Rubber for sealing metal and preparation method thereof

A rubber and metal technology, applied in the field of rubber for sealing metals and its preparation, can solve problems such as loosening and falling off, inconvenient replacement and use, unfavorable sealing, etc., to achieve the effect of avoiding loosening and falling off, convenient taking and replacement, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

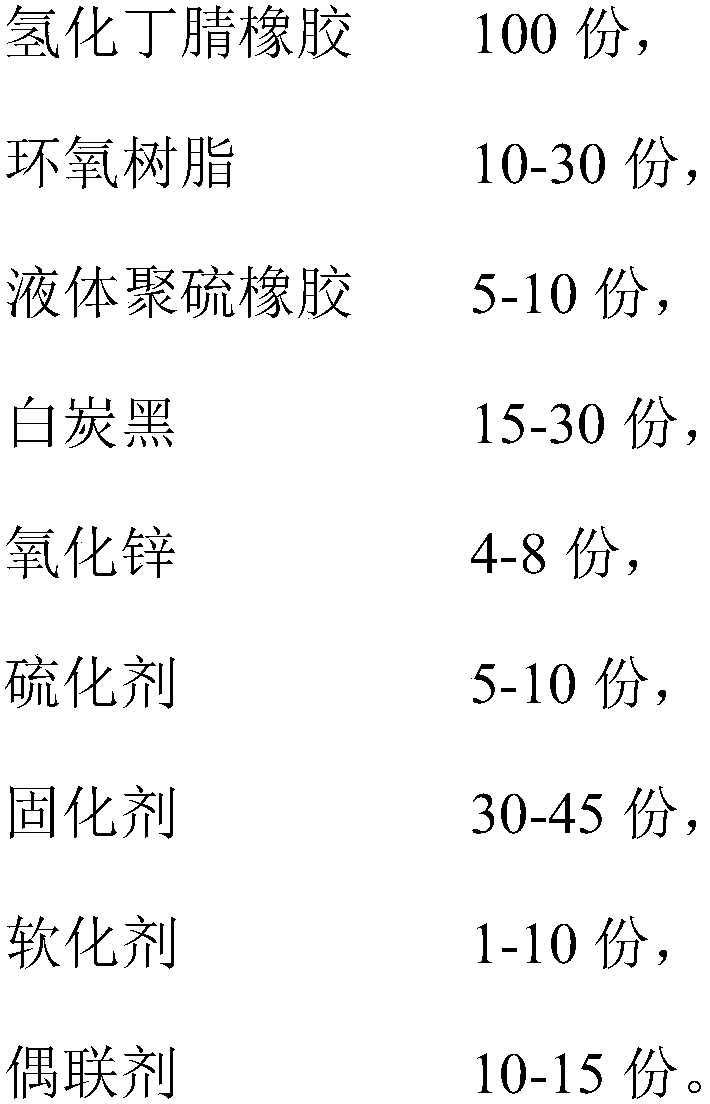

[0023] A kind of rubber for sealing metal, described rubber is made up of following raw materials in parts by weight:

[0024]

[0025] A preparation method of rubber for sealing metal, comprising the following steps:

[0026] (1) Pre-mixing treatment: Mix hydrogenated nitrile rubber, fumed silica, zinc oxide and softener evenly, then add them to the internal mixer for 20 minutes of plastic training, and the plastic training temperature is 60°C to obtain hydrogenated nitrile butadiene masterbatch Rubber mixing: adding epoxy resin, liquid polysulfide rubber with an average molecular weight of 1000, and coupling agent into the internal mixer for plasticizing for 6 minutes at a temperature of 80°C to obtain modified rubber mixing;

[0027] (2) Mixing: mix the above-mentioned hydrogenated nitrile masterbatch, modified rubber mixing, curing agent and KH-560 organosilane coupling agent in the internal mixer for 20min, the temperature in the internal mixer is 60 ℃, extrude Go out...

Embodiment 2

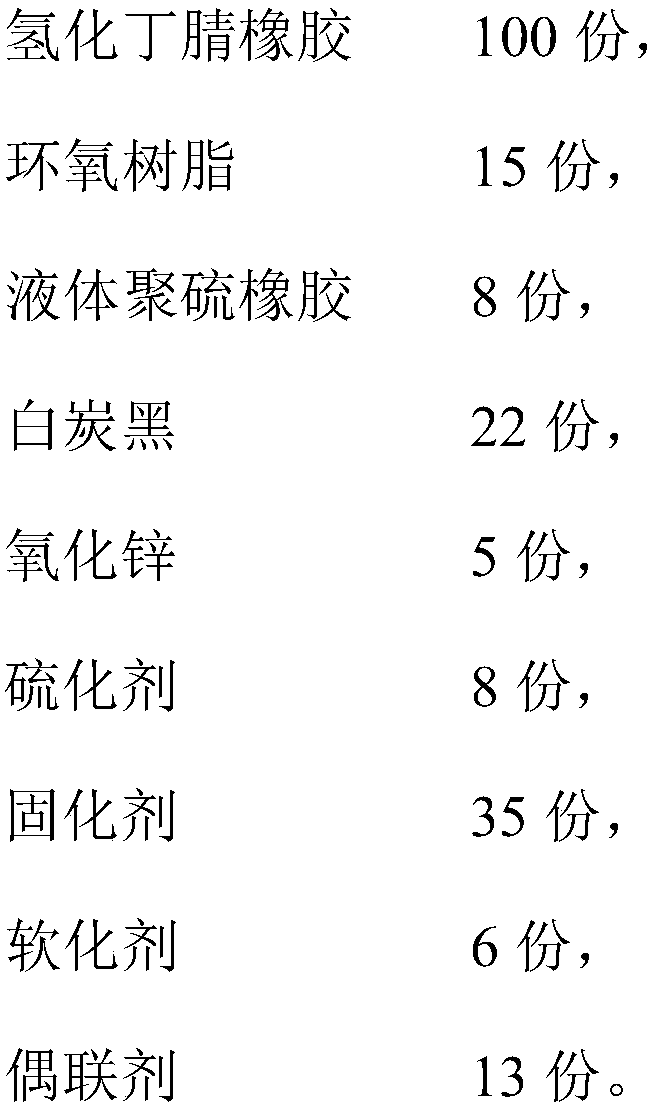

[0030] A kind of rubber for sealing metal, described rubber is made up of following raw materials in parts by weight:

[0031]

[0032]

[0033] A preparation method of rubber for sealing metal, comprising the following steps:

[0034] (1) Premixing treatment: Mix hydrogenated nitrile rubber, fumed silica, zinc oxide and softener evenly, then add them to the internal mixer for 5 minutes of plasticizing, and the plasticizing temperature is 90°C to obtain hydrogenated nitrile butadiene master Rubber mixing: Add epoxy resin, liquid polysulfide rubber with an average molecular weight of 800, and a coupling agent to the internal mixer for 2 minutes of plasticizing, and the plasticizing temperature is 100°C to obtain modified rubber mixing;

[0035] (2) Mixing: mix the above-mentioned hydrogenated nitrile masterbatch, modified rubber mixing, curing agent and KH-570 organosilane coupling agent in the internal mixer for 10min, the temperature in the internal mixer is 70°C, and e...

Embodiment 3

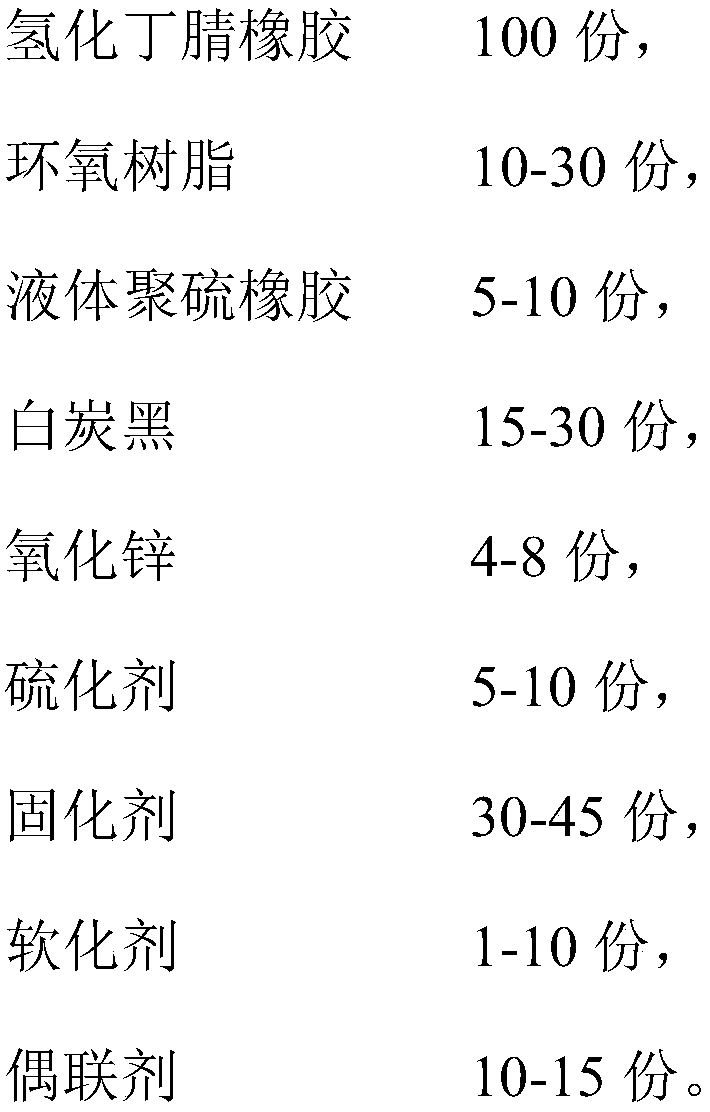

[0038] A kind of rubber for sealing metal, described rubber is made up of following raw materials in parts by weight:

[0039]

[0040]

[0041] A preparation method of rubber for sealing metal, comprising the following steps:

[0042] (1) Pre-mixing treatment: Mix hydrogenated nitrile rubber, fumed silica, zinc oxide and softener evenly, then add them to the internal mixer for 10 minutes of plasticizing, and the plasticizing temperature is 78°C to obtain hydrogenated nitrile butadiene masterbatch Rubber mixing: adding epoxy resin, liquid polysulfide rubber with an average molecular weight of 900, and a coupling agent into the internal mixer for plasticizing for 4 minutes at a temperature of 90°C to obtain modified rubber mixing;

[0043] (2) Mixing: Mix the above-mentioned hydrogenated nitrile masterbatch, modified rubber, curing agent and KH-570 organosilane coupling agent in an internal mixer for 15min, the temperature in the internal mixer is 65°C, and extrude Go ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com