Method for controlling flame brazing machine

A technology of flame brazing and control methods, applied in the direction of manufacturing tools, welding equipment, auxiliary devices, etc., can solve the problems of slow change in line speed, low production efficiency, and no fundamental improvement in flame quality, and achieve stable control of welding quality , The control logic is simple, the effect of improving the flame quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

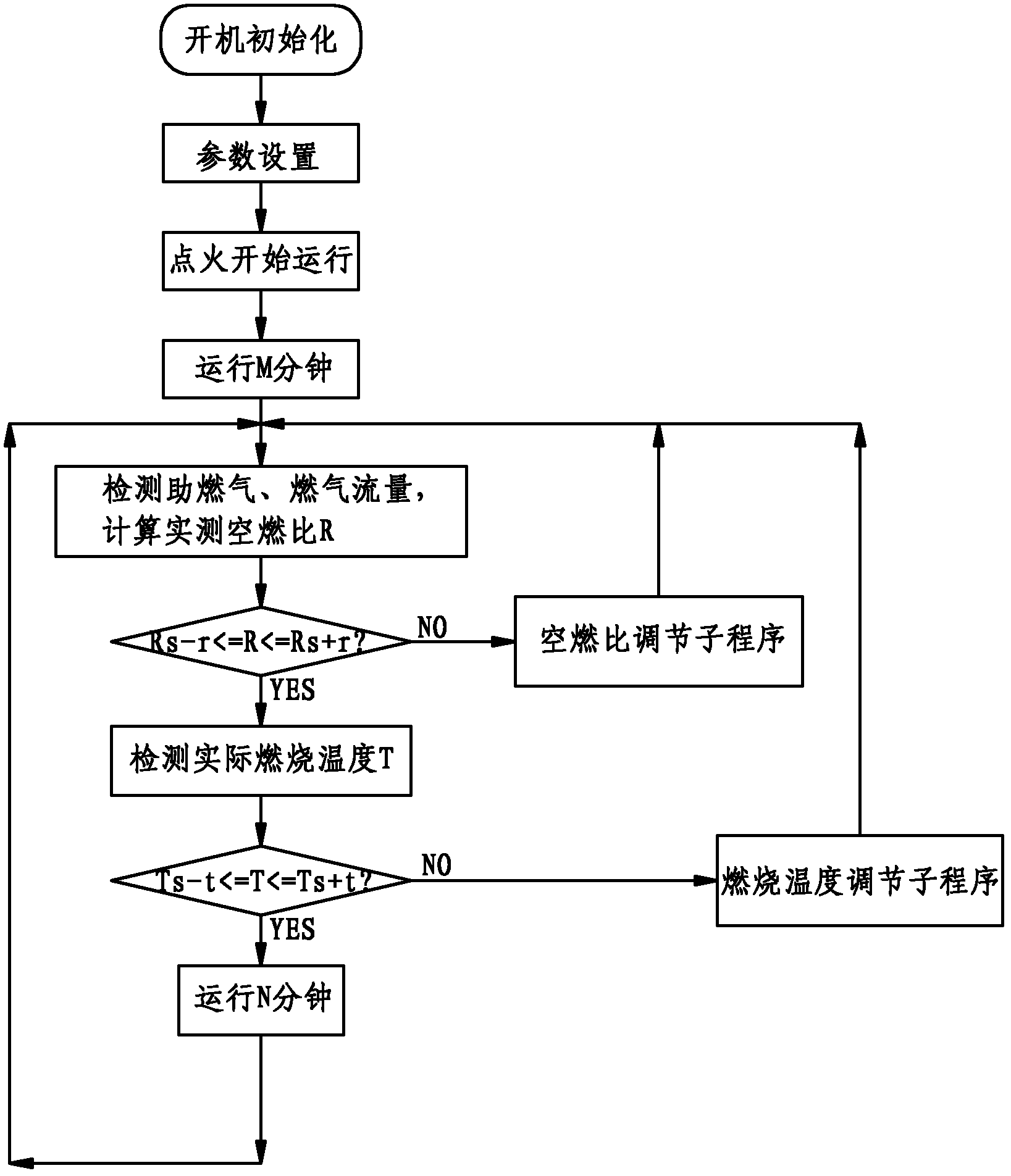

[0039] see figure 1 , the control method of this flame brazing machine comprises the following steps:

[0040] Step 1, power on and initialize; that is to say, the flame brazing machine is powered on and reset, and the flame brazing machine initializes the system.

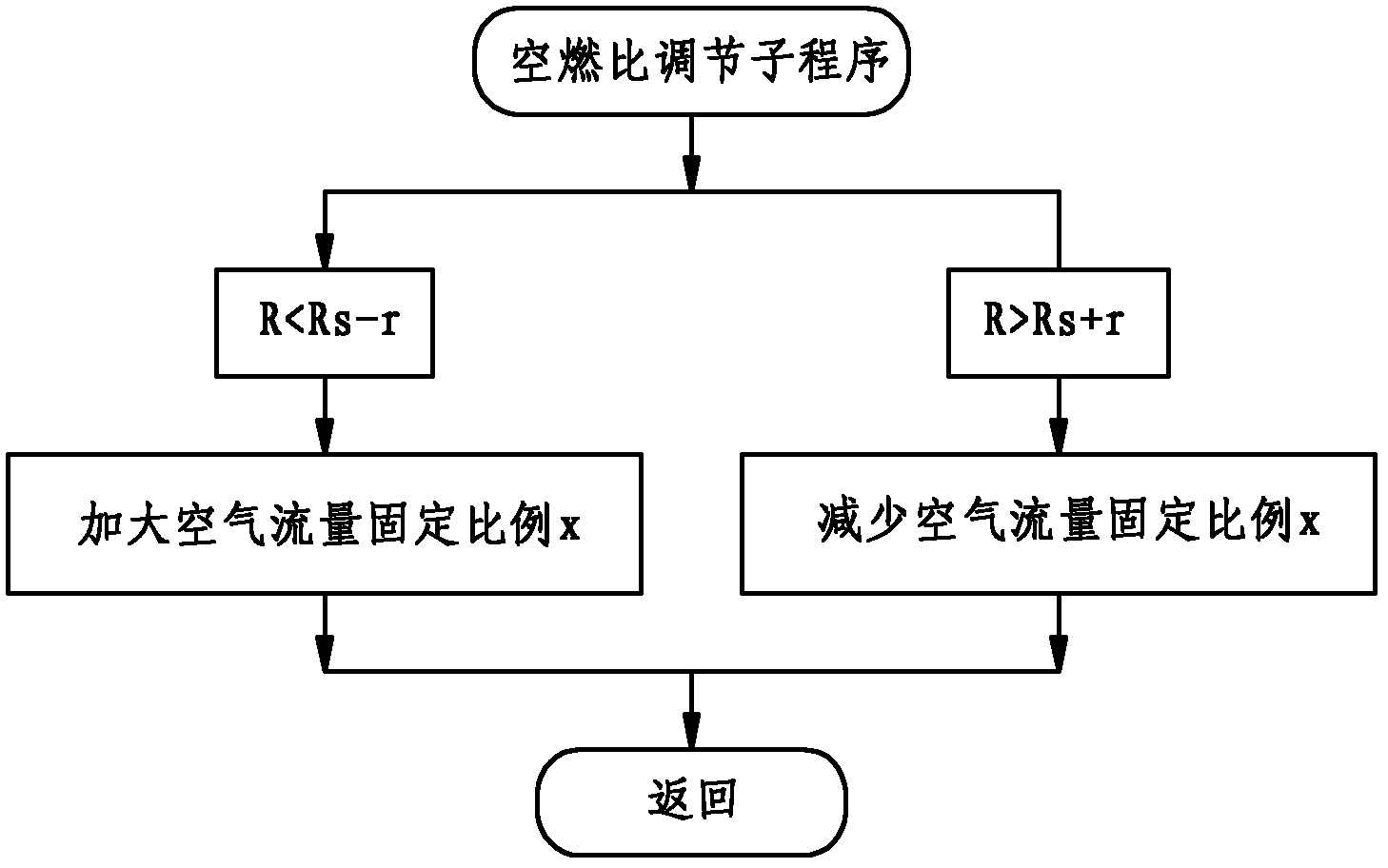

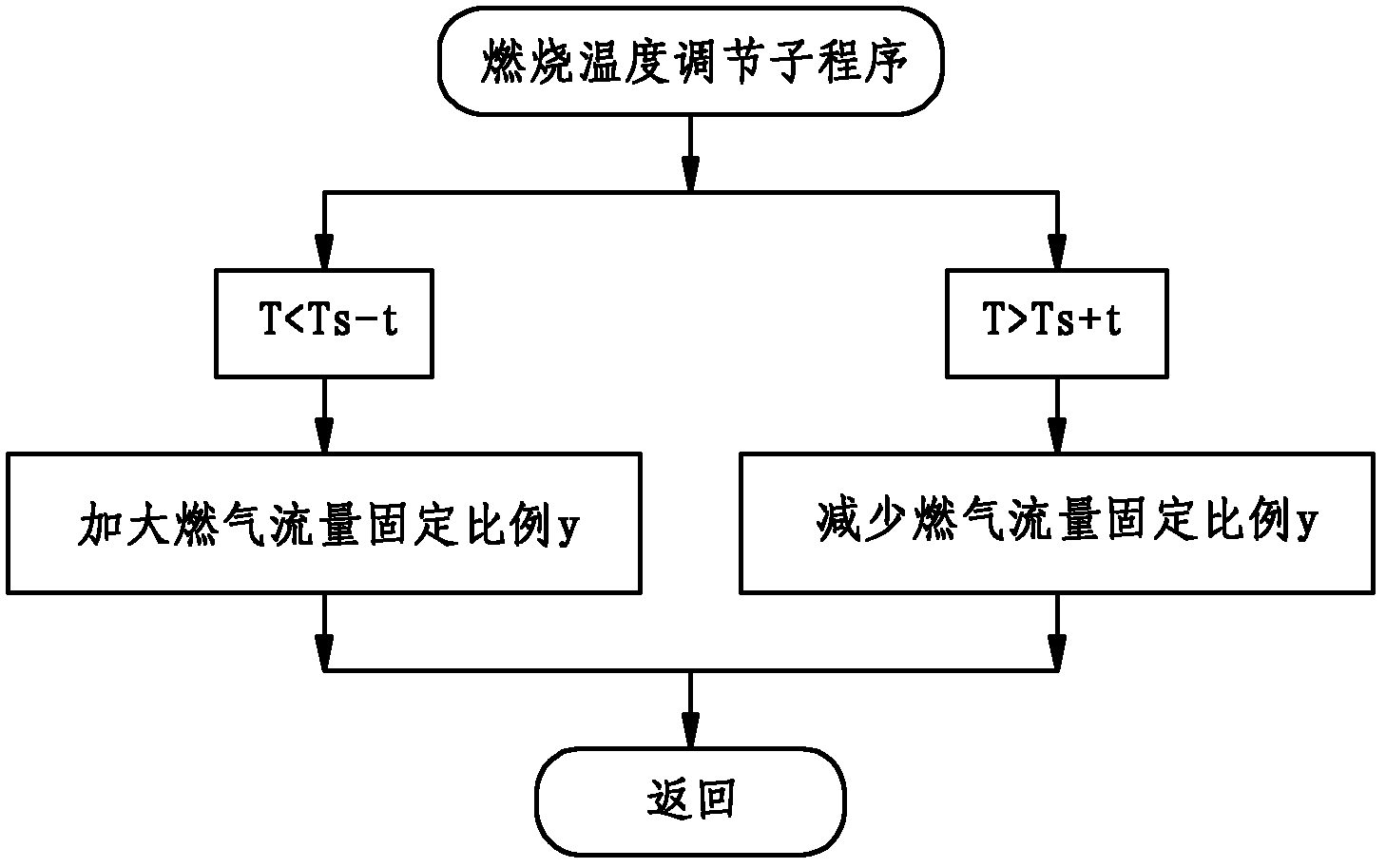

[0041] Step 2, the user sets the parameters, the parameters include the preset air-fuel ratio Rs and the deviation r, and the preset combustion temperature Ts and the deviation t.

[0042] The user presets the welding parameters, mainly the preset air-fuel ratio Rs and deviation r, the preset combustion temperature Ts and deviation t, the fixed ratio of combustion gas flow rate x, the gas flow rate fixed ratio y and the running time N.

[0043] The preset combustion temperature Ts varies according to the type of welded heat exchanger, and is determined according to actual experience, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com