Ultra-precise processing method for circular conical surface of fluid static pressure sealing ring for nuclear primary pump

An ultra-precision machining and hydrostatic pressure technology, applied in metal processing equipment, manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, etc. The effect of stable machining state, low surface roughness and simple machine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings.

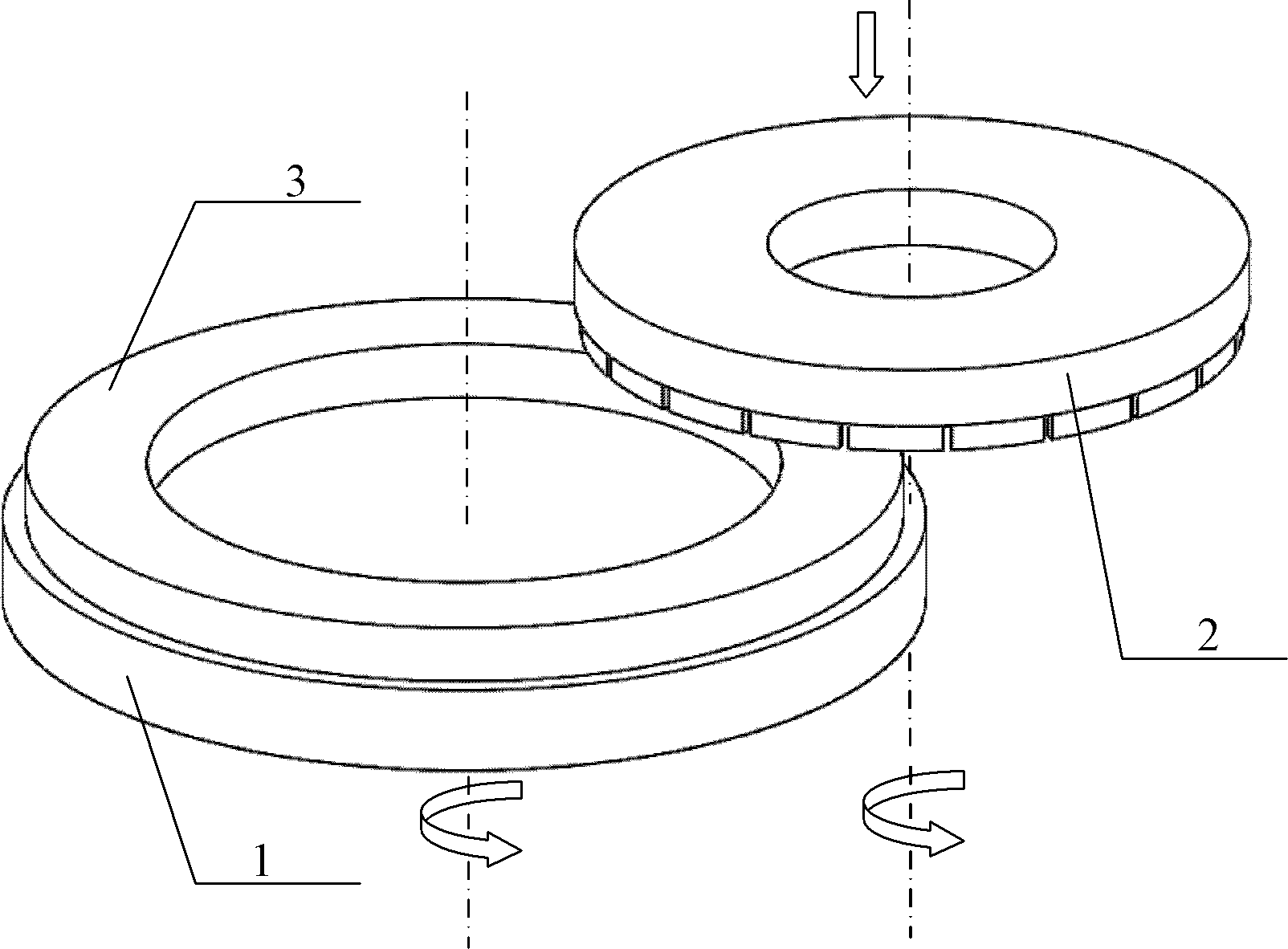

[0015] The technical scheme of the present invention adopts the method of rotating the sealing ring and cutting the end face of the cup-shaped grinding wheel. The cup-shaped grinding wheel as shown in the figure is installed on the ultra-precision air bearing electric spindle. The abrasive grains used for the cup-shaped grinding wheel are diamonds. The radius of the cup-shaped grinding wheel is 50-250 mm, and the working face width of the end face of the cup-shaped grinding wheel is 2-5 mm. The axial runout and radial runout of the ultra-precision air bearing electric spindle are less than 0.05 microns, and the ultra-precision air bearing electric spindle can drive the cup-shaped grinding wheel to perform high-precision rotary motion around the rotation axis of the ultra-precision air bearing electric spindle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com