Band-shaped lubricating material for dry wiredrawing and process for producing same

A technology of lubricating materials and dry wire drawing, which is applied in the direction of lubricating compositions, base materials, additives, etc., to achieve reliable plastic deformation and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

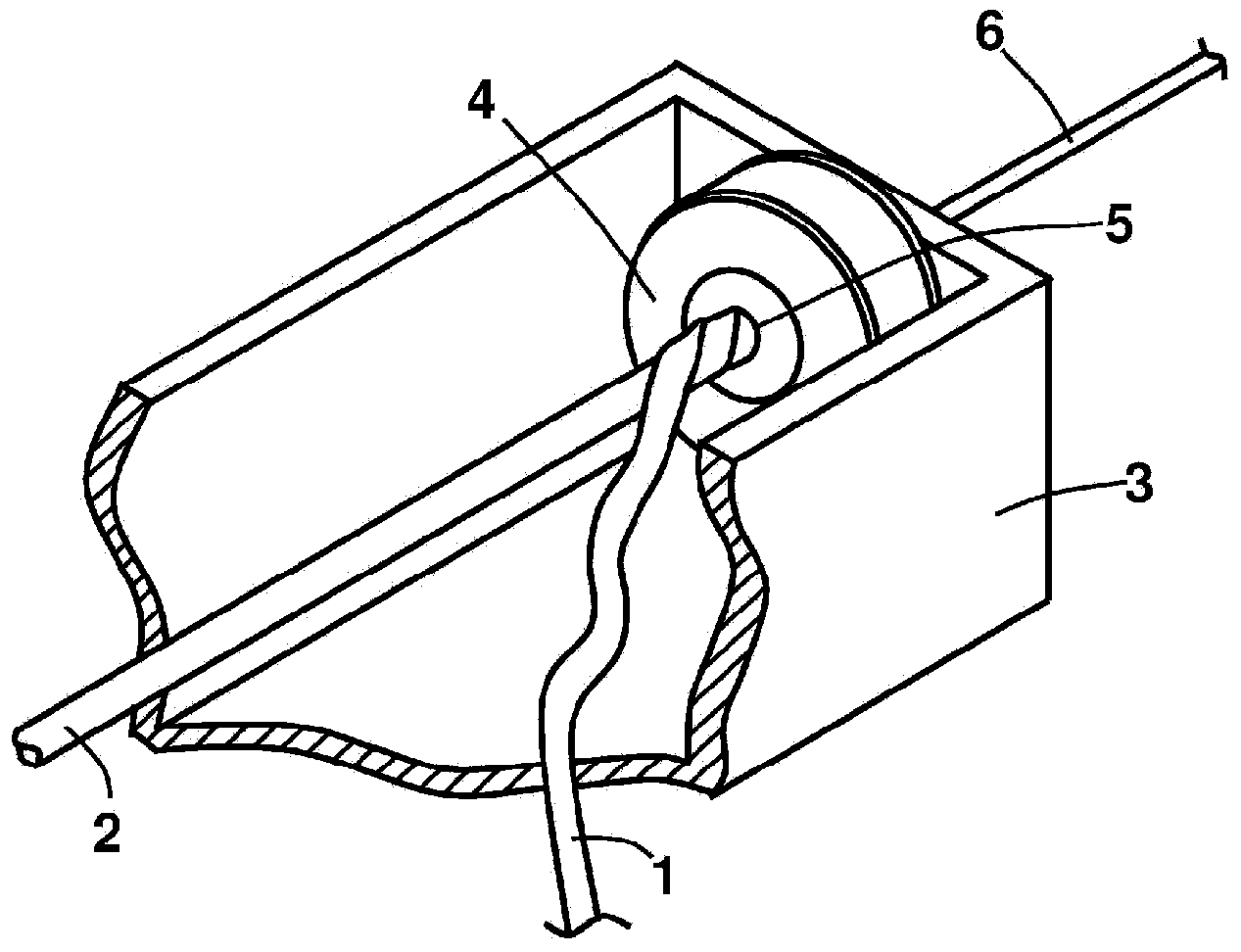

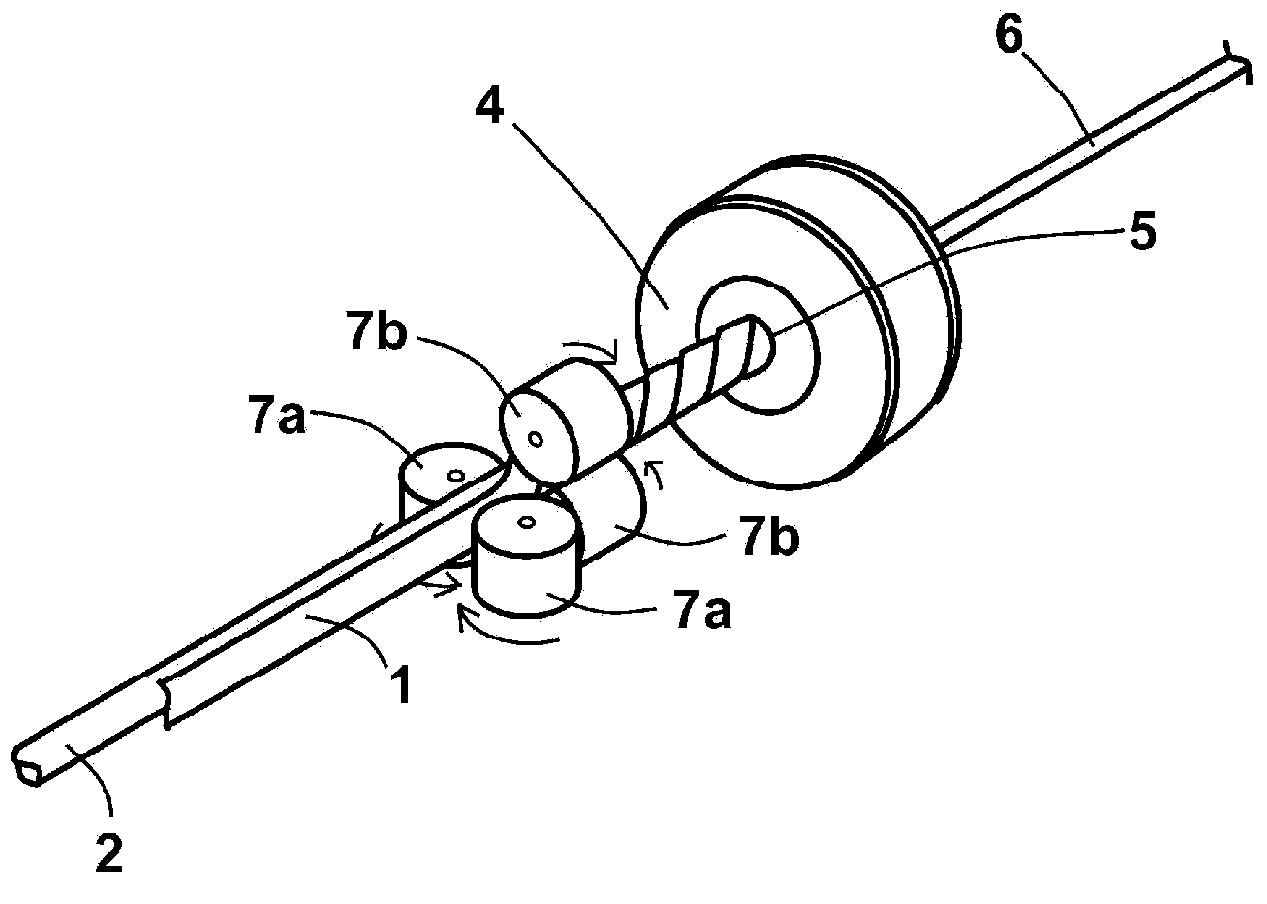

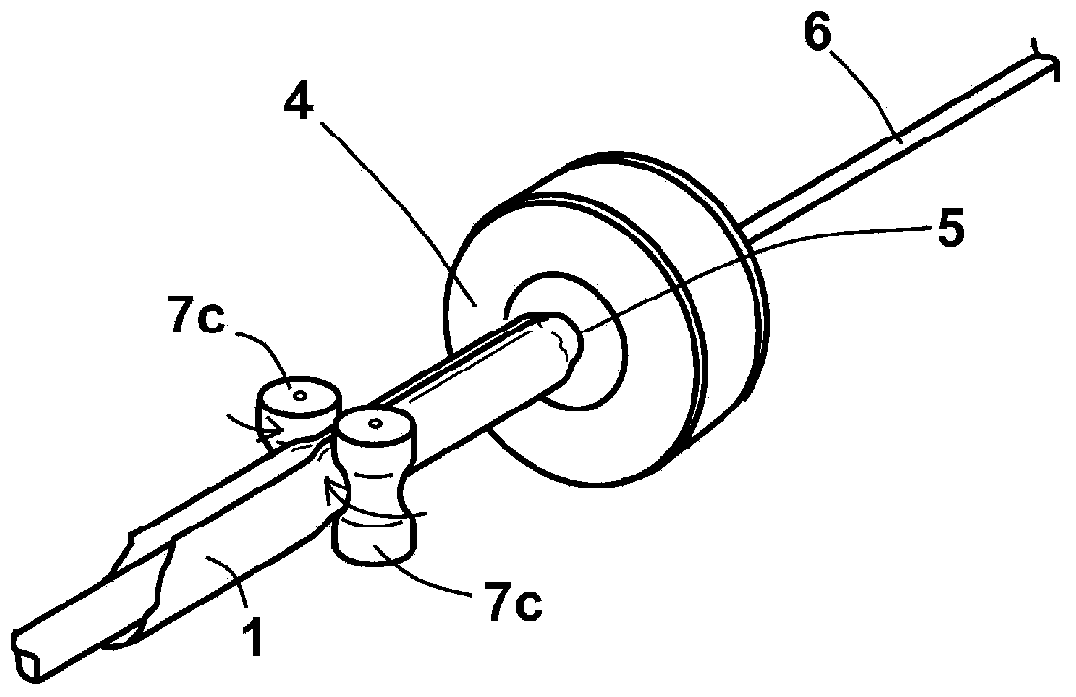

Image

Examples

Embodiment 1

[0061] Example 1 shows an example of the strip-shaped lubricating material that is suitable for the present invention and is experimentally prepared for dry wire drawing. Comparative Example 1 shows the powder lubricant that is not applicable to the present invention and is used for dry wire drawing. Comparative Example 2 shows The strip-shaped polyethylene that is not applicable to the present invention has been eliminated.

Embodiment 1)

[0063] In a reaction vessel equipped with a stirring device, 75 parts by weight of industrial stearic acid were heated / melted under stirring, and then 25 parts by weight of slaked lime were added. This mixture was heated / stirred continuously until viscous. When the mixture becomes hard, stop heating / stirring, take out, cool and grind, so that its 500 mesh molecular sieve passing rate is about 60%, thus obtaining a calcium-based lubricant as a saturated fatty acid metal salt. 70 parts by weight of the obtained saturated fatty acid metal salt and 20 parts by weight of polyethylene as a thermoplastic resin were heated / kneaded at 180° C. with a hot kneader (trade name: Labo Plasto Mill). The obtained solid was formed into a sheet having a film thickness of 0.5 mm or less by a heating type press, and then cut into a tape having a width of 8 mm with a slicer, thereby obtaining a tape-shaped lubricating material for dry wire drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com