Machining method for complex surfaces of liquid hybrid type mechanical seal rings

A mechanical seal, complex surface technology, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of large surface roughness, low processing efficiency, fast grinding wheel wear, etc., to achieve simple machine structure, avoid surface shape The effect of high error and machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

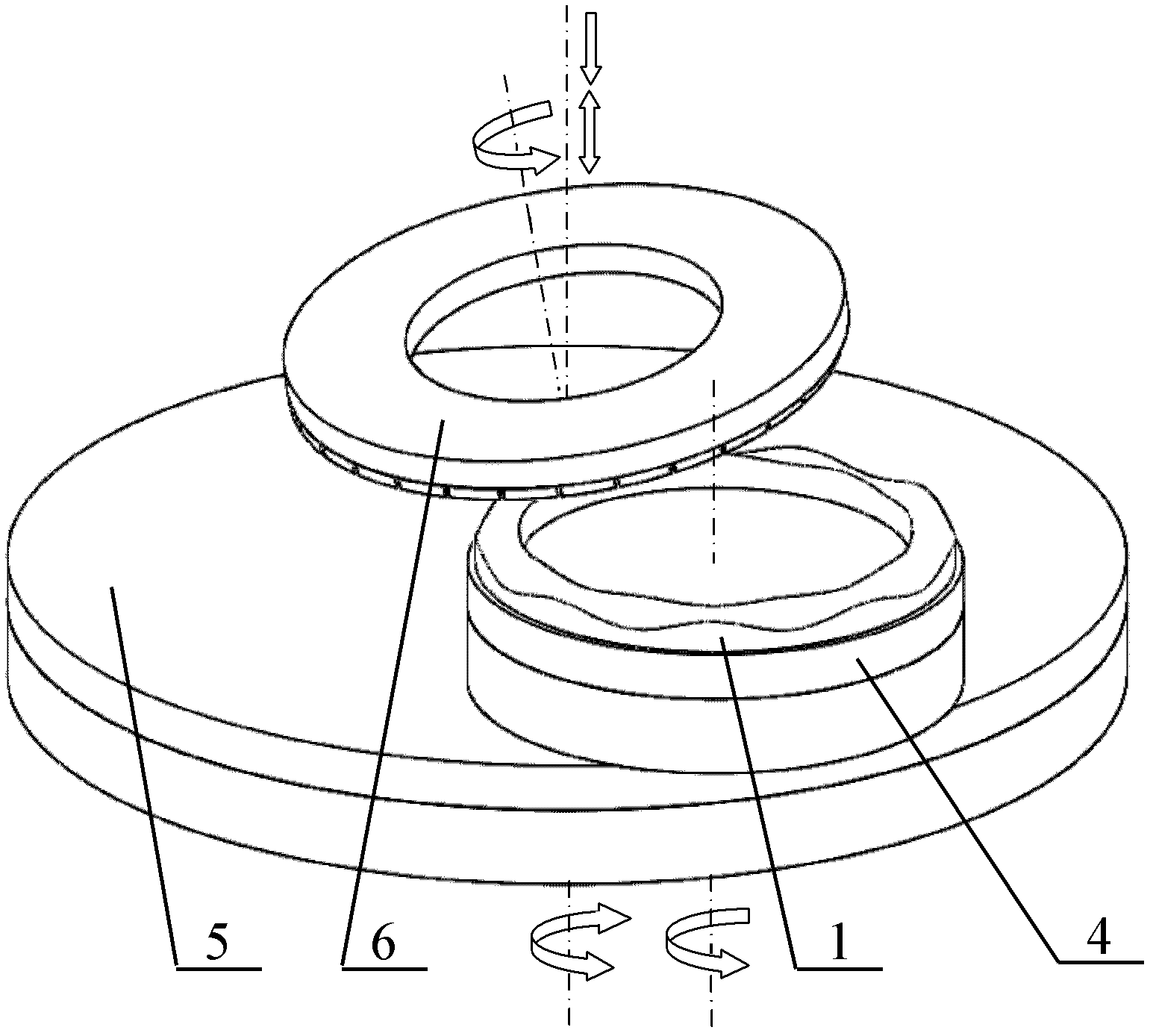

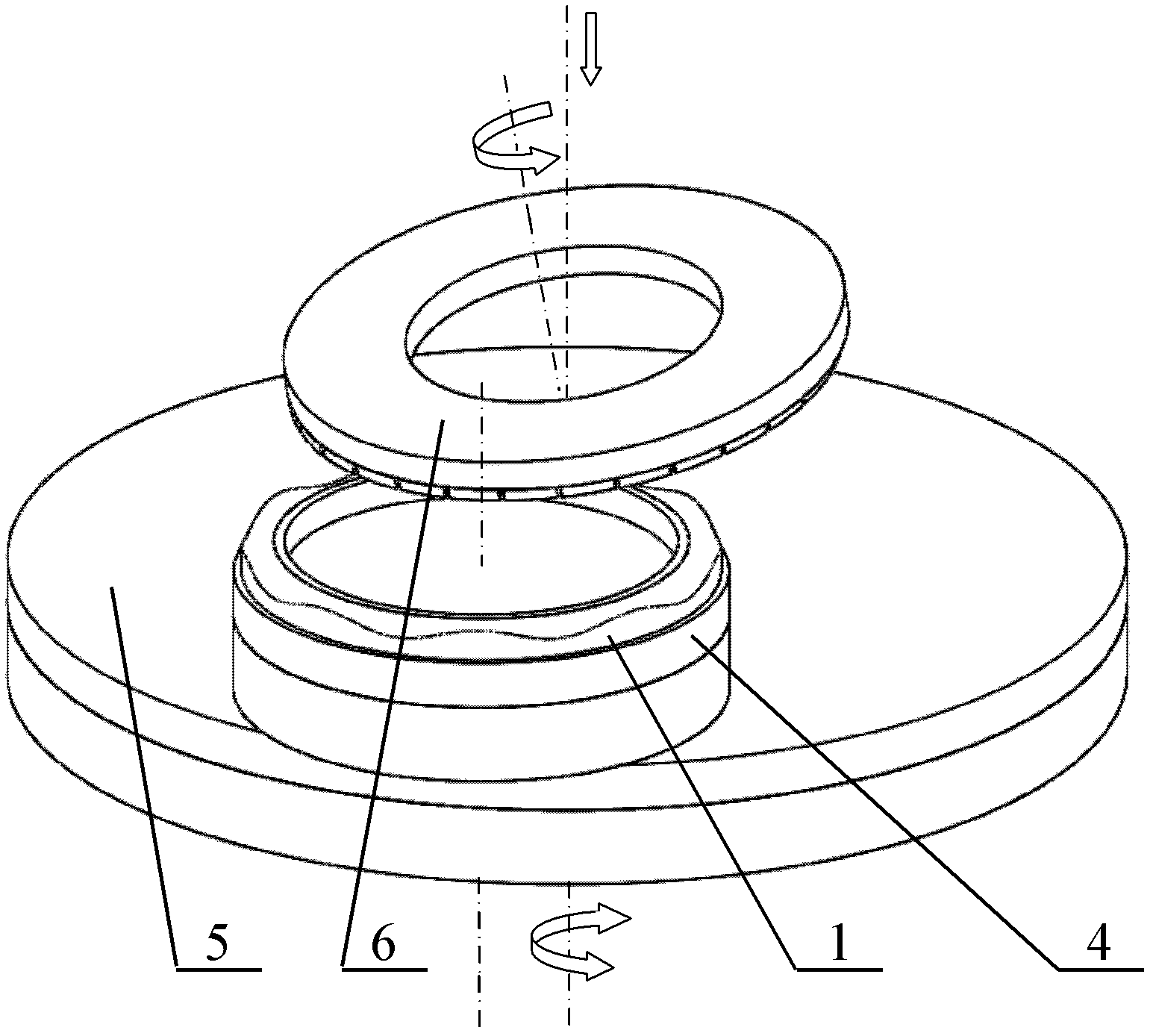

[0016] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

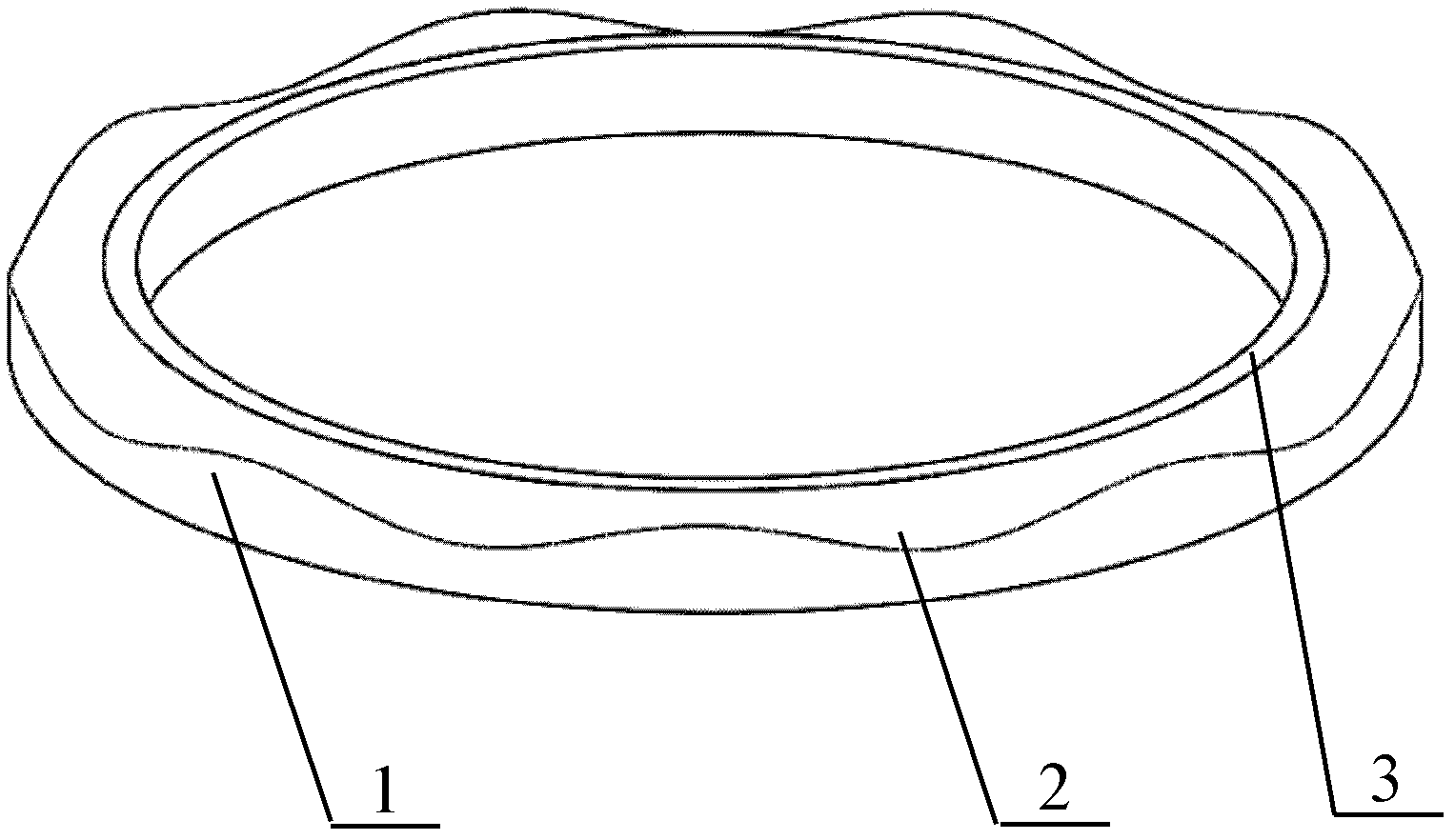

[0017] as attached figure 1 As shown, the end face of the seal ring to be processed is a complex hydrodynamic and static pressure combined mechanical seal ring composed of a flat circular dam surface and a slightly inclined straight line whose radial profile changes periodically along the circumferential direction. Shaped surface, the inner diameter is 260 mm, the outer diameter is 300 mm, the outer diameter of the sealing dam surface is 270 mm, the inclination angle of the radial contour line of the oblique corrugated surface changes periodically along the circumferential direction between 0 and 0.0002 radians, and the number of corrugations is 9 One, the material is pressureless sintered silicon carbide.

[0018]The diameter of the cup-shaped grinding wheel is 350 mm, the width of the working surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com