A fully automatic steamed bun steaming equipment

A fully automatic, steamed bun technology, applied in food preparation, steam cooking utensils, food science and other directions, can solve the problems of complex operation, inability to precisely control the air pressure, and enhanced steamed bun steaming quality. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

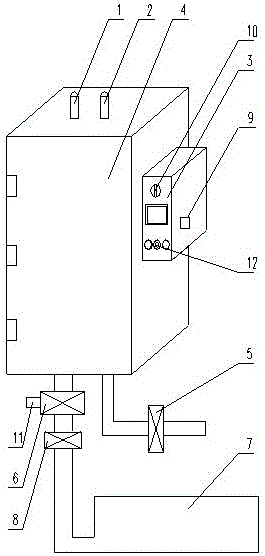

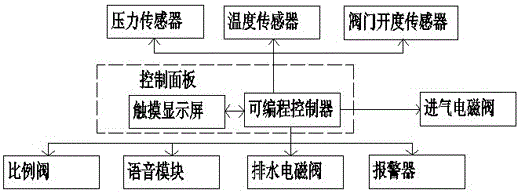

[0012] Such as figure 1 and figure 2 As shown, a fully automatic steamed bun steaming equipment includes a box body 4, an air pressure sensing device is arranged inside the box body 4, and the air pressure sensing device is a pressure sensor 1; a steam generator 7 is arranged outside the box body 4 , The box body 4 is provided with a control panel 3, and the control panel 3 includes a programmable controller and a touch display screen connected thereto. The programmable controller makes it possible to set the parameters at the initial stage of the machine, which is convenient for adjustment according to different needs, so that the steamed buns can be steamed with better quality.

[0013] The control panel 3 is connected to the actuator through the control circuit, and also includes a start switch arranged on the casing, which is a rotary switch 10, a temperature sensor 2 arranged in the casing and a drain solenoid valve 5 on the casing drain pipe, The output end of the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com