Patents

Literature

32results about How to "Realize fool-like operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

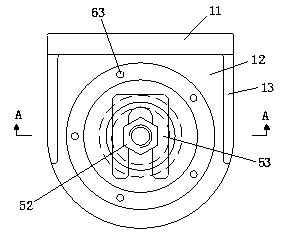

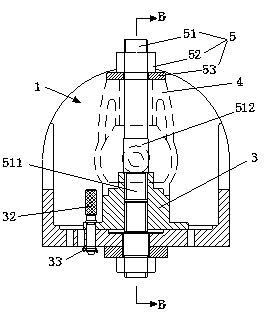

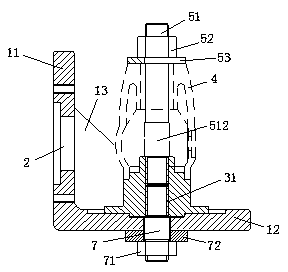

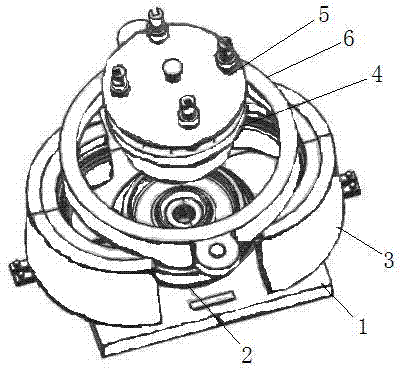

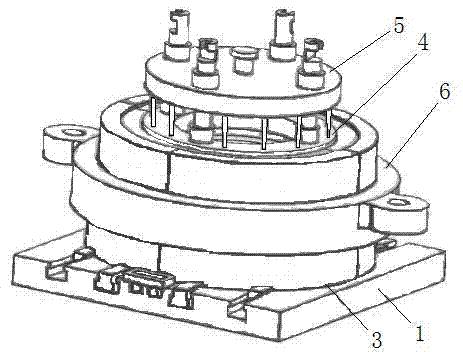

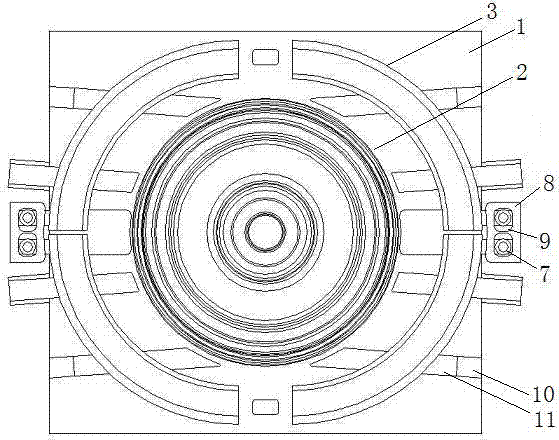

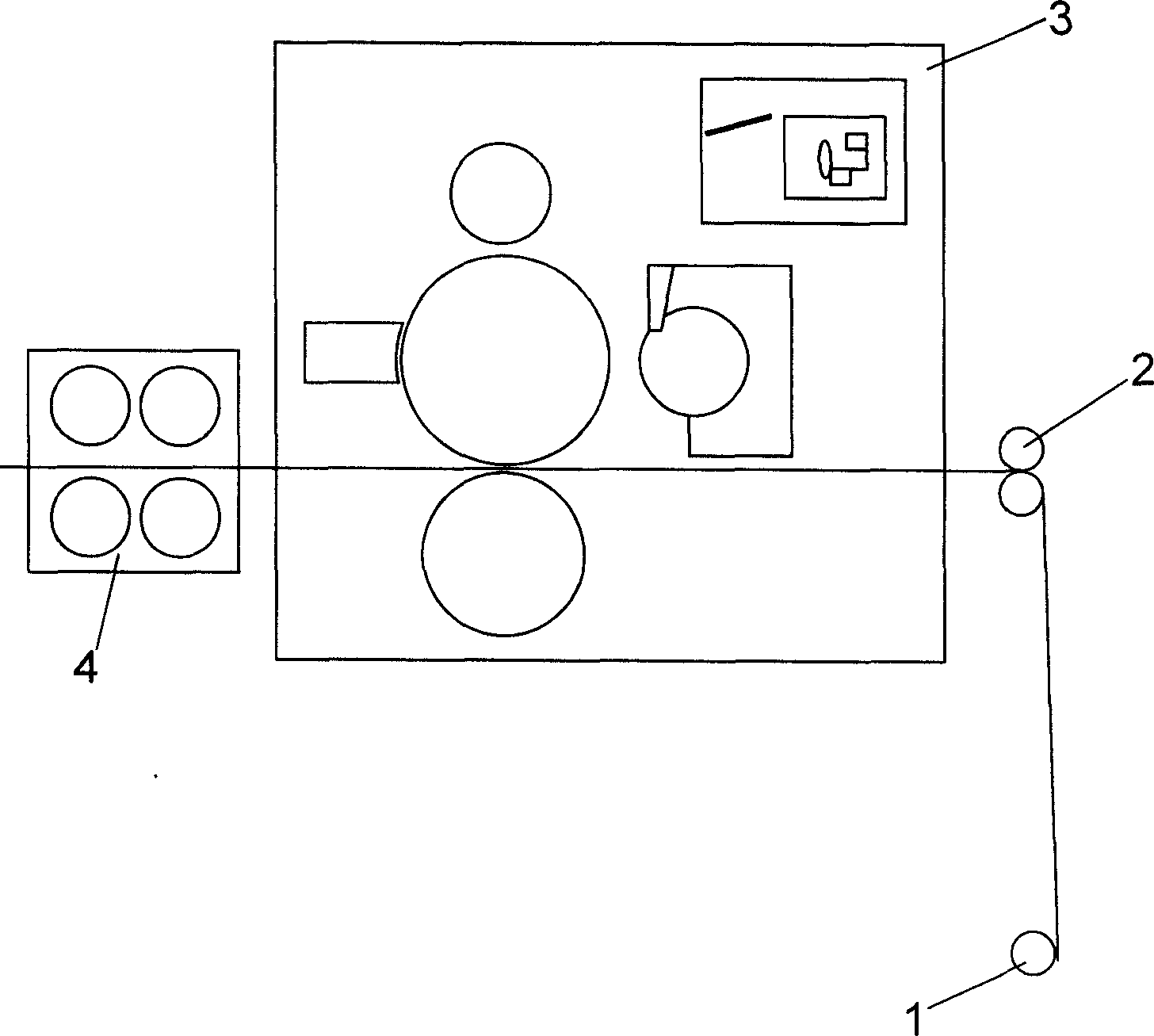

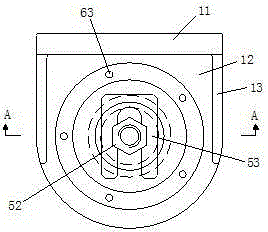

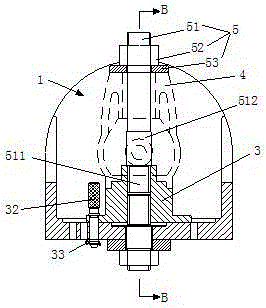

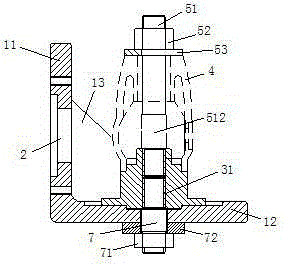

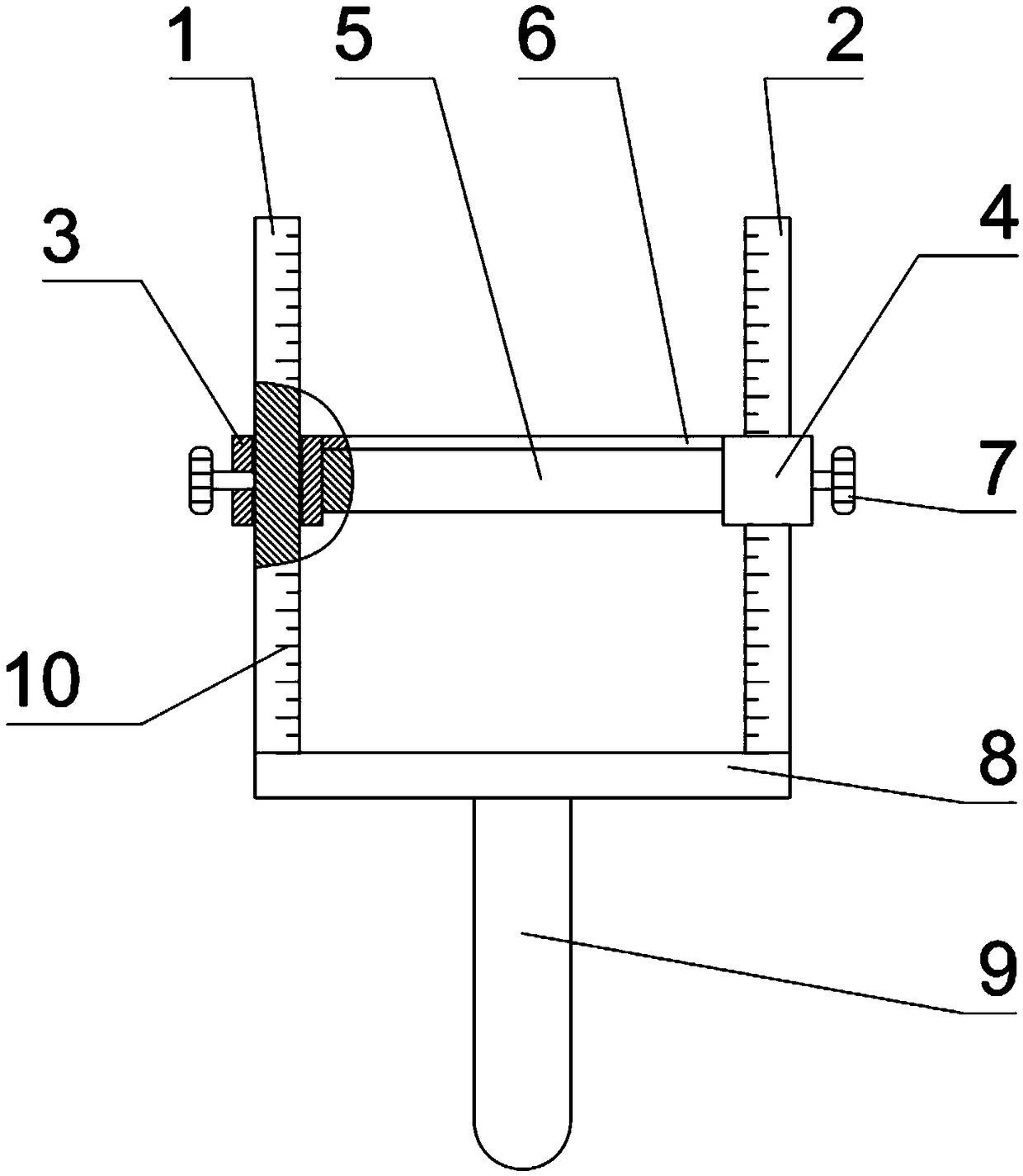

Tool used for machining blade holes of axial flow pump impeller body

ActiveCN103707106ASolving Concentricity ProblemsSolve the measurement datum problem of key dimensionsPositioning apparatusMetal-working holdersAxial-flow pumpImpeller

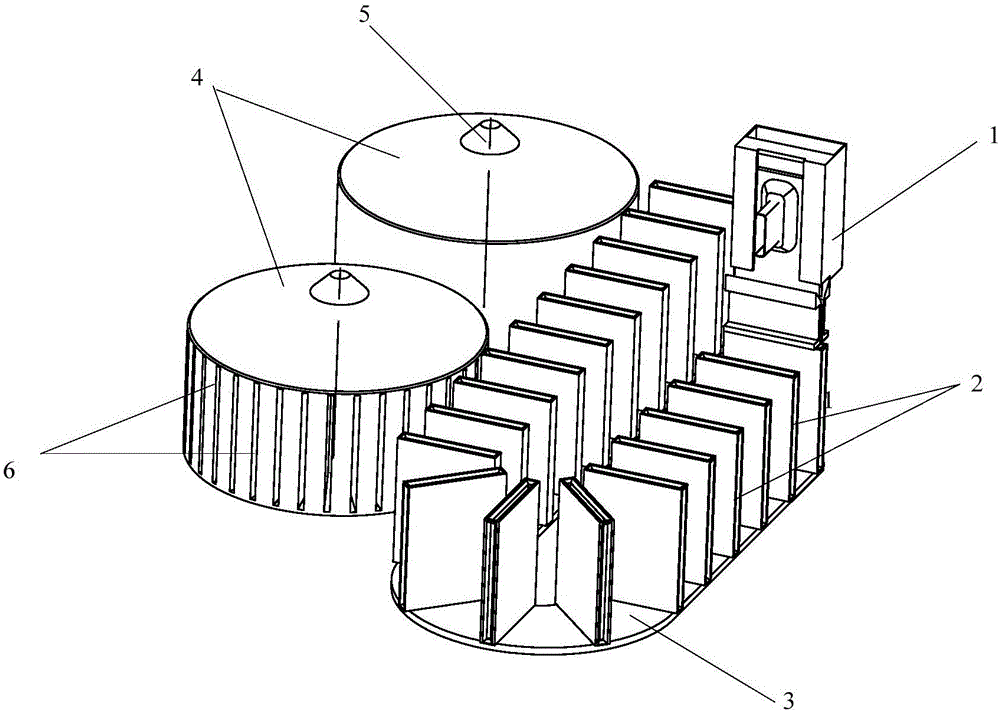

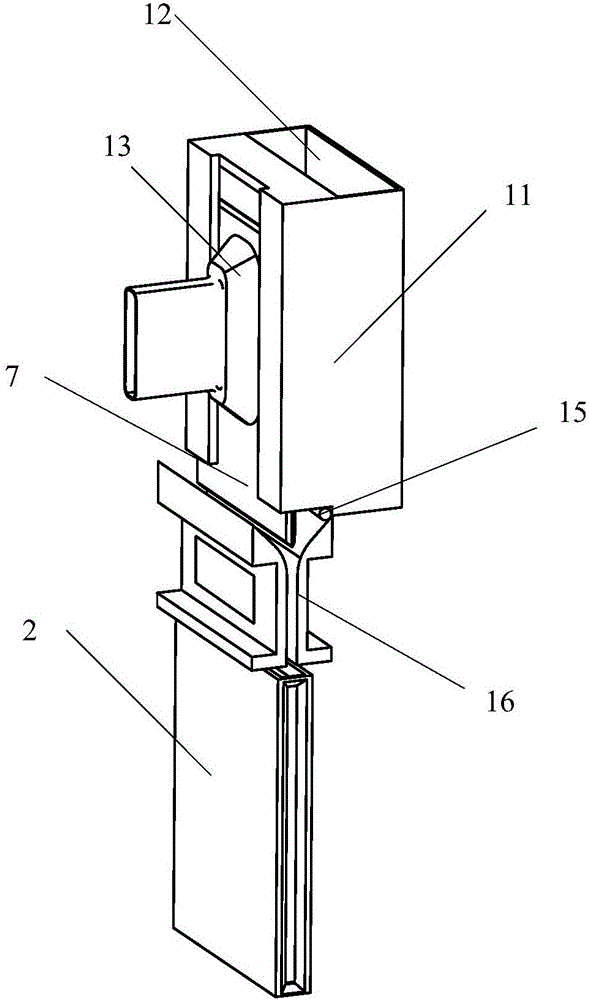

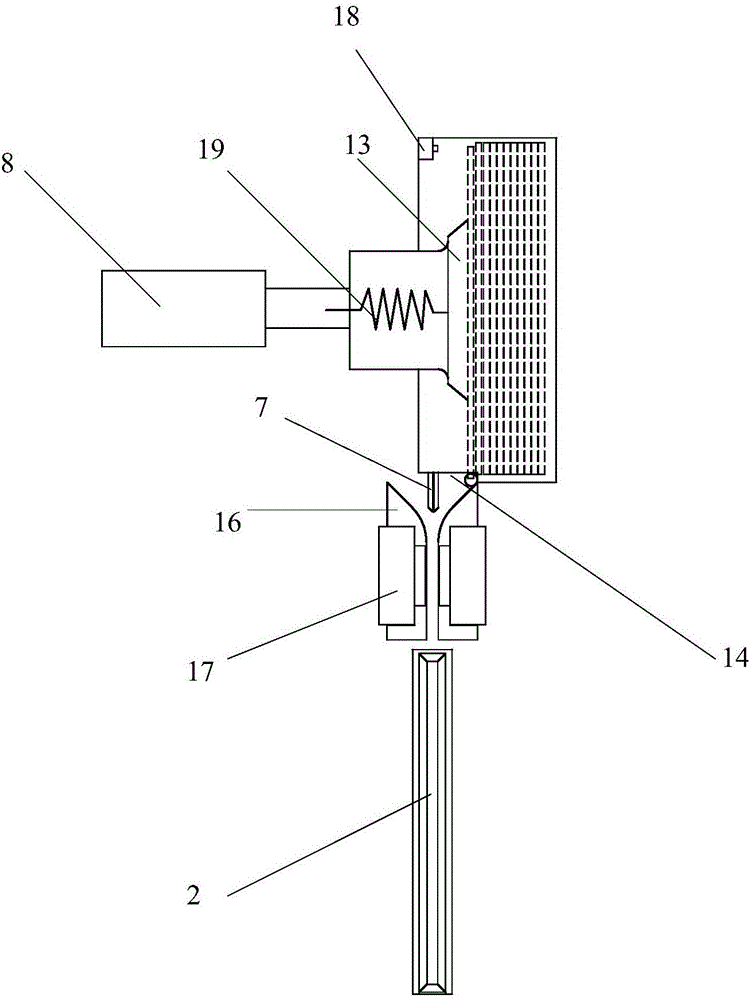

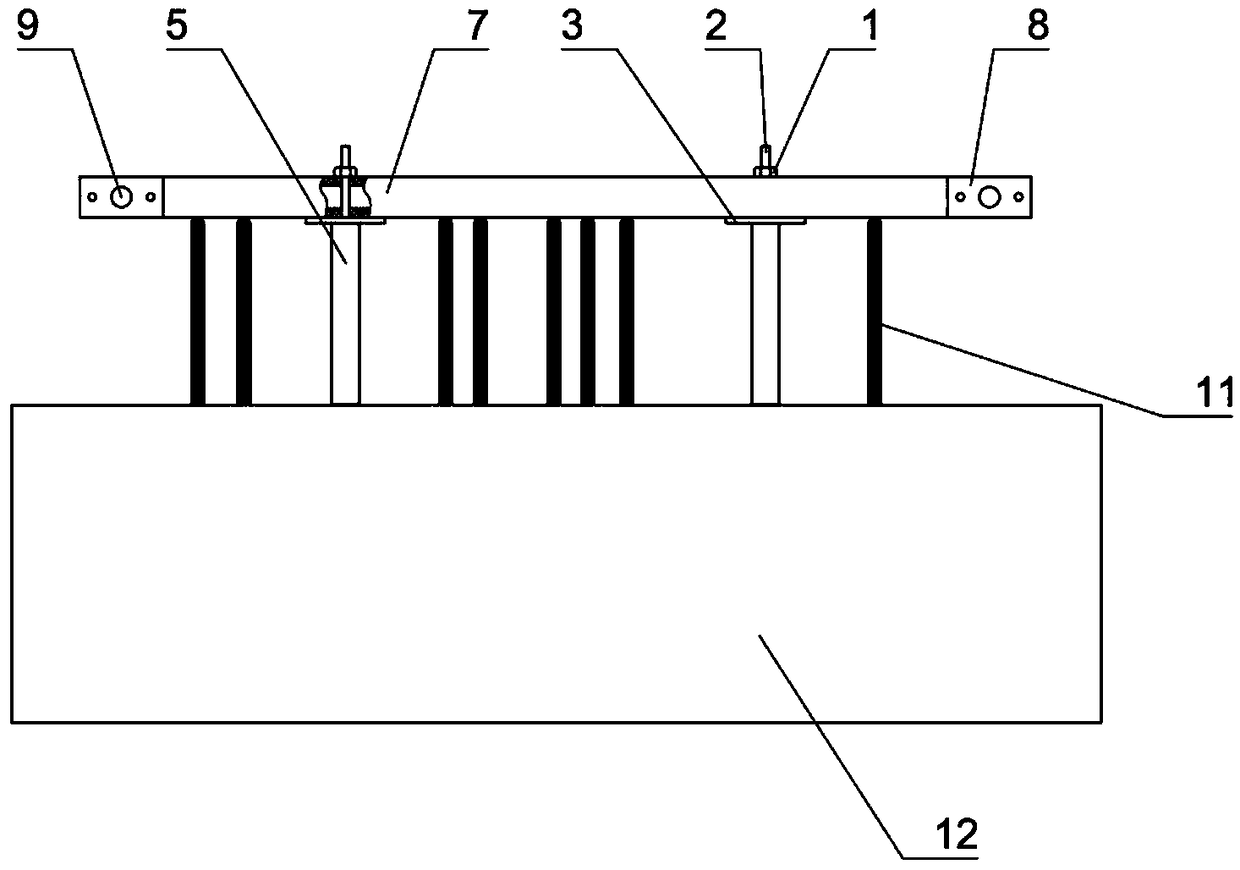

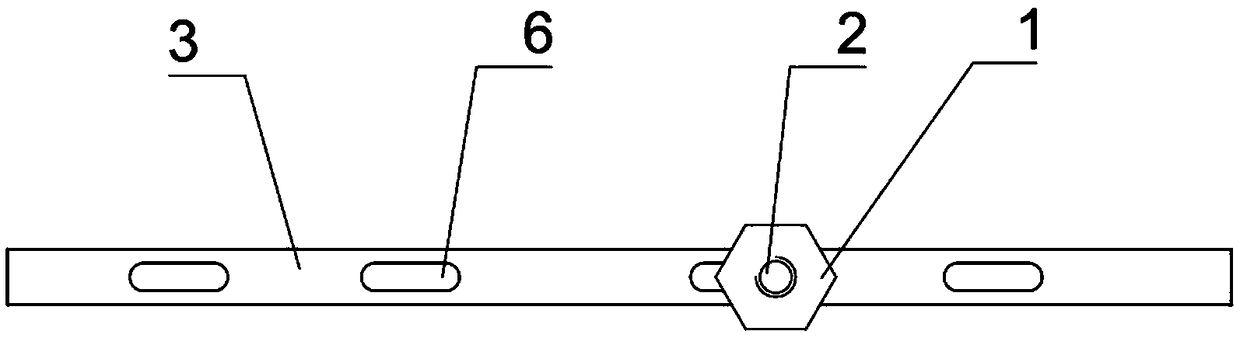

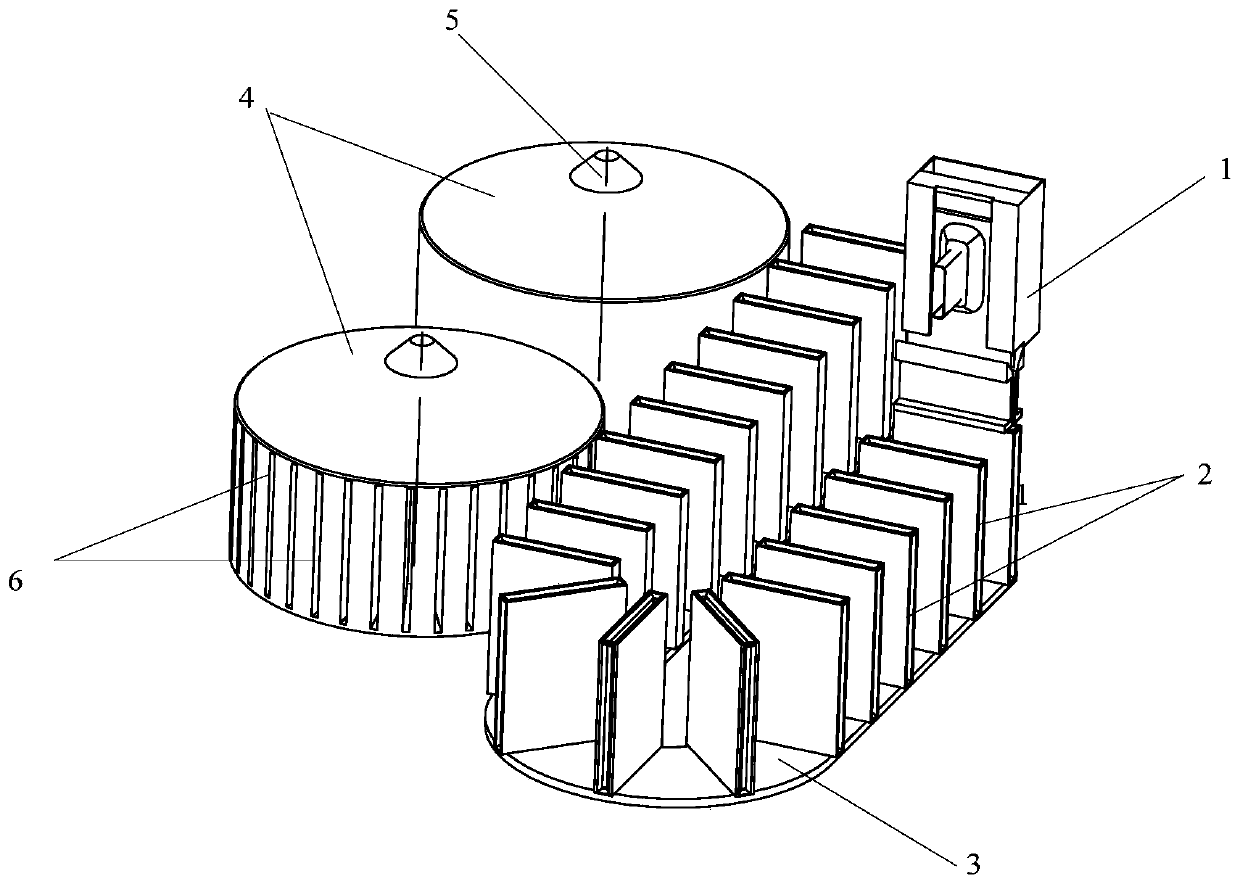

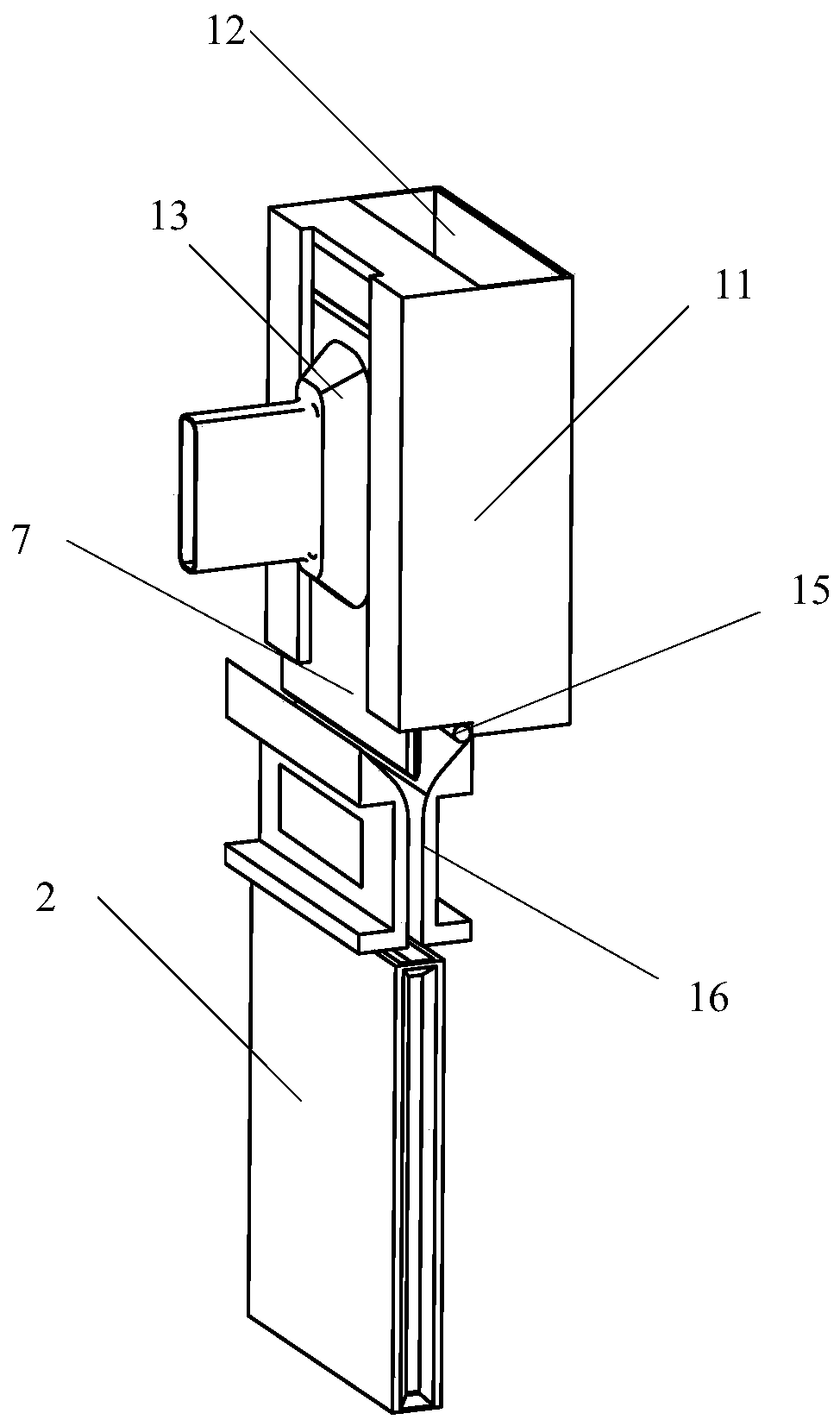

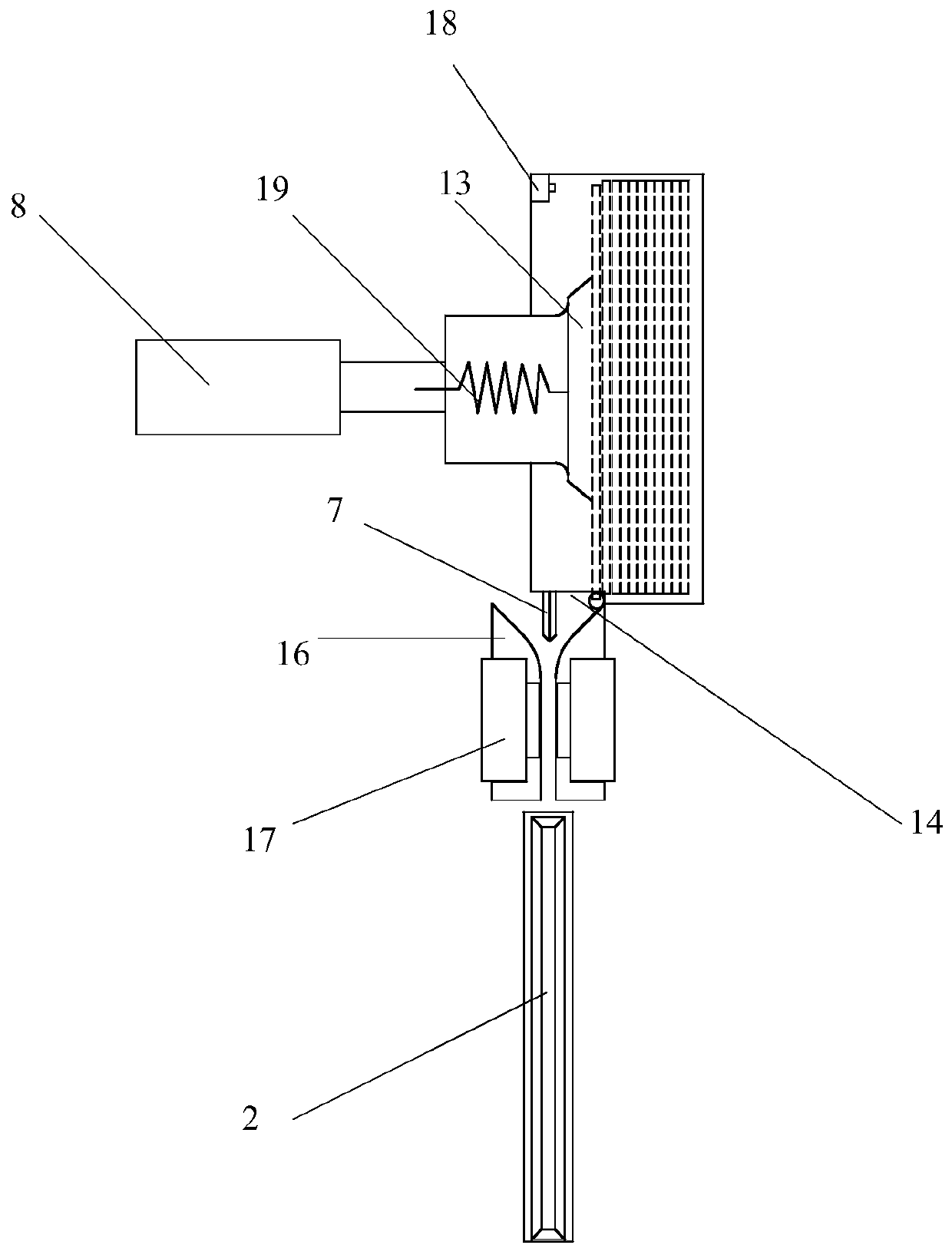

The invention relates to a tool used for machining blade holes of an axial flow pump impeller body. The tool comprises a rotary body fixed to a lathe spindle, wherein a scale dividing block is fixed on the rotary body, a fastening device used for fixing a workpiece on the scale dividing block is arranged above the scale dividing block, a first layer of positioning pin holes, a second layer of positioning pin holes and a third layer of positioning pine holes are formed in the outer side of the scale dividing block in the circumferential direction from inside to outside, and positioning pins matched with the positioning pin holes are arranged on the scale dividing block. According to the technical scheme, an installation method with the tool directly connected with a lathe is adopted, a rotating center in the direction same as the rotating direction of the lathe spindle is generated for each blade hole to be machined, and concentricity is achieved between the blade holes to be machined and the lathe spindle; by means of the cooperation between the scale dividing block and the rotary body and the utilization of a scale dividing mechanism, fast and accurate scale division is achieved easily when the blade holes rotate along with the scale dividing block during machining; a cylindrical section arranged on a pull rod enables the measuring basis of the critical dimension to be available during lathe machining.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

Hub die-casting mould

ActiveCN104759604ALow manufacturing costIncrease the pressure resistance of the cavityCavity pressureEngineering

The invention discloses a hub die-casting mould. The hub die-casting mould comprises a lower die, a side die and an upper die which are combined to form a hub casting cavity; the lower die is arranged on a lower template, and the side die is formed by glidingly connecting four sections to an arc part of the lower template; four arc parts are respectively located at two groups at left and right sides of the lower die; an included angle at 3-10 degrees is arranged between the gliding traces of two arc parts of every group and diameters in left and right directions of the lower die. The hub die-casting mould further comprises two connecting blocks respectively arranged at outsides of two groups of arc parts, wherein connecting holes are arranged on the connecting blocks, the outer walls of the two arc parts of every group are respectively provided with pulling hooks, and the pulling hooks are glidingly connected to the connecting holes. Through two connecting blocks, two section arc parts of one group are respectively pulled; two connecting blocks are not required to drive by two oil cylinders, thus the oil cylinder energy consumption in the pouring process is reduced by a half, and the manufacturing cost of the hub is greatly reduced; the cavity pressure is provided through a lock die sleeve; the hub die-casting mould overcomes the limit of the oil cylinder specification, and further reduces the manufacturing cost of the hub.

Owner:SIYANG MINGYUXING PRECISION MACHINERY CO LTD

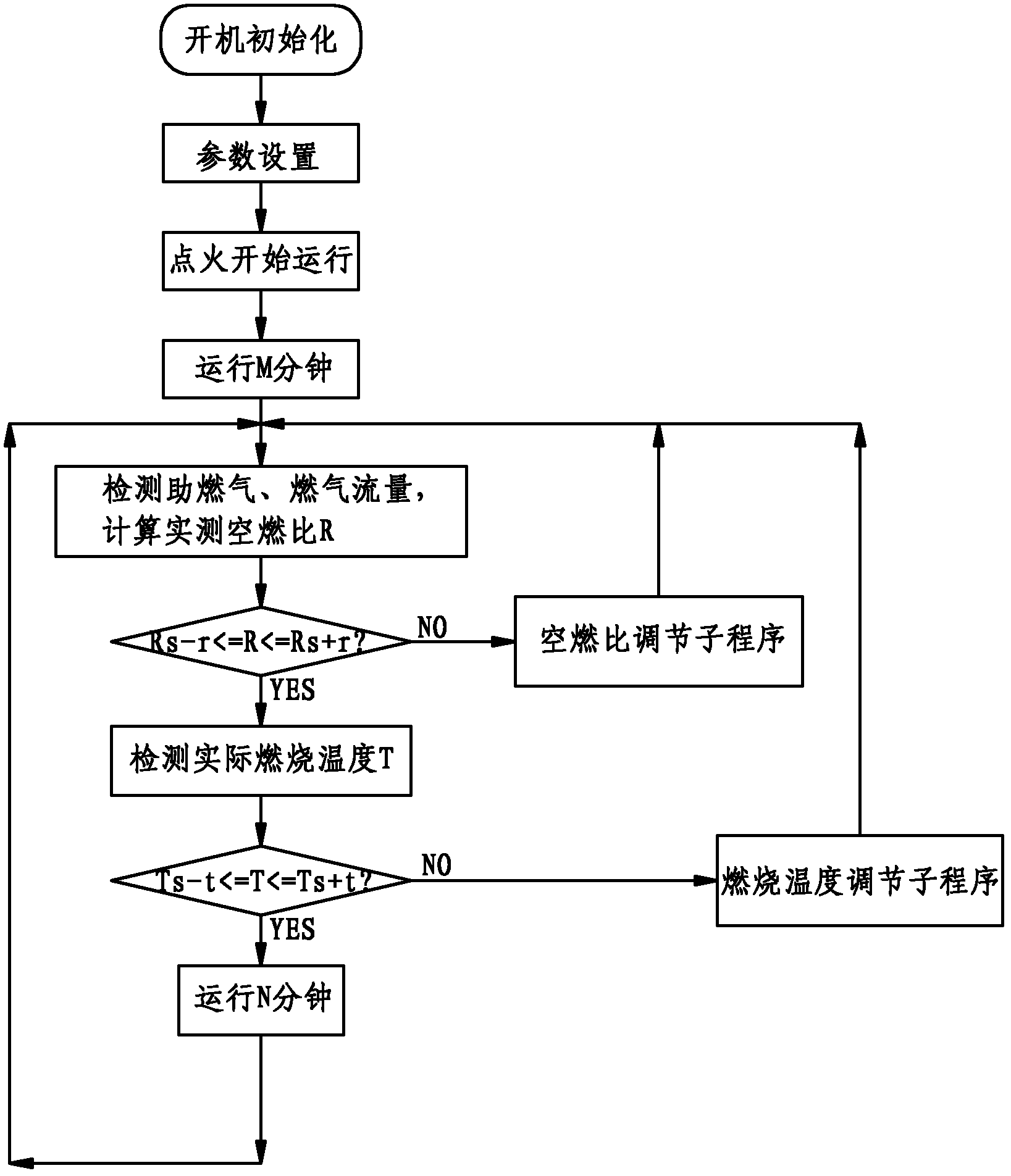

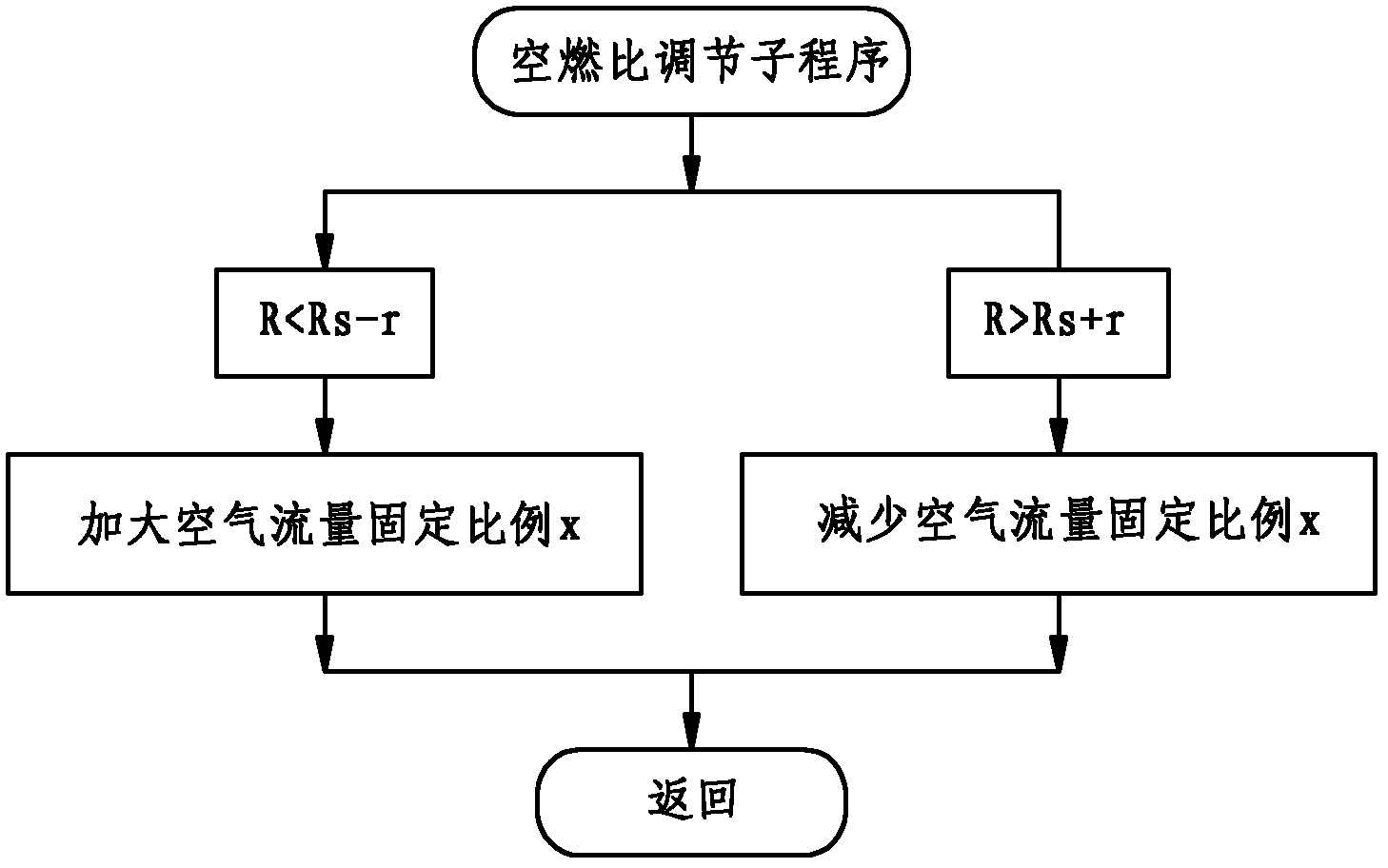

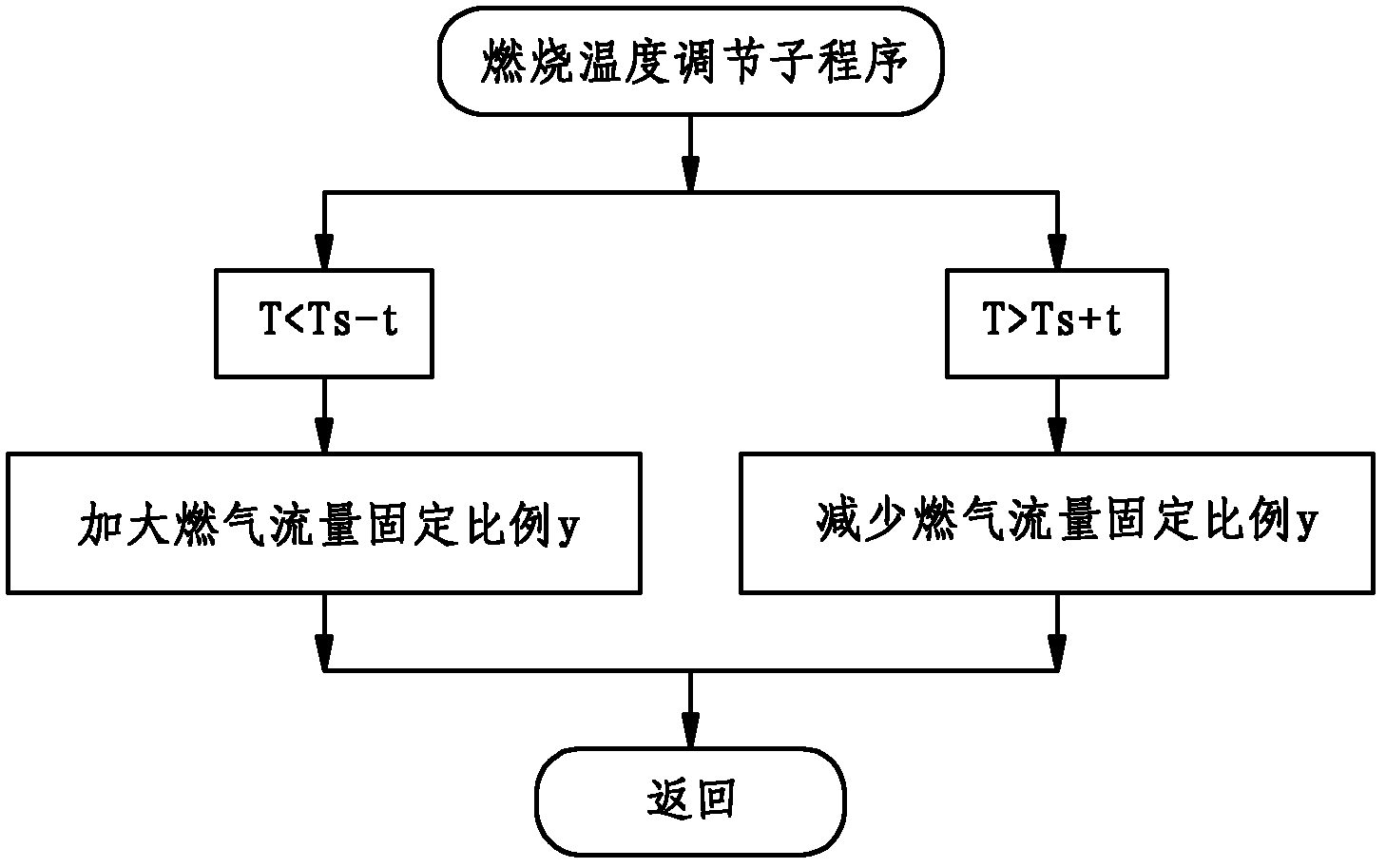

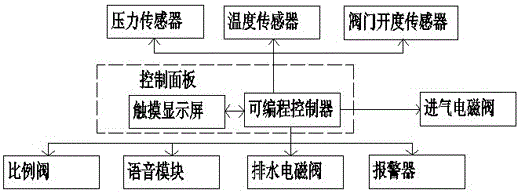

Method for controlling flame brazing machine

InactiveCN102615368AGuaranteed uptimeImprove welding qualityHeat exchange apparatusHollow articlesTemperature controlEngineering

A method for controlling a flame brazing machine comprises the following steps: 1, a machine is started up and initialized; 2, a user sets parameters, wherein the parameters comprises preset air-fuel ratio Rs and deviation r as well as preset combustion temperature Ts and deviation t; 3, a fire is set to burn, and the operation lasts M minutes; 4, flow rates of combustion-supporting gas and fuel gas are detected through a flow sensor, and the actual air-fuel ratio R is calculated; 5, the actual air-fuel ratio R and the preset air-fuel ratio Rs are compared, and when the value of Rs minus r is equal to or less than R and R is equal to or less than the value of Rs plus r, the step 6 is carried out, and when the situation above does not exist, an air-fuel ratio regulation subprogram is operated first, and then the step 4 is operated; and 6, the actual combustion temperature is detected through a temperature sensor. The method provided by the invention has the characteristics of flexibility in operation, accuracy in temperature control, good flame quality, small variation in combustion temperature, and high welding quality.

Owner:MIDEA GRP CO LTD

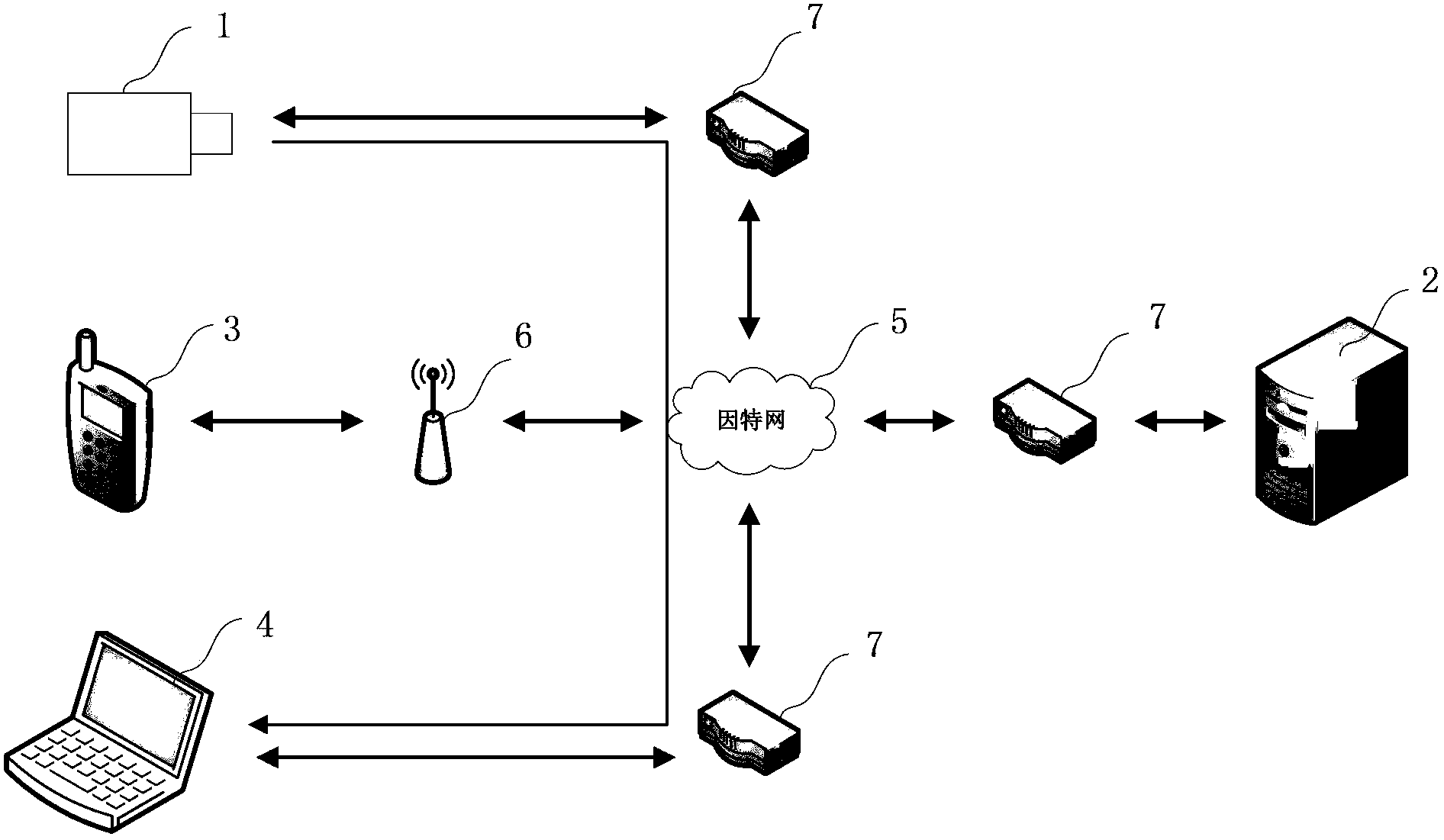

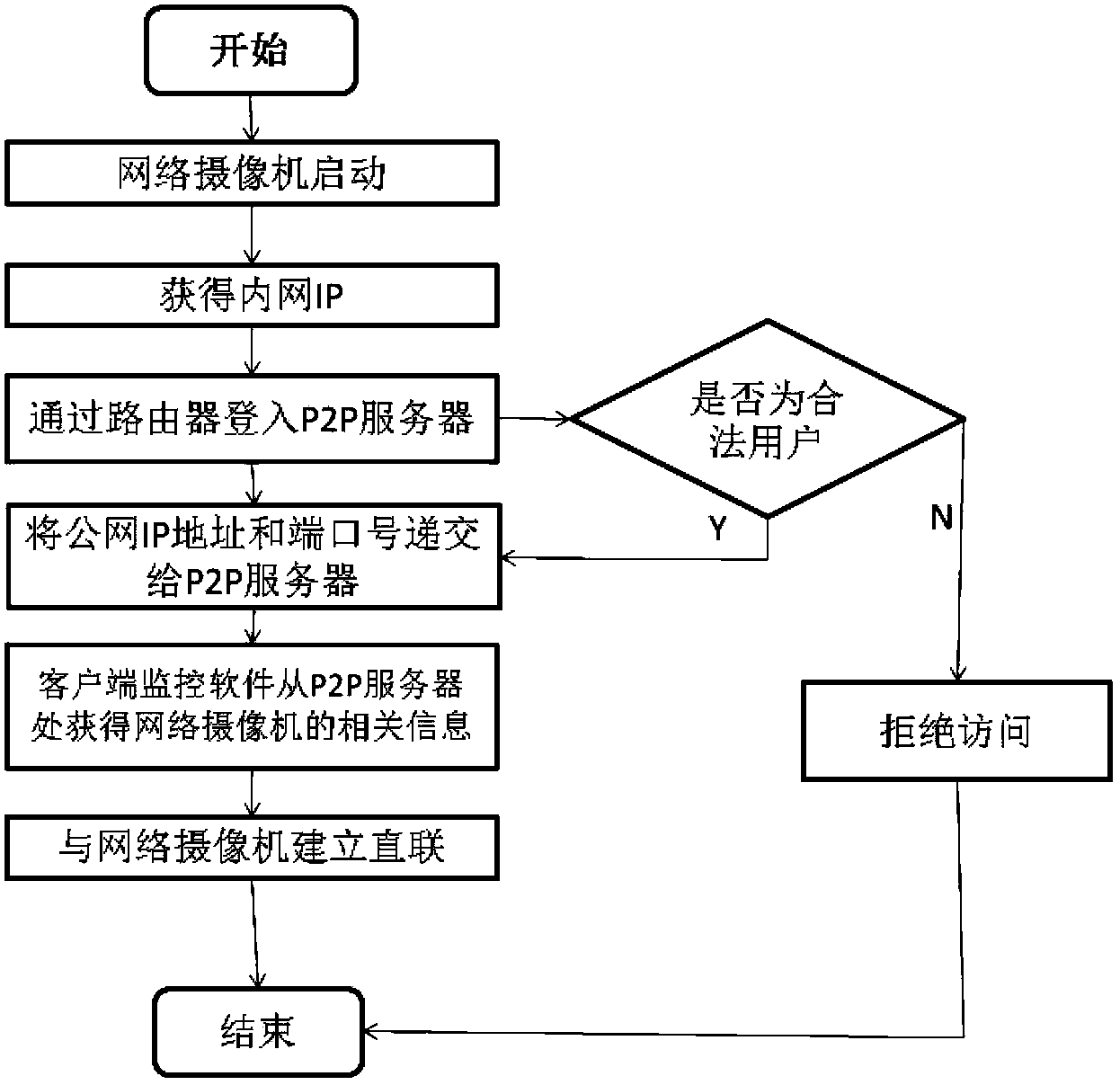

P2P video security and protection monitoring platform of 3G Internet of things

InactiveCN103517036ARealize fool-like operationEasy to installClosed circuit television systemsSelective content distributionThe InternetThird generation

The invention relates to a P2P video security and protection monitoring platform of the 3G Internet of things. The P2P video security and protection monitoring platform comprises an IP camera, a P2P server, the Internet and a monitoring terminal, wherein the IP camera, the P2P server and the monitoring terminal are connected through the Internet, the monitoring terminal comprises a mobile phone which is connected to the Internet through the 3G network, the IP camera is connected with the monitoring terminal point to point through the P2P server, and after the point-to-point connection of the IP camera and the monitoring terminal is built, the IP camera directly transmits image data to the monitoring terminal. Compared with the prior art, the P2P video security and protection monitoring platform has the advantages of being simple in installation, convenient to debug, strong in expandability, good in information security and the like.

Owner:SHANGHAI E WAN DIGITAL TECH

A laser printing method for cloth breadth and apparatus thereof

InactiveCN1952801AFast productionClear performanceElectrographic process apparatusOther printing apparatusEngineeringComputer design

This invention relates to cloth laser print method and its device, which comprises cloth in system, image forming system and image position system, wherein, it sets cloth in system in front of image forming system by use of computer design and edit; directly printing words or pattern through the device onto cloth or other print medium; according to matched carbon powder it loads the cloth into laser print device; finally computer sends print signals to print words or pattern onto cloth through laser device.

Owner:高本强

Automatic letter sorting mechanism

The invention discloses an automatic letter sorting mechanism. The automatic letter sorting mechanism comprises a sorting machine. A conveying belt is arranged below the sorting machine and vertically provided with a plurality of letter storing grids. At least one storage rotary disc is arranged beside the conveying belt. The sorting machine comprises a shell. An inlet is formed in the upper surface of the shell, an outlet is formed in the lower surface of the shell, and a suction cup is arranged on one side face of the shell. A friction stop block is arranged at the outlet position. A guiding groove is formed in the lower portion of the shell. Scanning devices are symmetrically arranged on the two sides of the guiding groove. The guiding groove corresponds to the side face, provided with the suction cup, of the shell. According to the provided technical scheme in the embodiment, after the sorting machine is used for scanning letters, the letters are temporally stored and then distributed into the corresponding storage rotary discs, high-efficiency, large-batch and continuous letter sorting can be achieved, it can be made that large-batch letter sorting work can be finished only by few people as much as possible, and manual operation links are simple. Meanwhile, the automatic letter sorting mechanism can be integrated with an intelligent express cabinet, and the fool-style operation of express and letter delivery is achieved.

Owner:SF TECH

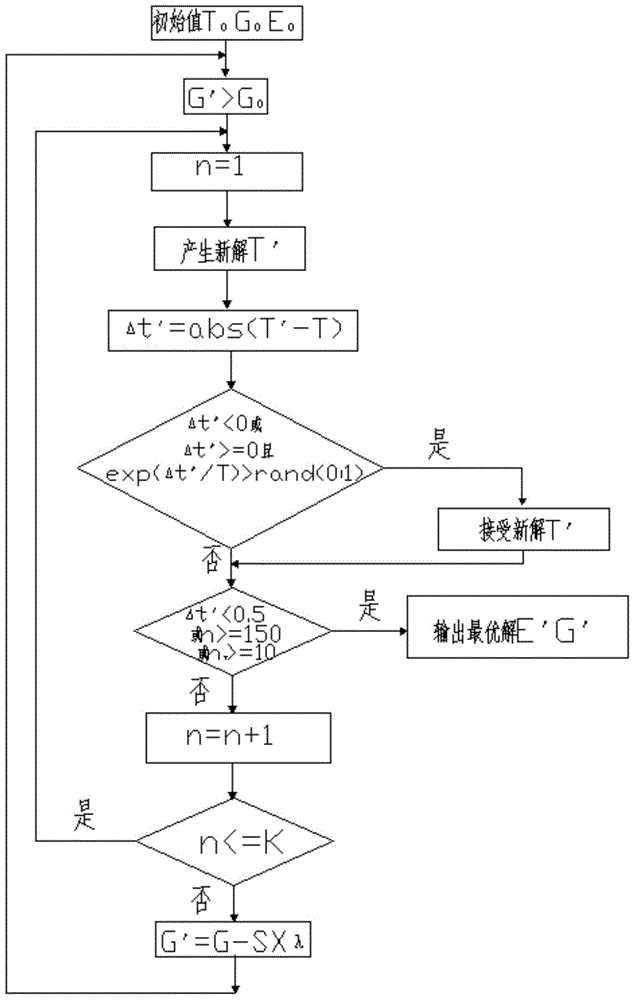

Automatic white balance method for camera based on simulated annealing algorithm

InactiveCN105791792ARealize automatic white balance operationEasy to detectColor signal processing circuitsSystem maintenanceSimulation based

The invention provides an automatic white balance method for a camera based on a simulated annealing algorithm. The basic idea of adopting the simulated annealing algorithm is to utilize a random optimization problem solution procedure and the similarity with a heat balance problem in the statistic mechanics, the automatic white balance is realized based on the simulated annealing algorithm to complete the exposure and gain regulation of the camera, and an automatic white balance of an industrial camera is realized. A collected image of an online detection system is stable and reliable, which is conducive to detection. Meanwhile, since the system adopts the automatic white balance algorithm based on the simulated annealing algorithm, the operation complexity for realizing the white balance of the system of laypeople is simplified, fool operation is realized, an automatic white balance function of the industrial camera is realized, and the system maintenance is reduced.

Owner:XIAN HENGCHUAN COMMERCE & TRADE

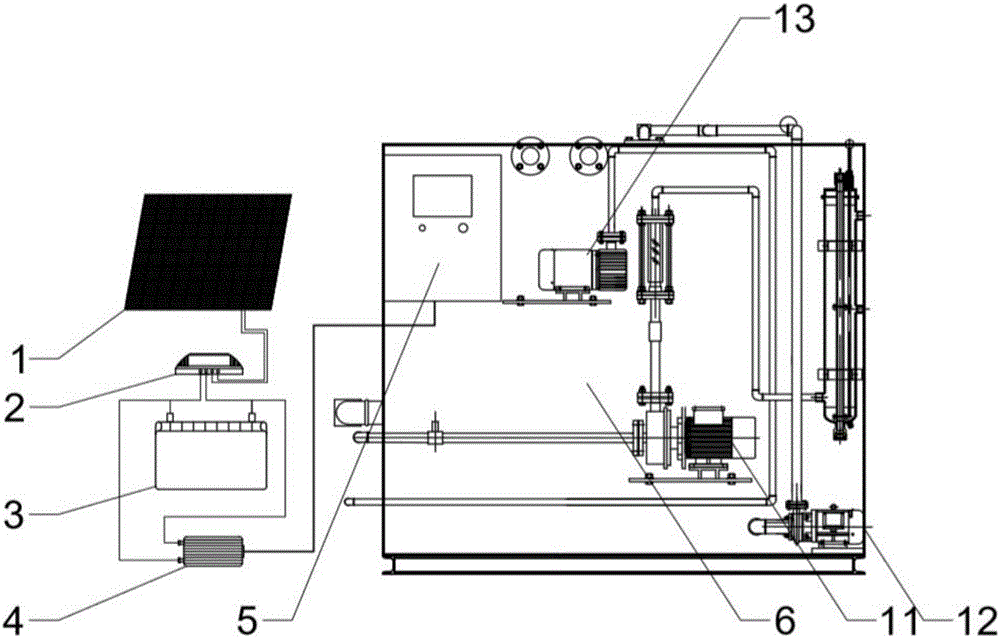

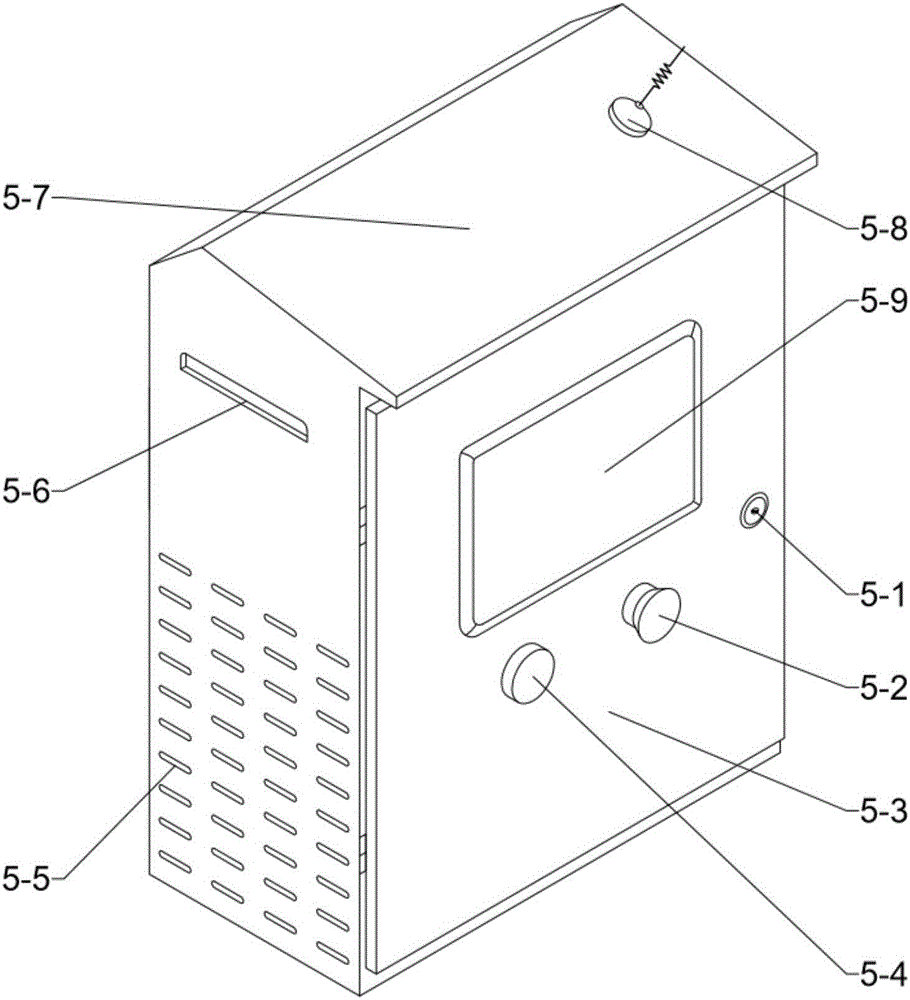

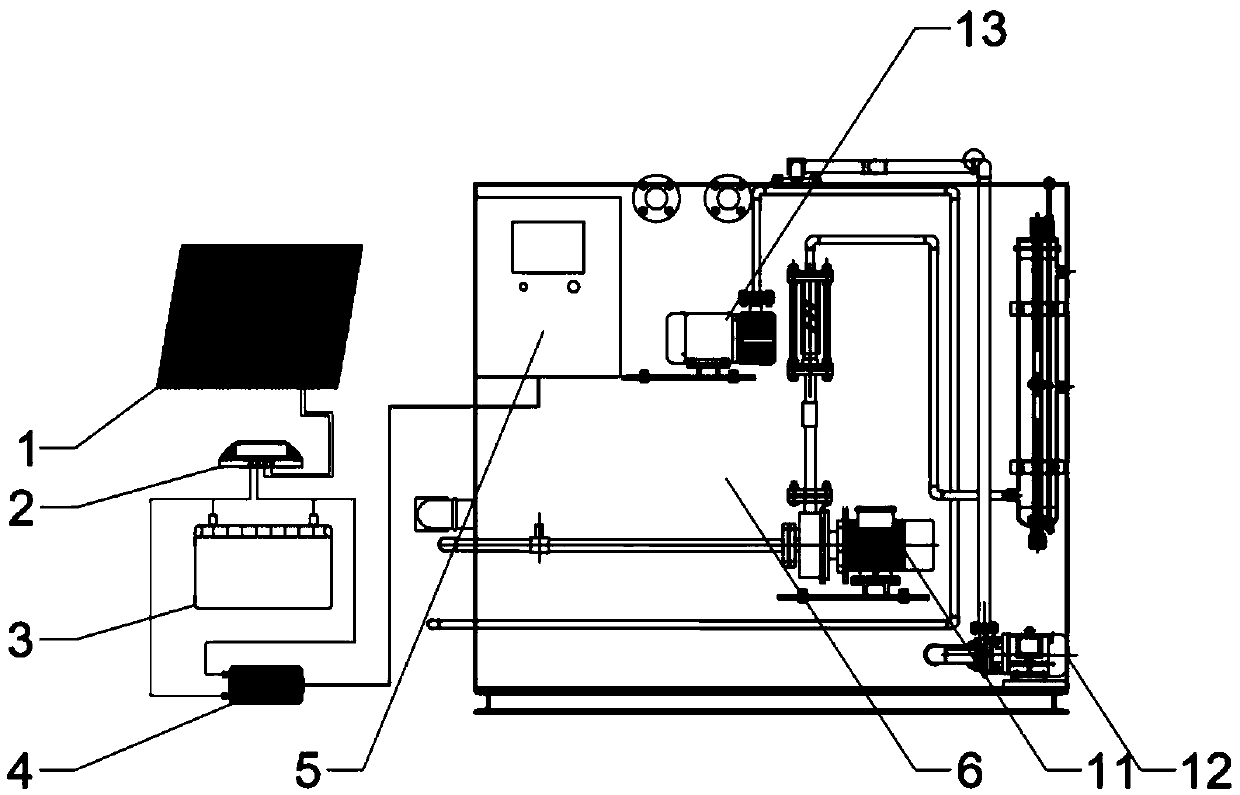

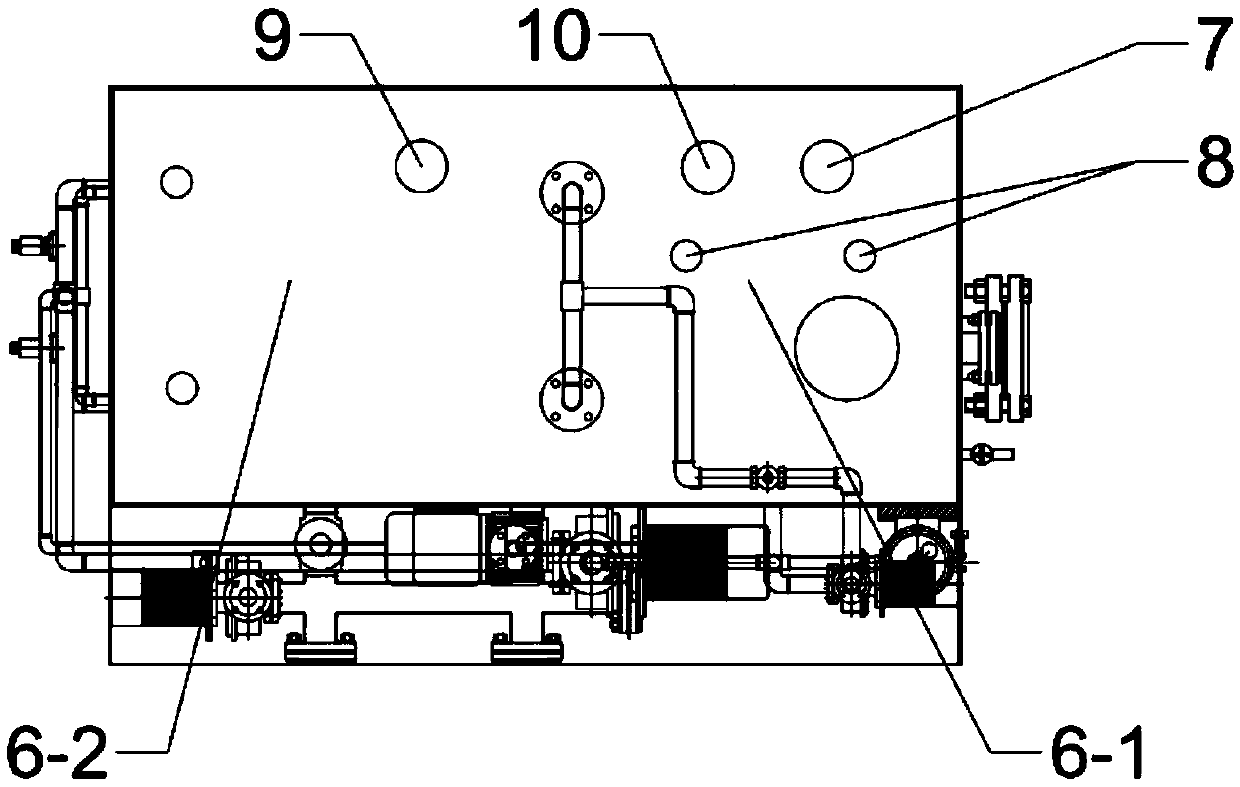

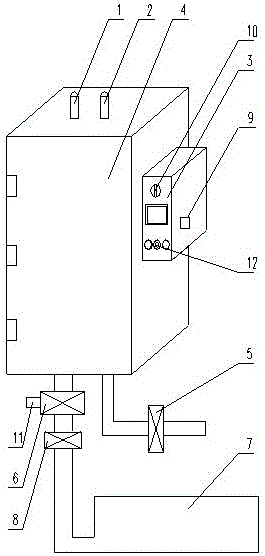

Optical self-driven intelligent vessel sewage recycling apparatus and control method thereof

ActiveCN106774139ASave electricity on boardImprove work efficiencyProgramme control in sequence/logic controllersEngineeringSewage treatment

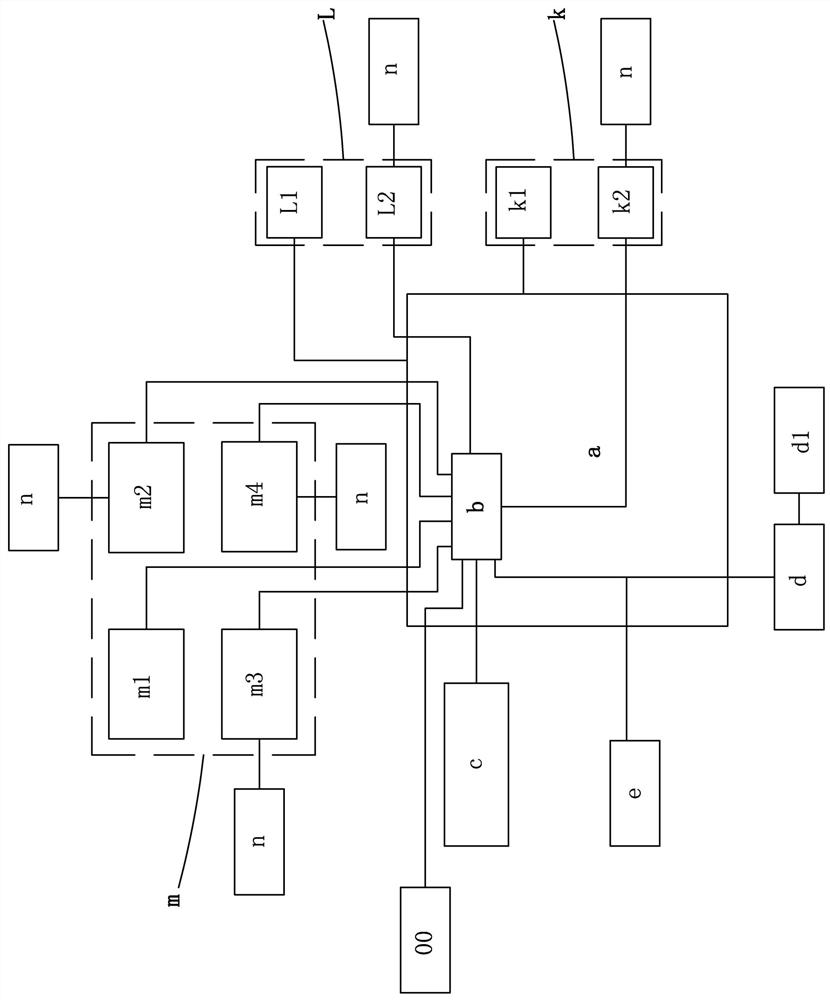

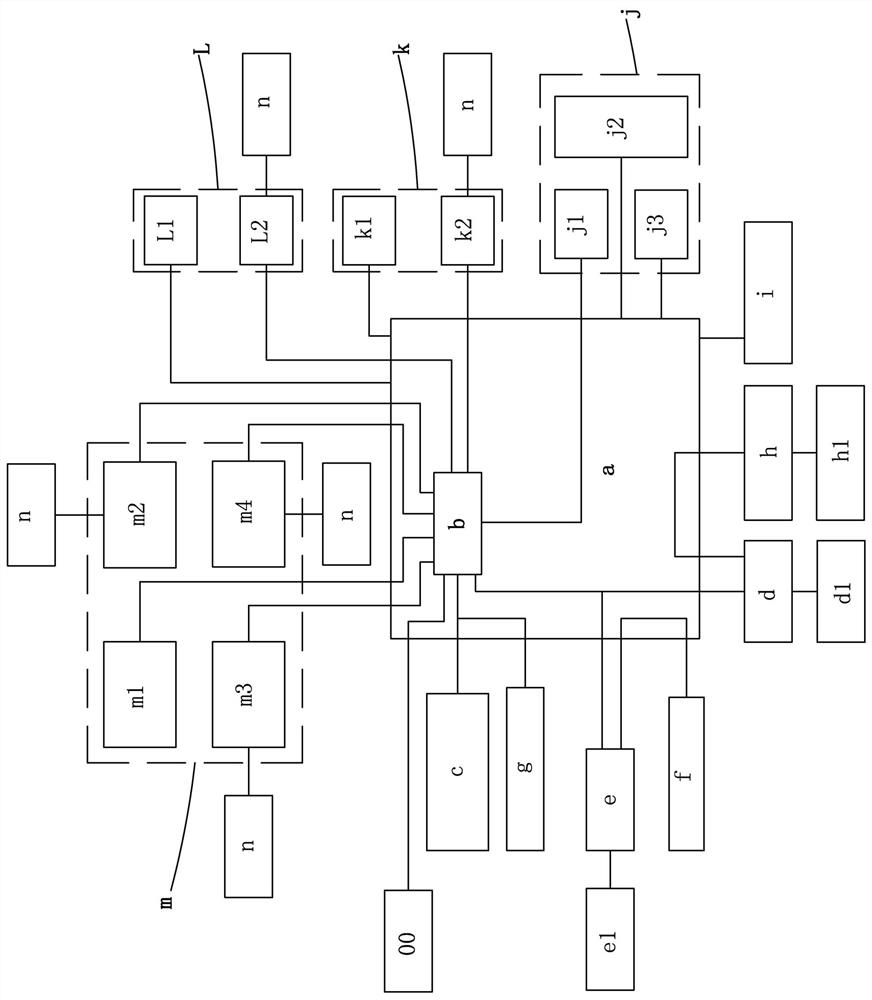

The invention provides an optical self-driven intelligent vessel sewage recycling apparatus and a control method thereof; a solar panel is arranged at the top of a vessel and connected with a controller, the controller is connected with two battery packs, the battery packs are connected with an inverter, the inverter is connected with an electric cabinet which is suspended in the front of the vessel sewage recycling apparatus and is connected with a level meter, a temperature and a heater in the vessel sewage recycling apparatus as well as a device to be controlled through internal junction terminals. In order to overcome the technical barriers of an existing vessel sewage treatment apparatus supporting system, such as poor intuitiveness of electric control process, operational difficulty, low efficiency, poor reliability and low operating performance, and also the problem that the vessel sewage recycling apparatus is unable to operate independently of a power supply system of the vessel, the invention provides an remotely-operable photovoltaic generation system and electric control system combine allowing optical self-driven intelligent operation for the vessel sewage treatment apparatus.

Owner:HARBIN ENG UNIV

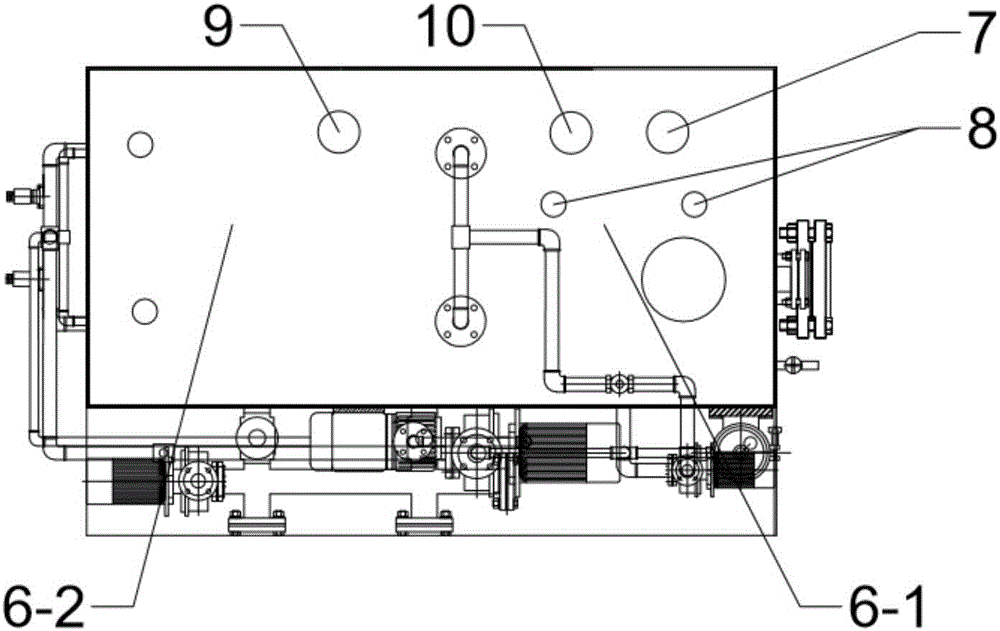

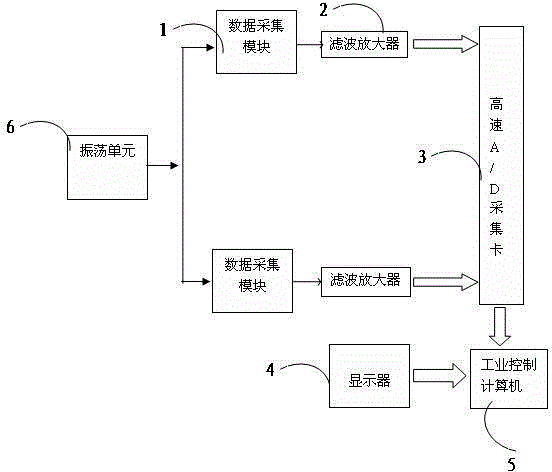

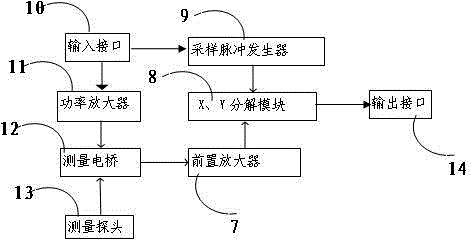

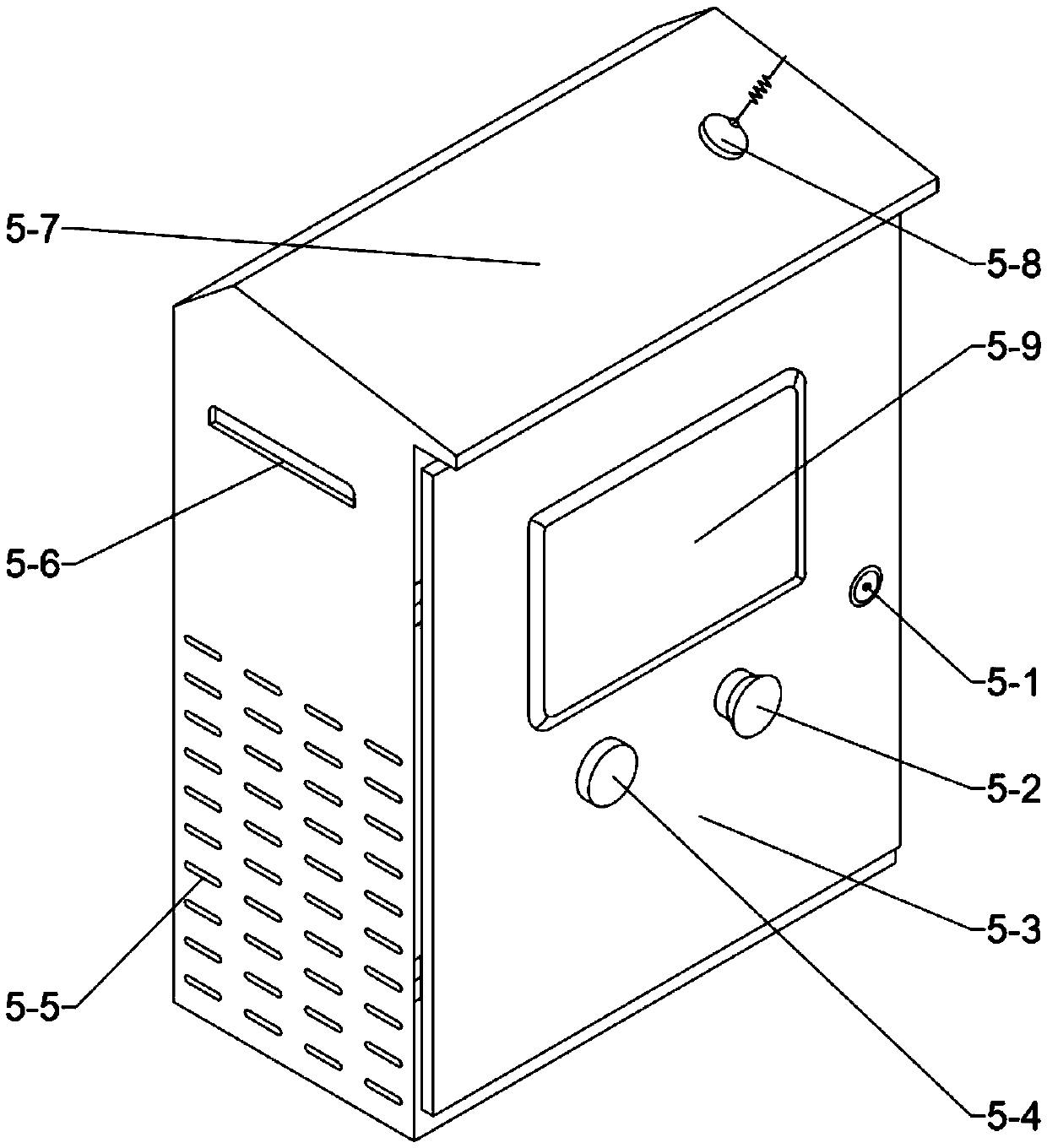

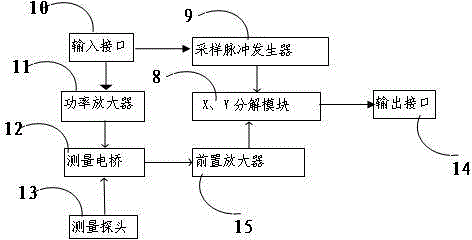

Two-channel detector

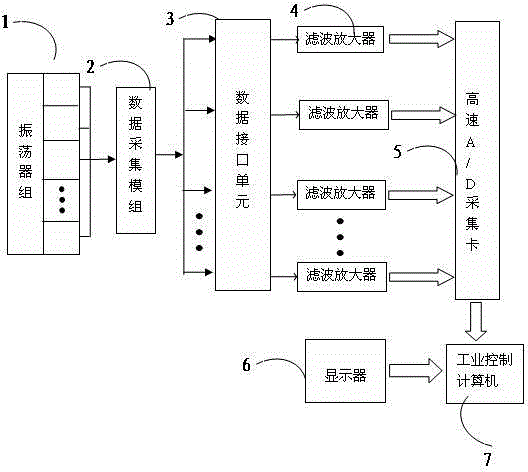

InactiveCN104569144ARealize fool-like operationMaterial magnetic variablesPhase detectorData acquisition

The invention relates to a two-channel detector which comprises an oscillation unit, two data acquisition modules, two filter amplifiers and an industrial control computer. Each of the data acquisition modules is provided with an output interface and an input interface. The oscillation unit is connected with the input interfaces of the data acquisition modules through signal lines. The filter amplifiers are connected with the output interfaces through signal lines. The filter amplifiers are connected with a high-speed AD acquisition card through signal lines. The high-speed AD acquisition card is connected to an input port of the industrial control computer through a signal line. The invention provides multiple display modes for selection, and a full-digital design technology is applied. When product specification of a product is changed, there is no need to readjust the detector.

Owner:QINGDAO GUANDA TRADE

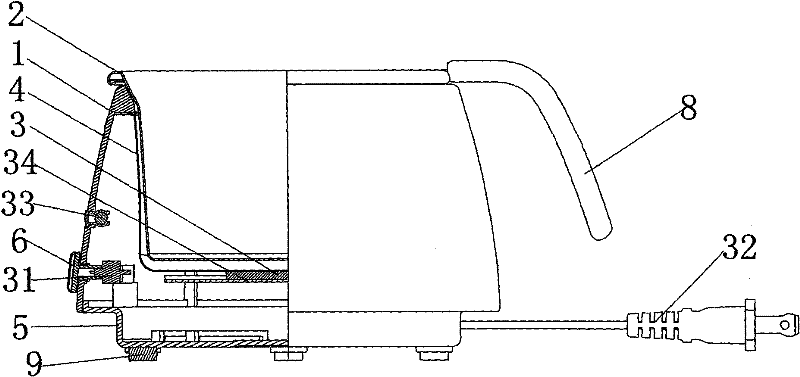

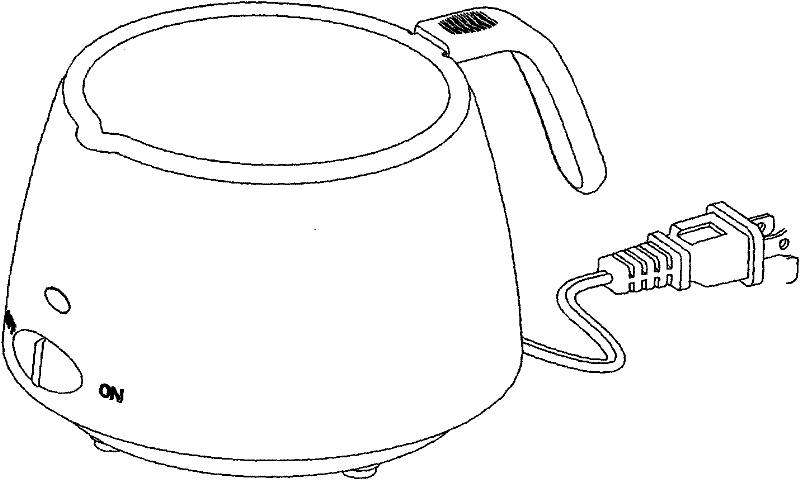

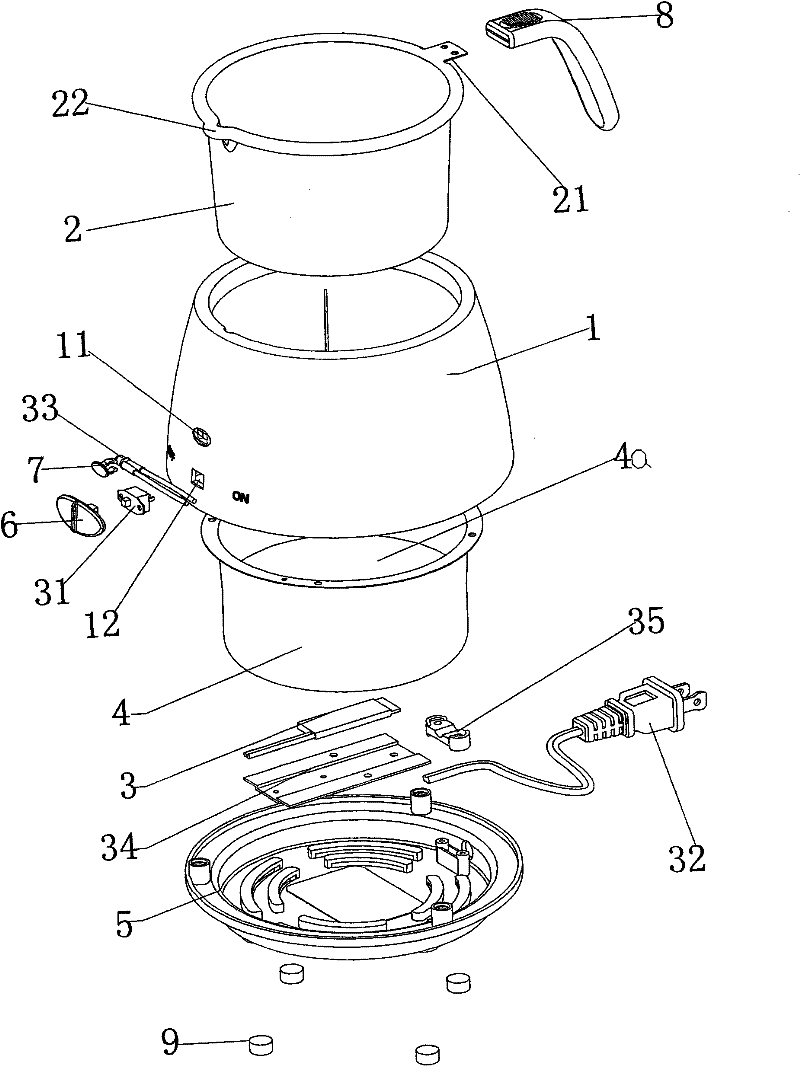

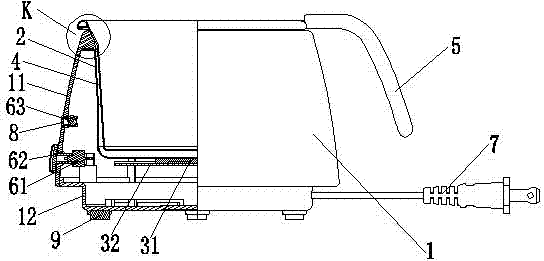

Chocolate melting furnace

InactiveCN101982083BImprove thermal conductivityEasy to cleanCooking vesselsCocoaChocolate cakeHeat conducting

The invention discloses a chocolate melting furnace. The furnace comprises a shell, a melting pot and a heater group, wherein an aluminum coated liner with excellent heat conducting performance is fixed and embedded in the shell; the melting pot is arranged in the heat cavity of the aluminum coated liner; the heater group is arranged under the aluminum coated liner and closely attached to the outer wall of the bottom of the aluminum coated liner; the heater group is connected and matched with a slide switch and a power supply connecting wire for controlling the heater group; and a neon lamp indicating work states is connected in series with the slide switch. The chocolate melting furnace can be used for preparing chocolate cakes, ensures nice appearance of common foods, can prepare handmade chocolate and other foods, and has the characteristics of uniform heating, high heat efficiency, nice and elegant product, precise process, energy conservation and the like, and is convenient in use. The chocolate melting furnace has small volume and cute model, and is suitable for household, handmade chocolate shops and the like.

Owner:NINGBO JINCHUN ELECTRIC APPLIANCE

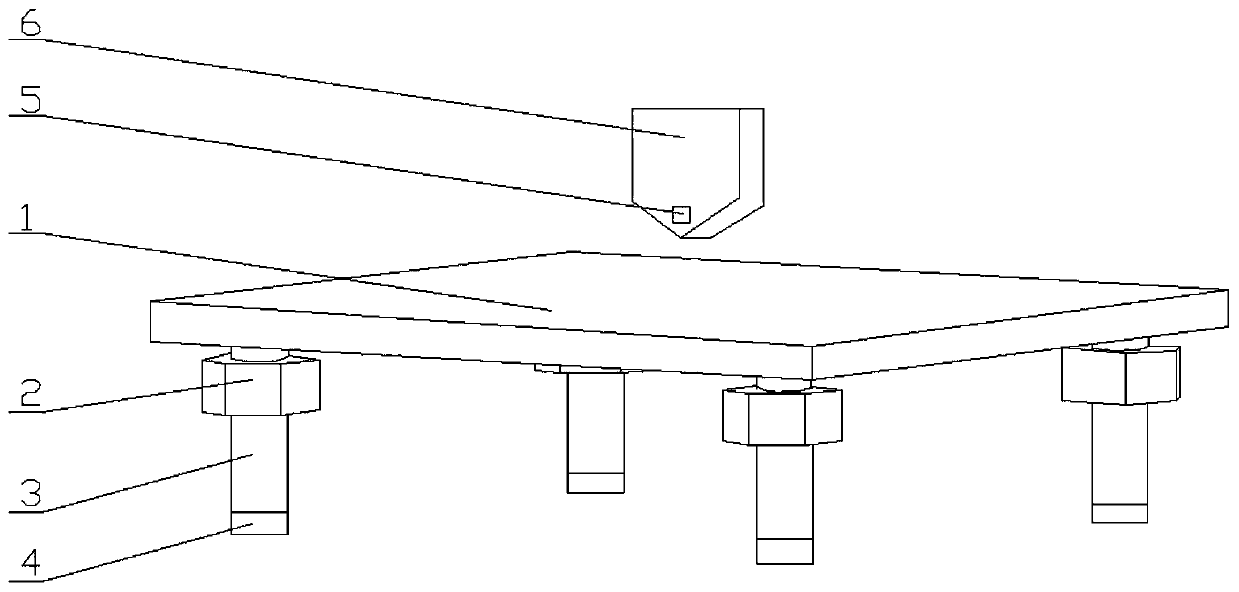

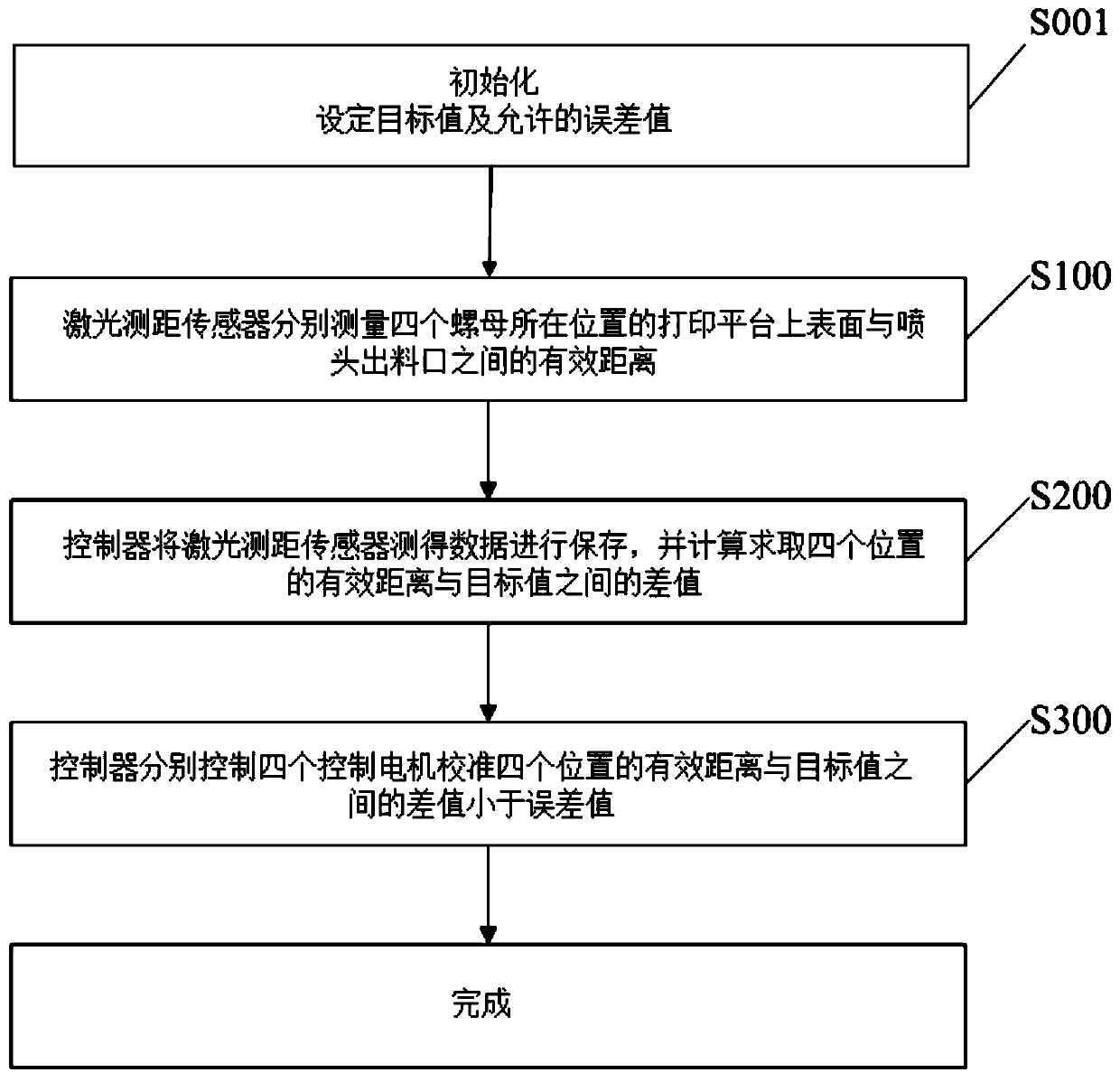

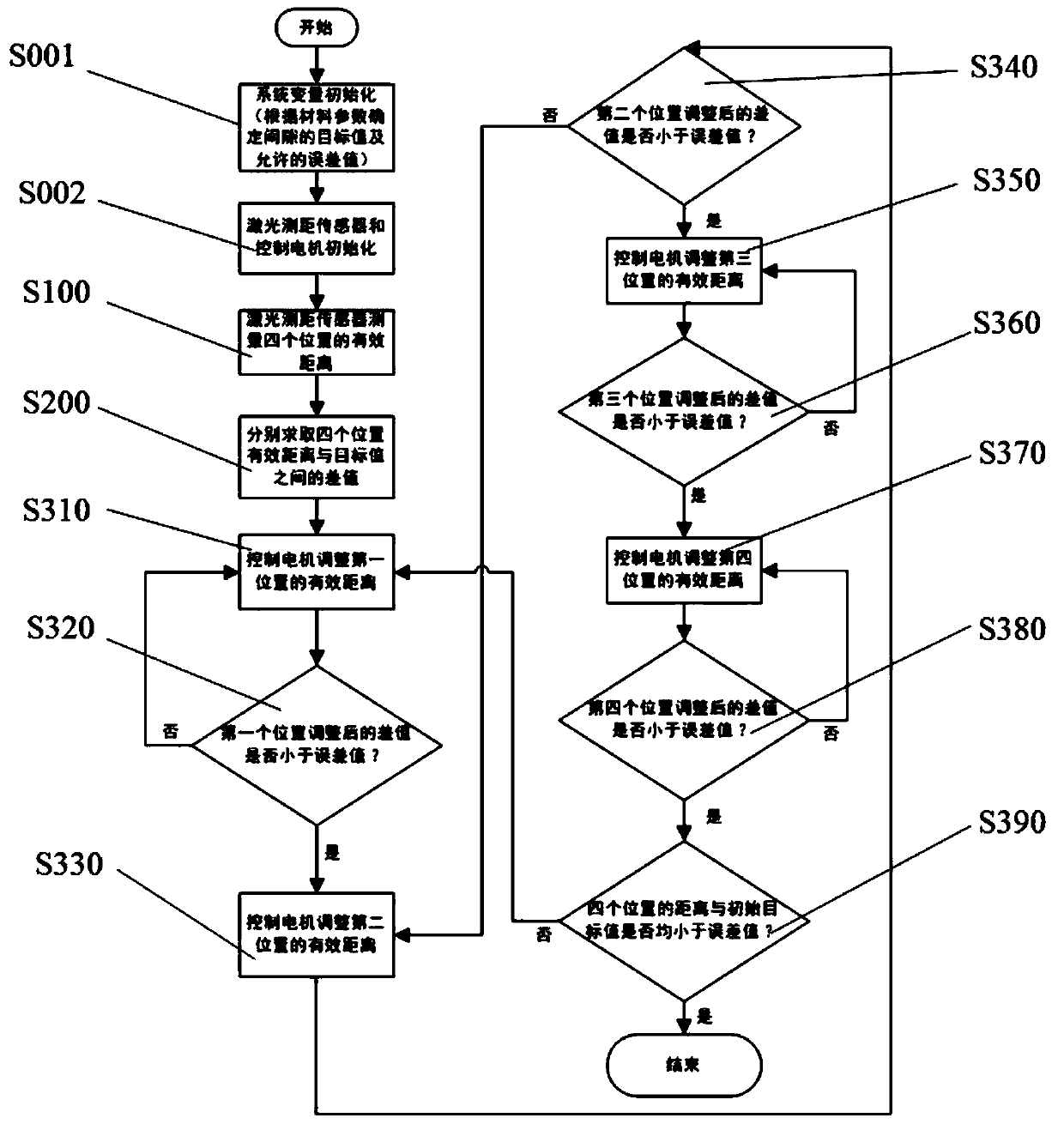

Automatic leveling device and leveling method for fused deposition additive manufacturing

InactiveCN110202786AEasy to operateImprove printing efficiency and printing accuracyManufacturing platforms/substratesManufacturing data aquisition/processingLaser rangingElectrical and Electronics engineering

The invention discloses an automatic leveling device and leveling method for fused deposition additive manufacturing, and belongs to the field of additive manufacturing. The problems that a printing platform of an existing 3D printer needs to be manually leveled by manual work, precision cannot be achieved, and efficiency is low are solved. A laser distance measuring sensor is used for measuring the distance between a nozzle and a printing platform, the measured distances of the four corners are fed back to a controller for calculation, the differences between the effective distances of the four position points and the target value are obtained, and according to the difference value and the screw pitch of screws, the the rotating speed direction and the needed rotating angle of a control motor can be obtained through calculation; and the controller controls a stepping motor for rotating the screws mounted on the four corners, the screws are matched with nuts for achieving up and down moving, and each point on the printing platform and the nozzle form the horizontal state. Automatic leveling of the printing platform is achieved, the printing precision and the printing efficiency areeffectively improved, and intelligence, automation and fool operation of the fused deposition additive manufacturing device are achieved.

Owner:HARBIN UNIV OF SCI & TECH

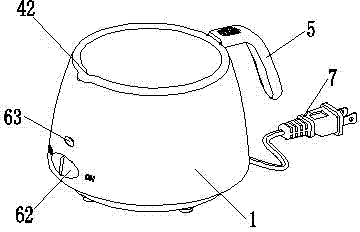

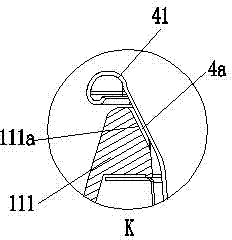

Chocolate melting oven

The invention discloses a chocolate melting oven which comprises an oven casing. An aluminized inner container is fixedly arranged in the oven casing. A positive temperature coefficient (PTC) ceramic heating assembly capable of converting electrical energy into heat energy is attached to the lower surface of the bottom of the aluminized inner container closely. An aluminum pot used for melting chocolate and using air as a medium to transmit the heat energy is movably installed in a heating cavity of the aluminized inner container in suspension and non-contact mode. A handle is assembled on the aluminum pot, and a power switch assembly controlling the PTC ceramic heating assembly to work is arranged on the oven casing. The chocolate melting oven is simple in structure, novel and attractive, can achieve automatic operation, has the advantages of being high in heat efficiency, saving energy and being equalized and uniform in temperature, and is especially suitable for families, handmade chocolate shops and the like.

Owner:宁波亿达电器有限公司

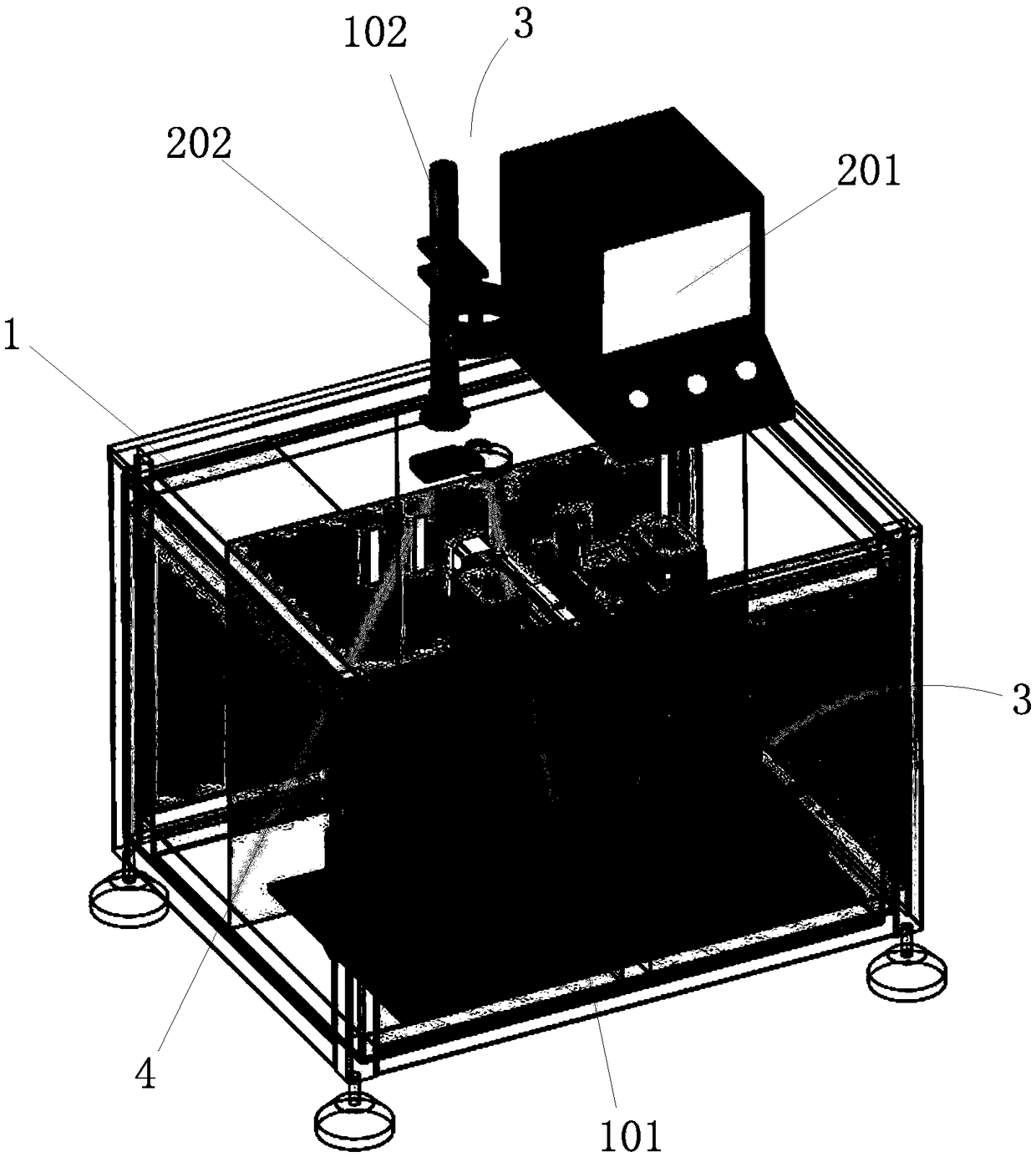

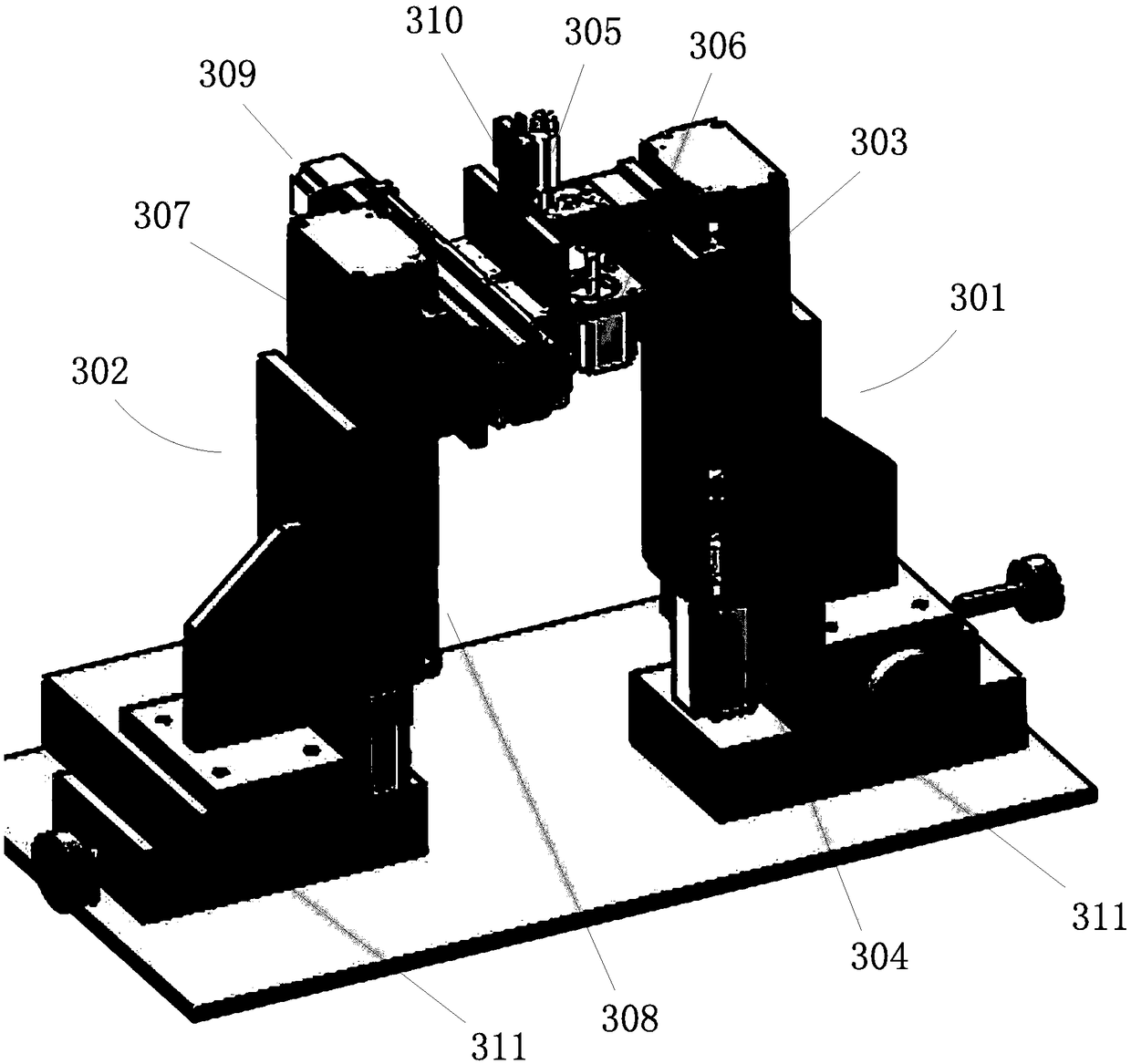

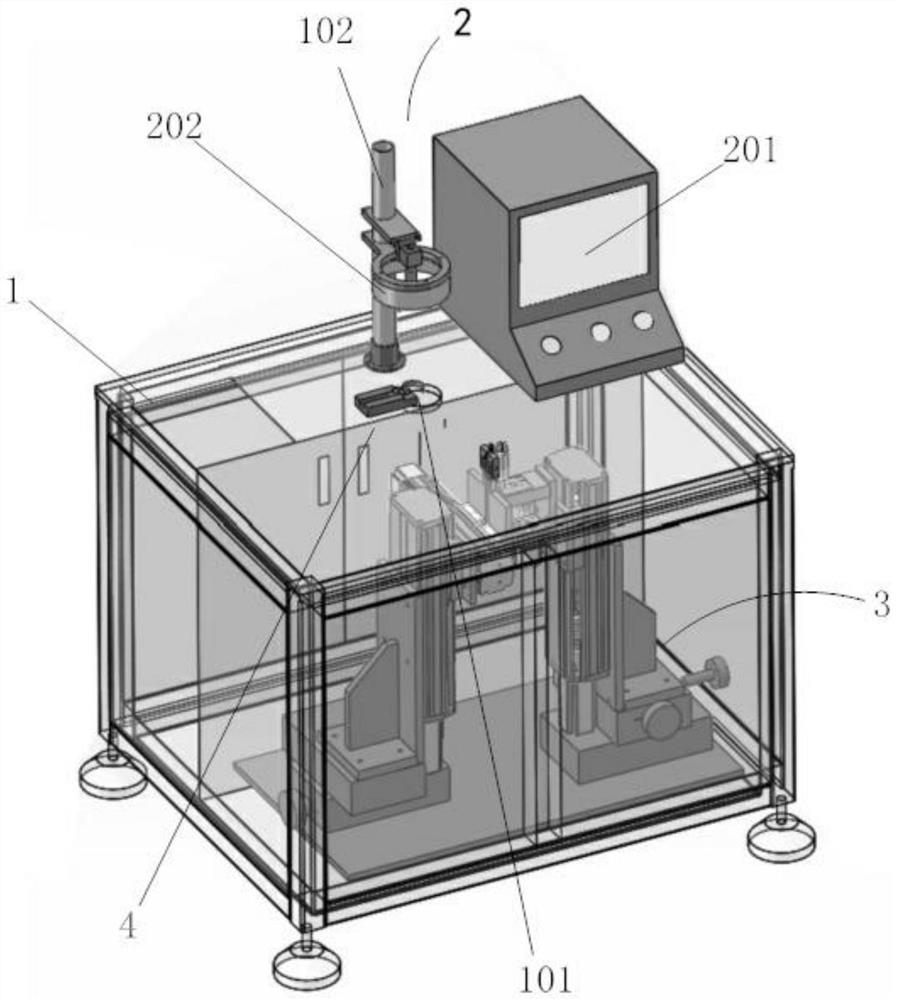

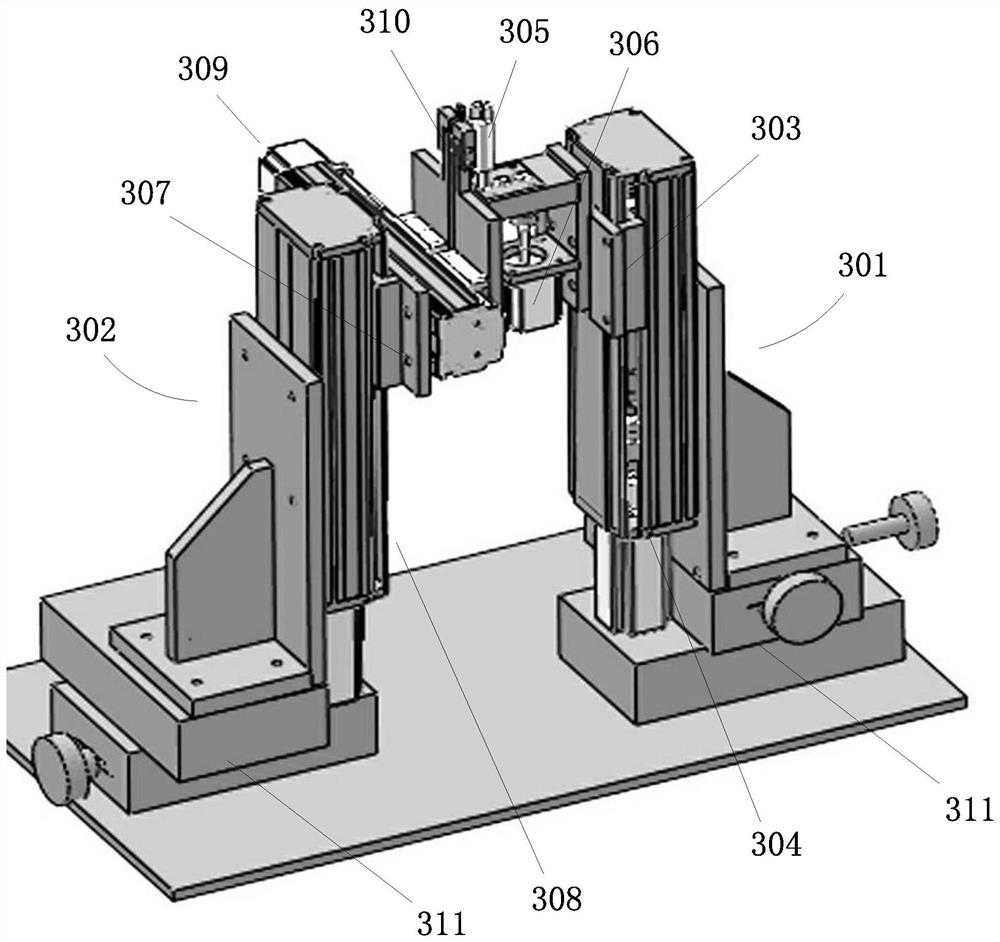

Automatic meter adjustment instrument

ActiveCN109240140AAuto-tuning implementationGuaranteed accuracyProgramme control in sequence/logic controllersElectric machineryControl theory

The invention discloses an automatic meter adjustment instrument, which comprises a bottom cabinet, a CCD (Charge Coupled Device) visual system and an adjustment system arranged in the bottom cabinet,wherein the CCD visual system comprises an industrial control host and a vision camera, and the industrial control host and the vision camera are arranged on the upper table board of the bottom cabinet; the vision camera is arranged on the upper table board of the bottom cabinet, and height is adjustable; the upper table board of the bottom cabinet is provided with a working window; the adjustment system comprises an angle adjustment device and an opening angle adjustment device, wherein the angle adjustment device comprises a sliding block A and a servo system A; the sliding block A is provided with an angle regulation rotation angle and an angle adjustment servo motor; the opening angle adjustment device comprises a sliding block B and a servo system B which is connected with the sliding block B and can push the sliding block B to vertically slide; the sliding block B is provided with a servo system C; the servo system C is provided with a clip capable of regulating the opening degree of a workpiece, and the servo motor C controls the clip to be opened and closed; and the angle regulation rotation rod corresponds to the working window. The automatic meter adjustment instrument has the characteristics of being automatic in adjustment, detection and calculation, manual work is saved, and efficiency is improved.

Owner:NINGBO ZHENGFENG ROBOT TECH

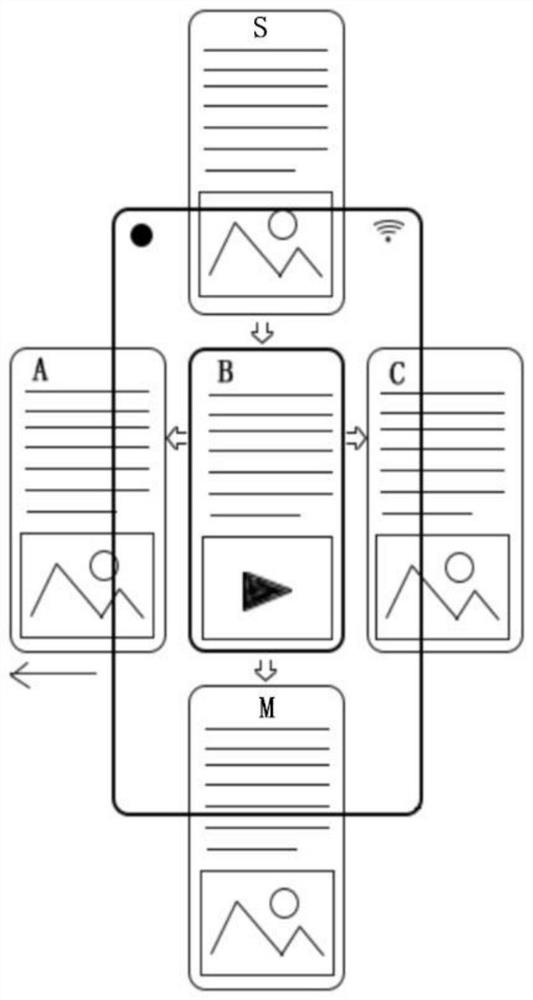

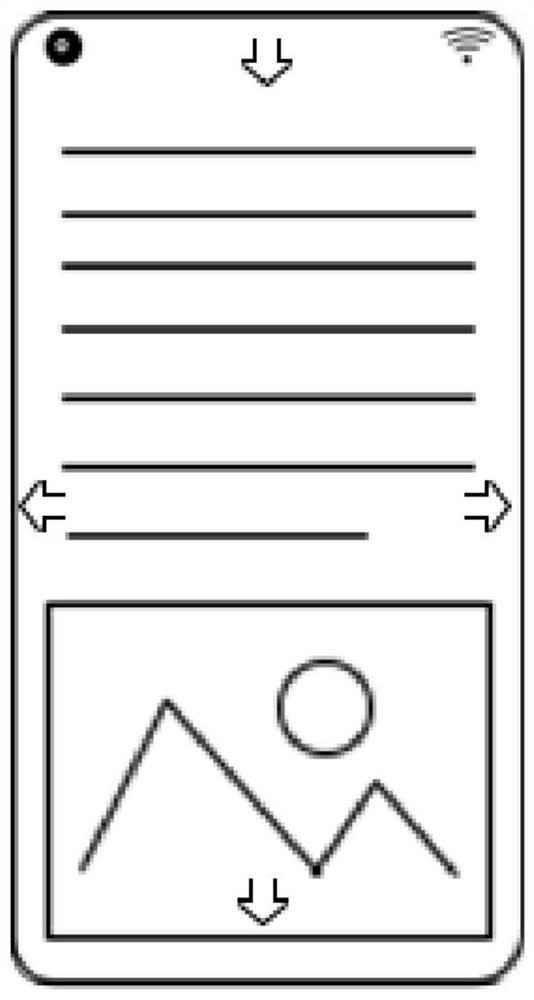

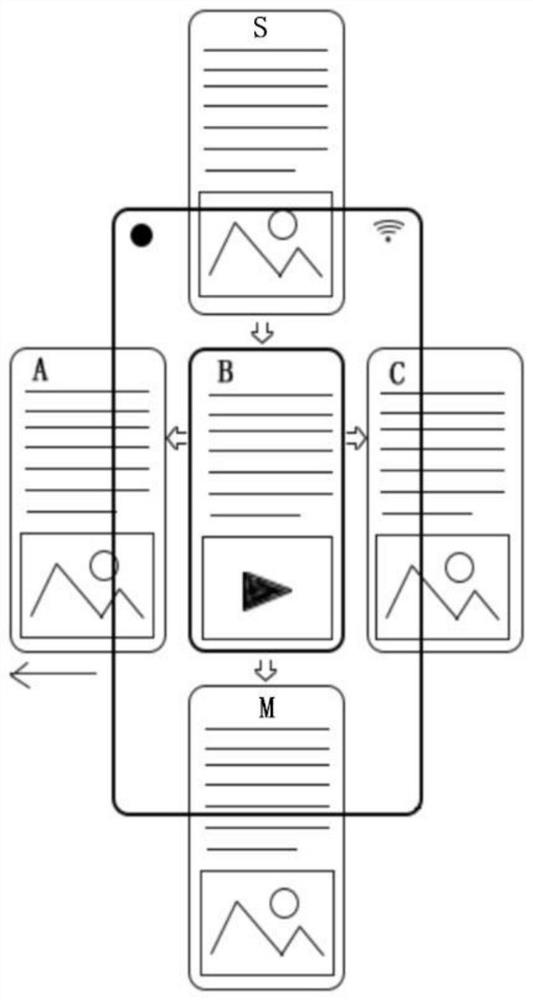

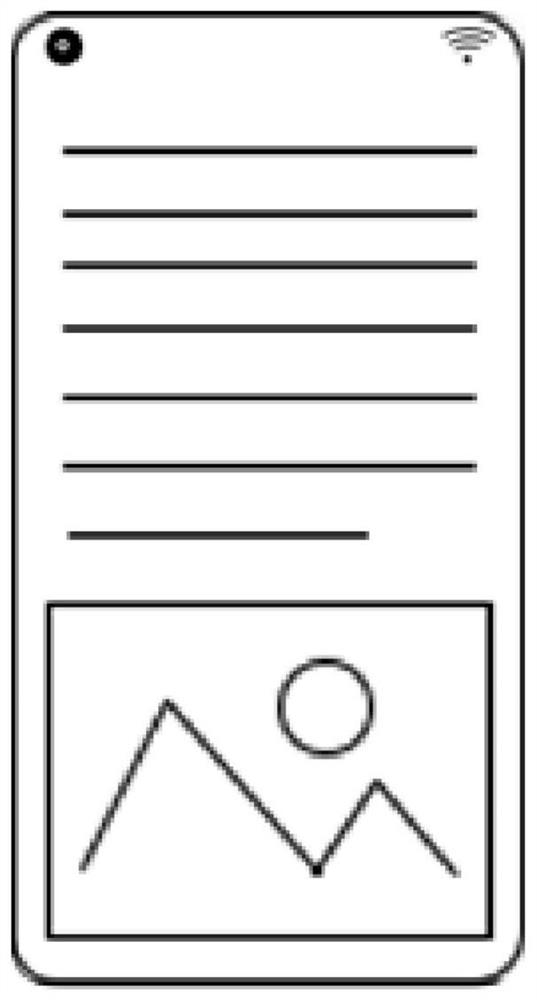

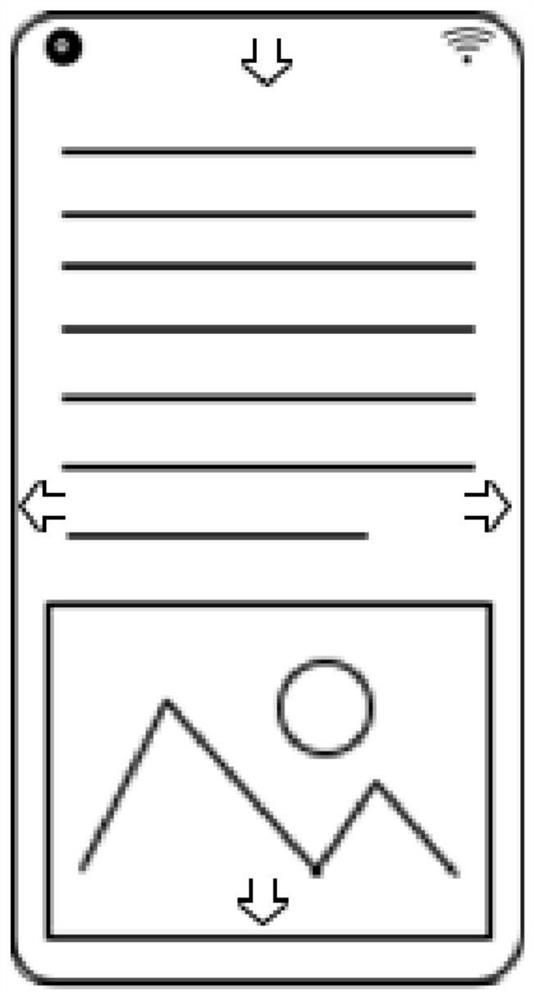

A method for making and displaying a flow chart on a computer

ActiveCN112783405BRealize fool-like operationSimplify the editing processDigital output to display deviceComputer graphics (images)Signal on

The invention discloses a method for making and displaying a flow chart on a computer, comprising: an electronic display screen coupled to a processor, the processor receives an input signal on the electronic display screen and operates the flow arrangement of a corresponding program in the computer system The process card in the figure; the process layout diagram refers to the layout diagram of multiple cards used to complete the process operation in a parallel or sequential relationship; in a specific display mode, by changing the position of the process cards existing in the display screen The electronic display screen is intended to respond to the operation of directional movement in a certain direction; when editing the flow chart, the present invention does not need to enter the editing interface separately and directly edits the steps in the flow chart, which is very convenient and intuitive, making editing The process becomes extremely simple, and it is easier for users to focus their attention resources on each refined step, improving efficiency.

Owner:张飞

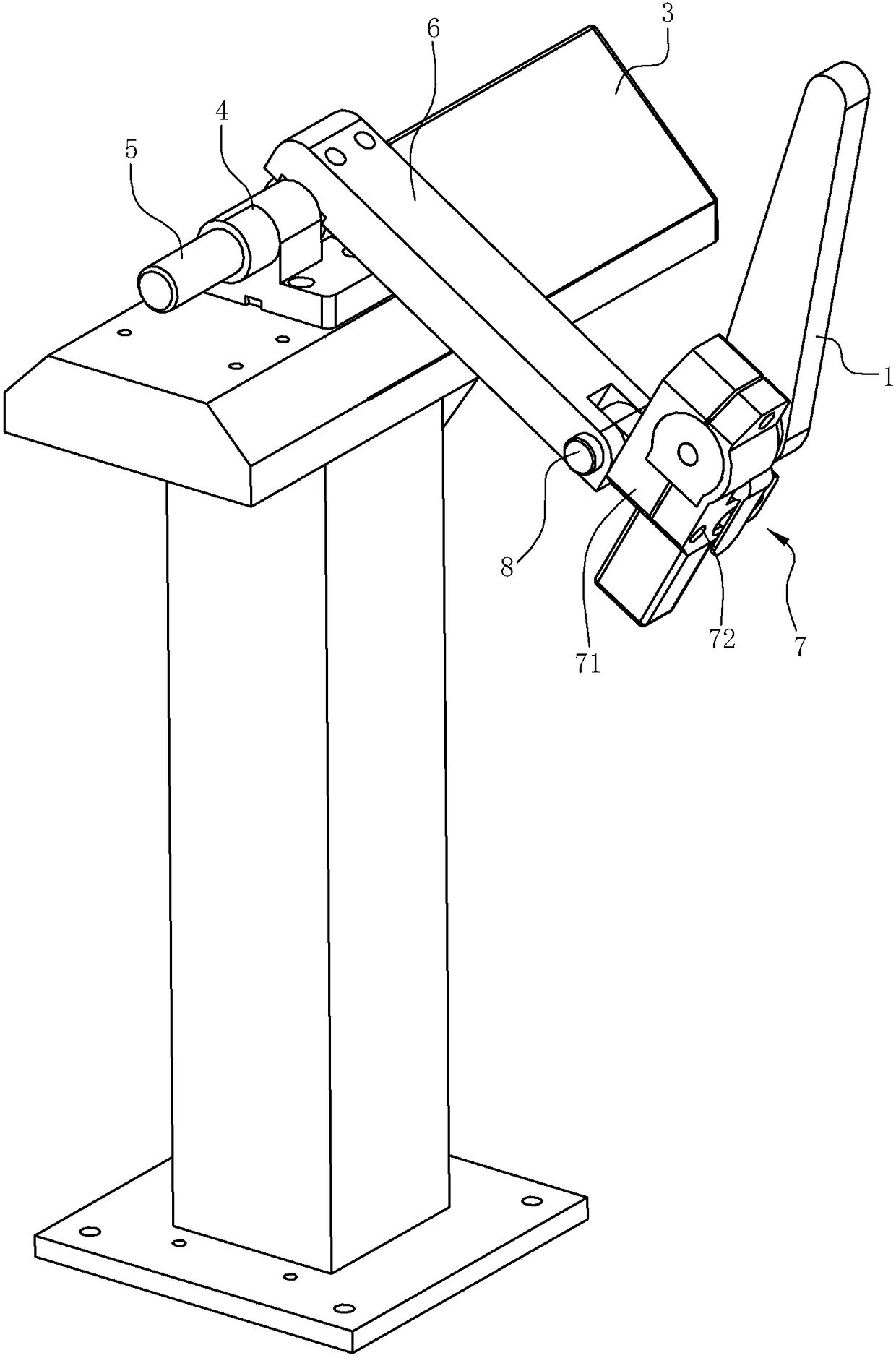

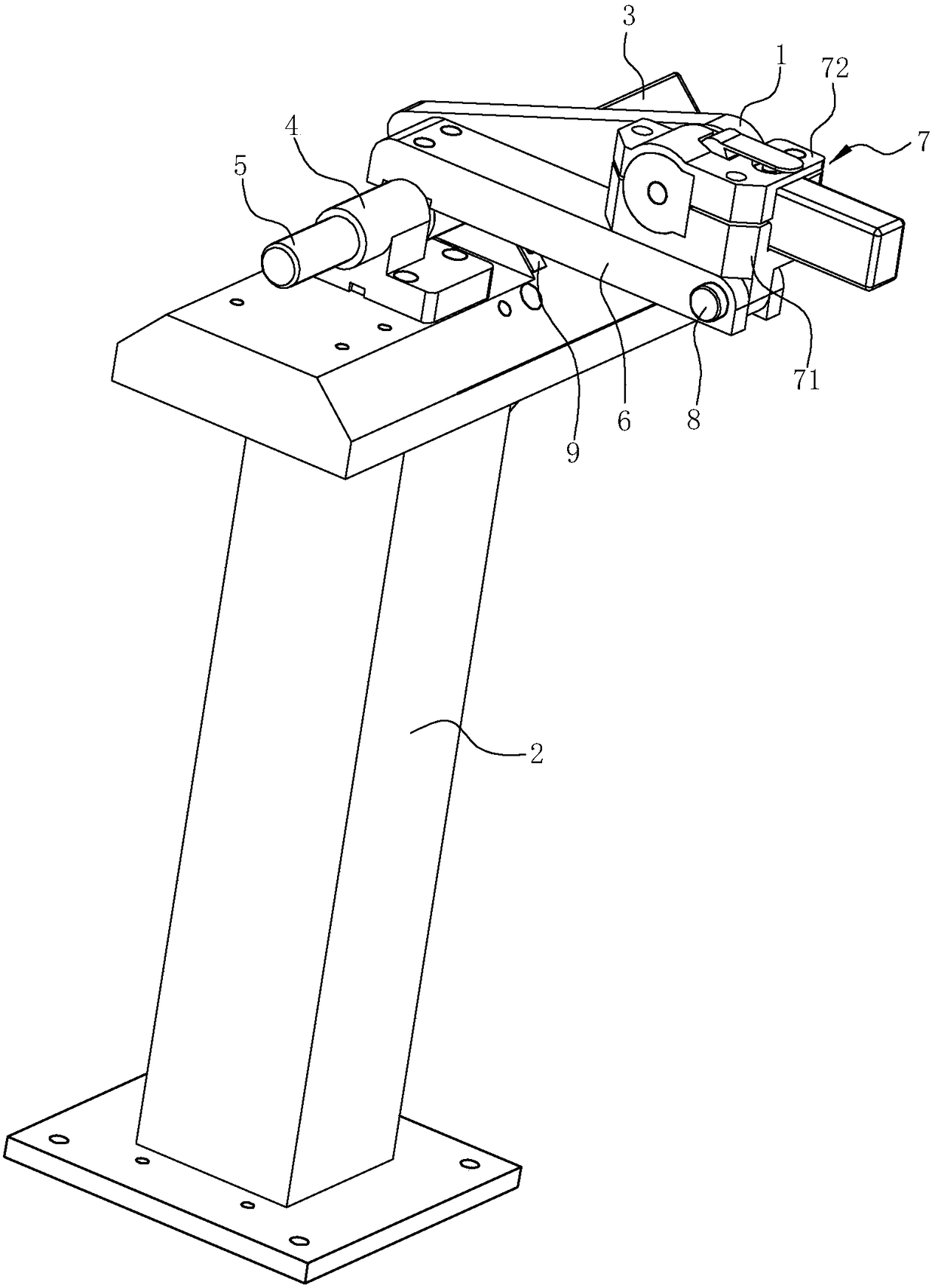

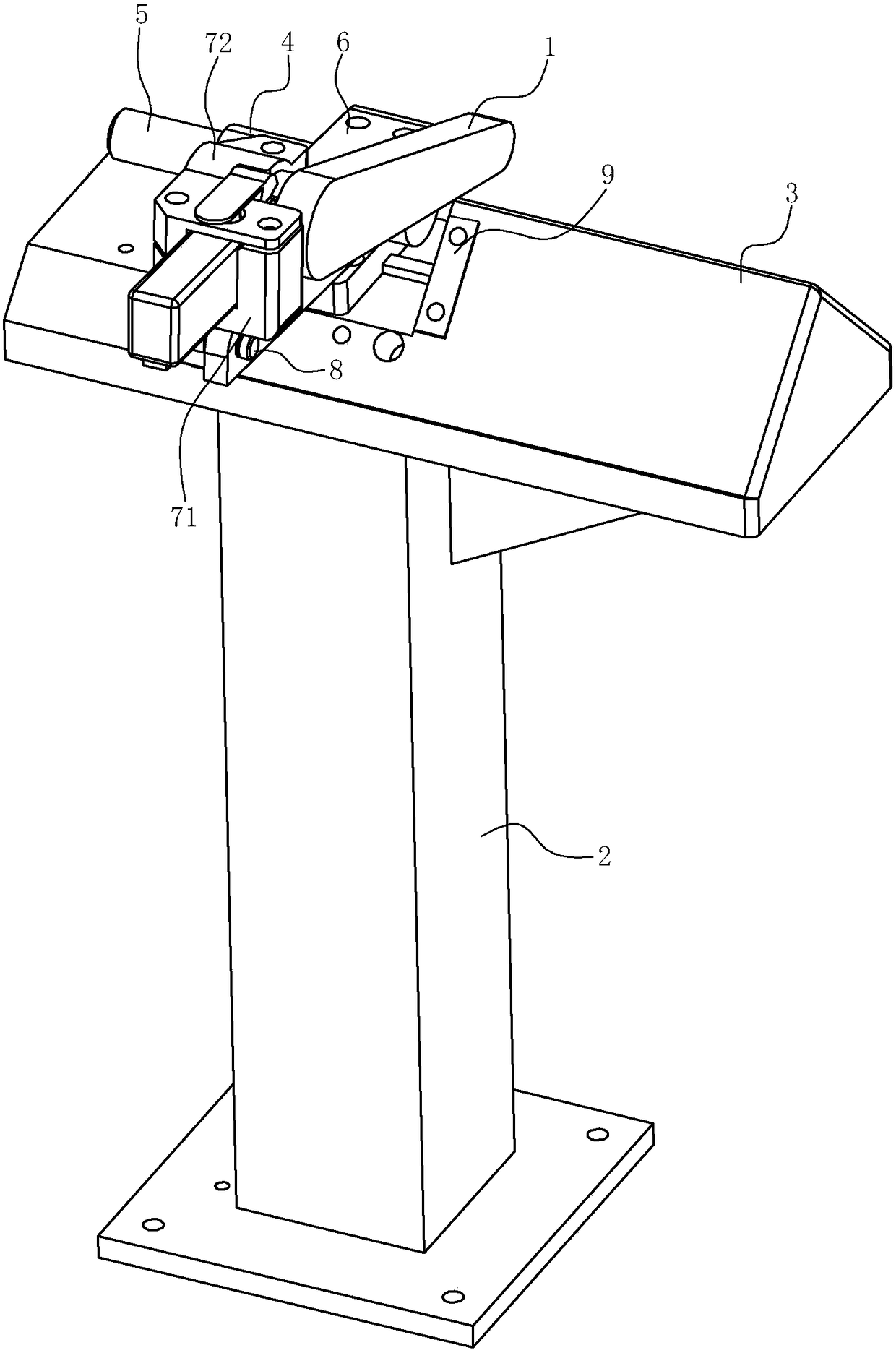

A fixed-size fillet grinding device

ActiveCN106041685BPrecise control of fillet radiusRealize fool-like operationBelt grinding machinesEngineeringRocker arm

The invention relates to a fixed-size round corner polishing device. The fixed-size round corner polishing device comprises a polishing machine for polishing a round corner on a workpiece to be polished. The fixed-size round corner polishing device is characterized by further comprising a support, a rotary shaft base and a rocker arm, wherein a workpiece holding base for holding the workpiece to be polished is arranged on one side of the upper portion of the support; the rotary shaft base is fixed to the other side of the upper portion of the support and provided with a rotary shaft capable of rotating around the axis of the rotary shaft, and the axis of the rotary shaft is coaxial with the center of the to-be-polished round corner of the workpiece to be polished; and the front end of the rocker arm is fixed to the rotary shaft, the rocker arm can rotate along with the rotary shaft, and the polishing machine is mounted on the rocker arm and can swing along with the rocker arm. The rocker arm is used for limiting the motion trail of the polishing machine so that the radius of the polished round corner can be controlled accurately. During polishing, the workpiece to be polished is mounted on the workpiece holding base, then the polishing machine is started to slowly get close to the to-be-polished edge of the workpiece, after an abrasive belt makes contact with the workpiece, the rocker arm starts to rotate, polishing is completed after the rocker arm moves along the polishing trail by a circle, and thus simple operation is achieved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

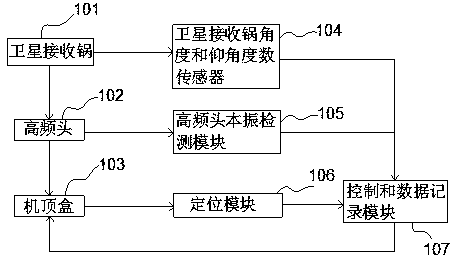

Simple and convenient satellite search method based on automatic identification of relevant parameters of high-frequency head

InactiveCN109752742AEasy to search starsSolve the problem that the specific parameters of the high-frequency head cannot be automatically identifiedSatellite radio beaconingSatelliteEnvironmental geology

The invention discloses a simple and convenient satellite search method based on automatic identification of relevant parameters of a high-frequency head. The method comprises the following steps of acquiring degrees of an azimuth angle and an elevation of a satellite receiving pot, positioning information of a set top box and a local oscillation frequency of the high-frequency head, and sending the acquired degrees of the azimuth angle and the elevation, the positioning information and the local oscillator frequency to a control and data recording module; prearranging parameter information ofeach satellite in the control and data recording module, making the control and data recording module generate chain table information of each satellite according to the acquired local oscillator frequency and send the generated linked list information to the set top box, selecting and confirming the satellite information by a user through the set top box, and feeding back the satellite information to the control and data recording module. According to the method, the azimuth angle and the elevation of the satellite receiving pot can be quickly acquired, the local oscillator frequency of thehigh-frequency head can be acquired, and a situation that the high-frequency head cannot be used when a high-frequency head identification is lost is avoided.

Owner:安徽站乾科技有限公司

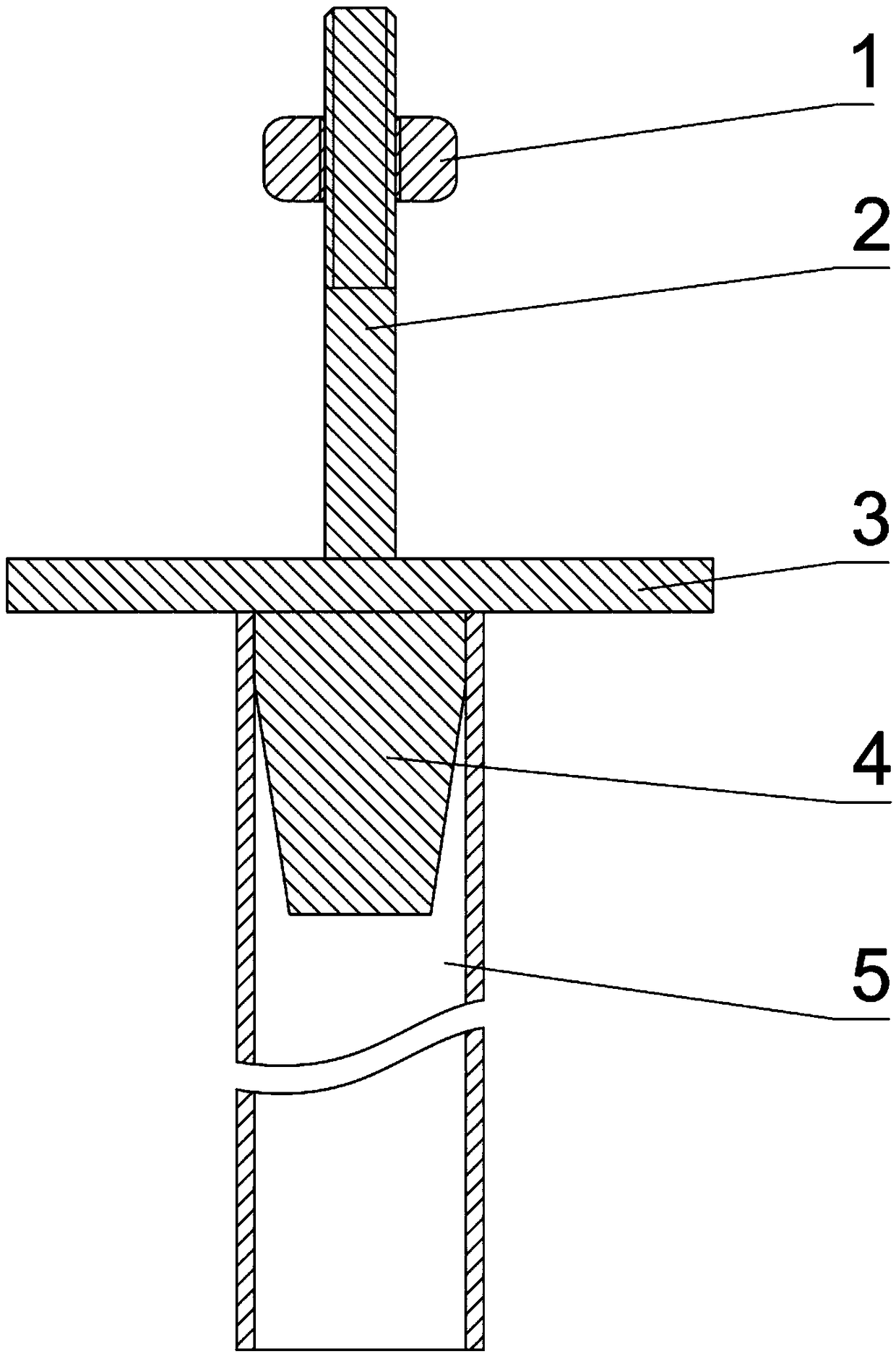

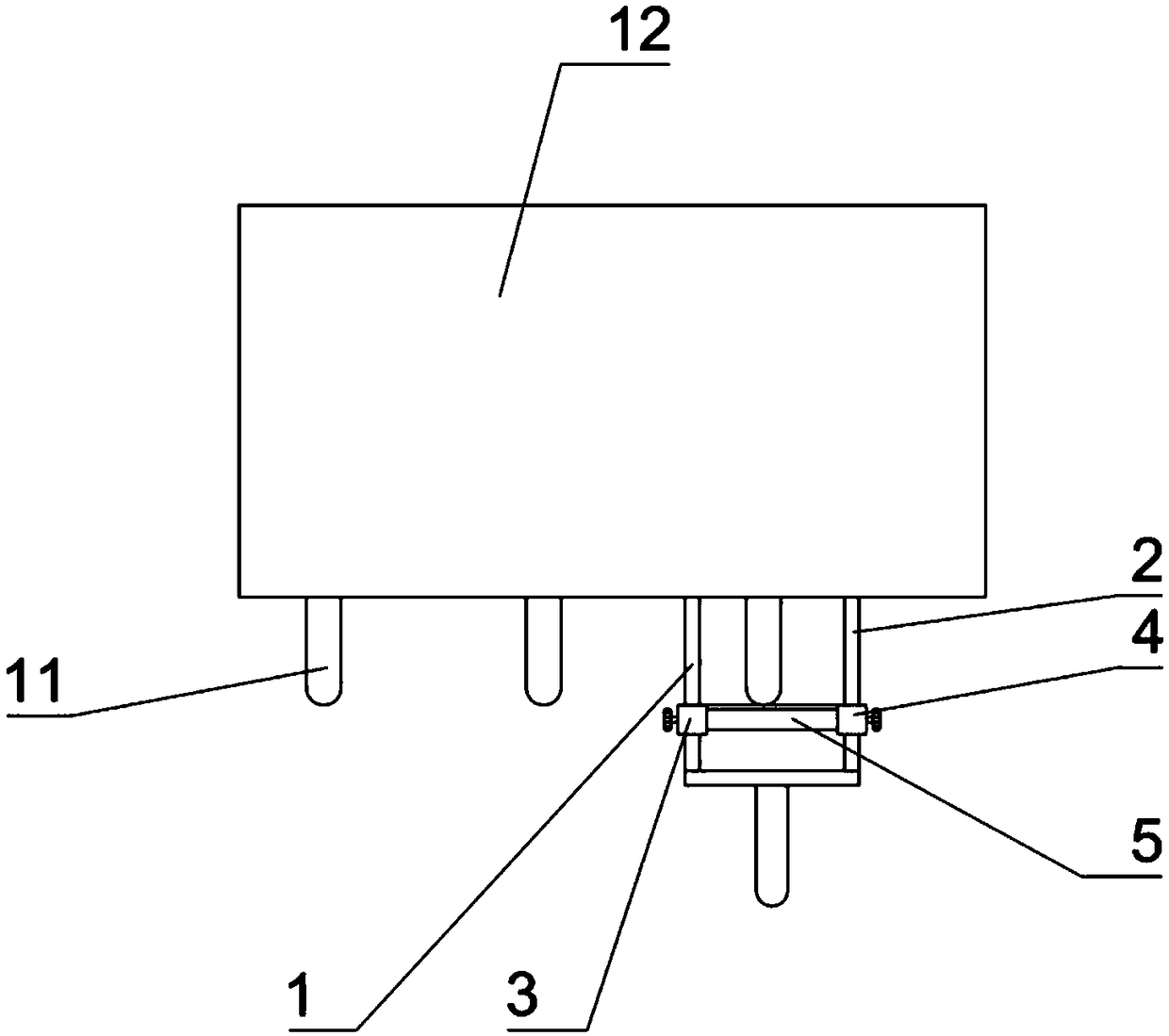

Magnetic positioning device for exposed steel bar of energy-saving prefabricated member and using method thereof

PendingCN109278183AGood effectImprove the quality of workCeramic shaping apparatusArchitectural engineeringRebar

The invention relates to the technical field of construction engineering construction tools, in particular to a magnetic positioning device for an exposed steel bar of an energy-saving prefabricated member and a using method thereof. The magnetic positioning device comprises a quantifying device and a magnetic support, the quantifying device comprises a connecting part, a base plate and a sleeve,the base plate is in a flat plate shape, the connecting part is fixedly arranged on one side face of the base plate, and the sleeve is detachably and vertically connected to the other side face of thebase plate; the magnetic support is in a square column shape and is connected with the quantitative device through the connecting part, and the sleeve and the magnetic support are perpendicular to each other. According to the magnetic positioning device, the position of the positioning device and the length of the exposed steel bar can be freely adjusted according to the size of the component, the overall device is light in weight and convenient to operate manually, in the using process, due to the fact that the positioning device is a whole, errors caused by manual disturbance are avoided, higher efficiency can be achieved when a large amount of products for fixing the exposed size are produced, the fool-type operation is basically realized, and the working quality of construction is effectively improved.

Owner:河南中安征信建筑科技有限公司

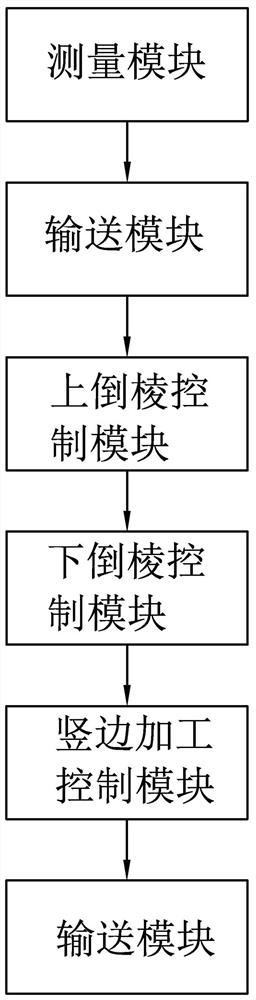

An automatic control system for glass edge grinding machine

ActiveCN112975647BRealize fool-like operationHigh degree of automationEdge grinding machinesGrinding feed controlAutomatic controlControl system

Owner:广东金玻智能装备有限公司

Automatic letter sorting mechanism

The invention discloses an automatic letter sorting mechanism. The automatic letter sorting mechanism comprises a sorting machine. A conveying belt is arranged below the sorting machine and vertically provided with a plurality of letter storing grids. At least one storage rotary disc is arranged beside the conveying belt. The sorting machine comprises a shell. An inlet is formed in the upper surface of the shell, an outlet is formed in the lower surface of the shell, and a suction cup is arranged on one side face of the shell. A friction stop block is arranged at the outlet position. A guiding groove is formed in the lower portion of the shell. Scanning devices are symmetrically arranged on the two sides of the guiding groove. The guiding groove corresponds to the side face, provided with the suction cup, of the shell. According to the provided technical scheme in the embodiment, after the sorting machine is used for scanning letters, the letters are temporally stored and then distributed into the corresponding storage rotary discs, high-efficiency, large-batch and continuous letter sorting can be achieved, it can be made that large-batch letter sorting work can be finished only by few people as much as possible, and manual operation links are simple. Meanwhile, the automatic letter sorting mechanism can be integrated with an intelligent express cabinet, and the fool-style operation of express and letter delivery is achieved.

Owner:SF TECH

automatic meter

ActiveCN109240140BAuto-tuning implementationGuaranteed accuracyProgramme control in sequence/logic controllersControl engineeringVisual perception

The invention discloses an automatic meter adjustment instrument, which comprises a bottom cabinet, a CCD (Charge Coupled Device) visual system and an adjustment system arranged in the bottom cabinet,wherein the CCD visual system comprises an industrial control host and a vision camera, and the industrial control host and the vision camera are arranged on the upper table board of the bottom cabinet; the vision camera is arranged on the upper table board of the bottom cabinet, and height is adjustable; the upper table board of the bottom cabinet is provided with a working window; the adjustment system comprises an angle adjustment device and an opening angle adjustment device, wherein the angle adjustment device comprises a sliding block A and a servo system A; the sliding block A is provided with an angle regulation rotation angle and an angle adjustment servo motor; the opening angle adjustment device comprises a sliding block B and a servo system B which is connected with the sliding block B and can push the sliding block B to vertically slide; the sliding block B is provided with a servo system C; the servo system C is provided with a clip capable of regulating the opening degree of a workpiece, and the servo motor C controls the clip to be opened and closed; and the angle regulation rotation rod corresponds to the working window. The automatic meter adjustment instrument has the characteristics of being automatic in adjustment, detection and calculation, manual work is saved, and efficiency is improved.

Owner:NINGBO ZHENGFENG ROBOT TECH

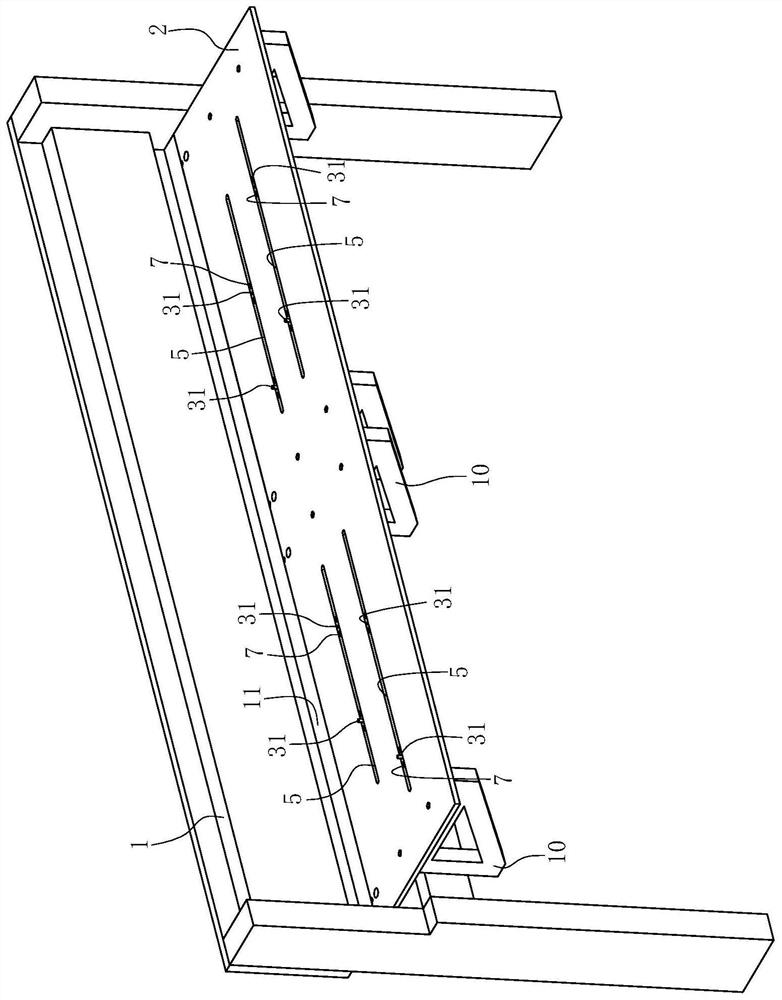

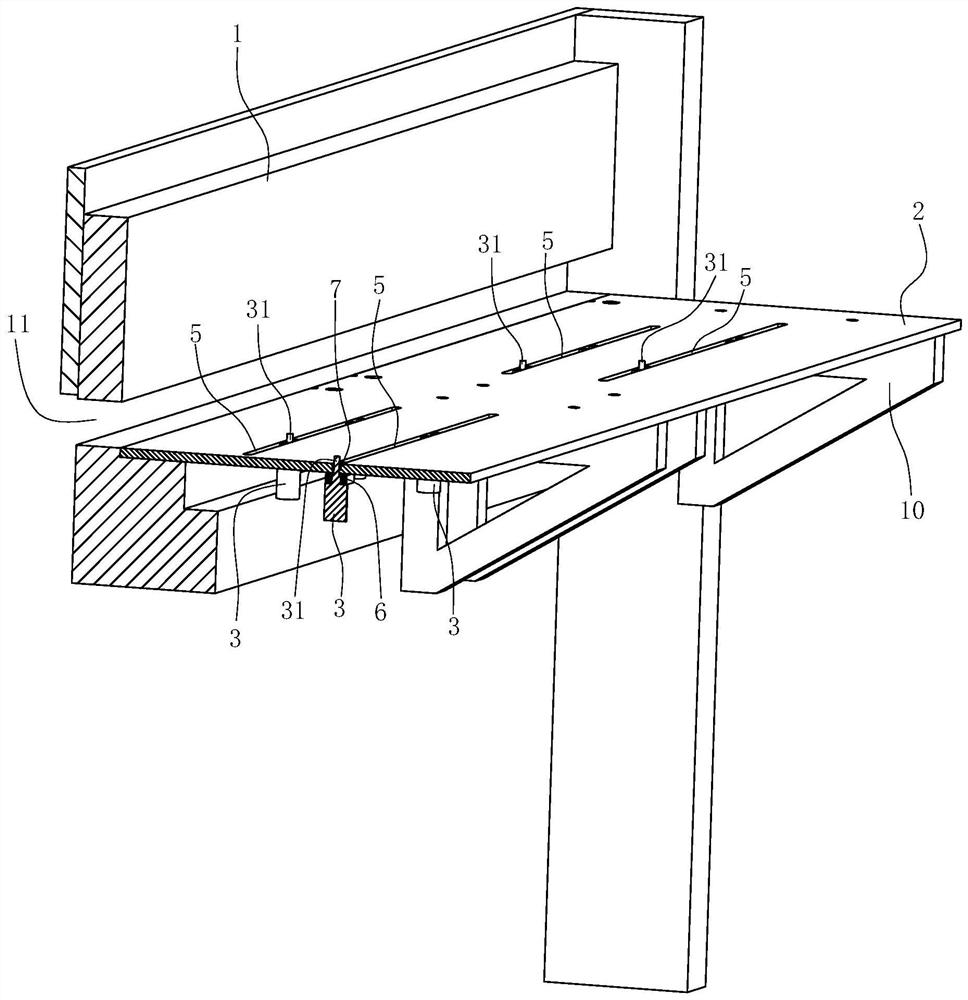

It can be installed on the universal shearing machine for the positioning of the shearing angle of rectangular plates.

ActiveCN111203583BIncrease flexibilityPositioning Dimensional StabilityShearing machine accessoriesEngineeringMachine

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A light energy self-driving intelligent ship sewage recovery device and control method

ActiveCN106774139BSave electricityAchieve zero energy operationProgramme control in sequence/logic controllersSupporting systemLight energy

Owner:HARBIN ENG UNIV

Method for making and displaying flow chart on computer

ActiveCN112783405AThe editing process is intuitive and simpleNot prone to confusionDigital output to display deviceSignal onAlgorithm

The invention discloses a method for making and displaying a flow chart on a computer, comprising: an electronic display screen coupled to a processor, the processor receiving an input signal on the electronic display screen and operating a flow card in a flow layout diagram of a corresponding program in a computer system; the flow layout diagram refers to a layout diagram of a plurality of cards which are used for completing flow operation and have a parallel or successive relationship; and, in the specific display mode, the operation of directionally moving towards a certain direction on the electronic display screen is responded to by changing the position of the flow card existing in the display screen. When the flow chart is edited, the steps in the flow chart are directly edited without independently entering an editing interface, so that the method is very convenient and intuitive, the editing process becomes very simple, a user can more easily concentrate attention resources in each refined step, and the efficiency is improved.

Owner:张飞

A fully automatic steamed bun steaming equipment

InactiveCN103385649BComplete shapeAutomatic temperature adjustmentSteam cooking vesselsFood preparationPressure senseEngineering

Owner:中原粮食集团多福多食品有限公司

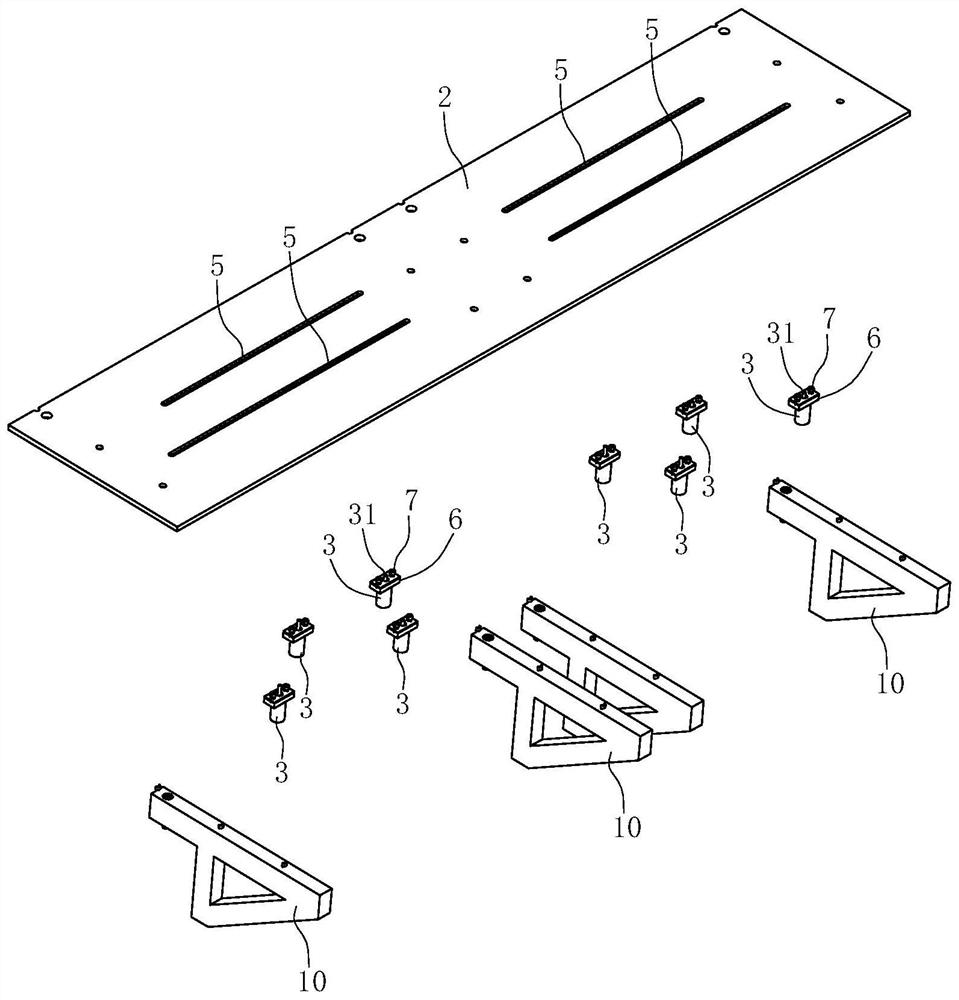

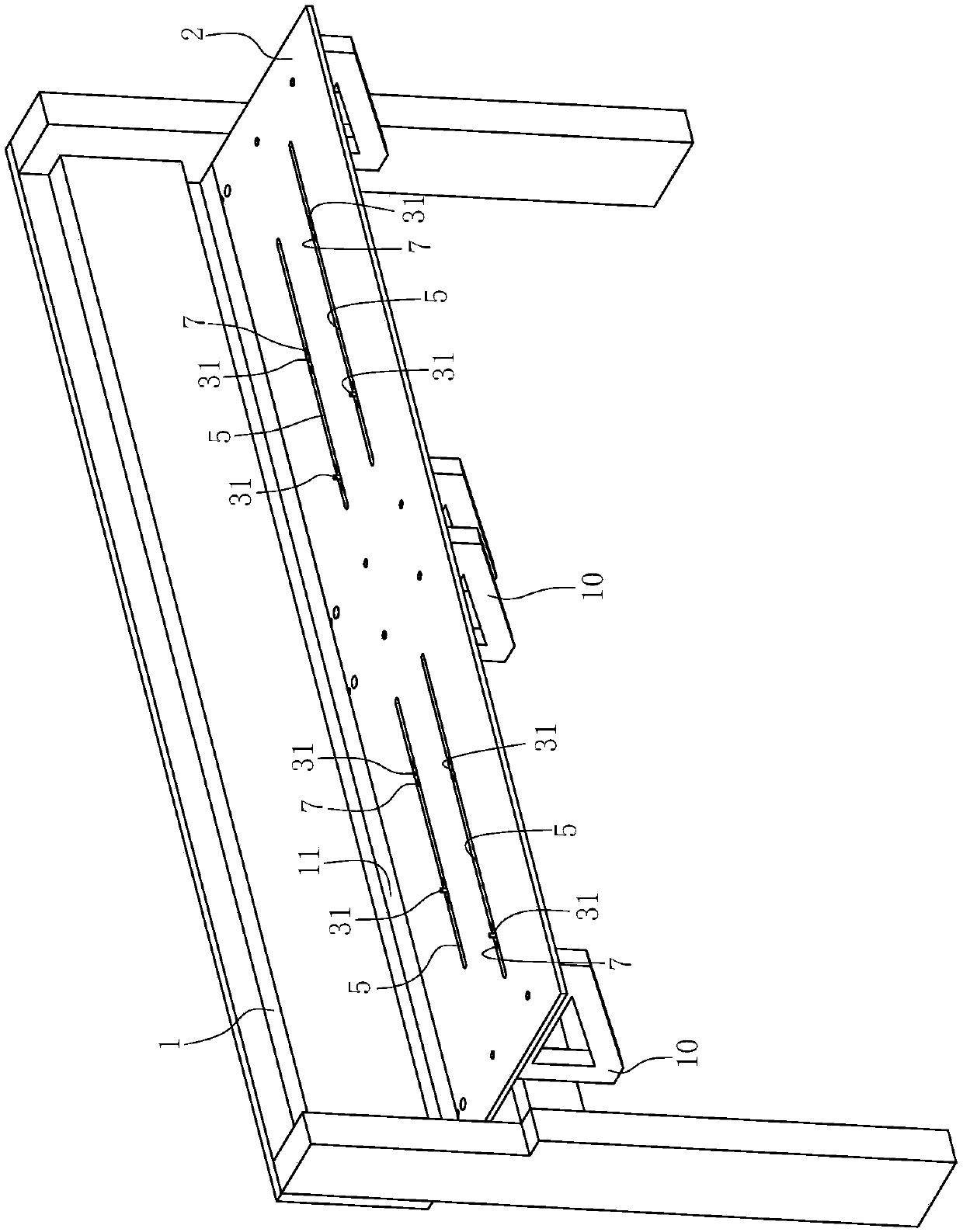

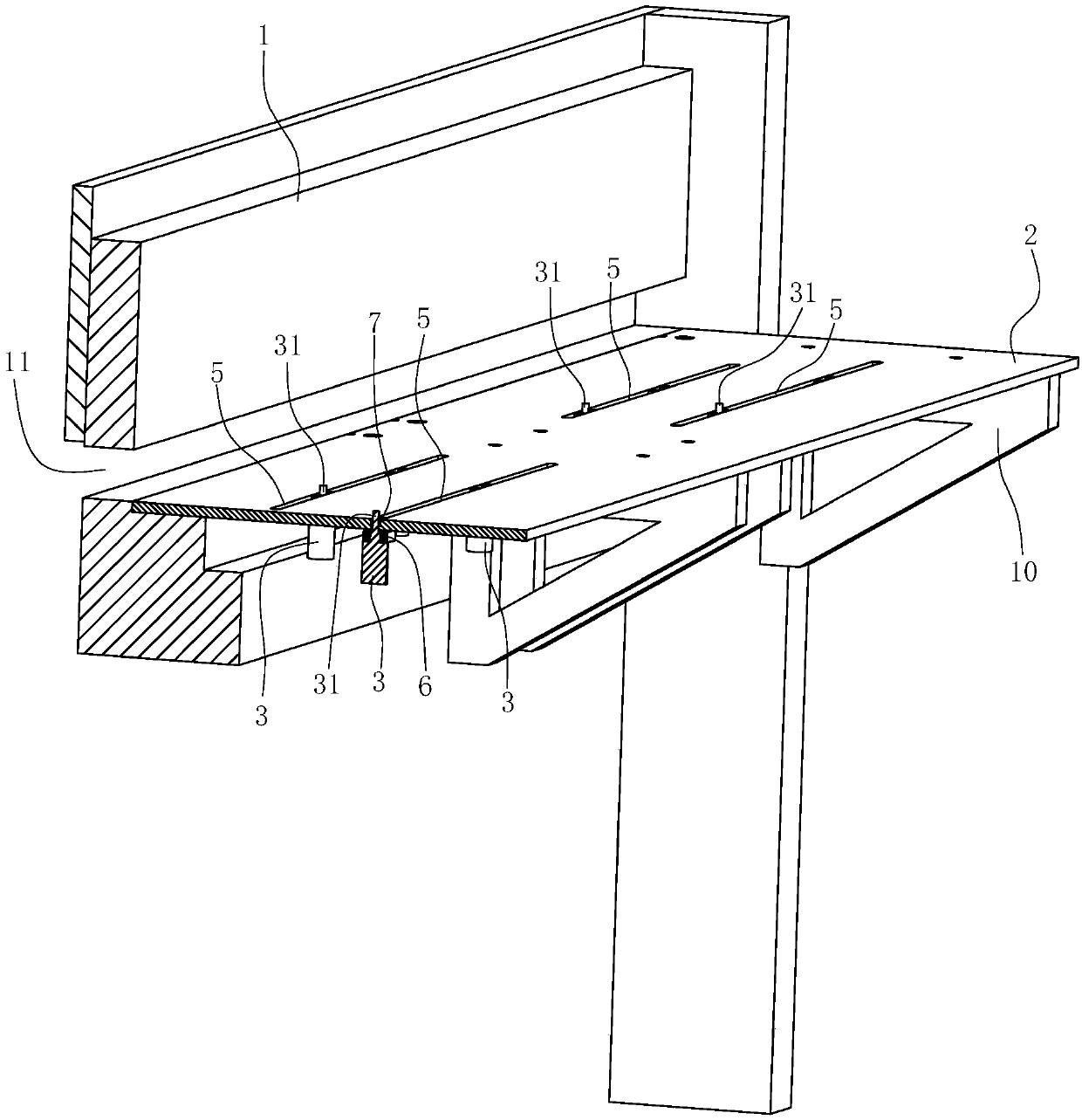

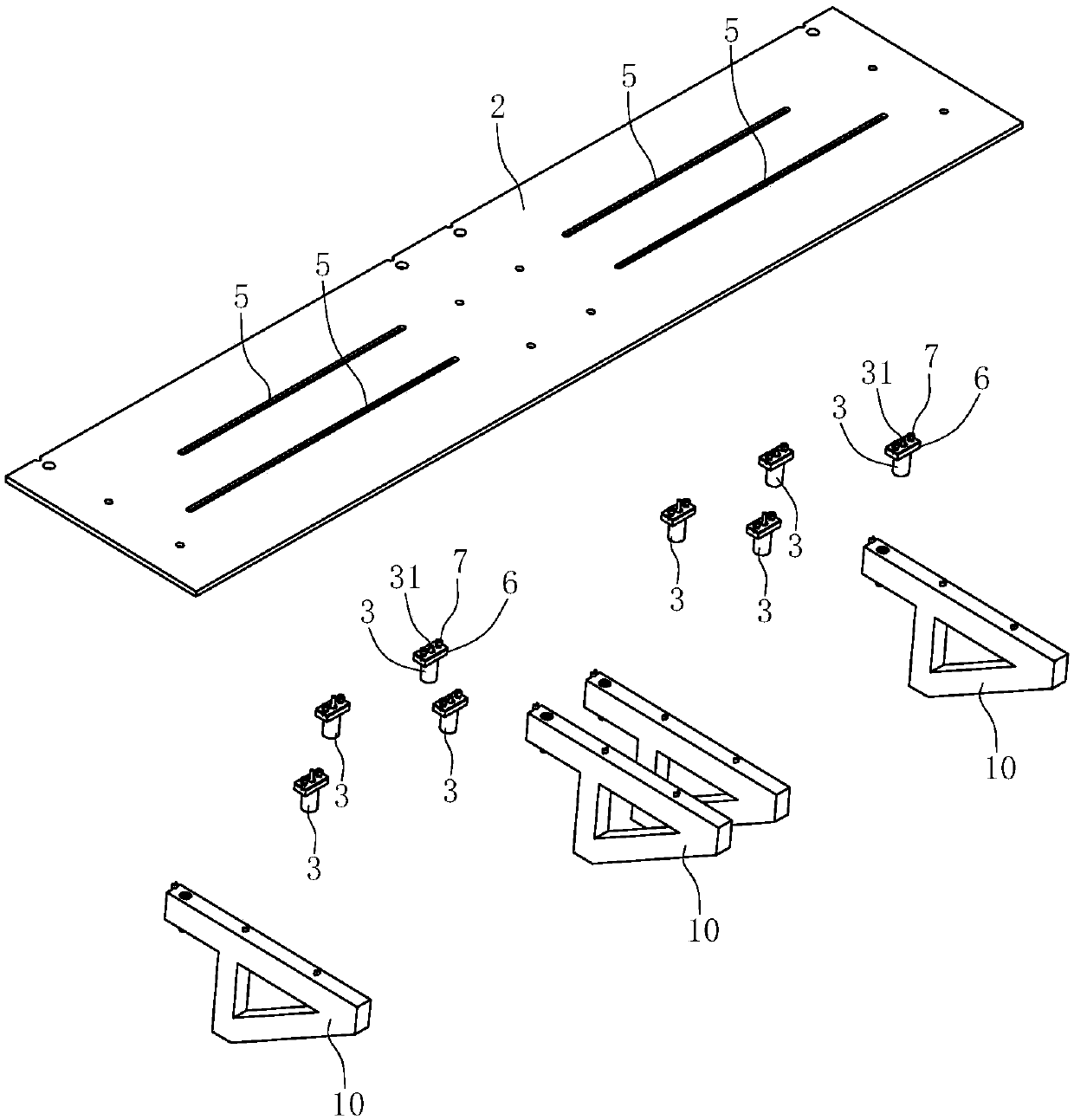

Supporting plate mechanism capable of being additionally installed on general plate shearing machine and used for positioning corner shearing of rectangular plate

ActiveCN111203583AIncrease flexibilityPositioning Dimensional StabilityShearing machine accessoriesStructural engineeringMachine

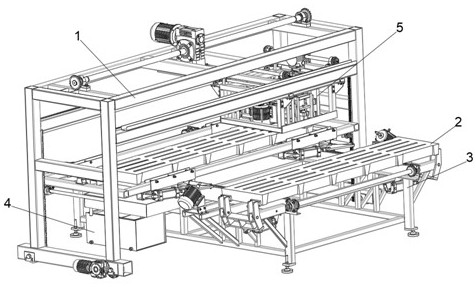

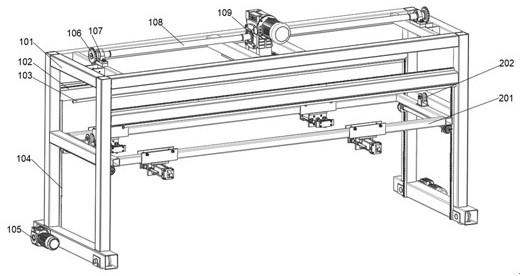

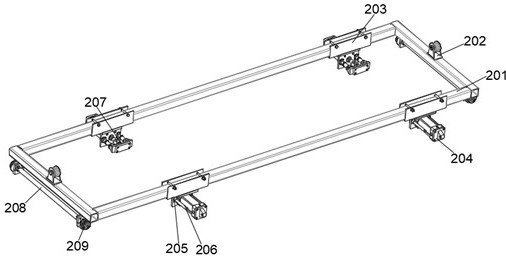

The invention relates to a supporting plate mechanism capable of being additionally installed on a general plate shearing machine and used for positioning the corner shearing of a rectangular plate. The supporting plate mechanism comprises a bedplate fixed on the plate shearing machine, and is characterized in that at least two sets of positioning structures are fixed on the bedplate; each set ofpositioning structure comprises two pairs of electric telescopic rods; the rod parts of one pair of electric telescopic rods limit one side edge of the rectangular plate, the rod parts of the other pair of electric telescopic rods limit another side edge of the rectangular plate, and the two side edges are adjacent; each pair of electric telescopic rods comprises at least two electric telescopic rods fixed at the bottom of the bedplate; and the rod part of each electric telescopic rod can extend upwards out of the top surface of the bedplate or retract downwards to be hidden below the top surface of the bedplate. According to the supporting plate mechanism, the positioning size is stable and accurate, the corner shearing speed is greatly increased, the corner shearing is not influenced byon-site light, and people do not need to visually observe whether the line drawing positions are aligned with the edges of the plate or not, so that the foolproof operation is realized, and the working efficiency of plate shearing is greatly improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Cement floor automatic hole grinding and stacking all-in-one machine and working method thereof

InactiveCN113649866AReduce labor costsPhysical limitationsEdge grinding machinesGrinding carriagesPalletizerElectric machinery

The invention belongs to the technical field of breeding house building materials, and particularly relates to a cement floor automatic hole grinding and stacking all-in-one machine. The cement floor automatic hole grinding and stacking all-in-one machine is used for solving the problem that the danger coefficient is large due to the fact that an existing grinding device for the cement manure leakage floor needs a special lifting appliance to hoist and grind. The cement floor automatic hole grinding and stacking all-in-one machine comprises a stacking mechanism, a positioning clamp, a conveying mechanism, a circulating water tank and a hole grinding mechanism, wherein the stacking mechanism comprises a rack, a first rack and a first guide rod are arranged on the lower sides of the front end and the rear end of the rack correspondingly, second racks are arranged on four stand columns at the two ends of the rack correspondingly, a first gear motor is arranged at the top of the rack, an output shaft is arranged at the output end of the first gear motor, a first bearing seat and a first chain wheel are arranged at the end of the output shaft, the first chain wheel is connected with a pulley through a first chain, and the two ends of the first chain are fixed to the rack. According to the cement floor automatic hole grinding and stacking all-in-one machine, by means of the automatic feeding and discharging process, the labor efficiency is improved, meanwhile, the labor cost of enterprises is saved, and limitation of physical ability of operators is avoided.

Owner:王丰存

Multi-channel detector

InactiveCN104569145ARealize fool-like operationMaterial magnetic variablesPhase detectorData acquisition

The invention relates to a multi-channel detector including an oscillator group, a data acquisition module, a data interface unit, a filter amplifier module and an industrial control computer; the data acquisition module includes a data acquisition module, and the data acquisition module is provided with an output interface; the oscillator group contains oscillators, and the oscillators are connected with the data acquisition module through signal lines; the output interface is connected with a corresponding input terminal inside the data interface unit through a signal line; the filter amplifier module includes a filter amplifier, the filter amplifier is connected with a corresponding output terminal inside the data interface unit through a signal line, and the filter amplifier is connected with a corresponding terminal inside a high-speed AD acquisition card through a signal line; the high-speed AD acquisition card is connected into an input port of the industrial control computer through a signal line.

Owner:QINGDAO GUANDA TRADE

A tool for machining the blade hole of the impeller body of the axial flow pump

ActiveCN103707106BSolving Concentricity ProblemsSolve the measurement datum problem of key dimensionsPositioning apparatusMetal-working holdersAxial-flow pumpImpeller

The invention relates to a tool used for machining blade holes of an axial flow pump impeller body. The tool comprises a rotary body fixed to a lathe spindle, wherein a scale dividing block is fixed on the rotary body, a fastening device used for fixing a workpiece on the scale dividing block is arranged above the scale dividing block, a first layer of positioning pin holes, a second layer of positioning pin holes and a third layer of positioning pine holes are formed in the outer side of the scale dividing block in the circumferential direction from inside to outside, and positioning pins matched with the positioning pin holes are arranged on the scale dividing block. According to the technical scheme, an installation method with the tool directly connected with a lathe is adopted, a rotating center in the direction same as the rotating direction of the lathe spindle is generated for each blade hole to be machined, and concentricity is achieved between the blade holes to be machined and the lathe spindle; by means of the cooperation between the scale dividing block and the rotary body and the utilization of a scale dividing mechanism, fast and accurate scale division is achieved easily when the blade holes rotate along with the scale dividing block during machining; a cylindrical section arranged on a pull rod enables the measuring basis of the critical dimension to be available during lathe machining.

Owner:ANHUI SHUNYU WATER AFFAIRS CO LTD

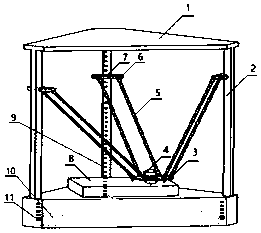

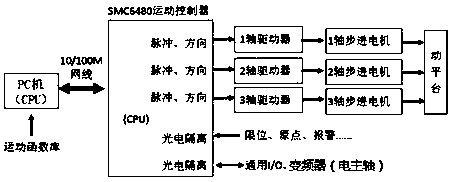

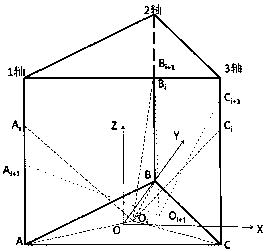

PCB quick plate-making machine with parallel structure

PendingCN108260284AImprove efficiencyQuality improvementPrinted circuit manufactureEngineeringWorkbench

The invention relates to a PCB quick plate-making machine with a parallel structure. The machine comprises a rack, a workbench, a moving platform, sliding blocks, synchronous belts and a motor, the workbench is arranged on a platform of the rack, and three synchronous belts are arranged; the three synchronous belts are respectively arranged on the rack through a belt wheel, the three synchronous belts are respectively connected with the motor, and the three synchronous belts are respectively perpendicular to the workbench; the three synchronous belts form a triangular structure distributed onthe rack, three sliding blocks are arranged, and the three sliding blocks are respectively and fixedly arranged on the three synchronous belts; each sliding block is fixedly arranged on one synchronous belt, the moving platform is connected with three sliding blocks through a connecting rod, and the connecting rod is respectively hinged to the three sliding blocks and the moving platform; the motor is connected with a PC machine, when the PC machine is in use, cutters are arranged on the moving platform, and a circuit board is placed on the workbench. The PCB quick plate-making machine with the parallel structure is adopted, the mechanical structure is simple, and the stiffness is high.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Handheld positioning device of energy-saving precast part exposed reinforcements and application method

PendingCN109333804AGood effectImprove the quality of workAuxillary shaping apparatusEngineeringRebar

The invention relates to a handheld positioning device of energy-saving precast part exposed reinforcements and an application method. The device comprises a guide rail, a bracket and a moving pair, wherein the guide rail comprises a first guide rail and a second guide rail; the first guide rail and the second guide rail are arranged in parallel; the bracket is strip-shaped; one ends of the firstguide rail and the second guide rail are connected to the bracket, and the end parts of the other ends are leveled; the first guide rail and the second guide rail are vertically connected with the bracket; the moving part comprises a first slide block, a second slide block and a connecting rod; the first slide block and the second slide block are slidingly connected with the first guide rail and the second guide rail, and are connected through a connecting rod; and the connecting rod is perpendicular to the first guide rail and the second guide rail. According to the sizes of components, the position of the positioning device and the lengths of the exposed reinforcements are freely adjusted; and the whole device is lower in weight and convenient for manual operation, prevents errors causedby manual disturbance, and effectively improves the construction working quality in mass production of products with fixed exposure sizes.

Owner:河南中安征信建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com