Chocolate melting furnace

A melting furnace and chocolate technology, applied in cocoa, cooking utensils, household utensils, etc., can solve the problems of poor chocolate taste, no temperature control, and insufficient melting, and achieve the effects of easy cleaning, uniform heating, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

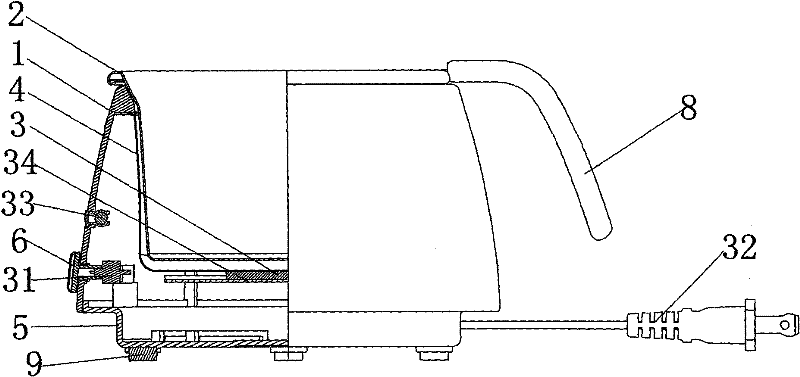

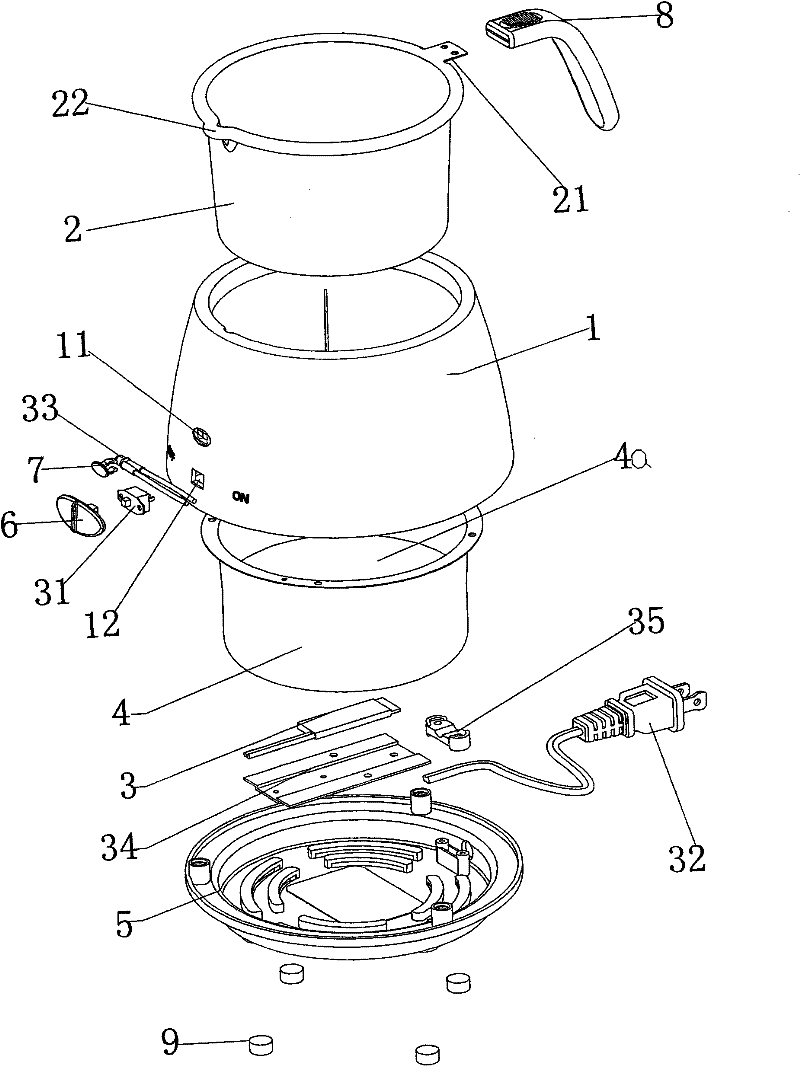

[0022] Figure 1 to Figure 7 Shown is the structural representation of the present invention.

[0023] The reference signs are: shell 1, observation window 11, installation port 12, melting pot 2, connecting tab 21, diversion protrusion 22, heating element group 3, slide switch 31, power connection line 32, neon lamp 33 , fixed connecting piece 34, positioning crimping plate 35, aluminized courage body 4, heating chamber 4a, bottom cover 5, switch knob 6, transparent lampshade 7, handle 8, rubber foot pad 9.

[0024] Such as figure 1 , image 3 As shown, the chocolate melting furnace of the present invention includes a casing 1, a melting pot 2 and a heating body group 3, wherein: the casing 1 is fixedly nested with an aluminum-coated courage body 4 with good thermal conductivity, and the melting pot 2 is placed on a plated In the heating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com