Patents

Literature

59results about How to "Follow-up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

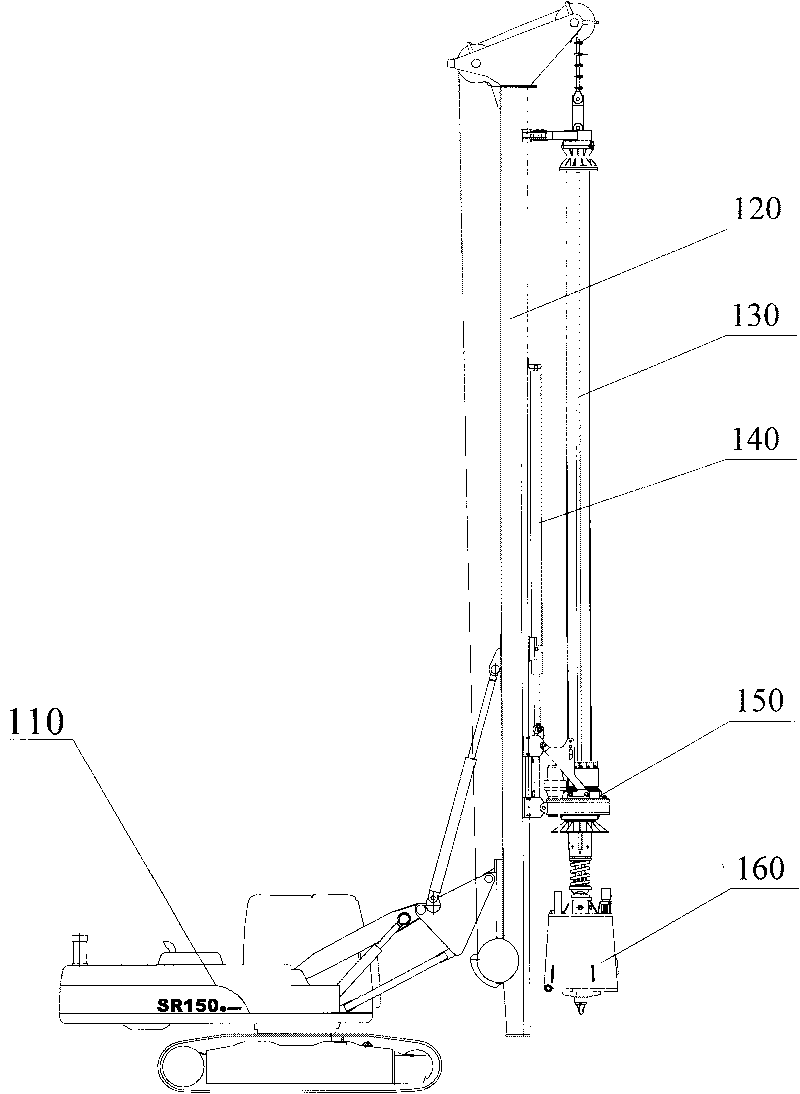

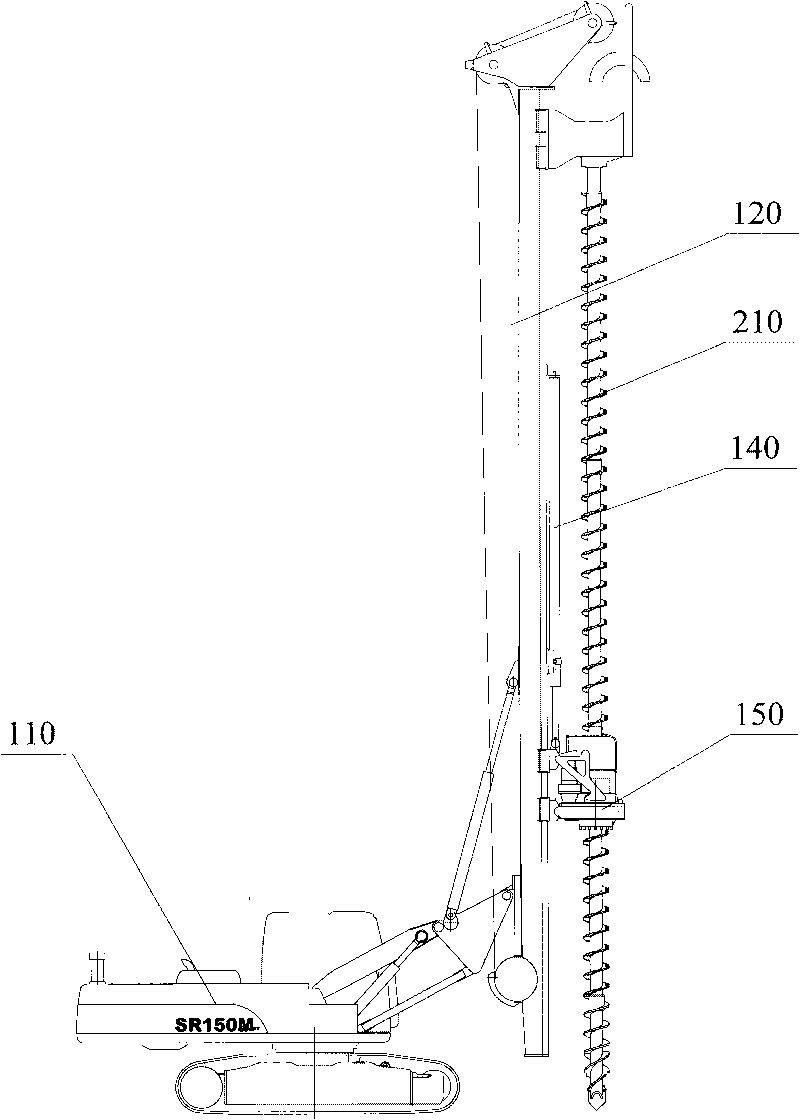

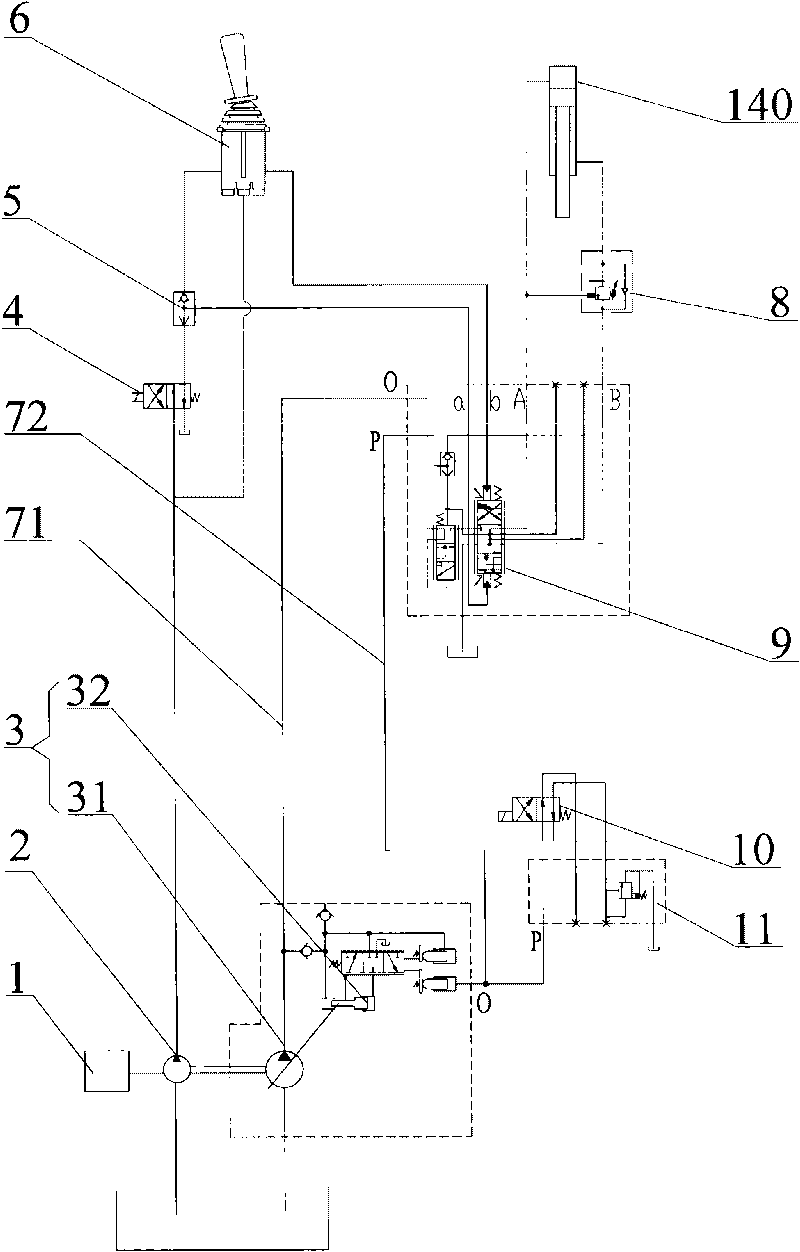

Hydraulic system and rotary drilling rig comprising same

ActiveCN101725589AFollow-up realizationReduce power lossConstructionsServomotor componentsLocking mechanismHydraulic pump

The invention discloses a hydraulic system and a rotary drilling rig comprising the same. The disclosed hydraulic system comprises a main hydraulic circuit, wherein the main hydraulic circuit comprises a hydraulic pump, a hydraulic actuator and a reversing valve; the reversing valve is connected between the hydraulic pump and a pressure oil cylinder; and a self-locking mechanism is arranged between two hydraulic chambers of the hydraulic actuator. Compared with the prior art, the hydraulic system also comprises a follow-up control valve and a follow-up control overflow valve, wherein the follow-up control valve is connected between an oil inlet of the follow-up control overflow valve and the main hydraulic circuit. In the disclosed hydraulic system, when the oil inlet of the follow-up control overflow valve is communicated with the main hydraulic circuit, the overflow pressure of the follow-up control overflow valve can be reflected on the main hydraulic circuit; and the action speed of the hydraulic actuator is adjusted by influencing the flow quantity of hydraulic oil which is supplied to the hydraulic actuator by the main hydraulic circuit, so that the hydraulic actuator keeps synchronous action with a load part to realize the follow-up of the hydraulic actuator and the load part.

Owner:BEIJING SANY HEAVY MASCH CO LTD

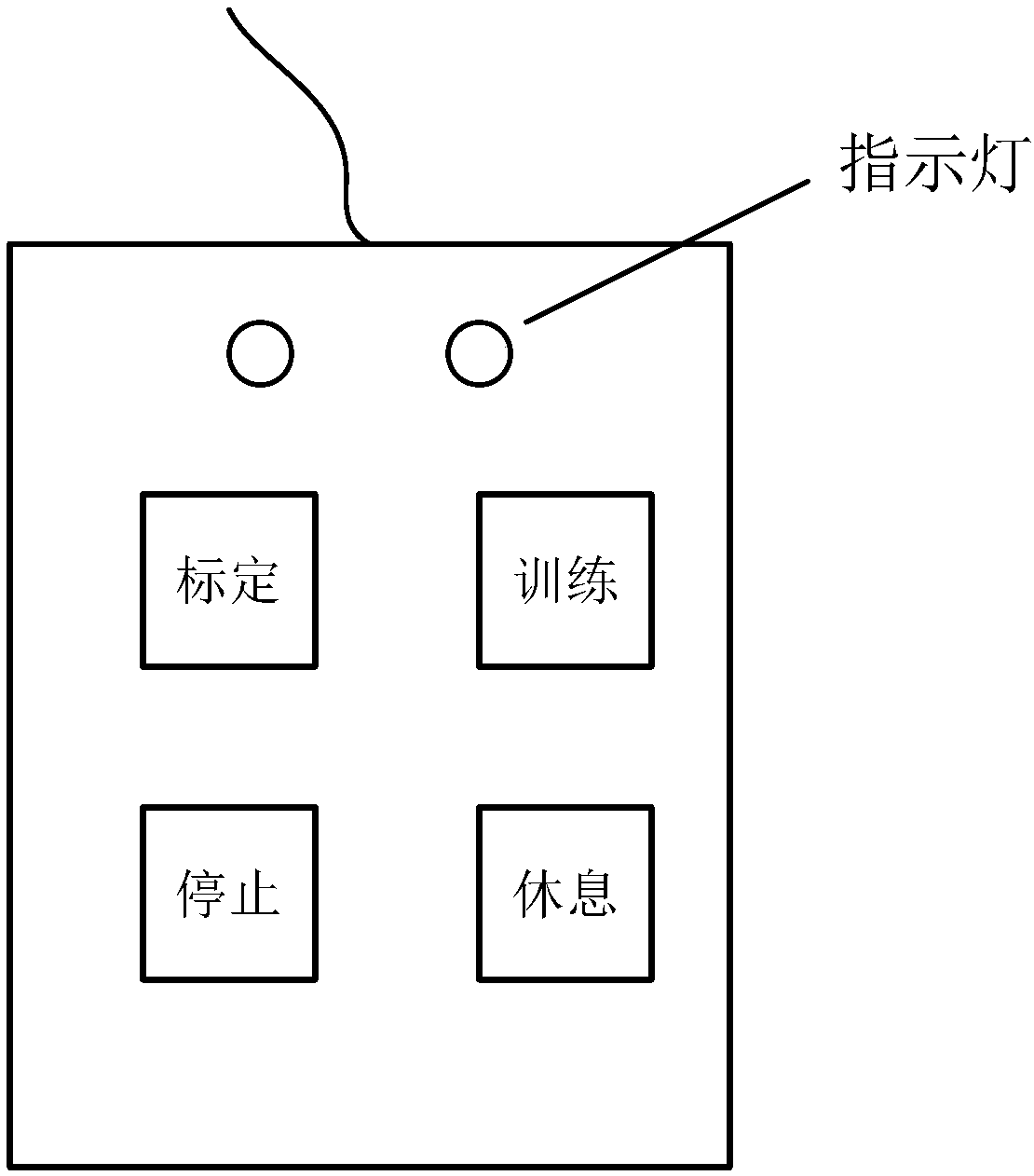

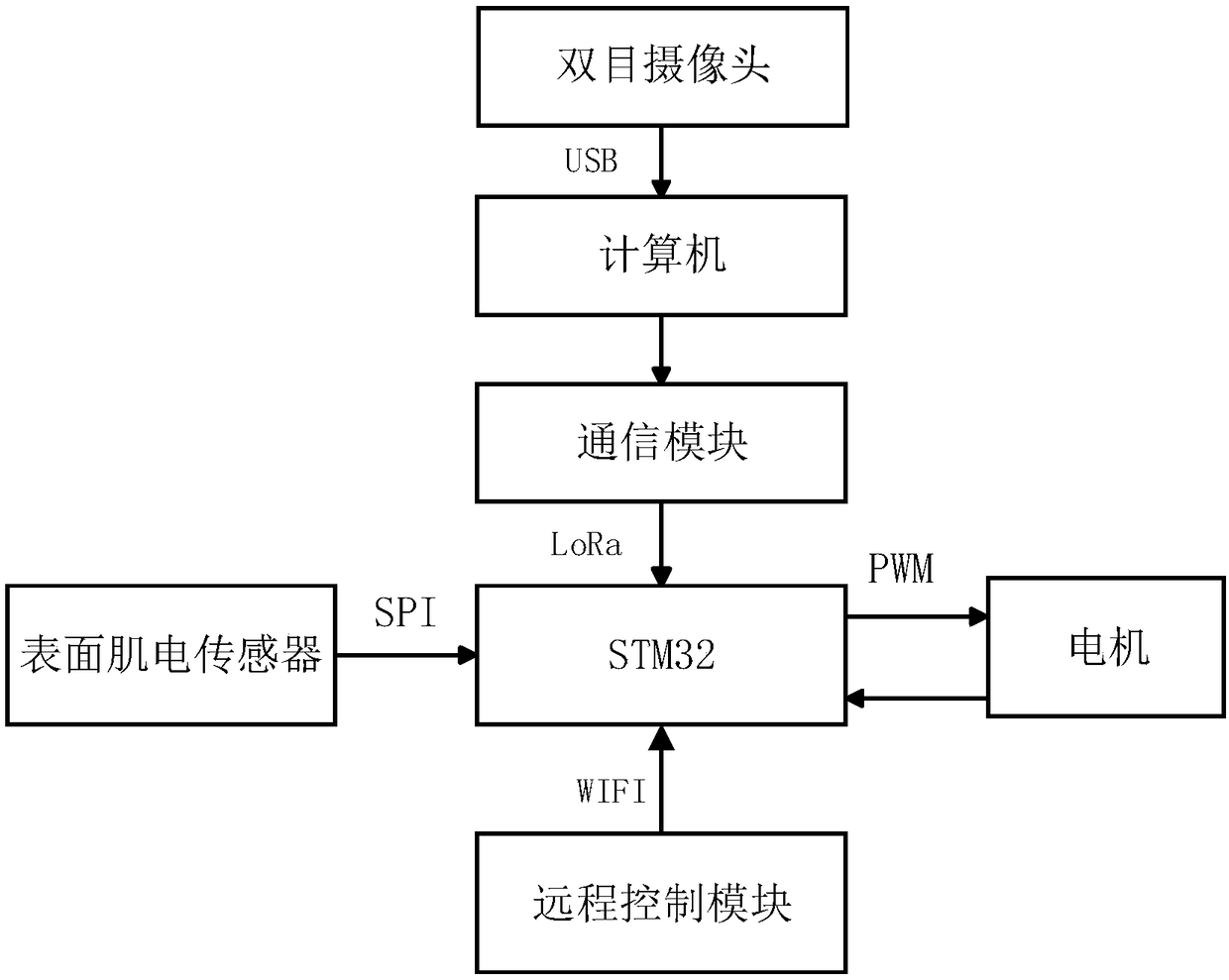

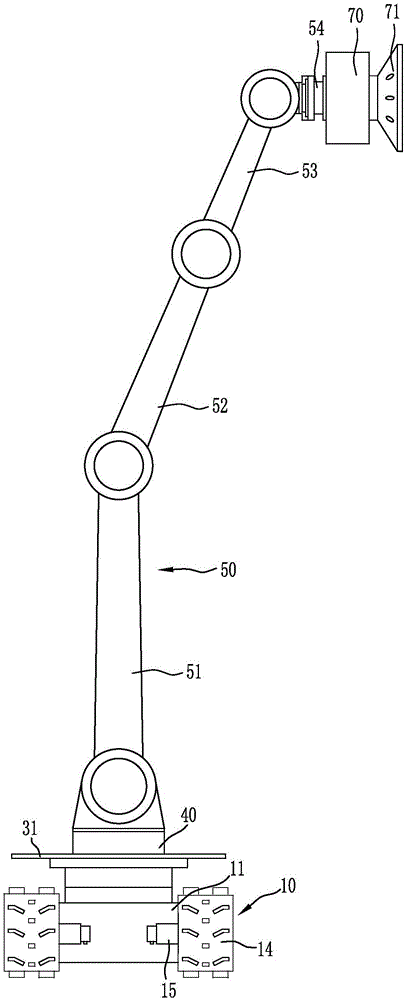

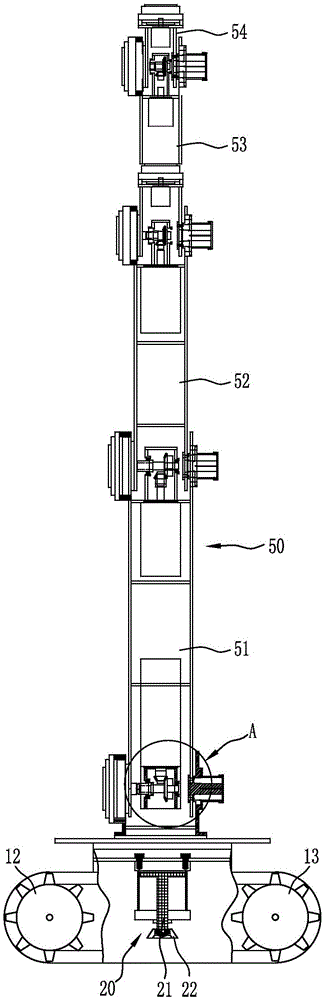

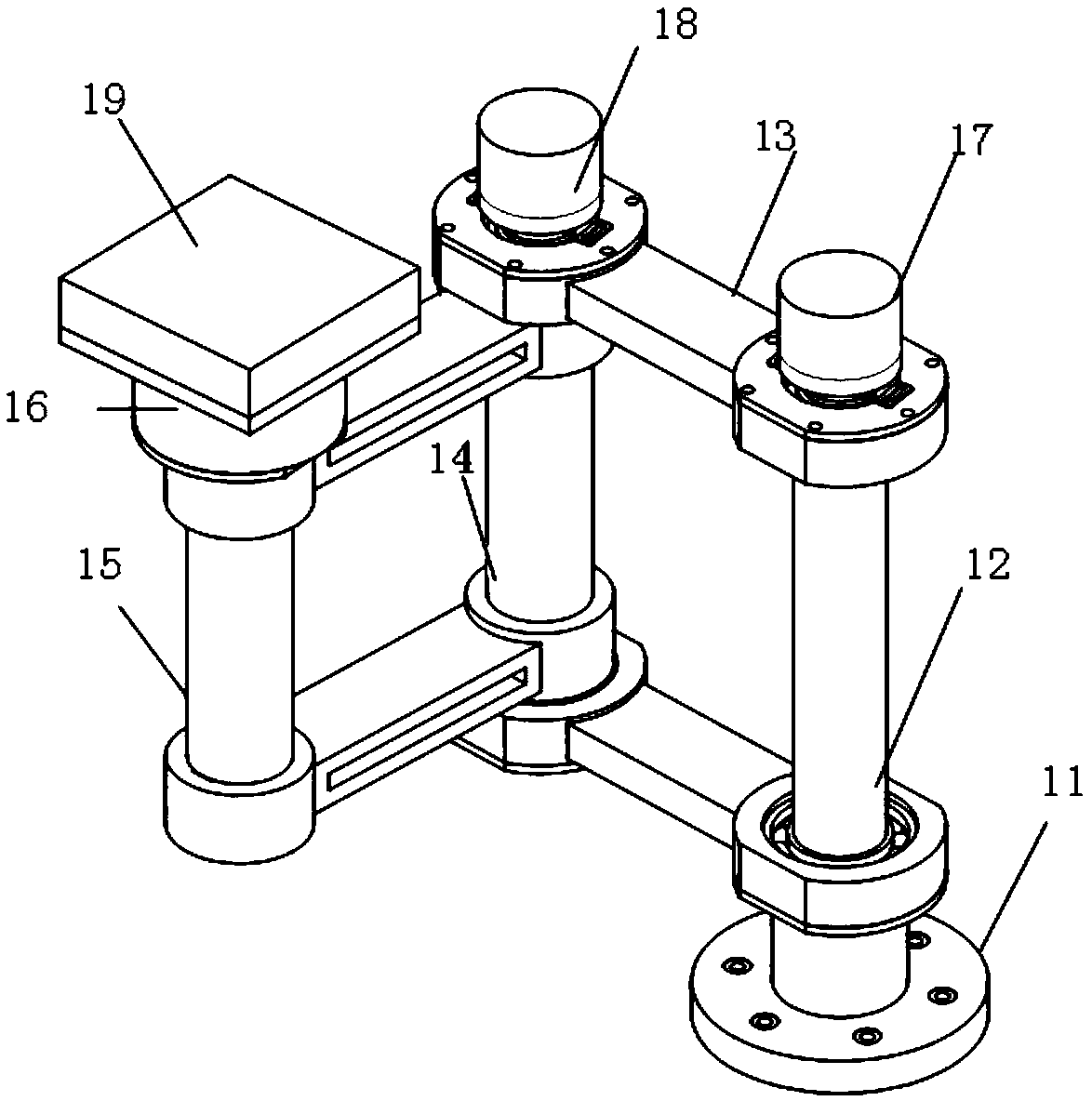

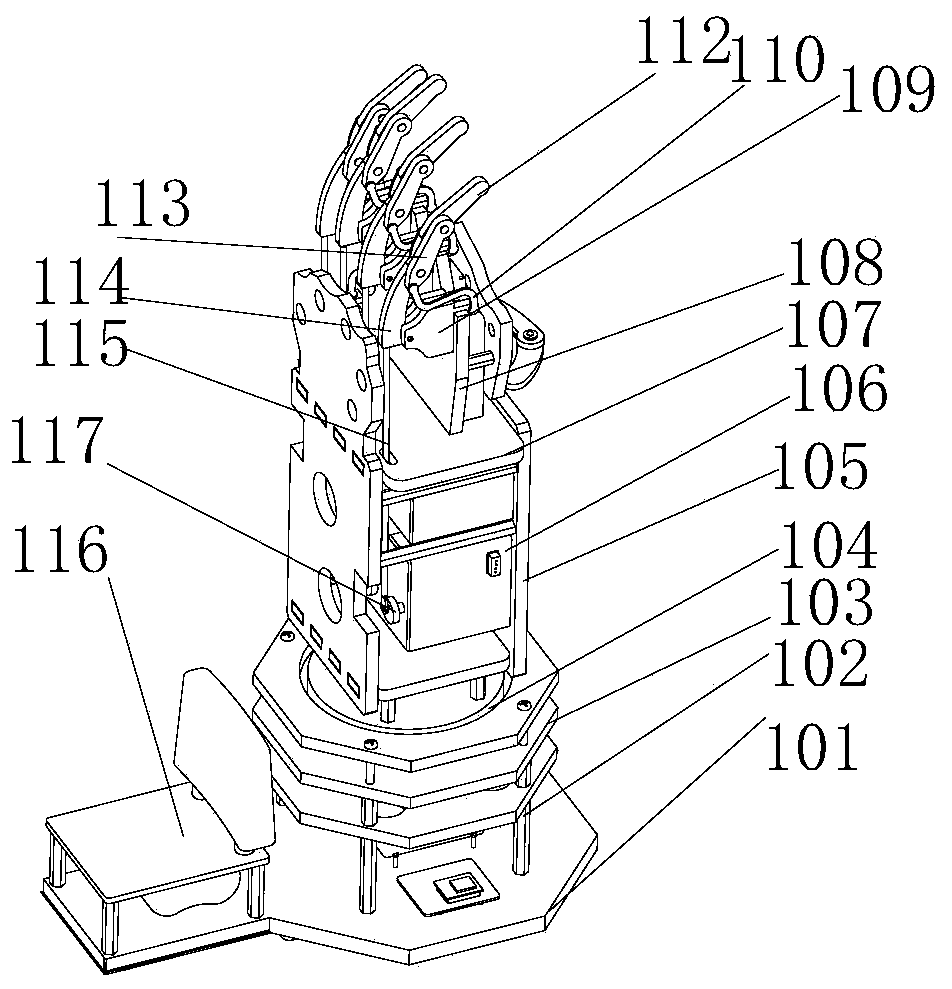

An upper limb rehabilitation robot based on binocular vision

InactiveCN108888478ARealize switchingProtection securityDiagnosticsChiropractic devicesProcess moduleEngineering

The invention discloses an upper limb rehabilitation robot based on binocular vision. The device comprises a mechanical structure, a main control module, a remote control module, a motor module, a limb information collection and processing module, a detection module, a communication module and a power module. Characterized in that the mechanical structure comprises a base assembly, a waist rotaryjoint, a main arm rotary joint, a main arm, a main arm external fixing sleeve, an auxiliary arm rotary joint, an auxiliary arm and an auxiliary arm external fixing sleeve; The main control module is aSTM32 single chip microcomputer; The motor module comprises a direct current deceleration motor and a motor driver; The limb information acquisition and processing module comprises a binocular cameraand a computer; The detection module is a surface myoelectric sensor; The communication module is a SX1278 chip. The surface electromyography sensor communicates with the main control module throughSPI, and the binocular camera communicates with the computer through USB interface. The invention discloses an upper limb rehabilitation robot based on binocular vision.

Owner:ZHENGZHOU UNIV

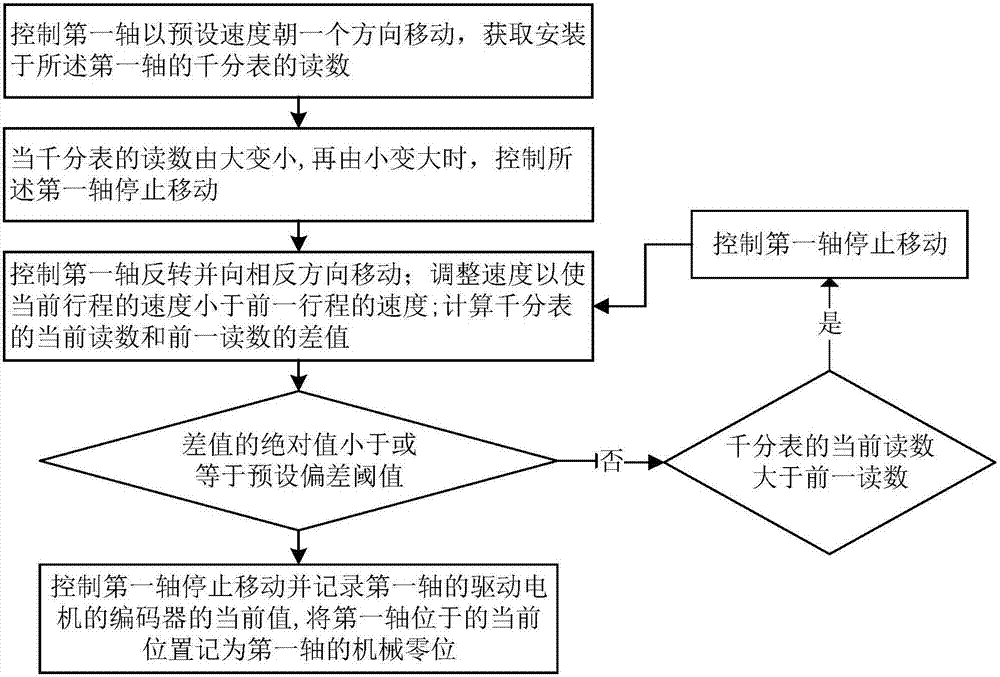

Robot zero point calibration method, storage equipment and control equipment

InactiveCN107322599AWide applicabilityFind out quicklyProgramme-controlled manipulatorElectric machineDrive motor

The invention relates to a robot zero point calibration method. The method comprises the steps that firstly, a first shaft is controlled to move in one direction with the preset speed, and the read number of a dial indicator arranged on the first shaft is obtained; secondly, when the read number of the dial indicator becomes small from large and then becomes large from small, the first shaft is controlled to stop moving, wherein one-time stroke of the first shaft is from movement starting to movement stopping; thirdly, the first shaft is controlled to reversely rotate and move in the opposite direction, and the difference value between the current read number and the previous read number of the dial indicator is calculated; fourthly, when the absolute value of the difference value is smaller than or equal to the preset deviation threshold value, the fifth step is executed, and when the absolute value of the difference value is larger than the preset deviation threshold value and the current read number of the dial indicator is larger than the previous read number, the first shaft is controlled to stop moving, and the third step is executed; and fifthly, the first shaft is controlled to stop moving, the current value of an encoder of a drive motor of the first shaft is recorded, and the current position of the first shaft is recorded as the mechanical zero point of the first shaft. By means of the robot zero point calibration method, the corresponding relation between the robot motor encoder value and zero point calibration shaft position is achieved.

Owner:国机智能技术研究院有限公司

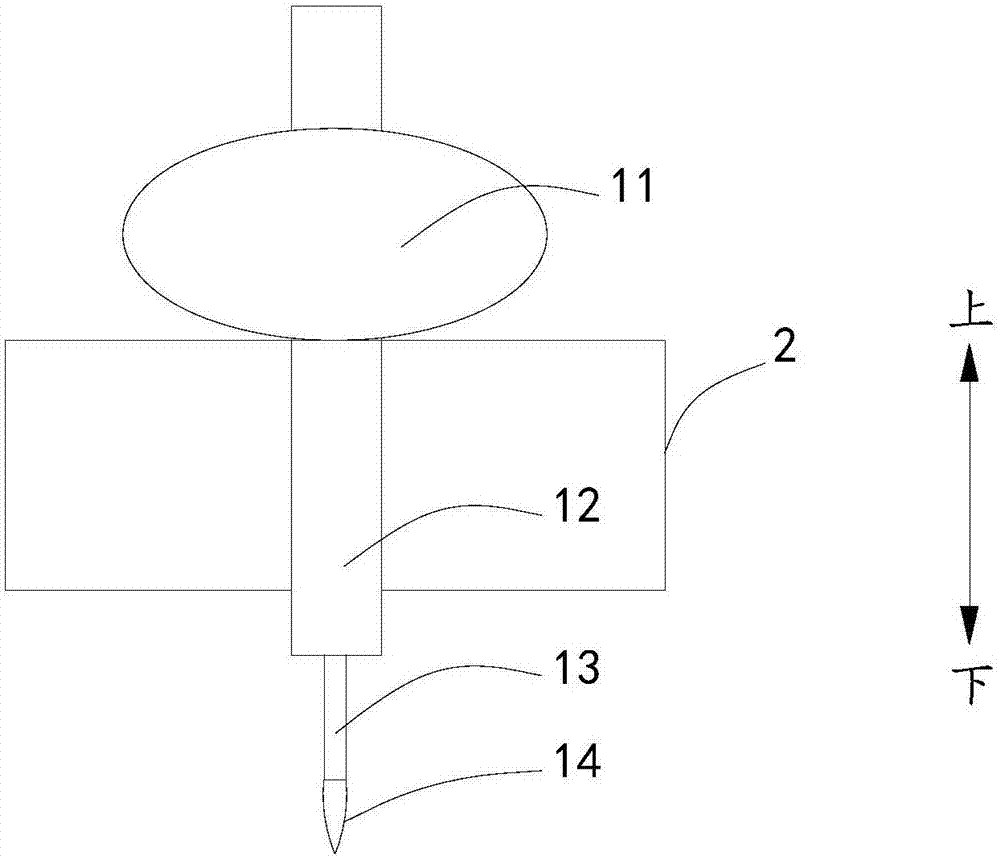

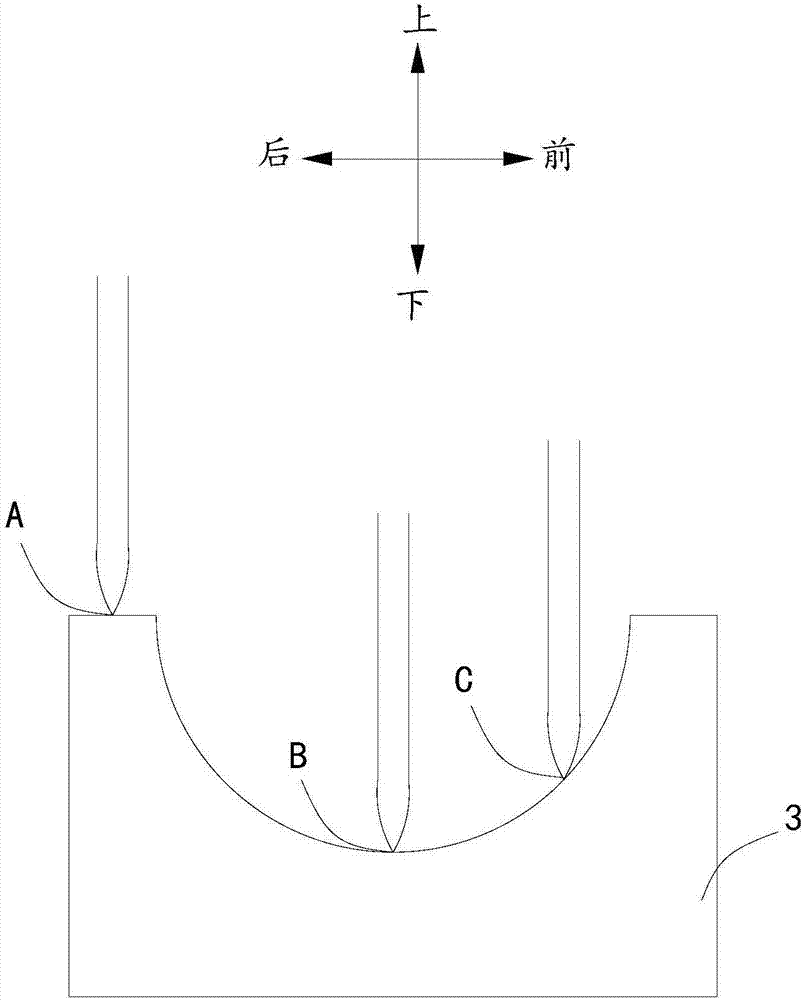

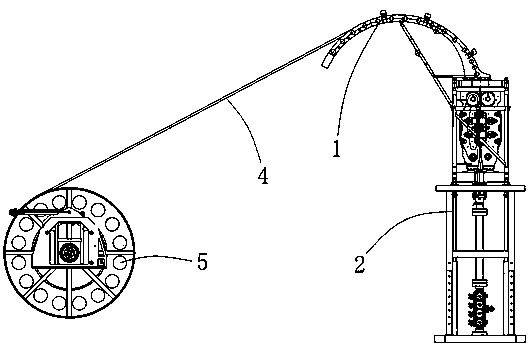

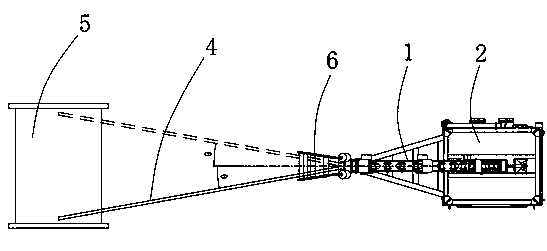

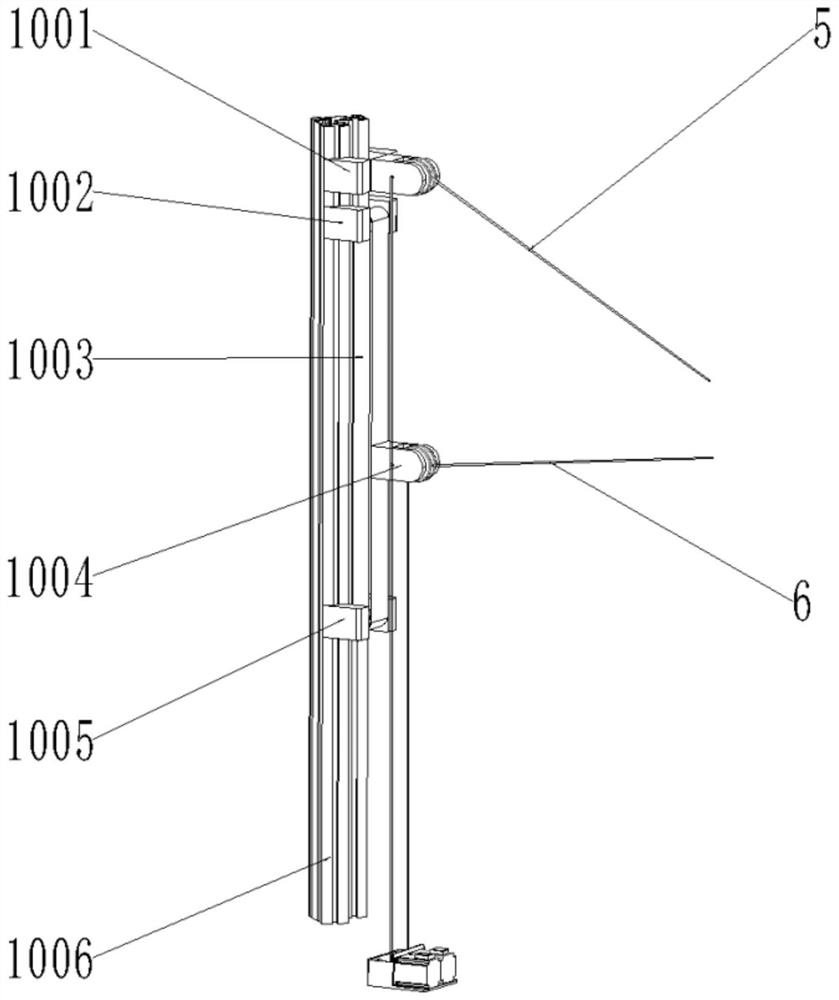

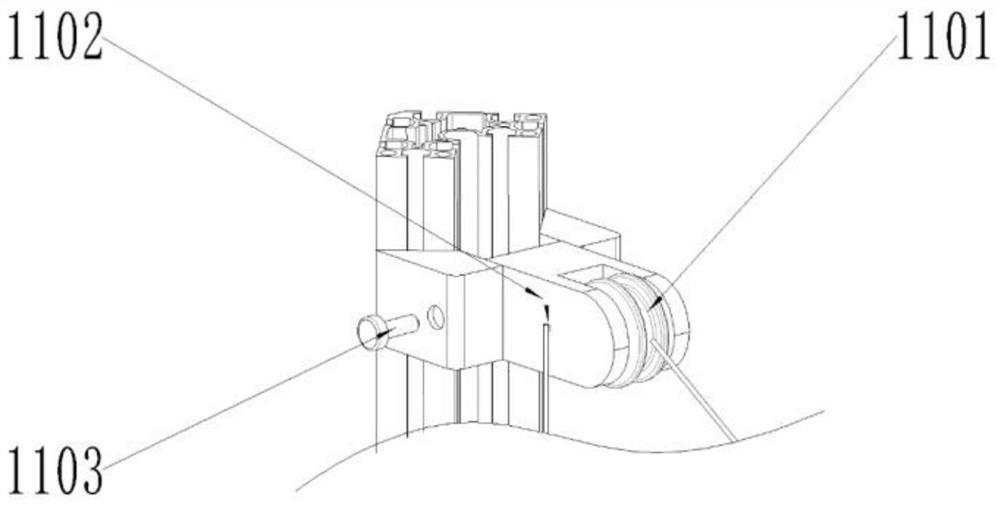

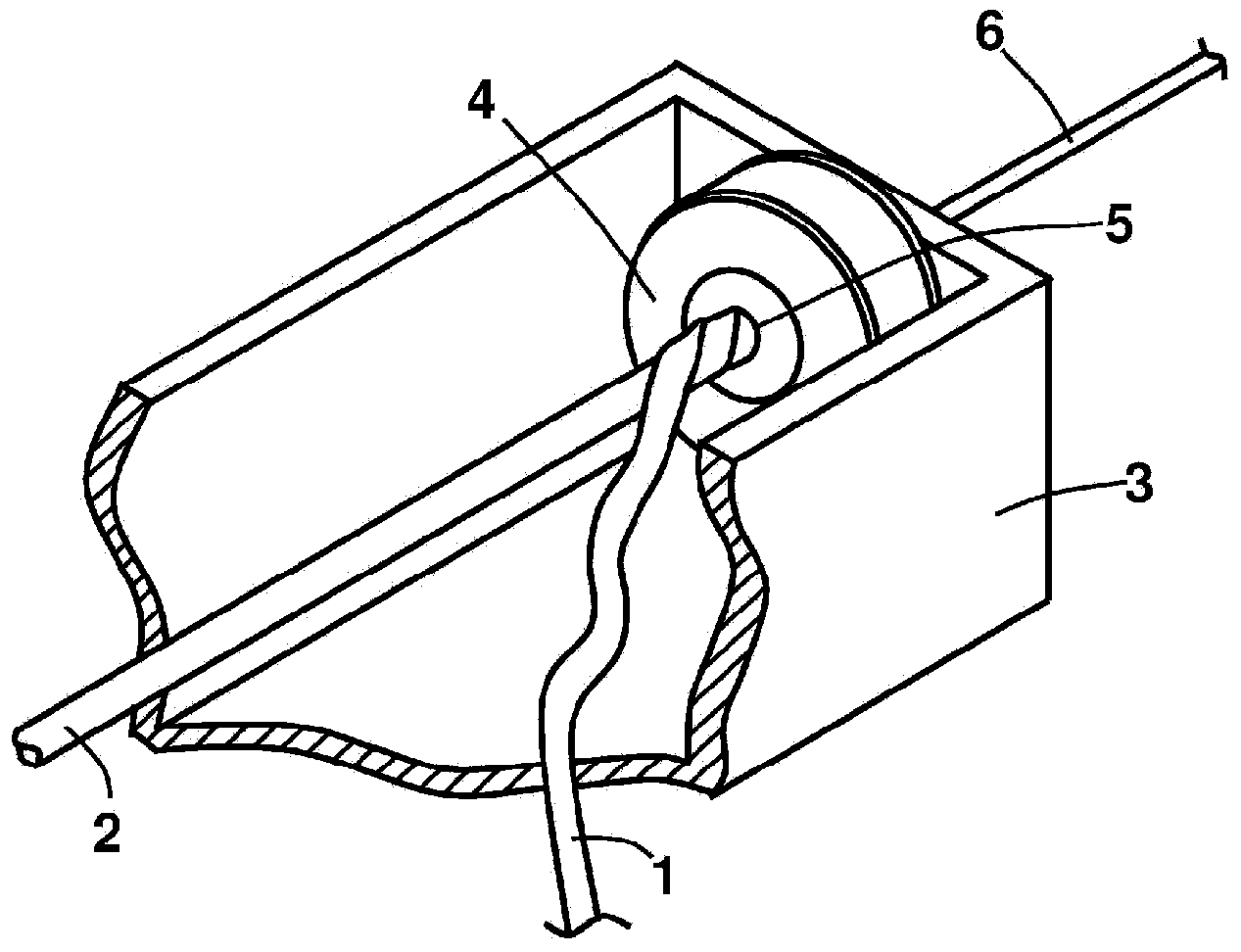

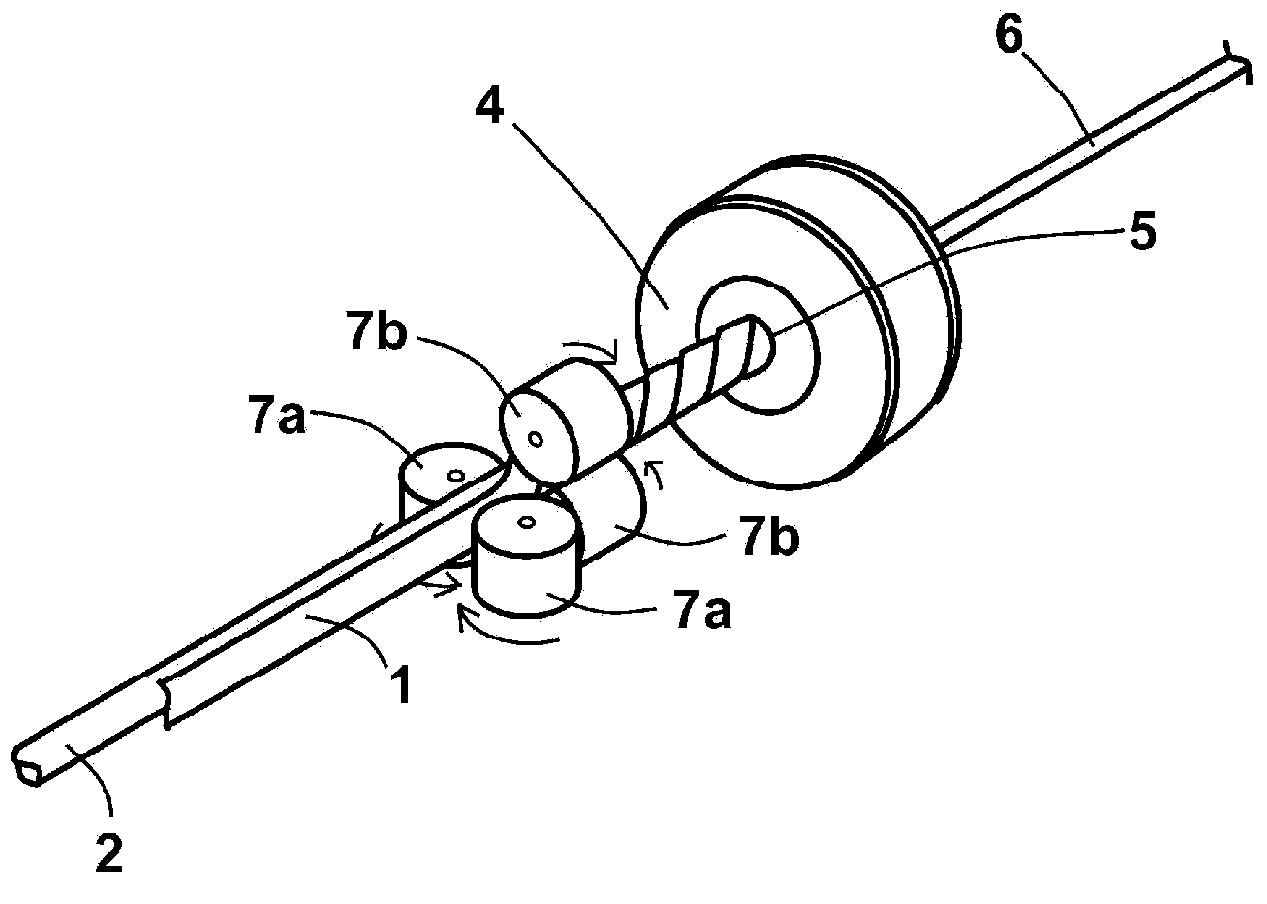

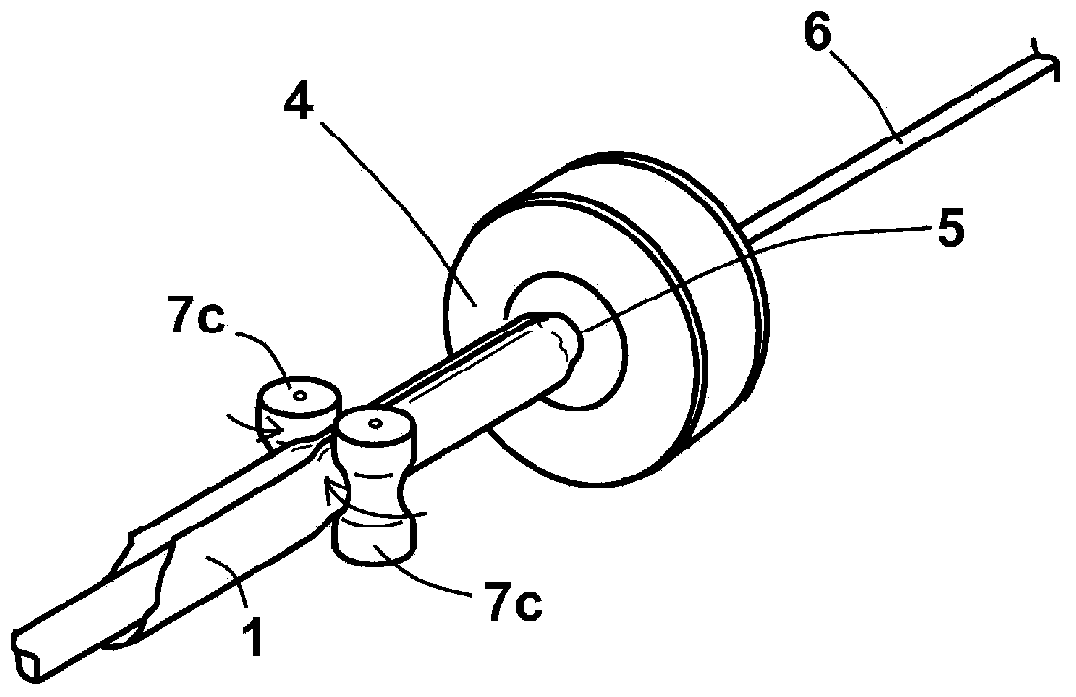

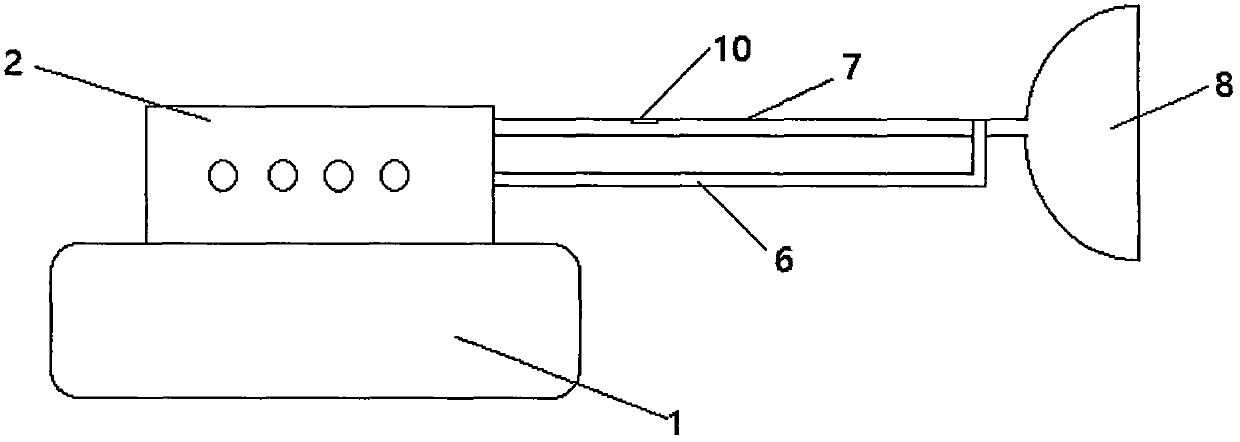

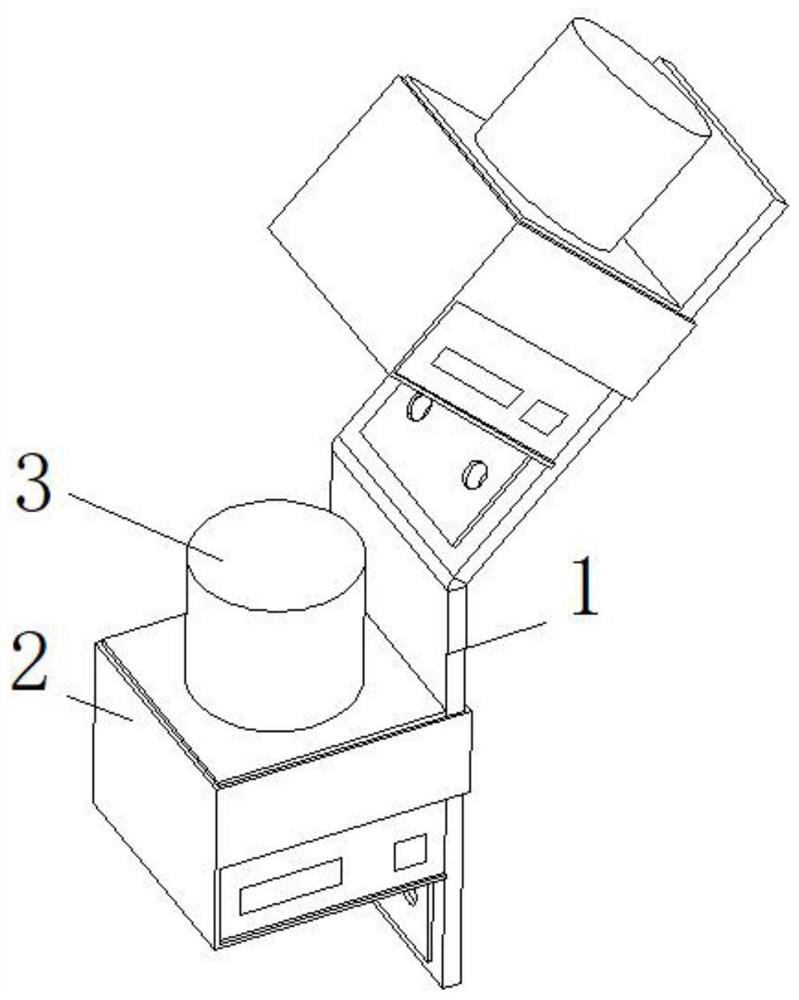

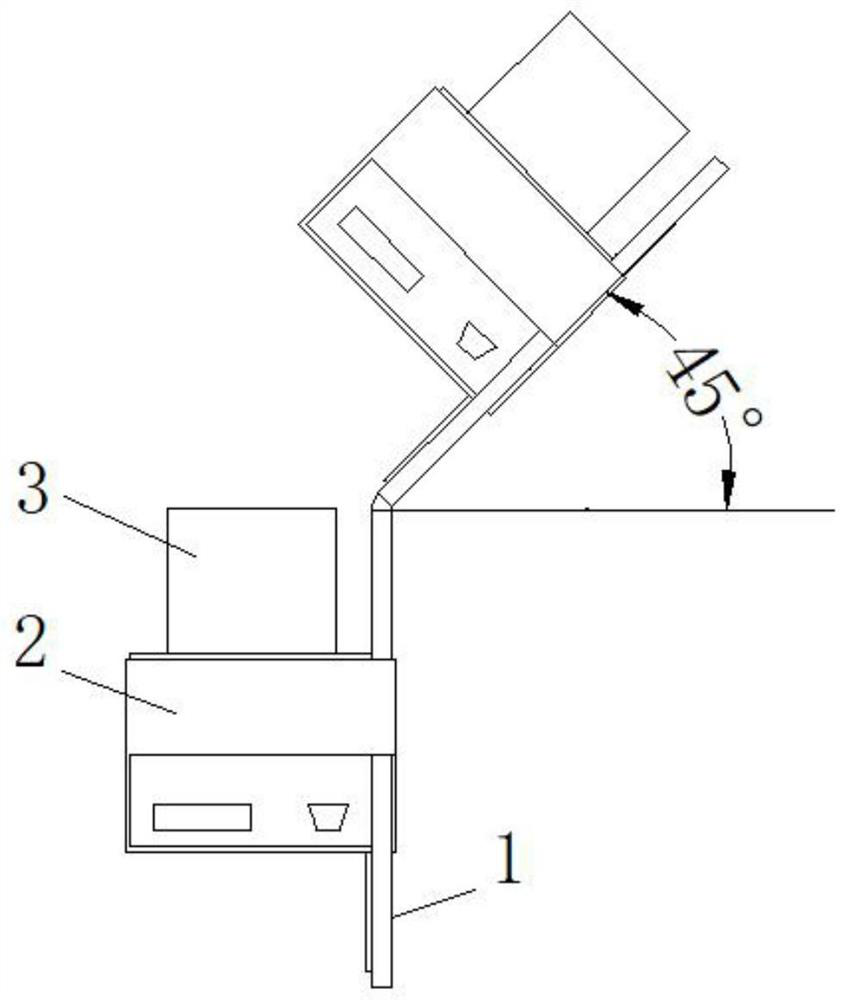

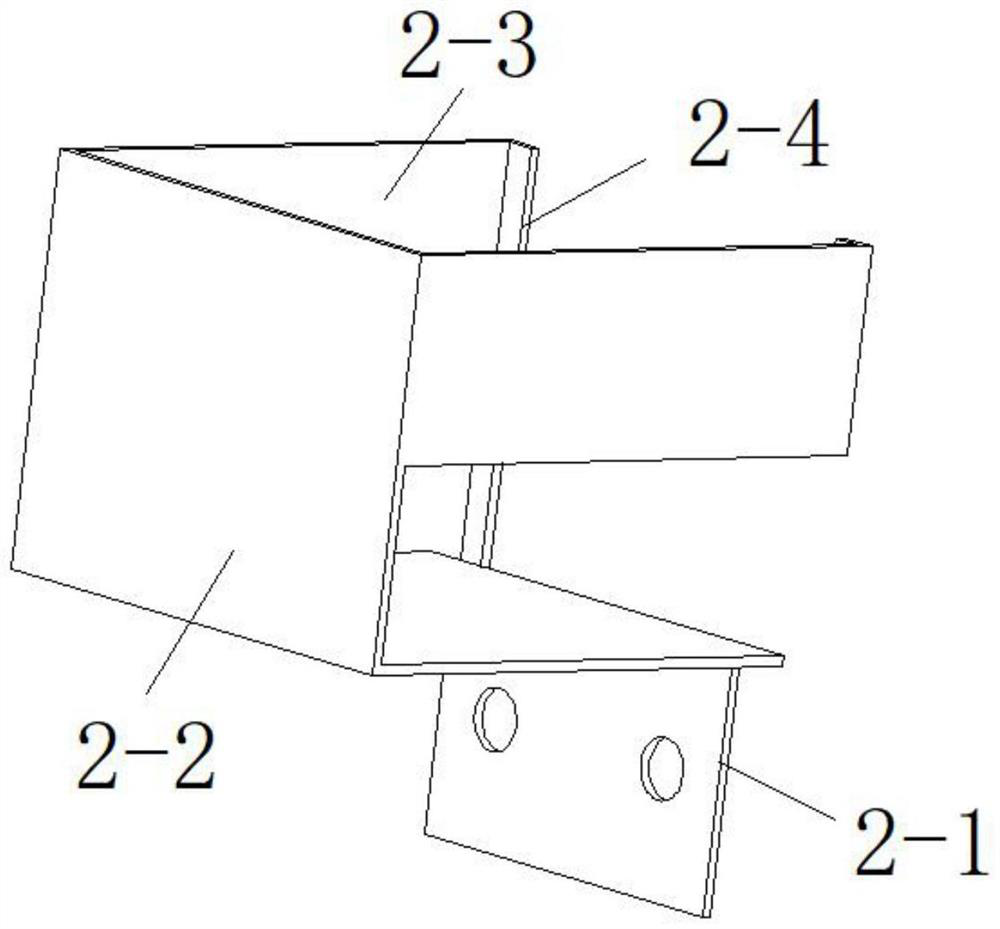

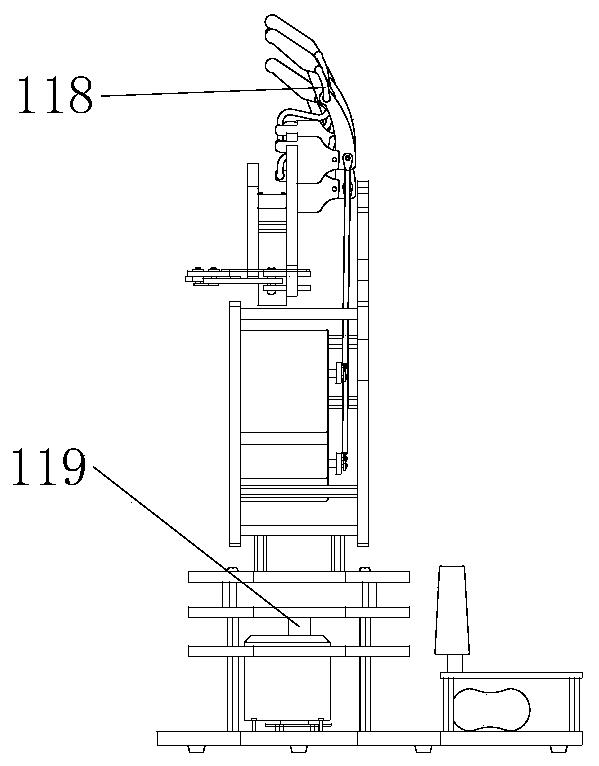

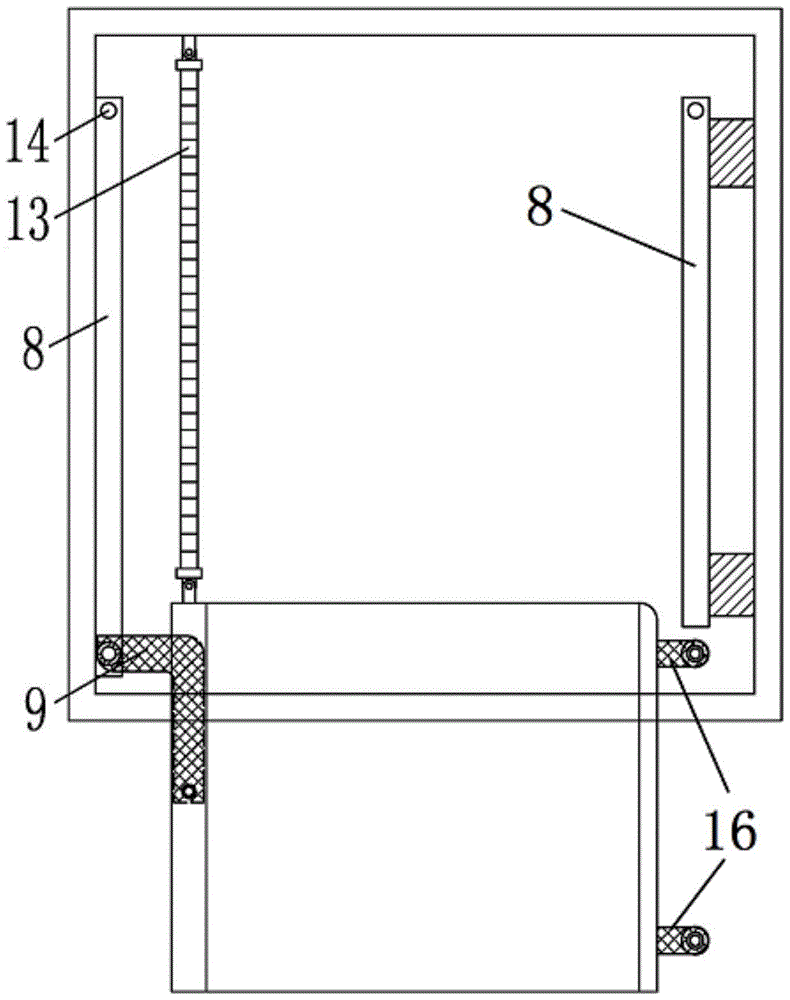

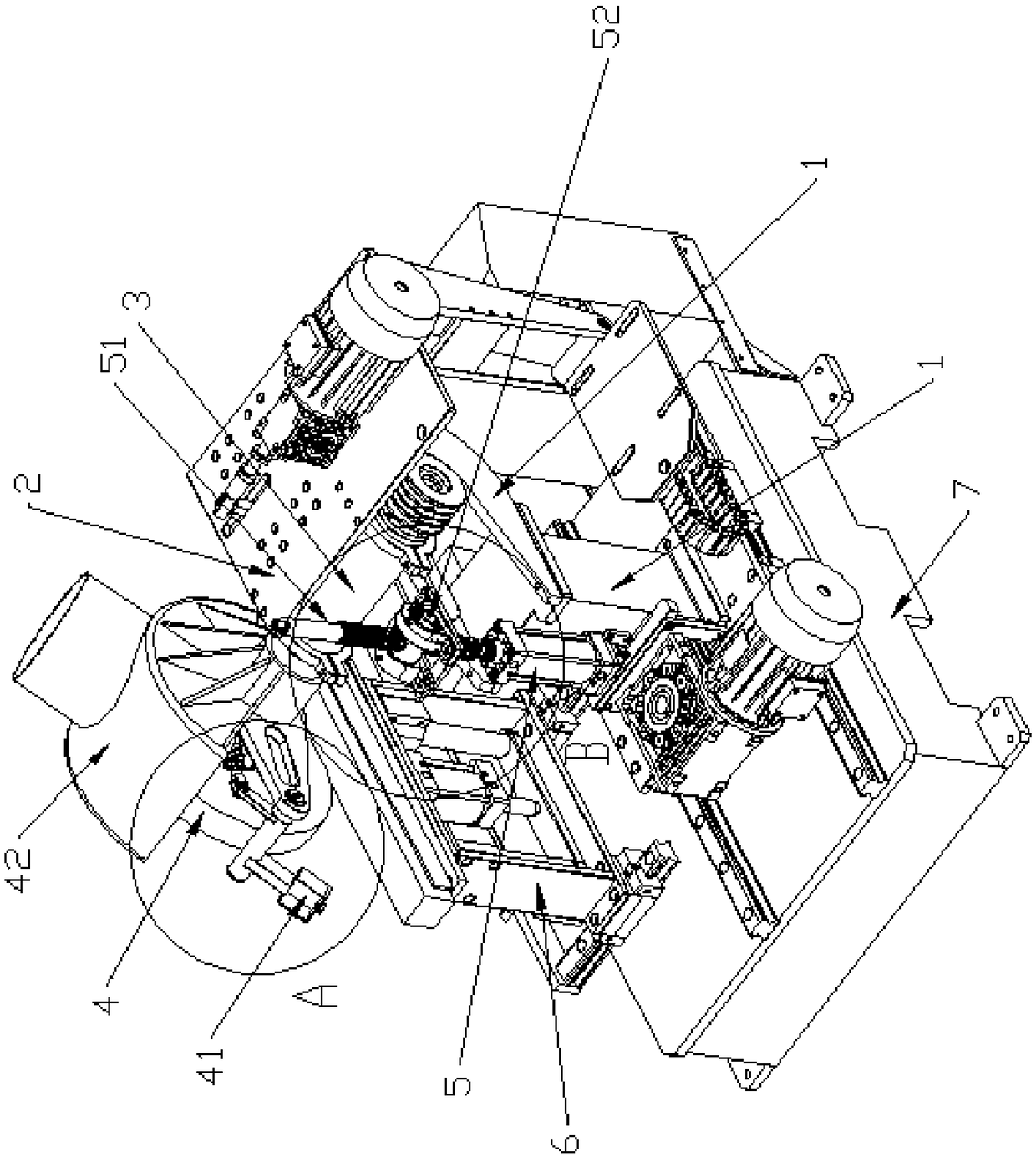

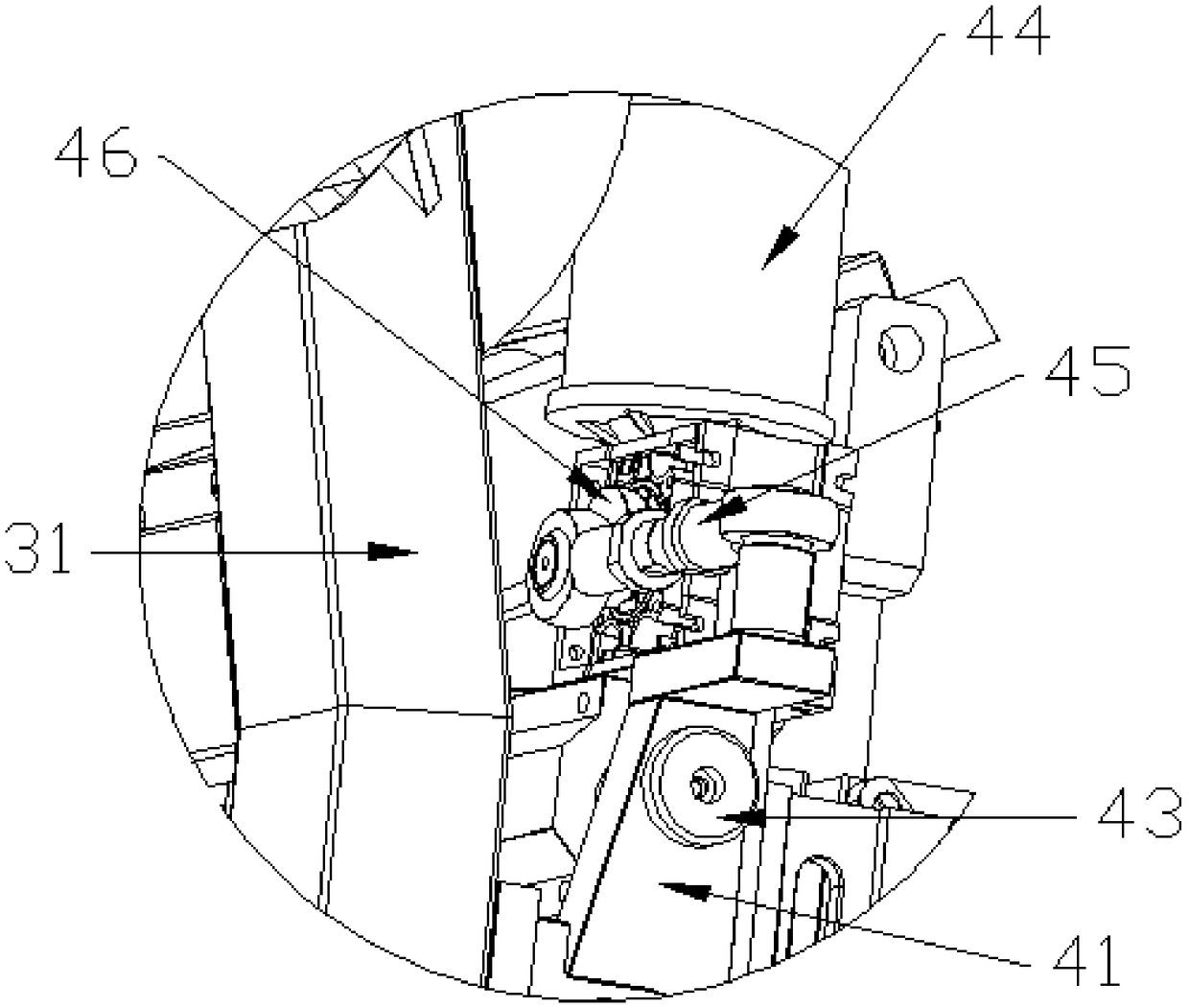

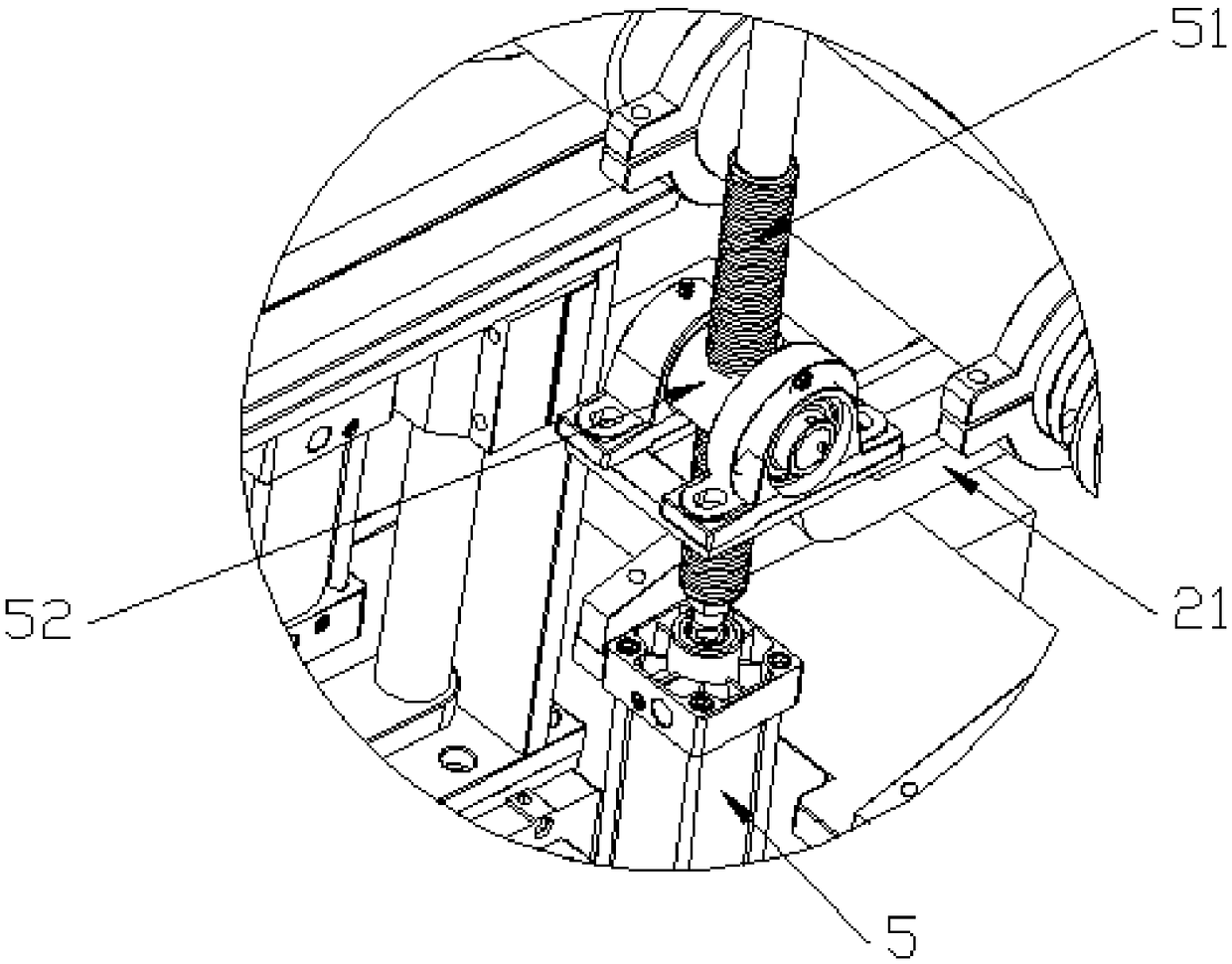

Novel injection head gooseneck servo mechanism

The invention relates to the technical field of drilling equipment, in particular to a novel injection head gooseneck servo mechanism. The mechanism comprises a gooseneck and an injection head, wherein a rotary device is arranged between the gooseneck and the injection head, and the gooseneck and the injection head are connected in a rotary mode through the rotary device. The gooseneck is arranged on the injection head in a rotary mode through the rotary device, a coiled tubing enters the gooseneck through a roller, the gooseneck rotates under the drawing of the coiled tubing when the coiled tubing is not at the center position, and then the gooseneck can move along with the coiled tubing, the coiled tubing is prevented from bending when the coiled tubing enters the gooseneck, and the service life of the coiled tubing is prolonged; furthermore, due to the fact that the gooseneck is not provided with a horn mouth structure, overall arrangement of a coiled tubing operation machine is not limited.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

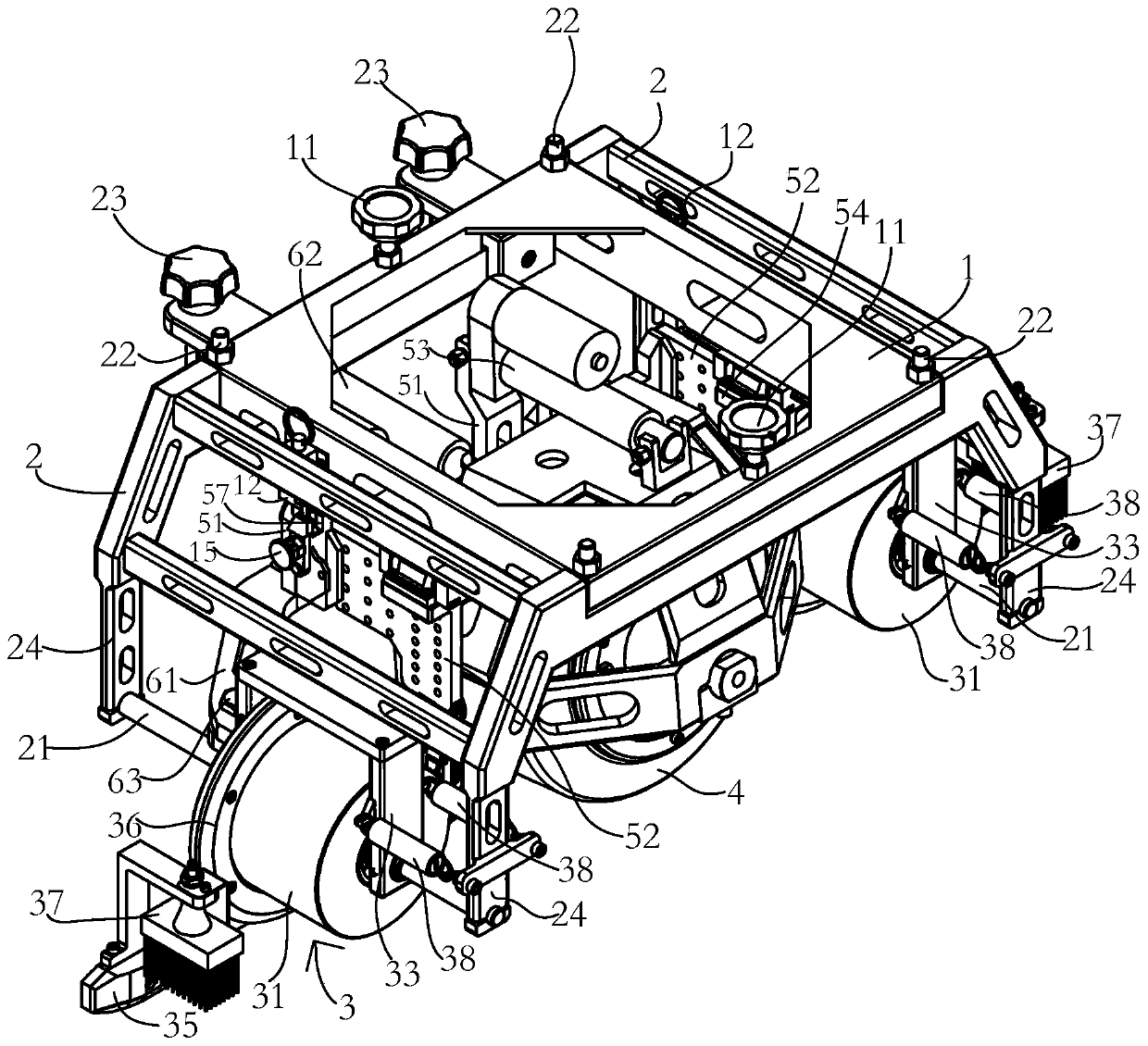

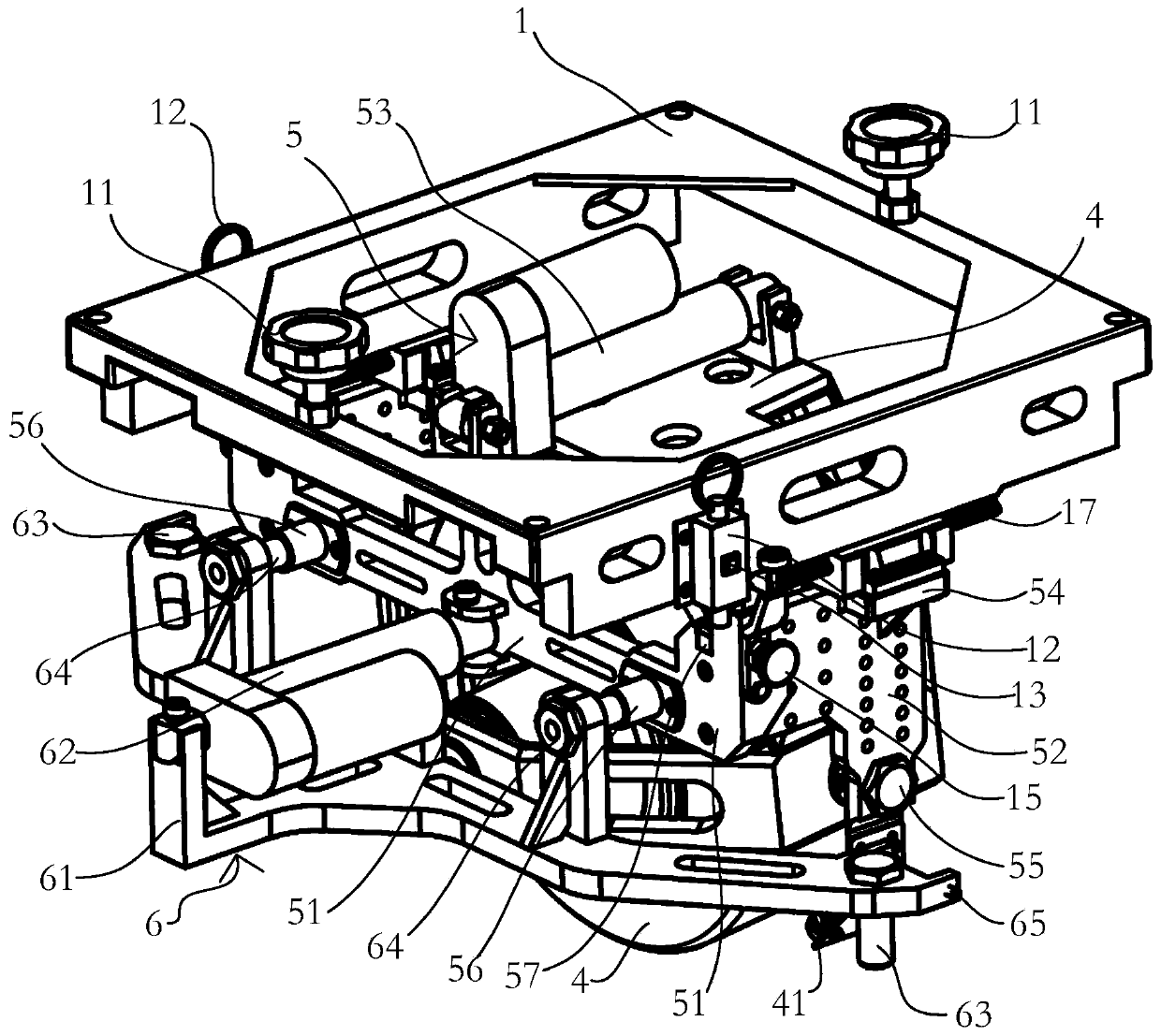

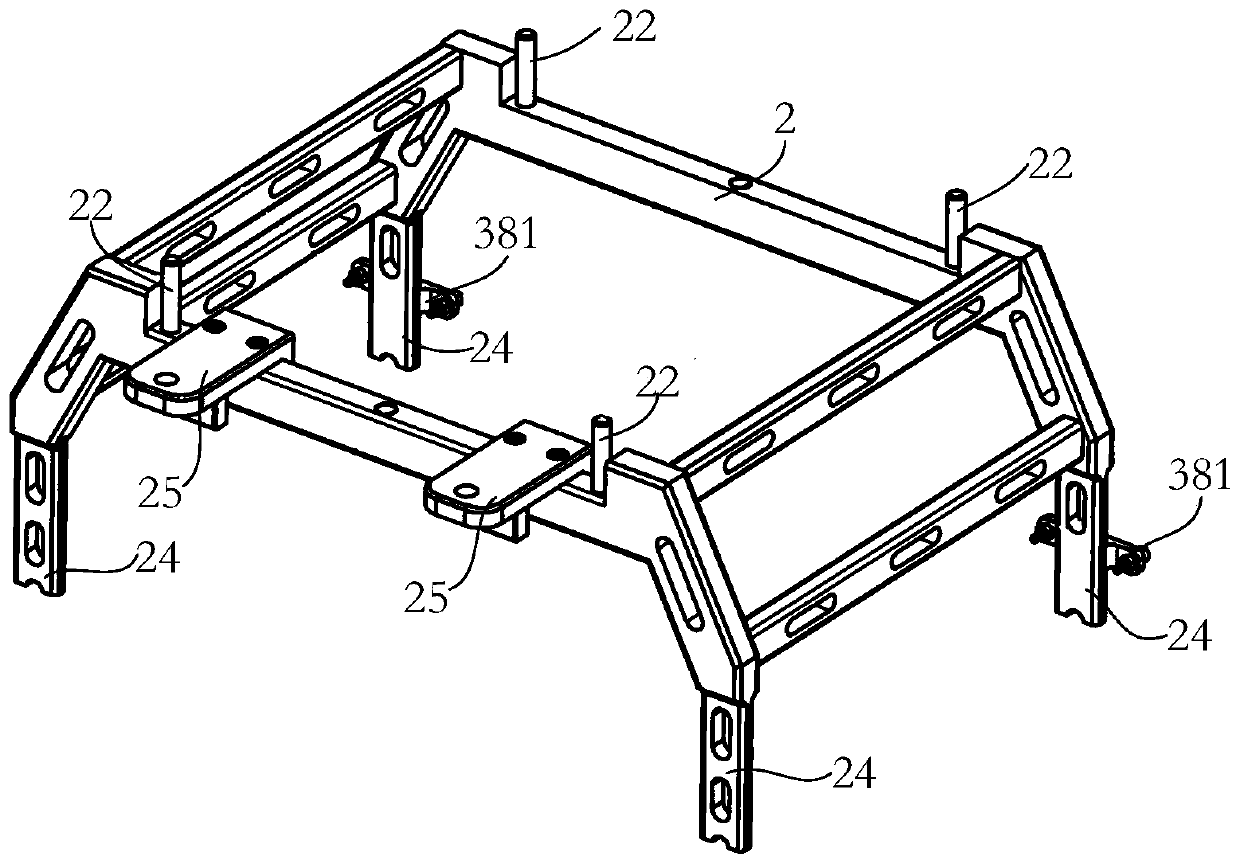

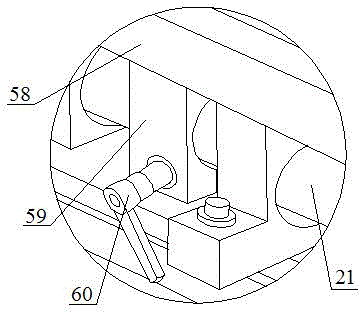

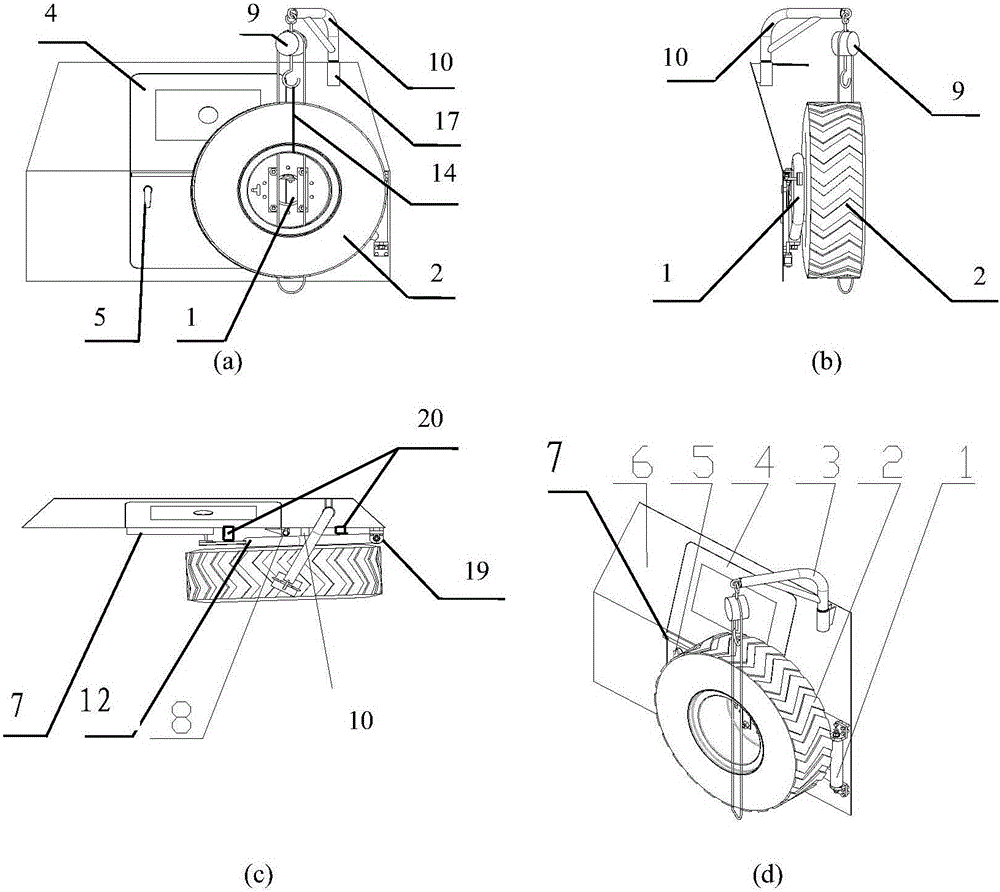

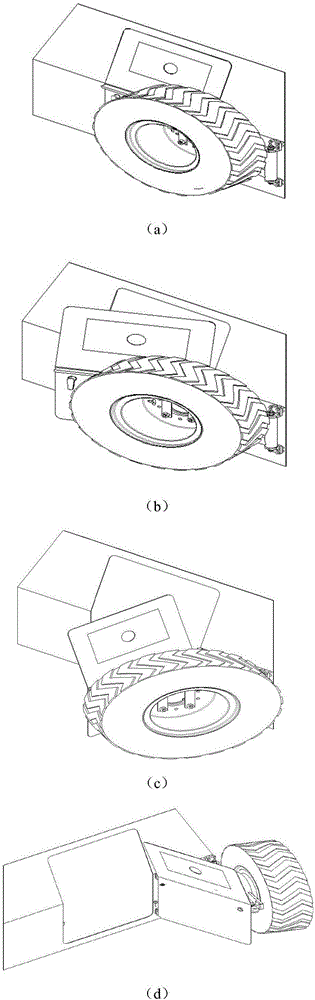

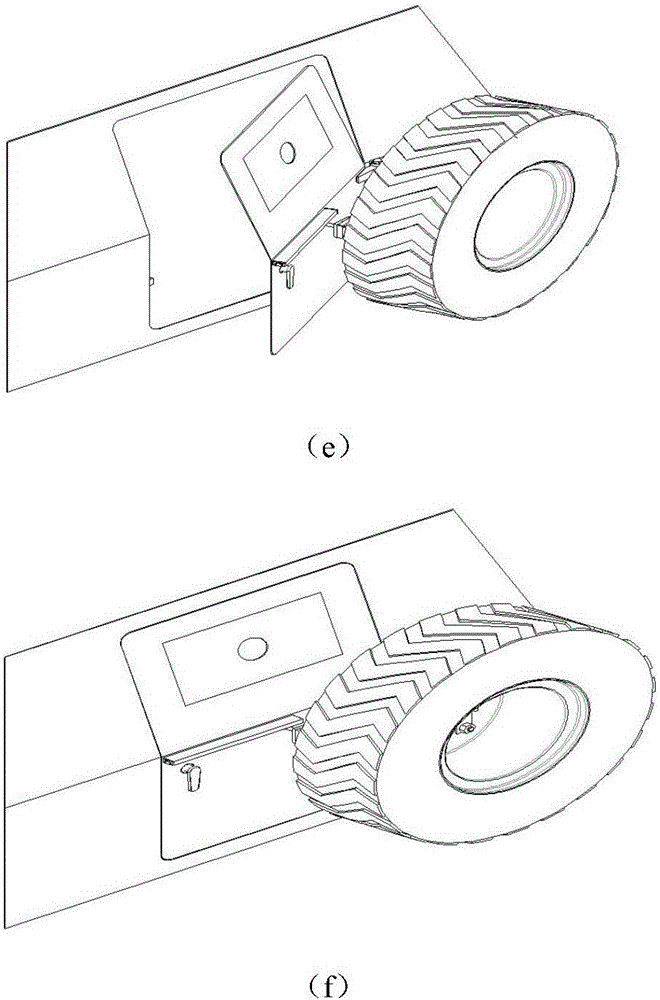

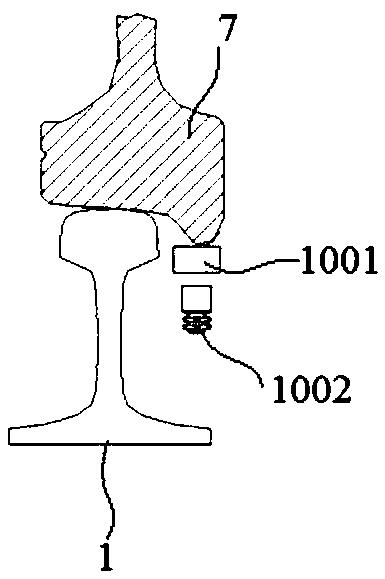

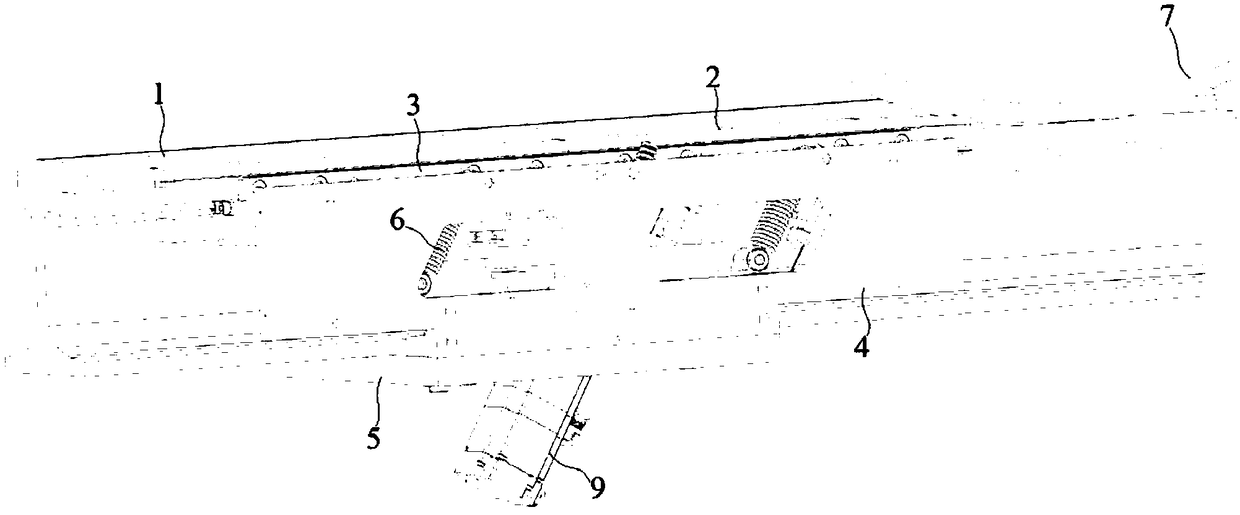

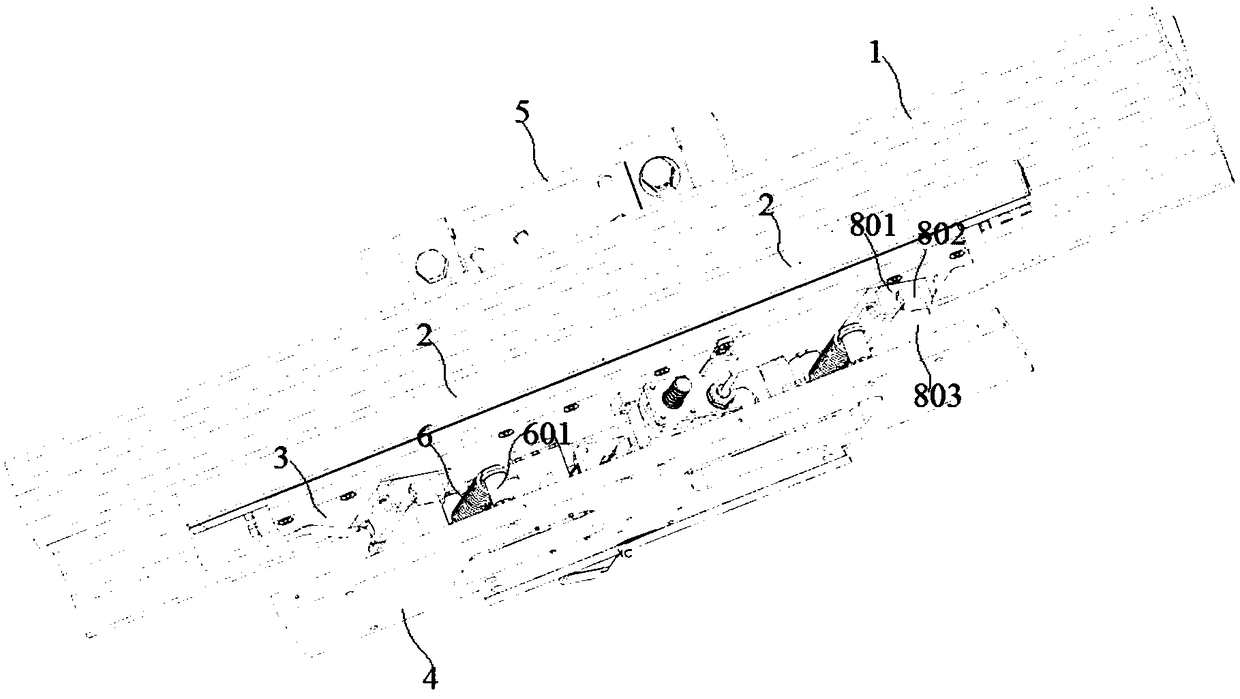

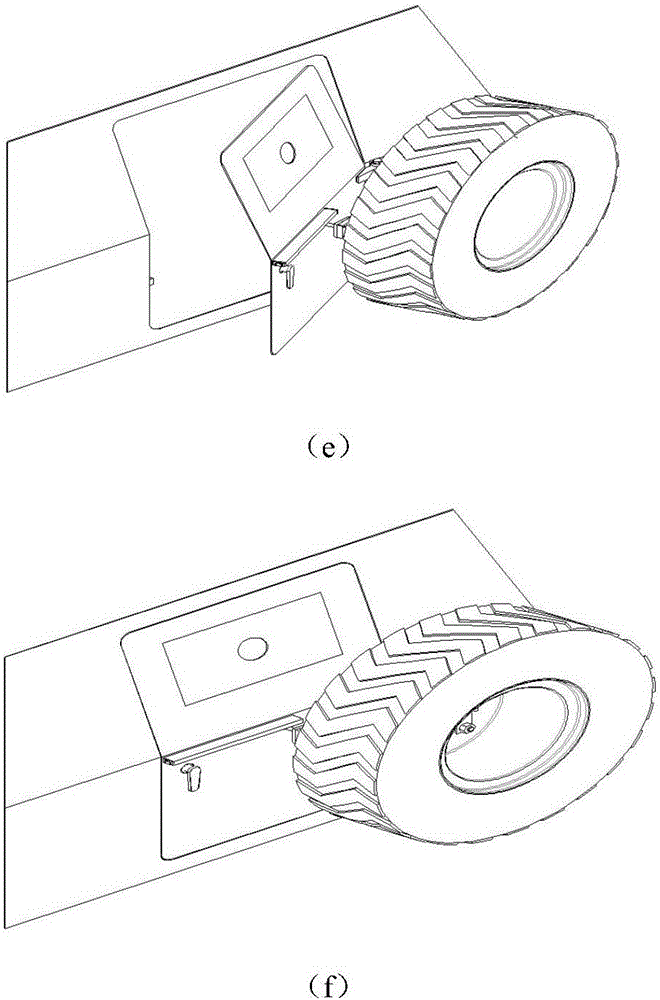

Detection wheel support of steel rail ultrasonic flaw detector

PendingCN110658262ARealize follow-up functionSimple structureMaterial analysis using sonic/ultrasonic/infrasonic wavesRailway auxillary equipmentVehicle frameControl theory

The invention relates to a detection wheel support of steel rail ultrasonic flaw detector. The support comprises an outer frame, an inner frame, a swing angle adjusting mechanism and a transverse adjusting mechanism; the outer frame is connected with a flaw detector frame, and provided with a guide wheel set; the inner frame is arranged on the outer frame through a thread adjusting piece; the swing angle adjusting mechanism is transversely connected with the inner frame in a sliding mode, and the driving end of the swing angle adjusting mechanism is connected with a detection wheel set and adjusts the deflection angle of the detection wheel set relative to the transverse center surface of the steel rail; the transverse adjusting mechanism is transversely limited on the guide wheel set andcan vertically move relative to the guide wheel set, and the driving end of the transverse adjusting mechanism is connected with the swing angle adjusting mechanism and drives the swing angle adjusting mechanism to drive the detection wheel set to transversely move along the inner frame; the thread adjusting piece is screwed to adjust the vertical displacement of the inner frame, the swing angle adjusting mechanism, the transverse adjusting mechanism and the detection wheel set, so that the downward pressing amount of the detection wheel set relative to a steel rail tread is adjusted, after the downward pressing amount is adjusted to proper amount, the transverse adjusting mechanism and the guide wheel set are locked and fixed.

Owner:北京地平线轨道技术有限公司

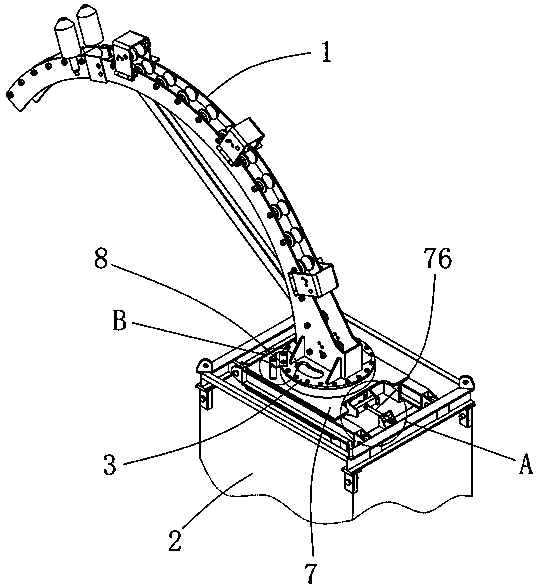

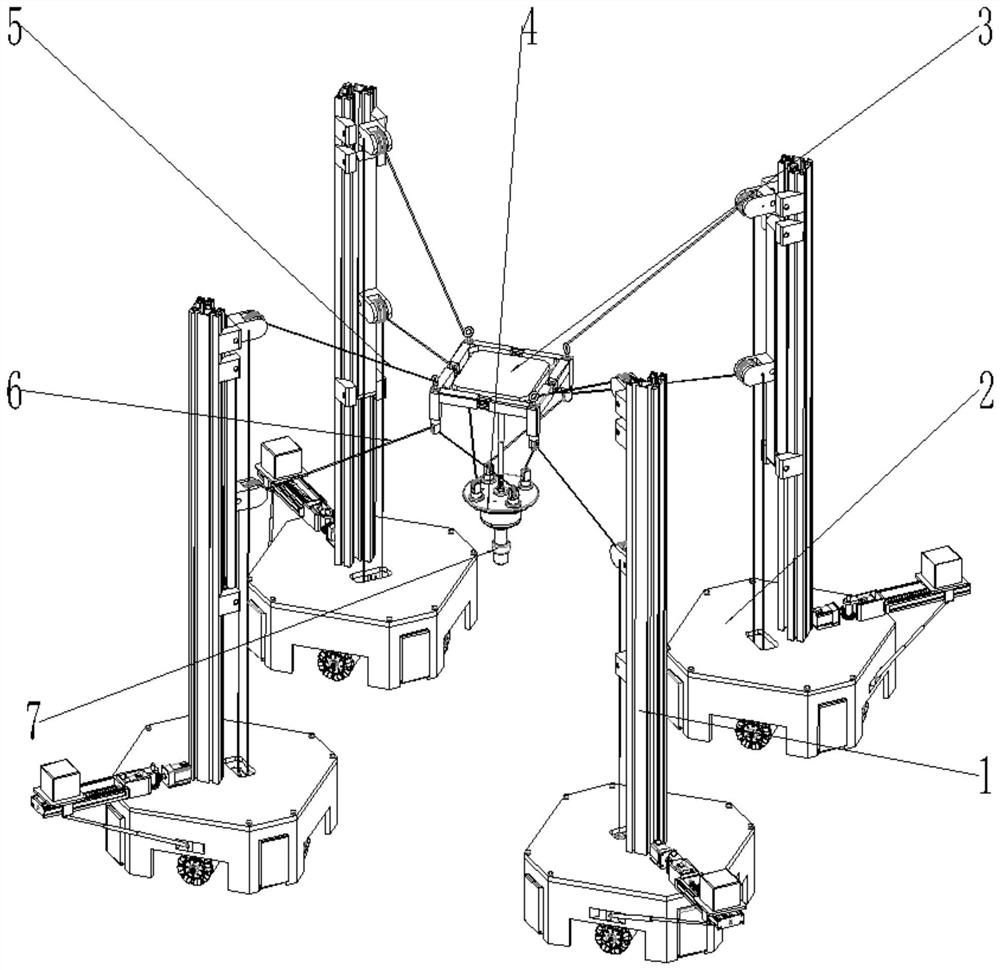

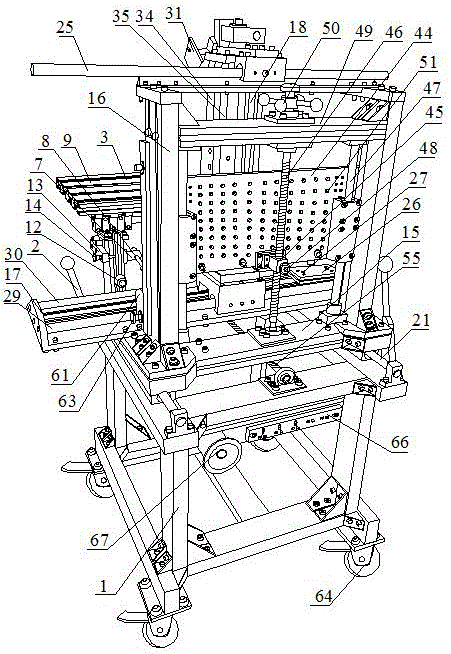

Movable electro-hydraulic composite drive spraying robot with large working space

ActiveCN113171906ALarge working spacePrevent rolloverSpraying apparatusManipulatorBalancing machineControl engineering

The invention discloses a movable electro-hydraulic composite drive spraying robot with a large working space. The movable electro-hydraulic composite drive spraying robot comprises a plurality of movable bases, the movable bases are matched with one another and are used for bearing drive rope adjusting modules, profile struts in the drive rope adjusting modules are respectively fixed on the movable bases, an operation space is defined by the multiple movable bases, a movable adjustable auxiliary motion platform is erected in the operation space, a rotary motion platform is arranged below the adjustable auxiliary motion platform, the adjustable auxiliary motion platform is connected with the rotary motion platform through a hydraulic push rod, a spray gun is installed on the bottom end face of the rotary motion platform, and a balance mechanism and a fixed supporting mechanism which are used for balancing the traction force of a rope and maintaining the balance of the mechanism are further installed on the movable bases. The movable electro-hydraulic composite drive spraying robot is reasonable in structural design, multi-degree-of-freedom movement in a large working space is achieved, meanwhile, interference between a traction rope and a machined workpiece is avoided, and the applicability of equipment is improved.

Owner:HEFEI UNIV OF TECH

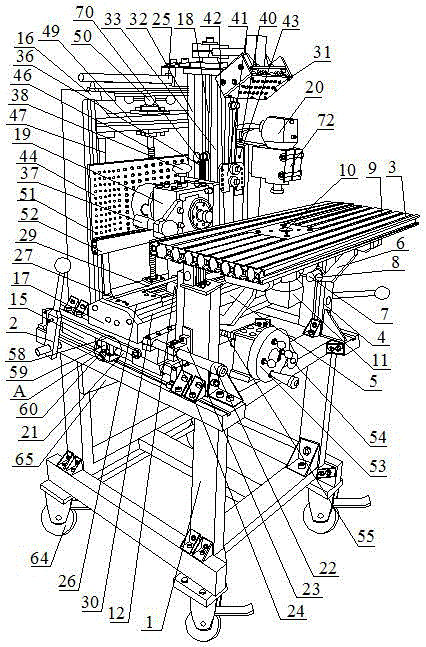

Special type woodworking compound milling machine

ActiveCN106738095AImprove use comfort performanceErgonomicLighting applicationsMechanical apparatusPunchingEngineering

The invention belongs to the technical field of machining equipment, in particular to a special type woodworking compound milling machine. The special type woodworking compound milling machine comprises a base frame, a main workbench mechanism, a feed mechanism, a power devive and a vice workbench mechanism. The main workbench mechanism comprises a main workbench and two fixed supports. The feed mechanism comprises a base, a gantry frame, a sliding table and the power device. The vice workbench mechanism comprises a vice workbench, a lead screw nut and a lead screw and is arranged in front of the gantry frame, a plurality of installing holes are formed in the vice workbench, the lead screw nut is fixed to the rear side of the vice workbench, and the lead screw penetrates through the lead screw nut and is connected with the lead screw nut in a threaded mode. The special type woodworking compound milling machine is reasonable in structure, capable of achieving multi-function and multi-angle milling, punching and copying machining of complicated surface woods, simple in operation, flexible in using, small in energy consumption and occupied area and has great application and promotion value.

Owner:曲艺

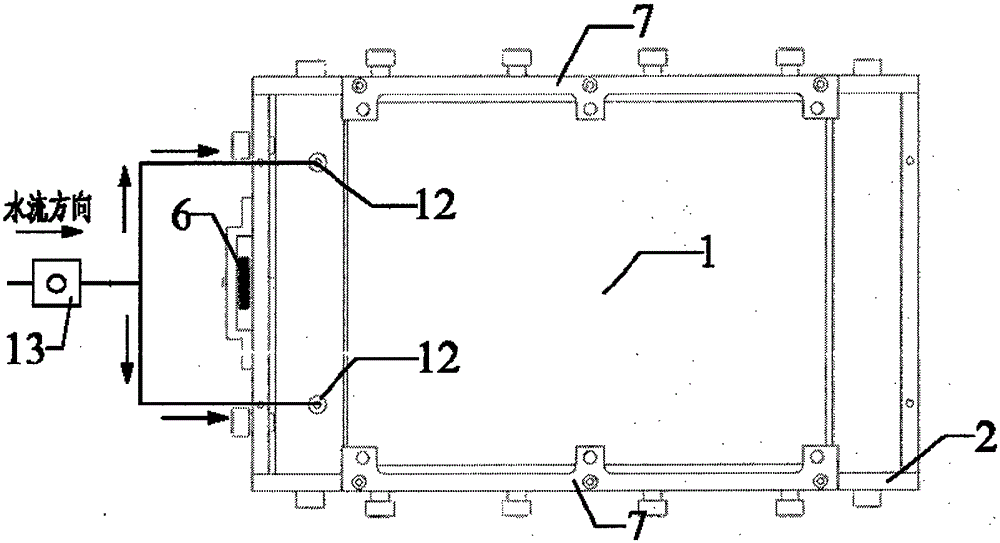

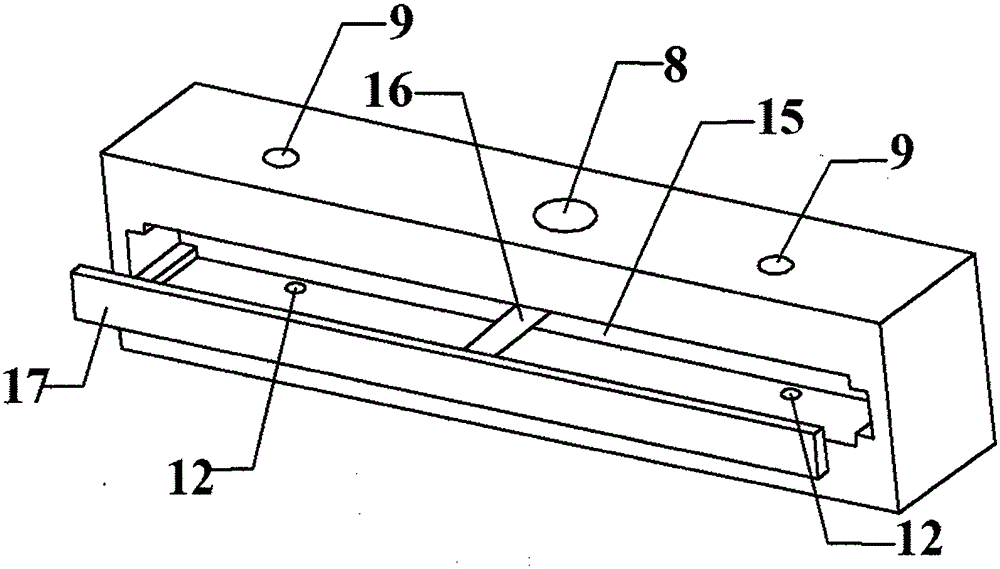

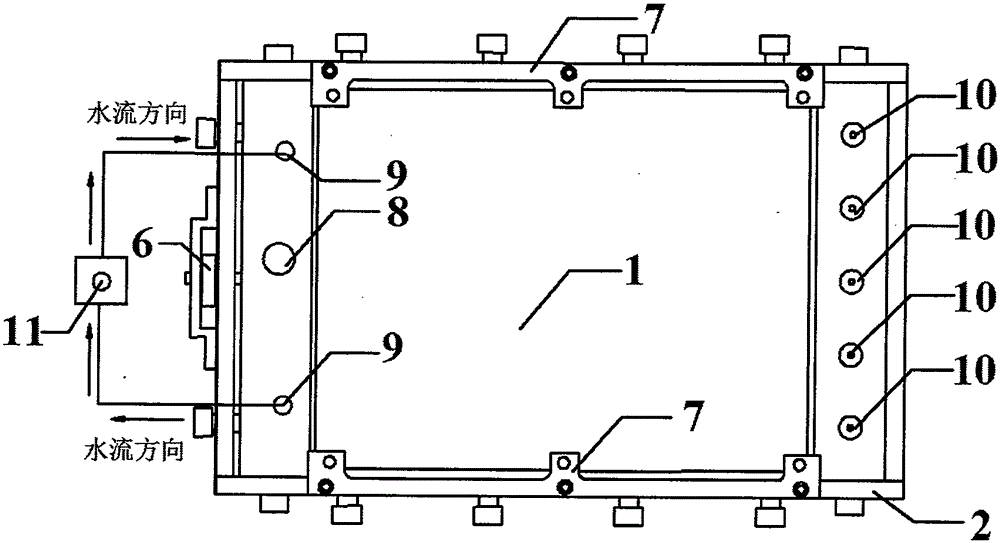

Multifunctional fissure medium underground water testing device

InactiveCN106546707AAchieve regulationFollow-upGeneral water supply conservationTesting waterWater flowBioremediation

The invention discloses a multifunctional fissure medium underground water testing device. The device utilizes a simulation transparent single fissure as a test object, can conveniently and rapidly simulate actual water flow and solute transport conditions in the fissure, can carry out ordinary fissure water flow and solute transport testing, fissure medium underground water pollution simulation testing and fissure medium underground water pollution bioremediation testing and can achieve adjustable fissure position and real time monitoring and data synchronous connection inside the fissure.

Owner:NANJING HYDRAULIC RES INST

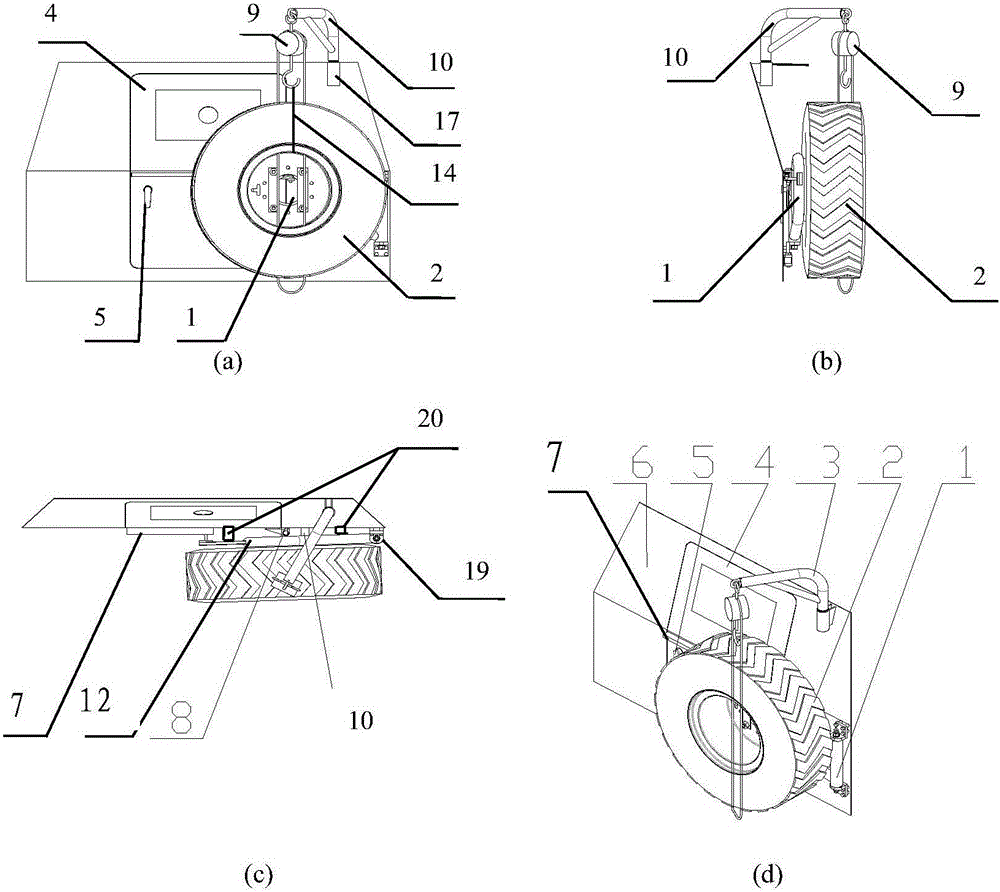

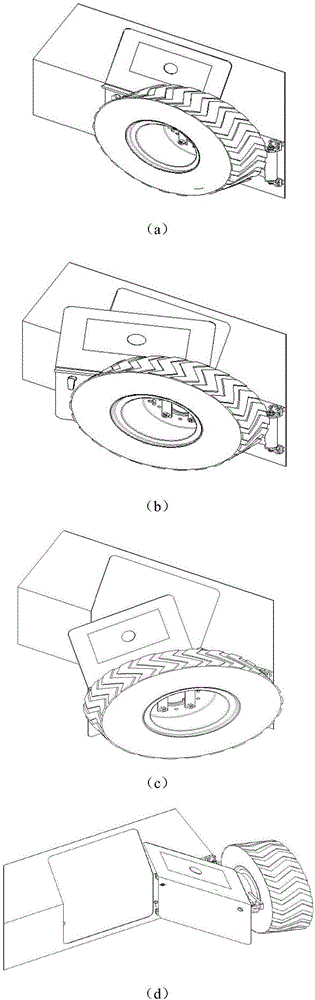

Spare wheel carrier for vehicle

Owner:NO 6409 FACTORY PLA

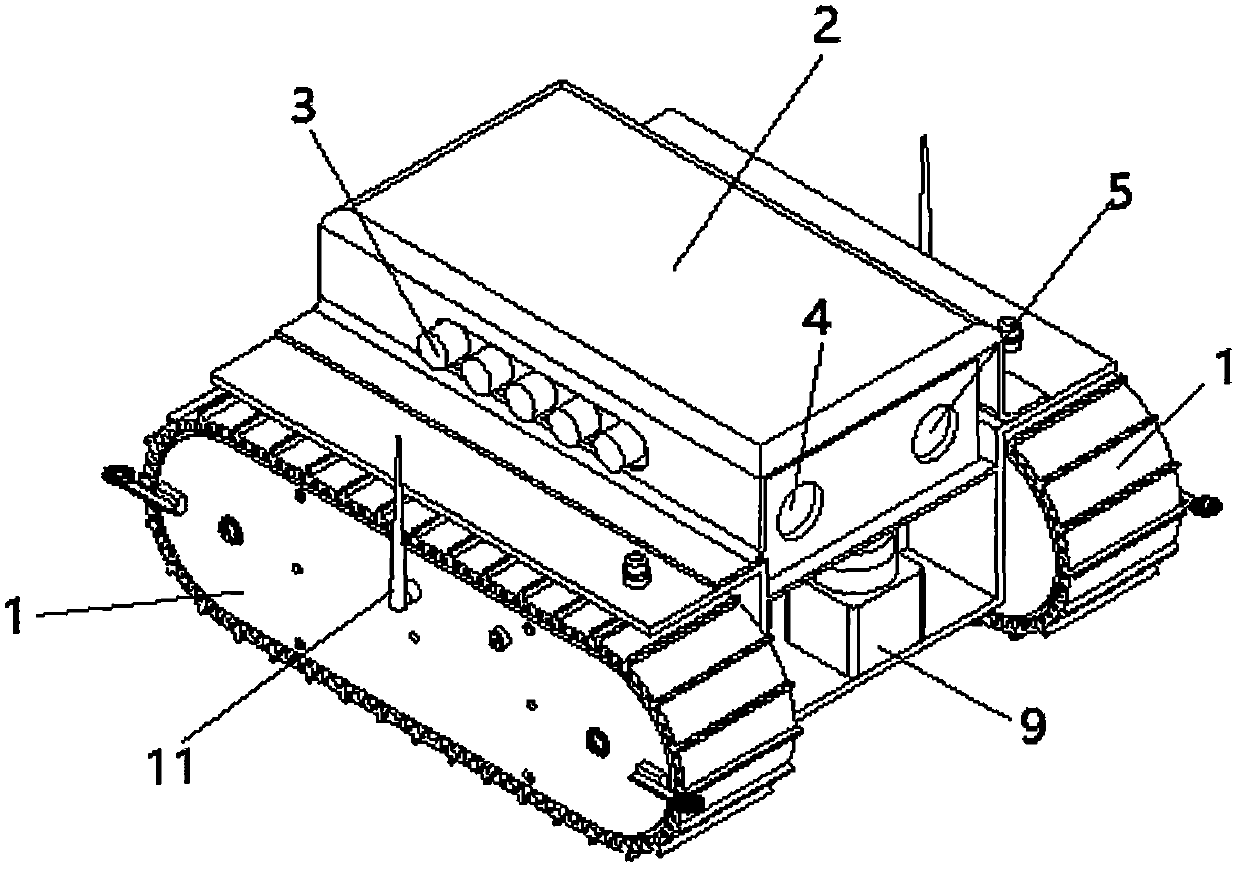

Intelligent robot for architectural ornament

InactiveCN106737560AAchieve stabilityFollow upProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses an intelligent robot for architectural ornament. The intelligent robot comprises a crawler walking mechanism, an origin rotating mechanism, a rotary turntable mechanism, an extension and retraction adjustment mechanical arm and a construction mechanism, wherein the origin rotating mechanism comprises a base plate lifting device mounted on a base plate, the base plate lifting device comprises a liftable rotary device, and a supporting device supported on the ground is mounted at the lower end of the rotary device; the rotary turntable mechanism comprises a rotary turntable rotationally mounted on the base plate, a rotary driving mechanism is arranged between the rotary turntable and the base plate, and a mechanical arm support base is mounted on the rotary turntable; the extension and retraction adjustment mechanical arm is fixedly mounted on the mechanical arm support base; and the construction mechanism is detachably mounted at the tail end of the extension and retraction adjustment mechanical arm. The intelligent robot is more compact in structural design and flexible and convenient in construction, and can realize various operations such as high-quality continuous spraying.

Owner:蒋学凯

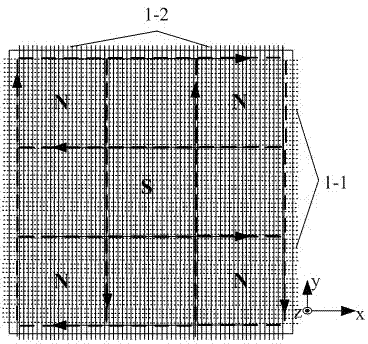

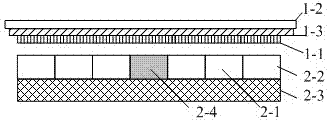

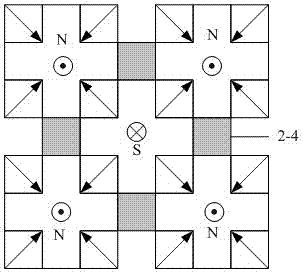

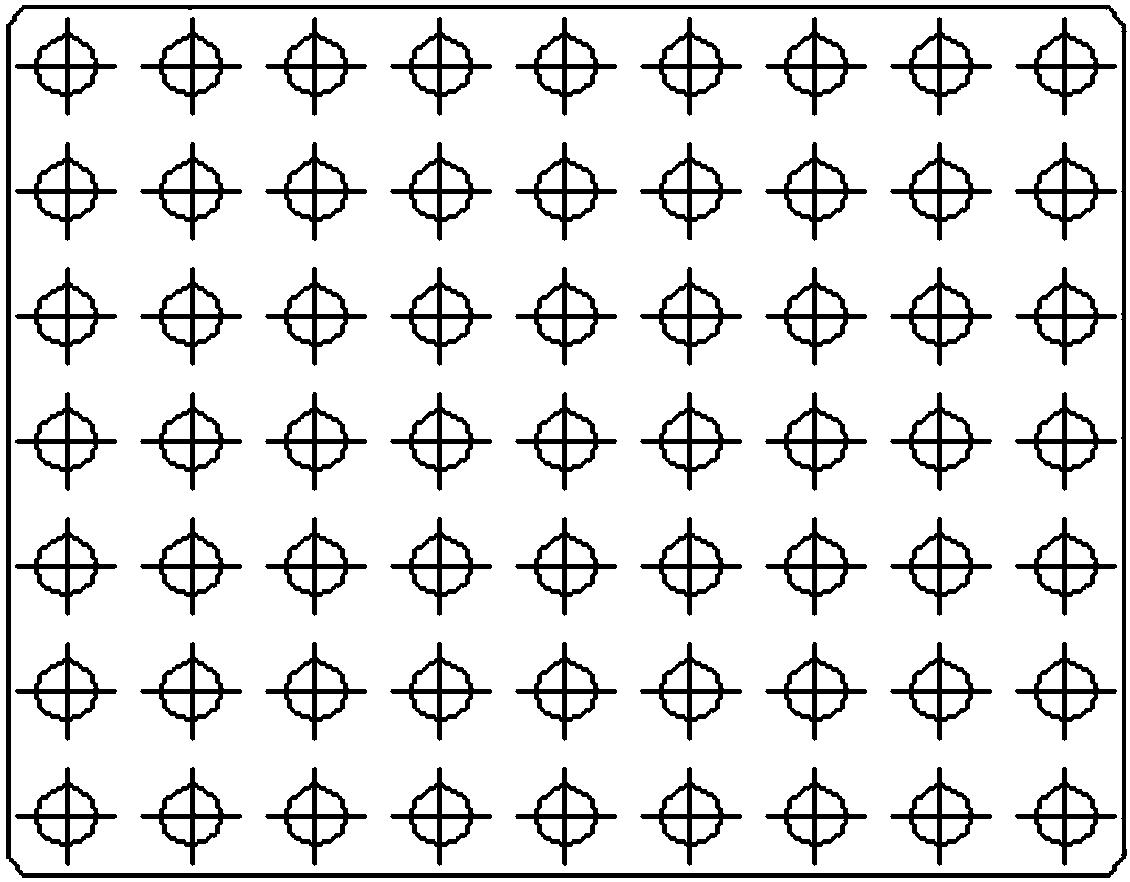

Micro actuator with adjustable local magnetic field

ActiveCN102647126AAvoid frictionReduce mover massMagnetic holding devicesMicro actuatorMicro robotics

The invention discloses a micro actuator with adjustable local magnetic field. The micro actuator comprises stators and rotors of armatures, wherein the stators consist of a two-dimensional permanent magnet array and back iron, and the rotors of the armatures are paved on the upper surface and the lower surface of an insulation body, and the armatures are arranged along the X-axis direction and the Y-axis direction in a staggered manner, and gaps are reserved between the stators and the rotors; the two-dimensional permanent magnet array is characterized by being rectangular cross-shaped integrally, and distributing main poles N and S in a staggered manner, and the adjacent poles N or the adjacent poles S are separated by non-magnetic-conduction blocks; and the armatures arranged along the X-axis direction and the Y-axis direction in a staggered manner consist of X-axis guide wire groups in parallel arrangement and Y-axis guide wire groups in parallel arrangement. According to the micro actuator with adjustable local magnetic field, the structure is simple, the manufacturing is convenient, the adjustment of a local magnetic field and the electromagnetic force is flexible due to the guide wire type armature structure, the decoupling control on suspension force and horizontal thrust is realized, meanwhile, the micro actuator has the advantages of quick response speed, wide driving range and the like and can be used for occasions of micro-robots, photoetching machines, microelectronic packaging equipment and the like which need to be driven and operated precisely.

Owner:ZHEJIANG SCI-TECH UNIV

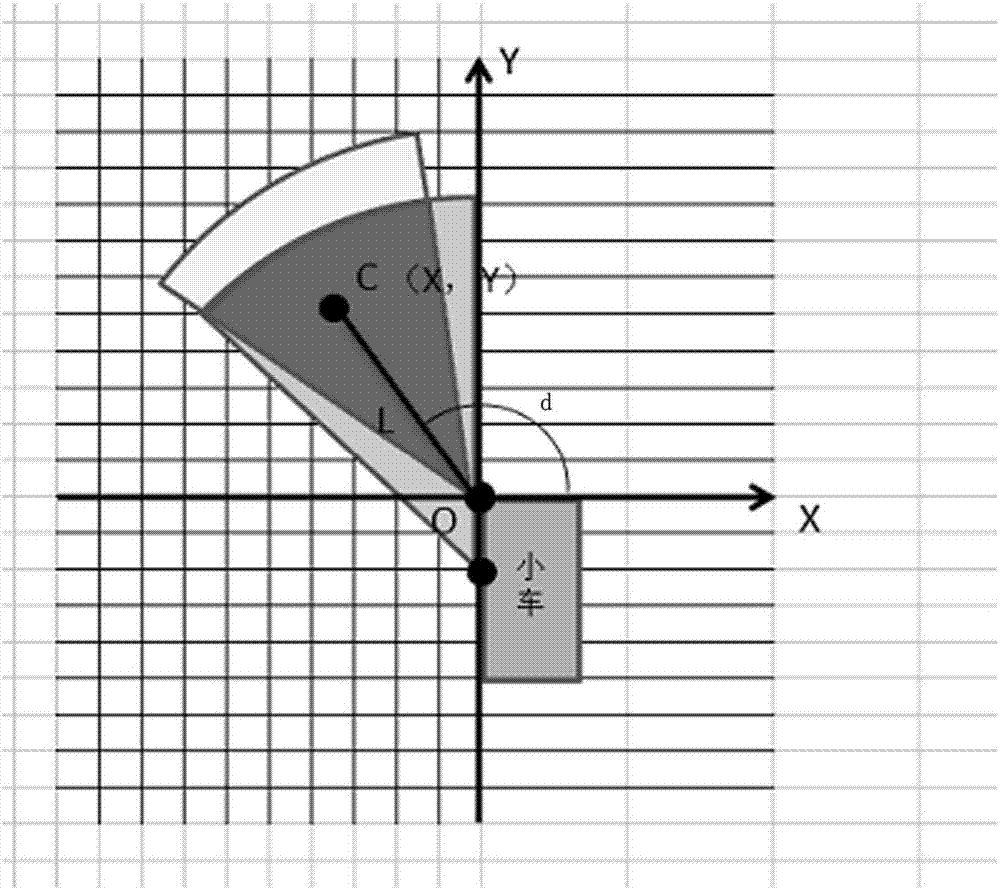

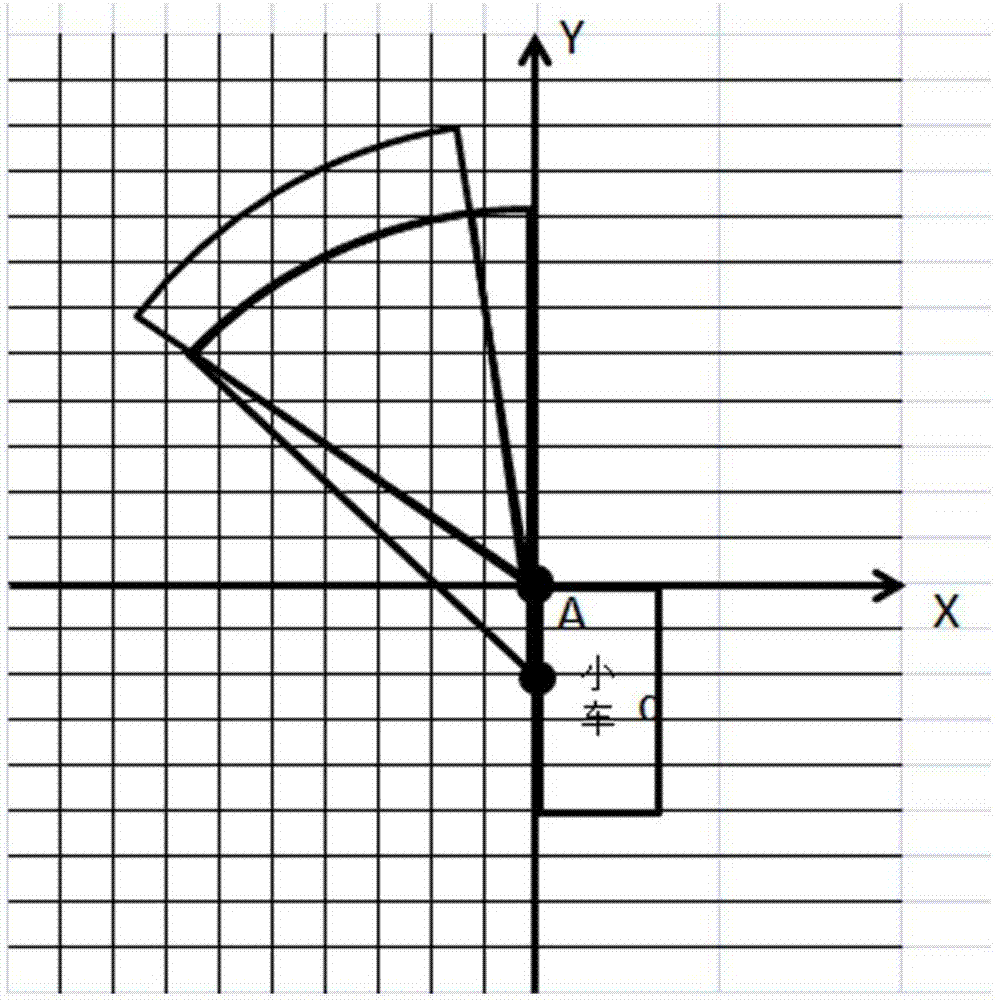

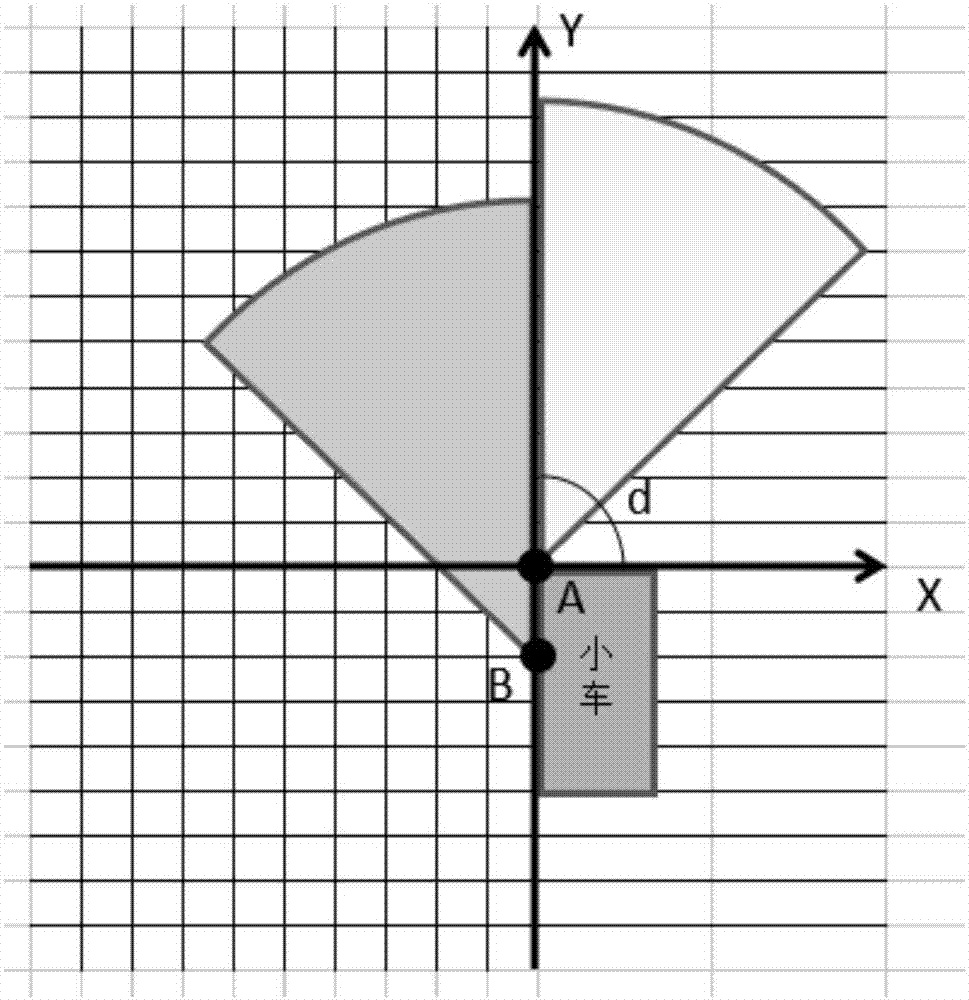

Infrared ranging and guiding method applied to servo-actuated dolly

ActiveCN107463174AAccurately determine the mobile locationAccurately judge the directionPosition/course control in two dimensionsMoving speedMobile object

The invention relates to an infrared ranging and guiding method applied to a servo-actuated dolly. According to the method, a module erected by an infrared ranging sensor is used for detecting location information of a followed object in real time, thereby realizing guidance of a servo-actuated dolly by a moving object within a certain range. The method comprises the following steps that: (1), two infrared ranging sensors are arranged on the dolly to erect an infrared ranging sensor device; (2), a two-dimensional coordinate system is established between the dolly and a followed object, the sensors scan corresponding ranges at certain frequencies continuously, and initial position information of the followed object is record; (3), the dolly moves based on the changing location information to realize accurate determination of a moving location, a moving direction, and a moving speed of the followed object, so that the dolly moves by following the target at any time and avoids obstacles in front of the dolly. Therefore, an objective of accurate determination of a moving location, a moving direction, and a moving speed of a target object by a dolly is achieved; and thus the dolly moves by following the target at any time and avoids obstacles in front of the dolly.

Owner:SHENYANG POLYTECHNIC UNIV

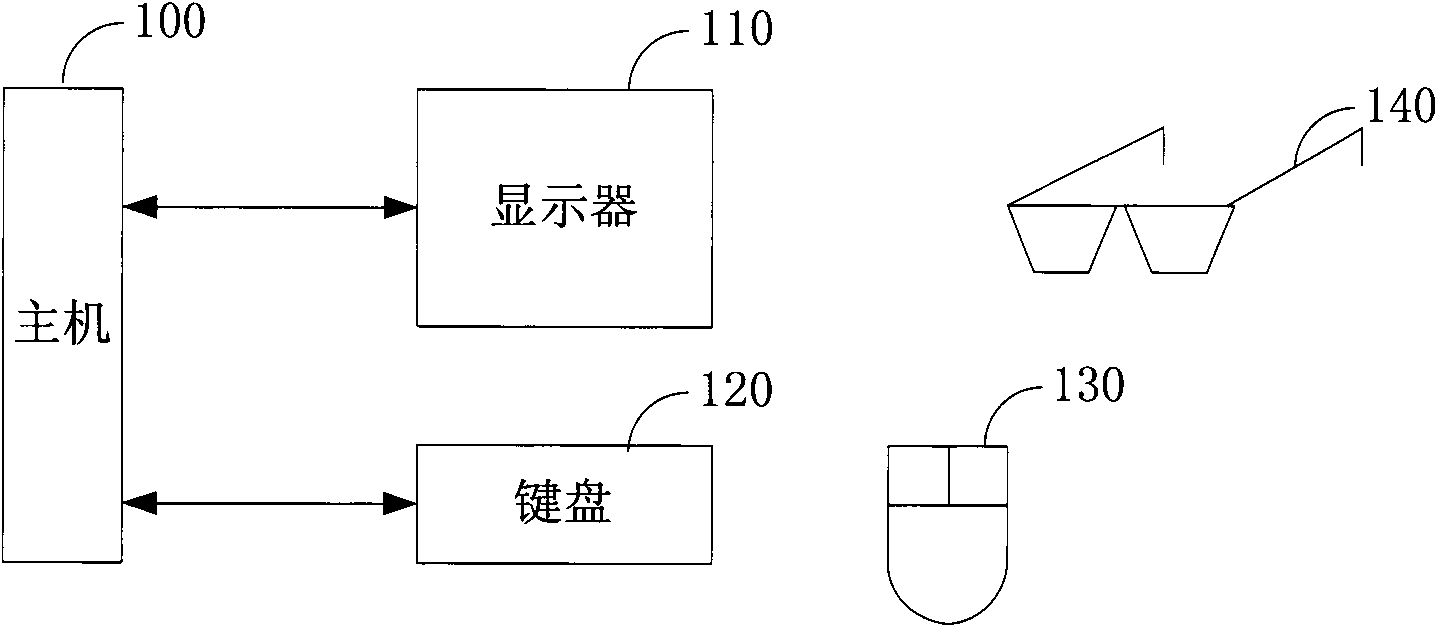

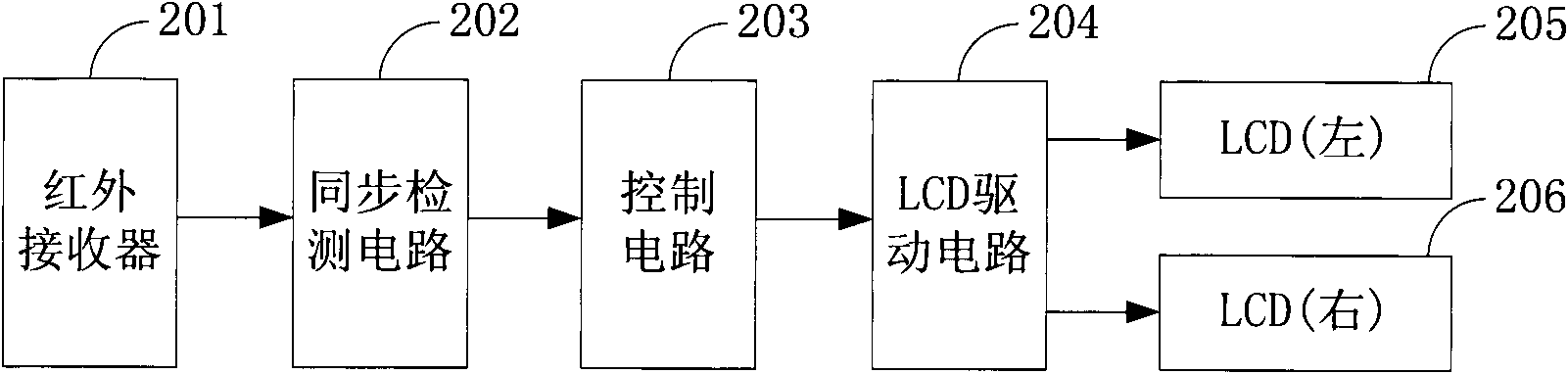

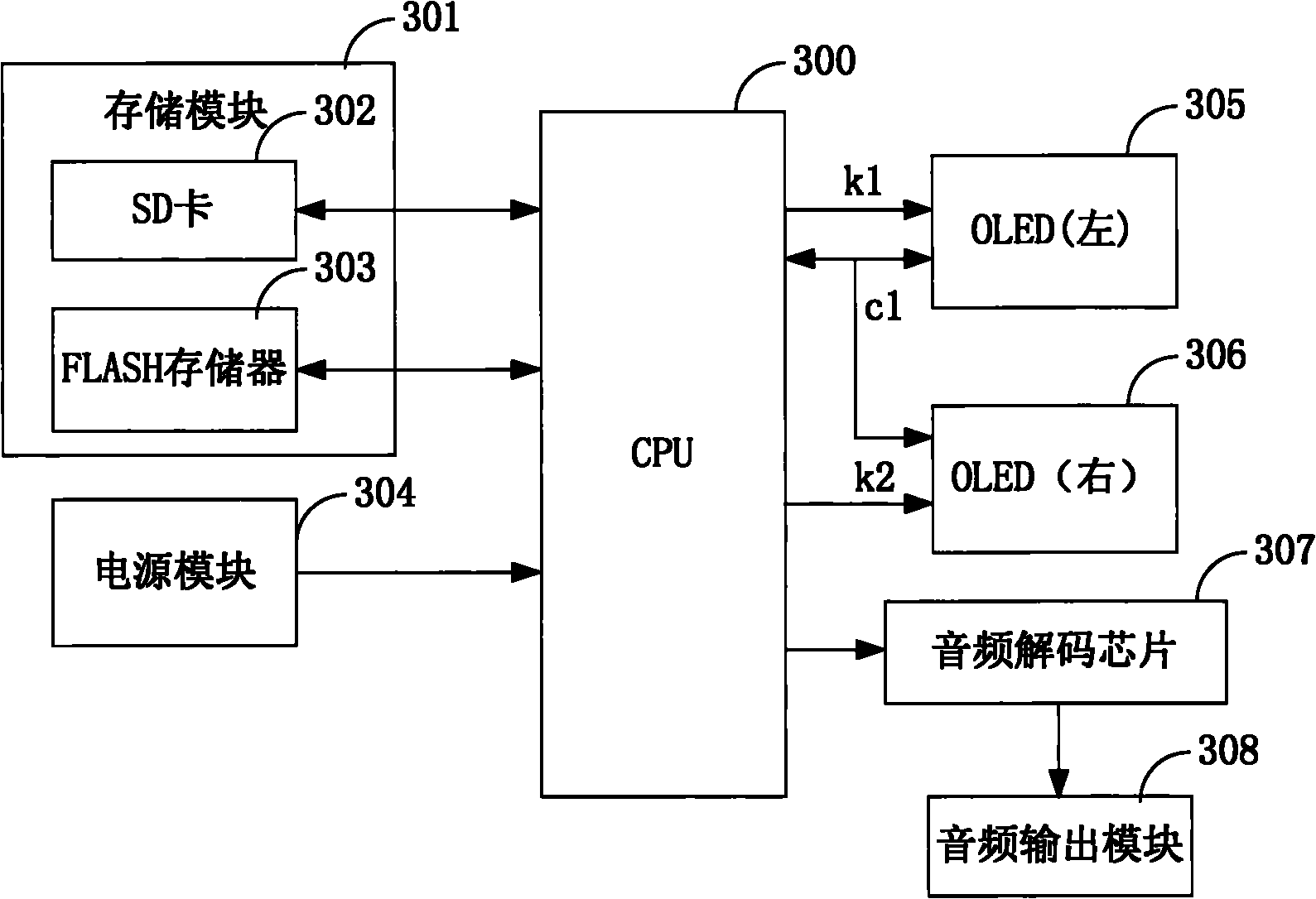

Active 3D glasses

InactiveCN102740087ASimple structureFollow-upSteroscopic systemsOptical elementsUses eyeglassesComputer module

The invention discloses active 3D glasses, comprising a circuit board arranged in a glass frame, two micro displayers which are arranged in lens positions, and two corresponding optical amplification modules. The circuit comprises a storage module, a control module, and a power supply module, wherein the storage module stores firmware programs, application programs and 3D video files, the control module is connected with the two micro displayers, the storage module and the power supply module respectively, and reads the 3D video files from the storage module to decode the video so that left-eye video signals are transmitted to a first micro displayer for displaying and right-eye video signals are transmitted to a second micro displayer for displaying, and the power supply module is connected with the two micro displayers, the storage module and the control module respectively, and supplies power for the modules. The two optical amplification modules are arranged between the two micro displayers and a user's eyes. The active 3D glasses of the invention realize independent 3D playing. And t watch 3D images / video, a user is only required to watch the active 3D glass, thereby enabling the 3D images to move with the user.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

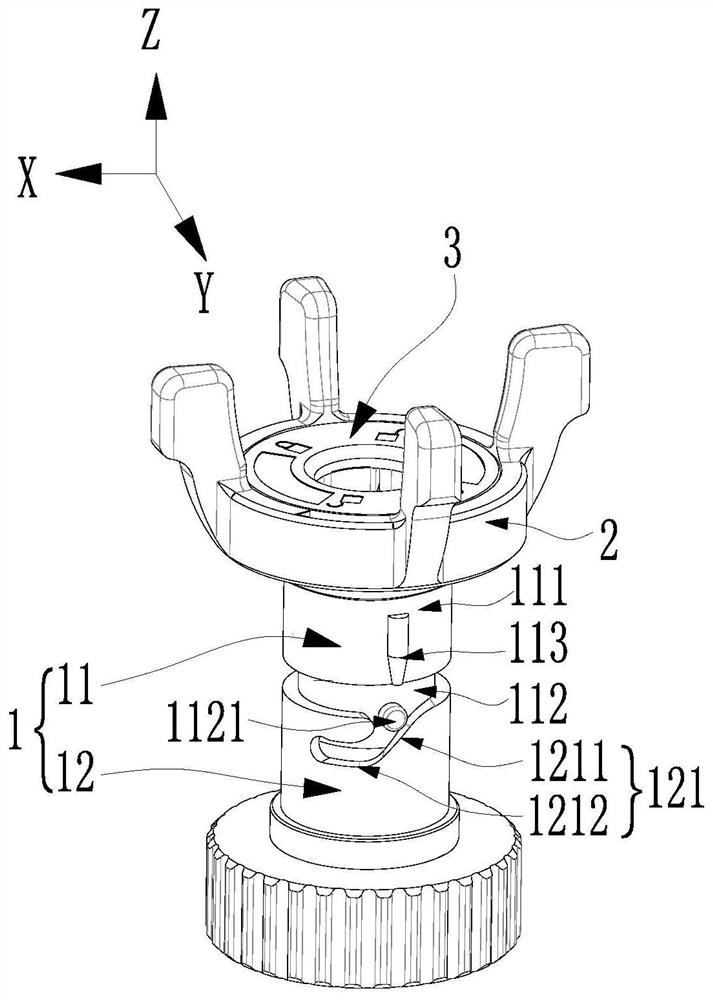

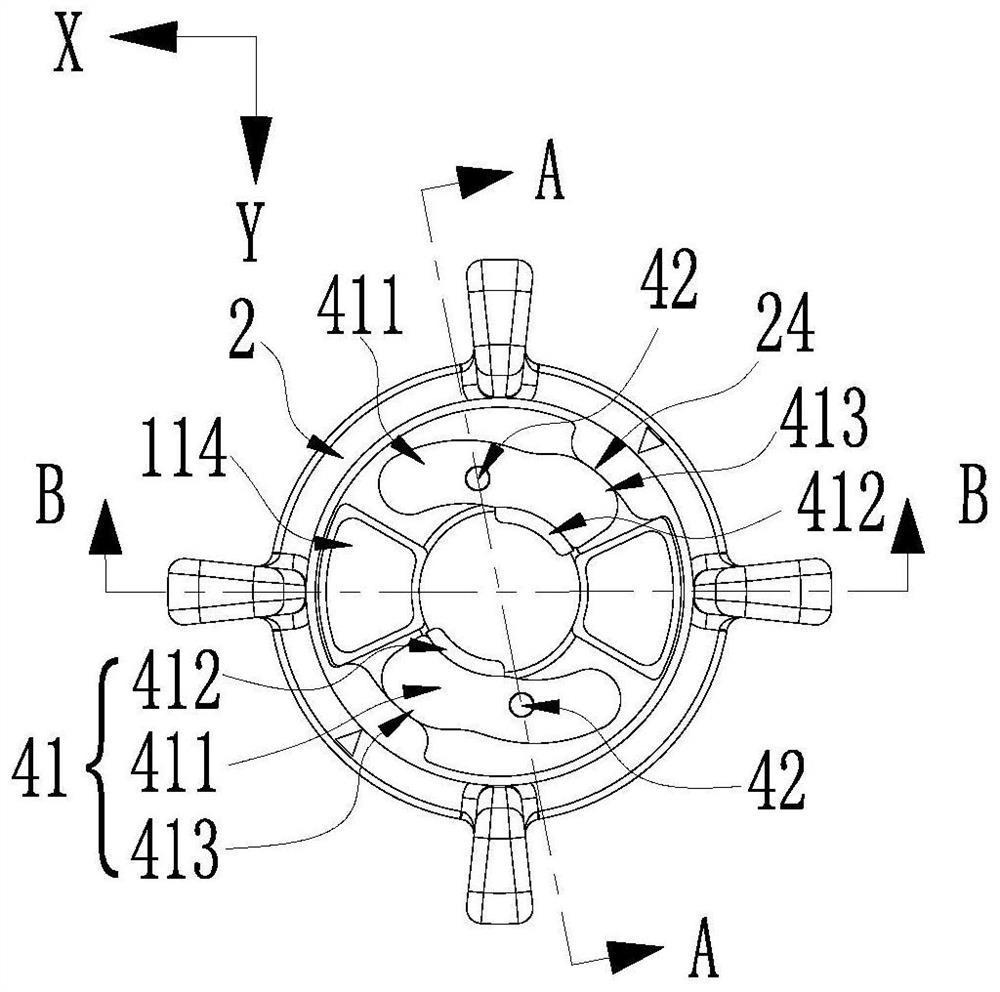

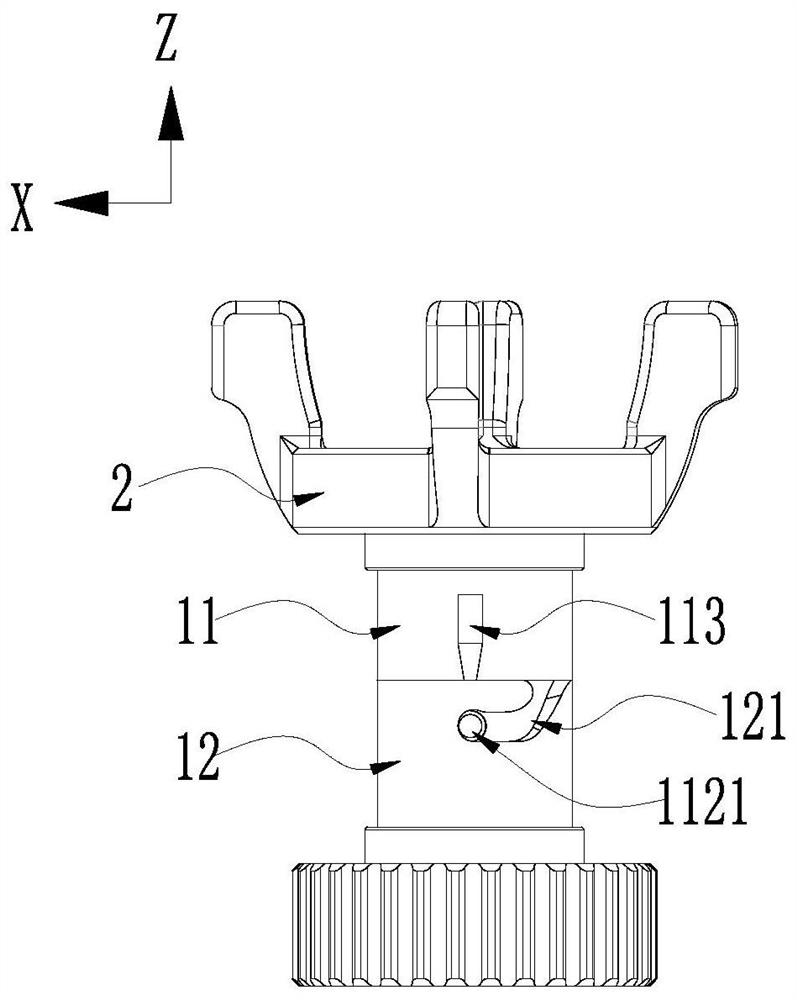

Special transmission device with flexible shock absorption structure for magnetic latching relay

ActiveCN103247482AReduce the impactImprove quality reliabilityNon-polarised relaysMagnetic polesRocker arm

The invention discloses a special transmission device with a flexible shock absorption structure for a magnetic latching relay, of which the quality is reliable and the work is stable. The transmission device comprises an insulation transmission rod, wherein one end of the insulation transmission rod is provided with a rocker arm, and the other end of the insulation transmission rod is connected with a magnetic driving device; one end of the rocker arm is provided with a rotating shaft, and the other end of the rocker arm is provided with an over travel piece; the magnetic driving device comprises coil racks rolled with electromagnetic coils, a static iron core and a movable iron core which can enable the insulation transmission rod to move along the axial direction of the magnetic driving device; the movable iron core is fixedly connected with the insulation transmission rod; the magnetic diving device also comprises a permanent magnet; and one magnetic pole of the permanent magnet is mounted through matching with the static iron core, and the other magnetic pole of the permanent magnet is mounted through matching with the movable iron core.

Owner:ANHUI YONG AN ELECTRONICS TECH CO LTD

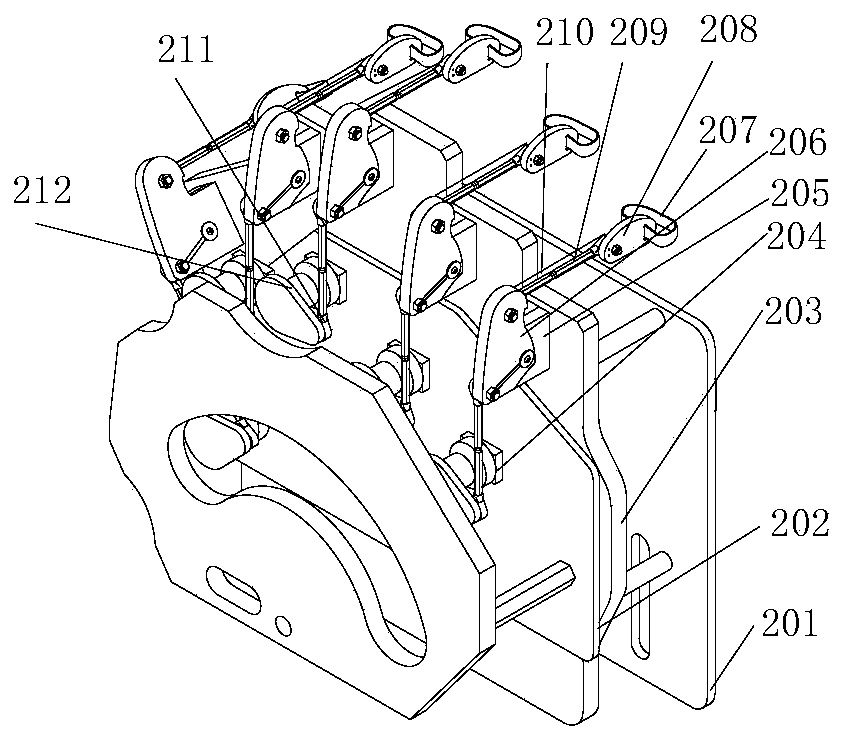

Laparoscope bacterium-isolating locking connector and laparoscope surgical robot

PendingCN111658150AField of view stabilizationFollow-upDiagnosticsSurgical manipulatorsSurgical robotApparatus instruments

The invention provides a laparoscope bacterium-isolating locking connector and a laparoscope surgical robot, and belongs to the technical field of medical instruments. The laparoscope bacterium-isolating locking connector comprises a laparoscope connector device, a laparoscope locking rotary knob, a laparoscope connector upper cover and a laparoscope locking device, wherein the laparoscope connector device is fixedly installed in an installation hole of a sliding table; a lower end hole of the laparoscope locking rotary knob is suitable for being connected with an end of the laparoscope connector device; the laparoscope connector upper cover is connected with an upper end hole of the laparoscope locking rotary knob in a matched mode; and the laparoscope locking device is installed betweenthe laparoscope connector device and the laparoscope connector upper cover, located in a middle hole of the laparoscope locking rotary knob and used for locking and unlocking a laparoscope. Accordingto the laparoscope bacterium-isolating locking connector and the laparoscope surgical robot, the sterile laparoscope is fixed to the sliding table on an operation arm through the bacterium-isolating locking connector, and the laparoscope is always in a sterile state under the condition that the laparoscope moves along with the operation arm of the robot.

Owner:HARBIN SIZHERUI INTELLIGENT MEDICAL EQUIP CO LTD

Band-shaped lubricating material for dry wiredrawing and process for producing same

InactiveCN103649286APrevent sinteringProcessing state is stableAdditivesBase-materialsWire speedLow speed

Owner:KYOEISHA CHEM CO LTD

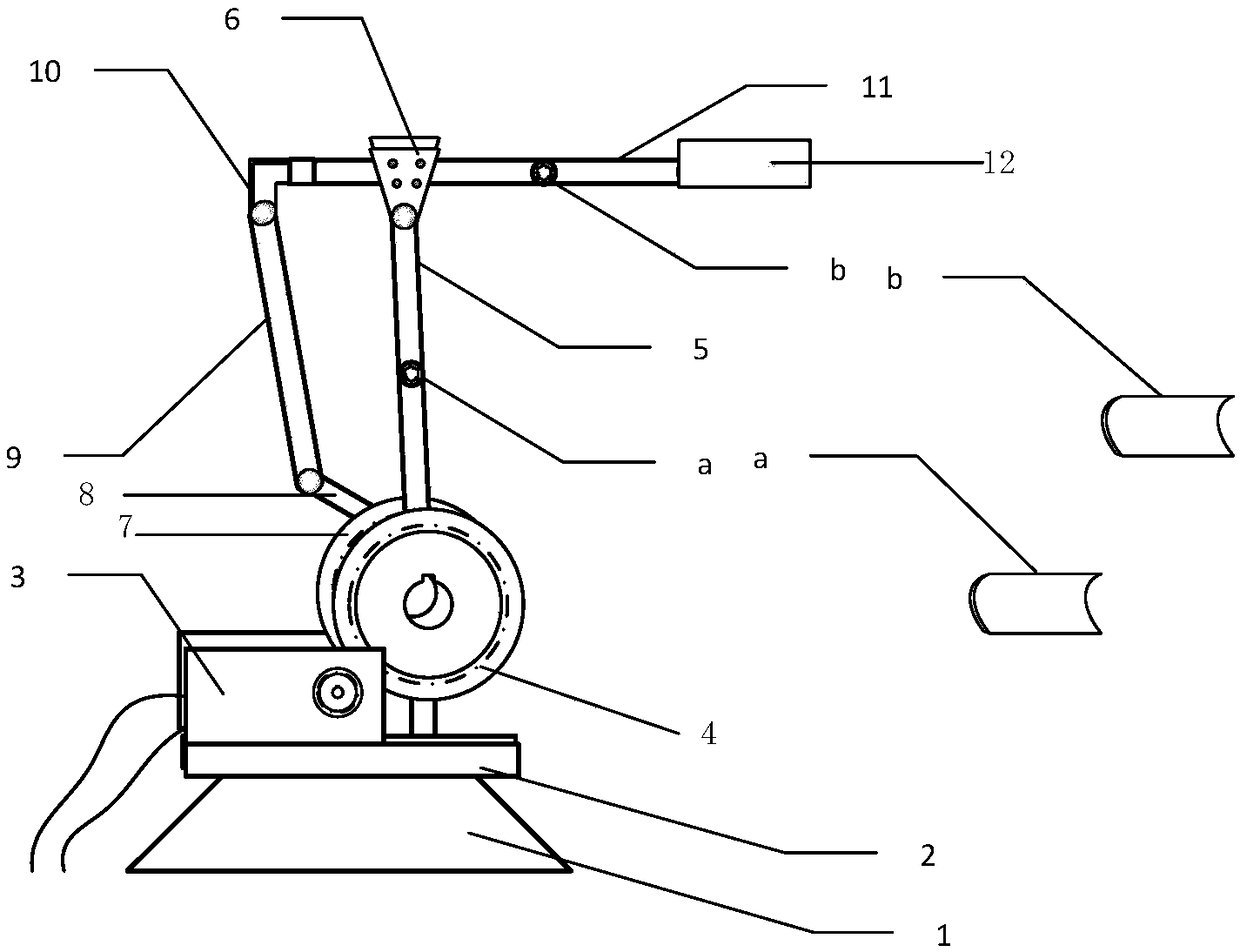

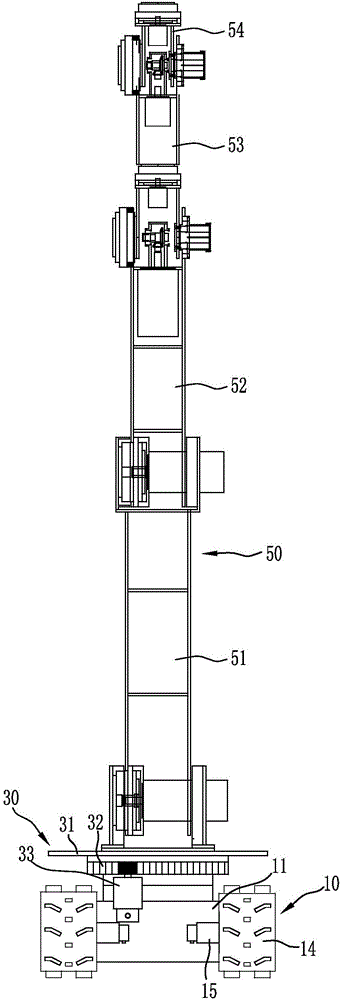

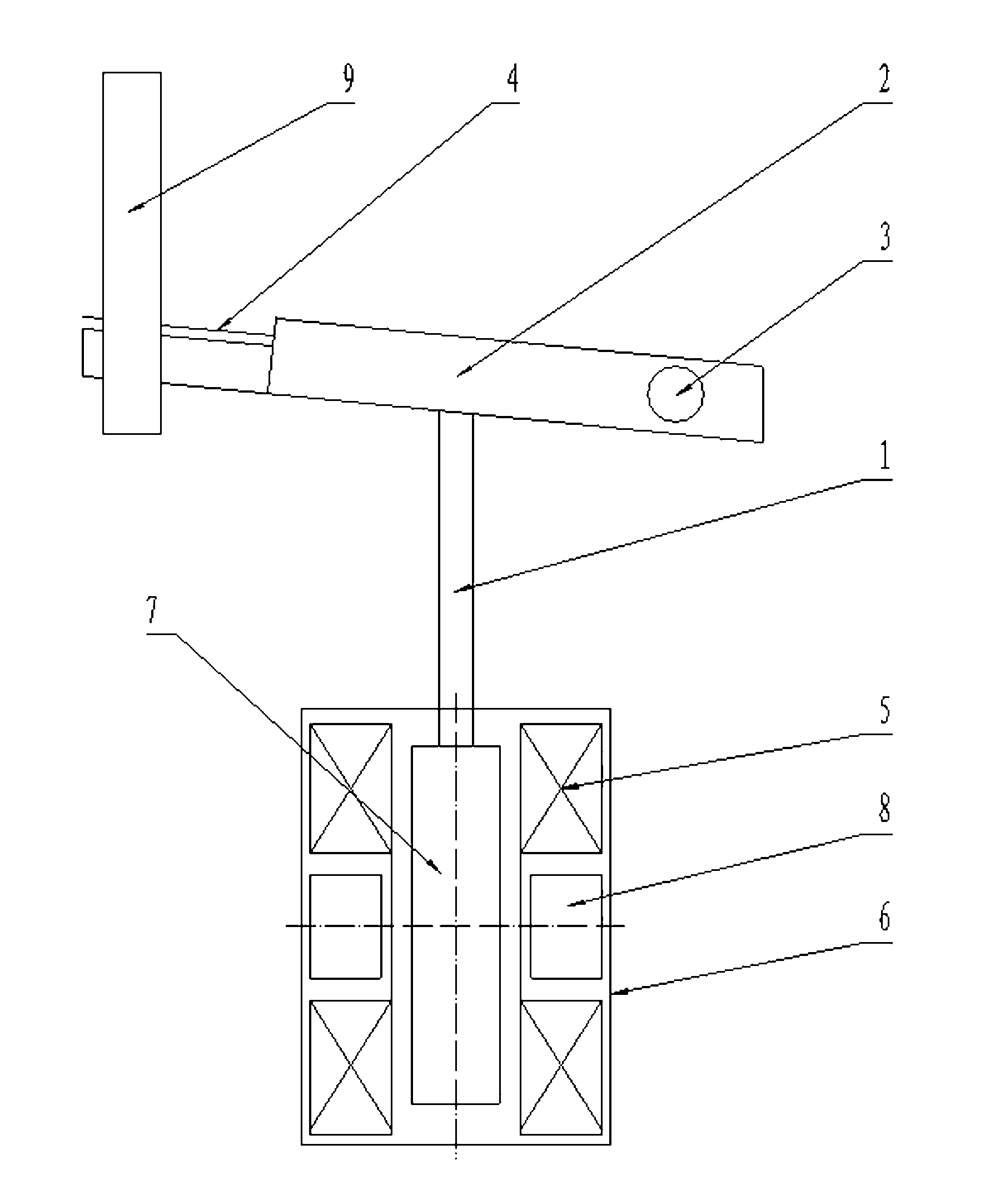

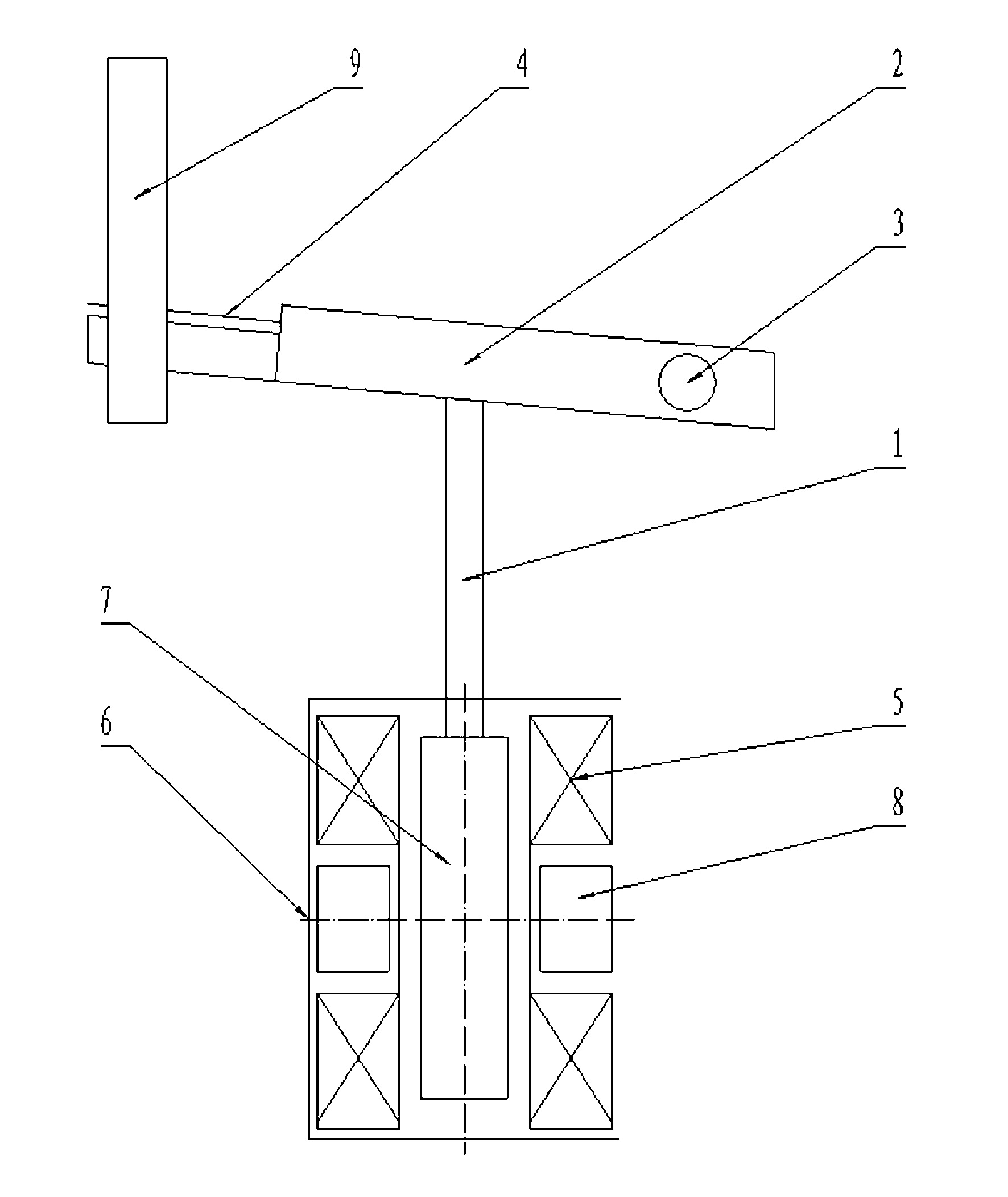

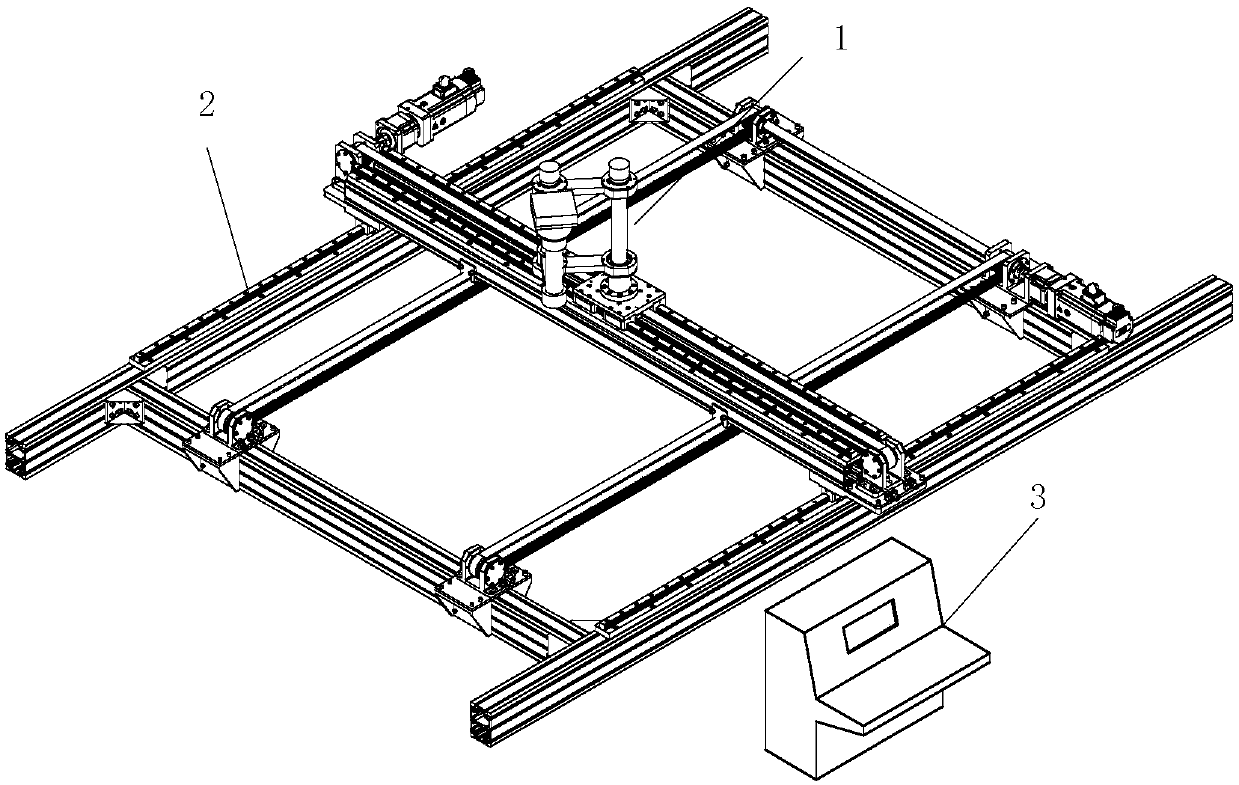

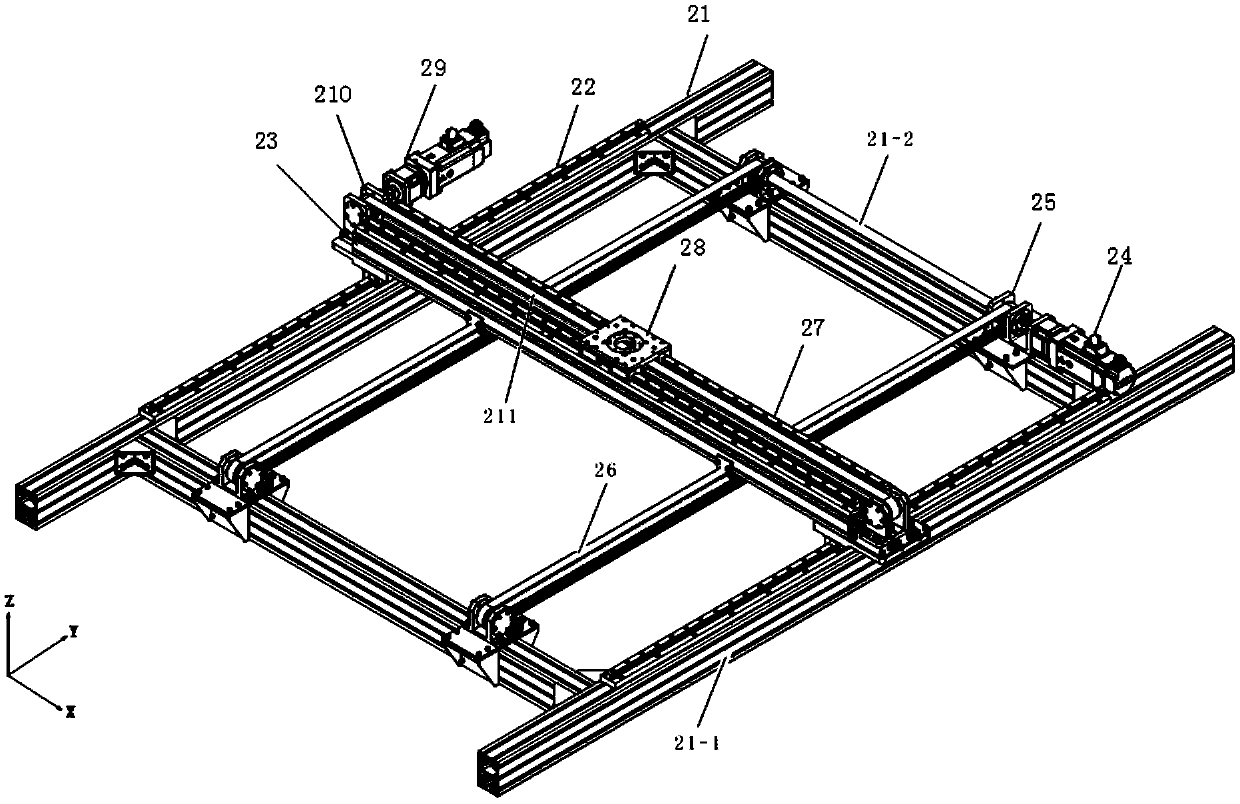

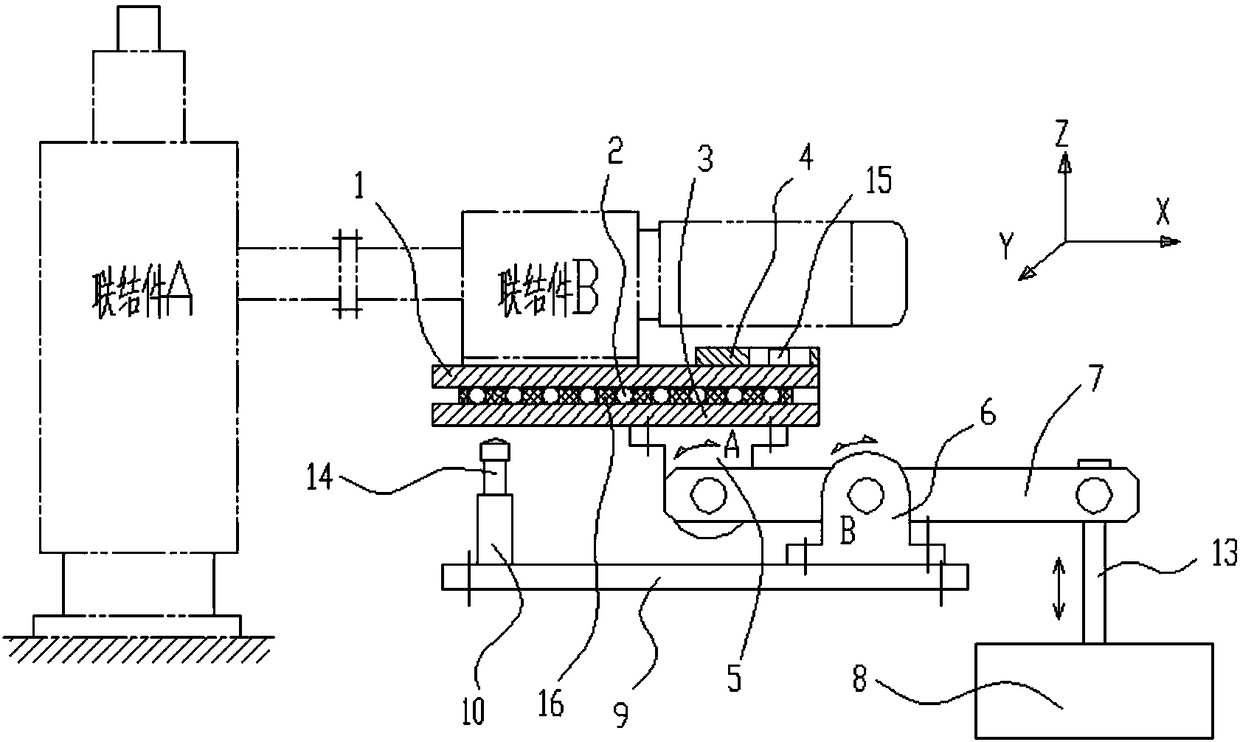

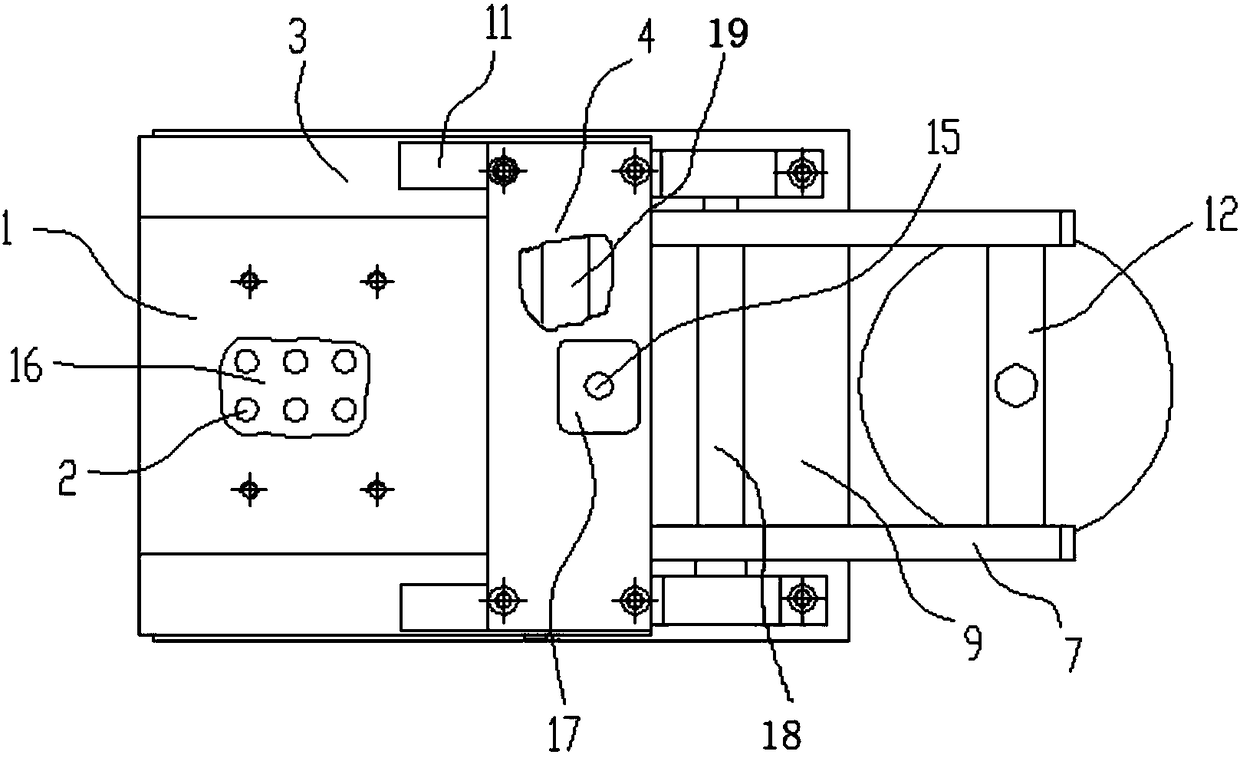

Supporting type plane-position follow-up tracking system based on series double-rod mechanism and with low disturbing force

ActiveCN108674700AVarious meansEnsure accuracy and referencingCosmonautic condition simulationsMicrogravity SimulationEngineering

The invention relates to a follow-up tracking system, in particular to a supporting type plane-position follow-up tracking system based on a series double-rod mechanism and with low disturbing force.The follow-up tracking system solves the problem of larger errors in motion except the motion in the direction of gravity due to the fact that an existing microgravity compensation system used by theground can realize the motion in the three-dimensional space of a current object and can introduce large inertia to a target object. The follow-up tracking system comprises the series double-rod mechanism, a two-dimensional motion platform, a control system, a first encoder, a second encoder and a horizontal two-dimensional force sensor, wherein the series double-rod mechanism is installed on thetwo-dimensional motion platform, the first encoder, the second encoder and the horizontal two-dimensional force sensor are installed on the series double-rod mechanism, and the control system is connected with the first encoder, the second encoder and the horizontal two-dimensional force sensor on the series double-rod mechanism through cables. The invention belongs to the field of ground microgravity simulation.

Owner:HARBIN INST OF TECH

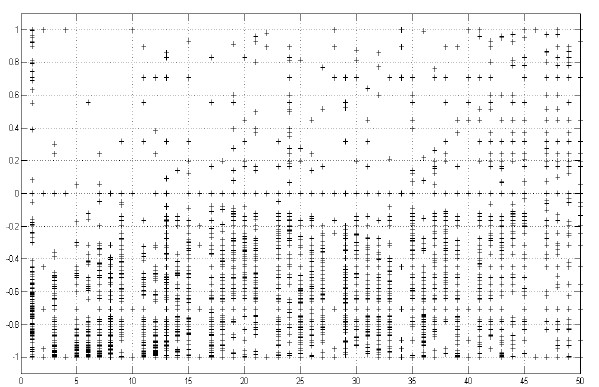

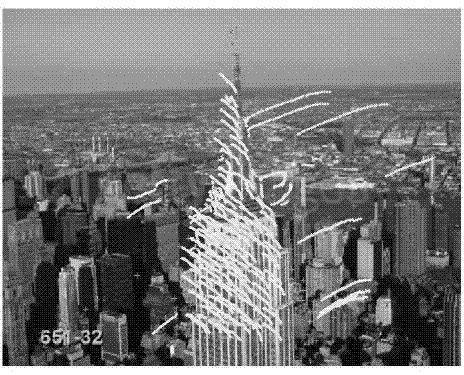

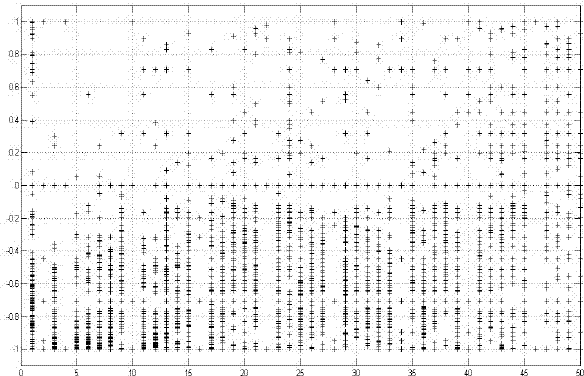

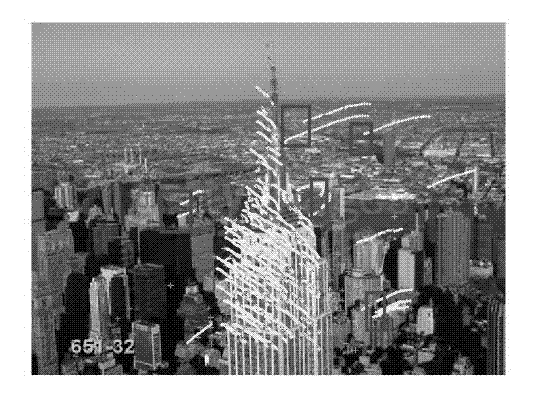

Characteristic point optimization method for three-dimensional reconstruction of video scene

The invention relates to a characteristic point optimization method for the three-dimensional reconstruction of a video scene, comprising the following steps: 1) in an image sequence I (X, t) of the video scene, X represents the position of the ith characteristic point, t represents the ordinal number of frames, and a Karhunen Loeve transform (KLT) tracker is used for tracking characteristic points; and 2) the direction of each tracked characteristic point between adjacent frames is calculated, a sine value is used for representing the vector direction theta, a mean value of the theta is calculated to determine the center c, and a threshold value a is set to eliminate vector directions with larger change; the absolute value of theta-c represents the absolute distance; when the absolute value of theta-c is less than or equal to a, a tracked data result of the KLT tracker is not changed; and when the absolute value of theta-c is larger than a, the tracking points are eliminated, therefore, the optimized characteristic points are obtained. The invention provides the characteristic point optimization method for the three-dimensional reconstruction of the video scene, which effectively improves the accuracy.

Owner:日照新睿招商发展有限公司

Defect detection device and method for train wheel tread

PendingCN109443289AImprove measurement efficiencyHigh measurement accuracyWheel-rims surveying/measuringMaterial analysisTreadAutomotive engineering

The invention discloses a defect detection device and method for a train wheel tread, and belongs to the technical field of train wheel detection. The detection device comprises a movable plate, a fixed plate, a movable plate displacement induction unit and a movable plate balancing mechanism distributed in the inner side of tracks along the length direction, the movable plate is connected with the fixed plate via a slide rail mechanism and an elastic mechanism, and the two ends of the movable plate are rotationally connected with the movable plate balancing mechanism. Thus, scratch, radial run-out and out-of-roundness of the train tire tread can be dynamically detected in real time in high-speed operation state of the train, the detection precision is higher, and the stability is high.

Owner:马鞍山市雷狮轨道交通装备有限公司

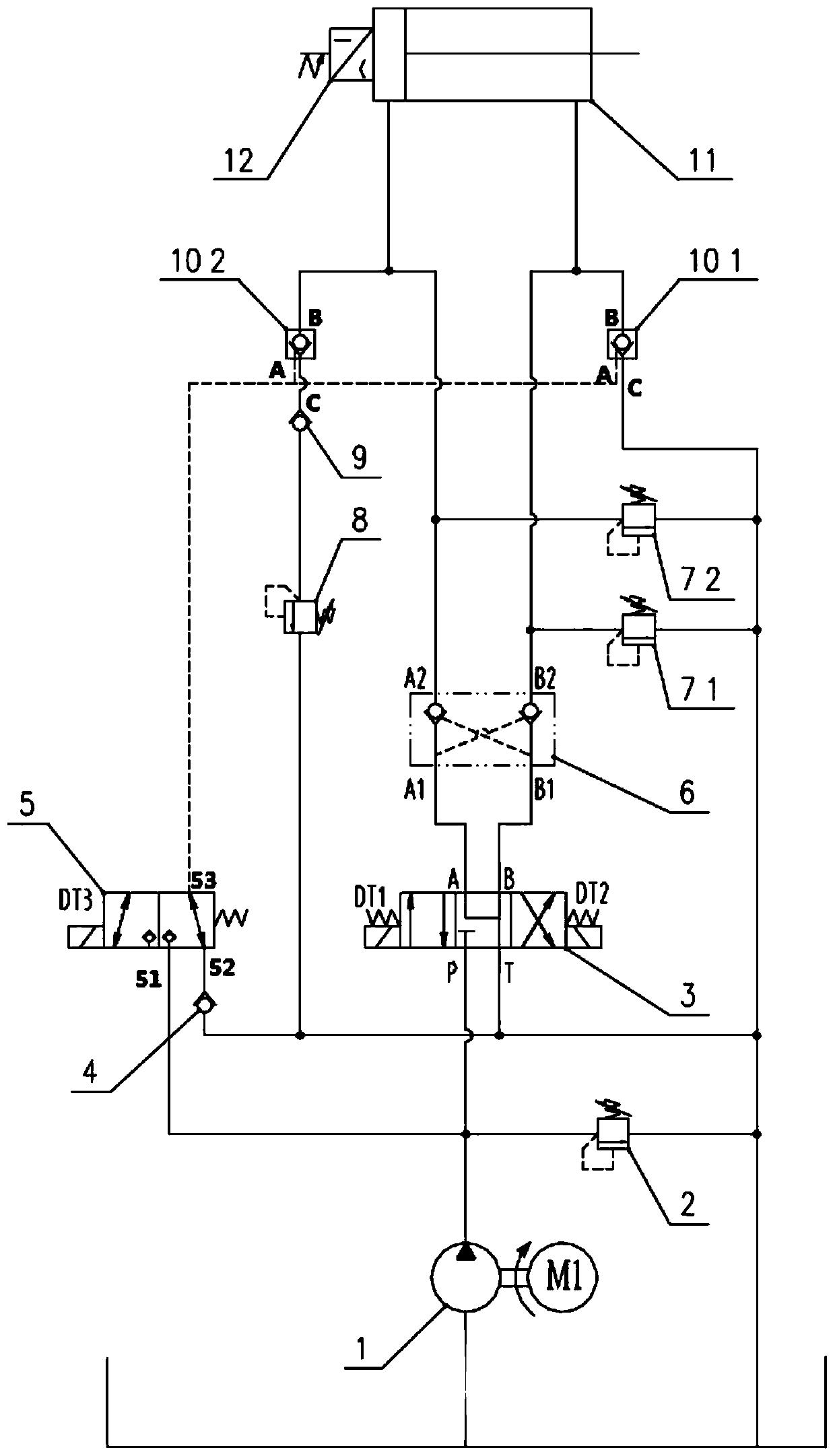

Hydraulic system for hinging of shield tunneling machine

PendingCN110735820AAchieve stretch outAchieve retractionServomotorsTunnelsHydraulic pumpShield tunneling

The invention discloses a hydraulic system for hinging of a shield tunneling machine. The system comprises a hydraulic oil tank, a hydraulic pump and a hinge oil cylinder. An oil inlet of the hydraulic pump is connected with the hydraulic oil tank, wherein an oil outlet of the hydraulic pump is connected with a port P of a first electromagnetic valve through a pipeline; a port T of the first electromagnetic valve is connected with the hydraulic oil tank through a pipeline; a port A of the first electromagnetic valve is connected with a port A1 of a hydraulic lock through a pipeline; a port B of the first electromagnetic valve is connected with a port B1 of the hydraulic lock through a pipeline; a port A2 of the hydraulic lock is connected with a rodless cavity of the hinge oil cylinder through a pipeline; a port B2 of the hydraulic lock is connected with a rod cavity of the hinge oil cylinder through a pipeline; a floating loop and a backpressure loop are arranged between the hinge oilcylinder and the hydraulic oil tank in parallel and connected through a pipeline; an unloading loop is arranged between the hydraulic lock and the hydraulic oil tank and connected through a pipeline;and a locking loop is arranged between the hydraulic pump and the hydraulic oil tank and connected through a pipeline. The shield tunneling machine hinge hydraulic system is mainly applied to a shield tunneling machine hinge device, and the functions of stretching, retracting, deflecting, following, locking and the like of the hinge device can be achieved.

Owner:CSSC HEAVY EQUIP CO LTD

Five-degree-of-freedom floating compensation device

ActiveCN108340357ACompact and reliableReduce manufacturing costProgramme-controlled manipulatorPhotovoltaic energy generationSteel ballDegrees of freedom

The invention discloses a five-degree-of-freedom floating compensation device. The five-degree-of-freedom floating compensation device comprises a mounting base plate; two hinge brackets B are symmetrically and fixedly connected to one end of the mounting base plate, and a limiting bracket is fixedly connected to the other end; two symmetrical swing rods are hinged between the hinge brackets B through a shaft B; the left ends of the two swing rods are hinged with hinge brackets A through shafts A; a rotating shaft C is hinged between the right ends of the swing rods; a counterweight is connected to the middle of the rotating shaft C through a suspension rod; support plates are fixedly connected above the hinge brackets A; limiting clamping plates are fixedly connected above the support plates through two cushion plates on the sides; mounting plates are arranged below the limiting clamping plates, and are fixedly connected with connecting pieces B; and multiple steel balls are arrangedbetween the mounting plates and the support plates. The device has the characteristics of automatic following compensation in connection of two devices or parts, low additional load in connected places and simple and reliable structure.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Intelligent assisted respiration system

InactiveCN109091736AFollow-upRealize follow-up work modeRespiratorsMedical devicesMachine visionEngineering

The invention discloses an intelligent assisted respiration system which comprises a cabinet, a controller mounted in the cabinet and track traveling modules symmetrically arranged on two sides of thecabinet, an oxygen support module is mounted at the bottom in the cabinet, and an oxygen delivery pipe outlet and a mechanical outlet are formed on one side of the upper end of the oxygen support module; the system further comprises an oxygen supply pipe and a snakelike mechanical arm, one end of the oxygen delivery pipe is in threaded connection with an oxygen delivery cover, a clamping arm is mounted at one end of the snakelike mechanical arm, a two-eye visual sensor is mounted on the clamping arm, a three-dimensional digital compass is mounted in the clamping arm, the snakelike mechanicalarm conveys the oxygen delivery pipe to a corresponding target position on the basis of the two-eye visual sensor and the three-dimensional digital compass, and a plurality of thin film pressure sensors are mounted on the inner wall of the oxygen delivery pipe at intervals in a pasted manner. Follow-up of the oxygen delivery cover is realized through collaborative working of machine vision and a manipulator, so that deviation of the oxygen delivery cover can be well avoided; the whole system is convenient for moving.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

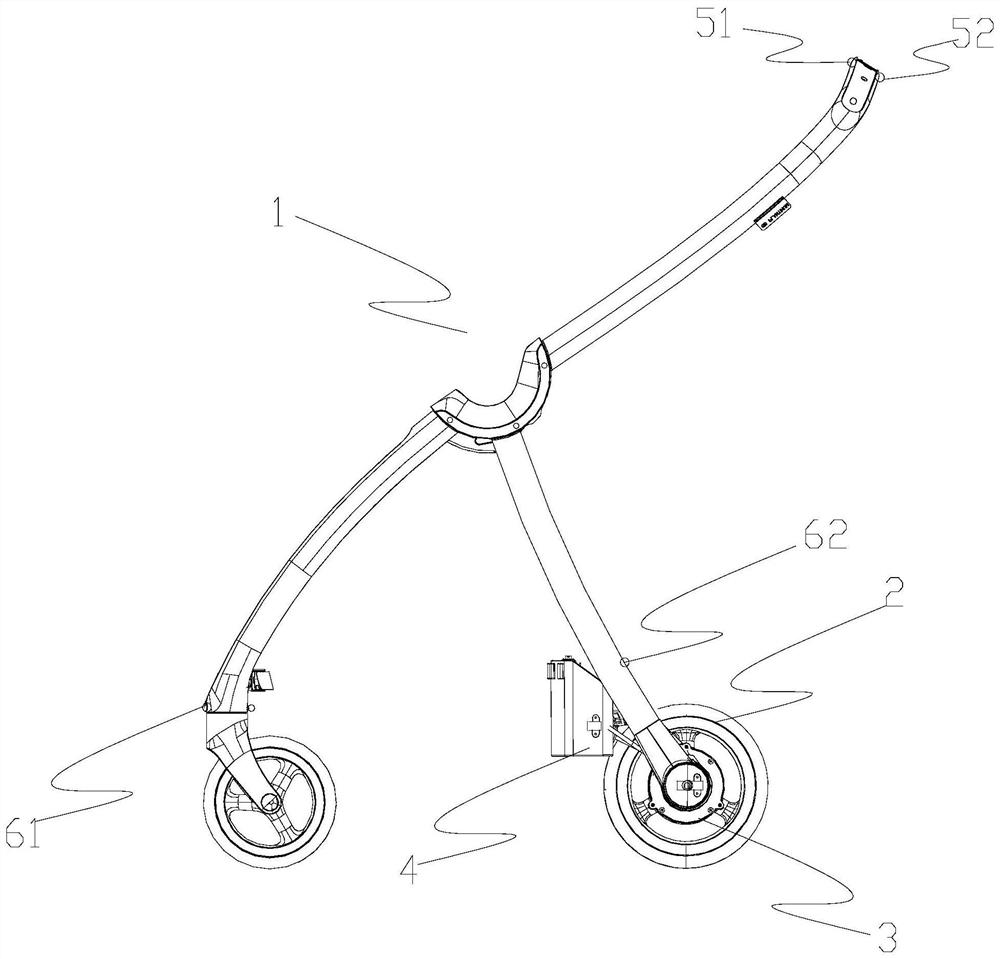

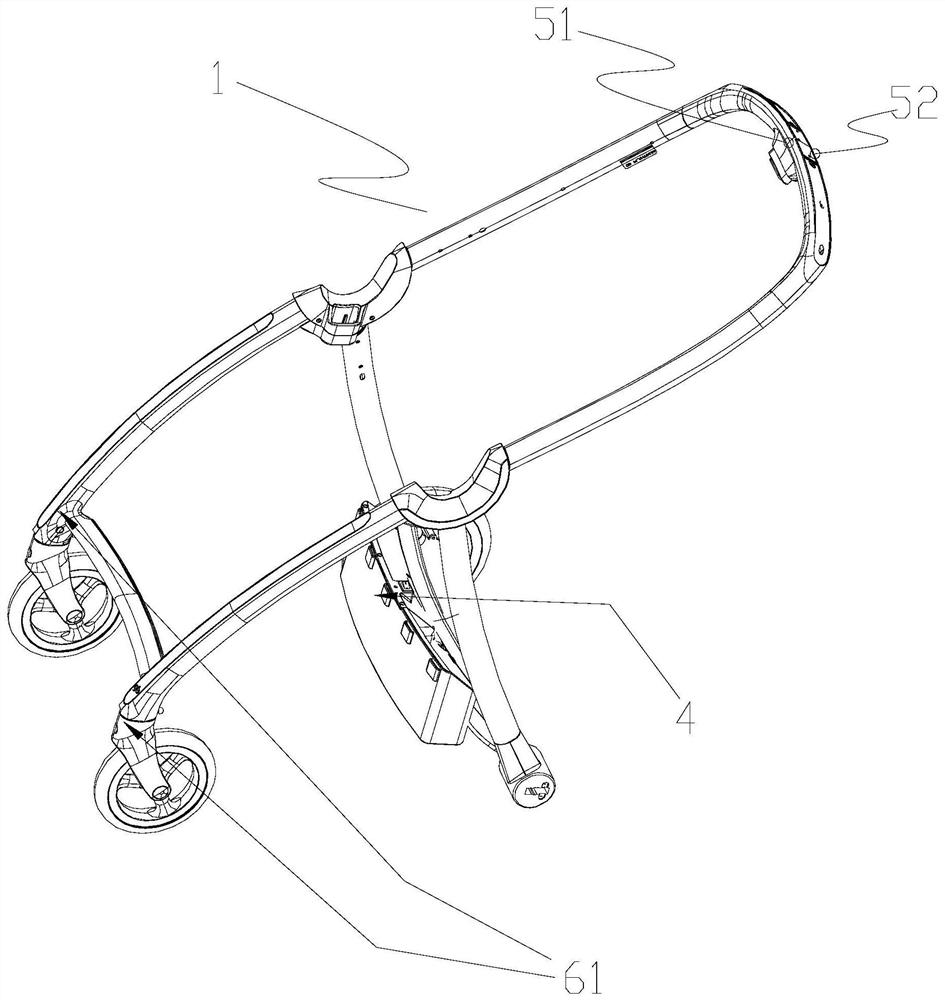

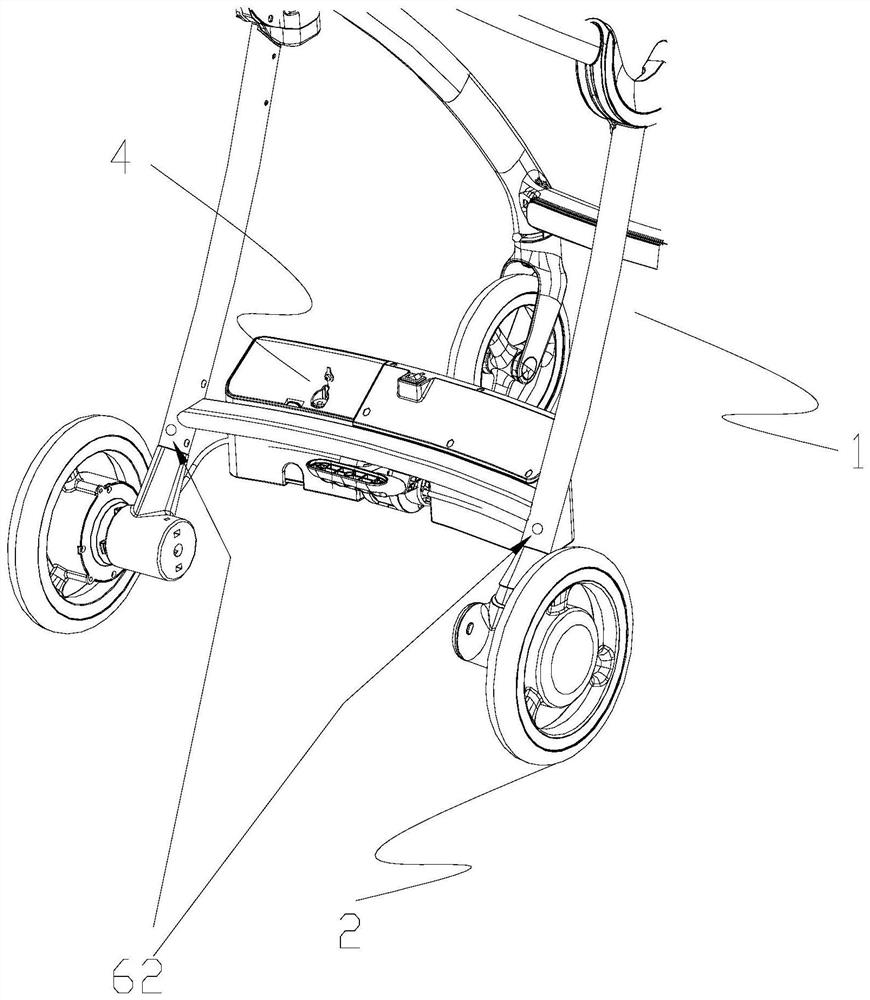

Cart with active following function

ActiveCN111634321APrevent pushing awayWith face recognition functionCarriage/perambulator accessoriesCharacter and pattern recognitionInformation repositoryInformation processing

The invention discloses a cart with an active following function. The cart comprises a frame, wheels, a driving mechanism, a main control board arranged on the frame and a camera component, wherein the camera component comprises a first camera for detecting a first image in front of the cart and / or a second camera for detecting a second image behind the cart, the main control board comprises an information processing module based on a pre-established permission surface image information database, the information processing module is used for retrieving and comparing the first image and / or thesecond image with an authority surface image in the information database, if the first image or the second image is matched with the permission surface image, and reduction of the human body in the first image or the second image is further analyzed, the main control board controls the driving mechanism to drive the wheels to rotate for autonomous following. The cart is advantaged in that the carthas a surface recognition function, the pushing permission of the cart is controlled, meanwhile, autonomous following of the cart can be triggered, and the cart has an obstacle avoidance function.

Owner:GOODBABY CHILD PROD CO LTD

Dynamic human body pose recognition embedded platform in trunk shielding state

InactiveCN112472481AMake up for the shortcomings of low recognition accuracy and large errors in collected informationAccurate identificationDiagnostic recording/measuringSensorsHuman bodyCare personnel

The invention discloses a dynamic human body pose recognition embedded platform in a trunk shielding state, and the platform comprises two pieces of galvanized flat steel which are connected with eachother, and the galvanized flat steel fixes a laser radar sensor through a metal buckle. The laser radar sensor is in electric signal connection with the host, the TTL-to-USB conversion module, the internal communication module, the external communication module, the RS232-to-TTL conversion module and the auxiliary equipment in sequence. According to the invention, a reliable detection platform isprovided for human body dynamic pose identification in limb shielding and leg random standing states. A two-dimensional laser radar sensor and a laser radar are mainly used for recognizing leg contours at original positions, and the laser radar is additionally arranged on the basis to form an angle of 45 degrees with the horizontal plane and is used for detecting waist and back position distribution of a patient. The fusion of the two pieces of radar information can more accurately identify and distinguish the positions of the overlapped patient and nursing personnel.

Owner:SHENYANG POLYTECHNIC UNIV

Electric insulation mechanical hand and control method

PendingCN110228056AStrong gripImprove securityProgramme-controlled manipulatorGripping headsHand palmsManipulator

The invention belongs to the field of electric equipment and particularly relates to an electric insulation mechanical hand and a control method. The mechanical hand comprises a far end executing endand a rear end operation end. The rear end operation end is in wireless communication with the far end executing end. Far end executing end executing mechanical fingers are five simulated human body finger joints which are rotationally connected with a simulated palm I through the root portions of the executing mechanical fingers, and a rotating motor drives the executing mechanical fingers to rotate around the simulated palm I to achieve grabbing. The rear end operation end comprises operation mechanical fingers which are five simulated human body finger joints, the simulated human body finger joints correspond to the executing mechanical fingers and are rotationally connected with a simulated palm II through the root portions of the operation mechanical fingers. The fingers of an operator drive the corresponding operation mechanical fingers to rotate around the simulated palm II correspondingly and drive rotating shafts connected with the operation mechanical fingers to rotate. By means of the electric insulation mechanical hand and the control method, following completely consistent with the human body action of the mechanical hand is achieved according to the hand action of thehuman body, and the operation convenience is improved.

Owner:孟繁丞

A spare tire rack for a vehicle

Owner:NO 6409 FACTORY PLA

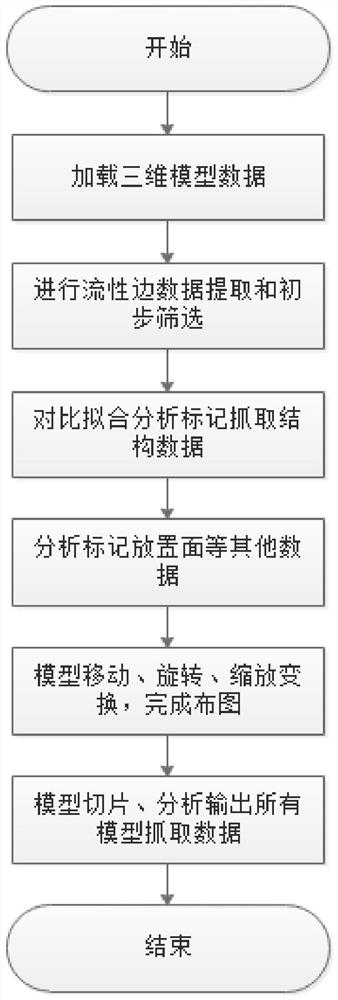

Automatic identification method for three-dimensional data of workpiece to be transferred

PendingCN113947767AFollow upImprove efficiencyAdditive manufacturing apparatusFoundry mouldsData setAlgorithm

An automatic identification method for three-dimensional data of a workpiece to-be-transferred is characterized by comprising the following steps: marking data of structural features such as the length, the width, the area and special identification of the to-be-produced workpiece on a three-dimensional model of the to-be-produced workpiece; loading the three-dimensional model marked with the structural features to software with a slicing function; extracting data of a flow edge of the three-dimensional model through data filtering analysis, where the flow edge is an edge which contains the same edge and has an included angle of normal vectors of two triangles larger than a set threshold value; subjecting the flow edges to preliminary filtering, where the preliminary filtering condition is that the flow edges are in the same plane and are connected end to end; collecting the flow edges meeting the preliminary filtering condition into a data set of the flow edges, and otherwise, the removing flow edges; and matching the flow edges meeting the requirements with the structural features of the three-dimensional model, and marking the qualified matched flow edges as a transfer stress structure. Therefore, the workpieces can be quickly transferred.

Owner:NINGXIA KOCEL MOLD

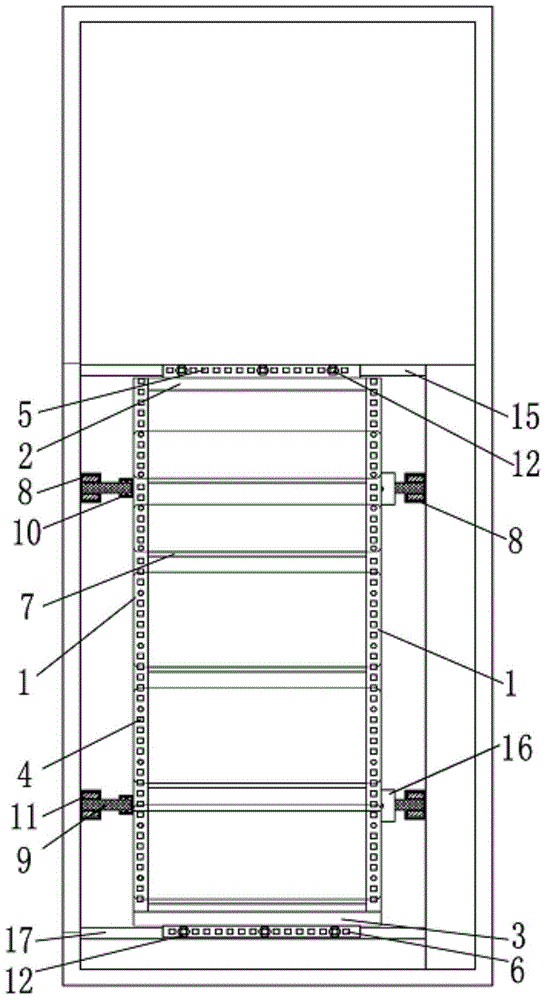

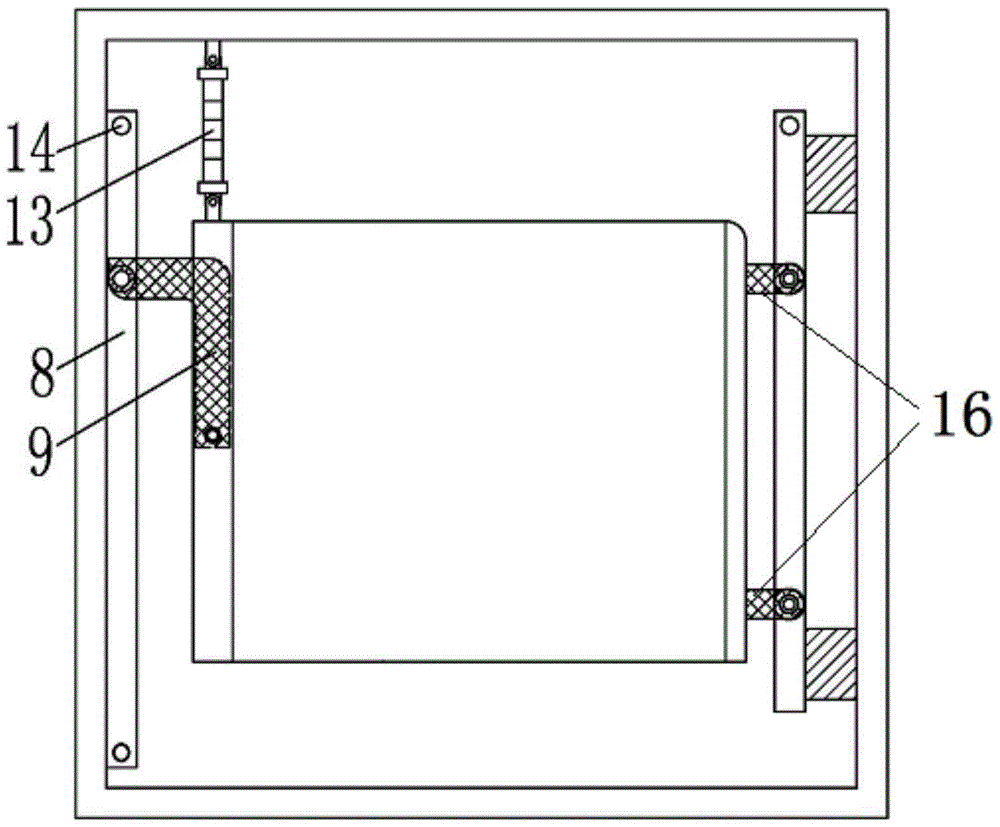

A rotating server rack

ActiveCN104202943BSimple structureReduce weightRack/frame constructionSupport structure mountingFixed bearingArchitectural engineering

The invention discloses a rotary server rack, which comprises four support columns, four upper beams and four lower beams fixedly connected to form a cube frame; the server control cabinet is provided with upper and lower fixed beams, and the upper beam It is fixedly connected with the upper fixed beam, and the lower beam is fixedly connected with the lower fixed beam; a set of slide rails are installed on the upper and lower positions of the inner walls on both sides of the server control cabinet, and the upper and lower rails on the left side are slidingly installed with L-shaped left supports The left support frame is fixedly connected with the two support columns on the left side through the side fixed support; the right support frame is fixedly installed on the upper and lower positions of the two support columns on the right side, and each right support frame The other end is sleeved in the slide rail on the right side through a sliding bearing. The device of the invention has simplified structure, reduced weight, and is very convenient for wiring and maintenance.

Owner:BAOJI PETROLEUM MASCH CO LTD

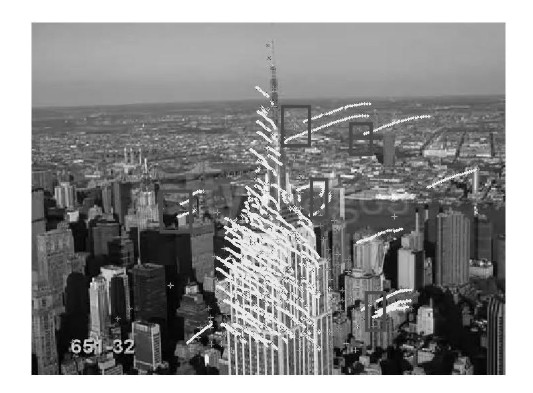

Characteristic point optimization method for three-dimensional reconstruction of video scene

The invention relates to a characteristic point optimization method for the three-dimensional reconstruction of a video scene, comprising the following steps: 1) in an image sequence I (X, t) of the video scene, X represents the position of the ith characteristic point, t represents the ordinal number of frames, and a Karhunen Loeve transform (KLT) tracker is used for tracking characteristic points; and 2) the direction of each tracked characteristic point between adjacent frames is calculated, a sine value is used for representing the vector direction theta, a mean value of the theta is calculated to determine the center c, and a threshold value a is set to eliminate vector directions with larger change; the absolute value of theta-c represents the absolute distance; when the absolute value of theta-c is less than or equal to a, a tracked data result of the KLT tracker is not changed; and when the absolute value of theta-c is larger than a, the tracking points are eliminated, therefore, the optimized characteristic points are obtained. The invention provides the characteristic point optimization method for the three-dimensional reconstruction of the video scene, which effectivelyimproves the accuracy.

Owner:日照新睿招商发展有限公司

Tableware vertical face filleted corner polisher

PendingCN109366340AAchieve positioningFollow-upGrinding carriagesPolishing machinesDrive shaftForce output

The invention provides a tableware vertical face filleted corner polisher, and belongs to the field of polishing equipment. The tableware vertical face filleted corner polisher comprises a supportingframe, a fixed assembly, a swing assembly and a driving shaft. One end of the swing assembly is hinged to the supporting frame, and the other end of the swing assembly is connected with a force outputshaft of a swing cylinder. The end, away from the force output shaft, of the swing cylinder is hinged to the supporting frame. The driving shaft is rotationally connected relative to the swing assembly. A polishing wheel is fixedly arranged at the end, away from the swing assembly, of the driving shaft. The polishing wheel is arranged over the fixed assembly. The swing assembly comprises an upperplate and a lower plate. The driving shaft is fixedly arranged on the upper plate. The upper plate and the lower plate are in sliding connection, and the sliding direction is parallel to the axis ofthe driving shaft. According to the tableware vertical face filleted corner polisher, tableware vertical face filleted corners can be polished, the automation degree is high, the work efficiency is greatly improved, and the labor intensity is reduced.

Owner:TIANJIN TTX GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com