A laser printing method for cloth breadth and apparatus thereof

A technology of laser printing and cloth width, which is applied in the direction of printing devices, digital output to printing units, and electrical recording technology equipment using charge graphics, etc. It can solve the problems of easy flaws in finished products, cumbersome operations, and slow production speed, etc., to achieve The machine performance is reliable, the production efficiency is improved, and the production speed is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

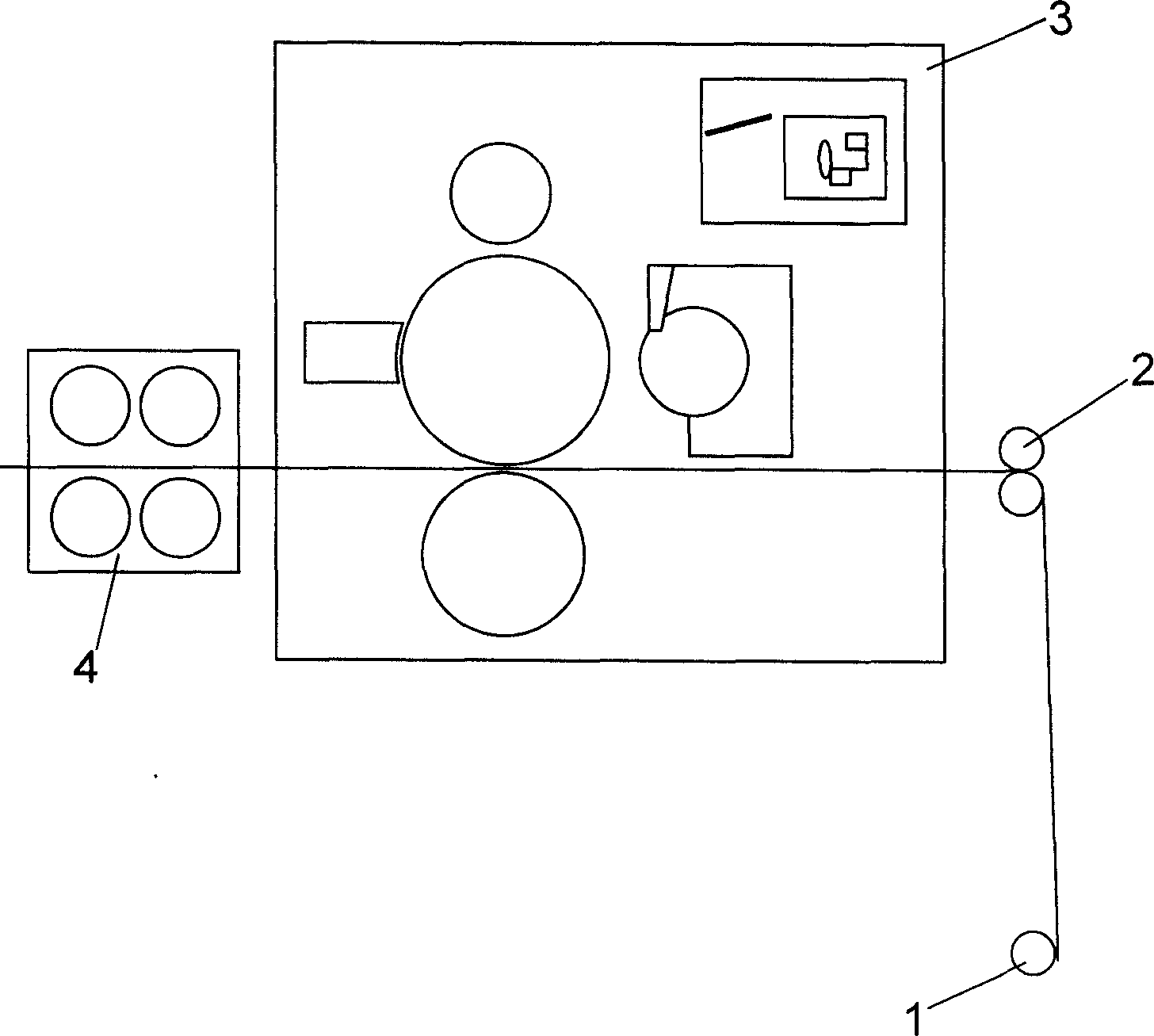

[0008] Referring to the accompanying drawings and specific embodiments, the following descriptions are given: In the cloth laser printing method of the present invention, firstly, a cloth whose surface melting point matches the melting point of the toner used is selected as the printing medium. At present, the melting point of general toner is about 160℃, that is to say, a cloth with a surface melting point of about 160℃ can be used as the printing medium, or a coating with a melting point of about 160℃ can be attached to the surface of the general cloth. Then prepare and select toner according to your needs. Said toner can be prepared into toners of various colors required according to the formula for making black toners in the prior art, which can be black or various monochromes such as red, green, yellow, blue, and white. toner. The selected toner is installed in the cloth laser printing equipment of the present invention. Load the cloth into the cloth feeding system of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com