Reversed alignment electrochemical discharge machining method and device

A discharge machining and electrochemical technology, which is applied in the field of inverted electrochemical discharge machining and devices, can solve the problems such as the difficulty in updating the electrolyte solution and the difficulty in processing depth exceeding 500 μm, and achieve stable spark discharge machining state, increased depth, and increased stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

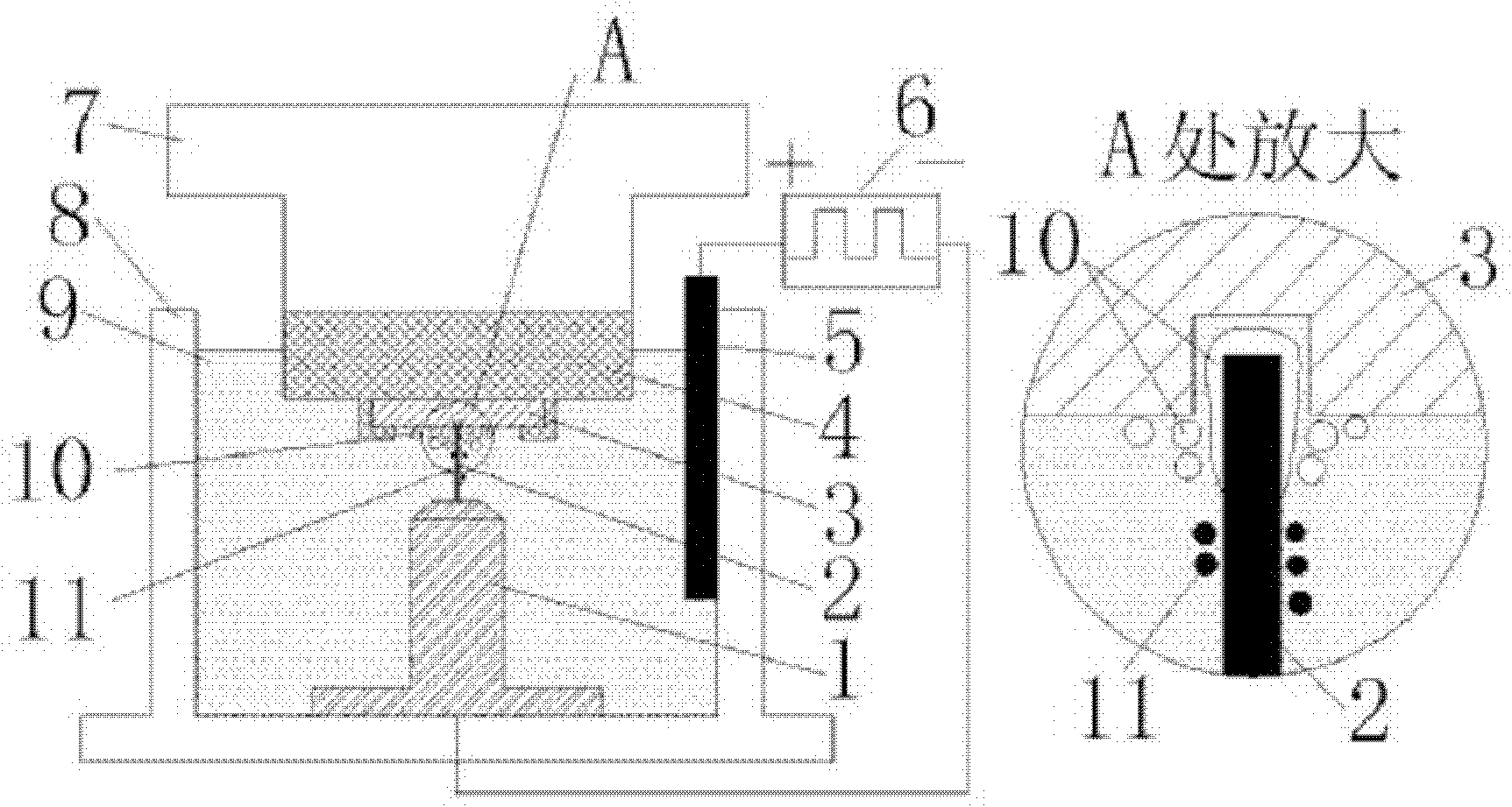

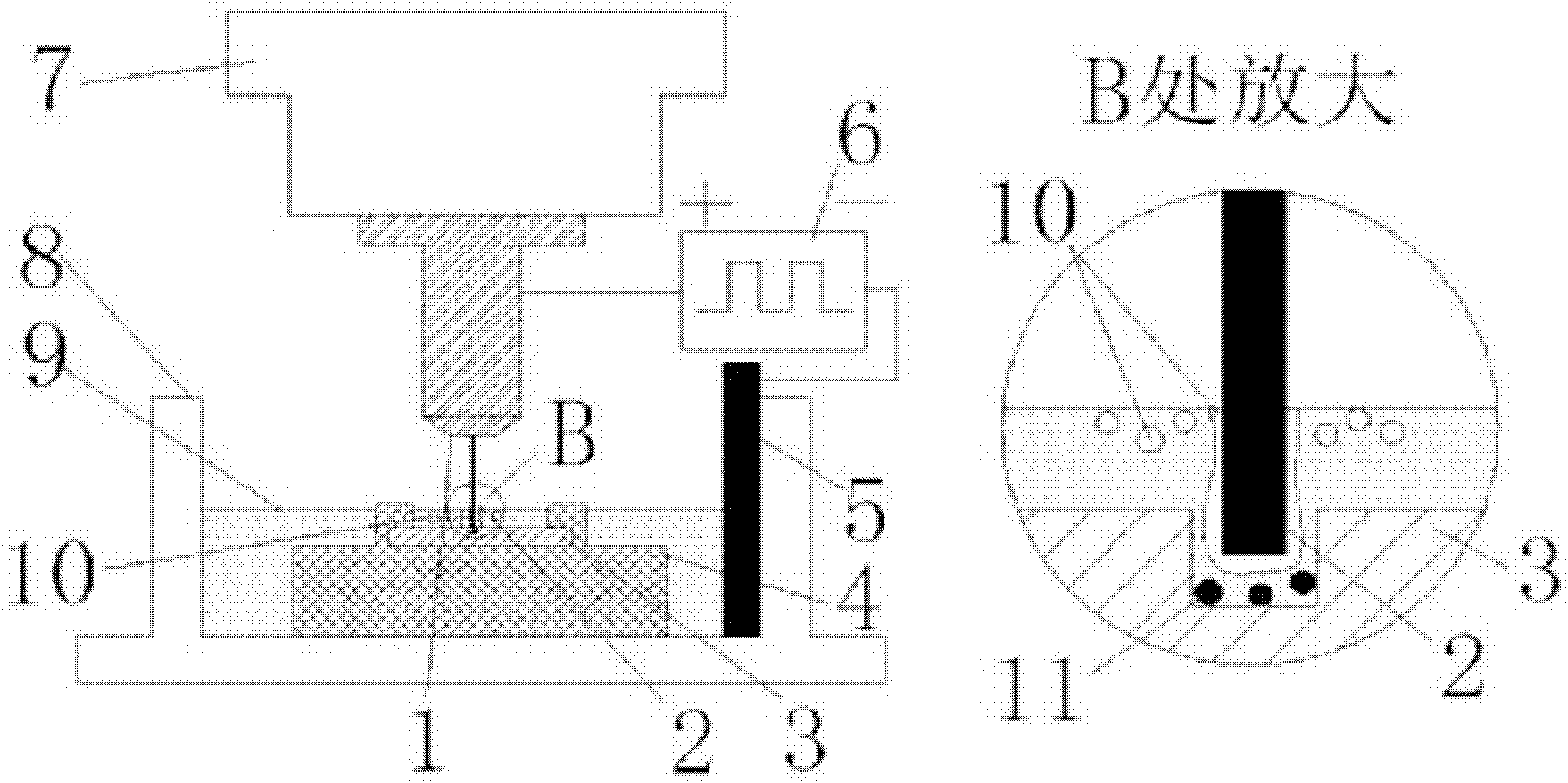

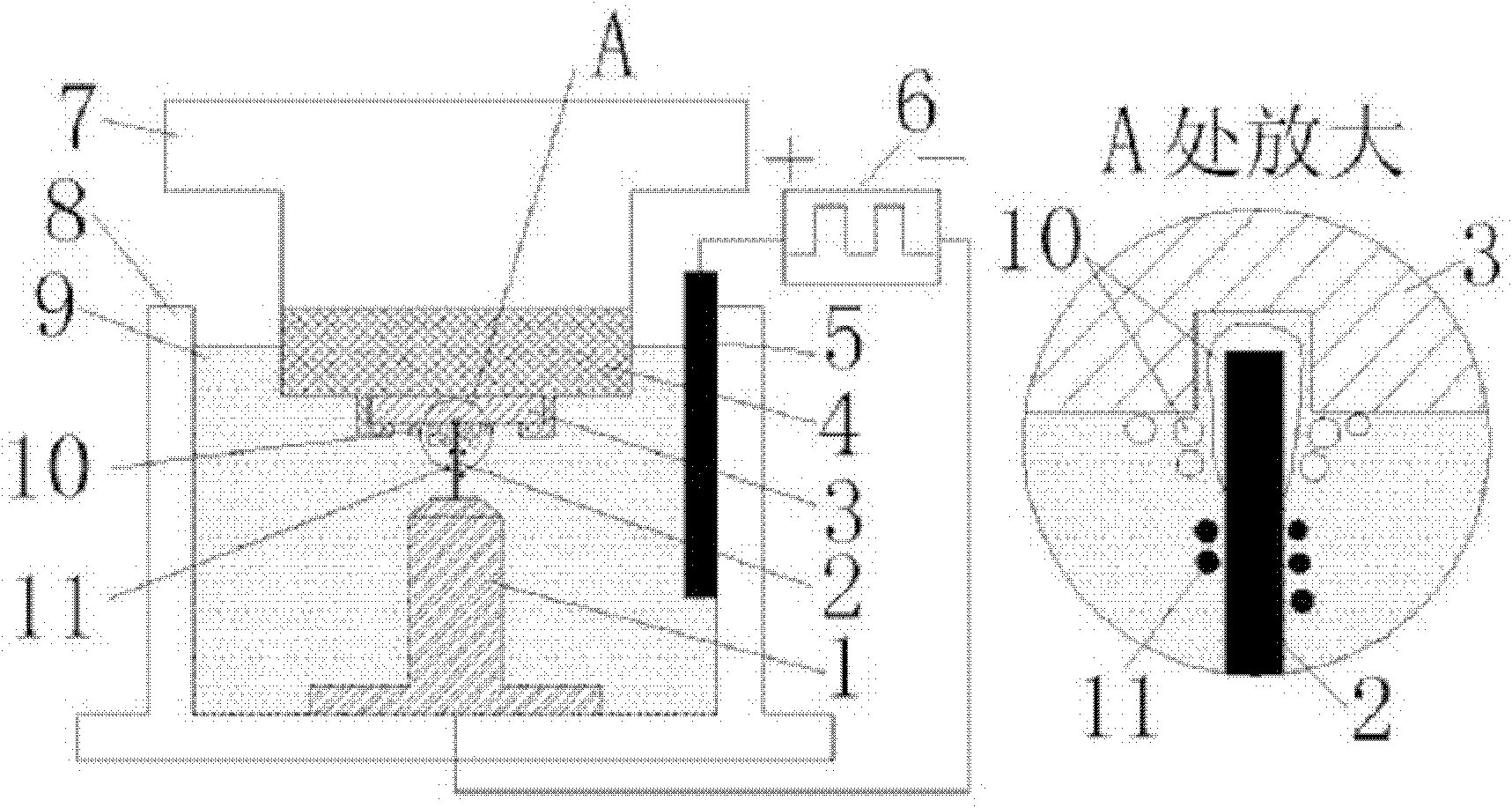

[0029] Such as Figure 1As shown, this embodiment includes an electrode chuck 1, a tool electrode 2, a workpiece 3, a workpiece holder 4, an auxiliary electrode 5, a power supply 6, a feeding device 7, a working tank 8, an electrolyte solution 9, an air film and air bubbles 10, and processing chips 11. The tool electrode 2 is connected to the negative pole of the power supply, and the auxiliary electrode 5 is connected to the positive pole of the power supply. The tool electrode 2 and the workpiece 3 are immersed in sodium hydroxide (NaOH) solution at the same time, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com