A fixed-size fillet grinding device

A technology of fixed size and rounded corners, which is applied in the field of fixed size rounded corner grinding devices, which can solve the problems of low production efficiency and low dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

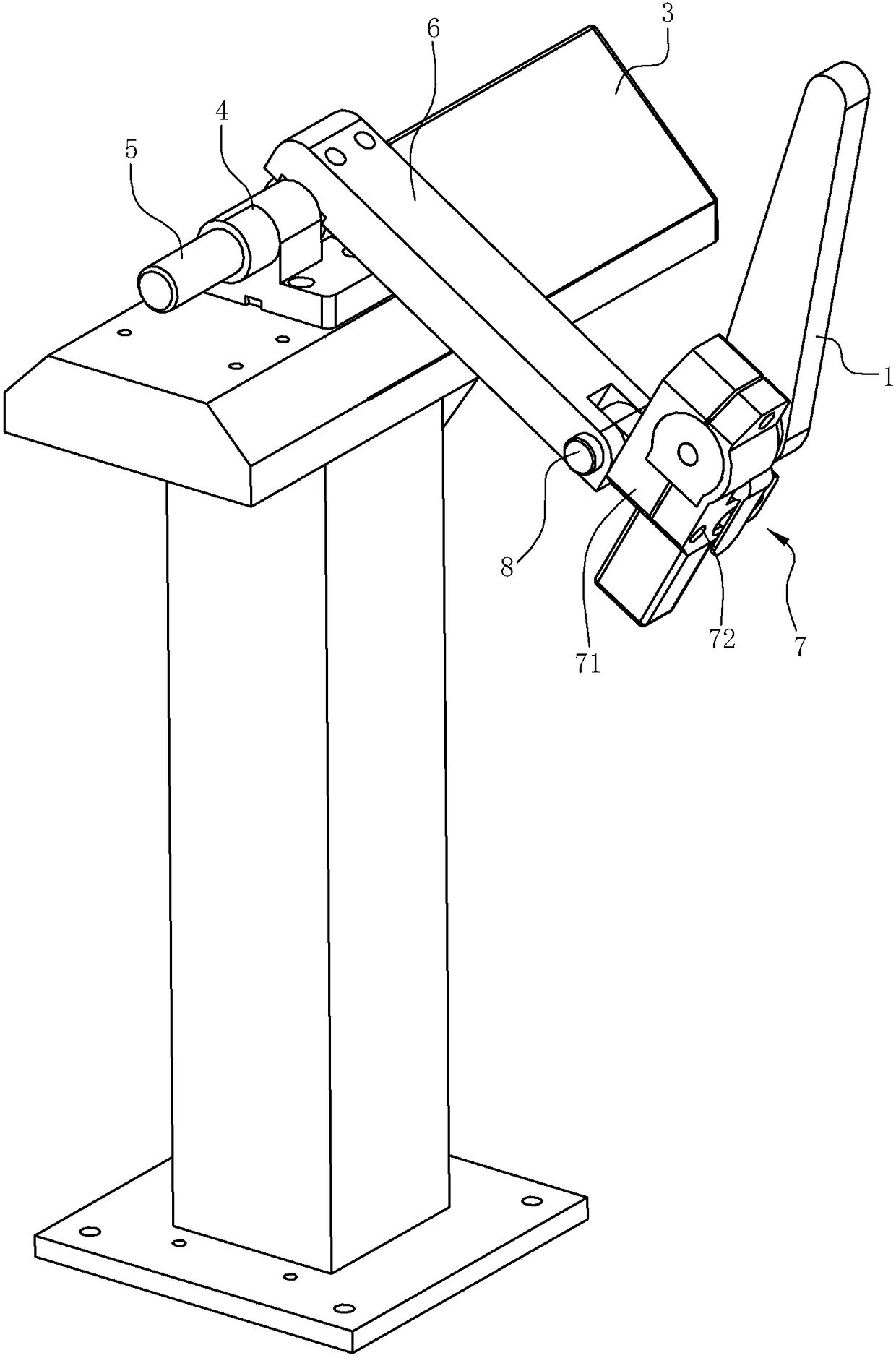

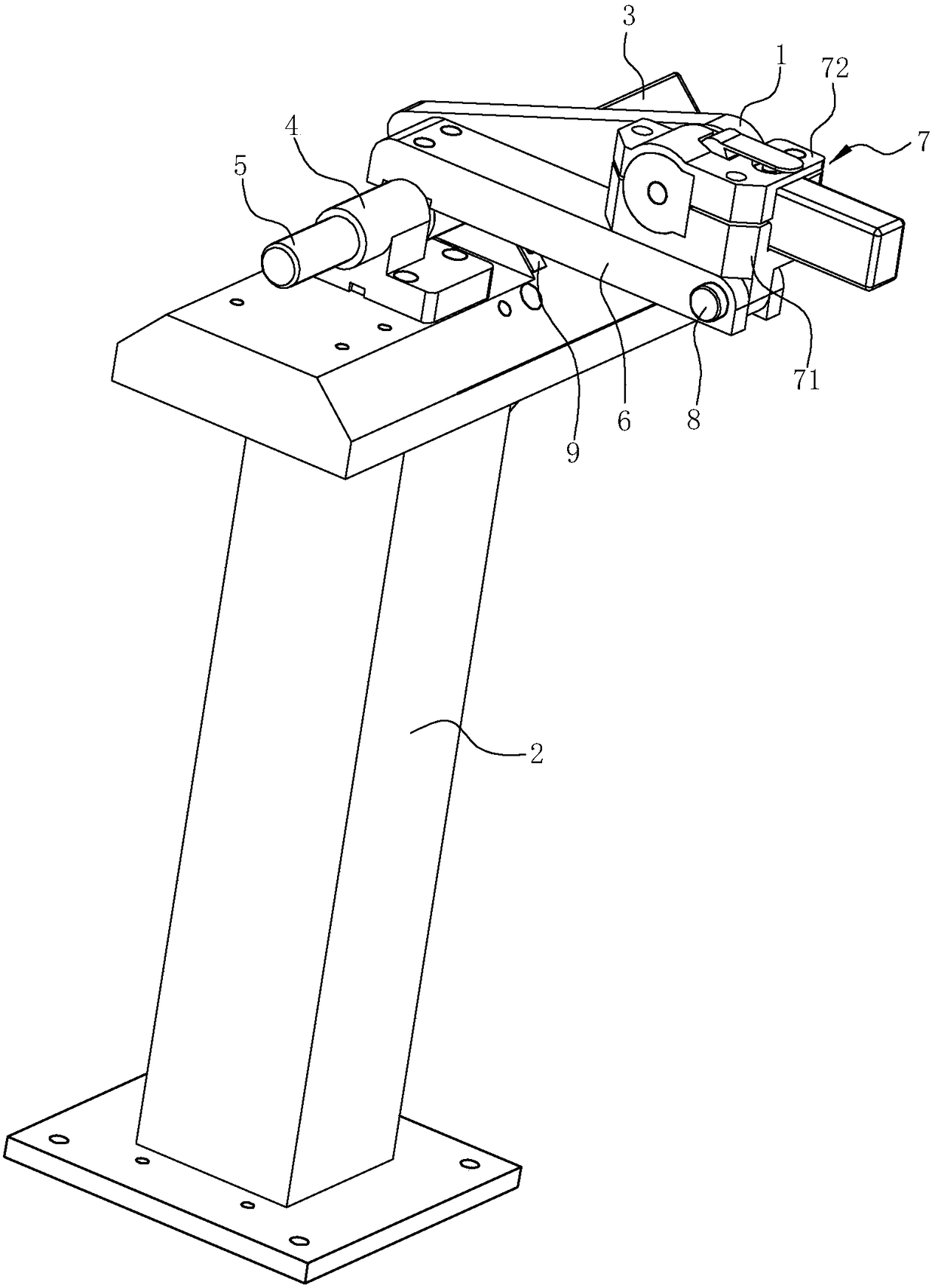

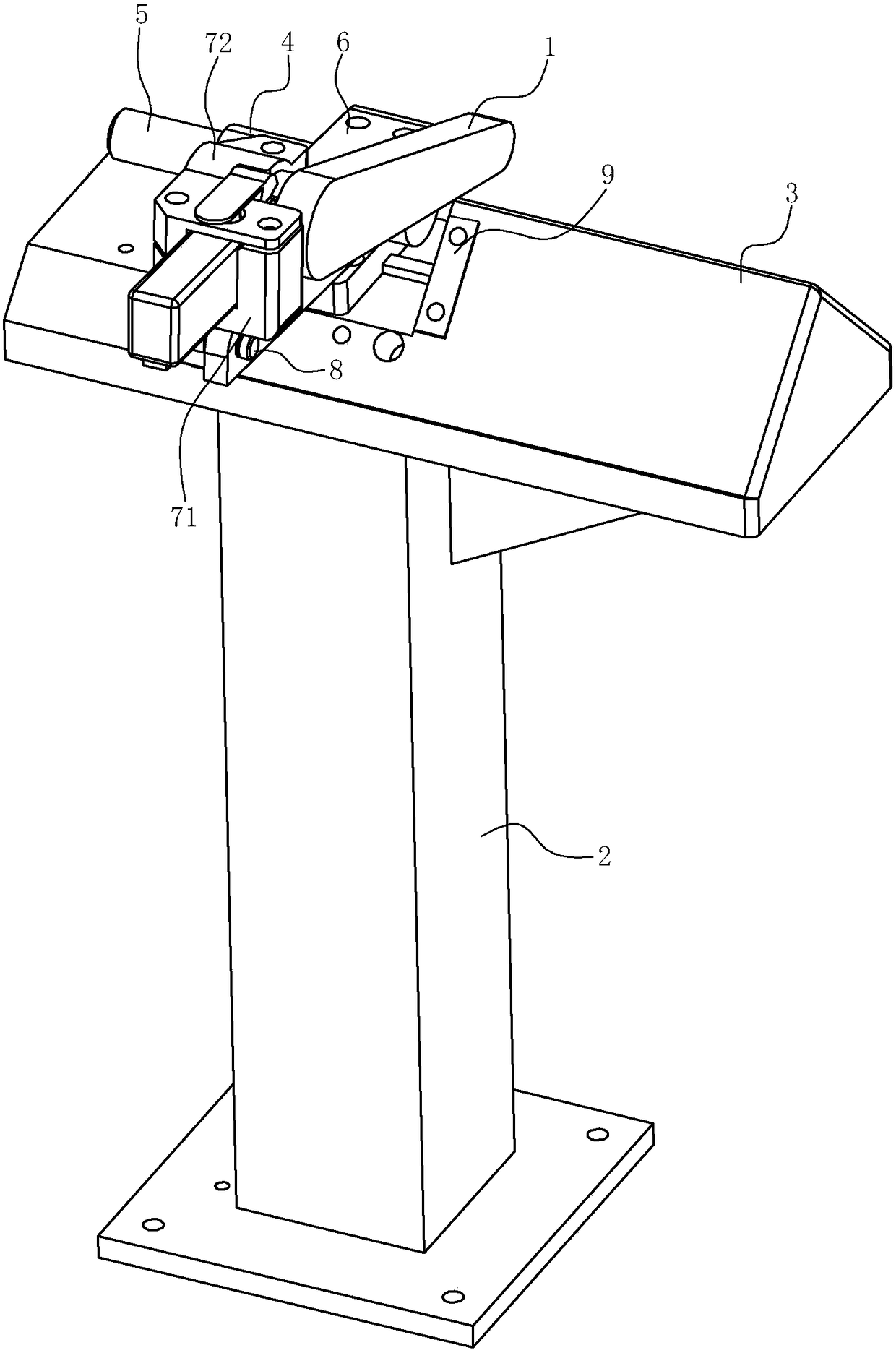

[0019] like Figure 1-5 shown, is a preferred embodiment of the present invention.

[0020] A fixed-size rounded corner grinding device includes a grinding machine 1 for grinding rounded corners on a workpiece to be ground. The grinding machine 1 is an abrasive belt grinding machine, which is in the prior art.

[0021] Bracket 2, one side of the upper part of the bracket 2 is provided with a workpiece rest seat 3 for the workpiece to be polished; the height of the bracket 2 is designed according to the height of the workpiece to be polished, and the shape of the workpiece rest seat 3 is designed according to the shape of the workpiece to be polished. Taking the polishing sink body as an example, its cross section is an isosceles right triangle, and the two right-angled sides are respectively set off on the two inner walls of the sink body th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com