Patents

Literature

47results about How to "Processing state is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

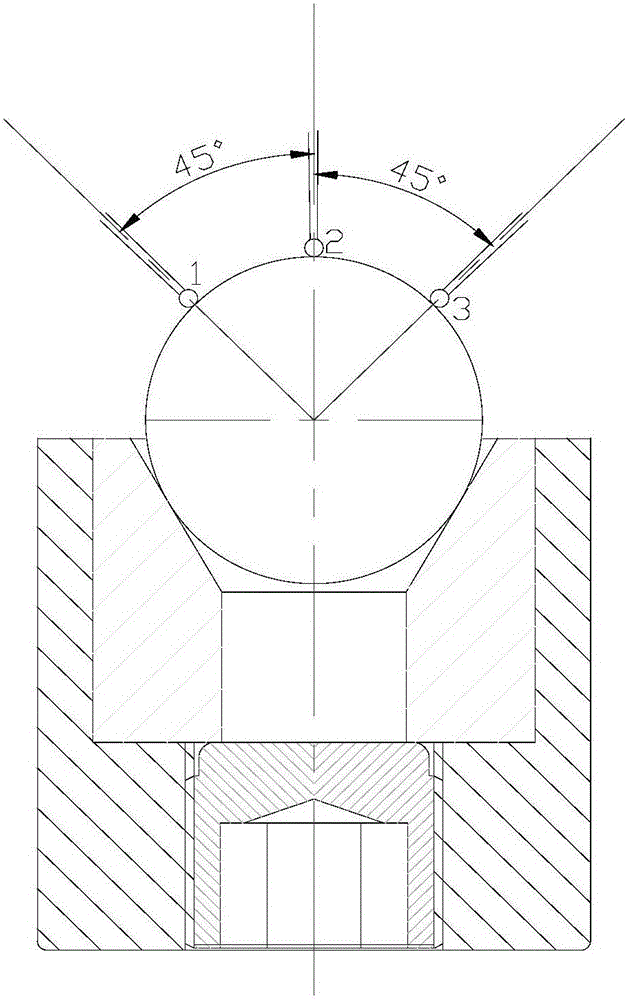

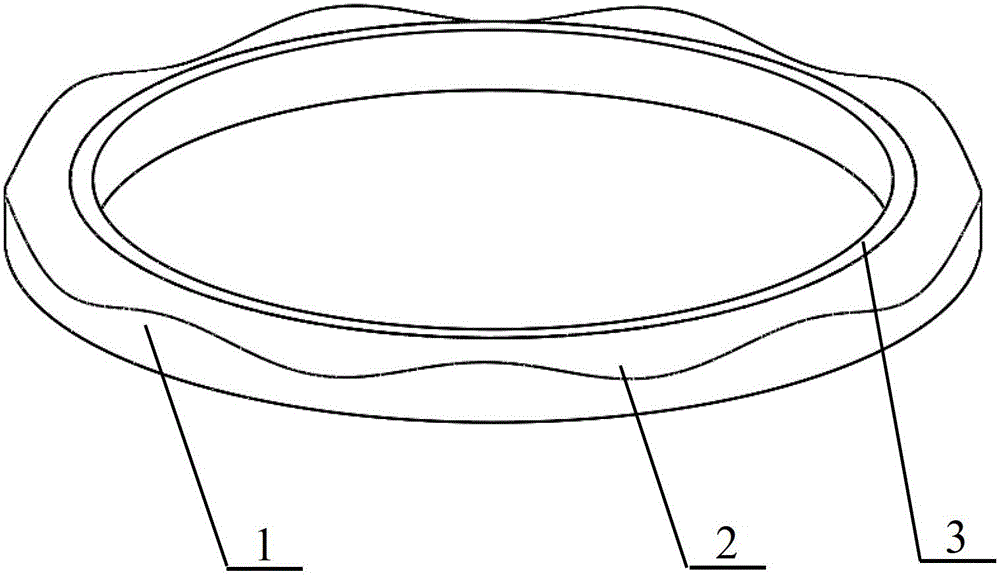

Ultra-precise processing method for circular conical surface of fluid static pressure sealing ring for nuclear primary pump

ActiveCN102350658AGrinding force remains constantProcessing state is stableRevolution surface grinding machinesCircular coneSurface roughness

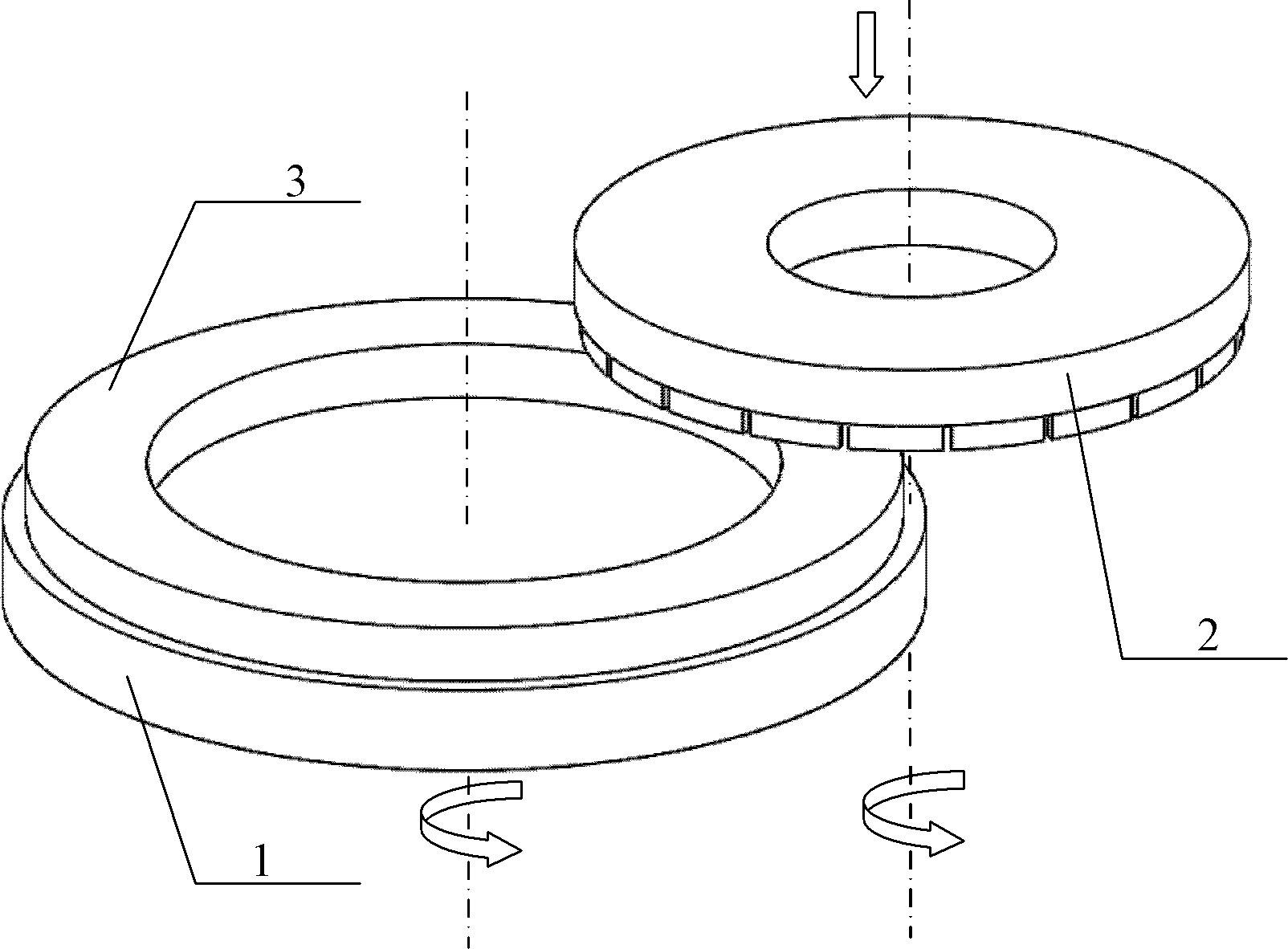

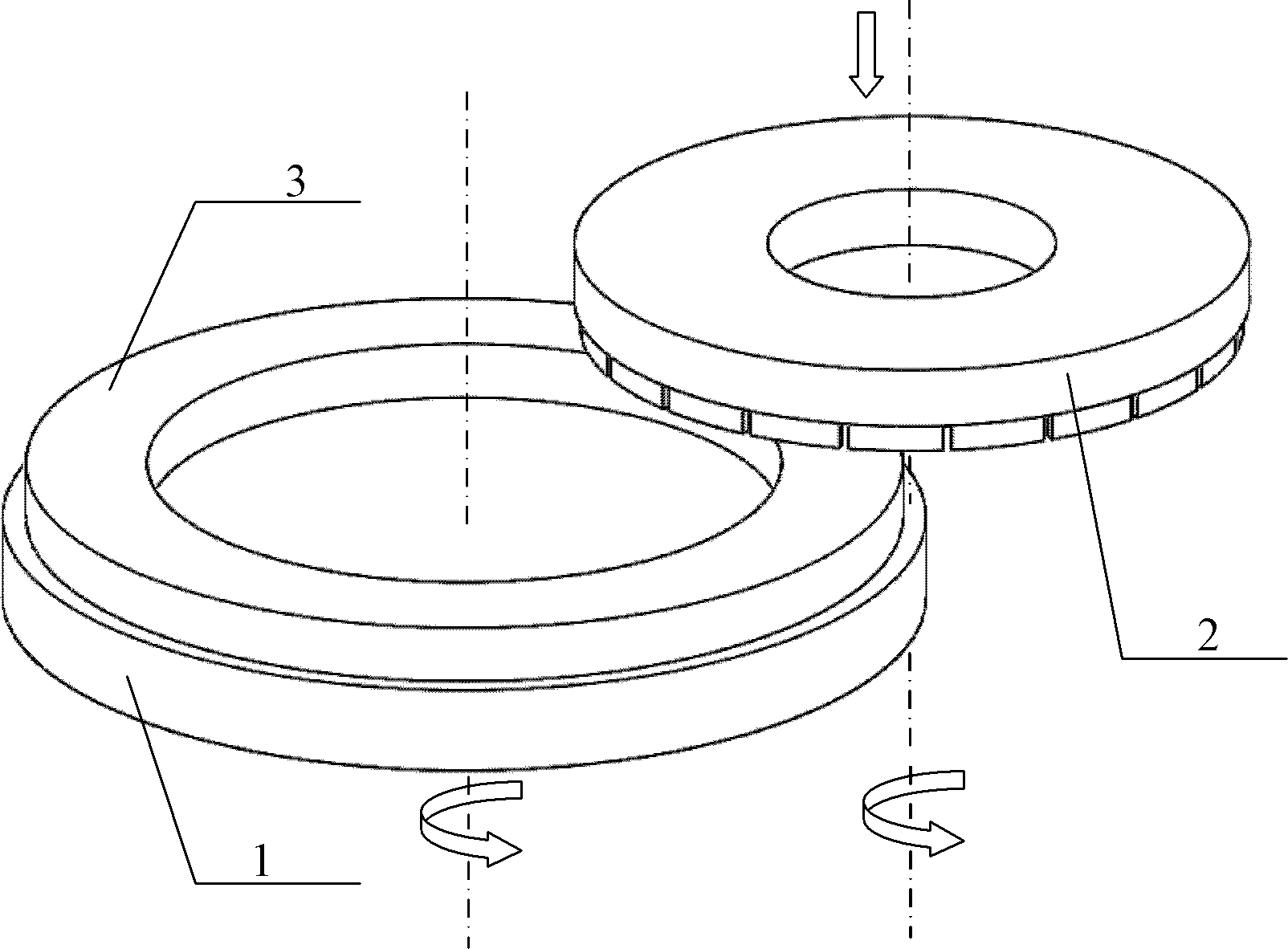

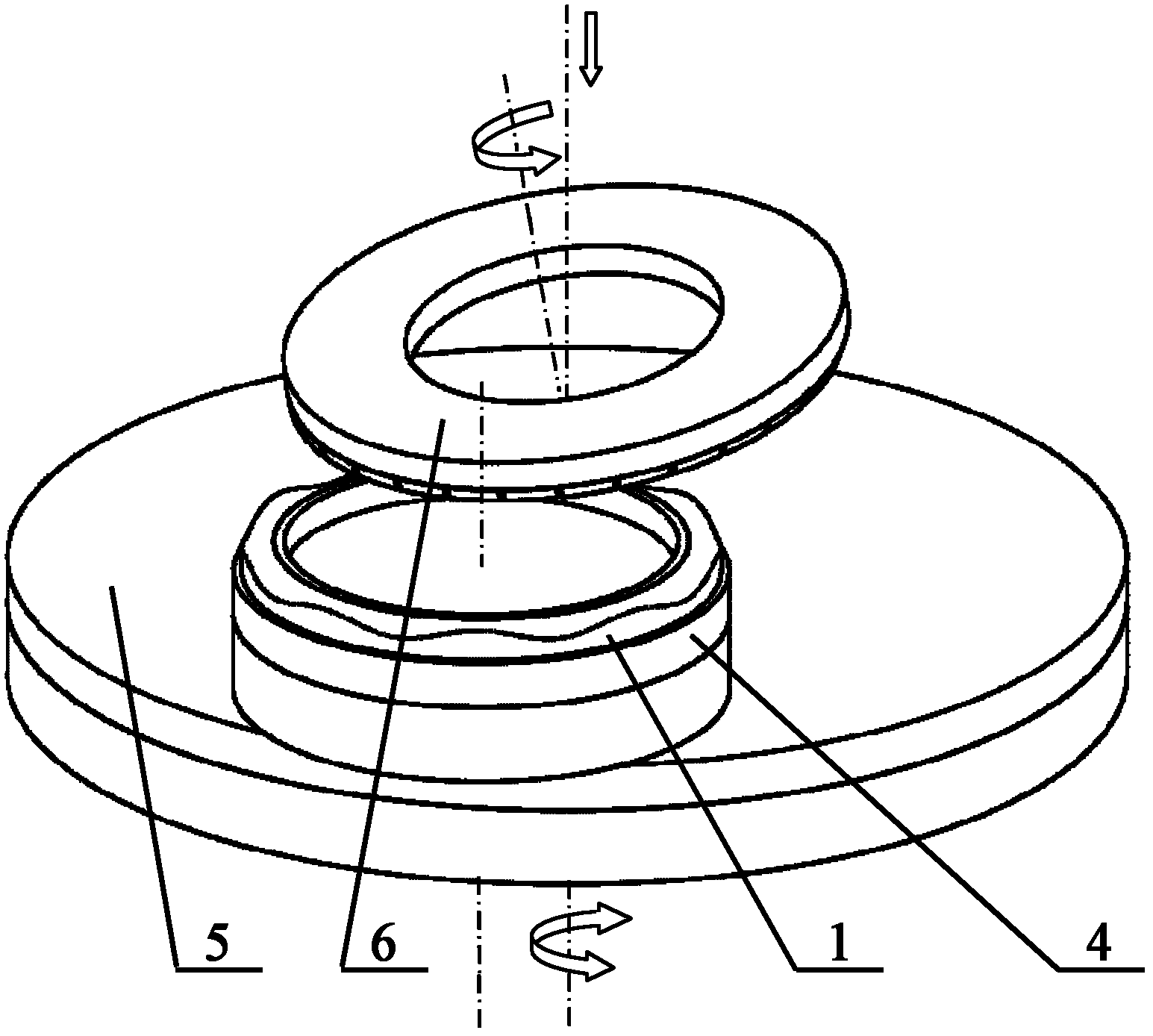

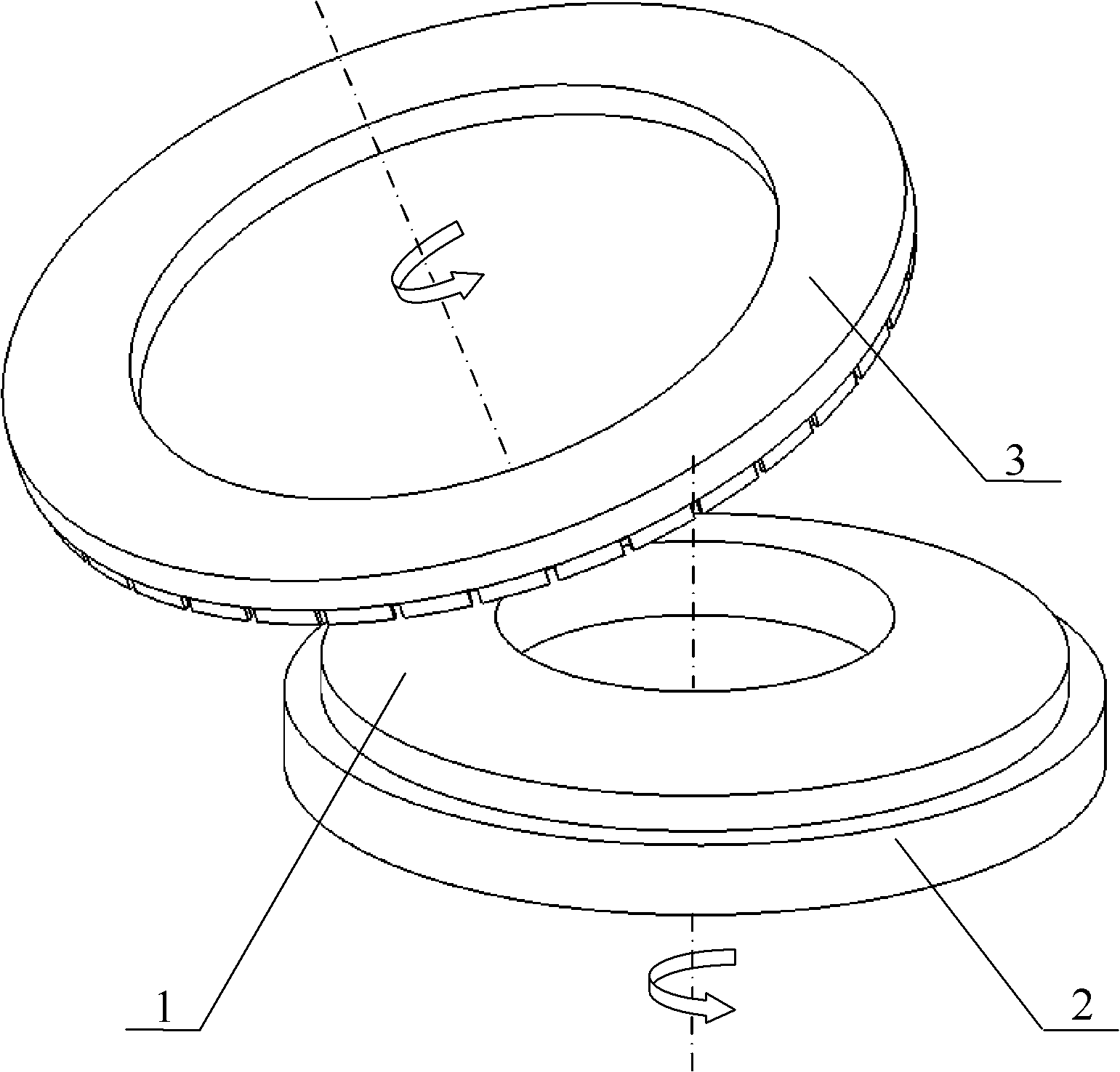

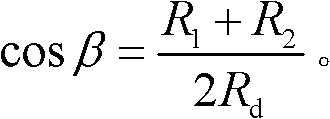

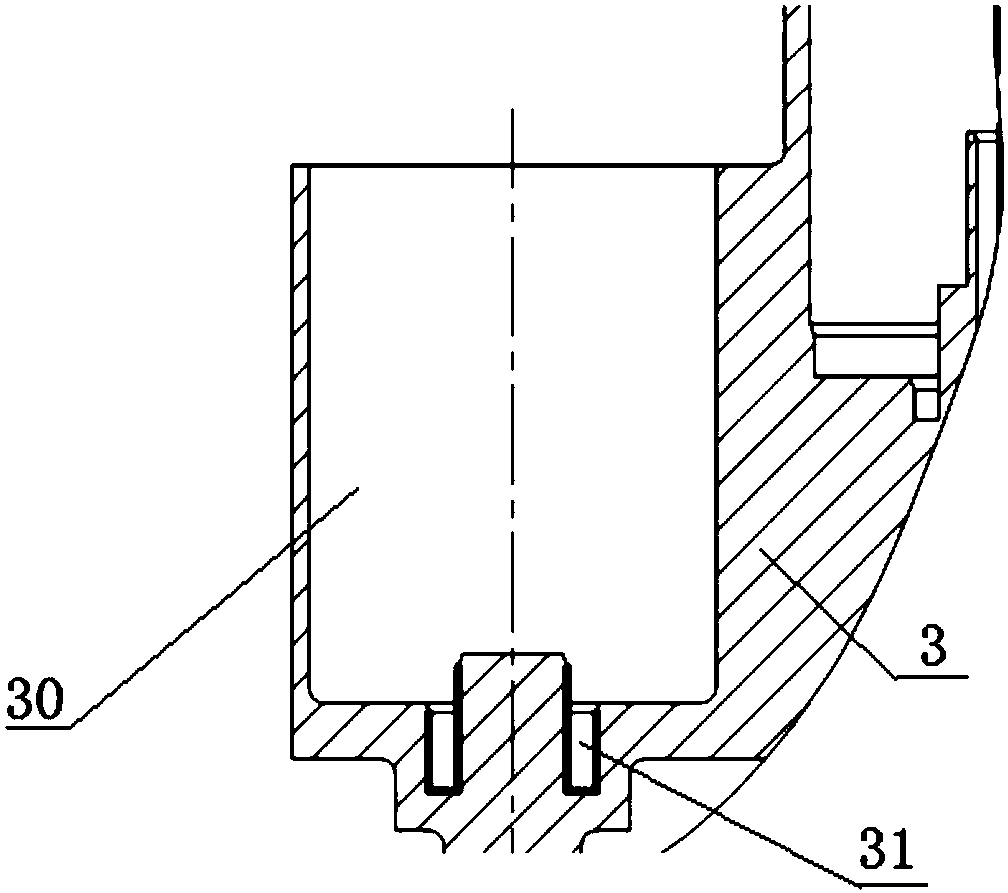

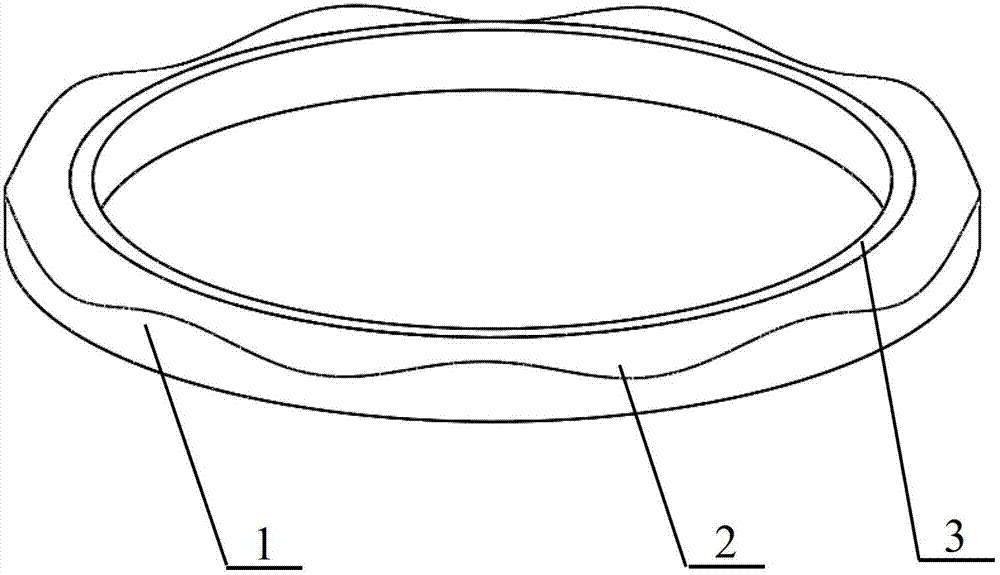

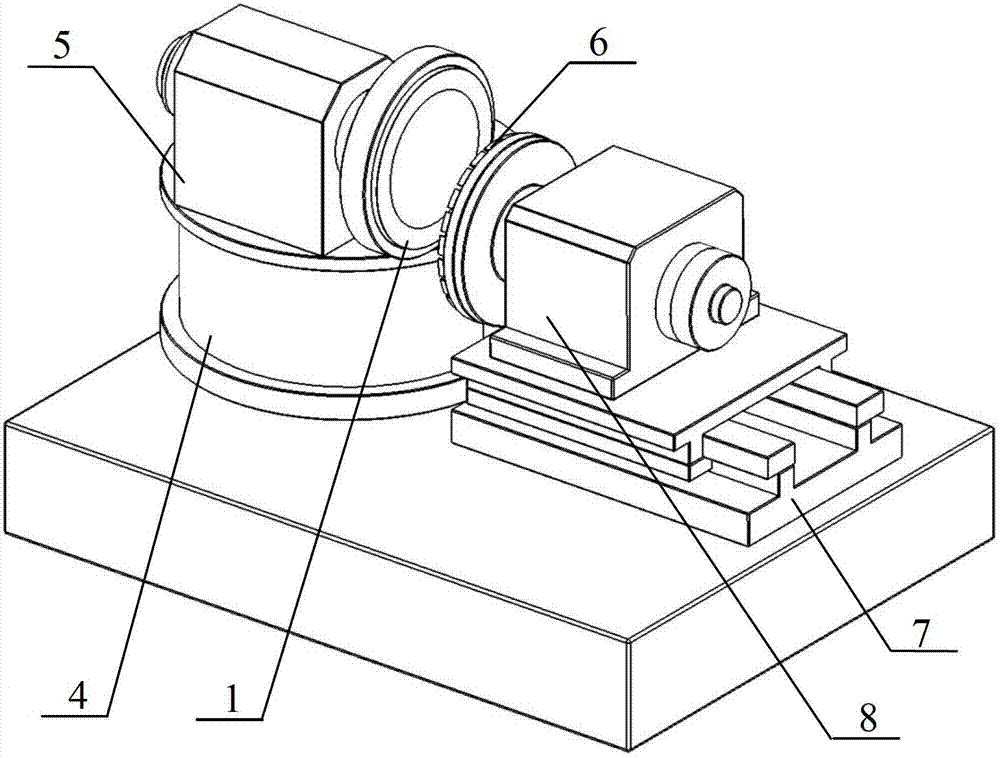

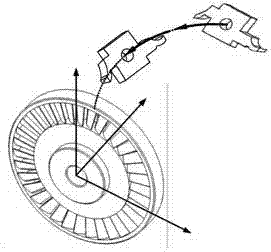

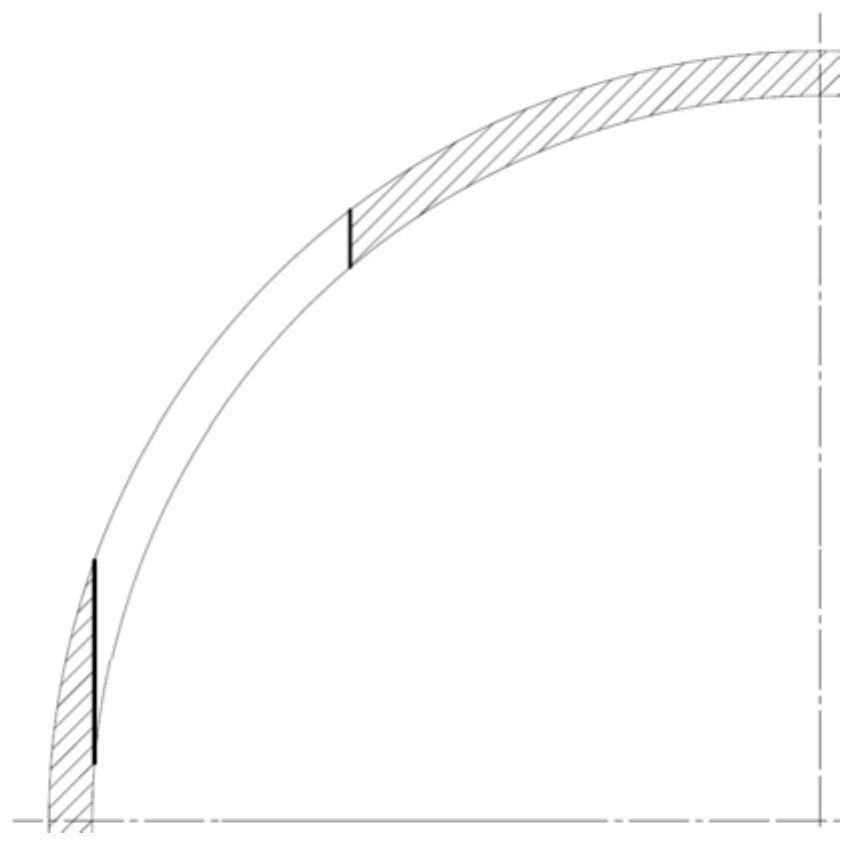

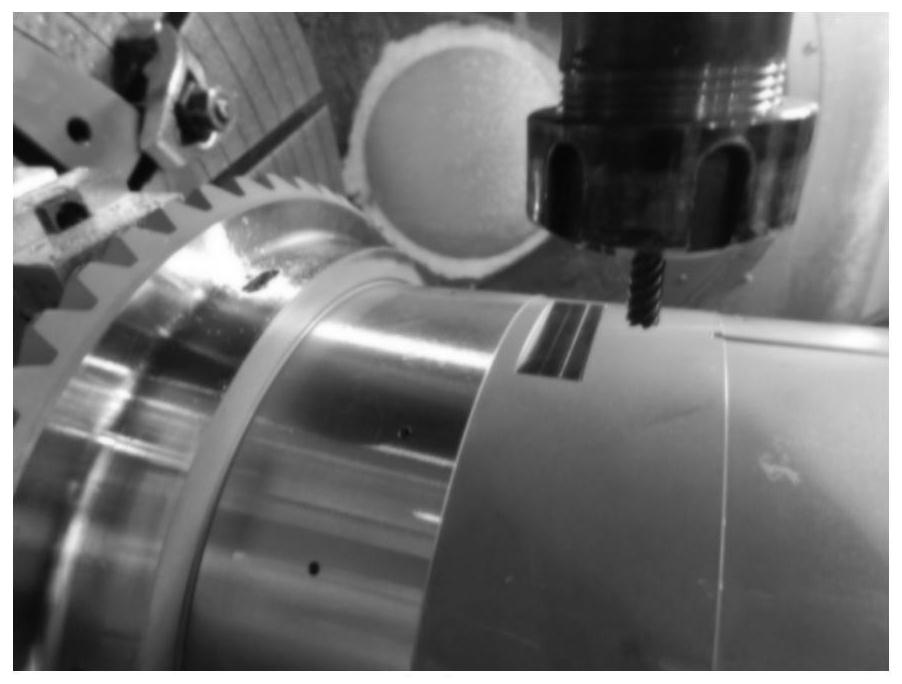

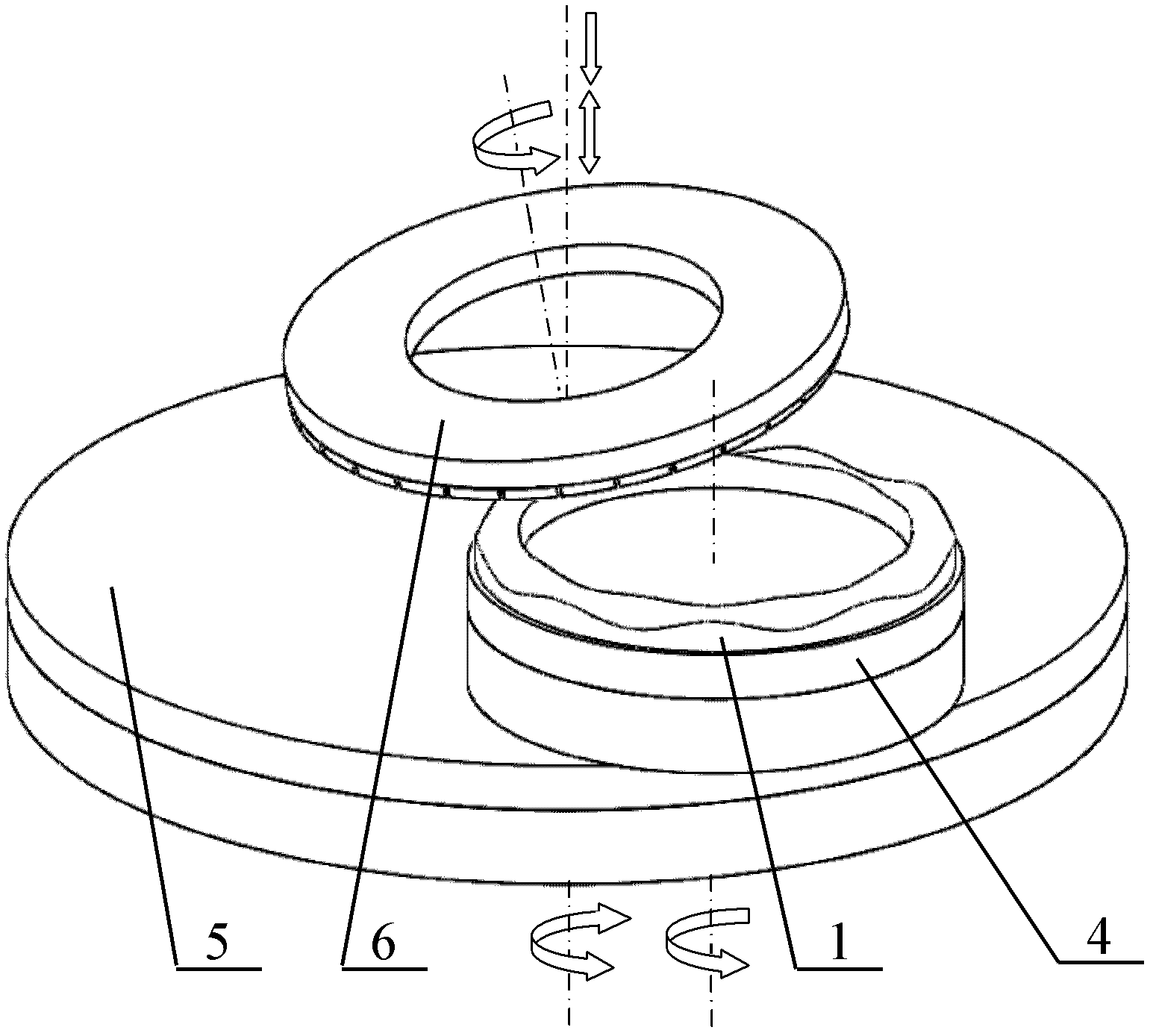

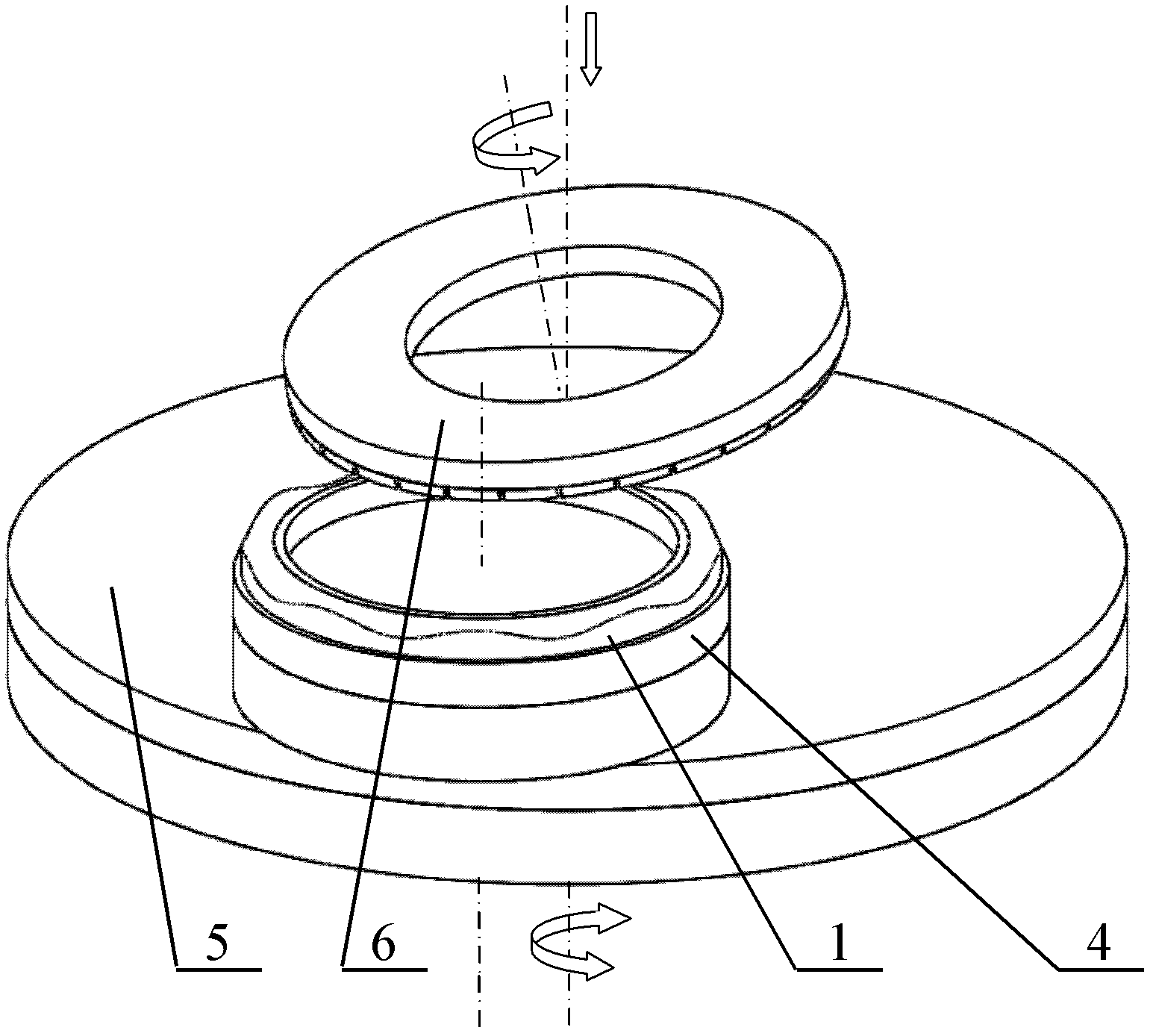

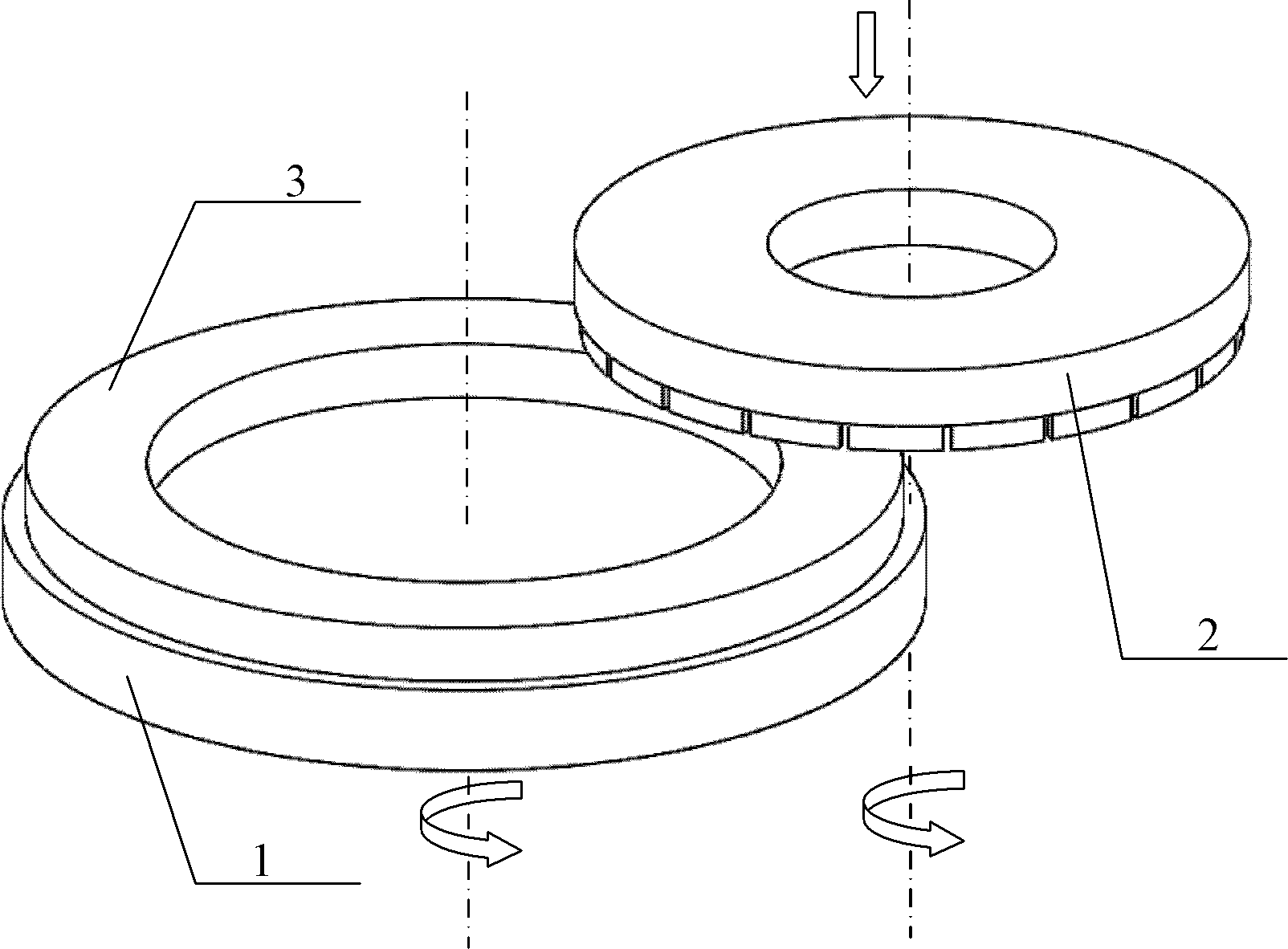

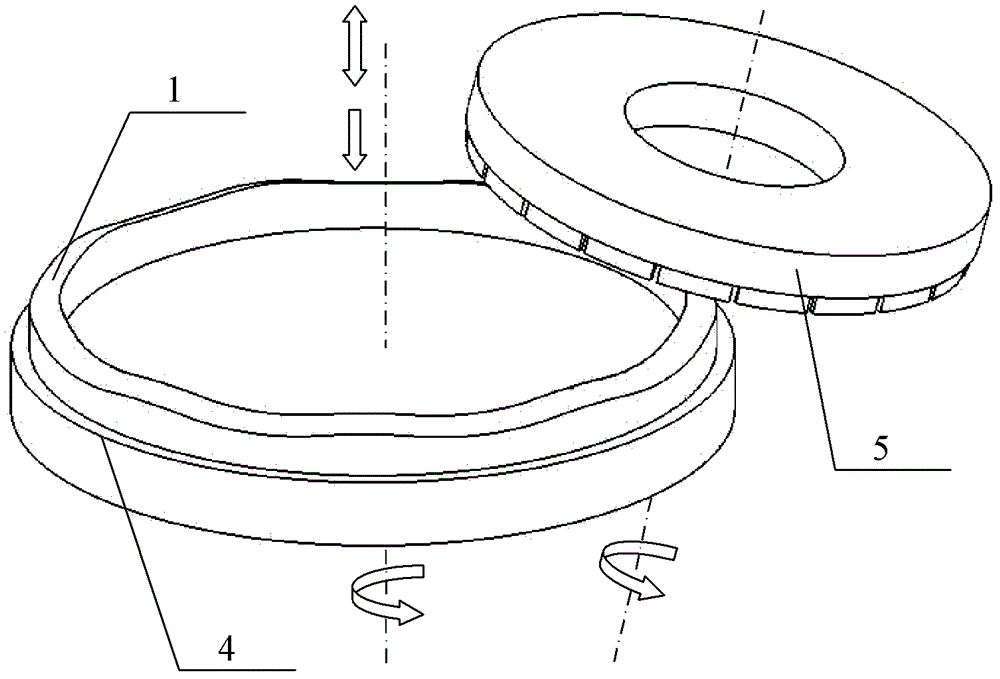

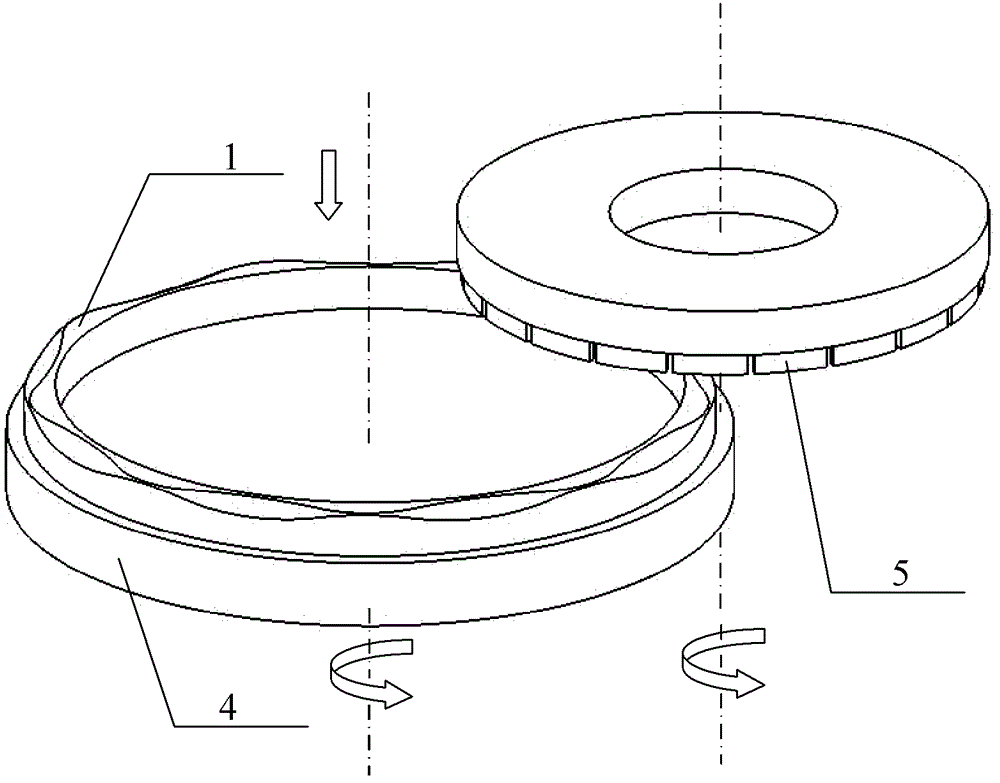

The invention relates to an ultra-precise processing method for the circular conical surface of a fluid static pressure sealing ring for a nuclear primary pump, which belongs to the technical field of precise processing and is characterized in that the sealing ring is clamped in the center of a rotating work table, the radius of a cup-shaped grinding wheel is 75 to 250mm, the distance from the crossing point of the end surface of the cup-shaped grinding wheel and a rotating axis of the cup-shaped grinding wheel to a rotating axis of the rotating work table is 100 to 350mm, according to the principle that the taper error of the surface generated by the grinding is smaller than the given taper tolerance, an inclination angle of the rotating axis of the cup-shaped grinding wheel relative to the rotating axis of the rotating work table and an included angle between the rotating axis of the cup-shaped grinding wheel and a straight line are selected, wherein the straight line passes throughthe crossing point of the end surface of the cup-shaped grinding wheel and the rotating axis of the cup-shaped grinding wheel and is vertically intersected with the rotating axis of the rotating worktable. During grinding, the rotating work table and the cup-shaped grinding wheel do rotating movement, the cup-shaped grinding wheel feeds along the rotating axis of the rotating work table, and thecutting-in grinding is carried out by the end surface of the cup-shaped grinding wheel. The ultra-precise processing method has the effects and benefits that the machine tool structure is simple, andthe high-precise and low-surface-roughness grinding of the circular conical surface of the fluid static pressure sealing ring for the nuclear primary pump can be realized.

Owner:DALIAN UNIV OF TECH

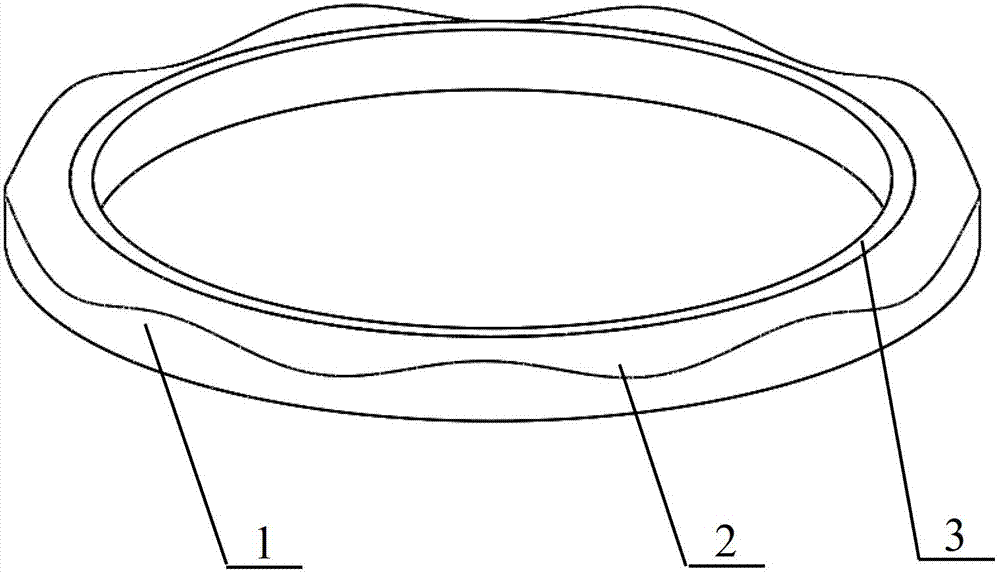

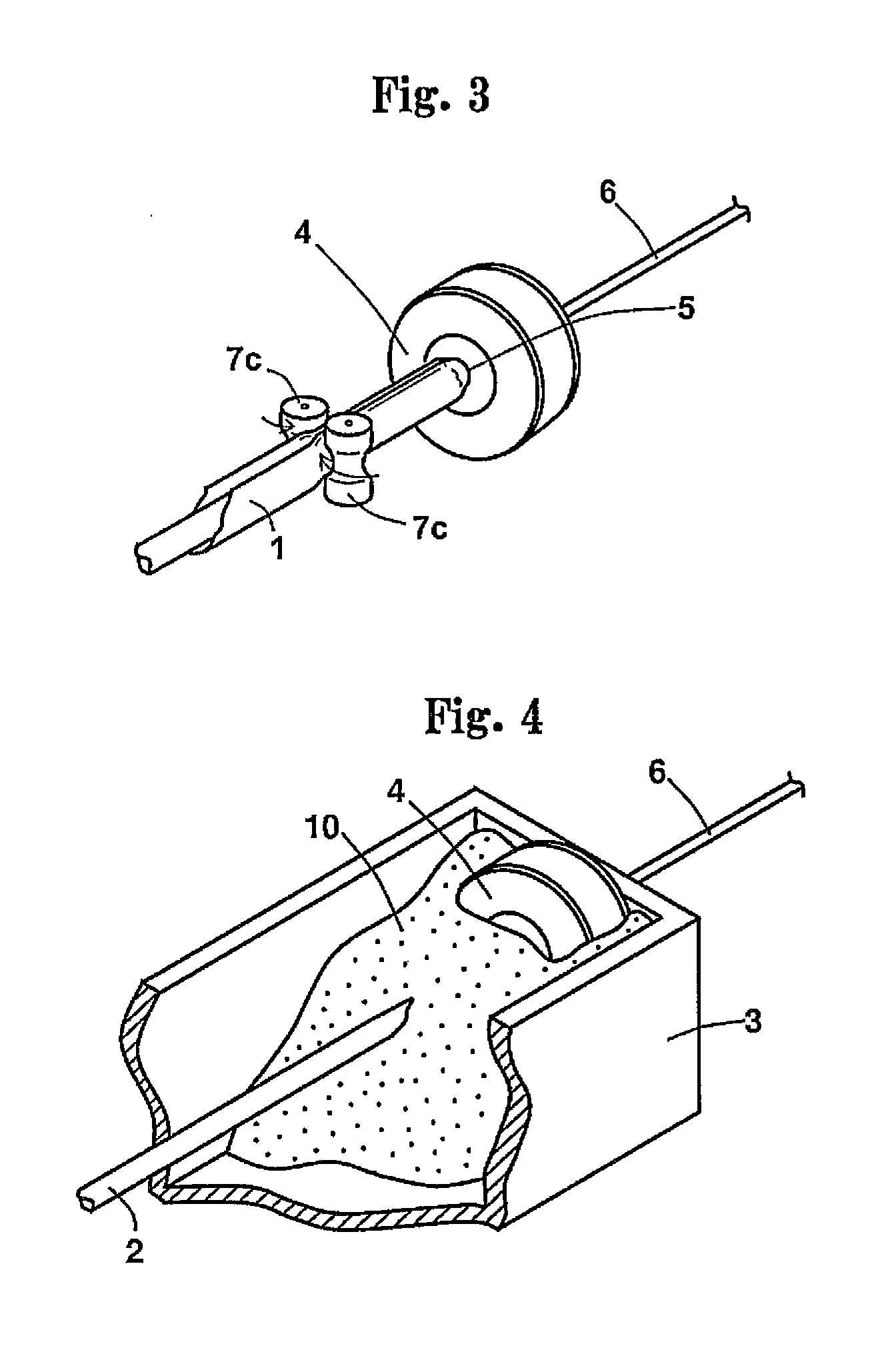

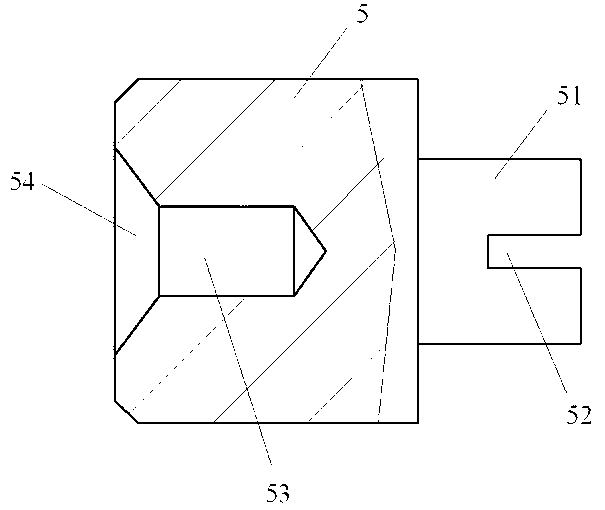

Machining method for complex surfaces of liquid hybrid type mechanical seal rings

ActiveCN102581728AConsistent cutting speedConsistent Depth of CutGrinding machinesHybrid typeRotational axis

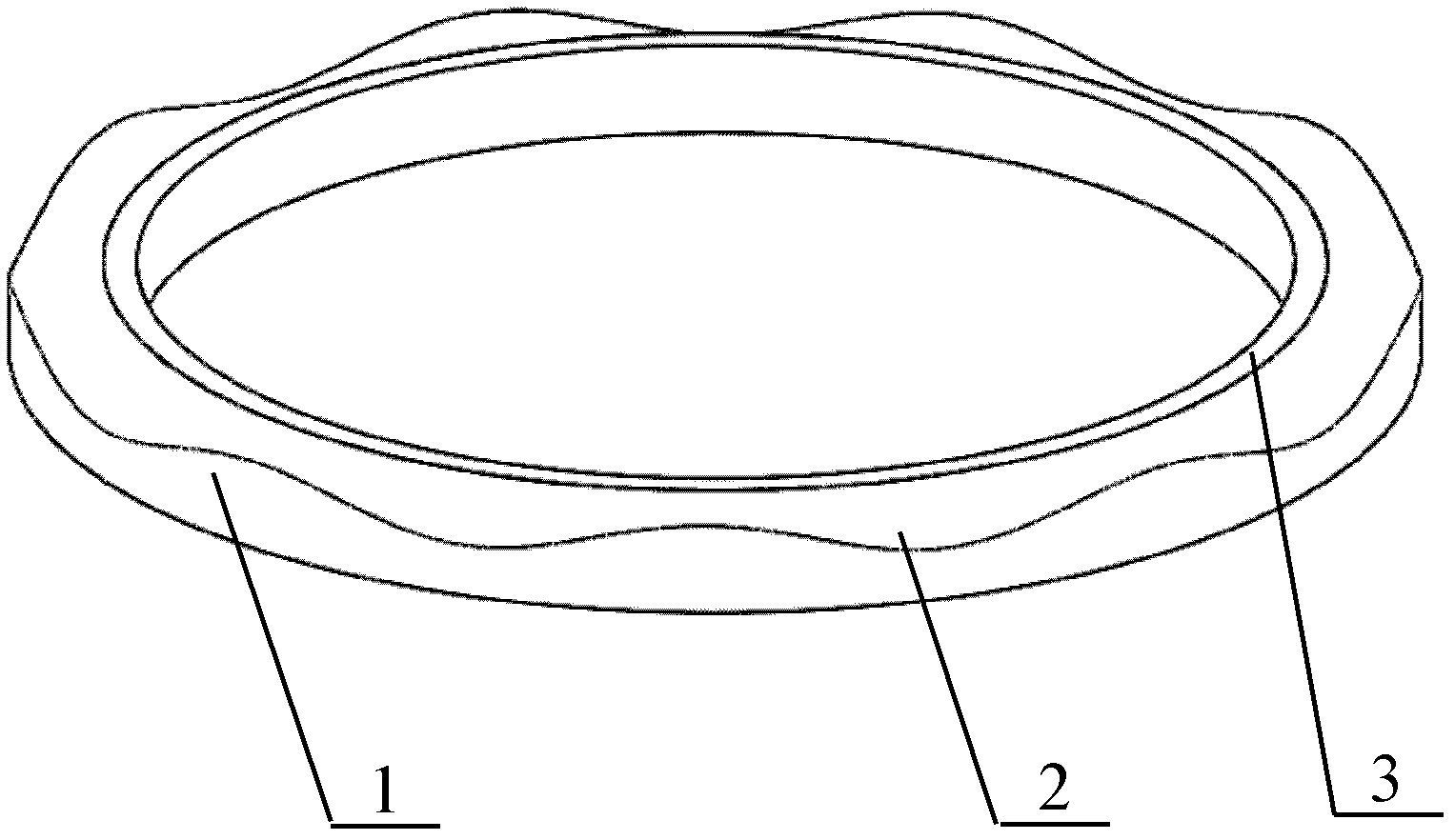

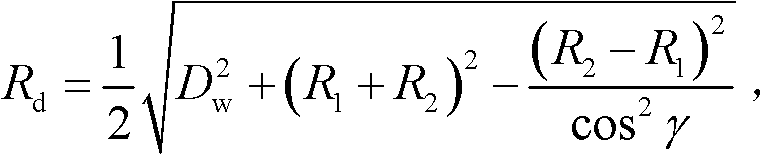

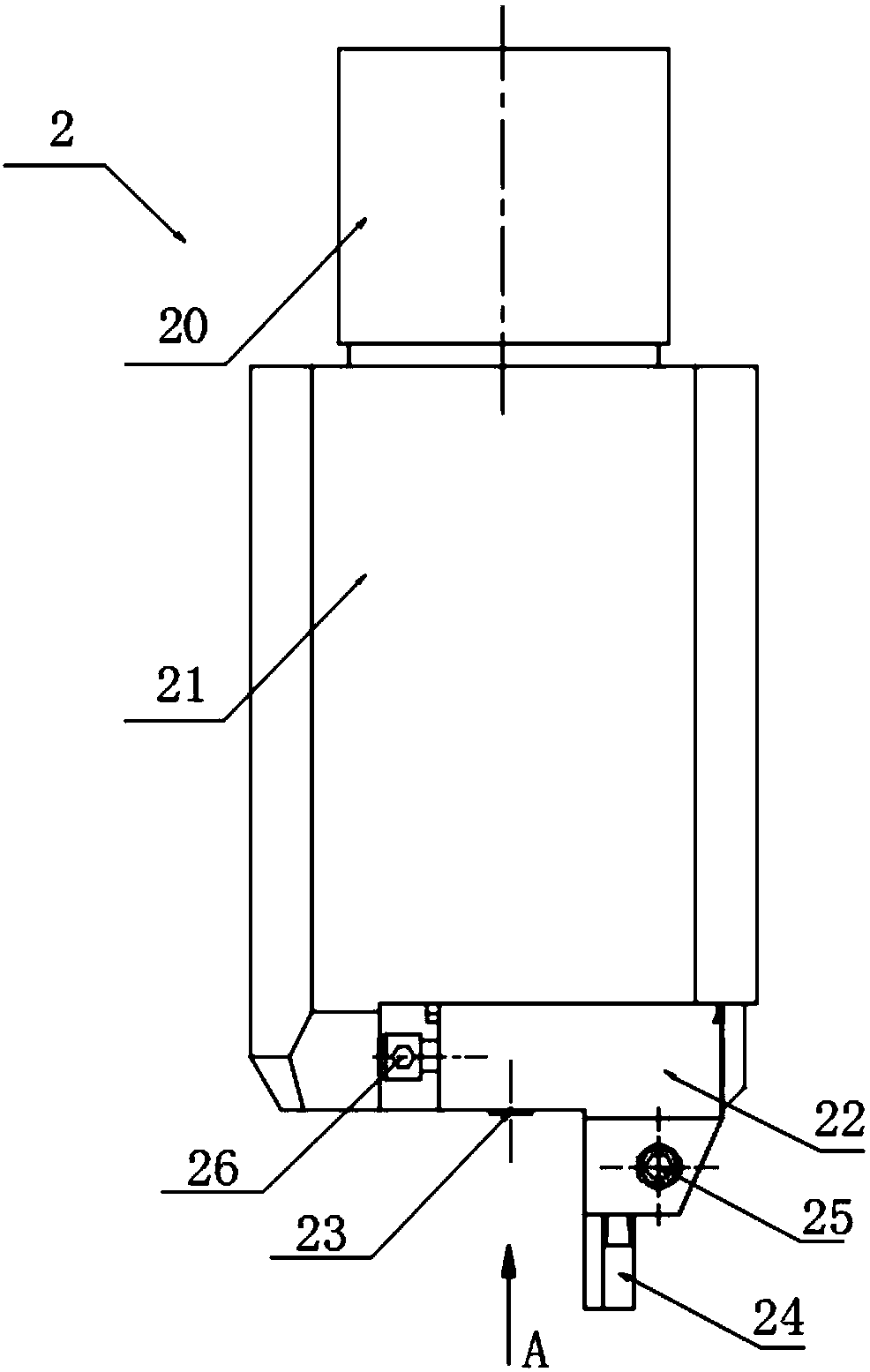

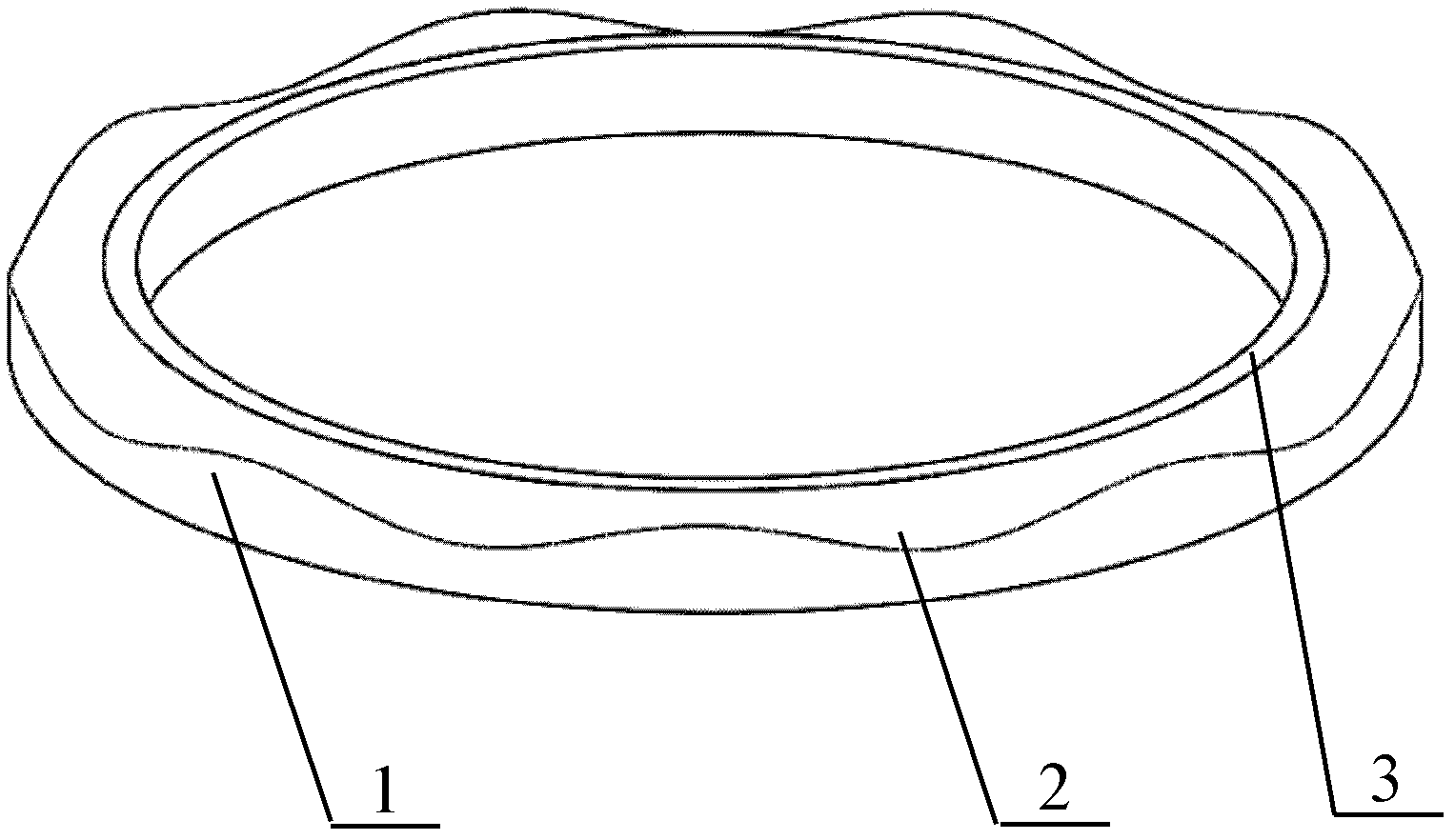

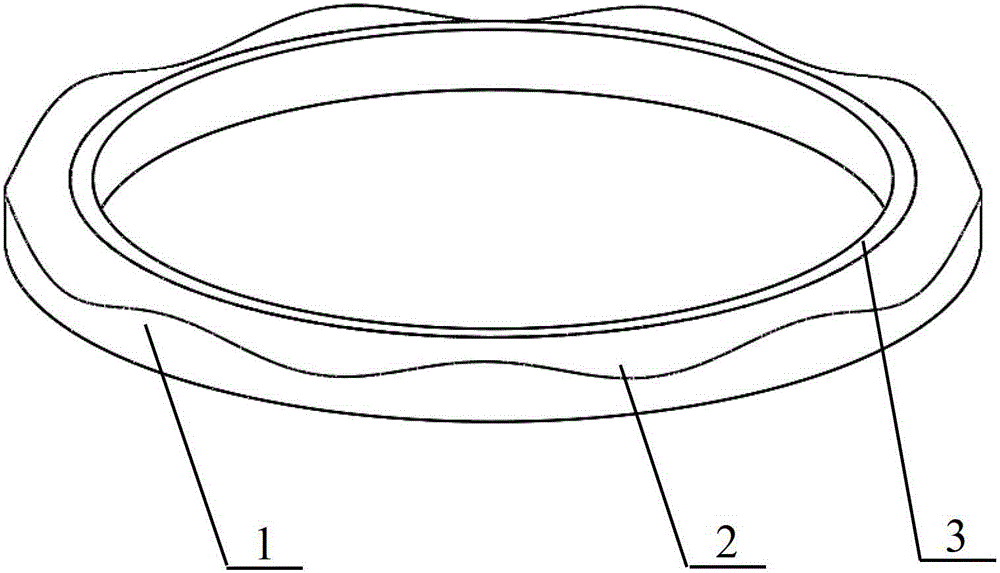

A machining method for complex surfaces of liquid hybrid type mechanical seal rings belongs to the technical field of precision machining and is characterized in that a sum of the square of diameter of a cup wheel and the square of medium diameter of a sloped corrugate face is equal to a square of a doubled distance from an intersection of the end face of the wheel and a rotational axis of the wheel to a rotational axis of a rotary worktable, an inclination angle of the wheel is equal to a largest radial outline inclination angle of the sloped corrugate face, rotation of the rotary worktable, reciprocating swing of a swing worktable and periodic following are in linked control when the sloped corrugate face is ground, the end face of the wheel is used for constant micro-feed cut-in grinding in the cutting depth direction of the wheel, the rotary worktable is in constant-speed rotation when a seal dam face is ground, and the end face of the wheel is used for constant micro-speed cut-in grinding in the cutting depth direction of the wheel. The machining method has the advantages that machining high in surface shape precision and low in surface roughness for the complex surface of a hydrodynamic pressure seal ring is achieved, while the hydrodynamic pressure seal ring is composed of a flat circular dam face and a sloped corrugate face which has slight inclined linear radial outline and peripherally and periodically changing inclination.

Owner:DALIAN UNIV OF TECH

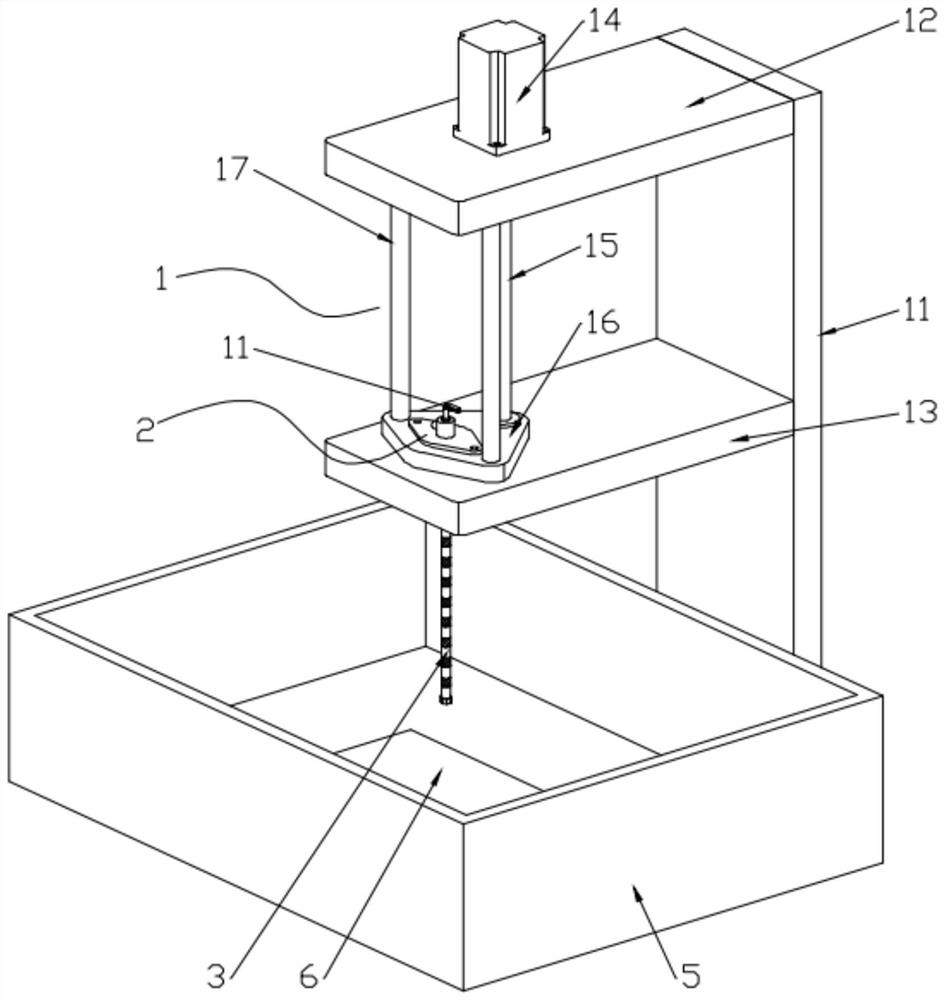

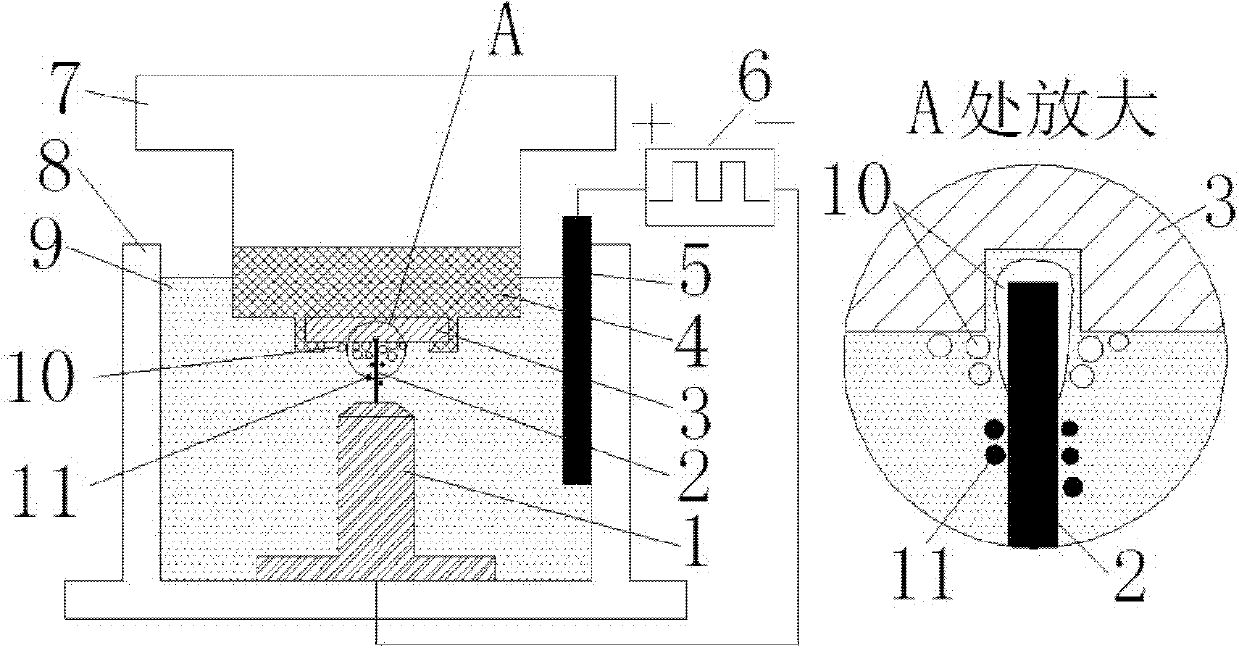

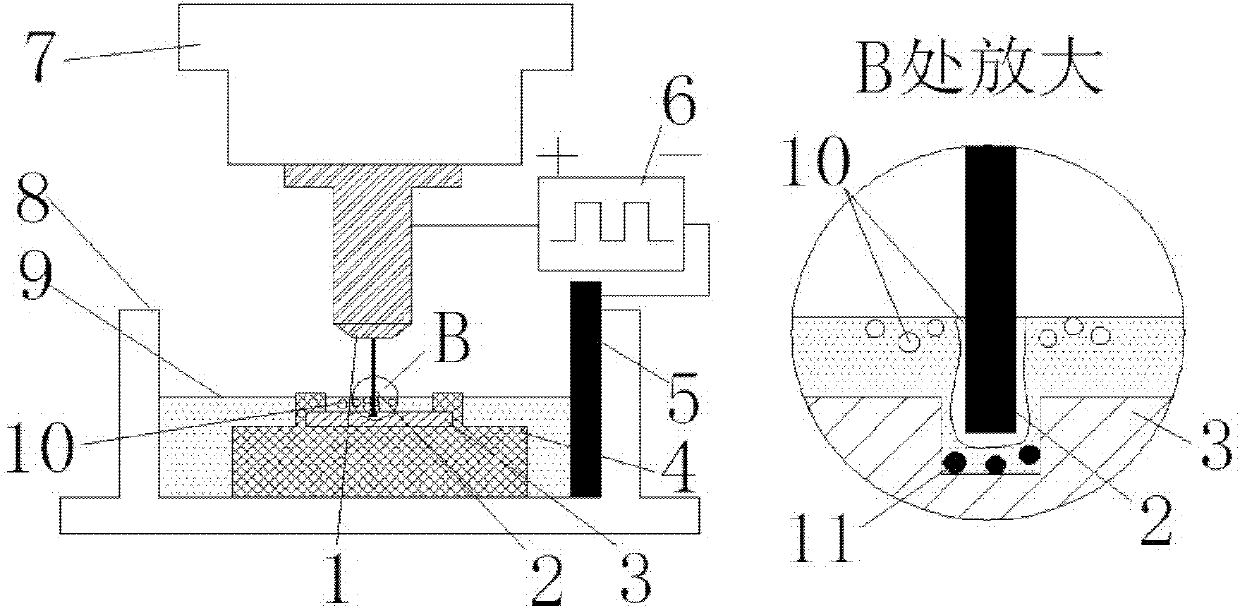

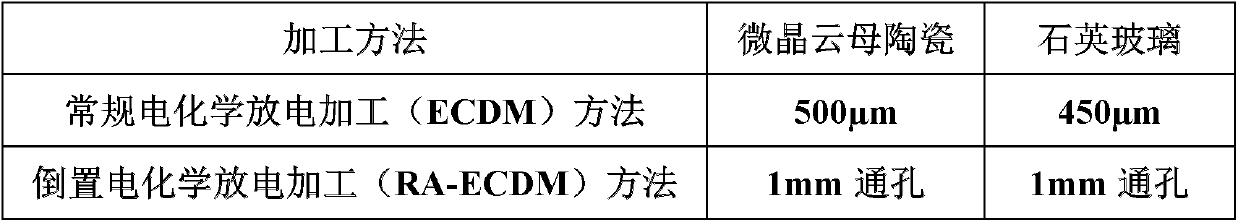

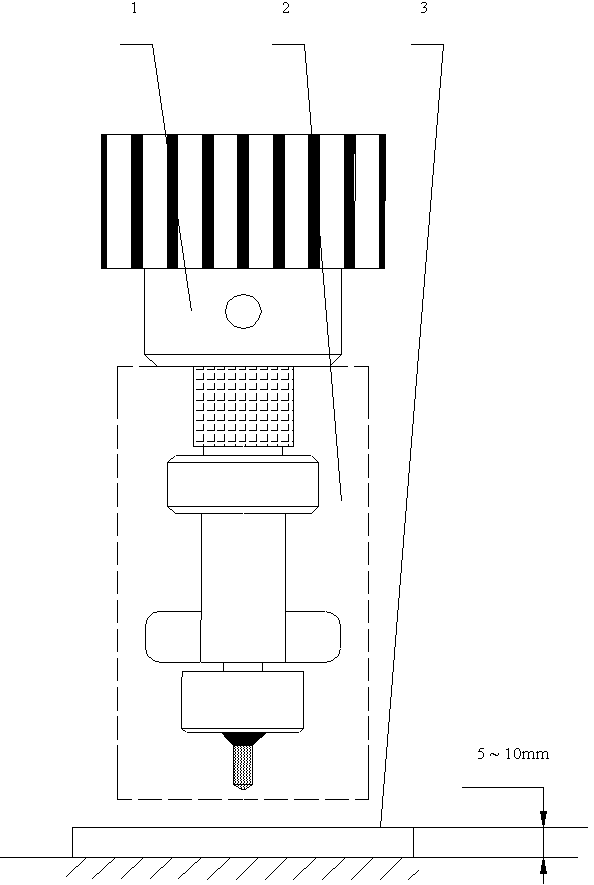

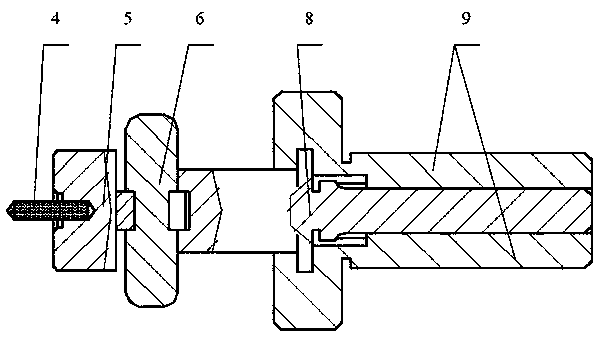

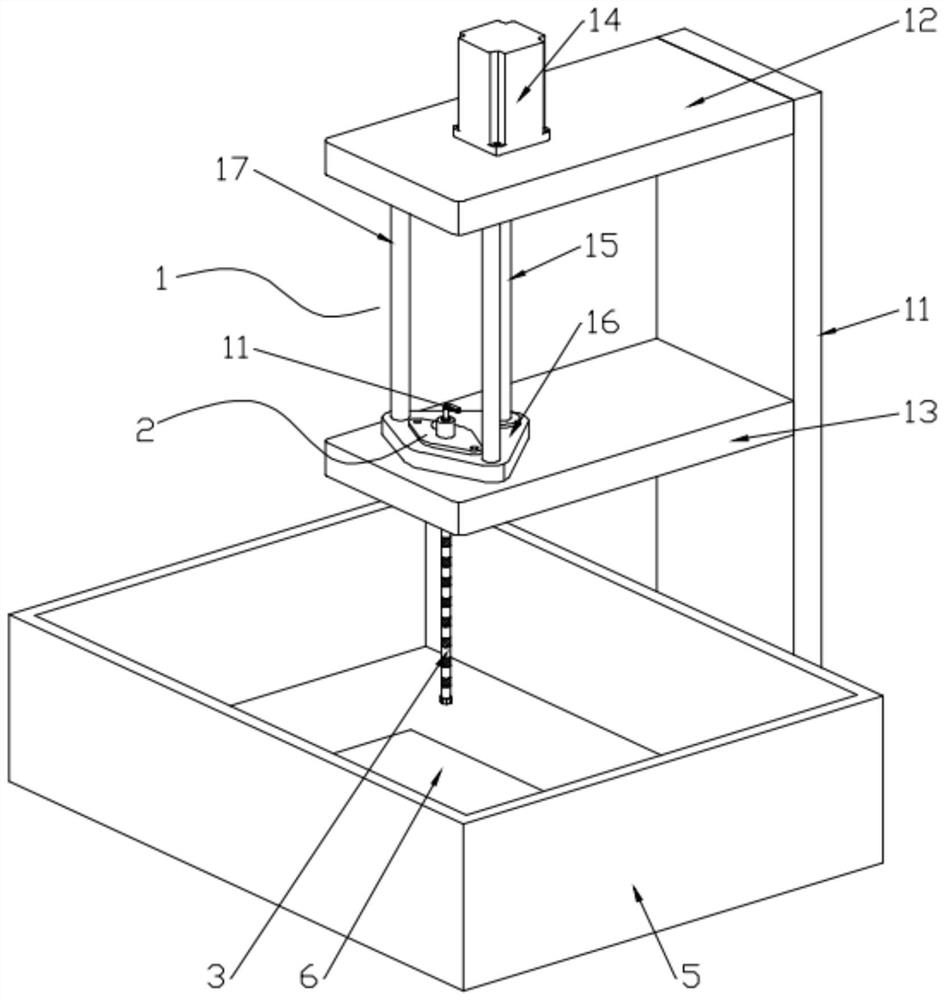

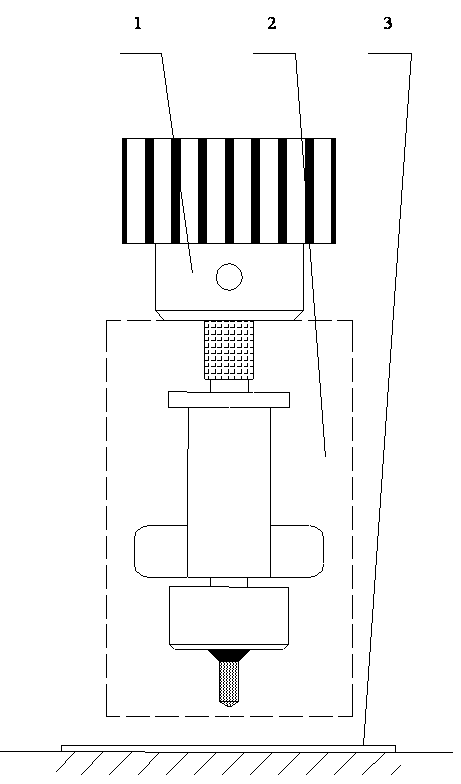

Reversed alignment electrochemical discharge machining method and device

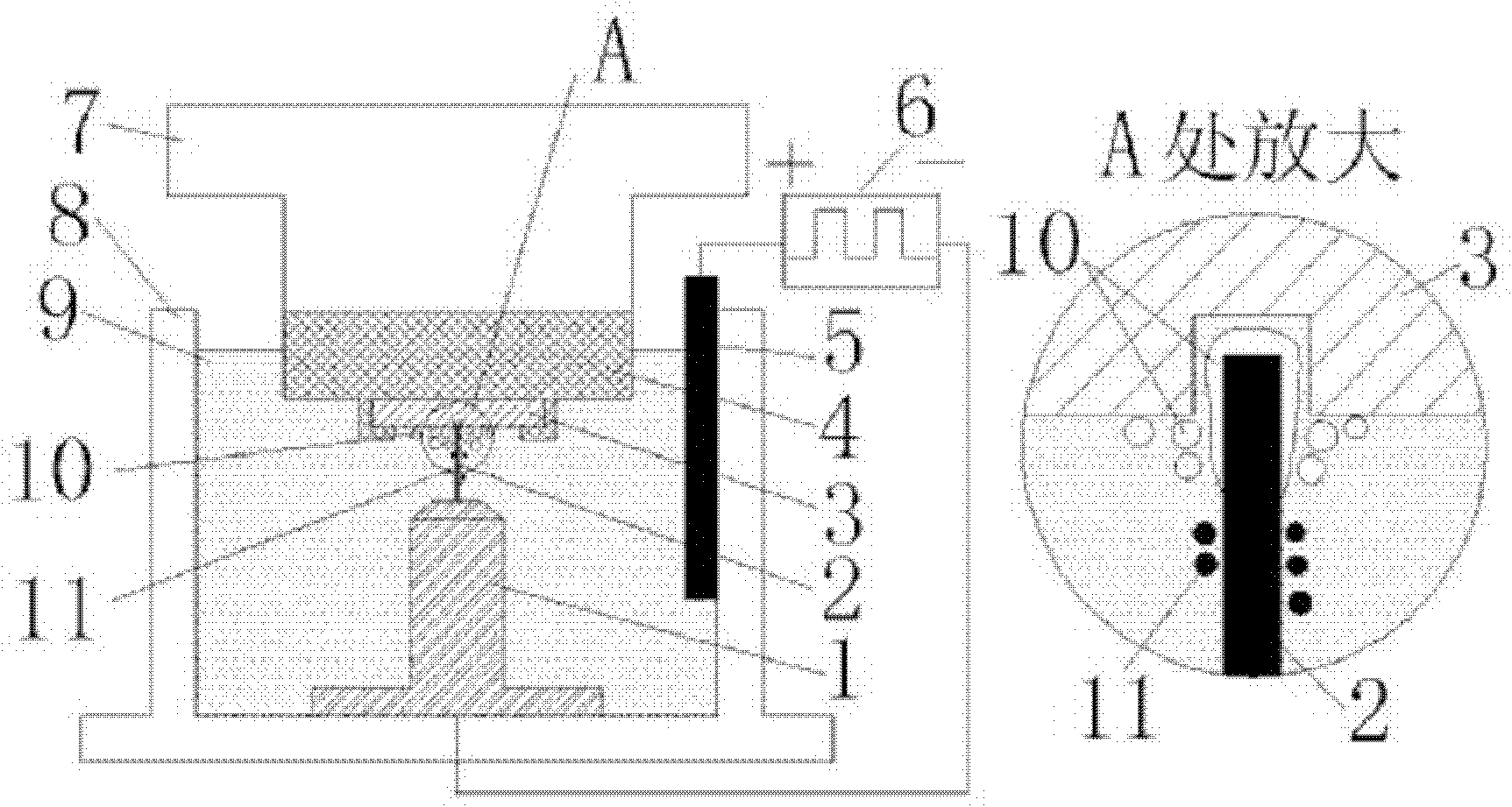

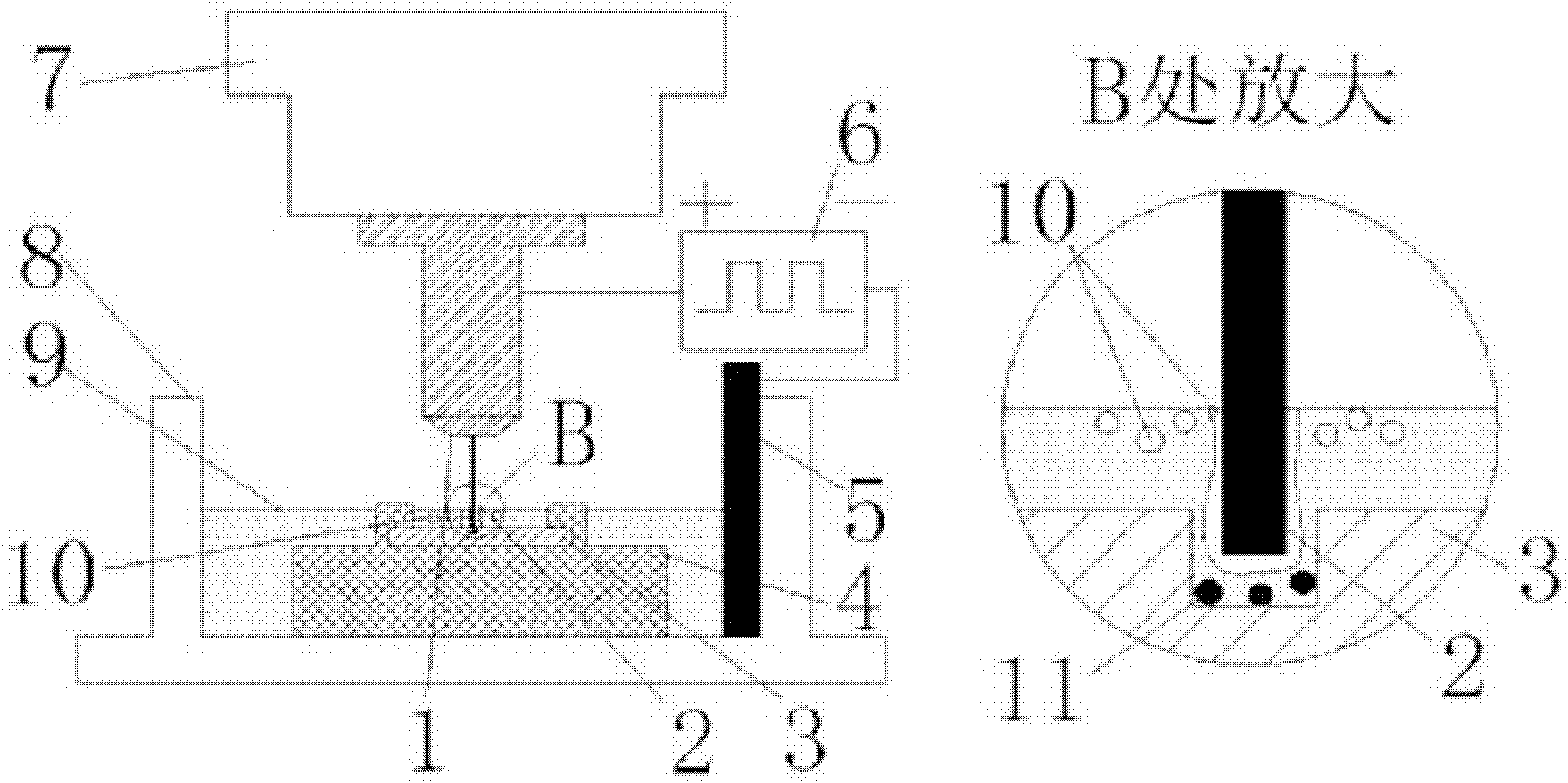

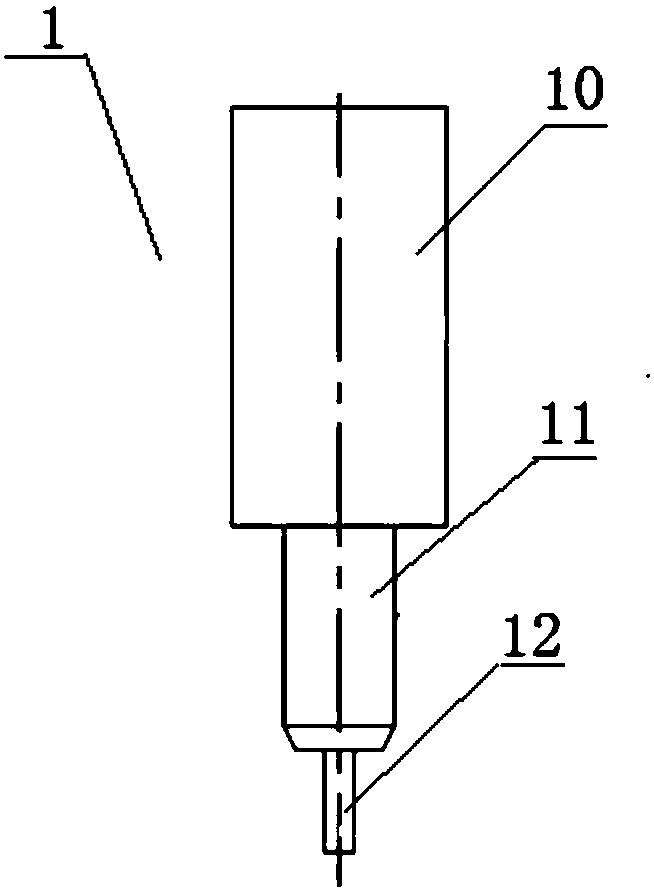

The invention provides a reversed alignment electrochemical discharge machining (RA-ECDM) method in the field of special machining. A tool electrode is arranged below a workpiece. The tool electrode is fixed on the bottom surface of a work slot by an electrode holder and is soaked in electrolyte solution. The workpiece is connected with a feeding device of a machine tool. The feed motion in the machining process is implemented by feeding of the workpiece. The invention also provides a corresponding device. According to the invention, by changing the relative positions between the tool electrode and the workpiece, machining scraps generated in the machining process can be easily discharged under the action of gravity, so that the flowing capacity of electrolyte in a machining process in the machining process is reinforced. Moreover, due to the adoption of the reversed layout, air bubbles generated in the electrolytic reaction can be concentrated around the end part of the electrode below the machined workpiece to form a stable air film, so that the stability and the machining depth of the ECDM are effectively improved.

Owner:SHANGHAI JIAO TONG UNIV

Conical surface grinding method

A conical surface grinding method belongs to the technical field of conical surface grinding. The conical surface grinding method is characterized in that a rotary operating table drives work pieces to rotate, the end face of a cup-shaped grinding wheel with the narrower end face is used for plunge-cut grinding, and an angle of inclination of the rotation axis of the cup-shaped grinding wheel relative to the rotation axis of the rotary operating table, an included angle between a plane passing the nadir of the pitch-diameter circumference of the grinding operational surface of the cup-shaped grinding wheel and the rotation axis of the cup-shaped grinding wheel and a plane passing the circle center of the pitch-diameter circumference of a grinding acting surface of the cup-shaped grinding wheel and the rotation axis of the rotary operating table, and the distance between the circle center of the pitch-diameter circumference of the grinding operational surface of the cup-shaped grinding wheel and the rotation axis of the rotary operating table are needed to be set according to the inner radius, the outer radius and the radial outline inclination angle of a conical surface to be machined and the pitch diameter of the cup-shaped grinding wheel. The conical surface grinding method has the advantages that high surface precision grinding of an external conical surface can be realized, machining efficiency is high and cost is low.

Owner:DALIAN UNIV OF TECH

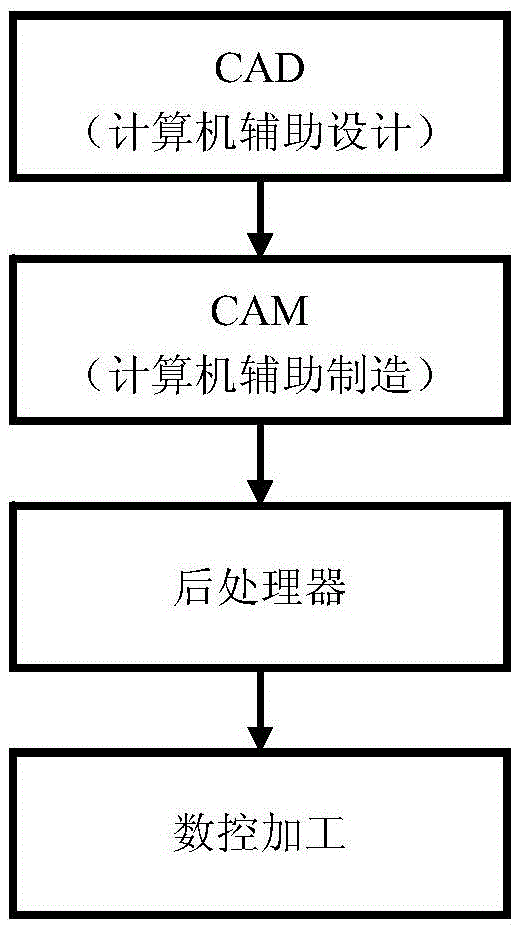

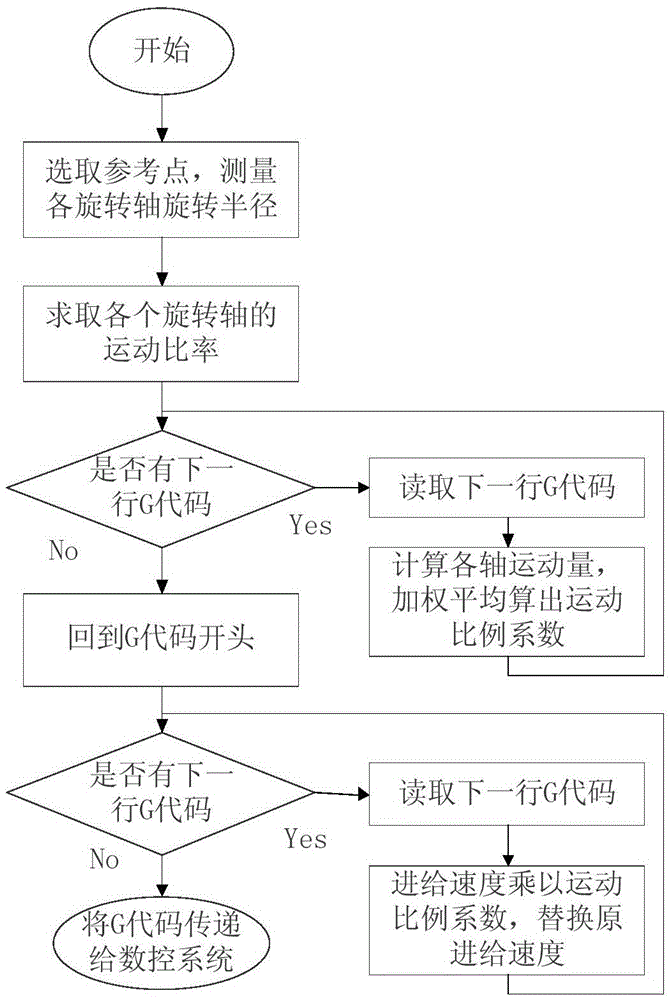

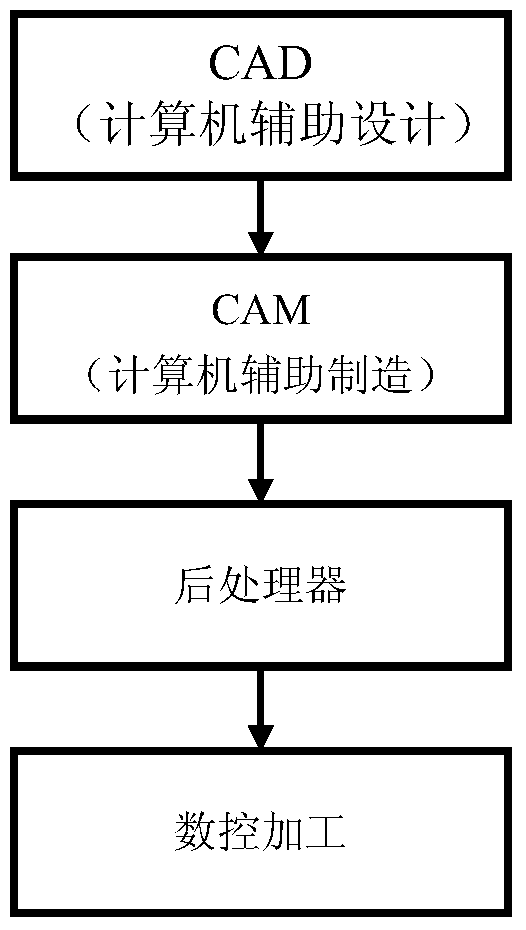

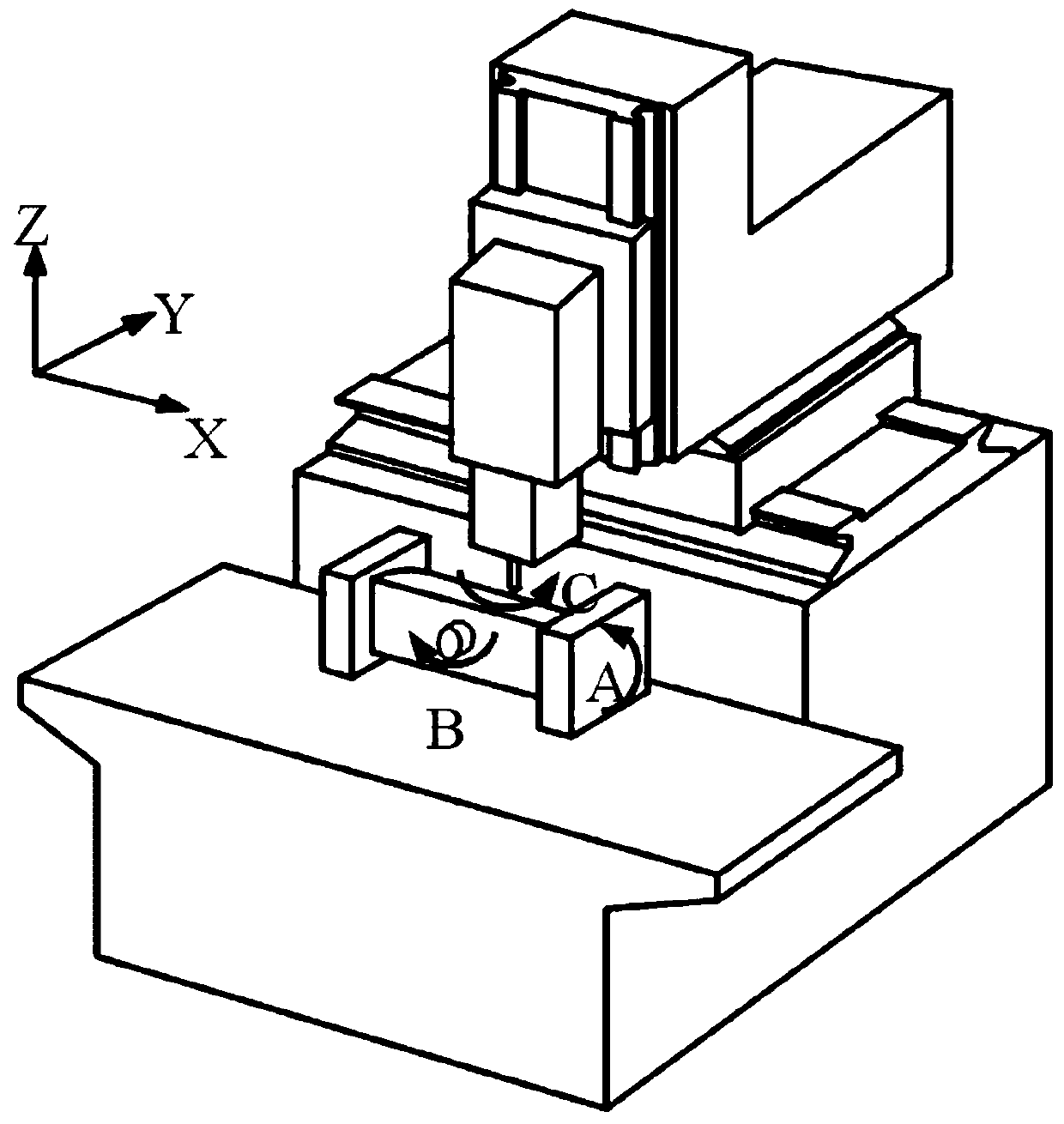

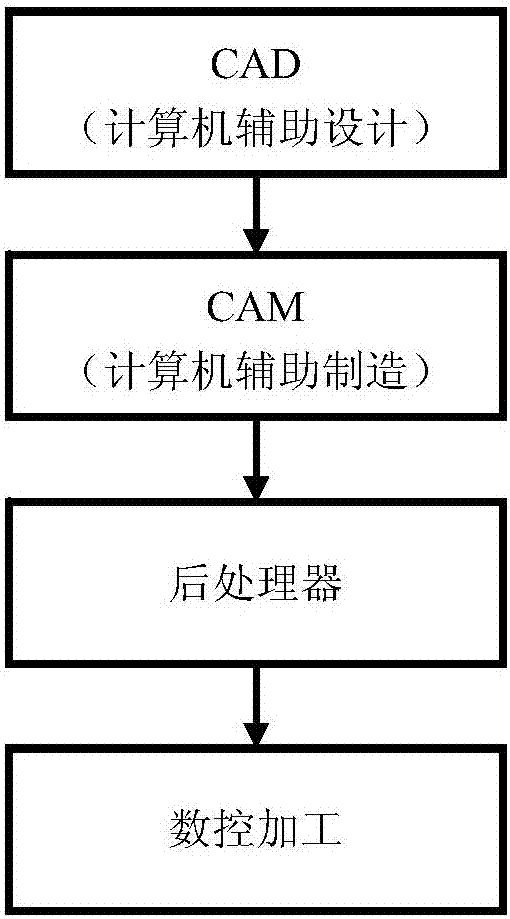

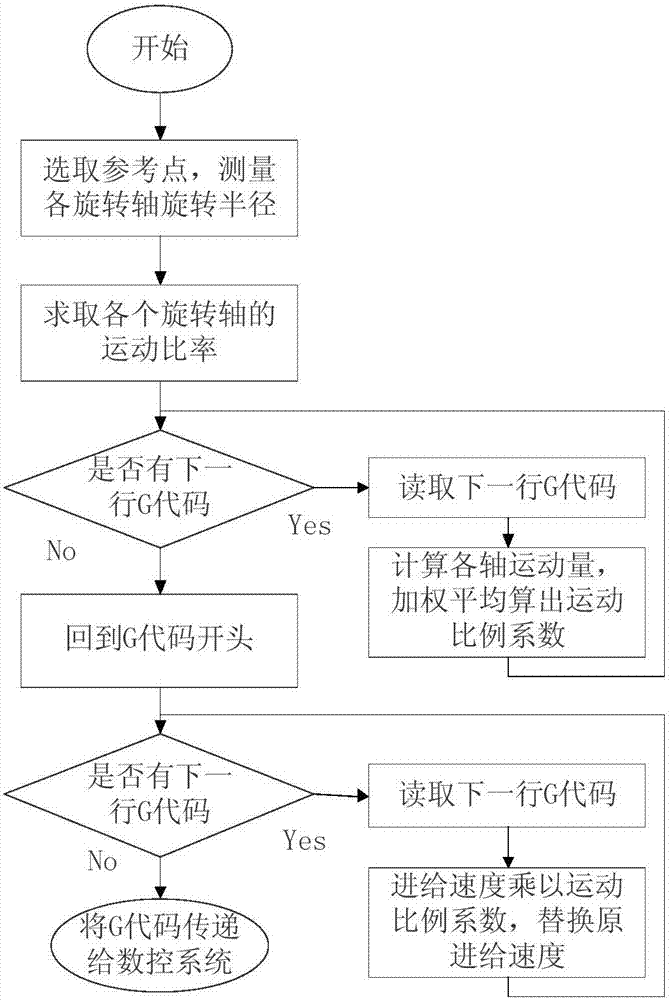

Designing method of feeding speed postprocessor used for multi-axis linkage electrosparking

ActiveCN105643030AProcessing state is stableLarge speed fluctuationElectric circuitsWeighted average methodMulti axis

The invention relates to a designing method of a feeding speed postprocessor used for multi-axis linkage electrosparking. For multi-axis linkage electrosparking machining in which rotary axes are involved, the control object is the relative distance between an electrode and a workpiece, and the unknown radiuses of the rotary axes cause fluctuation of the machining speed. From models of the electrode and the workpiece, the movement coefficients of all movement axes are defined through the rotary radiuses. On the basis, each line of G code movement coefficients are synthesized through a weighted average method to obtain a movement proportionality coefficient, the originally planned feeding speed of each line of G codes is multiplied by the movement proportionality coefficient of the line, and the machining program is updated. Speed fluctuation caused by unmatched dimension can be greatly reduced, the unstable discharging state of movement in which the rotary axes are involved is avoided, the frequency of open circuits and short circuits is reduced, and the electrosparking efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

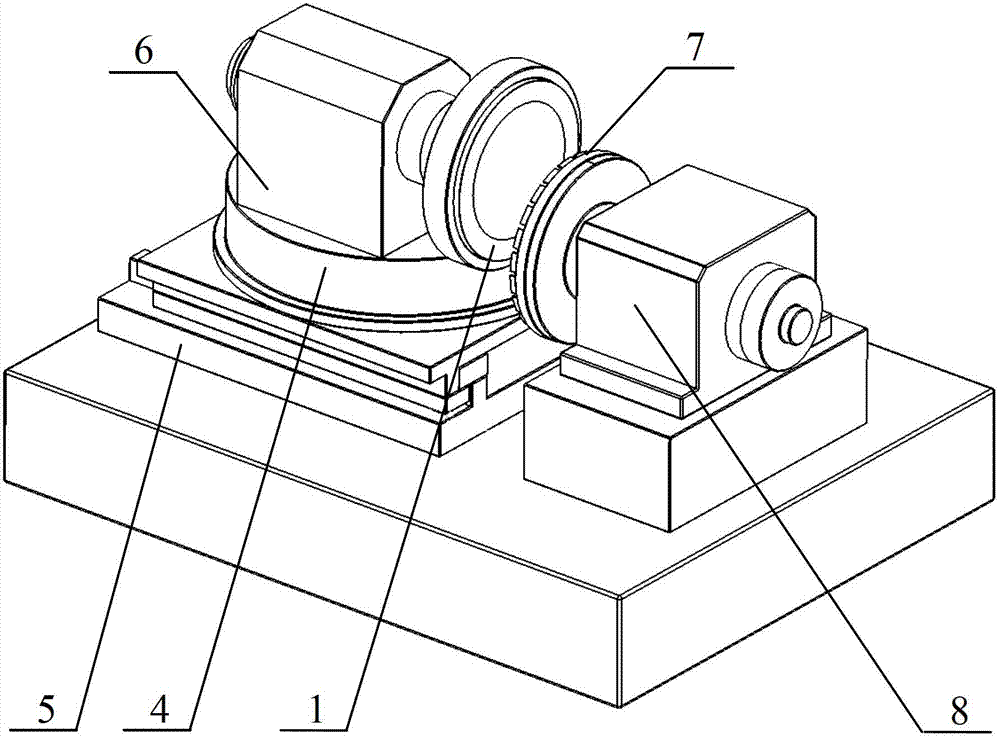

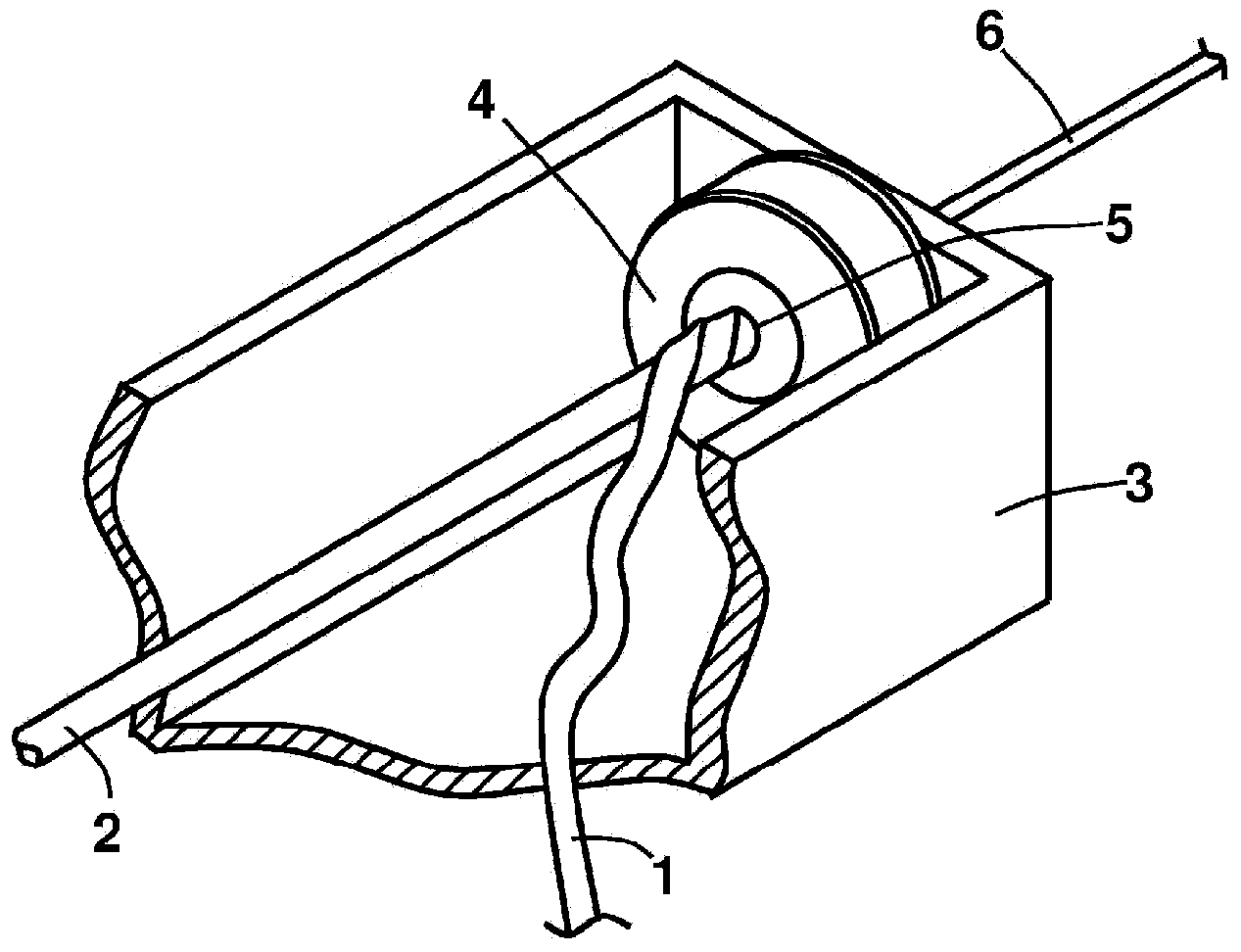

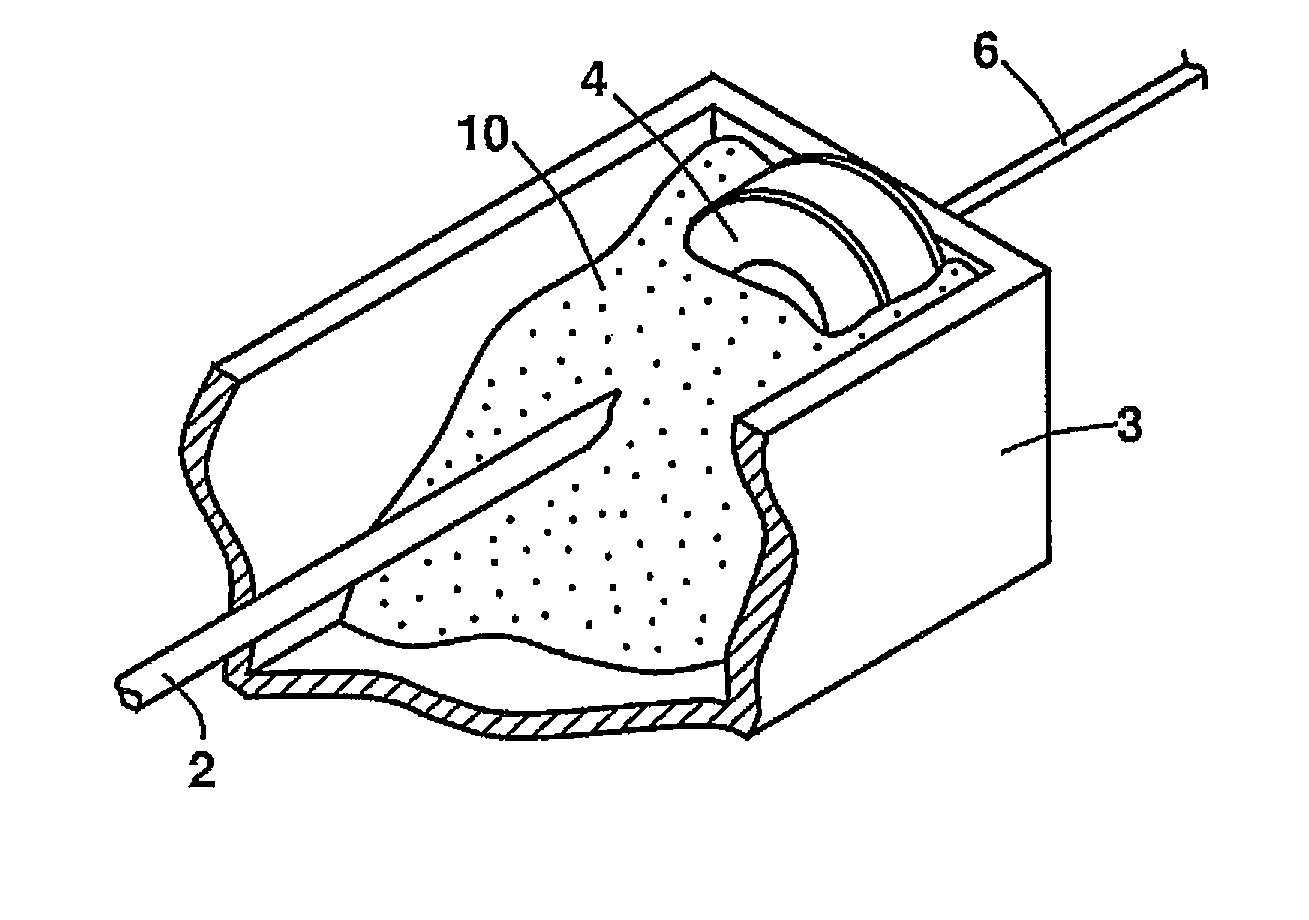

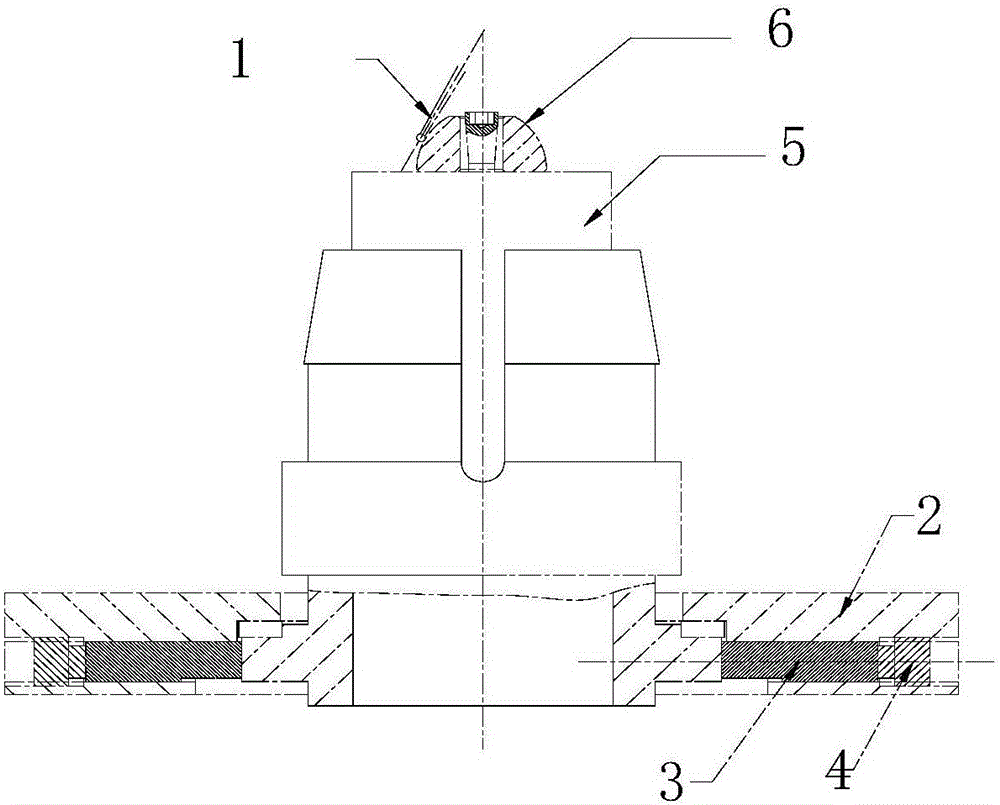

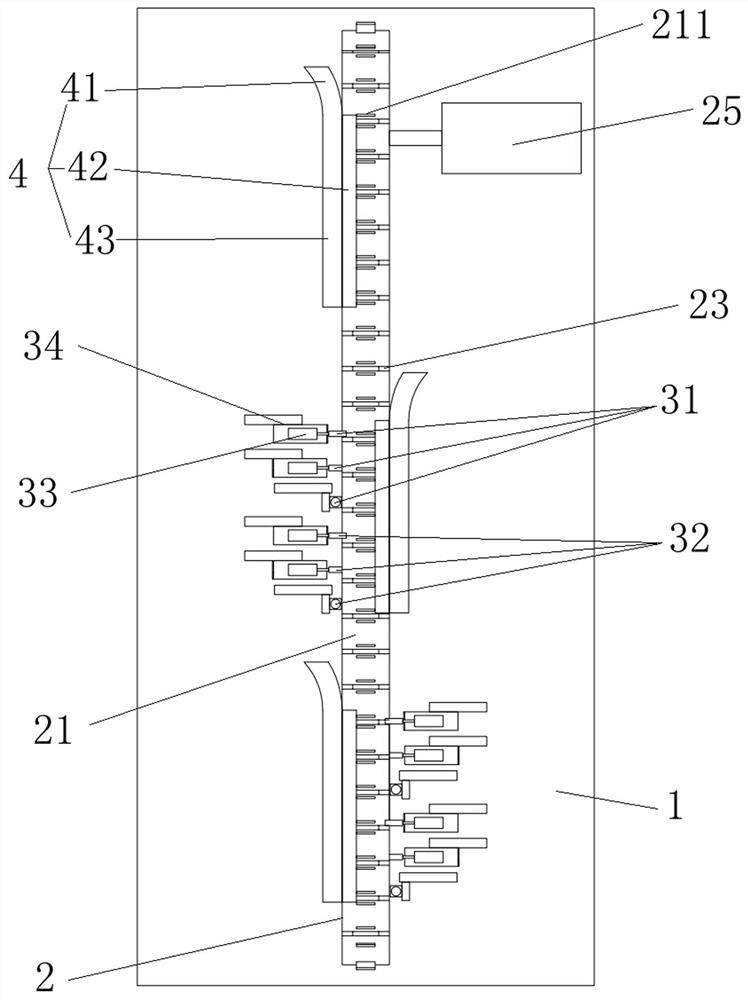

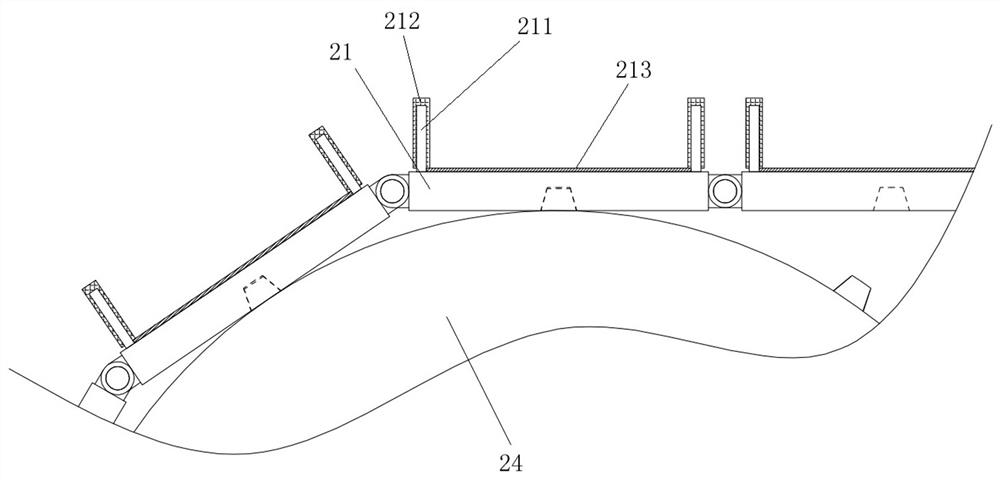

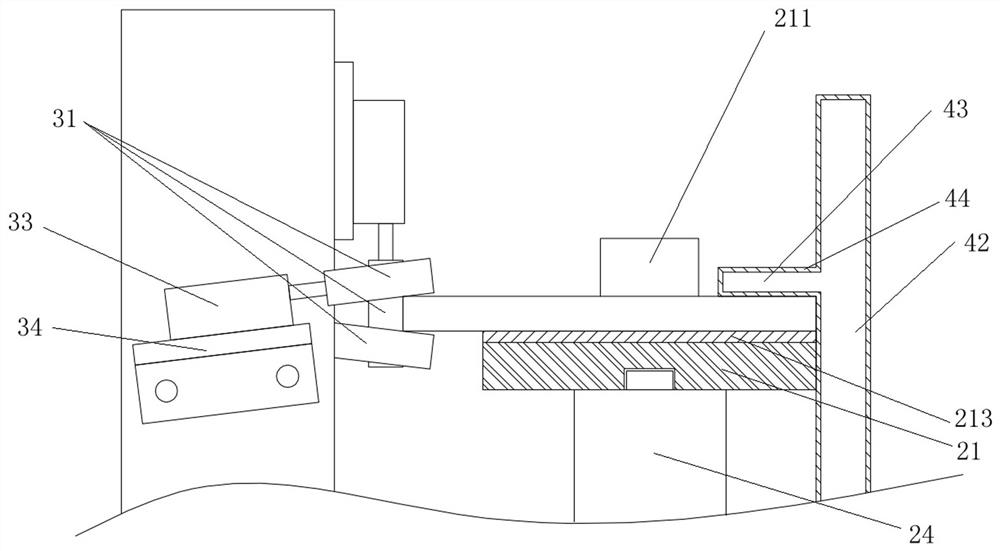

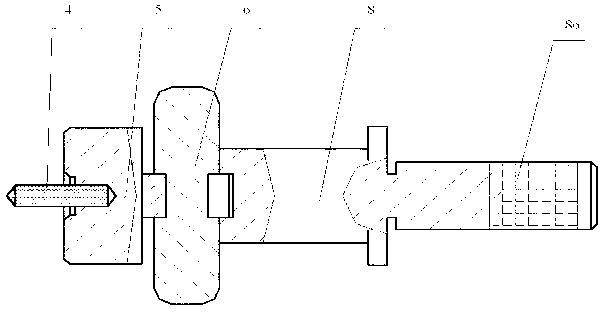

Method for grinding sealing ring

InactiveCN102806507AGrinding force remains constantProcessing state is stableGrinding machinesSurface roughnessEngineering

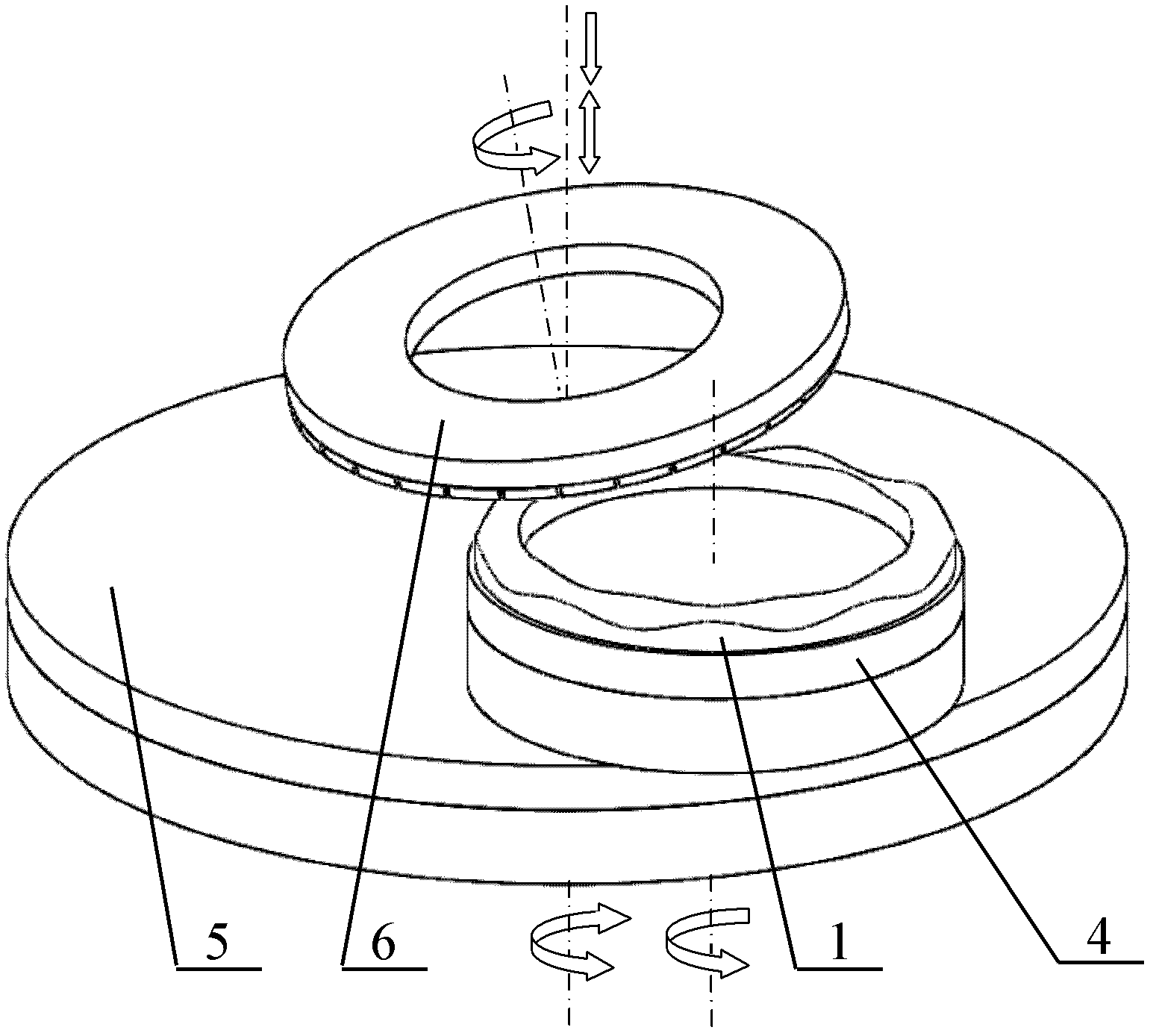

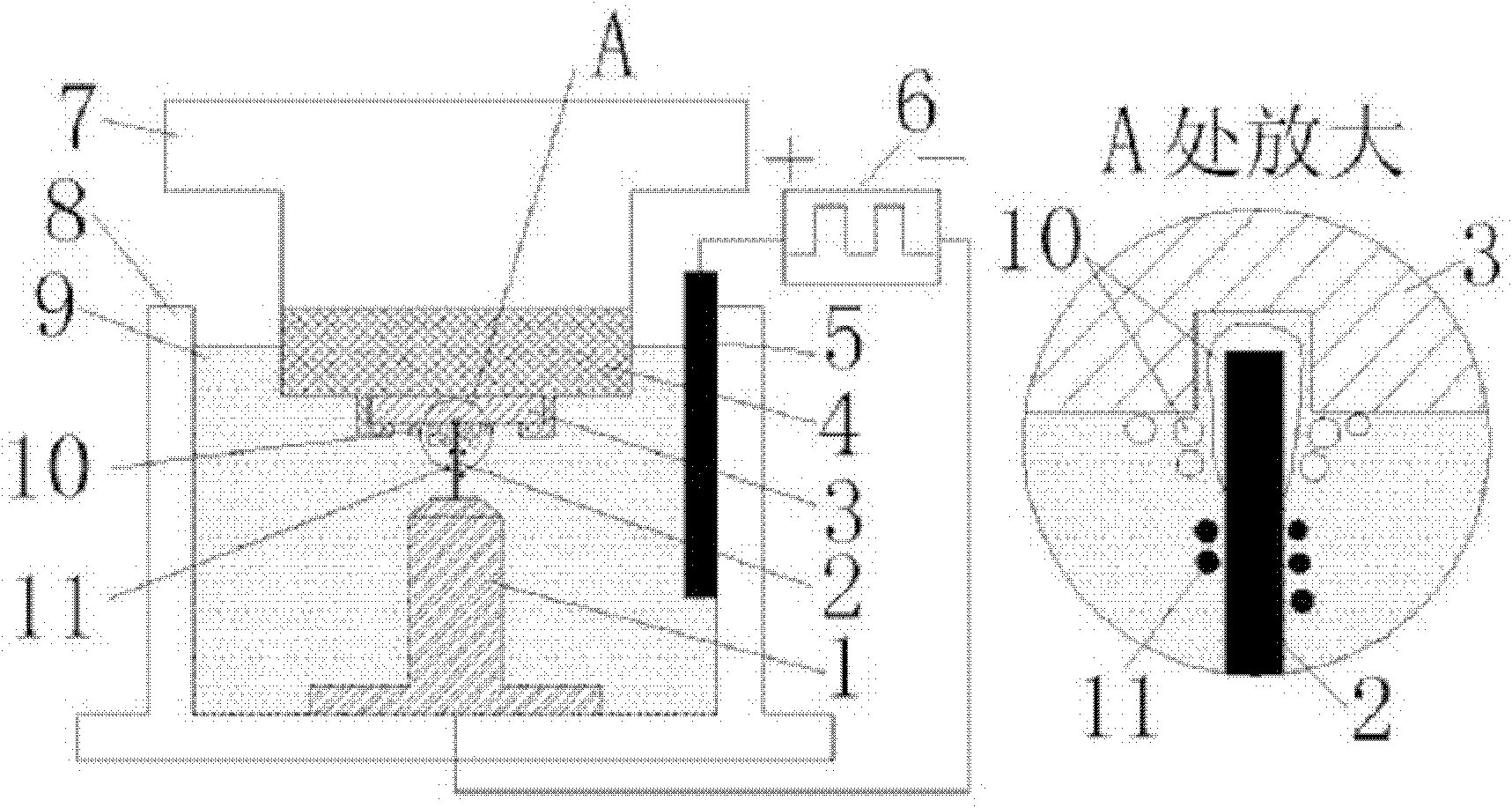

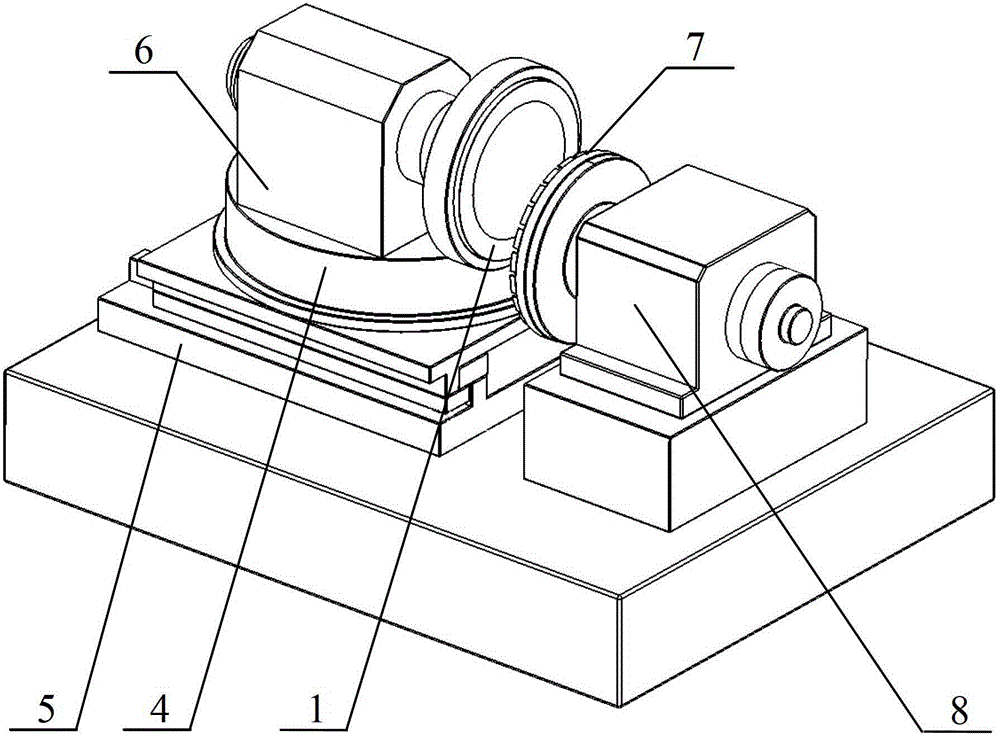

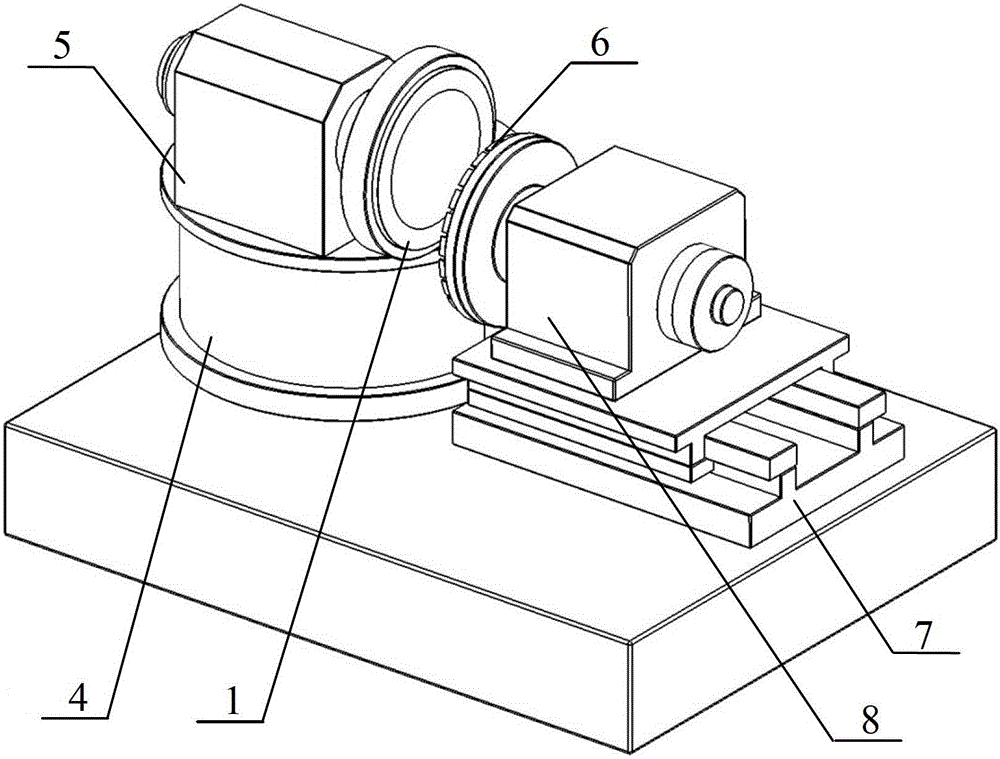

The invention discloses a method for grinding a sealing ring and belongs to the technical field of complex molded surface grinding. The method is characterized in that a workpiece shaft, a cup-shaped grinding wheel, a grinding wheel shaft, a swinging work table, and a linear movement platform are adopted; the workpiece shaft is arranged on the swinging work table; the swinging work table is arranged on the linear movement platform; the direction of the rotation axis of the grinding wheel shaft is parallel to the movement direction of the linear movement platform; the rotation axis of the grinding wheel shaft is perpendicularly intersected with the swinging axis of the work table, and crush grinding is performed through the end face of the cup-shaped grinding wheel. When an inclined corrugated surface is ground, the rotary motion of the workpiece shaft, the swinging of the swinging work table and the linear movement of the linear movement platform are controlled in a coordinated way. When a dam face is ground, the rotation axis of the cup-shaped grinding wheel is parallel to that of the workpiece shaft. The method has the advantages that high-surface shape accuracy and low-surface roughness complex molded surface machining of a fluid dynamic pressure sealing ring consisting of the flat annular dam face and the inclined corrugated surface of which the radial contour is a slightly inclined straight line and the inclined angle changes periodically along the circumferential direction can be realized.

Owner:DALIAN UNIV OF TECH

Machining method of irregular shell component inner cavity bottom annular groove

ActiveCN108406233AProcessing state is stableImprove processing stabilityNumerical controlHigh volume manufacturing

The invention relates to a machining method of an irregular shell component inner cavity bottom annular groove. The machining method comprises following steps that firstly, according to the size and precision needs of the annular ring groove required to be machined in the bottom of an inner cavity of an irregular shell component, a milling cutter used for rough machining of the annular groove anda turn milling knife used for semi finishing of the annular groove and the finishing of the annular groove are customized; secondly, the turn milling knife is subject to trial cutting and adjusting; thirdly, the irregular shell component is clamped on a worktable of a numerical control machining center, and is fixed; fourthly, the annular groove is roughly machined; fifthly, the annular groove issubject to semi-finishing operation; sixthly, the annular groove is subject to finishing. The method is good in machining stability, the machined annular groove is good in surface quality, high in size precision, high in cutting efficiency, capable of achieving large-batch production and good in consistency.

Owner:重庆天骄航空动力有限公司

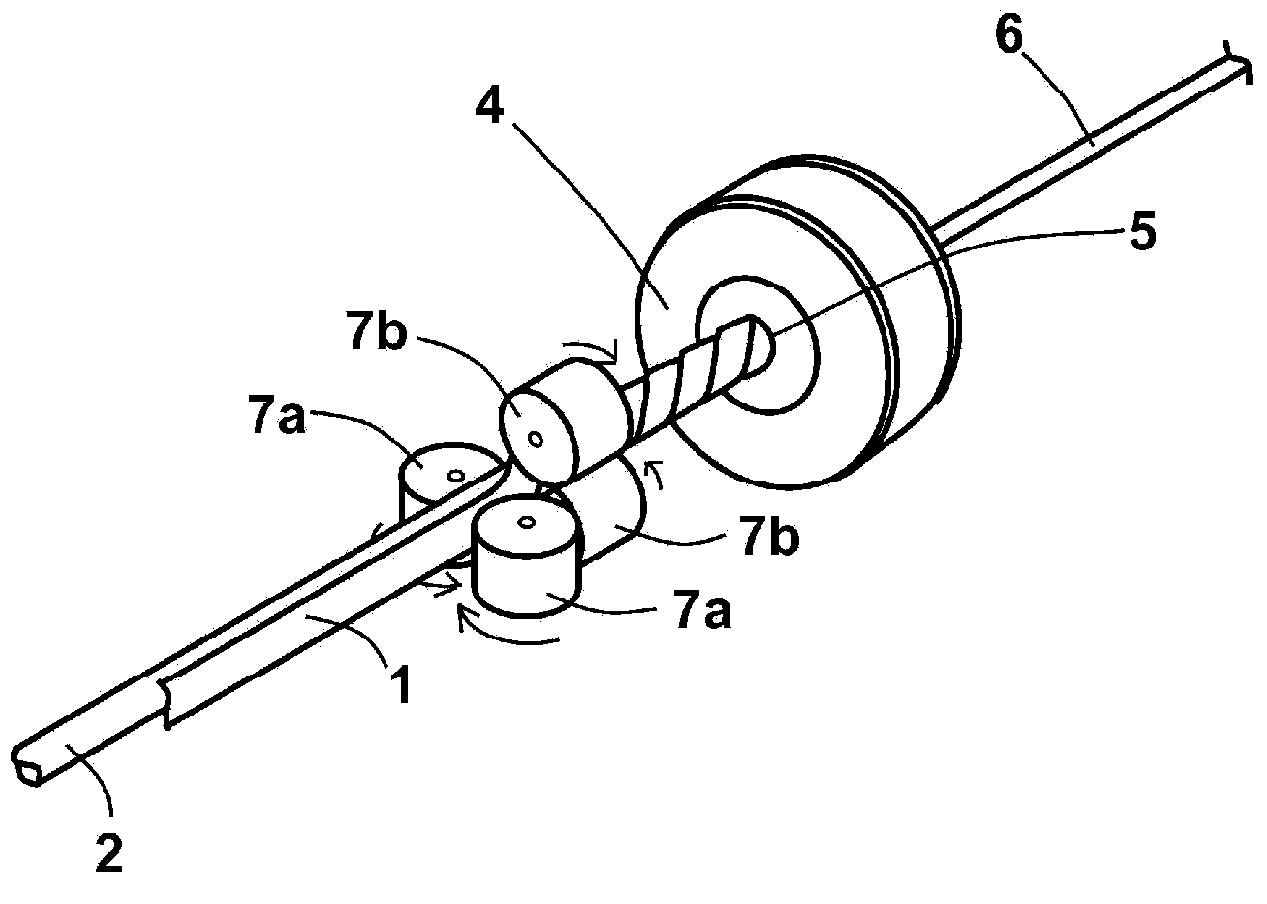

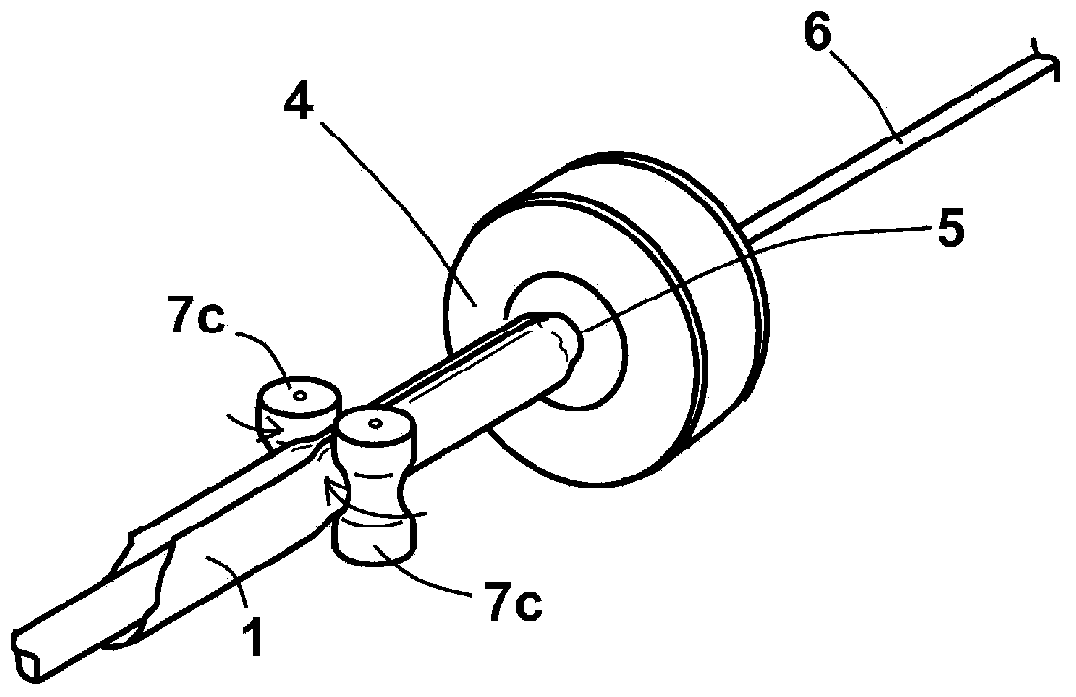

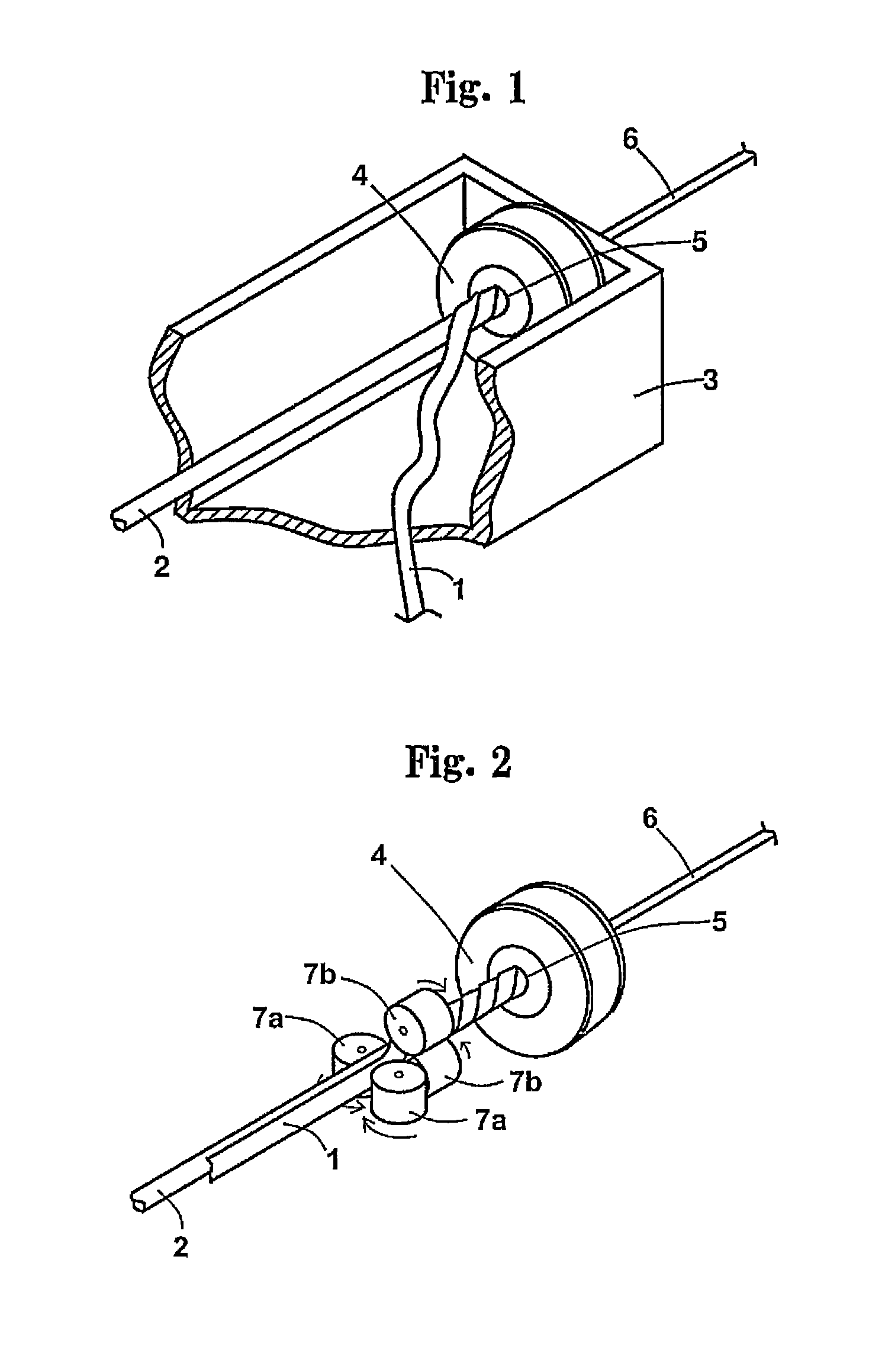

Complex molded surface grinding method for three-axis linkage mechanical sealing ring

InactiveCN102806508AGrinding force remains constantProcessing state is stableGrinding machinesSurface grindingEngineering

The invention discloses a complex molded surface grinding method for a three-axis linkage mechanical sealing ring and belongs to the technical field of complex molded surface grinding. The method is characterized in that a workpiece shaft, a cup-shaped grinding wheel, a grinding wheel shaft, a swinging work table, and a linear movement platform are adopted; the workpiece shaft is arranged on the swinging work table; the grinding wheel shaft is arranged on the linear movement platform; the rotation axis of the grinding wheel shaft is perpendicularly intersected with the swinging axis of the swinging work table; and the direction of the rotation axis of the grinding wheel shaft is parallel to the movement direction of the linear movement platform, and crush grinding is performed through the end face of the grinding wheel. When an inclined corrugated surface is ground, the rotary motion of the workpiece shaft, the reciprocating swinging of the swinging work table and the linear movement of the linear movement platform are controlled in a coordinated way. When a dam surface is ground, the rotation axis of the cup-shaped grinding wheel is parallel to that of the workpiece shaft. The method has the advantages that the high-surface shape accuracy and low-surface roughness complex molded surface machining of a fluid dynamic pressure sealing ring consisting of the flat annular dam face and the inclined corrugated surface of which the radial contour is a slightly inclined straight line and the inclined angle changes periodically along the circumferential direction can be realized.

Owner:DALIAN UNIV OF TECH

Clamping device for a tool

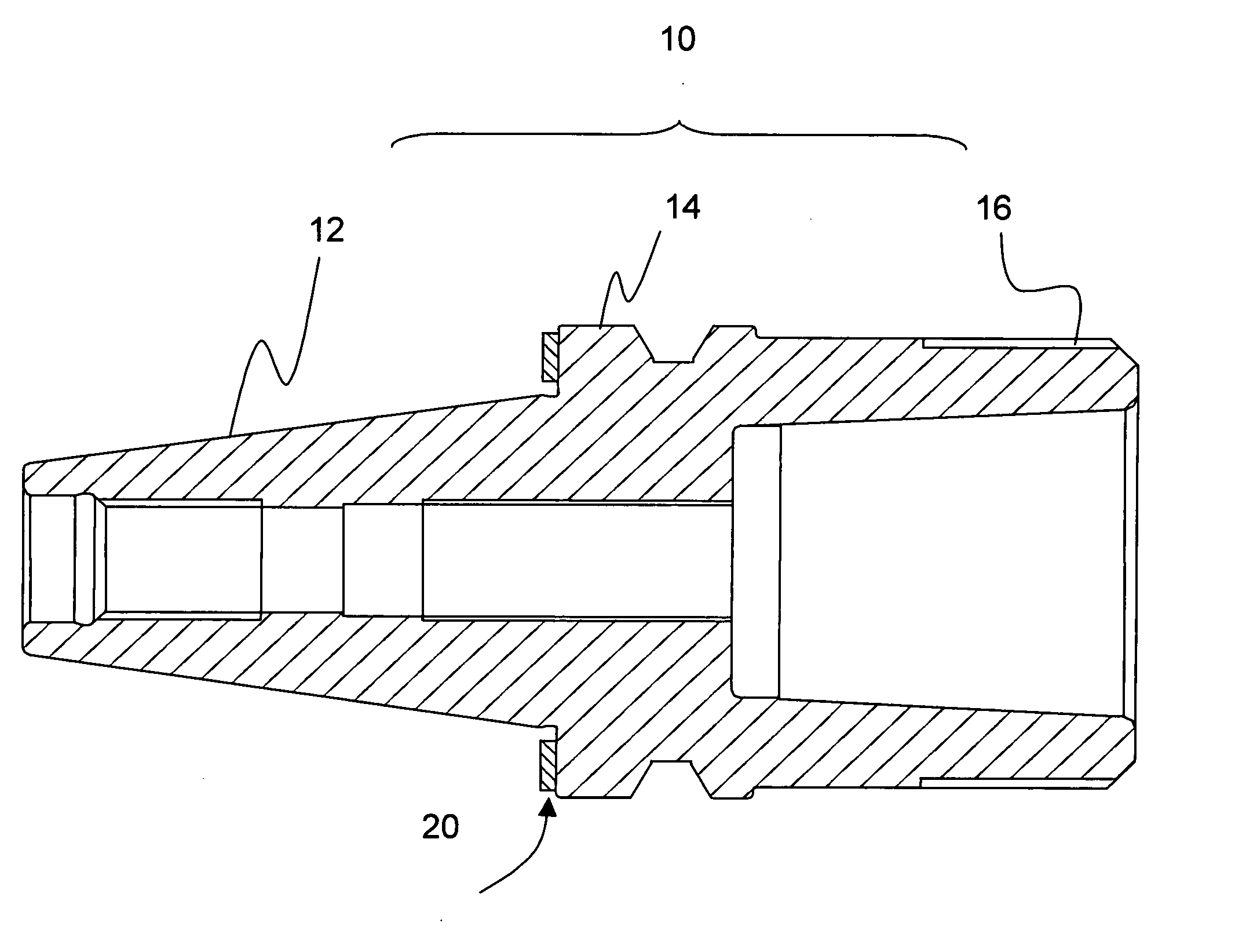

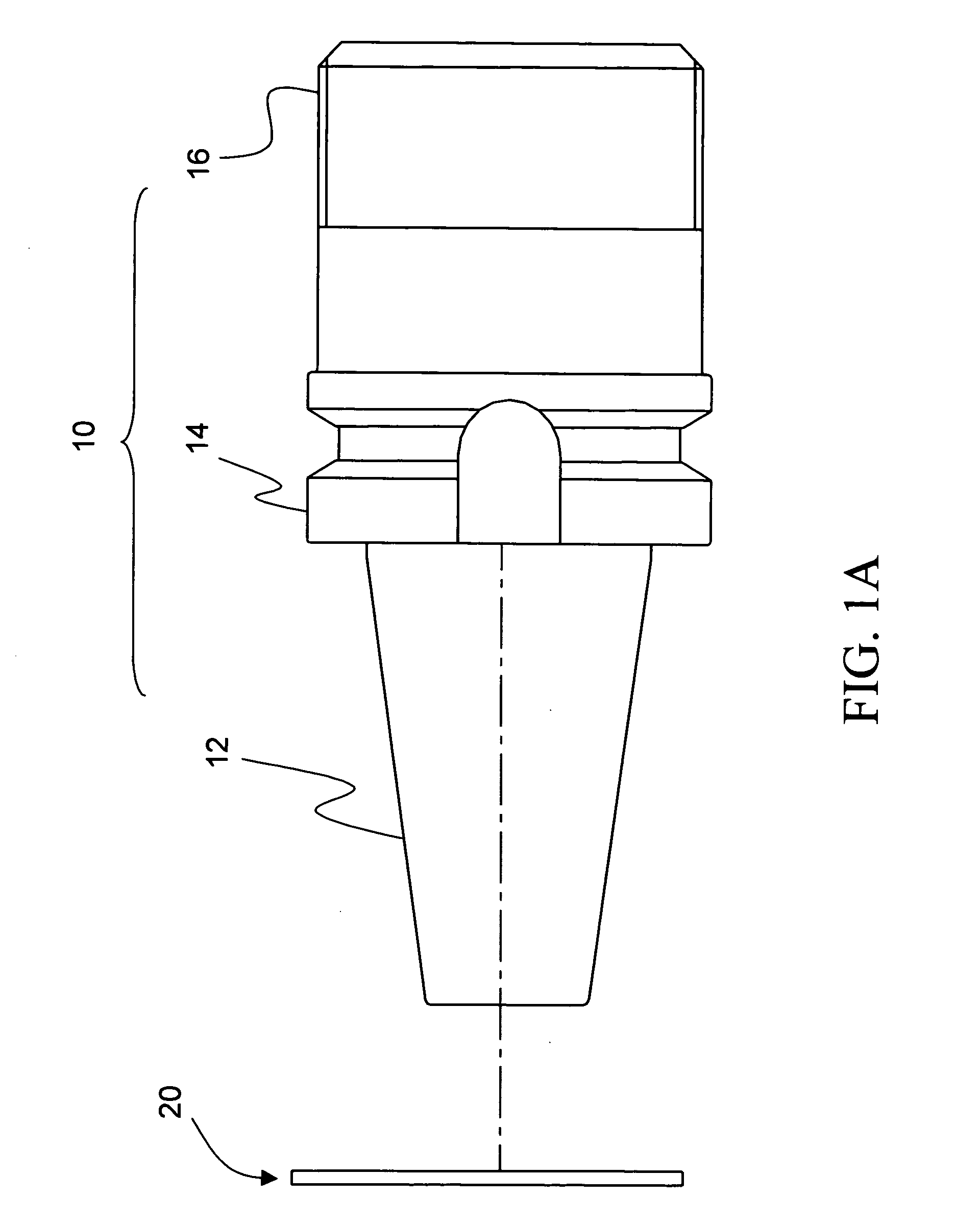

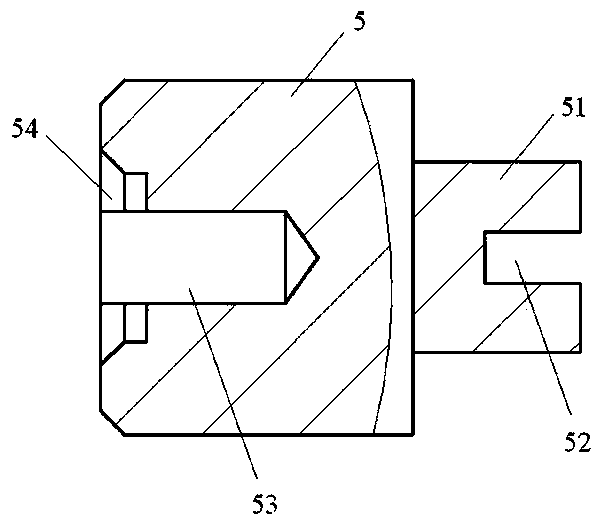

InactiveUS20070098512A1Processing state is stableImprove accuracyTool workpiece connectionThread cutting machinesMachine pressEngineering

A clamping device for a tool being joined to a machine includes a clamping member and a fitting ring. Thickness of the fitting ring being greater than a length between the conical part and the holding part of the clamping member allows the machine pressing against the fitting ring in case of the machine clamping the conical part with more steady clamping and achieving an effect of cushion.

Owner:PRIMETOOL MFG

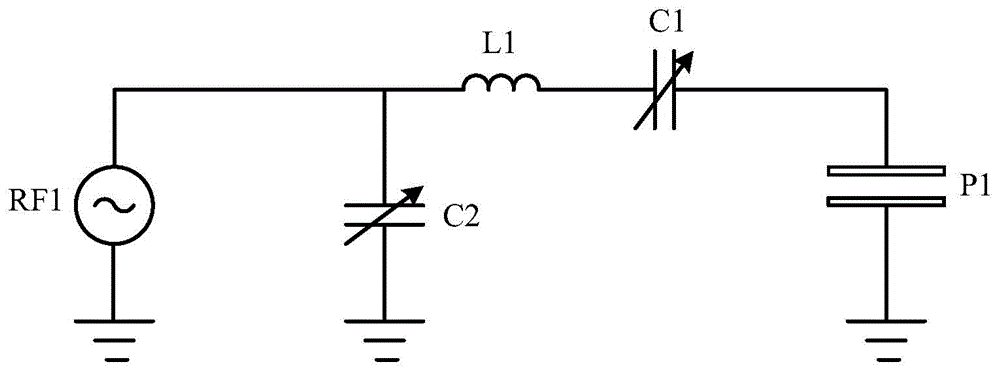

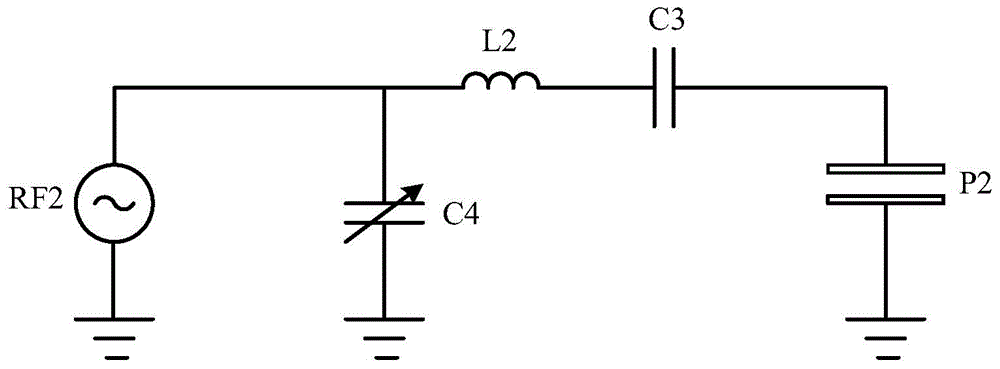

Impedance matching method for plasma processing device

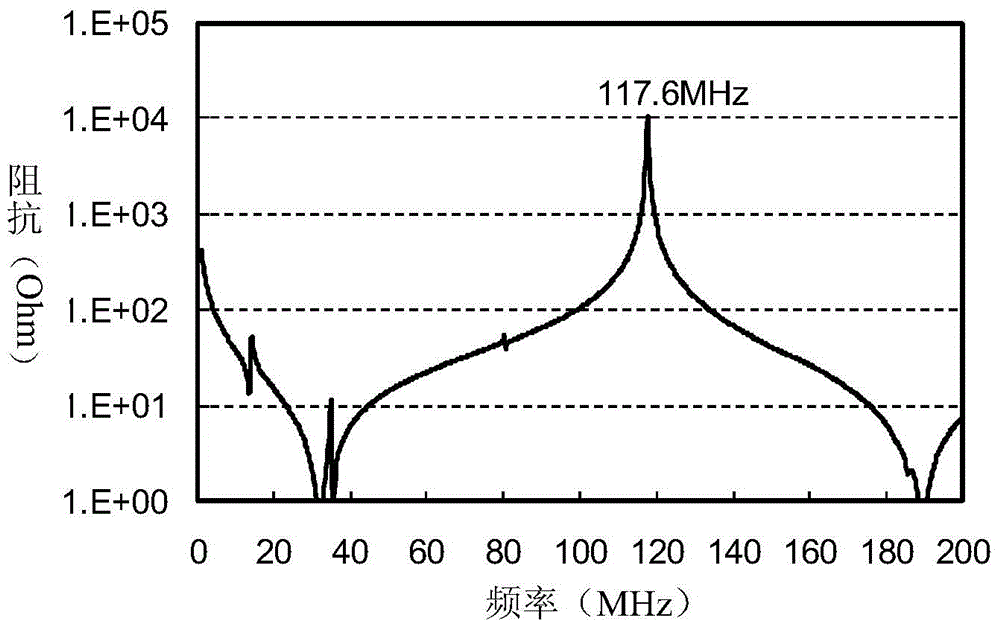

ActiveCN105810547AStable stateQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceInductor

An impedance matching method for a plasma processing device is disclosed. The method comprises the following steps: the impedance matching device is connected between a plasma processing device and a variable frequency power source; the impedance matching method comprises the variable frequency power source, a first variable capacitor, a second variable capacitor and an electric inductor; a resonant frequency scope of the plasma processing device is obtained; the impedance matching device enters a frequency adjusting mode which comprises a plurality of frequency adjusting steps; an output frequency of the variable frequency power source in a next step is obtained; if the output frequency in the next step is not in the resonant frequency scope, loop execution the frequency adjusting steps is carried out till impedance matching is realized; if the output frequency in the next step is in the resonant frequency scope, the frequency adjusting mode is halted, and the impedance matching device enters a capacitance adjusting step; the first variable capacitor is adjusted according to currently detected reflection power signals of the plasma processing device. The impedance matching method for the plasma processing device enables state stability of plasmas, plasma processing quality improvement, and plasma processing state stability.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

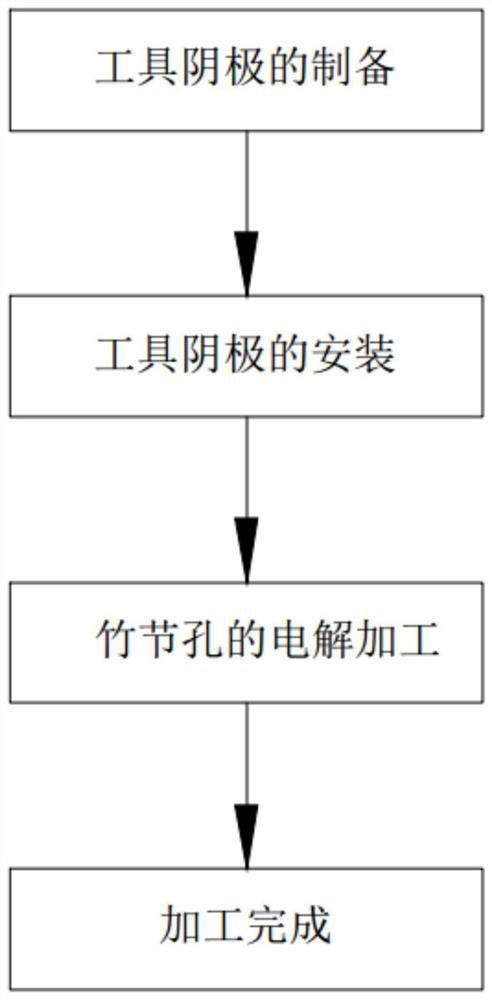

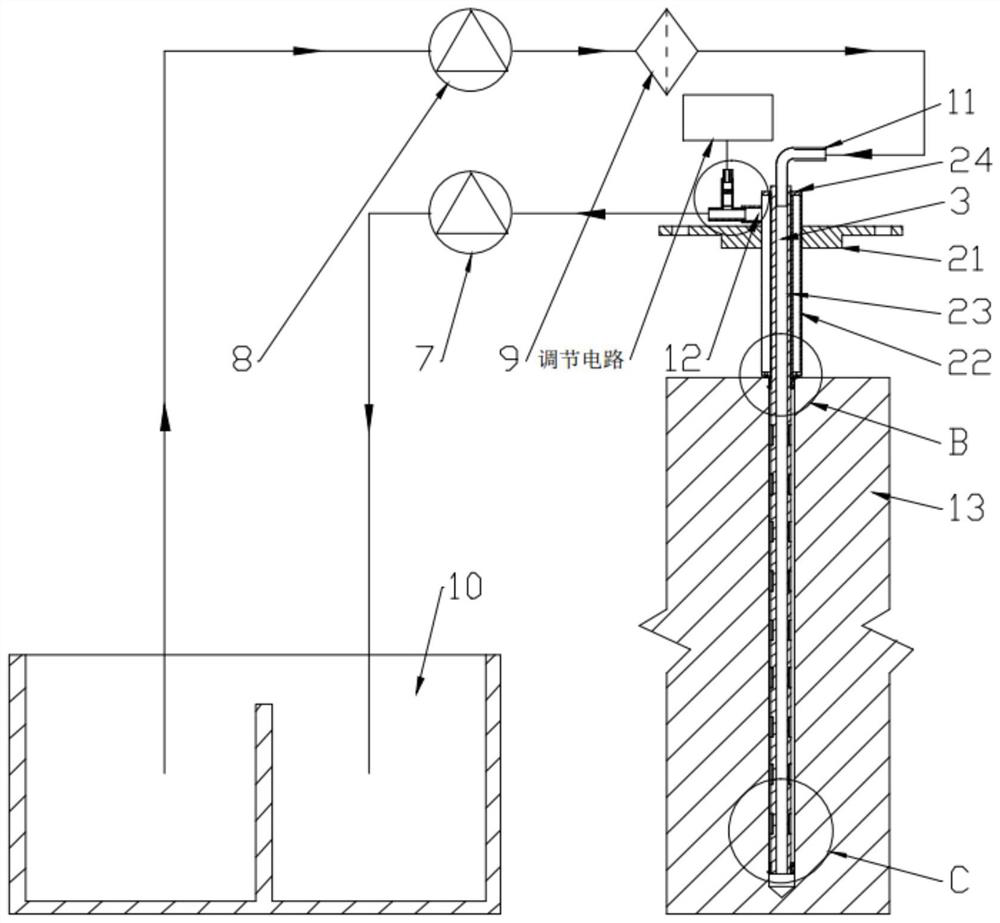

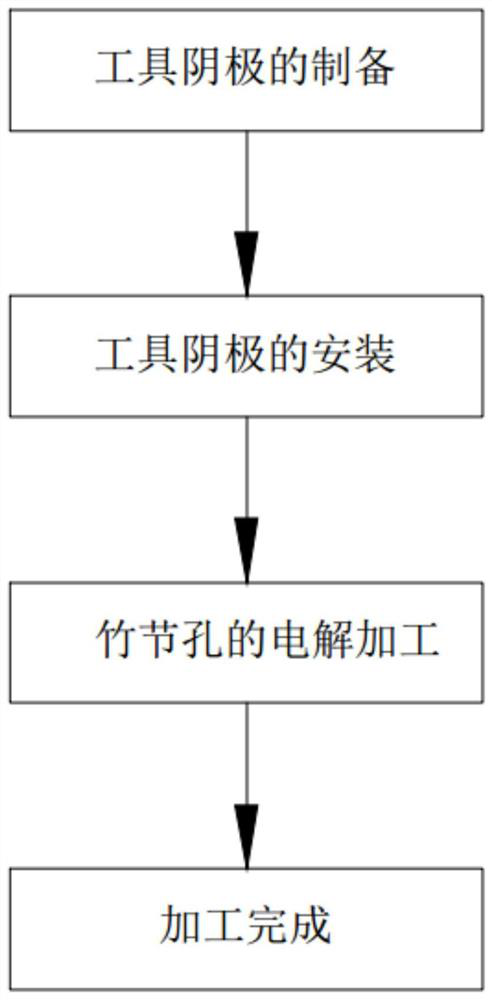

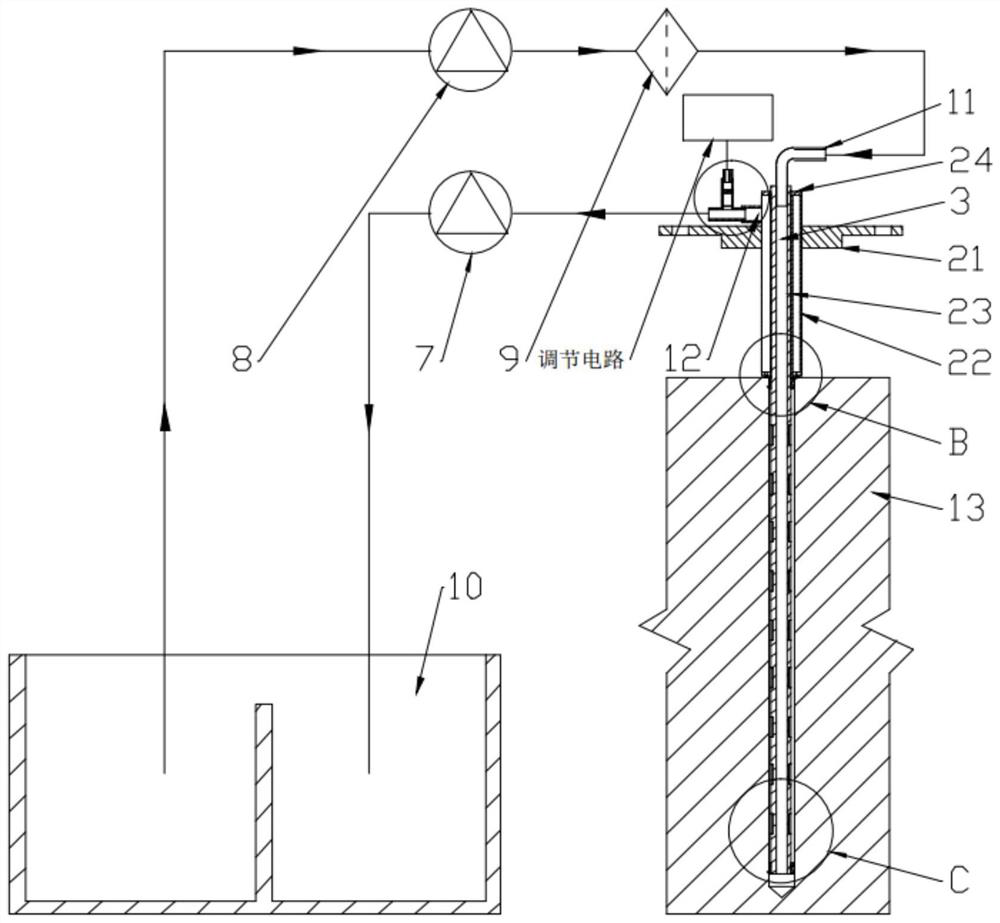

Precise electrolytic machining process for multi-tooth turbine blade

ActiveCN113182625AStable temperature controlAccelerate the lossMachining electrodesMachining working mediaElectrolytic agentTurbine blade

The invention discloses a precise electrolytic machining process for a multi-tooth turbine blade, and relates to the technical field of electrolytic machining for turbine blades. The precise electrolytic machining process for the multi-tooth turbine blade comprises the steps of preparation for a tool cathode, installation for the tool cathode, electrolytic machining for a bamboo joint hole and the like. According to the invention, the defects of a traditional method are overcome, and under the condition of high voltage, the stability of the machining process can still be guaranteed, so that the electrolytic machining efficiency is increased, and the machining time is shortened; and when the temperature of an electrolyte rises, the flow speed of the electrolyte can be adjusted through an adjusting module so as to accelerate heat dissipation of an electrolytic machining area, so that stable control over the temperature of the electrolyte is achieved.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

Band-shaped lubricating material for dry wiredrawing and process for producing same

InactiveCN103649286APrevent sinteringProcessing state is stableAdditivesBase-materialsWire speedLow speed

Owner:KYOEISHA CHEM CO LTD

Layered machining technology of laser equipment

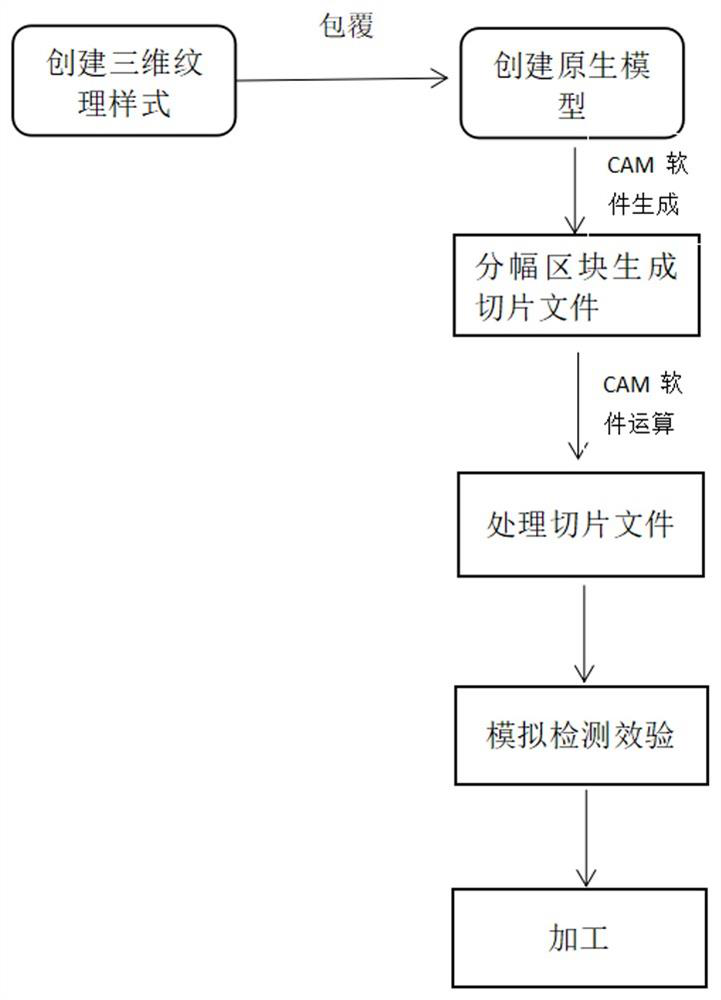

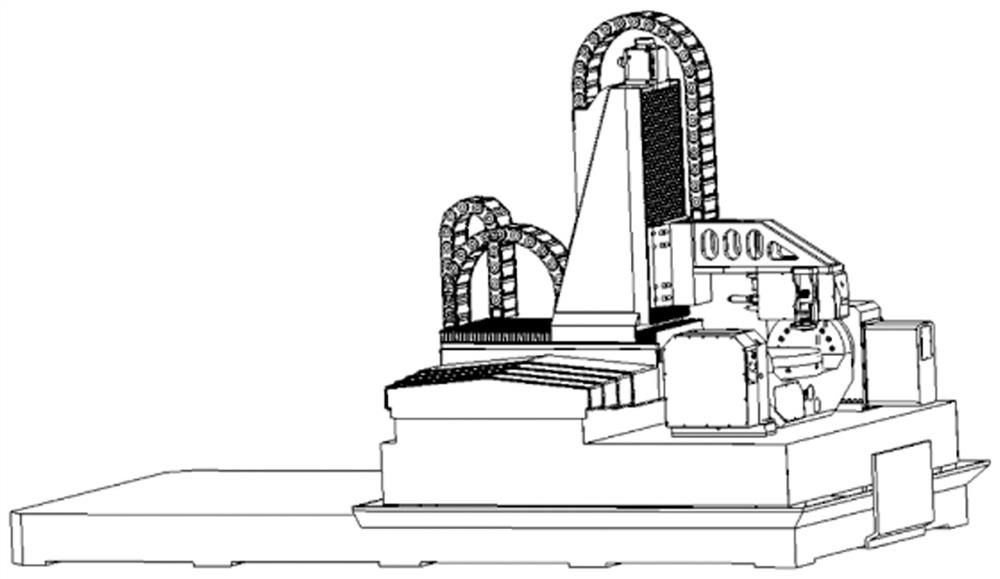

PendingCN112719606ABeautiful appearanceDifficulty of SimplificationLaser beam welding apparatusLaser processingEngineering

The invention provides a layered machining technology of laser equipment. The layered machining technology comprises a laser device, a transfer assembly for driving the laser device to perform three-axis operation, and a five-axis convex rotating wheel table positioned below the laser device and used for a product to be placed, wherein a laser head is arranged in the laser device, and the layered machining technology comprises the following steps of S1, framing, specifically, coating a native model of a product needing to be covered with textures obtained through conversion or created by three-dimensional software with a three-dimensional texture style obtained through conversion or created by CAM software, generating framing blocks by utilizing the CAM software, and generating a slice file; S2, machining depth setting, specifically, setting the machining depth according to the requirement of product machining precision, and automatically calculating a framed hierarchical three-dimensional texture file through CAM software; S3, operation; and S4, machining. By means of the layered machining technology of the laser equipment, layered laser machining can be conducted on irregular three-dimensional products, the laser machining quality and machining precision of the products are improved, and large-scale assembly line production can be achieved.

Owner:镭泽精密制造(苏州)有限公司

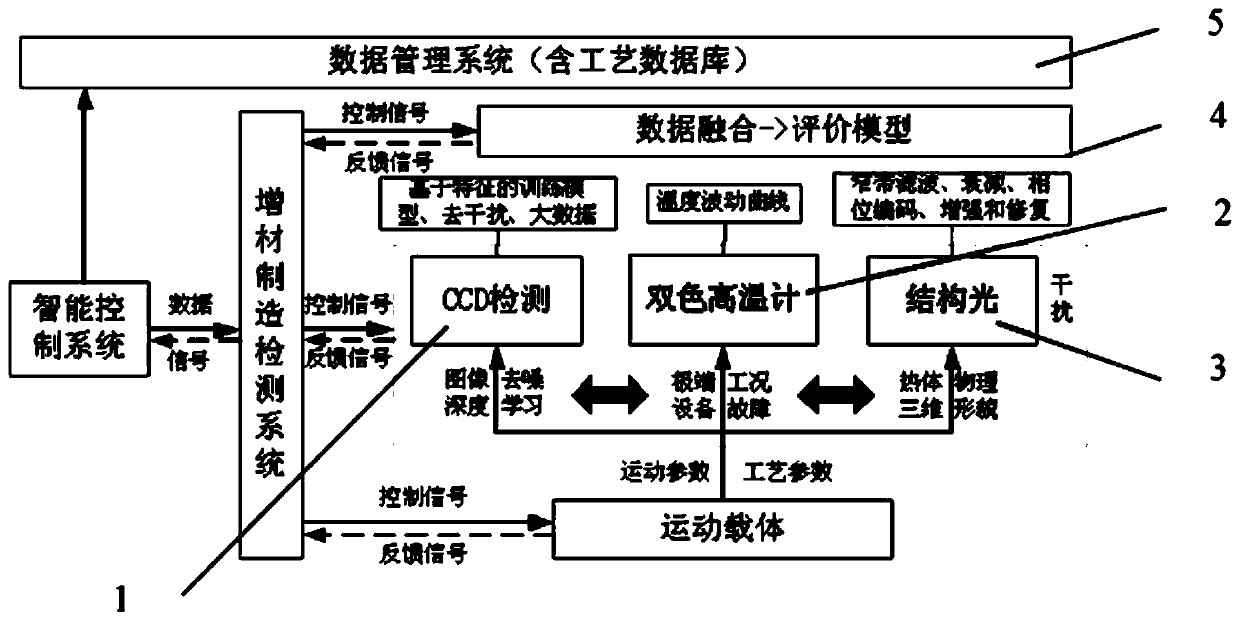

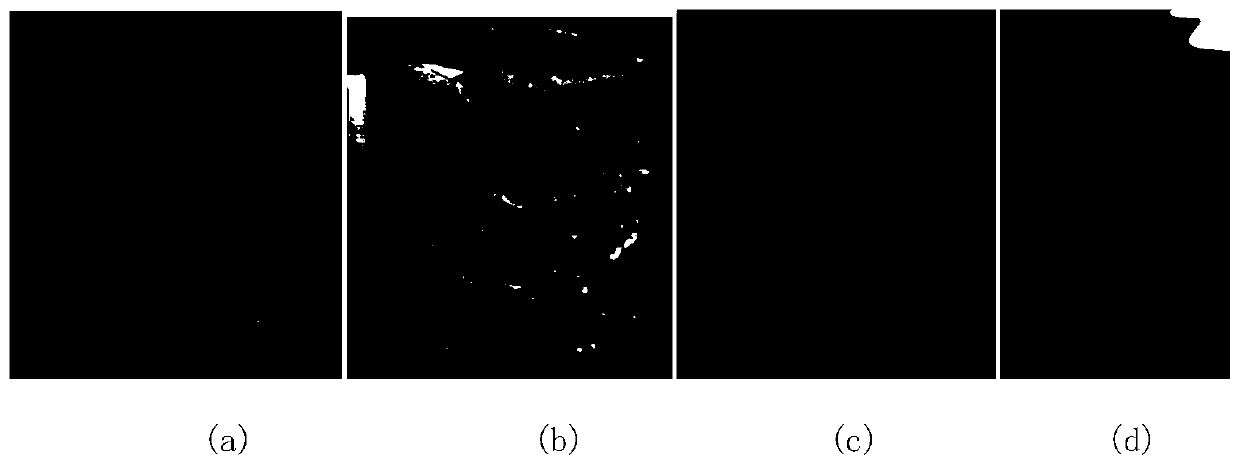

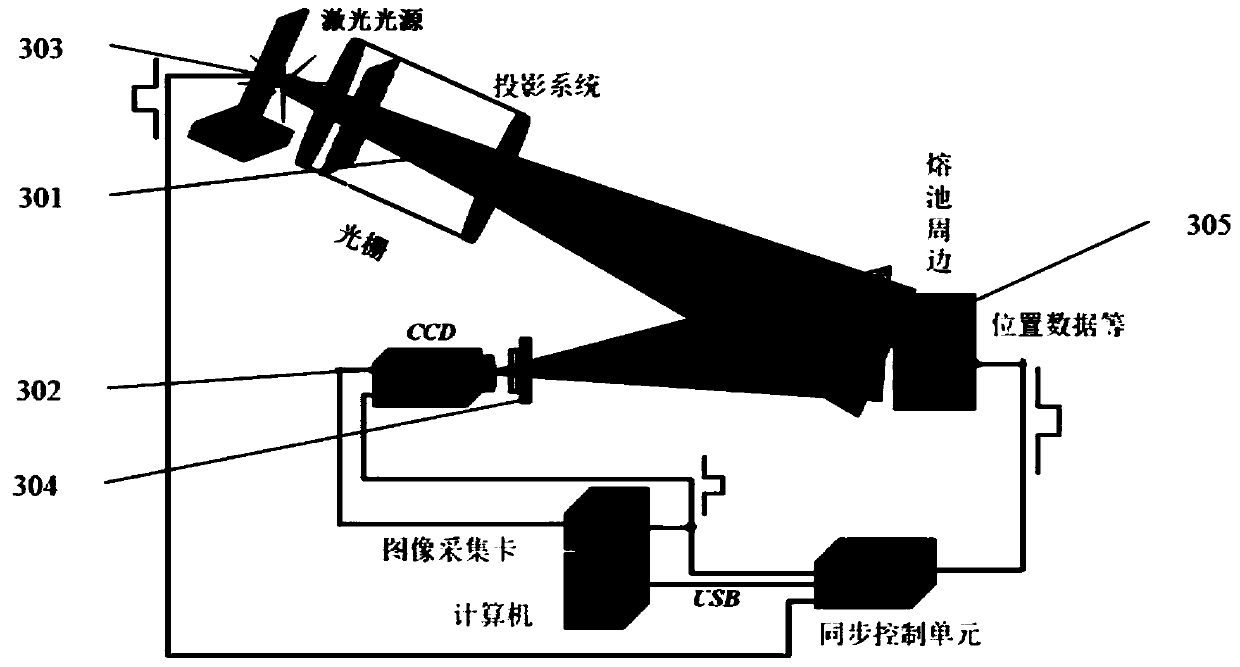

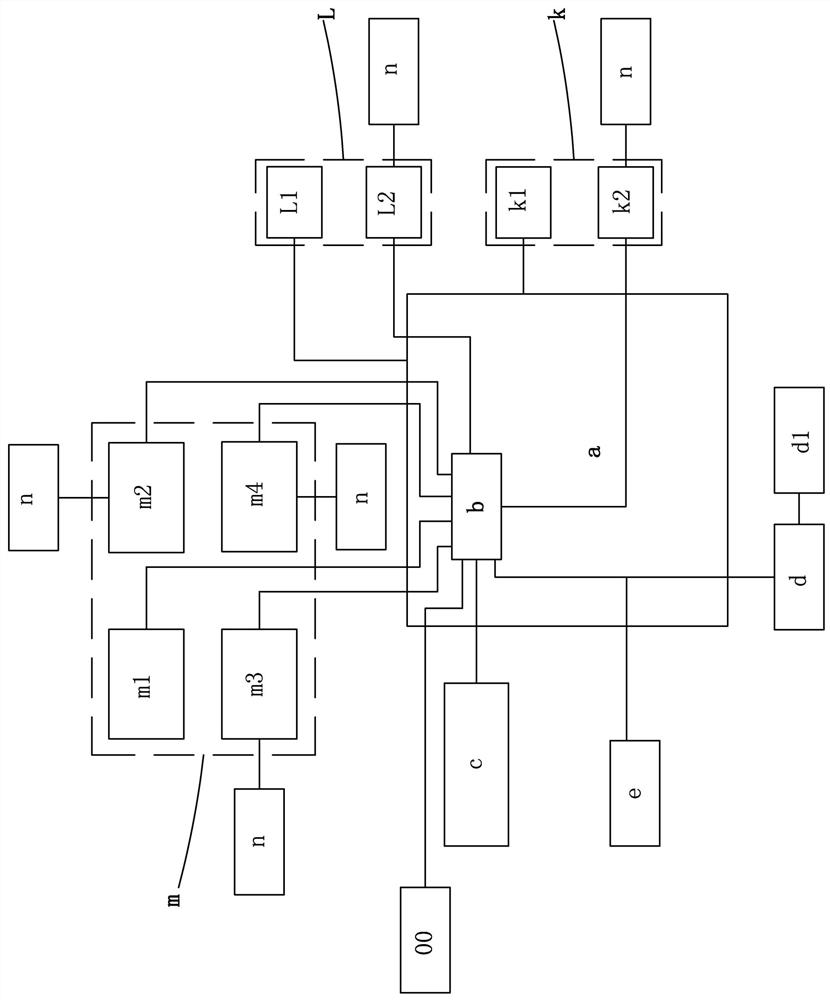

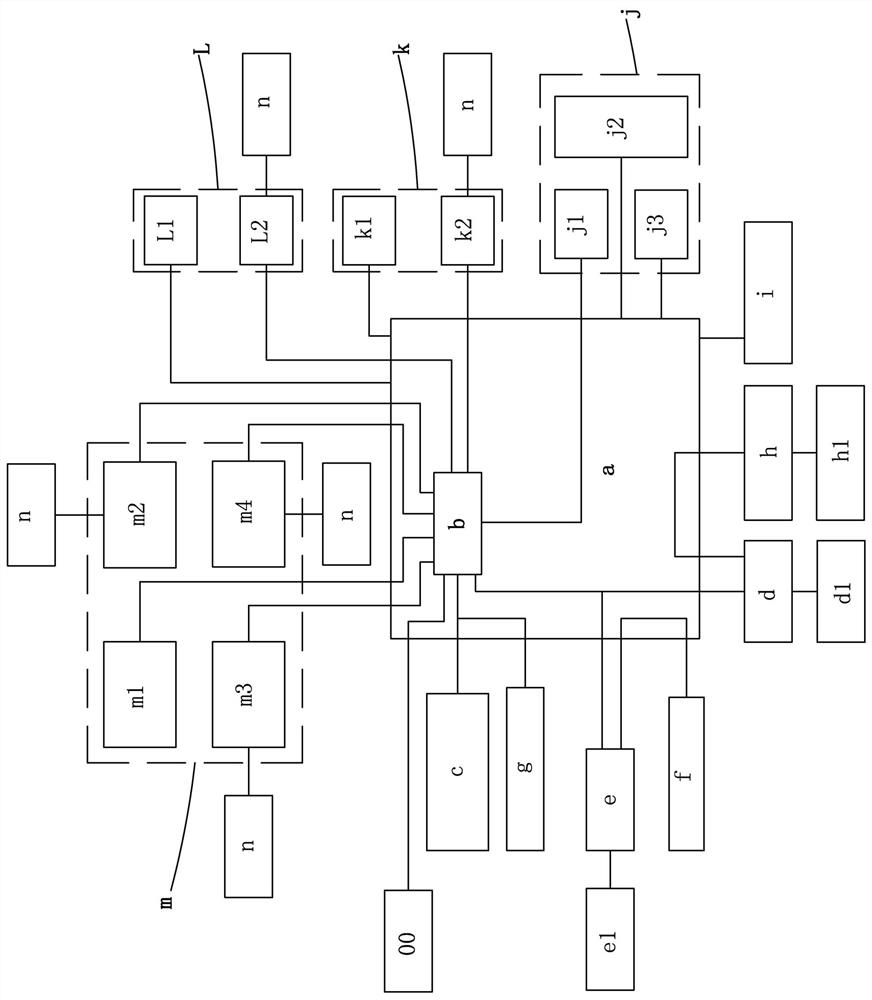

Adaptive control system architecture for powder-feeding laser additive manufacturing

ActiveCN110597065AProcessing state is stableStable and high-performance laser three-dimensional forming partsAdaptive controlData acquisitionData management

The invention belongs to the technical field of additive manufacturing control, and particularly relates to an adaptive control system architecture for powder-feeding laser additive manufacturing. Thesystem comprises a complete system architecture including process planning, equipment composition, an industrial control system, data acquisition and display, data management, online detection, and PSD control. The adaptive control system can not only significantly improve the forming quality and forming precision of the powder-feeding laser additive, but also can achieve the purposes of increasing the strength of the formed part and reducing the external defects of the formed part.

Owner:中国兵器装备集团自动化研究所有限公司

Band-shaped lubricating material for dry wiredrawing and process for producing same

InactiveUS20140290320A1Processing state is stableAvoid seizuresWork treatment devicesCeramic shaping apparatusLow speedBand shape

Provided is an innovative belt-shaped lubricating material for dry wiredrawing which not only can be used under severe wiredrawing processing conditions such as those of high temperature / high pressure / high speed as well as conventional powdered or granular lubricants for dry wiredrawing but also can cope with diameter reduction to a wide range of wire diameters ranging from a small diameter to a large diameter and a wide range of linear speeds ranging from a low speed to a high speed, has excellent functionalities such as lubricity, followability, spreadability, adhesiveness, heat resistance, processability, workability, safety, durability and productivity irrespective of a processed shape, is effective in improving work environments and is friendly to the global environment.The belt-shaped lubricating material for dry wiredrawing includes a film containing 10 to 90% by weight of a metal salt of a saturated fatty acid and 10 to 90% by weight of a thermoplastic resin.

Owner:KYOEISHA CHEM CO LTD

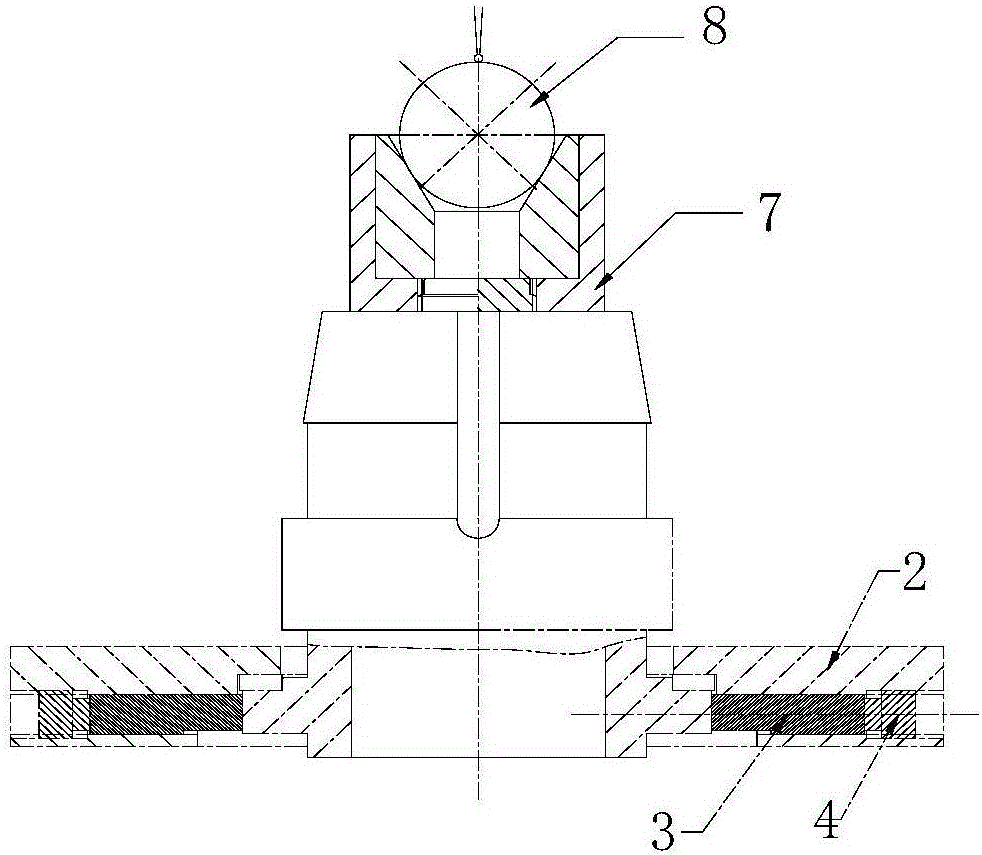

Hemispherical dynamic pressure bearing part grinding tool and grinding method

ActiveCN105834885ASolve the technical problems of precision grindingMeet working clearance requirementsGrinding machine componentsLapping machinesMicrometerEngineering

The invention provides a hemispherical dynamic pressure bearing part grinding tool and grinding method. The grinding tool comprises a transmission base, a tool main shaft and a positioning block; pins are evenly distributed on the periphery of the transmission base, and socket head cap screws are arranged on the outer sides of the pins; the bottom end of the tool main shaft is arranged in the center of the transmission base, and a positioning block is arranged at the top end of the tool main shaft; and a horn opening used for containing steel balls is arranged on the positioning block. The grinding method includes the steps that (1) the accuracy of the gyration center of a main shaft of a grinding machine is adjusted; (2) the coincident accuracy of a swing shaft of the grinding machine and the perpendicular main shaft axis is adjusted; (3) the height of the sphere centre of the main shaft of the grinding machine is adjusted; and (4) grinding is carried out. By means of the hemispherical dynamic pressure bearing part grinding tool and grinding method, the technical problems in hemispherical part premise grinding are solved; compared with traditional manual grinding and polishing, the high machining efficiency is achieved; and meanwhile, in the premise grinding process, the machining state is stable, the high machining quality can be achieved, the machining accuracy can reach 0.02 micrometer, and the requirement for a working gap of a dynamic pressure bearing is met.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Reversed alignment electrochemical discharge machining method and device

The invention provides a reversed alignment electrochemical discharge machining (RA-ECDM) method in the field of special machining. A tool electrode is arranged below a workpiece. The tool electrode is fixed on the bottom surface of a work slot by an electrode holder and is soaked in electrolyte solution. The workpiece is connected with a feeding device of a machine tool. The feed motion in the machining process is implemented by feeding of the workpiece. The invention also provides a corresponding device. According to the invention, by changing the relative positions between the tool electrode and the workpiece, machining scraps generated in the machining process can be easily discharged under the action of gravity, so that the flowing capacity of electrolyte in a machining process in the machining process is reinforced. Moreover, due to the adoption of the reversed layout, air bubbles generated in the electrolytic reaction can be concentrated around the end part of the electrode below the machined workpiece to form a stable air film, so that the stability and the machining depth of the ECDM are effectively improved.

Owner:SHANGHAI JIAOTONG UNIV

Sleeve embedding groove type clamp spring component and method for boring thick-plate type hard alloy

InactiveCN102699392BComplete appearanceProcessing state is stableTransportation and packagingTool adaptersThick plateAlloy

The invention discloses a sleeve embedding groove type clamp spring component and a method for boring a thick-plate type hard alloy. The sleeve embedding groove type clamp spring component comprises a drill bit, a top end sleeve, a rod body piece, a clamp spring positioning piece and a sleeve. The method for boring the thick-plate type hard alloy by using the sleeve embedding groove type clamp spring component comprises the following steps: step 1. fixing the hard alloy material; step 2. clamping the sleeve embedding groove type clamp spring component through a spanner drill chuck; and step 3. boring the hard alloy material. By the adoption of the sleeve embedding groove type clamp spring and the method, through holes can be effective bored, the appearance is complete, the state of the entire machining process is stable; and moreover, the sleeve embedding groove type clamp spring and the method are beneficial to process.

Owner:SHANGHAI MARITIME UNIVERSITY

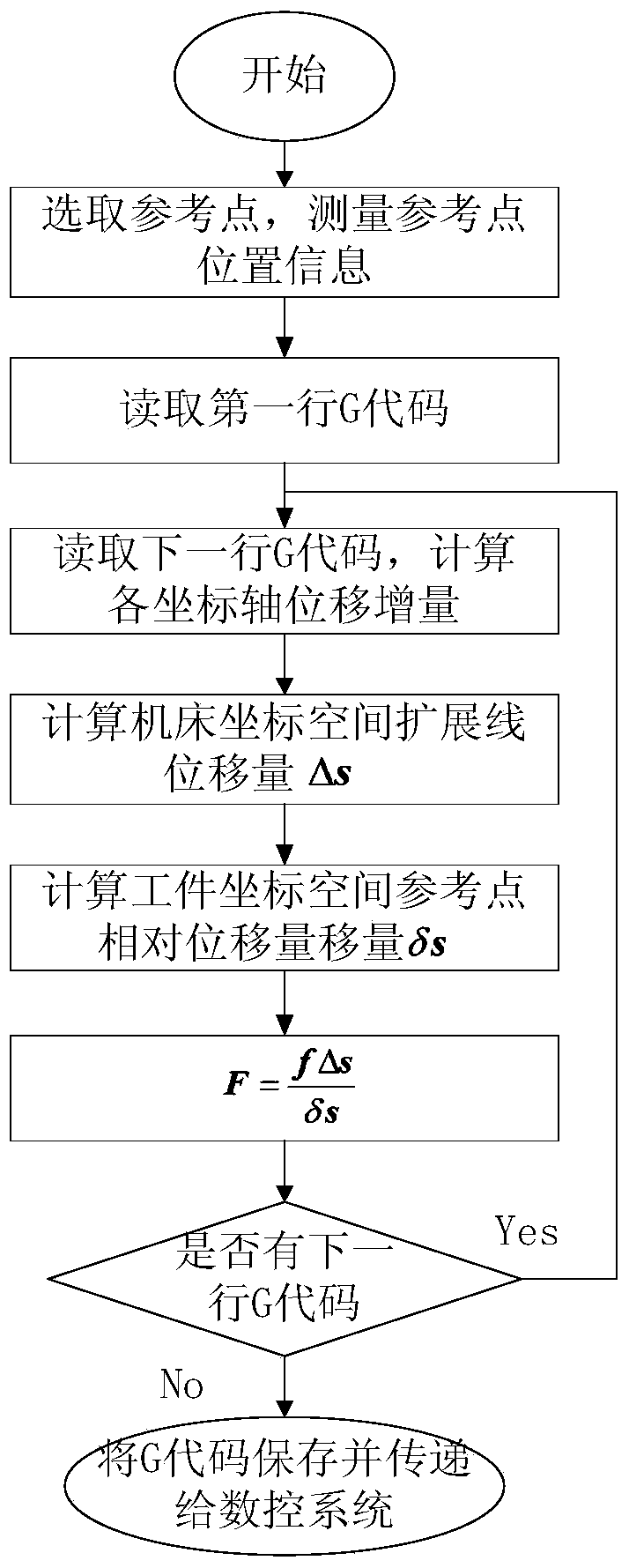

Data processing method of multi-axis linkage electric discharge machining feed rate post-processor based on space mapping

ActiveCN105930589BProcessing state is stableReduce processing efficiencyGeometric CADComplex mathematical operationsElectric dischargeSpatial mapping

The invention relates to the data processing method of a multi-axis linked electric discharge machining feeding speed postprocessor based on spatial mapping. With respect to electric discharge machining participated by a rotation axis, a control object is a relative distance between an electrode and a workpiece. According to the method, through start from a model of the electrode and the workpiece, displacements of each line of G codes under a machine tool coordinate system and a workpiece coordinate system are solved through spatial mapping; the ratio of the displacements is solved; the ratio is multiplied by an originally planned feeding speed of each line of G codes; and a machining program is updated. According to the method, speed fluctuation resulting from spatial transformation can be greatly reduced; the discharge state of movement participated by the rotation axis is protected from instability; occurrence of open circuit and short circuit states can be reduced; and the electric discharge machining efficiency can be improved.

Owner:SHANGHAI JIAOTONG UNIV

A Feed Rate Post-Processor Design Method for Multi-axis EDM

ActiveCN105643030BProcessing state is stableLarge speed fluctuationElectric circuitsRotational axisWeighted average method

The invention relates to a designing method of a feeding speed postprocessor used for multi-axis linkage electrosparking. For multi-axis linkage electrosparking machining in which rotary axes are involved, the control object is the relative distance between an electrode and a workpiece, and the unknown radiuses of the rotary axes cause fluctuation of the machining speed. From models of the electrode and the workpiece, the movement coefficients of all movement axes are defined through the rotary radiuses. On the basis, each line of G code movement coefficients are synthesized through a weighted average method to obtain a movement proportionality coefficient, the originally planned feeding speed of each line of G codes is multiplied by the movement proportionality coefficient of the line, and the machining program is updated. Speed fluctuation caused by unmatched dimension can be greatly reduced, the unstable discharging state of movement in which the rotary axes are involved is avoided, the frequency of open circuits and short circuits is reduced, and the electrosparking efficiency is improved.

Owner:SHANGHAI JIAOTONG UNIV

Efficient machining method for complex window in thin-wall carburizing area

PendingCN113857779AReduce overhang lengthImprove rigidityPositioning apparatusMaintainance and safety accessoriesLayer removalEnd mill

The invention relates to an efficient machining method for a complex window in a thin-wall carburizing area, and belongs to the technical field of cutting machining. The method comprises the steps that firstly, a small-diameter end mill is adopted to conduct layered removal on a carburized layer from two perpendicular angles of a window, then a drill bit is adopted to conduct drilling removal on four corner positions of the window, and finally a large-diameter end mill is adopted to conduct layered removal on the window.

Owner:HARBIN DONGAN ENGINE GRP

Machining method for complex surfaces of liquid hybrid type mechanical seal rings

A machining method for complex surfaces of liquid hybrid type mechanical seal rings belongs to the technical field of precision machining and is characterized in that a sum of the square of diameter of a cup wheel and the square of medium diameter of a sloped corrugate face is equal to a square of a doubled distance from an intersection of the end face of the wheel and a rotational axis of the wheel to a rotational axis of a rotary worktable, an inclination angle of the wheel is equal to a largest radial outline inclination angle of the sloped corrugate face, rotation of the rotary worktable, reciprocating swing of a swing worktable and periodic following are in linked control when the sloped corrugate face is ground, the end face of the wheel is used for constant micro-feed cut-in grinding in the cutting depth direction of the wheel, the rotary worktable is in constant-speed rotation when a seal dam face is ground, and the end face of the wheel is used for constant micro-speed cut-in grinding in the cutting depth direction of the wheel. The machining method has the advantages that machining high in surface shape precision and low in surface roughness for the complex surface of a hydrodynamic pressure seal ring is achieved, while the hydrodynamic pressure seal ring is composed of a flat circular dam face and a sloped corrugate face which has slight inclined linear radial outline and peripherally and periodically changing inclination.

Owner:DALIAN UNIV OF TECH

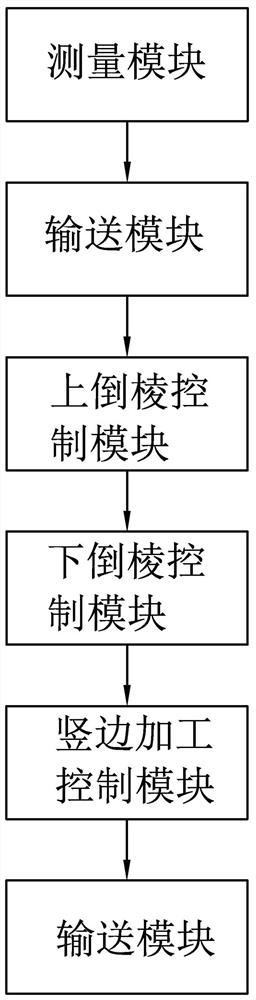

An automatic control system for glass edge grinding machine

ActiveCN112975647BRealize fool-like operationHigh degree of automationEdge grinding machinesGrinding feed controlAutomatic controlControl system

Owner:广东金玻智能装备有限公司

Ultra-precise processing method for circular conical surface of fluid static pressure sealing ring for nuclear primary pump

ActiveCN102350658BGrinding force remains constantProcessing state is stableRevolution surface grinding machinesCircular coneSurface roughness

The invention relates to an ultra-precise processing method for the circular conical surface of a fluid static pressure sealing ring for a nuclear primary pump, which belongs to the technical field of precise processing and is characterized in that the sealing ring is clamped in the center of a rotating work table, the radius of a cup-shaped grinding wheel is 75 to 250mm, the distance from the crossing point of the end surface of the cup-shaped grinding wheel and a rotating axis of the cup-shaped grinding wheel to a rotating axis of the rotating work table is 100 to 350mm, according to the principle that the taper error of the surface generated by the grinding is smaller than the given taper tolerance, an inclination angle of the rotating axis of the cup-shaped grinding wheel relative to the rotating axis of the rotating work table and an included angle between the rotating axis of the cup-shaped grinding wheel and a straight line are selected, wherein the straight line passes throughthe crossing point of the end surface of the cup-shaped grinding wheel and the rotating axis of the cup-shaped grinding wheel and is vertically intersected with the rotating axis of the rotating worktable. During grinding, the rotating work table and the cup-shaped grinding wheel do rotating movement, the cup-shaped grinding wheel feeds along the rotating axis of the rotating work table, and thecutting-in grinding is carried out by the end surface of the cup-shaped grinding wheel. The ultra-precise processing method has the effects and benefits that the machine tool structure is simple, andthe high-precise and low-surface-roughness grinding of the circular conical surface of the fluid static pressure sealing ring for the nuclear primary pump can be realized.

Owner:DALIAN UNIV OF TECH

Method for grinding sealing ring

InactiveCN102806507BGrinding force remains constantProcessing state is stableGrinding machinesSurface roughnessHigh surface

The invention discloses a method for grinding a sealing ring and belongs to the technical field of complex molded surface grinding. The method is characterized in that a workpiece shaft, a cup-shaped grinding wheel, a grinding wheel shaft, a swinging work table, and a linear movement platform are adopted; the workpiece shaft is arranged on the swinging work table; the swinging work table is arranged on the linear movement platform; the direction of the rotation axis of the grinding wheel shaft is parallel to the movement direction of the linear movement platform; the rotation axis of the grinding wheel shaft is perpendicularly intersected with the swinging axis of the work table, and crush grinding is performed through the end face of the cup-shaped grinding wheel. When an inclined corrugated surface is ground, the rotary motion of the workpiece shaft, the swinging of the swinging work table and the linear movement of the linear movement platform are controlled in a coordinated way. When a dam face is ground, the rotation axis of the cup-shaped grinding wheel is parallel to that of the workpiece shaft. The method has the advantages that high-surface shape accuracy and low-surface roughness complex molded surface machining of a fluid dynamic pressure sealing ring consisting of the flat annular dam face and the inclined corrugated surface of which the radial contour is a slightly inclined straight line and the inclined angle changes periodically along the circumferential direction can be realized.

Owner:DALIAN UNIV OF TECH

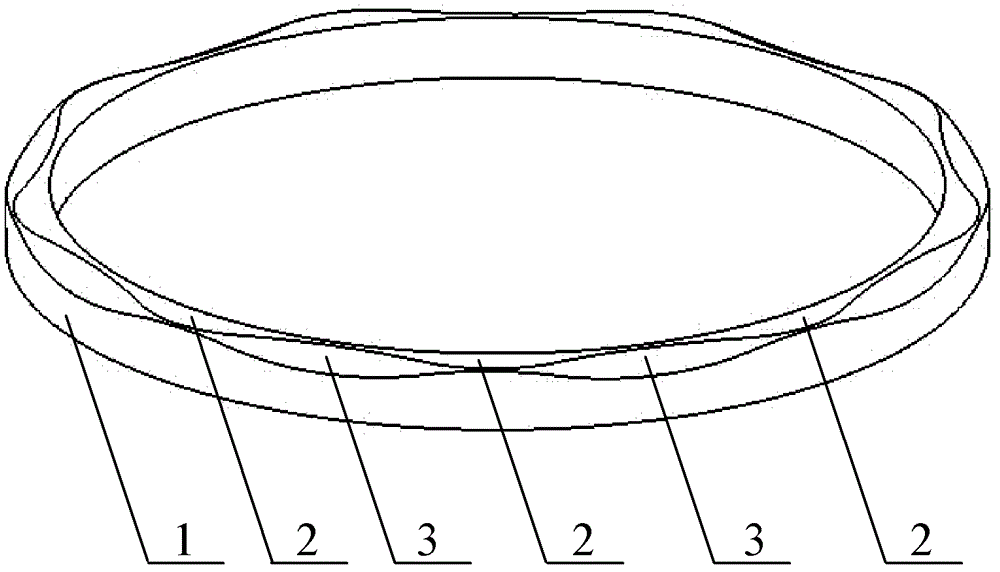

Machining method for complex surface of fluid dynamic pressure and static pressure combined mechanical seal ring for nuclear main pump

ActiveCN102528613BConsistent cutting speedSame lengthBonded abrasive wheelsGrinding machinesSurface roughnessHigh surface

The invention discloses a machining method for a complex surface of a fluid dynamic pressure and static pressure combined mechanical seal ring for a nuclear main pump, and belongs to the technical field of precision machining. The machining method is characterized in that: the sum of square of the diameter of a cup-shaped grinding wheel and the square of a middle diameter of an isoclinal wavelike surface of the seal ring is equal to the square of double the distance from an intersection point of an end face of the cup-shaped grinding wheel and a revolving axis of the cup-shaped grinding wheel to the revolving axis of a revolving table; an included angle of two revolving axes during grinding of the isoclinal wavelike surface is equal to a radial profile inclination angle of the isoclinal wavelike surface; the distance from the cup-shaped grinding wheel to the middle point of a grinding contact camber line of a seal ring is equal to the distance from the intersection point of the end face of the grinding wheel and the revolving axis of the grinding wheel to the revolving table; and when a sealed dam face is ground, the two revolving axes are parallel, micro feed plunge-cut grinding of constant grinding wheel cutting depth is performed through the end face of the grinding wheel. The machining method has the effect and the benefit that: machining of high surface accuracy and low surface roughness of the complex surface of the fluid dynamic pressure seal ring for the nuclear main pump, which is constituted by a flat cam face and the isoclinal wavelike surface with a radial profile of a slightly oblique straight line and with constant circumferential inclination angle, is realized.

Owner:DALIAN UNIV OF TECH

A precision electrolytic machining process for multi-tooth turbine blades

ActiveCN113182625BStable temperature controlAccelerate the lossMachining electrodesMachining working mediaElectrolytic agentTurbine blade

The invention discloses a multi-tooth turbine blade precision electrolytic machining process, which relates to the technical field of turbine blade electrolytic machining, including the preparation of tool cathodes, the installation of tool cathodes, and the electrolytic machining of slub holes. The invention overcomes the limitations of traditional methods. Defects, it can still ensure the stability of the processing process under the condition of high voltage, thereby improving the efficiency of electrolytic processing and shortening the processing time. When the temperature of the electrolyte rises, the flow rate of the electrolyte can be adjusted by the adjustment module to accelerate The loss of heat in the electrolytic processing area achieves stable control of the temperature of the electrolyte.

Owner:JIANGSU JIANGHANGZHI AIRCRAFT ENGINE COMPONENTS RES INST CO LTD

Bamboo chip end machining equipment

InactiveCN111618700AProcessing state is stableNot easy to damageEdge grinding machinesPolishing machinesElectric machineryDrive motor

The invention aims at providing bamboo chip end machining equipment which is used for solving the problems in the prior art. The equipment comprises a support, a conveying assembly extending from upstream to downstream and used for conveying bamboo chips and multiple grinding and polishing assemblies sequentially mounted in the extending direction of the conveying assembly are arranged on the support, each grinding and polishing assembly comprises multiple dull polish parts and polishing parts driven by driving motors, the dull polish parts in each grinding and polishing assembly are located on the upstream side of the polishing parts, the dull polish parts and the polishing parts are connected to the support through angle adjusting devices and point to bamboo chips on the conveying assembly, according to the bamboo chip end machining equipment, automatic high-efficiency bamboo chip end grinding and polishing machining can be achieved, and the equipment can produce products with high quality and good stability.

Owner:浙江茂林竹木工艺有限公司

Embedded groove type clamp spring assembly and method for drilling hard alloy materials by using embedded groove type clamp spring assembly

InactiveCN102699369AComplete appearanceProcessing state is stableBoring/drilling machinesTool adaptersAlloyMachining process

The invention discloses an embedded groove type clamp spring assembly and a method for drilling hard alloy materials by using the embedded groove type clamp spring assembly. The embedded groove type clamp spring assembly comprises a drilling bit, a top end external member, a rod body piece and a clamp spring positioning piece. The method for drilling hard alloy materials by using the embedded groove type clamp spring assembly comprises the following steps of: step 1, fixing the hard alloy materials; step 2, clamping the embedded groove type clamp spring assembly through a spanner drill chuck; and step 3, drilling the hard alloy materials. The embedded groove type clamp spring assembly and the method for drilling hard alloy materials by using the embedded groove type clamp spring assembly can effectively drill through holes, the appearance of the through holes is complete, the whole machining process is stable, and machining is facilitated.

Owner:SHANGHAI MARITIME UNIVERSITY

A three-axis linkage mechanical seal ring complex surface grinding method

InactiveCN102806508BGrinding force remains constantProcessing state is stableGrinding machinesSurface roughnessHigh surface

The invention discloses a complex molded surface grinding method for a three-axis linkage mechanical sealing ring and belongs to the technical field of complex molded surface grinding. The method is characterized in that a workpiece shaft, a cup-shaped grinding wheel, a grinding wheel shaft, a swinging work table, and a linear movement platform are adopted; the workpiece shaft is arranged on the swinging work table; the grinding wheel shaft is arranged on the linear movement platform; the rotation axis of the grinding wheel shaft is perpendicularly intersected with the swinging axis of the swinging work table; and the direction of the rotation axis of the grinding wheel shaft is parallel to the movement direction of the linear movement platform, and crush grinding is performed through the end face of the grinding wheel. When an inclined corrugated surface is ground, the rotary motion of the workpiece shaft, the reciprocating swinging of the swinging work table and the linear movement of the linear movement platform are controlled in a coordinated way. When a dam surface is ground, the rotation axis of the cup-shaped grinding wheel is parallel to that of the workpiece shaft. The method has the advantages that the high-surface shape accuracy and low-surface roughness complex molded surface machining of a fluid dynamic pressure sealing ring consisting of the flat annular dam face and the inclined corrugated surface of which the radial contour is a slightly inclined straight line and the inclined angle changes periodically along the circumferential direction can be realized.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com