A cutter head with evenly distributed diamonds and its preparation process

A technology of uniform distribution and preparation process, applied in the direction of manufacturing tools, stone processing equipment, stone processing tools, etc., can solve the problems affecting the cutting efficiency of saw blades, poor diamond holding force, and high diamond concentration, and is conducive to forming automation. The effect of improving cutting performance and avoiding dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

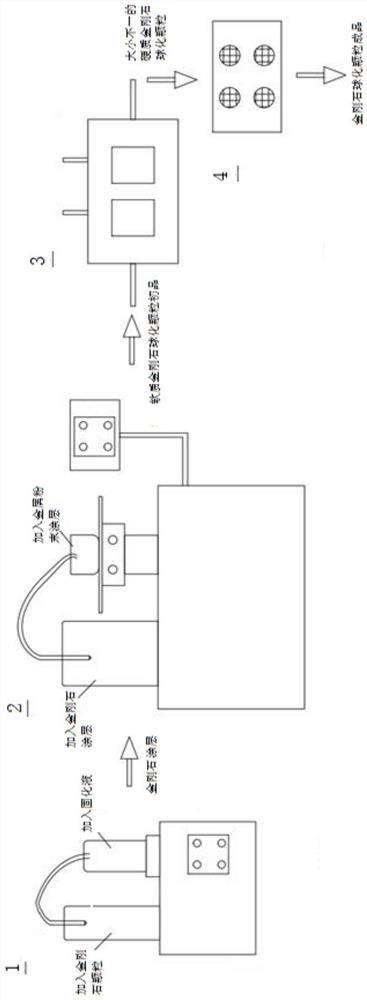

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

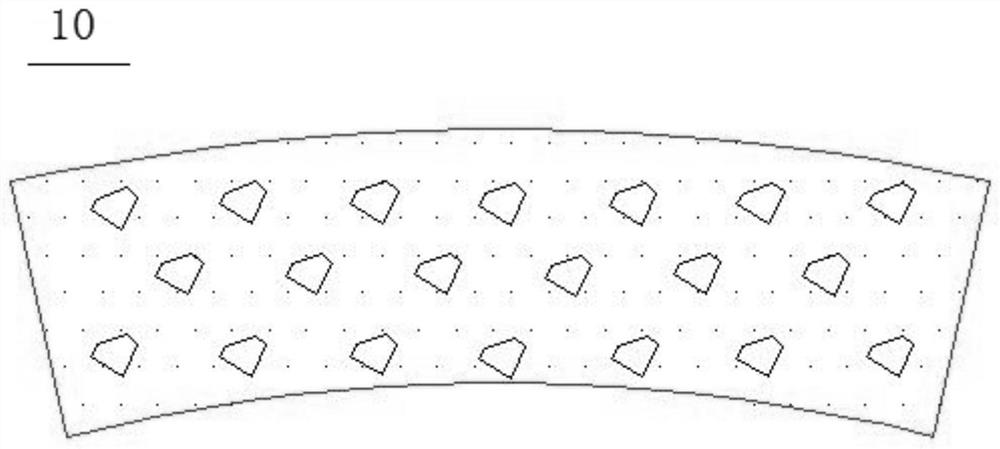

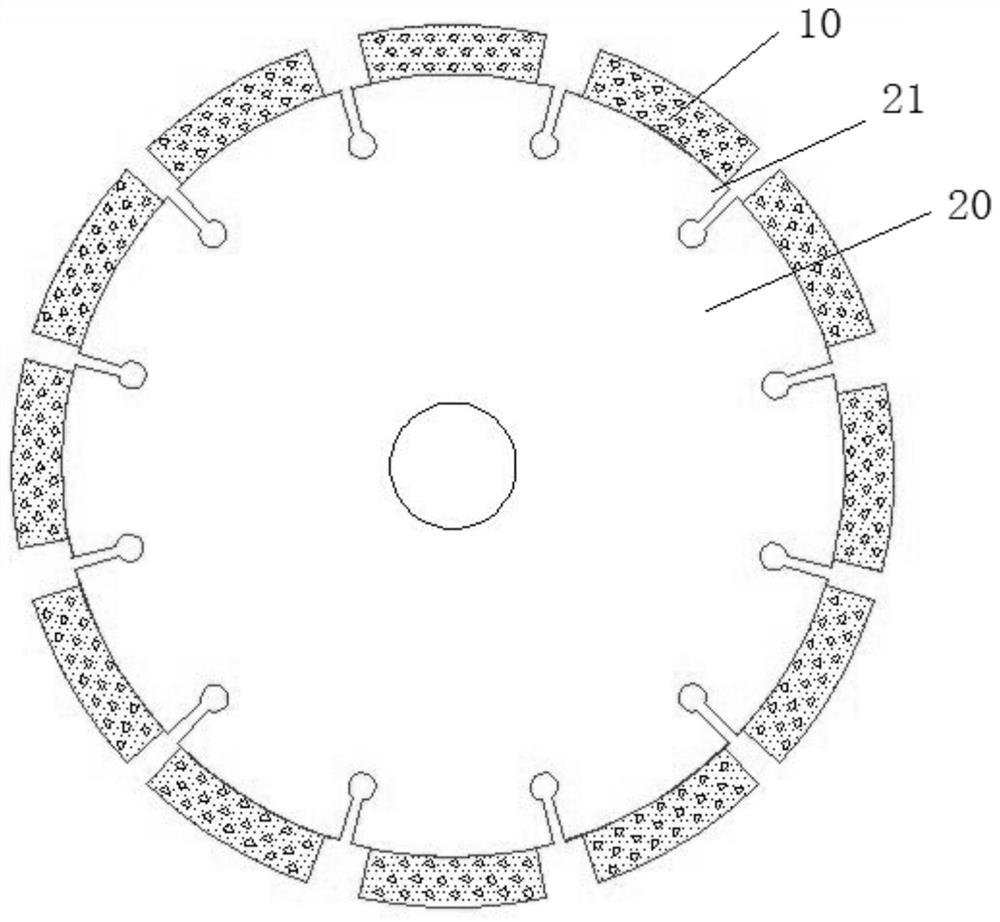

[0043] Such as figure 1 As shown, a cutter head 10 with evenly distributed diamonds includes a cutter head body, and the cutter head body is formed by pressing multi-layer sheets, and each layer of sheets is composed of diamond spheroidized particles and metal powder spheroidized particles according to the comprehensive The ratio is fully mixed and cold-pressed;

[0044] The diamond spheroidized particles are formed by wrapping diamond spheroids with a metal powder coating; the size of the diamond spheroidized particles is 30-80 mesh;

[0045] The metal powder spheroidized particles are directly spheroidized metal powder; the size of the metal powder spheroidized particles is 15-120 mesh;

[0046] The diamond spheroidized particles and metal powder spheroidized particles are mixed in a ratio of 10% to 20%.

[0047] Preferably, the metal powder coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com