass substrate is cleaned and pretreated. Then, a PI layer was prepared and formed on the glass substrate by a spin-coating process. Furthermore, a BL layer is formed on the protective film by using a CVD process. Further, the TFT structural part and the anode part are sequentially prepared on the surface of the BL layer. Among them, the preparation process of the TFT structure part and the anode part is mainly CVD / Sputter, yellow light, etching, etc.

[0097] Further, the OLED layer is prepared. Specifically, firstly, a hole injection layer (HIL) is prepared on the surface of the anode layer. Wherein, the hole injection layer is made of an organic material, which is made by evaporation, and the hole injection layer is the main carrier of holes. Then, a hole transport layer (HIL) was prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com