Flexible array substrate and manufacturing method thereof

A technology of flexible array and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., and can solve problems such as irreparable film layers, increased stress of inorganic film layers, and affecting the display effect of flexible display devices. To achieve the effect of guaranteeing the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

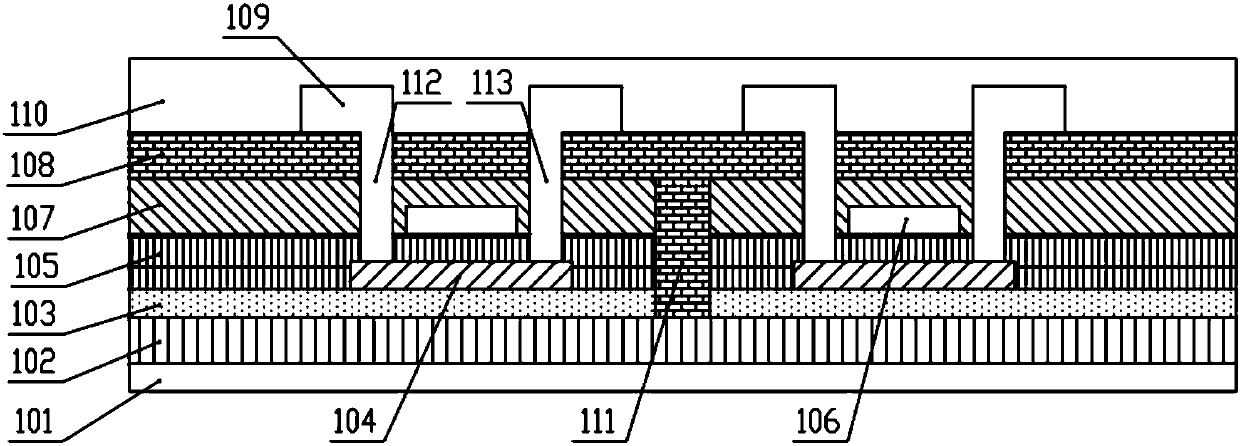

[0059] figure 1 It is a film structure diagram of a flexible array substrate according to a preferred embodiment of the present invention. The flexible array substrate includes: a glass substrate 101, a flexible substrate substrate 102, a buffer layer 103, an active layer 104, a gate insulating layer 105, a second A metal layer 106 , an insulating layer 107 , a flexible organic layer 108 , a second metal layer 109 and a passivation layer 110 .

[0060] The flexible base substrate 102, that is, a polyimide film, is formed on the surface of the glass substrate 101 as the base of the flexible display panel;

[0061] The polyimide film is the film insulation material with the best performance in the world, and has strong tensile strength. It is made of pyromellitic dianhydride and diaminodiphenyl ether through polycondensation and It is cast into a film and then imidized.

[0062] The buffer layer is disposed on the surface of the flexible substrate 102, and the active layer 104...

Embodiment 2

[0074] Figure 5 It is a film structure diagram of a flexible array substrate according to the preferred embodiment 2 of the present invention. The flexible array substrate includes: a glass substrate 201, a flexible substrate substrate 202, a buffer layer 203, an active layer 204, a gate insulating layer 205, a second A metal layer 206 , an insulating layer 207 , a flexible organic layer 208 , a second metal layer 209 and a passivation layer 210 .

[0075] The difference from Embodiment 1 is that the flexible organic layer 208 is formed on the surface of the inter-insulating layer 207, and the flexible organic layer 208 is processed by patterning the flexible organic material deposited on the surface of the inter-insulating layer 207. , formed by retaining at least a part of the flexible organic material that has been patterned;

[0076] The second metal layer 209 is formed on the surface of the inter-insulating layer 207, the second metal layer 209 is patterned to form the ...

Embodiment 3

[0080] Figure 6 It is a flowchart of steps of a method for manufacturing a flexible array substrate in a preferred embodiment, Figure 7 Shown is a process completion diagram of a method for manufacturing a flexible array substrate according to Embodiment 3 of the present invention. The method includes:

[0081] In step S10 , a glass substrate is provided, and the flexible substrate 302 , the buffer layer 303 , the active layer 304 and the gate insulating layer 305 are sequentially deposited on the glass substrate.

[0082] Provide a glass substrate, first deposit a flexible substrate substrate 302 on the glass substrate, that is, a polyimide film, formed on the surface of the glass substrate, as the base of the flexible display panel;

[0083] The polyimide film is the film insulation material with the best performance in the world, and has strong tensile strength. It is made of pyromellitic dianhydride and diaminodiphenyl ether through polycondensation and It is cast into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com