Patents

Literature

59results about How to "Strong grip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

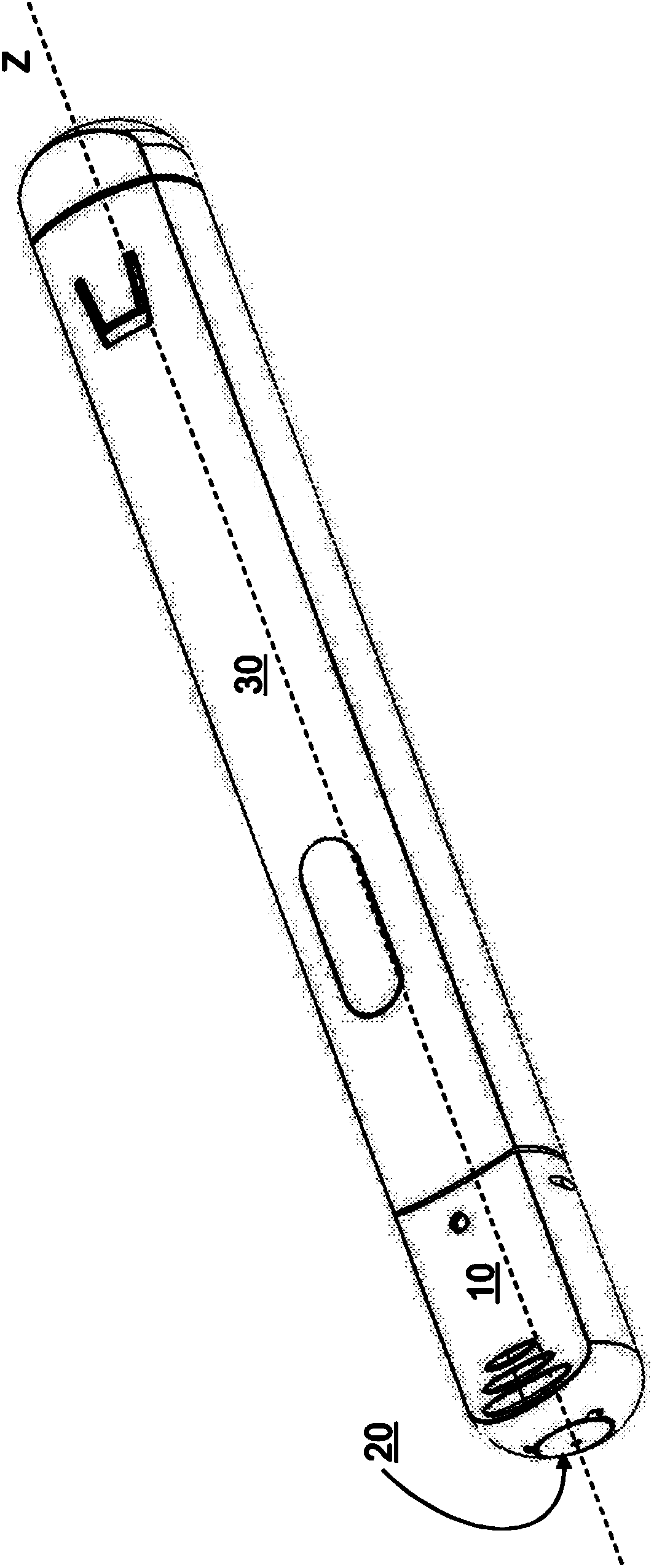

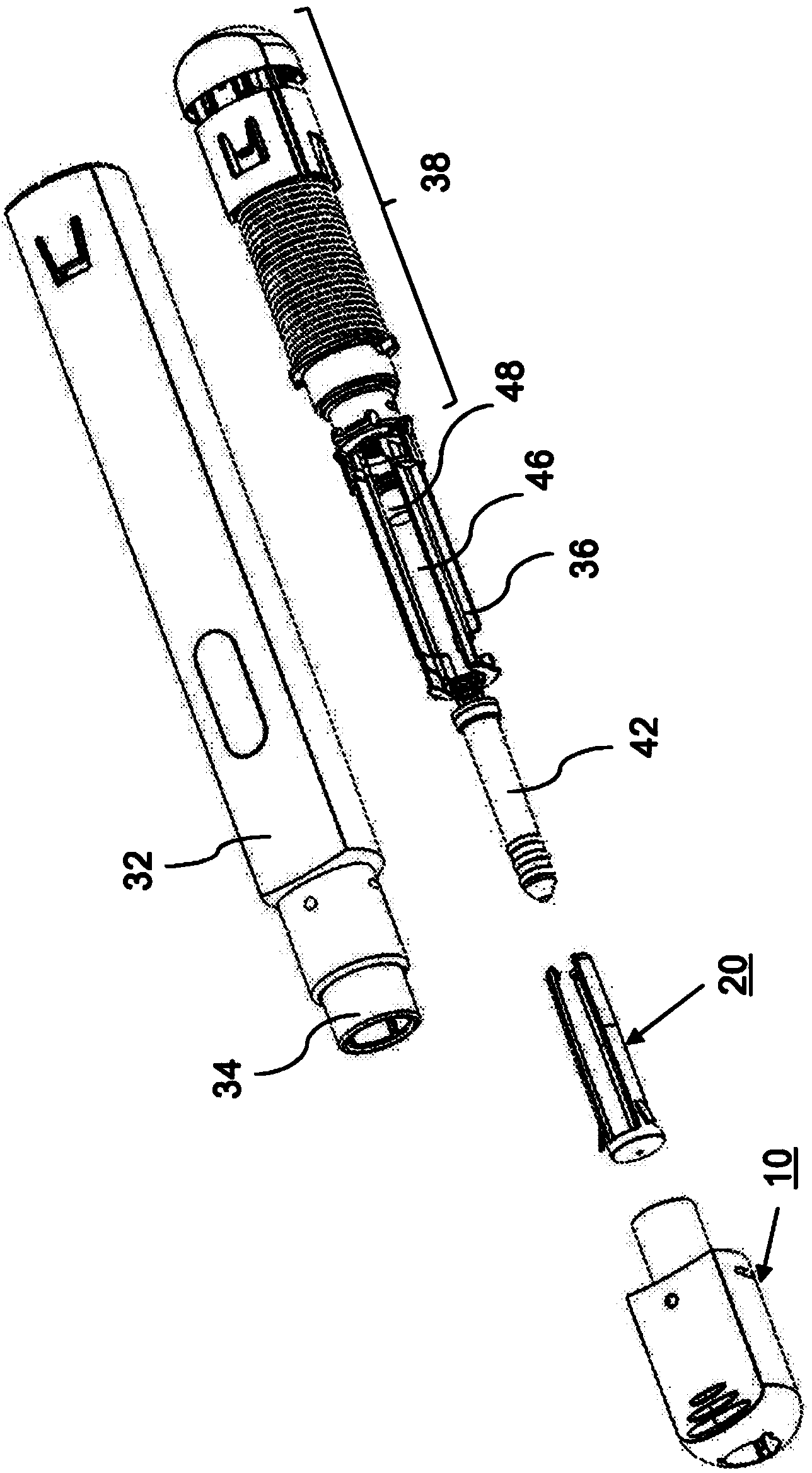

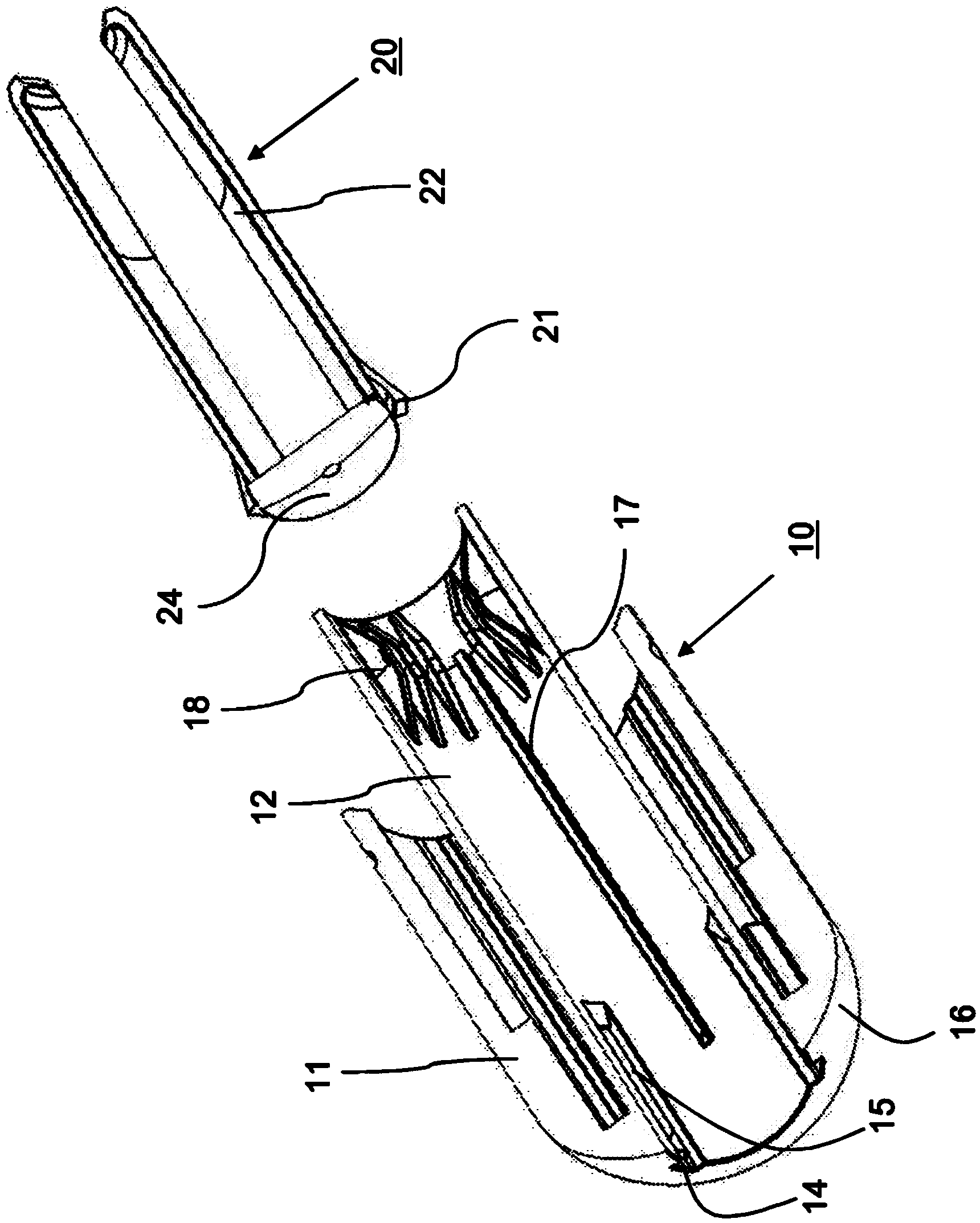

Needle sheath remover assembly

Owner:SHL MEDICAL AG

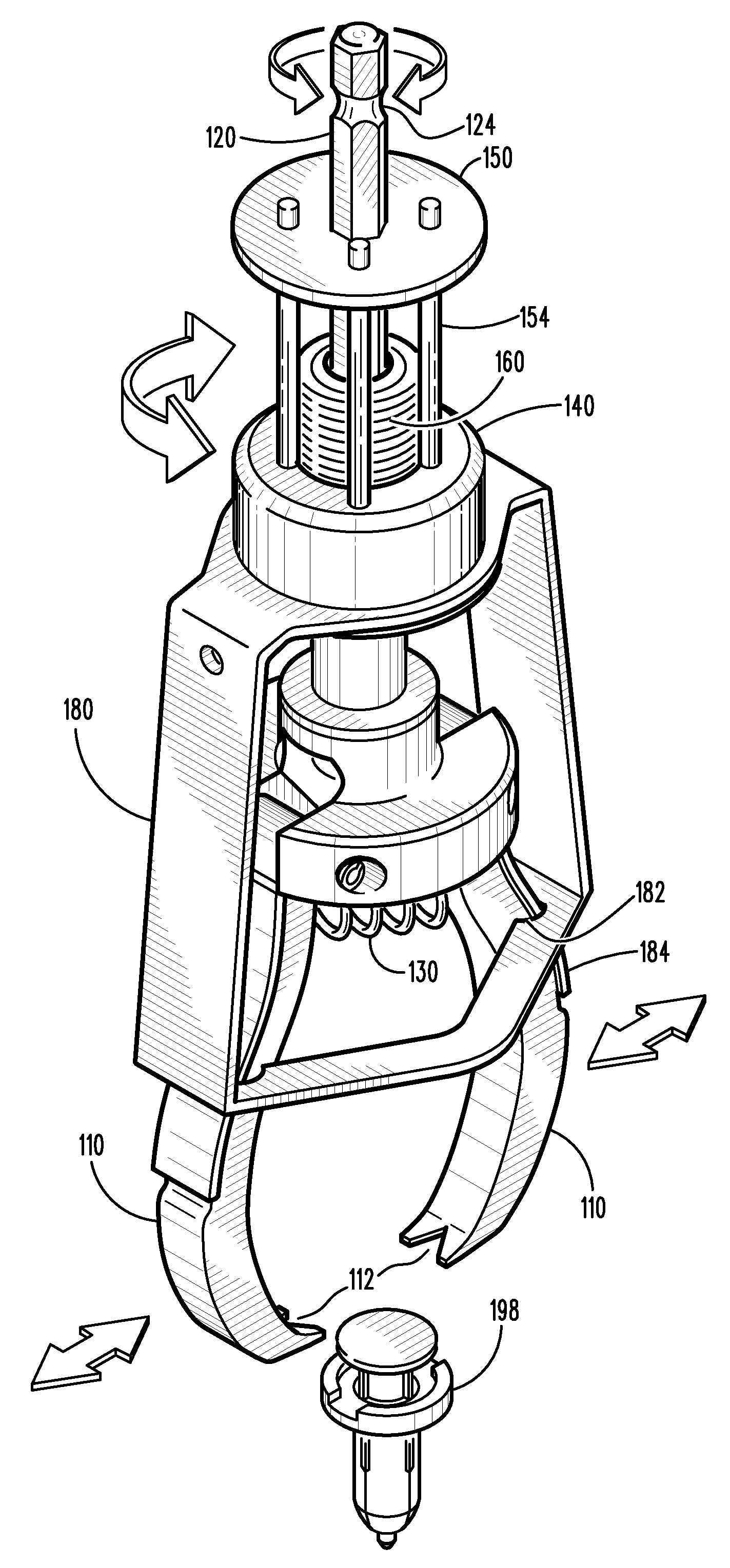

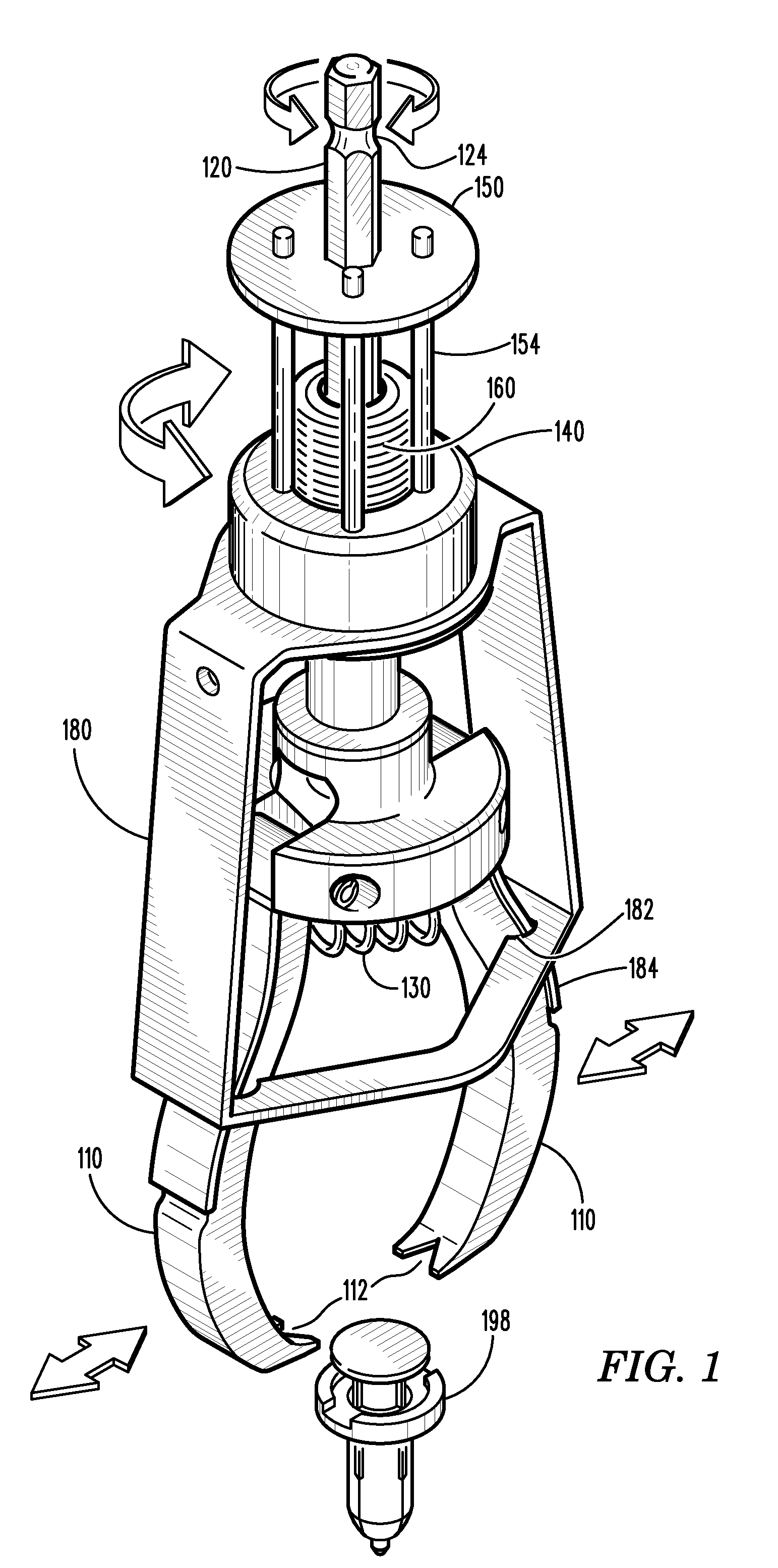

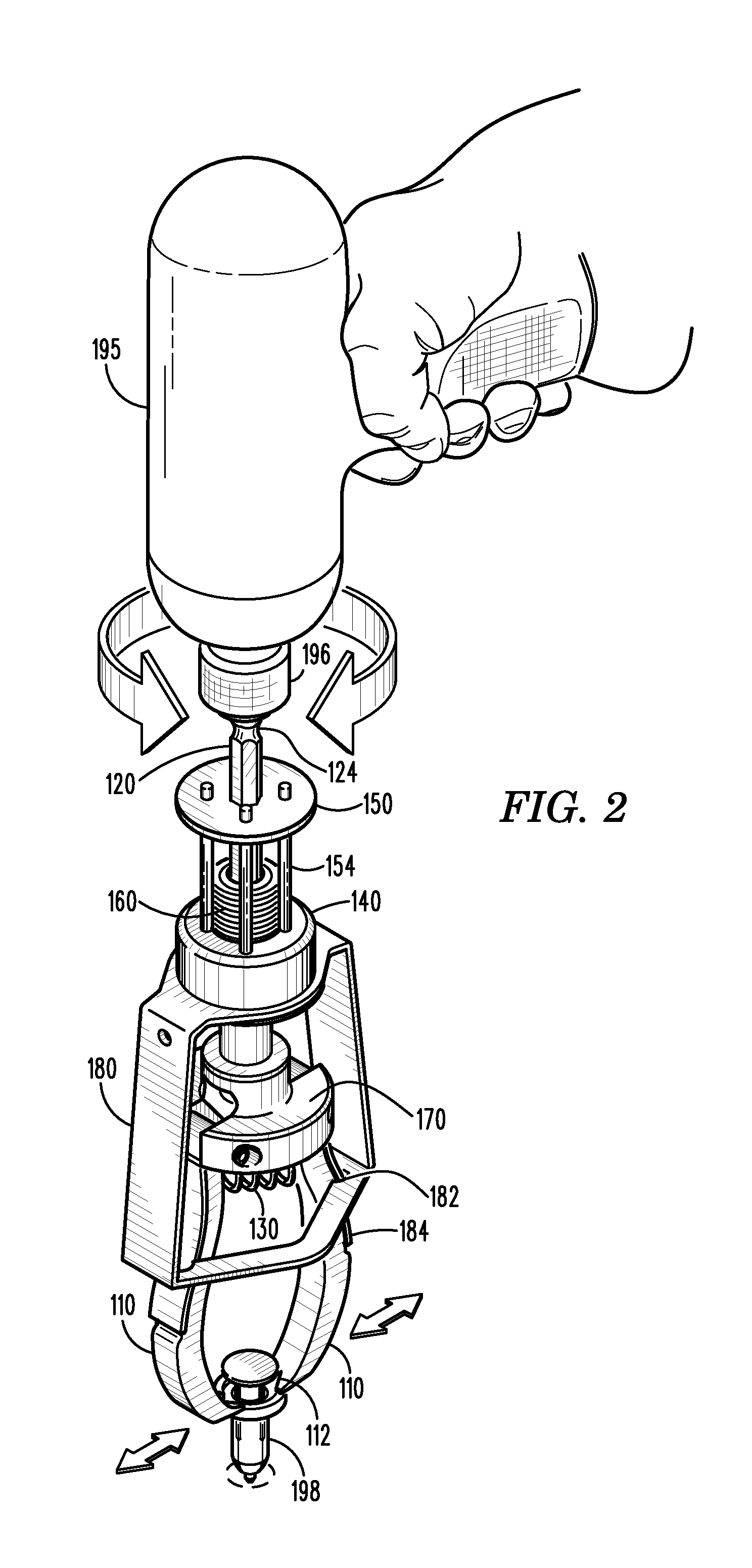

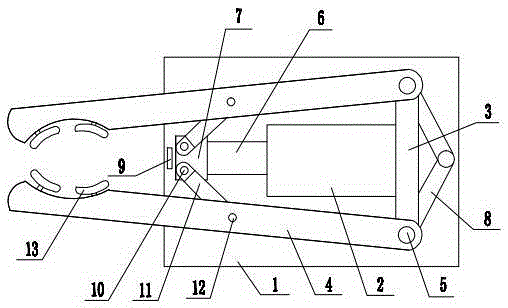

Rotary tool accessory for grabbing

A rotary tool attaches to a reversible hand drill for assisted grabbing and releasing of an automotive plastic rivet using a pair of claws. A spindle attaches to a quick release chuck of the drill. The rotary tool converts rotary motion to linear motion causing the claws to open and close when the spindle is turned by a drill.

Owner:ESPOSITO ADAM A

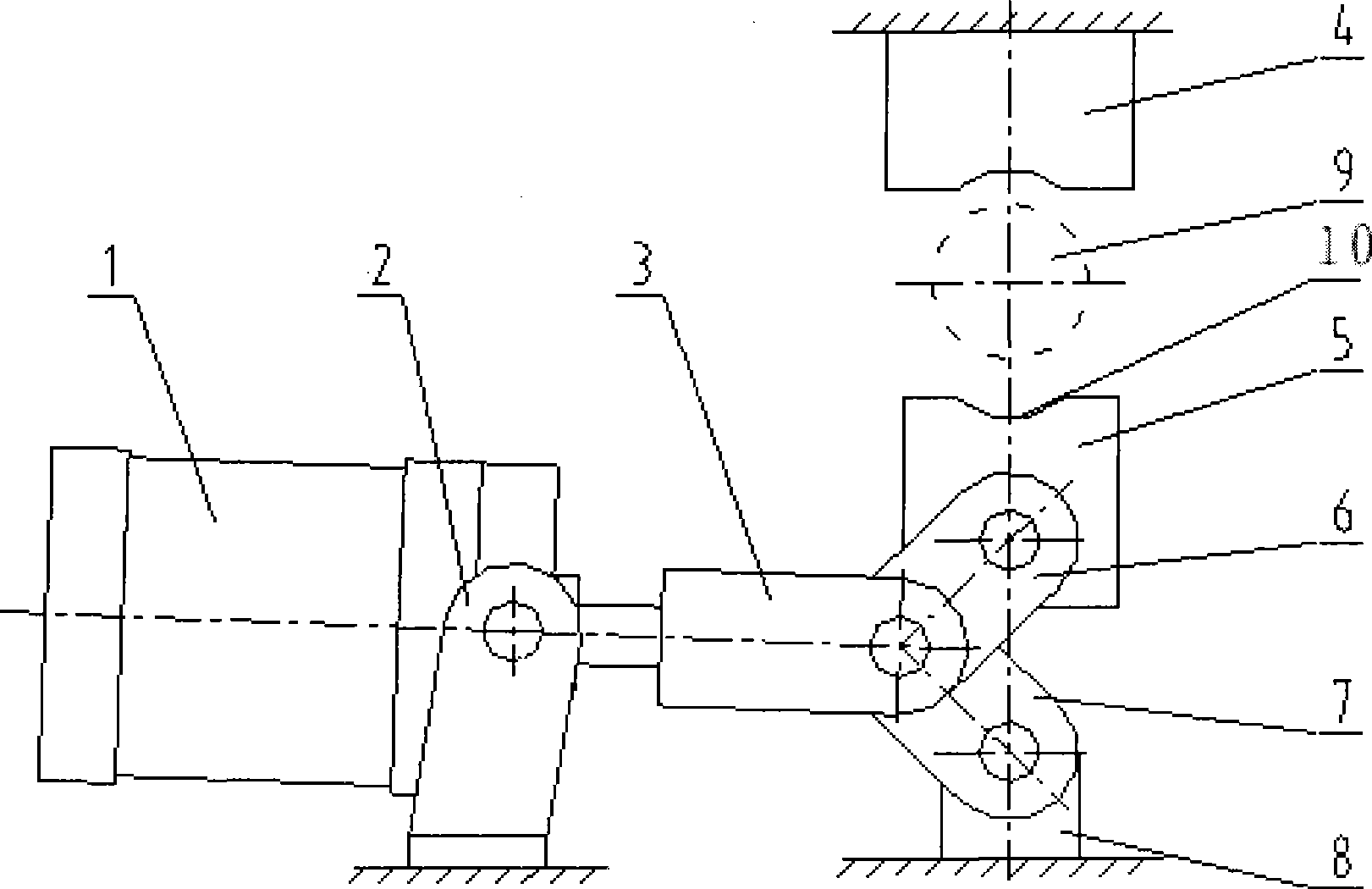

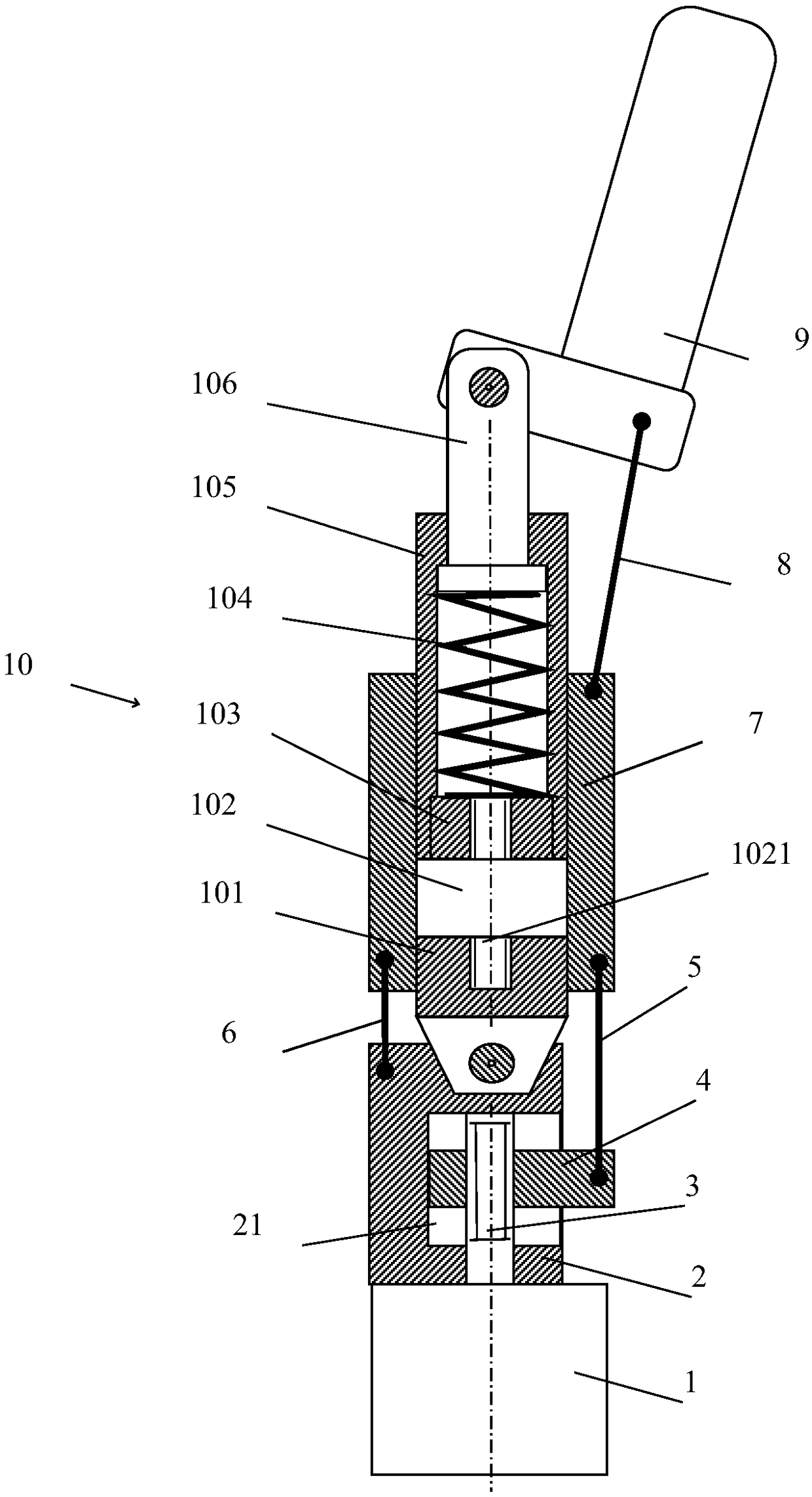

Cramping apparatus for screwing helical burr

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

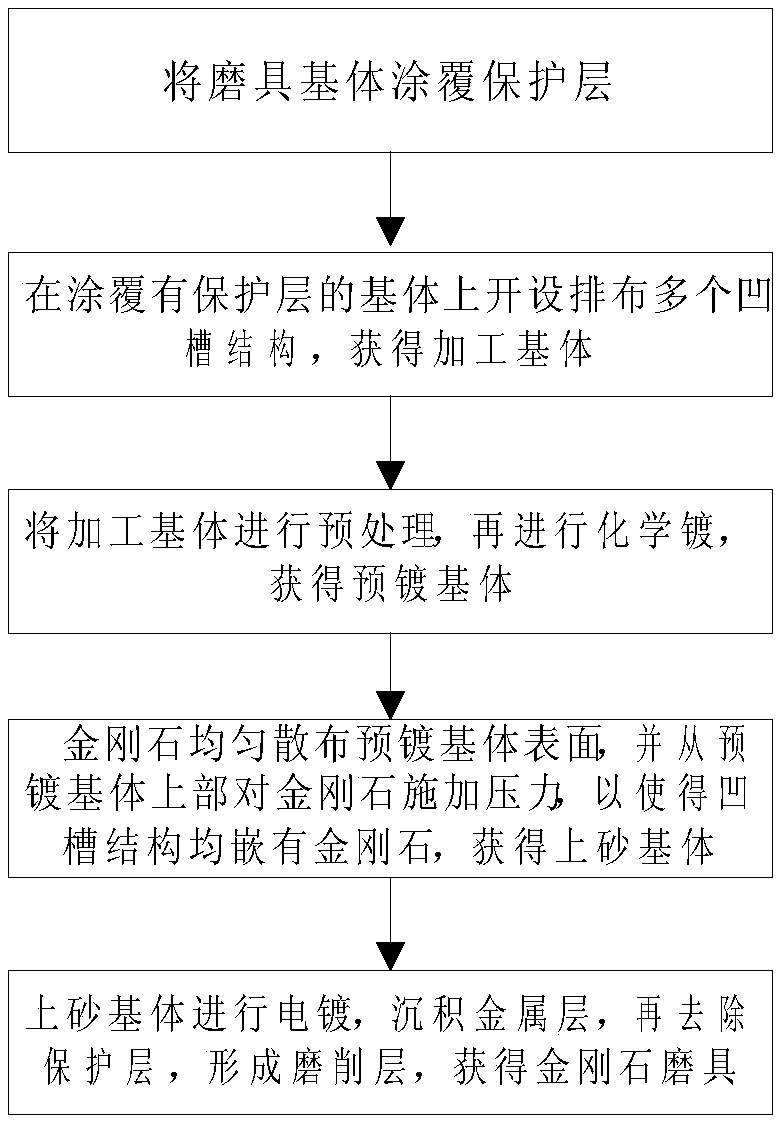

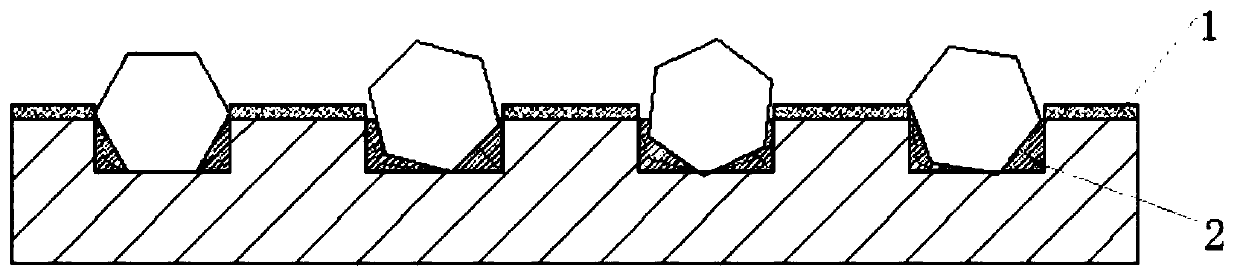

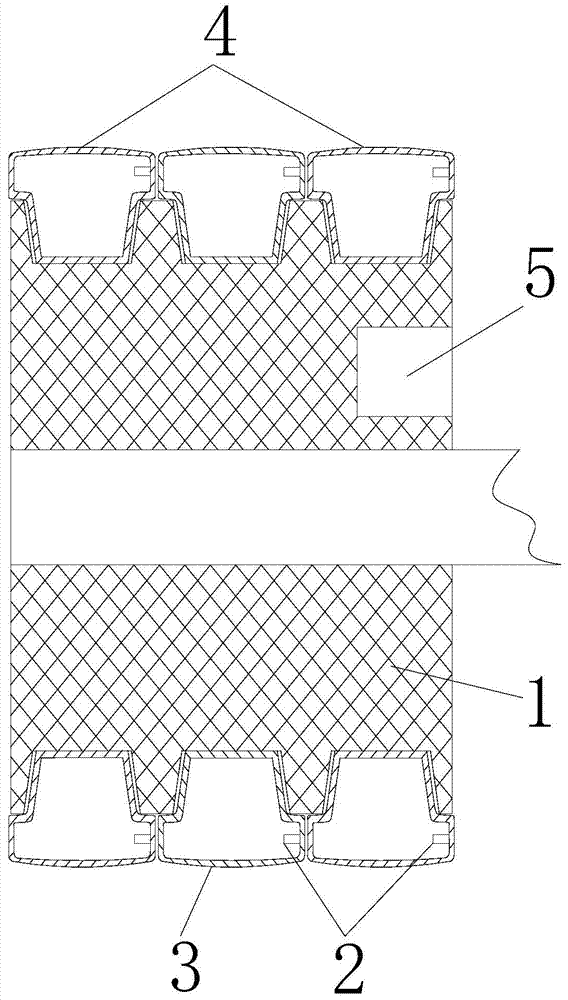

Diamond grinding tool and preparing method thereof

The invention discloses a diamond grinding tool and a preparing method thereof. The preparing method of the diamond grinding tool comprises the following steps that a grinding tool base body is coatedwith a protection layer; multiple groove structures are formed in the base body coated with the protection layer, and a machining base body is obtained; the machining base body is pre-treated, chemical pre-plating is carried out, and a pre-plated base body is obtained; diamond is evenly distributed on the base body of the pre-plated base body, pressure is applied to the diamond from the upper portion of the pre-plated base body, the diamond is embedded in the groove structures, and a sand feeding base body is obtained; the sand feeding base body is electroplated, metal layers are deposited inthe diamond surface and the groove structures, the protection layer is removed, a grinding layer is formed, and the diamond grinding tool is obtained. The preparing method of the diamond grinding tool is simple, short in time, low in cost and little in equipment funding, no pores exists in the base body and the grinding layer, and the structure is compact.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

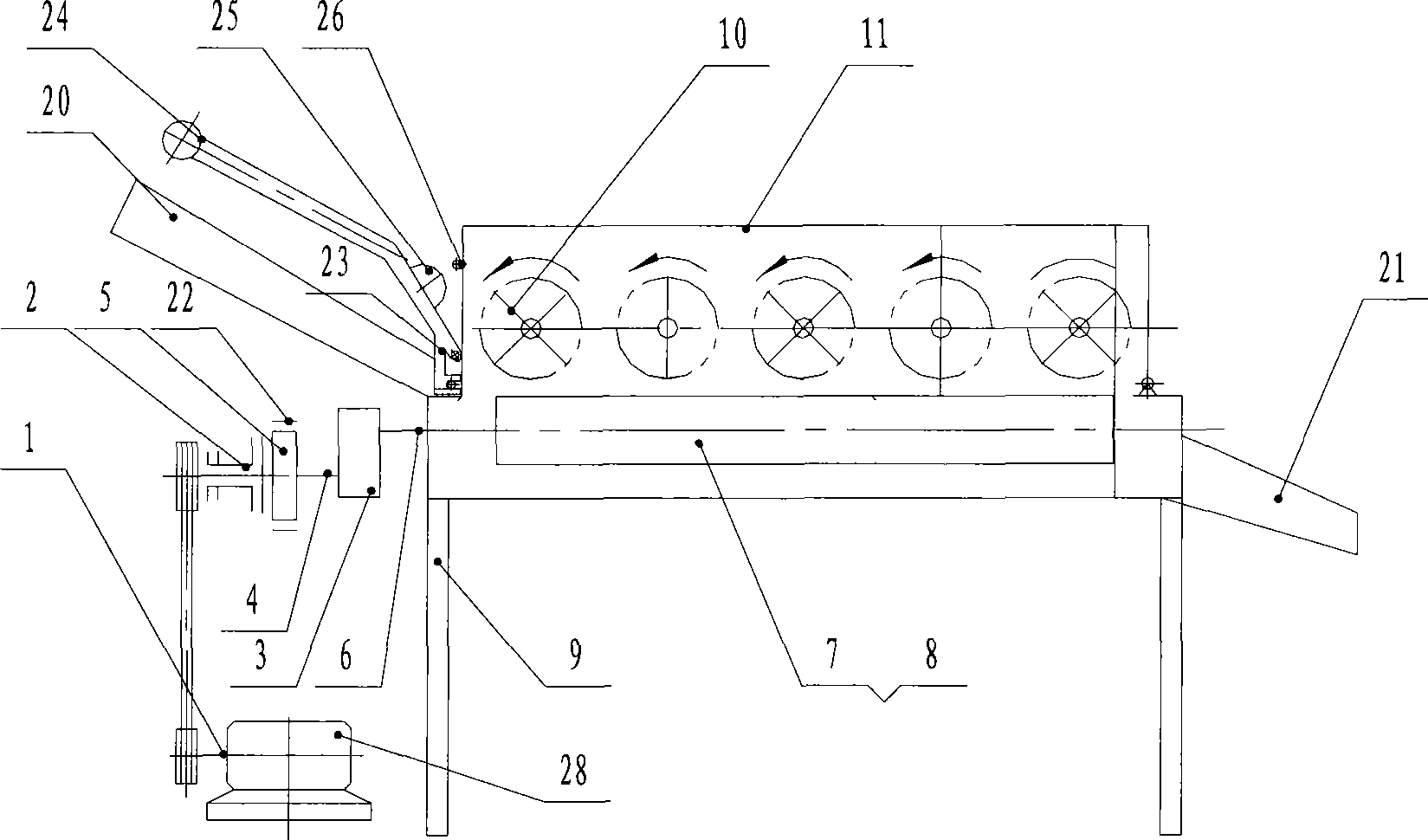

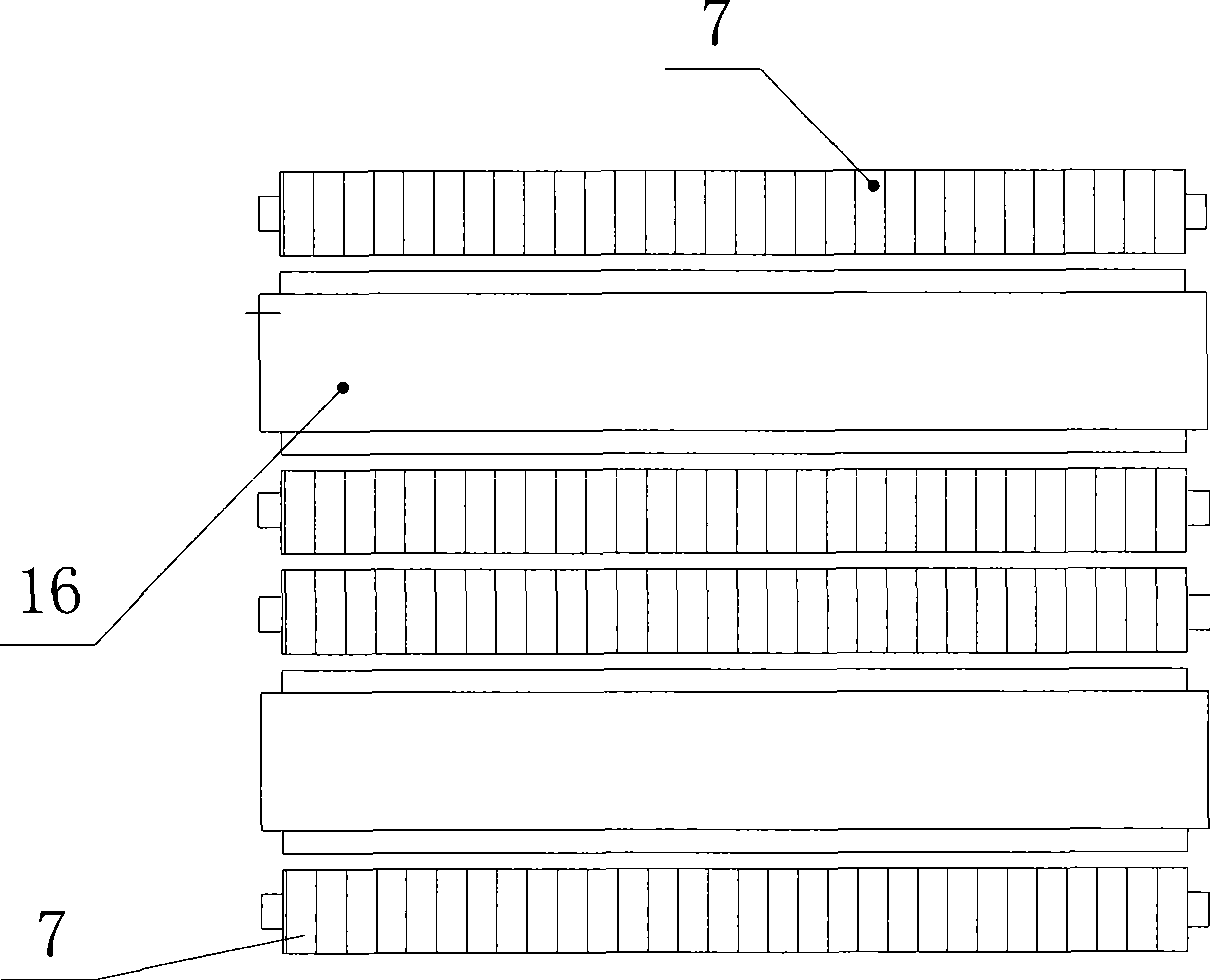

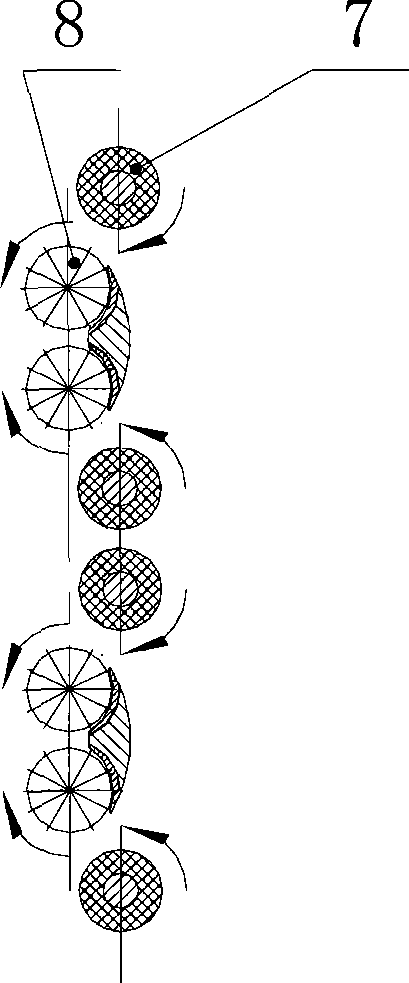

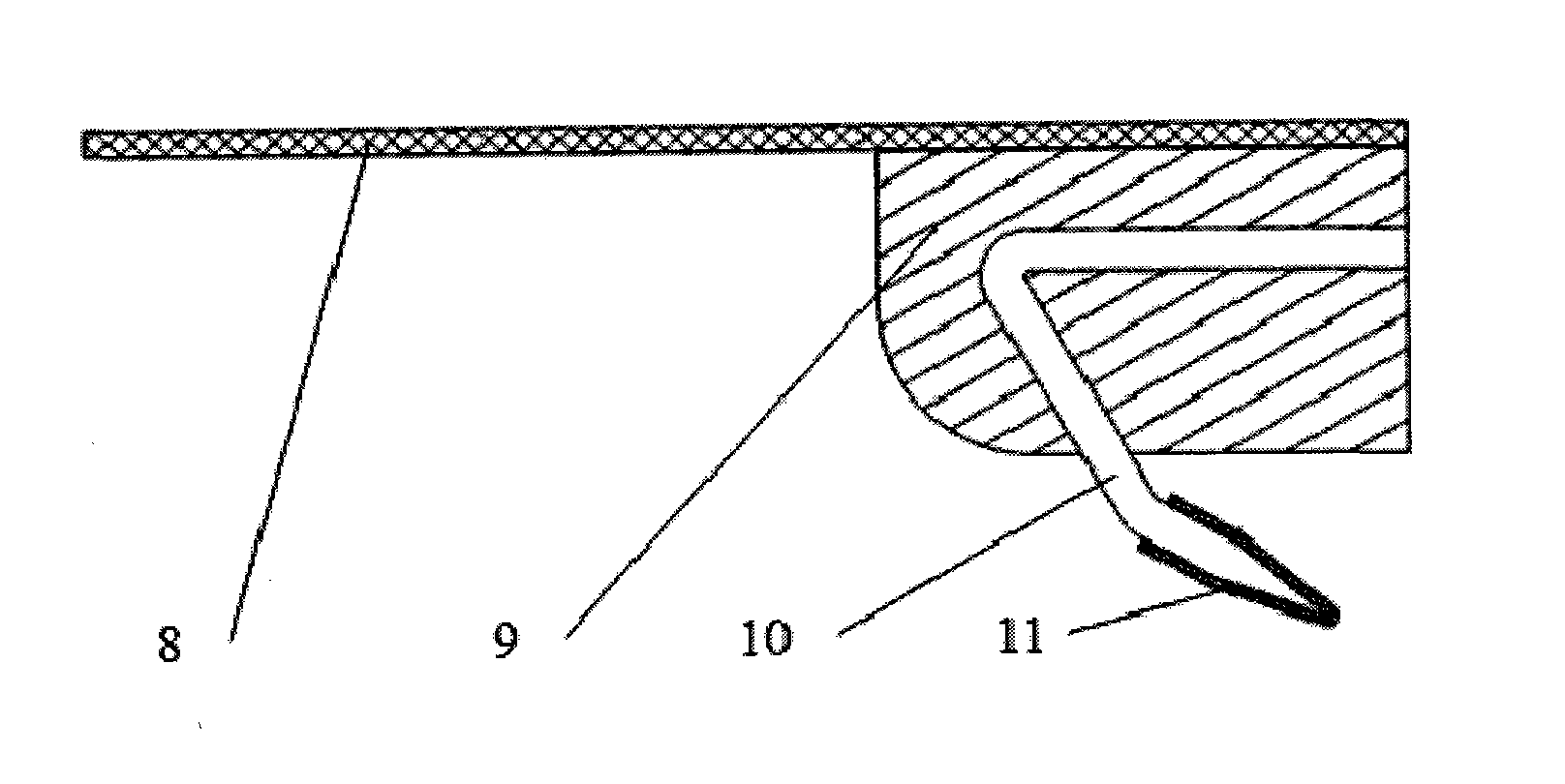

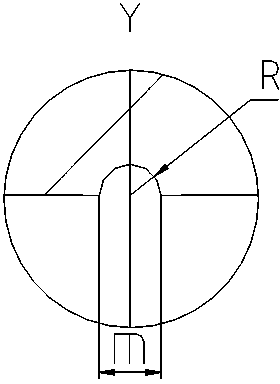

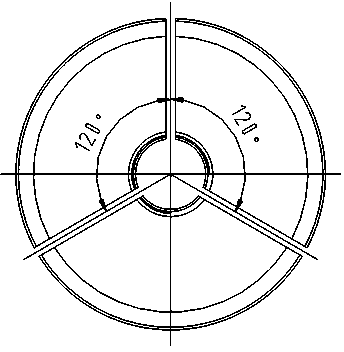

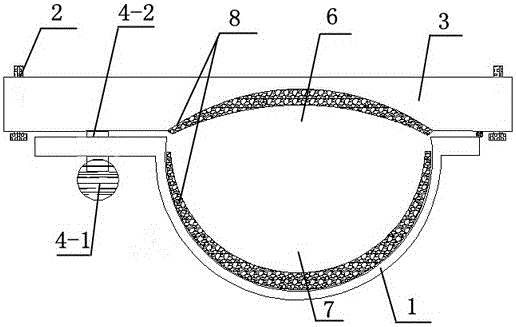

Device for peeling ear of corn and corn ear peeling machine with the device

ActiveCN101496474AMeet the needs of harvesting mechanizationImprove productivityHarvestersThreshersProduction rateEngineering

The invention relates to a corn ear peeling device and a corn ear peeling machine with the corn ear peeling device. The corn ear peeling device comprises an ear pressing and sending mechanism and a peeling mechanism which are arranged on a machine frame and are driven by a power source. The ear pressing and sending mechanism which is arranged above the peeling mechanism comprises a plurality of ear pressing and sending shifting wheels. The peeling mechanism comprises at least two pressure rollers with the reverse rotating directions, at least two peeling rollers with the reserve rotating directions, and anti-damage protective plates. The pressure rollers are arranged on the two sides of the peeling rollers and the anti-damage protective plates respectively; and the anti-damage protective plates are arranged adjacently above the peeling rollers. The corn ear peeling machine adopting the corn ear peeling device can meet the requirements on the mechanized corn harvest, is provided with an energy storage device so as to be adapted to the varied feed quantity of corn ears or stems and leaves, is provided with the anti-damage protective plates so as to protect the corn seed grains against any damage, is provided with the peeling rollers which has great grabbing force so as to improve the productivity of the peeling machine, and is provided with a reliable safe operation mechanism to ensure the safety of an operator.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

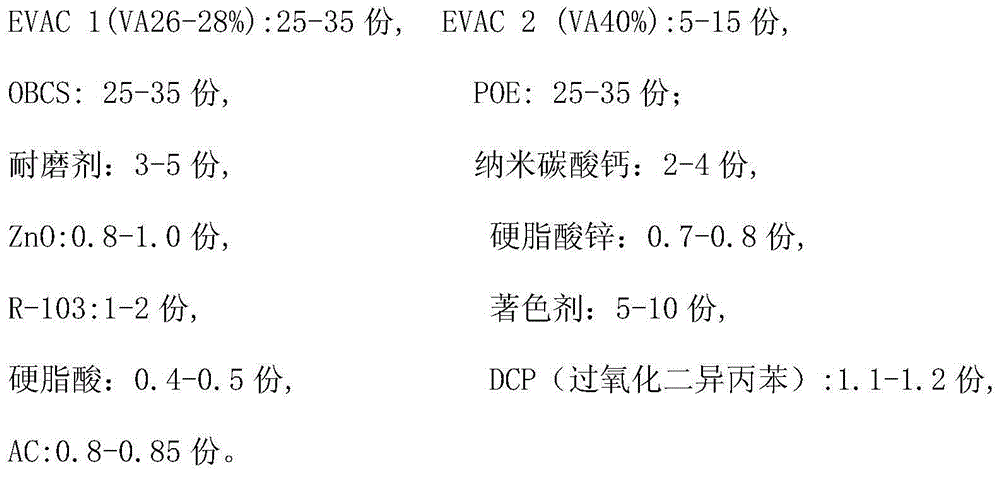

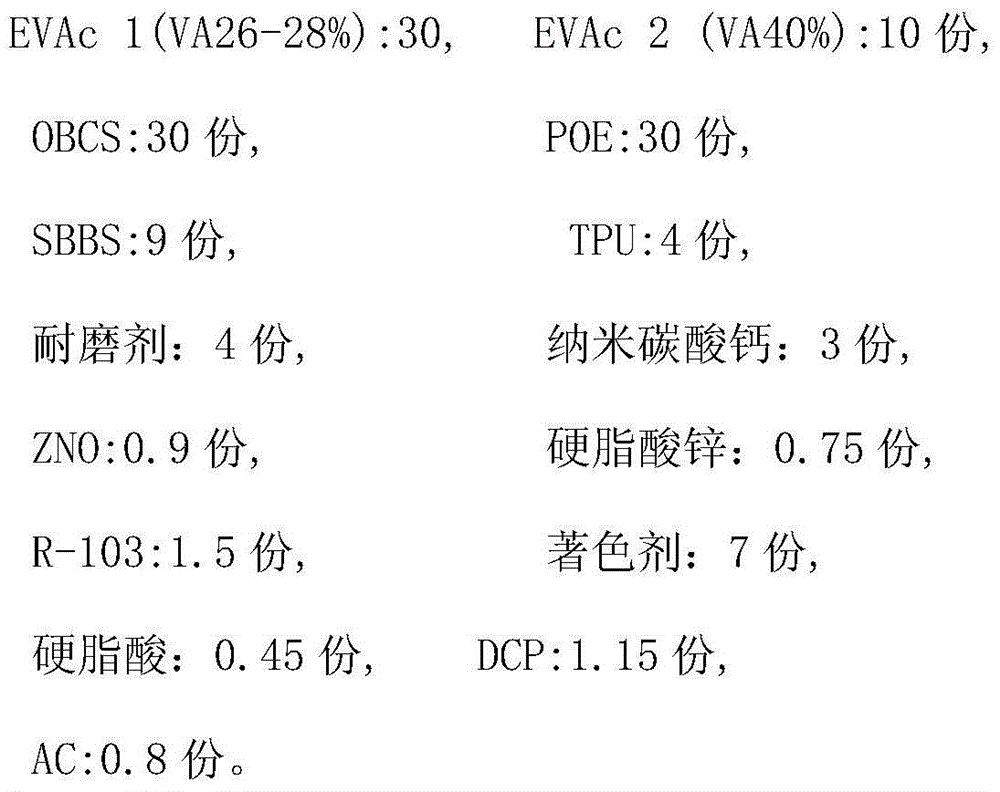

Composite foaming material injection midsole and manufacturing method thereof

Owner:PUTIAN LONGXIANG SHOES

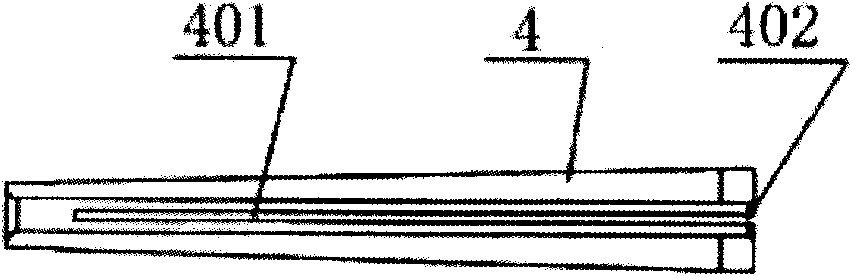

Wall-climbing robot with passive compression structure and biomimetic claws

The invention belongs to the technical field of machine manufacturing, and particularly relates to a wall-climbing robot with a passive compression structure and biomimetic claws. The wall-climbing robot comprises an upper machine body plate, a lower machine body plate, a crank block, the claws and a tail. The upper machine body plate and the lower machine body plate are respectively connected with at least three claws, wherein the claws are symmetrically distributed left and right, and all the claws are connected with the upper machine body plate and the lower machine plate body through elastic leaf springs. The elastic leaf springs deform directionally to provide pre-compression for the claws in a passive mode. According to the wall-climbing robot, the structural design of the one-way elastic claws is adopted, and the claws have the characteristics of being capable of sliding and fixedly clawing and adhering when the wall-climbing robot moves. When the claws slide upward along a wall face along with a machine body, the claws cock backward, and therefore the resistance of upward movement is reduced; when the claws claw and adhere to a wall, the claws are fixed in position due to structural limit, and therefore clawing and adhering are firmer. In addition, the wall-climbing robot is simple in structure, convenient to operate and use, low in manufacturing cost, and suitable for being popularized and applied in related technical fields.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

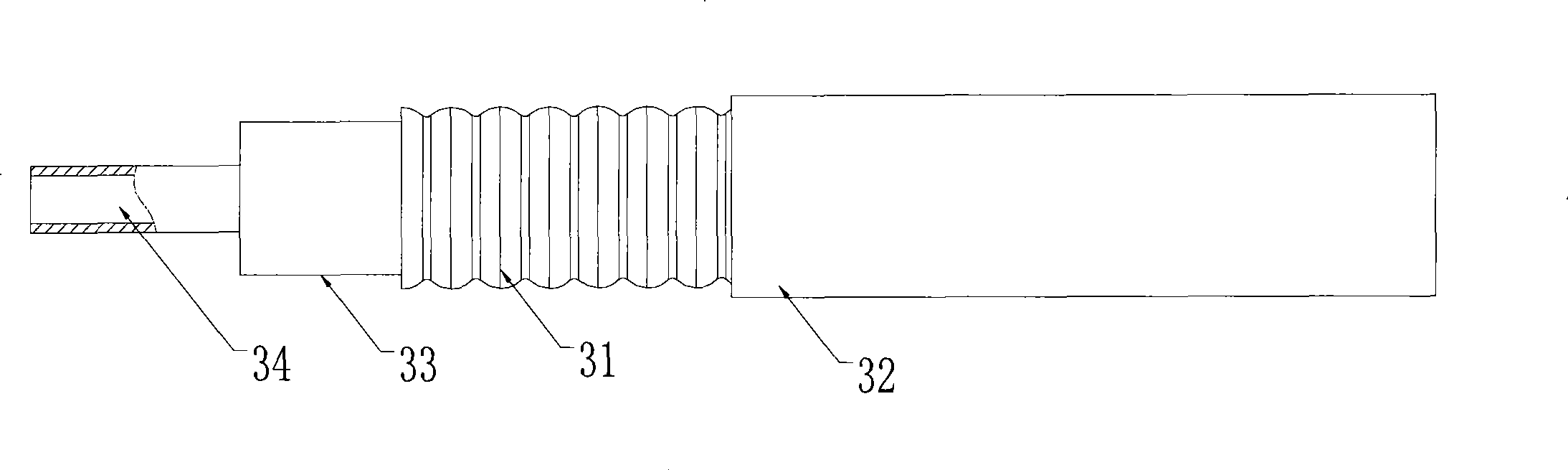

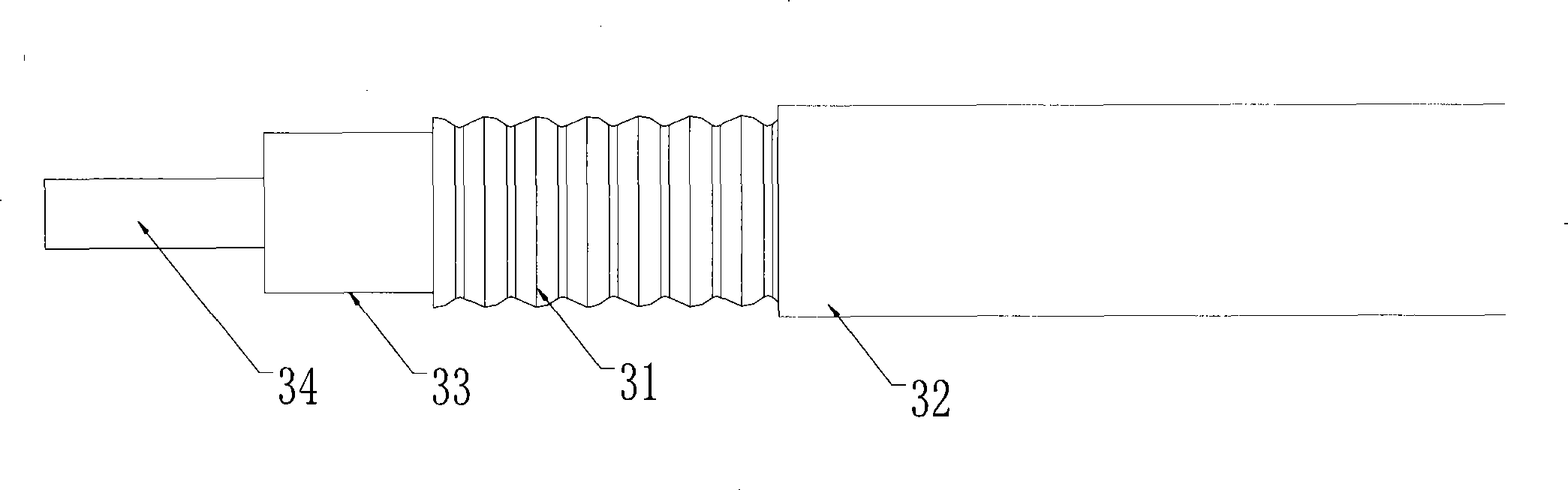

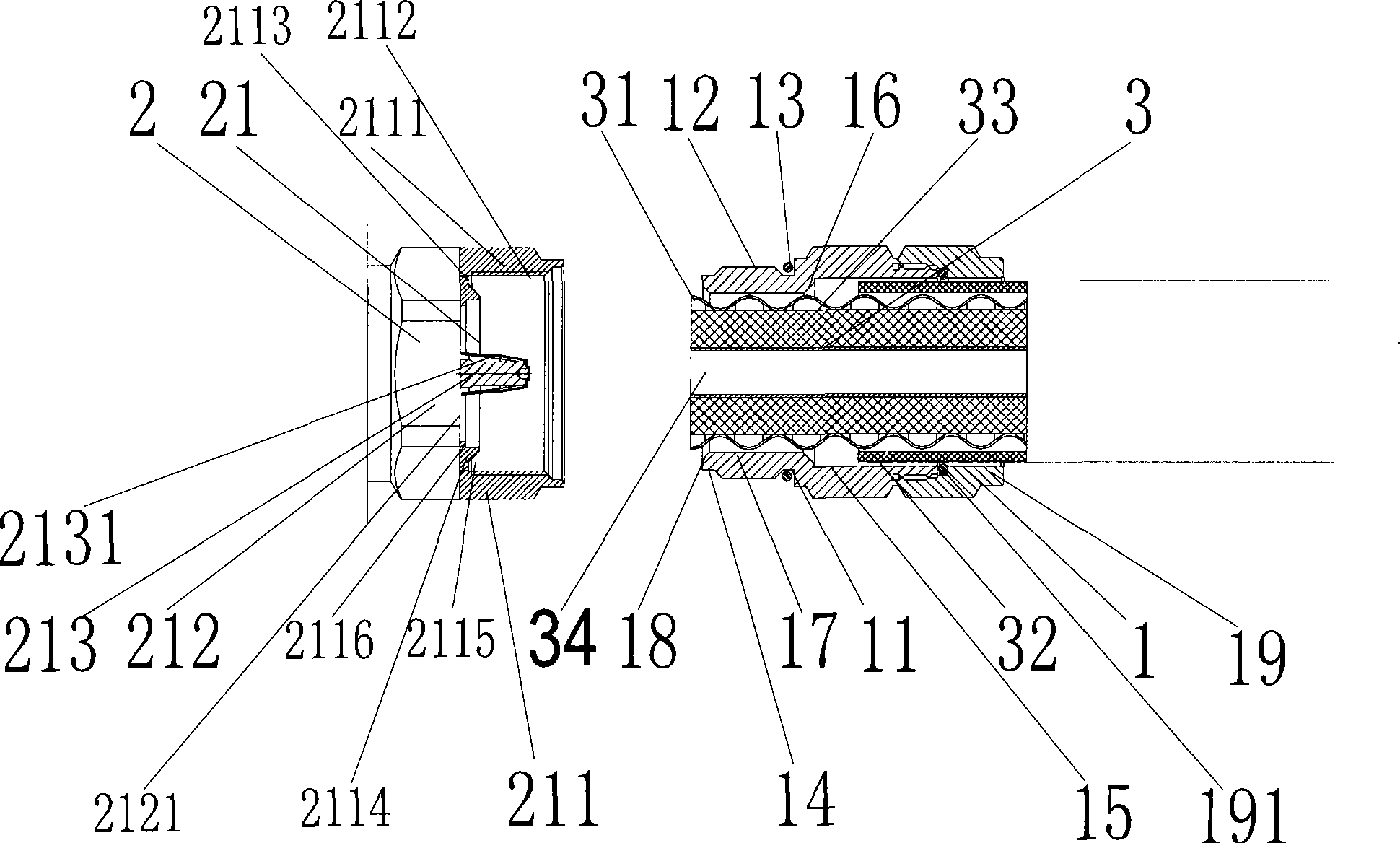

Coaxial electric cable connector for sylphon bellowss

ActiveCN101483282AEasy to use and installStrong gripTwo-part coupling devicesClamped/spring connectionsElectrical conductorCoaxial cable

The invention provides a corrugated pipe coaxial cable connector comprising a muff-coupling helicoid and an termination section. The coaxial cable is covered by the muff-coupling helicoid, an external thread is opened on a front end outer diameter surface of the muff-coupling helicoid, and a chamfer angle is arranged on an inner diameter at the front end port. The termination section is divided into a termination segment and an inserting segment for the axial direction forward and backward two segments. The termination segment is used for terminal connection with the coaxial cable. The inserting segment is used for inserting cooperation with other cable plugs. The termination segment comprises an external conductor, an isolator and a center conductor. The external conductor is provided with a thin wall barrel-shaped outer wall, and an internal thread matched with the external thread on the muff-coupling helicoid front end outer diameter surface is arranged on the internal diameter. A first step is arranged at the bottom of the external conductor internal diameter surface, and a ring conical convex with a cone matching with the chamfer angle of the muff-coupling helicoid is arranged along the first step edge. The technical scheme of the invention totally cancels the arrangement of a clamping ring and obtains a firm holding.

Owner:ROSENBERGER ASIA PACIFIC ELECTRONIC CO LTD

Robot finger mechanism

Owner:YANSHAN UNIV

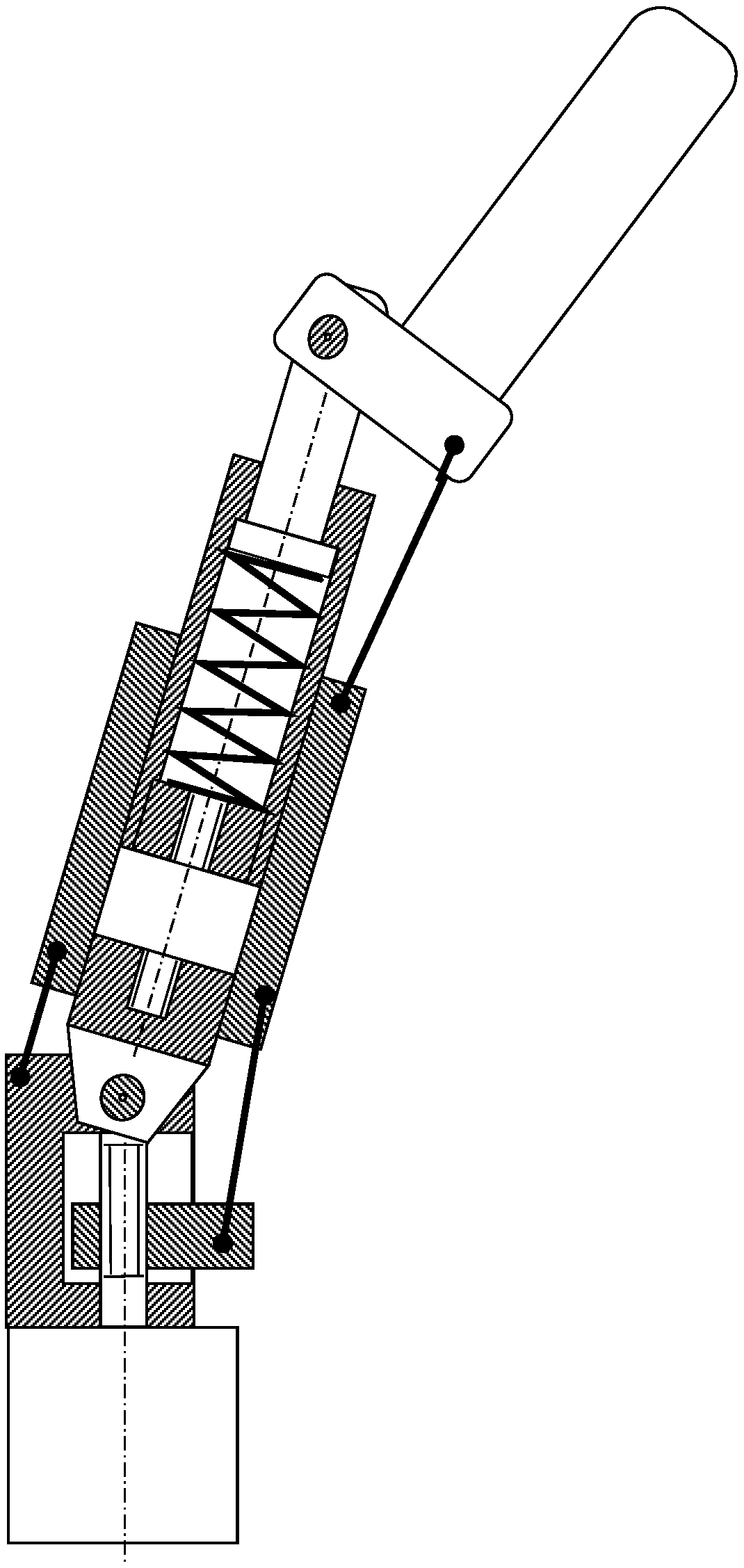

Machine tool adjustment cushion

The invention discloses a machine tool adjustment cushion. The machine tool adjustment cushion comprises a groove base. Two opposite sliding cushion pieces are arranged in the groove base. Each sliding cushion piece comprises an upper cushion block and a lower cushion block, the contact faces of the upper cushion block and the lower cushion block are inclined faces, the portion, close to the edge of the groove base, of the lower cushion block is high, two set bolts penetrating through the edge of the groove base are connected with the upper cushion block and the lower cushion block respectively, and a gap is reserved between the two sliding cushion pieces. Compared with the prior art, the machine tool adjustment cushion has the advantages that the two corresponding inclined blocks are adjusted, the height can be adjusted, the inclination degree can be adjusted as well, and a machine tool device can be supported generally through only two long adjustment cushion bodies.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

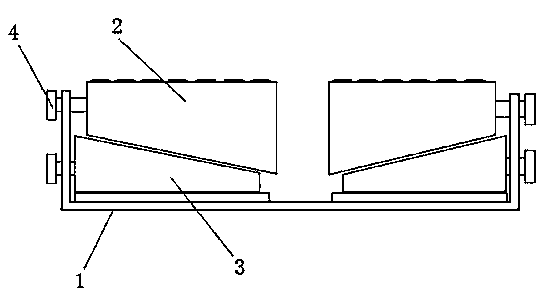

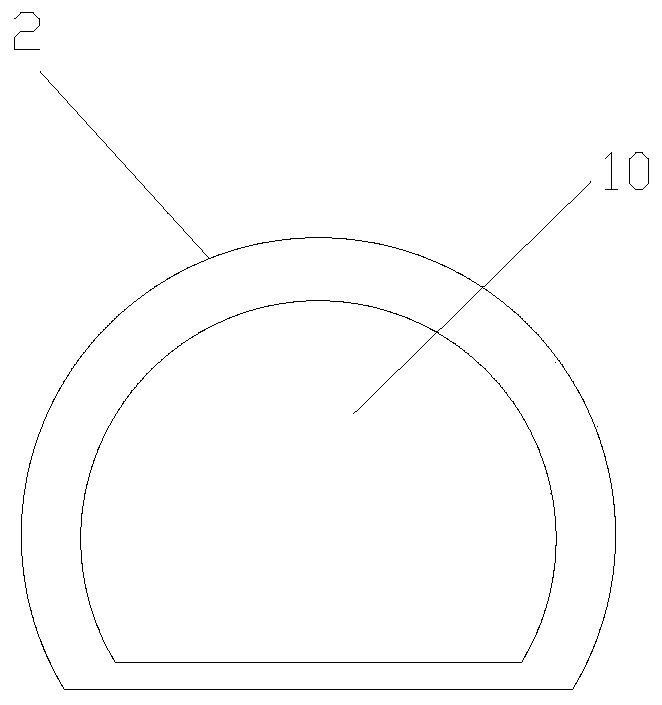

Head fixing bracket used for ophthalmologic operation

The invention provides a head fixing bracket used for ophthalmologic operation. The head fixing bracket comprises double clamps and bolts for fastening the clamps, wherein the double clamps are provided with support plates for connecting upper and lower clamp plates, a cubic base is arranged between the two support plates, a stud groove is formed in the middle of the cubic base, the stud groove is adaptive to a stud, an arm used for controlling the lifting height of the stud in the cubic base is fixedly arranged at one side of the upper end surface of the stud, the middle of the upper end surface of the stud is fixedly connected with the lower end of a support rod, the upper end surface of the support rod is connected with the lower end surface of an arc-shaped head support, the upper end surface of the arc-shaped head support is adaptive to an elastic cushion, and head binding belts are arranged on the left and right sides, close to the rear part, of the arc-shaped head support. The head fixing bracket is reasonable in structure, strong in stability, comfortable to use and adjustable in height, is suitable for fixing the head during the ophthalmologic operation, can be detached to be mounted on the bedside or the chair back, and is strong in practicability.

Owner:杜佳雨

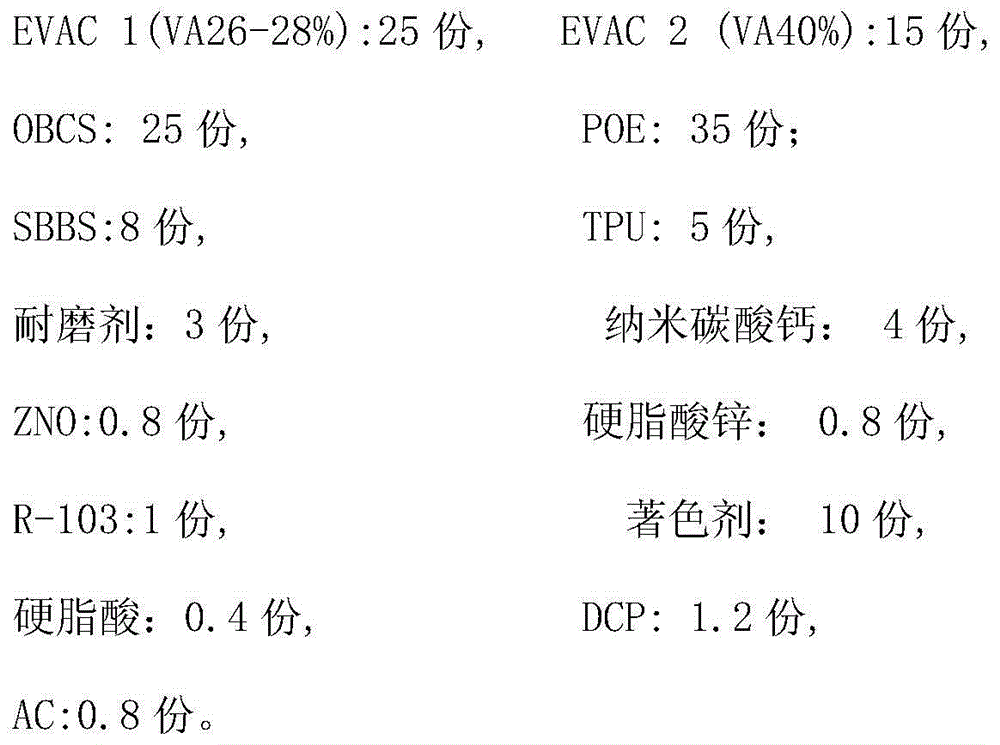

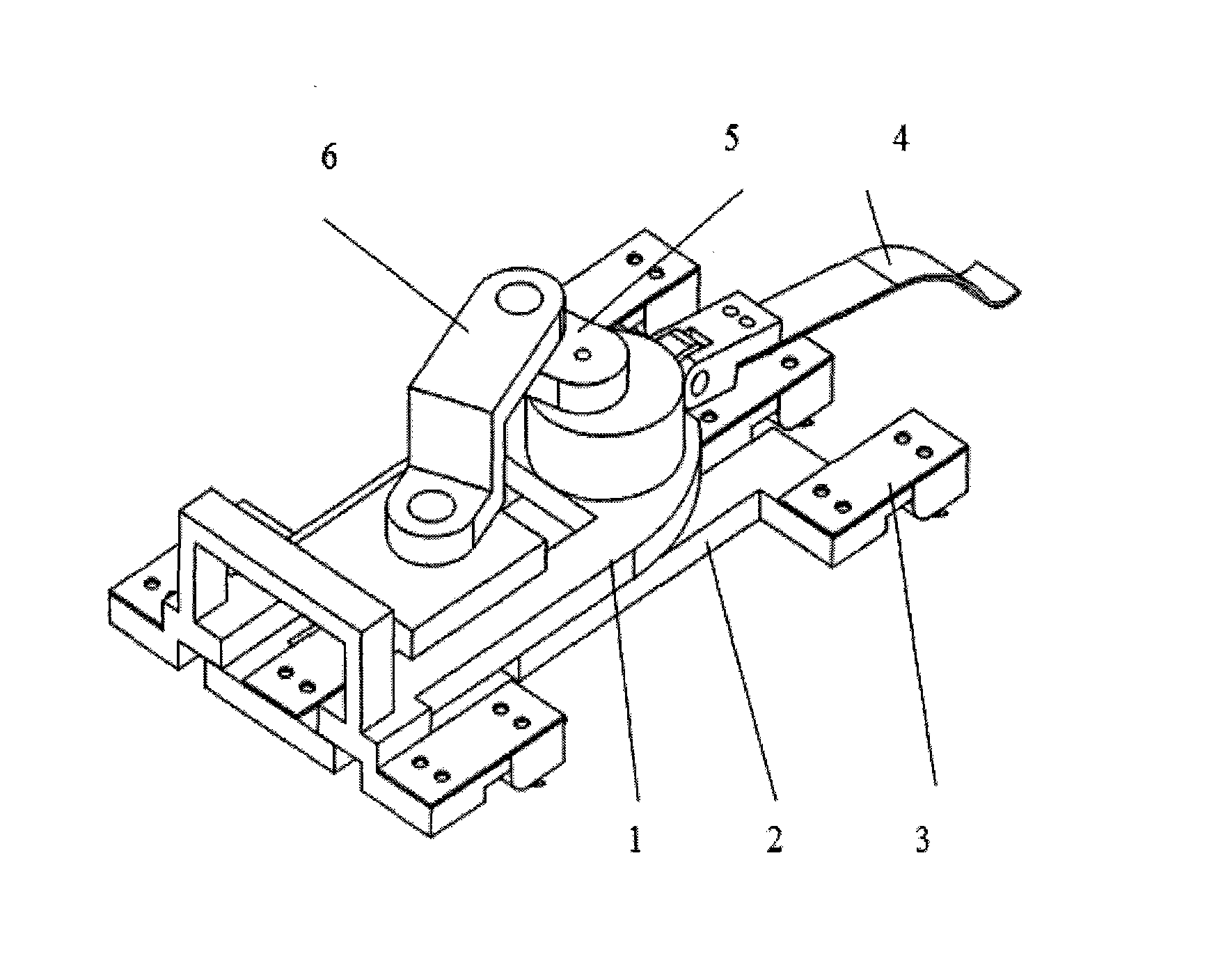

Pneumatic fixture

InactiveCN105291127AStrong gripEasy to implementProgramme-controlled manipulatorGripping headsEngineeringMechanical engineering

The invention relates to a pneumatic fixture. The pneumatic fixture is characterized in that a cylinder is fixed on a cylinder fixed plate; a push block is arranged at the tail end of a push rod of the cylinder; two connecting rods movably connected with the push block are symmetrically arranged on the push block; the other ends of the connecting rods are connected to clamping rods through pin shafts; connecting shafts are respectively arranged at the two ends of a cylinder fixed plate; fixed ends of the clamping rods are movably connected to the connecting shafts; clamping ends of the clamping rods can be driven by the cylinder to perform a clamping action; and a travel switch is arranged on a baseplate, and is positioned in the operation direction of the cylinder and within the travel of the cylinder. The fixture is suitable for clamping pipes or cylindrical objects, and adopts a pneumatic mode to clamp, so that the clamping is firm and easy to be realized; and the travel switch is arranged in the moving travel of the cylinder, so that the sizes of clamped workpieces can be adjusted through adjusting the position of the travel switch on the slide block, and the application range of the fixture is widened.

Owner:新昌县中环磨料有限公司

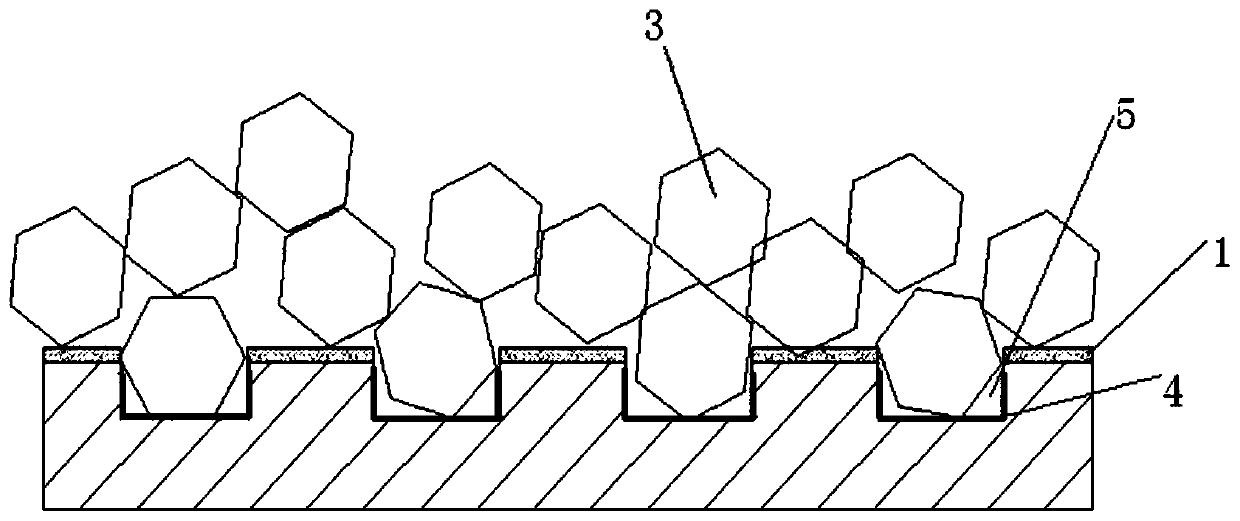

Preparation method of diamond grinding wheel with ordered abrasive materials

InactiveCN109825860AImprove gripStrong gripElectrolytic coatingsLiquid/solution decomposition chemical coatingDiamond grindingChemical plating

The invention discloses a preparation method of a diamond grinding wheel with ordered abrasive materials. The preparation method comprises the following steps that S1, a matrix is prepared; S2, inkjetis carried out; S3, holes are formed; S4, chemical plating is carried out; and S5, sanding is performed. In the S1, a grinding wheel substrate is prepared by numerical control machining; in the S2, an ink layer is sprayed on the substrate; in the S3, a laser engraving machine is adopted to carving out the blind holes in size with diamonds in an ordered arrangement mode on the upper sand surface;in the S4, chemical plating is carried out on the substrate treated in the S3, so that metal pre-coatings are deposited on the bottoms and the side walls of the blind holes; and in the S5, excess diamond grinding materials are placed on the surface of the pre-plating substrate obtained in the step S4 for rolling, and the lower parts of the grinding materials are embedded into the blind holes and put into an electroplating solution for electroplating, so that the grinding materials are solidified in the blind holes to form a grinding material layer. According to the method, the ink layer is sprayed on the grinding wheel substrate, so that the substrate is isolated, and diamonds roll to enter the blind holes to be electroplated and solidified during sanding, ink shielding layers in other areas cannot be coated with nickel, and the ink shielding layers can automatically fall off during scrubbing in the electroplating solution, so that regular and ordered arrangement of the diamond abrasive materials on the surface of the grinding wheel substrate is realized.

Owner:LOUDI ANTAEUS ELECTRONICS CERAMICS

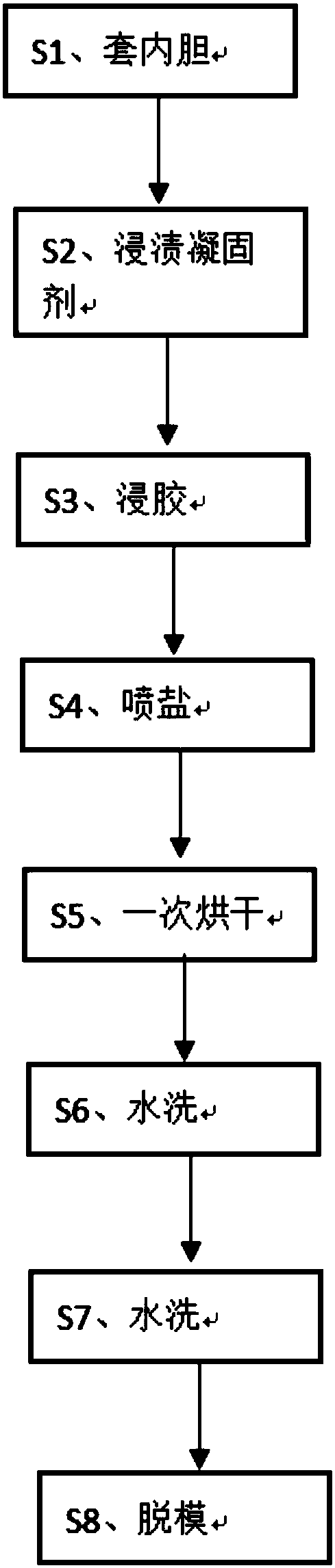

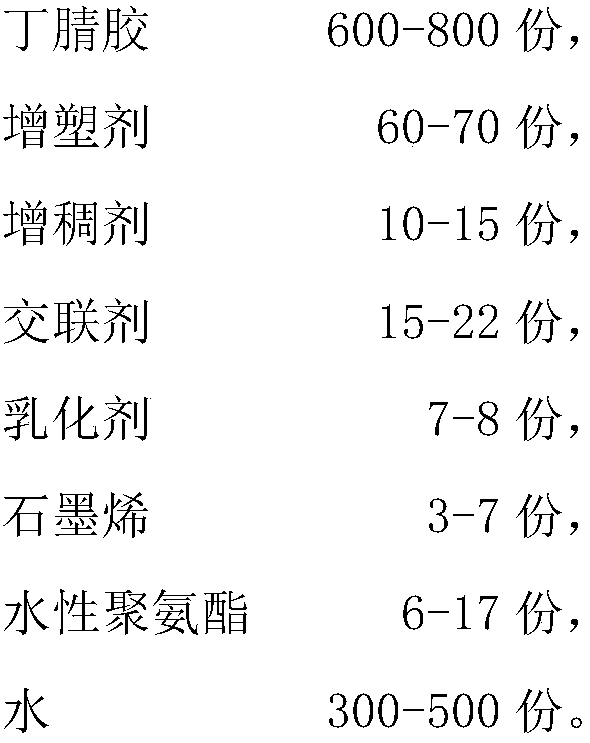

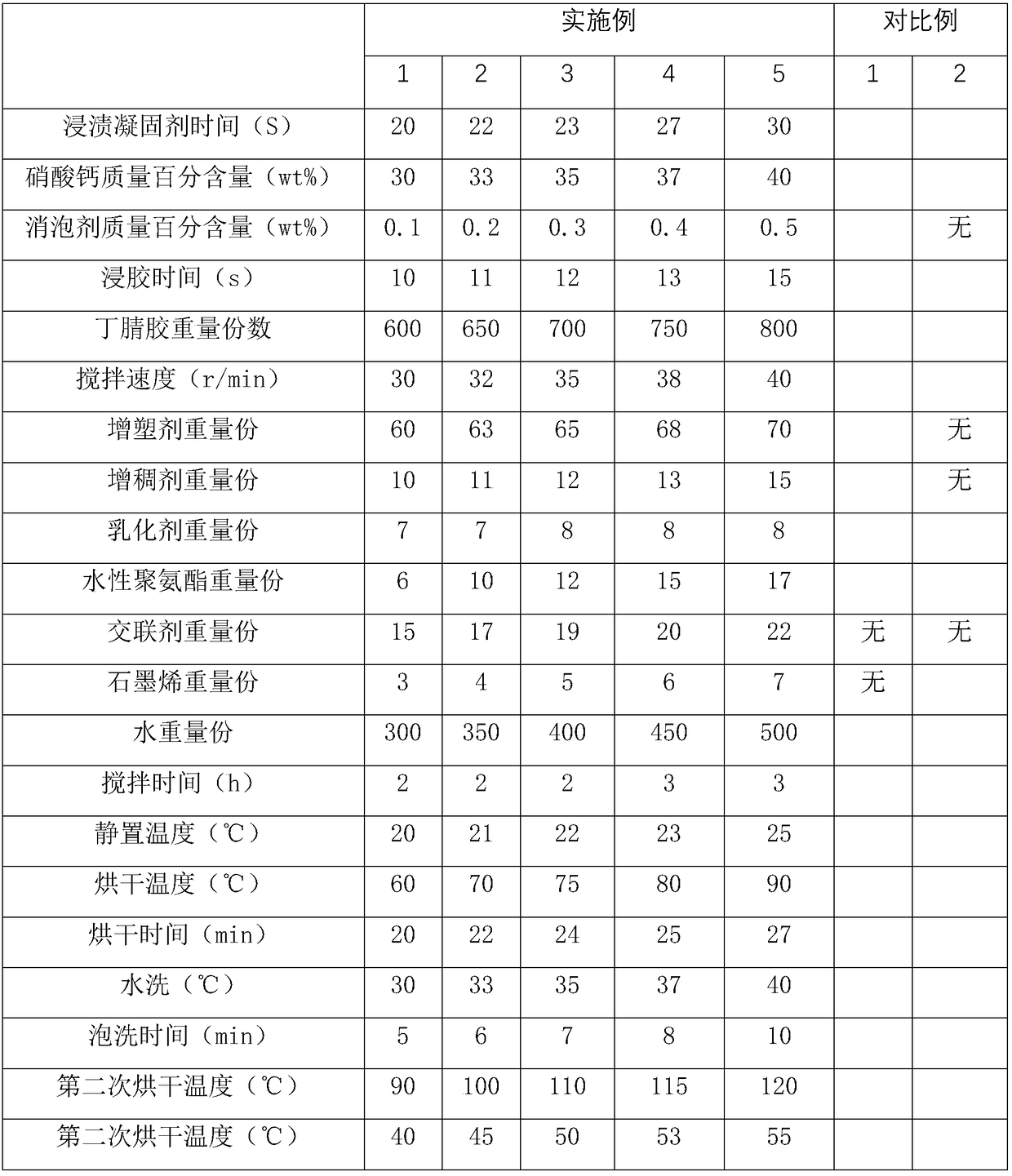

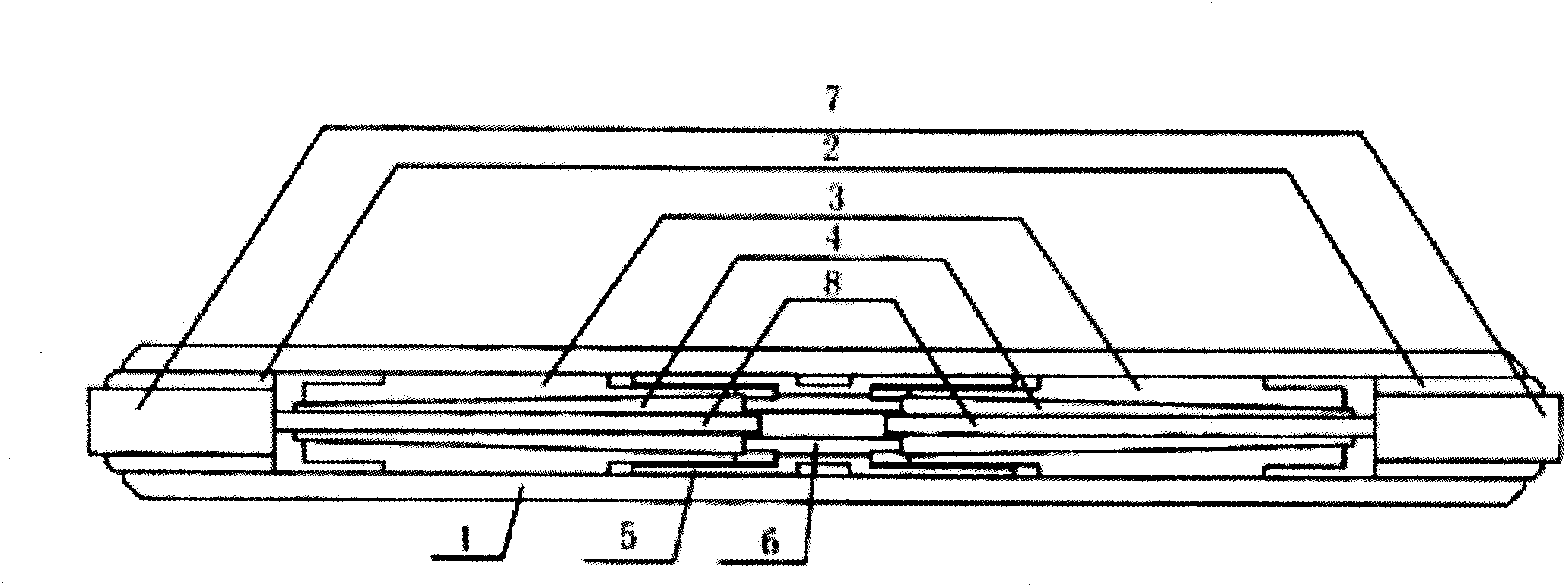

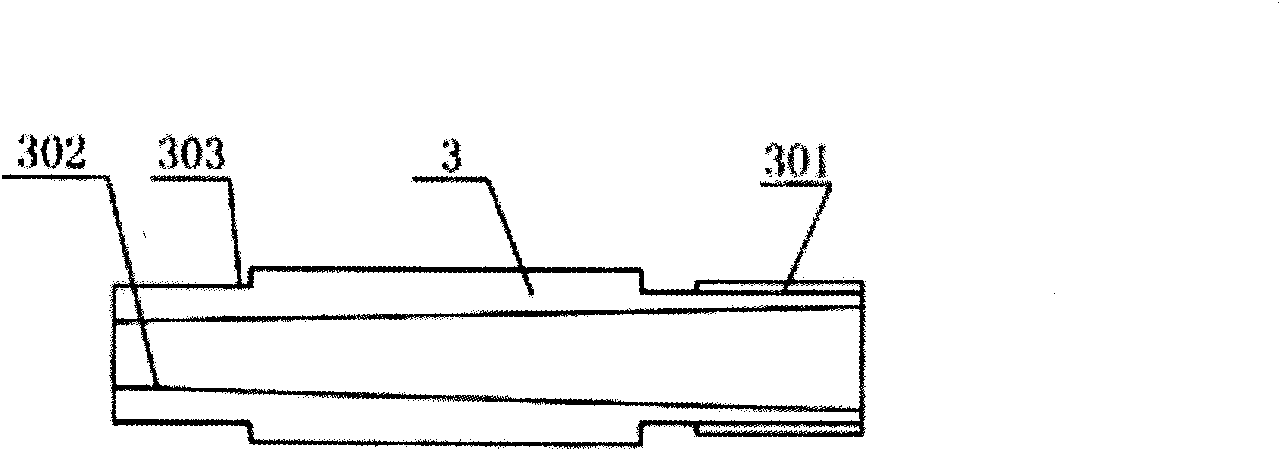

Preparation method of graphene-butadiene-acrylonitrile rubber latex matting glove

InactiveCN109457465AStrong gripWith body temperature far infraredGlovesLight resistant fibresGlove linerPuncture resistance

The invention relates to a preparation method of a graphene-butadiene-acrylonitrile rubber latex matting glove. The preparation method comprises, S1, arranging a glove liner on a hand mould in a covering mode; S2, impregnating the glove liner into curing agent for 20-30 s; S3, totally immersing the glove liner into graphene-butadiene-acrylonitrile composite slurry at a latex viscosity of 600-700 cp for 10-15 s; S4, performing salt spray treatment on the immersed glove liner; S5, performing primary drying inside a vulcanization crosslinking drying oven; S6, washing the dried glove; S4, performing secondary drying on the washed glove inside the oven; S8, performing cooling and demoulding to obtain the graphene-butadiene-acrylonitrile rubber latex matting glove. The prepared graphene-butadiene-acrylonitrile rubber latex matting glove is high in wearing resistance, puncture resistance, tear resistance and cutting resistance, highly antibacterial, capable of achieving far infrared radiationand the like.

Owner:NANTONG JIADELI SAFETY PROD CO LTD

Twisted carbon fibre composite core lead splicing sleeve

InactiveCN101916922AHigh strengthStrong gripConnections effected by permanent deformationMulticonductor cable end piecesCarbon fiber compositeCorrosion

The invention discloses a twisted carbon fibre composite core lead splicing sleeve, which comprises two sets of internal-cone-external-thread sleeves, positive and negative internal-tread connectors, lead particles, two sets of lined pipes and a casing pipe. The splicing sleeve is characterized in that a positive and negative internal-tread connector is arranged in the middle of the internal part of the casing pipe; a lead particle is arranged in the middle of the positive and negative internal-tread connector; two ends of the positive and negative internal-tread connector are respectively connected with one set of the internal-cone-external-thread sleeve in which an external-cone-internal-tread core is arranged; the internal parts of two ends of the casing pipe are provided with one set of lined pipe respectively. The twisted carbon fibre composite core lead splicing sleeve has the advantages of scientific design, high strength, large gripping power, stable performance, high-temperature and corrosion resistance, good diversion effect, smooth passing of pulleys, convenient installation, labor intensity reduction and the like.

Owner:JIANGSU YIDING POWER TECH

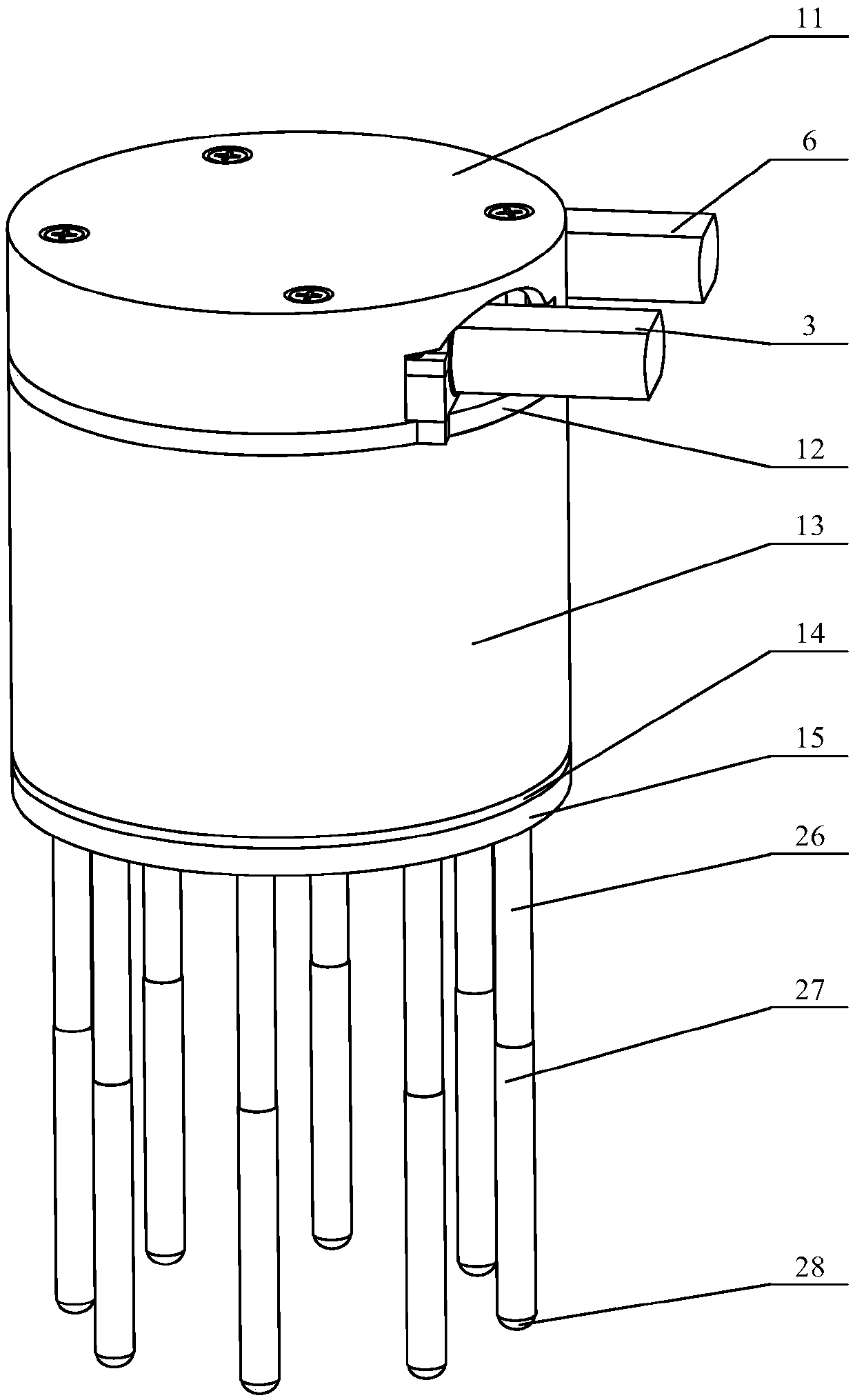

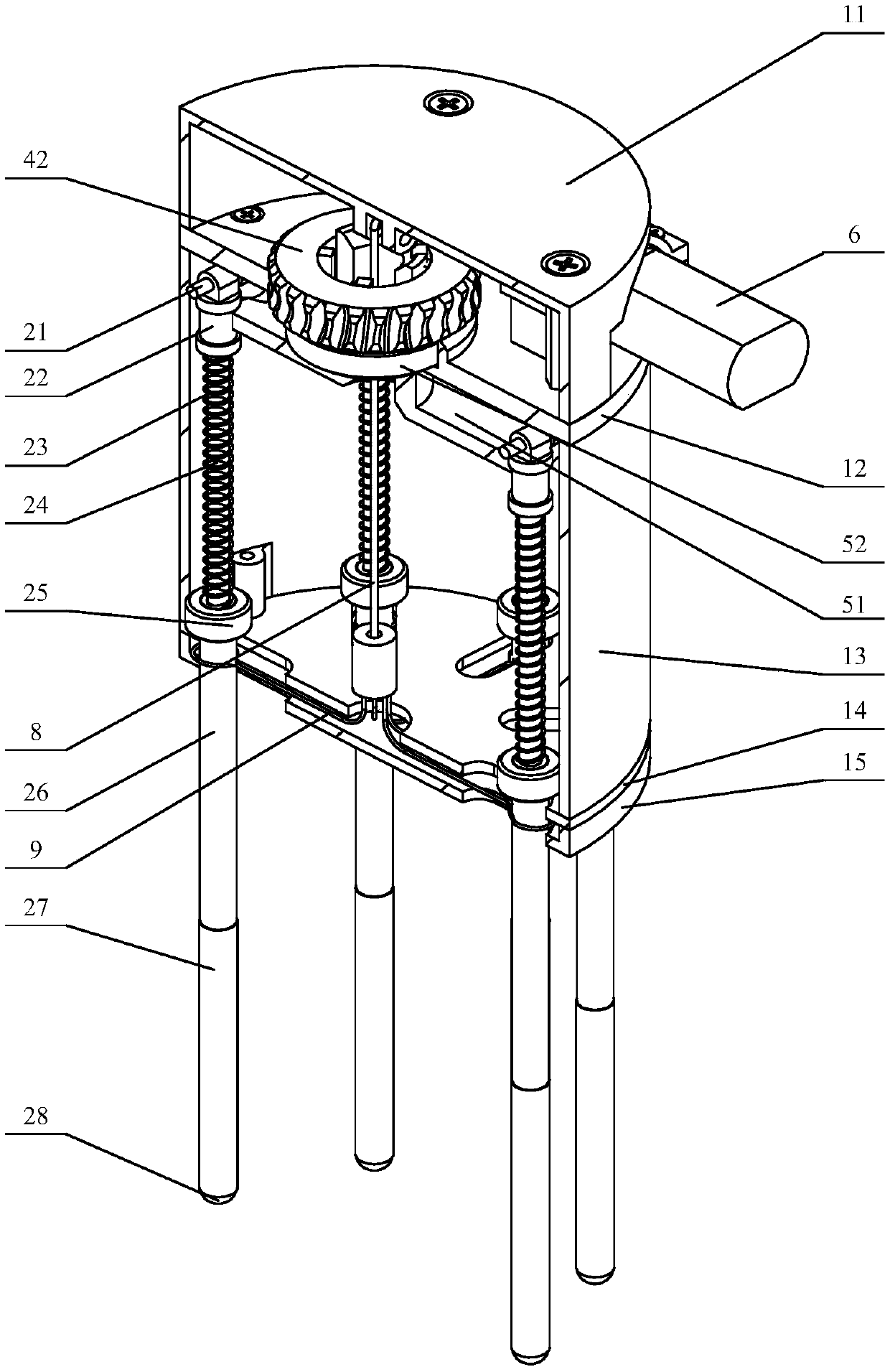

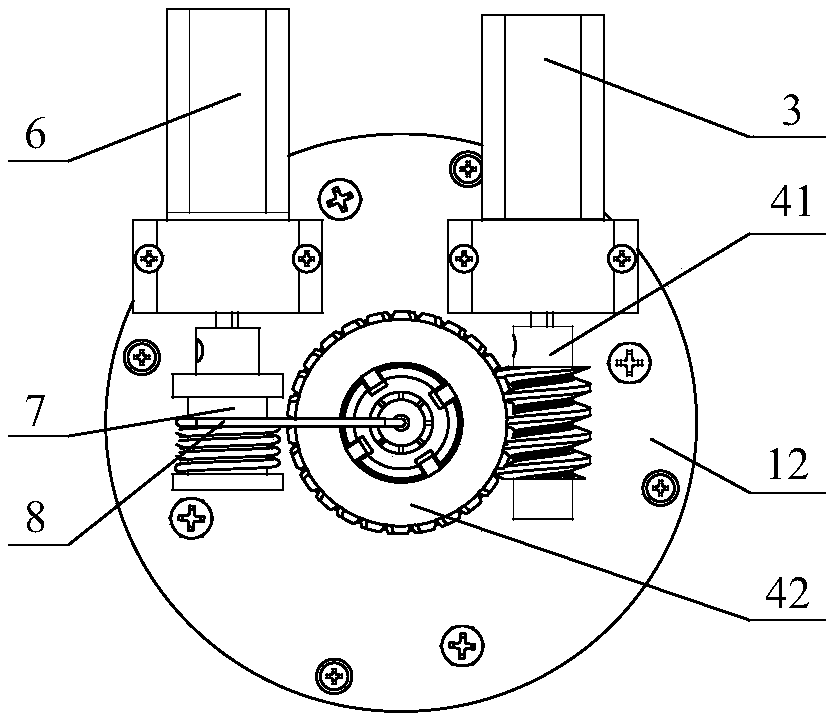

Controllable-force fast-grabbing rod cluster self-adaptive robot hand device

The invention discloses a controllable-force fast-grabbing rod cluster self-adaptive robot hand device and belongs to the technical field of robot hands. The device comprises a base, a first motor, asecond motor, a cam, a tendon rope, a second spring part, a plurality of push rod assemblies and the like. The device is used for grabbing objects, and the spatial dispersion self-adaptive grabbing function is achieved; the object size and shape self-adaptive function is achieved through the plurality of push rod assemblies; fast grabbing and grabbing force controlling are achieved through combination of the cam and the second spring part; the object multi-direction grabbing effect is achieved through the device, the grabbing force can be provided for the objects in multiple directions, and the objects which are placed in different directions and are different in shape (including long-strip shape) can be effectively grabbed; the device is not limited by power of a driving source and can simultaneously achieve the extremely high grabbing speed and extremely large grabbing force; and the device is simple in structure, low in energy consumption, suitable for various robots which are required for universal grabbing and particularly suitable for occasions with the requirement for the controllable force and fast grabbing.

Owner:TSINGHUA UNIV

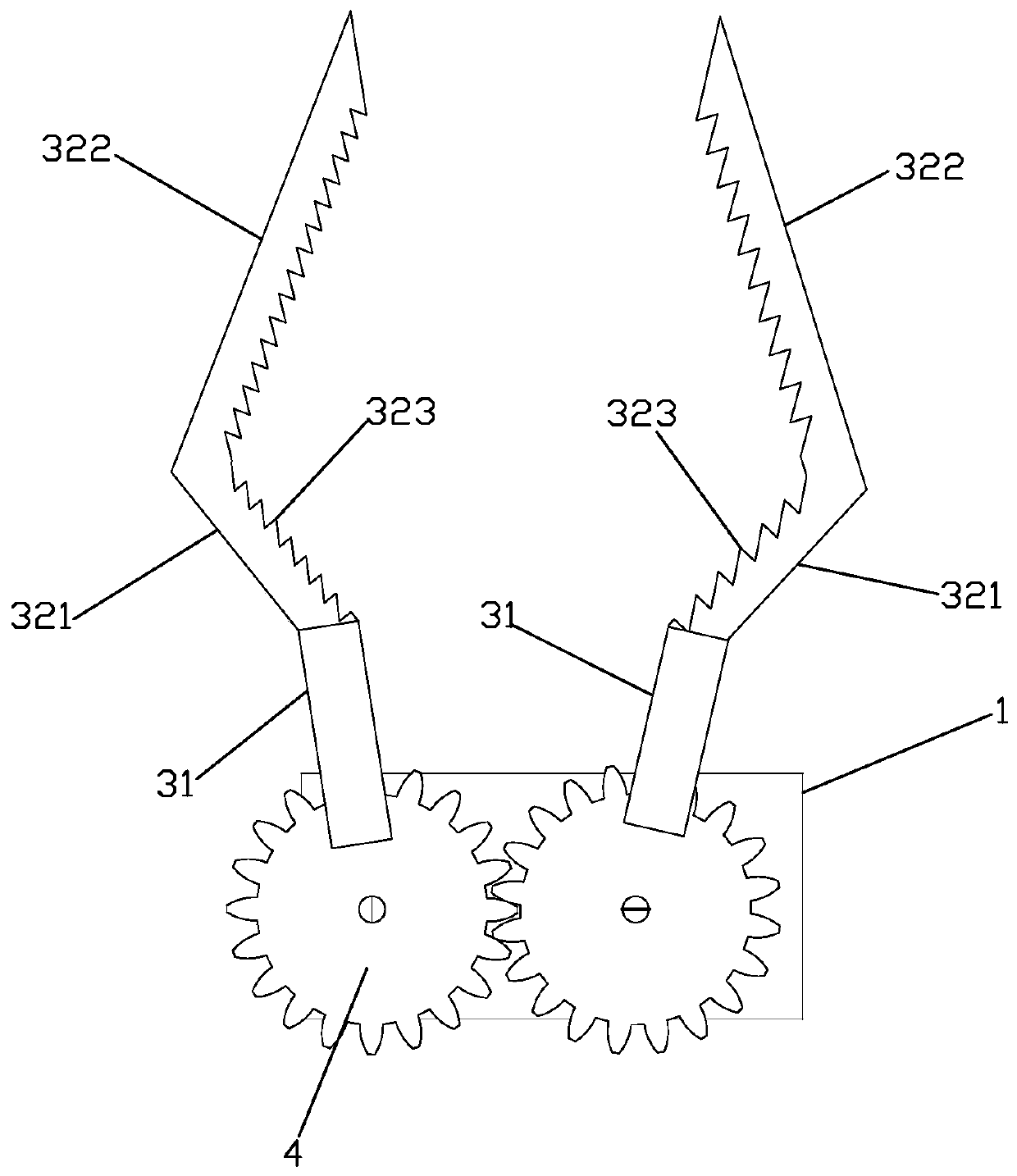

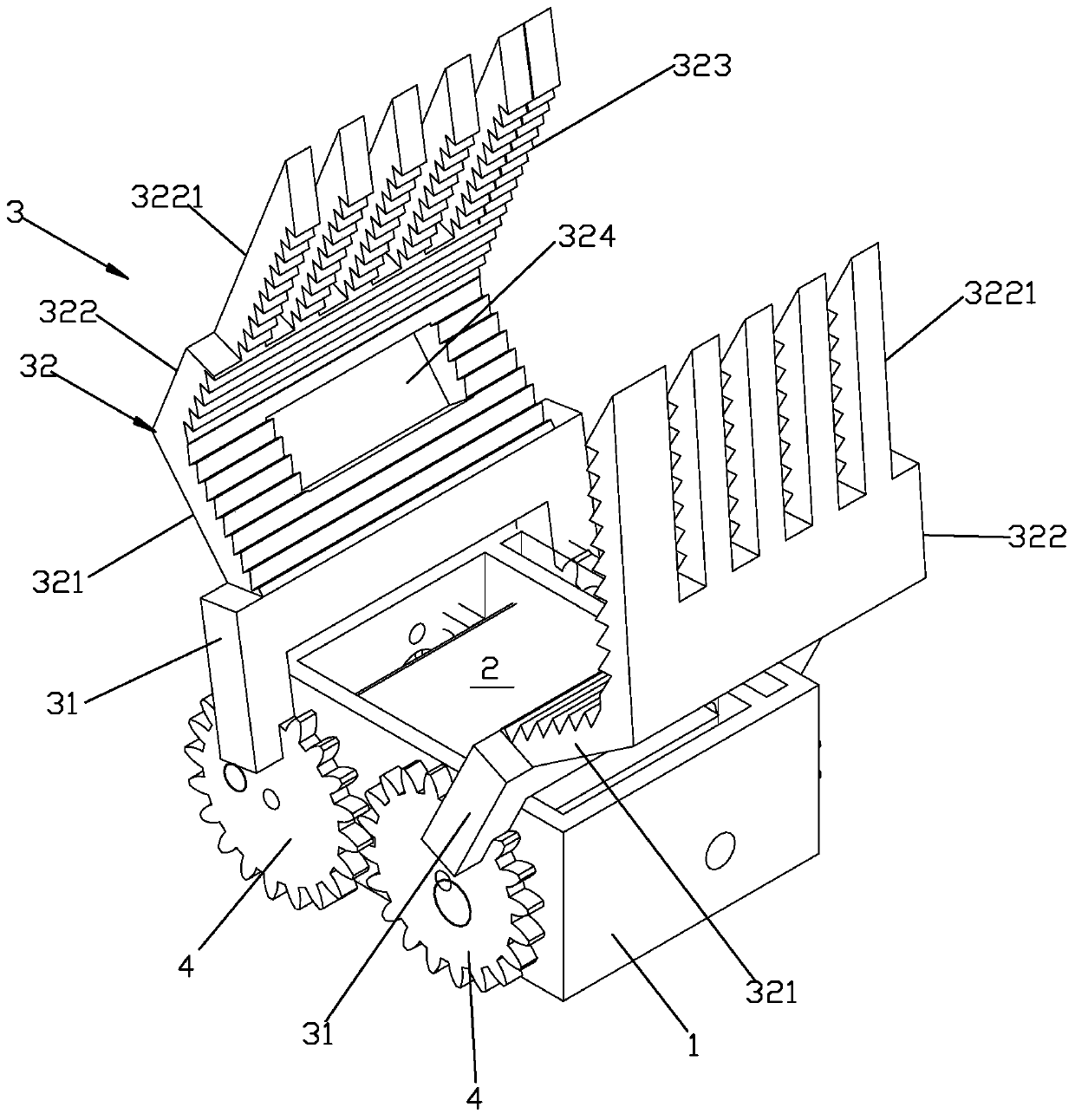

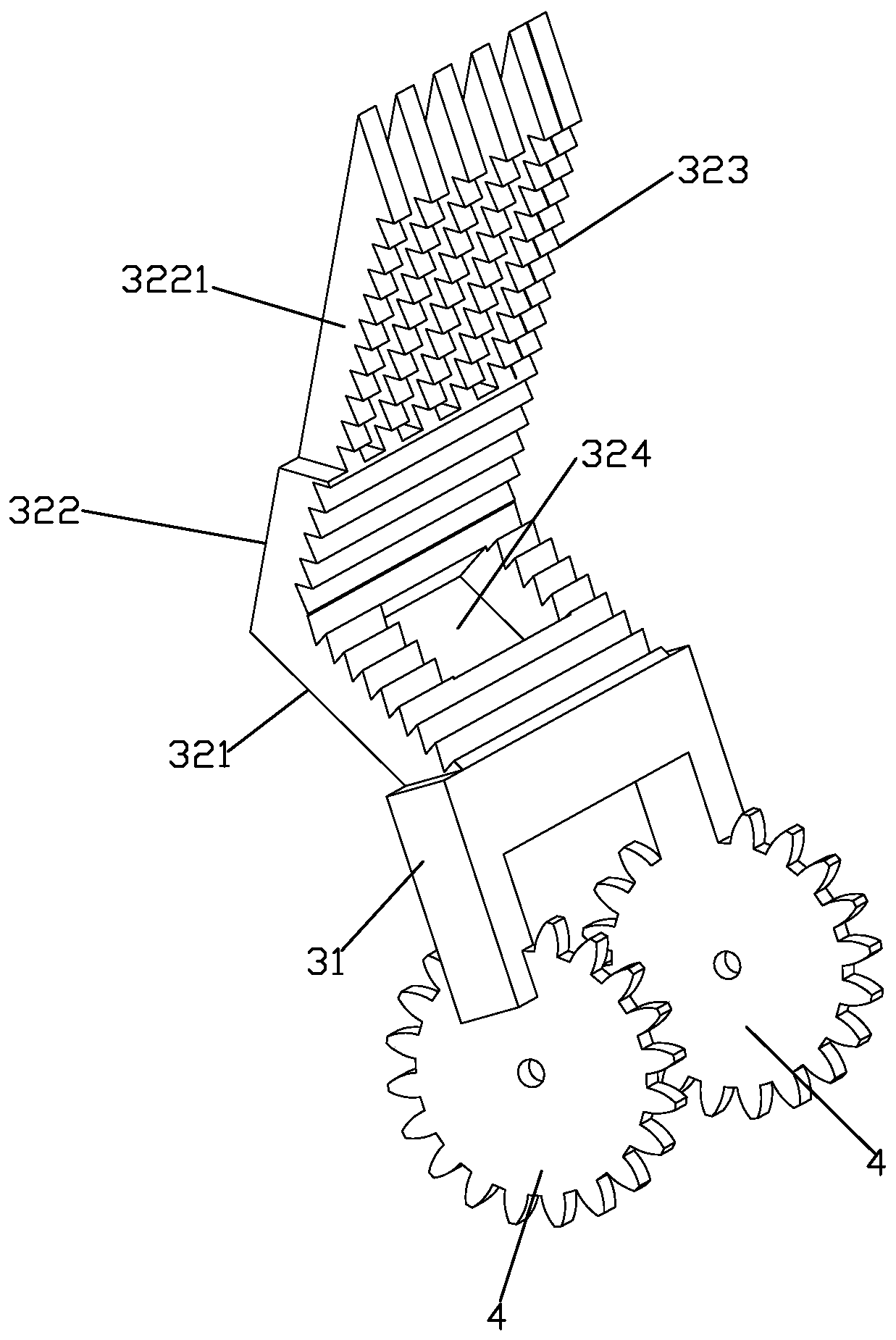

Mechanical gripper mechanism for transfer robot

The invention discloses a mechanical gripper mechanism for a transfer robot. The mechanical gripper mechanism for the transfer robot comprises a steering engine and a mechanical gripper unit; the mechanical gripper unit comprises two gear parts which are engaged with each other; a gripper is eccentrically and fixedly arranged on each gear part; a gripper part is of a V-shaped structure; the V-shaped openings of the gripper parts of the two grippers are opposite to each other; the steering engine drives the two gear parts to rotate reversely and synchronously to drive the two grippers to swingeccentrically face to face to clamp a cargo, or swing eccentrically back to back to loosen the cargo; the mechanical gripper mechanism for the transfer robot is compact in structure; the required avoiding space is smaller; the cargo can be gripped and loosened in a narrow space; the gripping strength is great; and the gripping is stable and reliable.

Owner:HUAQIAO UNIVERSITY

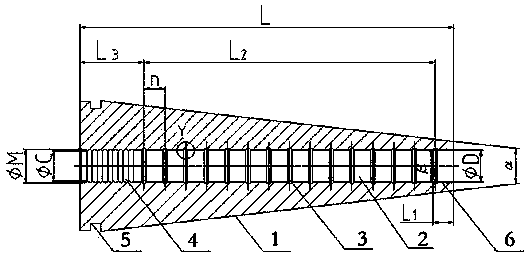

Anchorage clip for steel strand fatigue test

ActiveCN103630443AStrong gripEven distribution of clamping forceStrength propertiesEngineeringFatigue fractures

The invention discloses an anchorage clip for a steel strand fatigue test. The anchorage clip comprises a plurality of clip bodies and clamping slots, wherein the plurality of clip bodies are enclosed together and can be extruded towards the axes; the outer surfaces of the plurality of clip bodies are spliced into a conical surface in which the front is narrow and the rear is wide, and the inner surfaces are enclosed into a cylinder; a circle of tightening spring fixing slots are arranged at the rear part of the conical surface; annular teeth are arranged at the inner surfaces of the clip bodies at the rear parts of the clamping slots; a plurality of annular pressure relief grooves which are arranged in parallel and at intervals are arranged on the inner surfaces of the clip bodies at the middle parts and the front parts of the clamping slots; a guide section is arranged at the front part of each clamping slot. The anchorage clip for the steel strand fatigue test has the beneficial effects of being firm and reliable in clamping a steel strand, and free of damage, the clamping force of the clip bodies on the steel strand is even in distribution by adopting the annular pressure relief grooves, a fatigue source is avoided, a fatigue fracture of the steel strand caused by clamping is prevented, the fatigue property of the steel strand can be correctly evaluated, meanwhile, the clip bodies are protected, and the service life is prolonged.

Owner:济南东测试验机技术有限公司 +1

Soft bionic finger and bionic manipulator

The invention discloses a soft bionic finger. The soft bionic finger comprises at least two knuckles and a telescopic structure, wherein the knuckles are hollow flexible pipe bodies, the telescopic structure is used for connecting the at least two knuckles, the knuckles communicate with the interior of the telescopic structure to form a closed air cavity, the telescopic structure comprises a linear bottom surface and a wave-shaped structure connected with the linear bottom surface, the wave-shaped structure comprises at least one wave crest and at least one wave trough, and the wave crests andthe wave troughs are sequentially connected. According to the soft bionic finger, by arranging the telescopic structure, the knuckles are connected, the process of inflating and deflating the air cavity in the telescopic structure is utilized to generate bending, meanwhile, due to the existence of the knuckles, the bionic effect similar to fingers of a human body is formed, and compared with an existing scheme, the soft bionic finger is better close to a real human finger, has stronger grasping and pressing functions, and has better bionic performance.

Owner:GUANGDONG NO 2 PROVINCIAL PEOPLES HOSPITAL +2

Mechanical claw

InactiveCN108529248AStrong gripImprove seismic performanceStacking articlesDe-stacking articlesTransverse planeEngineering

The invention discloses a mechanical claw. The mechanical claw comprises a mechanical claw frame, air cylinders and claw clamps; the frame comprises a transverse plate and three vertical plates arranged under the transverse plate, connecting clamps are arranged on the middle vertical plate, and rotating frames are arranged on the vertical plates on the left side and the right side; each rotating frame comprises two arc-shaped plates and a rotating column fixed on the arc-shaped plates; the claw clamps are rotationally connected with the rotating frames; each claw clamp comprises tooth claws and tooth claw arms, and the tooth claw arms are rotationally connected with the rotating columns; and one ends of the air cylinders are hinged to the connecting clamps, and the other ends of the air cylinders are hinged to the tail ends of the tooth claw arms. The mechanical claw has the relatively large grabbing force, the working state is stable during product grabbing, and the anti-seismic property is high.

Owner:河南浩德科技有限公司

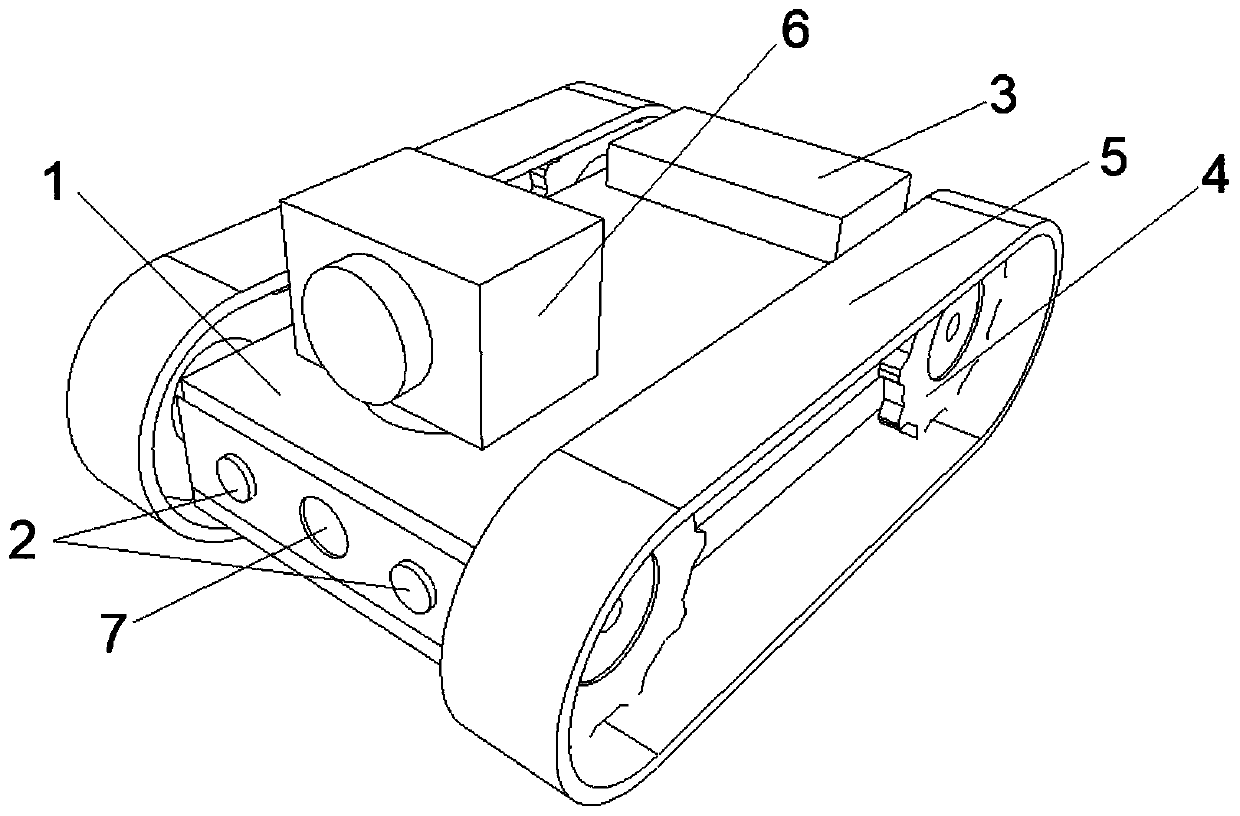

Intelligent cable duct detection robot

InactiveCN111017056AStrong gripAvoid getting out of controlHollow article cleaningOptical signallingDistance sensorsRoboty

The invention, which belongs to the technical field of detection, particularly relates to an intelligent cable duct detection robot. According to the invention, a caterpillar band is adopted in a moving mechanism, so that the ground gripping capacity is high; the good road holding walking performance can be kept in any direction of the duct, so that out-of-control caused by complex road conditionsin the duct is avoided and thus the intelligent detection robot can smoothly pass through the duct. A camera device comprises a camera and a searchlight; duct image information can be obtained as much as possible and the line duct is inspected effectively; the camera device and a distance sensor are all connected with a control box, duct information can be transmitted to the control box, the control box controls a grabbing mechanism to clean duct sundries through a driving mechanism, so that the intelligent cable duct detection robot can achieve the effect of detecting and cleaning distribution line duct sundries.

Owner:GUANGDONG POWER GRID CO LTD +1

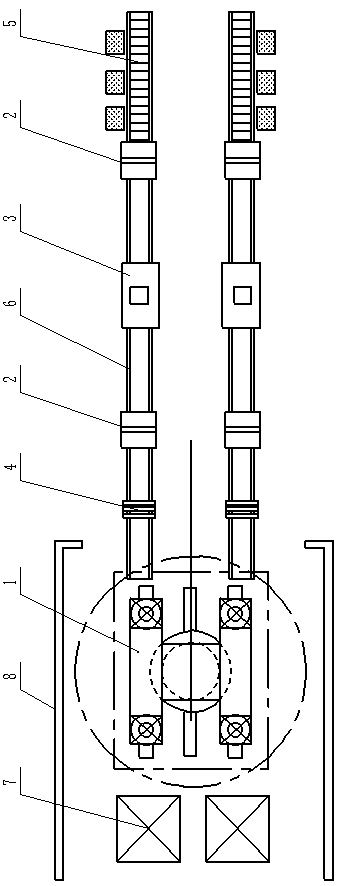

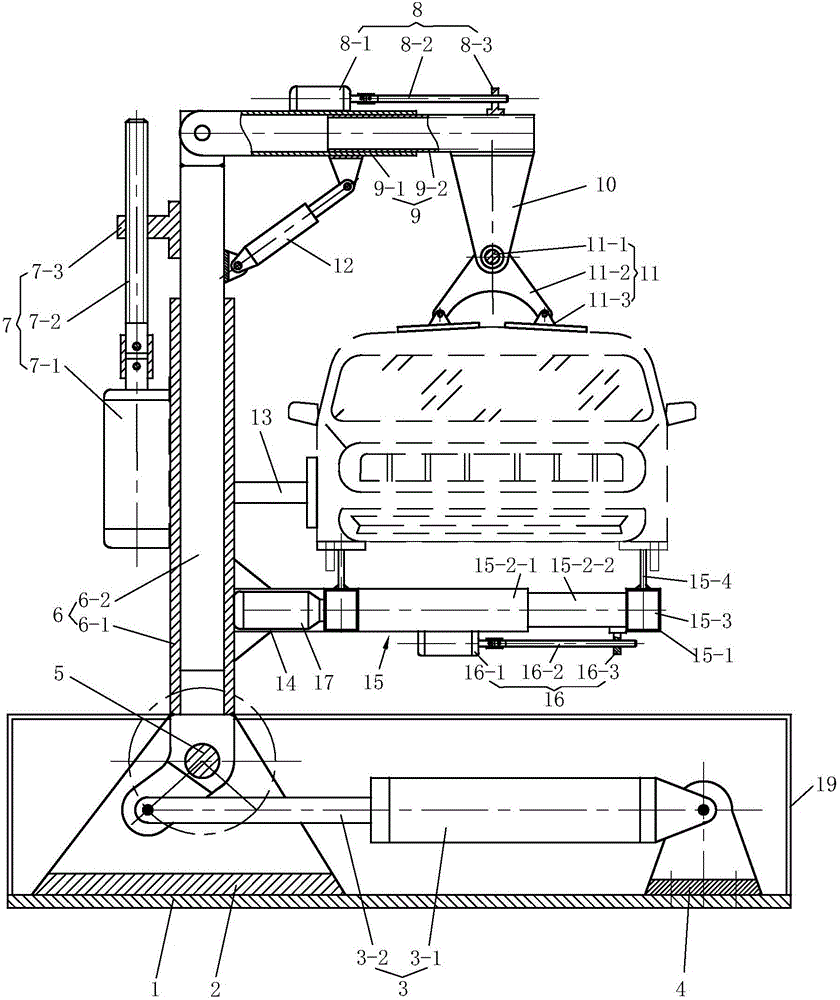

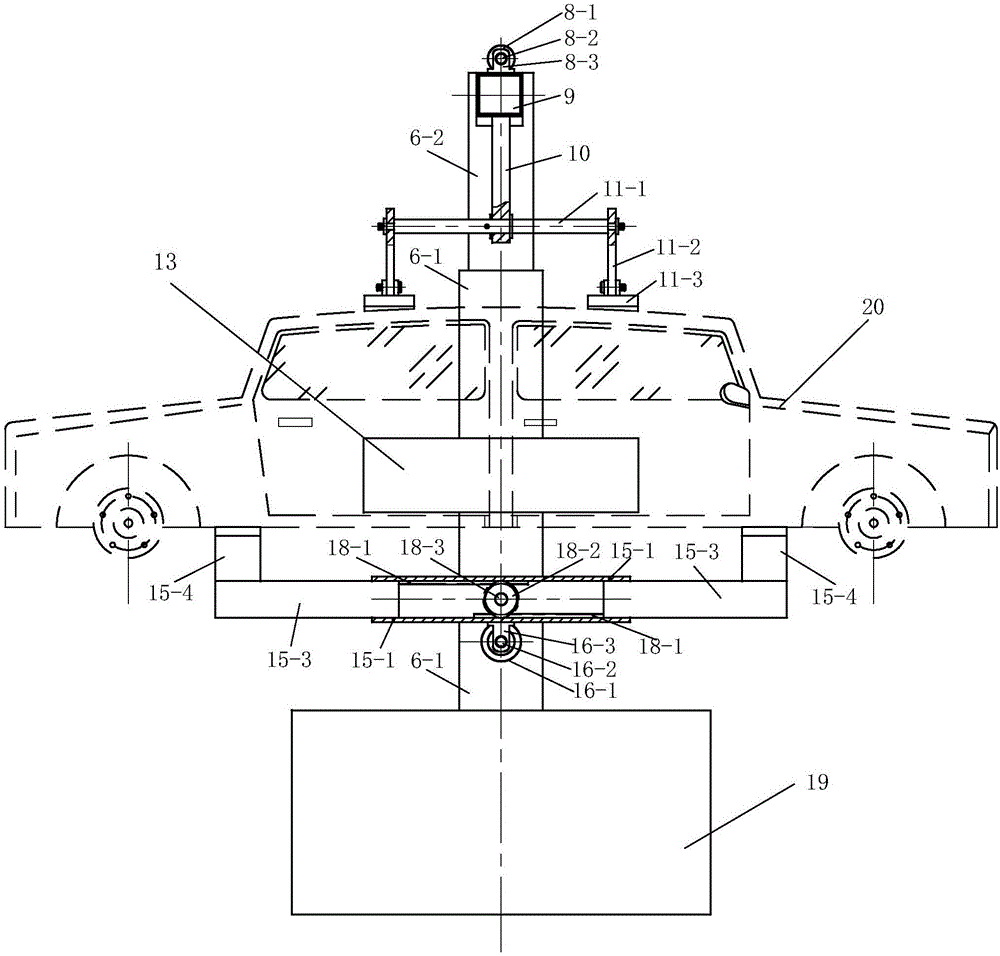

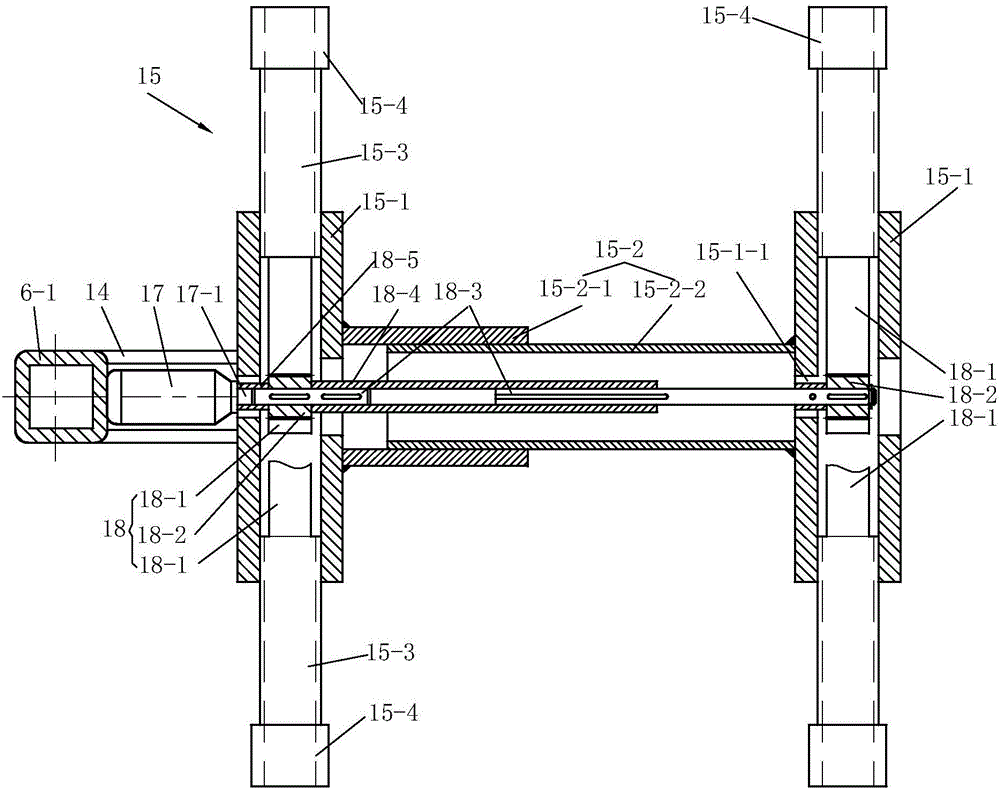

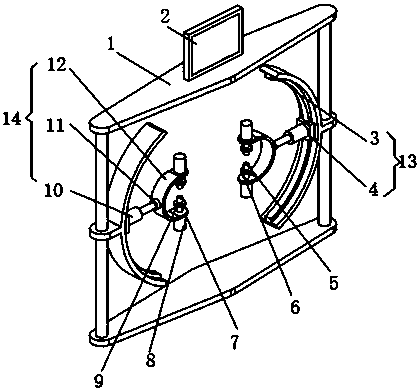

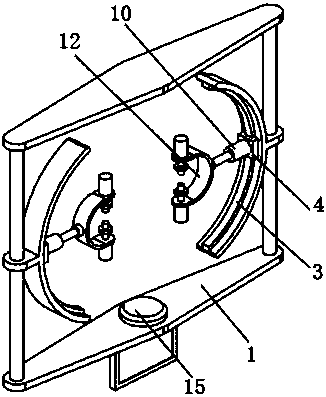

Scrapped vehicle detachment flexible turnover machine

ActiveCN106276734AIncrease the scope of applicationStrong gripLifting devicesHoisting equipmentsEngineeringHydraulic cylinder

The invention relates to a scrapped vehicle detachment flexible turnover machine. The scrapped vehicle detachment flexible turnover machine is provided with a base, vertical columns, transverse beams, a carrying frame, a turnover hydraulic cylinder and a clamping hydraulic cylinder, wherein the base is provided with a first hinge seat and a second hinge seat; the vertical columns consist of a hollow vertical column and a lifting vertical column, the lower end of the hollow vertical column is hinged to the first hinge seat through a first pin shaft, and the turnover hydraulic cylinder is connected between the hollow vertical column and the second hinge seat; the carrying frame is fixedly arranged on the lower part of the hollow vertical column, and is provided with two carrying main pipes and a carrying transverse pipe, the carrying transverse pipe is connected between the two carrying main pipes, support rods are respectively arranged at the two ends of each carrying main pipe, a bottom bracket is fixedly arranged at the outer end of each support rod, and the carrying transverse pipe consists of a fixed transverse pipe and a movable transverse pipe; the transverse beams consist of a fixed transverse beam and a movable transverse beam, one end of the fixed transverse pipe is hinged to the top end of the lifting vertical column, the clamping hydraulic cylinder is connected between the lifting vertical column and the fixed transverse beam, and a connecting plate is fixedly arranged on the bottom surface of the outer end of the movable transverse beam, and is connected with a floating press plate assembly. The scrapped vehicle detachment flexible turnover machine is suitable for different models of vehicles, so that the application range is widened.

Owner:JIANGSU UNIV OF TECH

New material quality testing machine

PendingCN109612825AStrong gripPrevent falling offMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesWorking capacityWork performance

The invention discloses a new material quality testing machine. The new material quality testing machine comprises a machine frame. An open source single chip microcomputer is mounted at the top of the machine frame. A CT scanner is mounted at the top of the inner side of the machine frame. Bending mechanisms are symmetrically mounted on the left side and the right side of the machine frame. Extending mechanisms are mounted on the lateral faces of the bending mechanisms. Clamping mechanisms are symmetrically mounted at ends of the extending mechanisms in an up and down mode. The input end of the open source single chip microcomputer is electrically connected with the output end of an external power source. The output end of the open source single chip microcomputer is electrically connected with the input end of the CT scanner. According to the new material quality testing machine, the clamping mechanisms are adopted to clamp the new material, and clamping is firm. New material fallingoff during the testing process can be avoided. Application security of the new material quality testing machine is guaranteed. Through the bending mechanisms, bending testing of the new material canbe conducted. Through the extending mechanisms, extending testing of the new material can be conducted. Testing items are various. Working performance is high. New material quality can be fully tested.

Owner:梁廷洲

Installing method for real-false-grass-mixed lawn

InactiveCN107409692AStrong gripUniform overall qualityHops/wine cultivationGrowth substratesPerliteMushroom

The invention discloses an installing method for a real-false-grass-mixed lawn. The installing method includes the steps of substrate preparing, wherein a mixture of fermented mushroom residues and leaves serves as a basic substance, a mixture of coal residues and perlite serves as an additive, and the basic substance, the additive and sand are mixed to obtain a substrate; paving, wherein the hardened ground is paved with the substrate, and the thickness of the paved substrate is 3 cm to 8 cm; water draining slope arranging, wherein the water-draining slope degree is set as 0.2% to 0.6%; turf arranging, wherein turf is arranged with the site paving method or the prearranging method; artificial grass (false grass) turf serves as a substrate, natural grass is additionally planted, and the mixed lawn is fast and convenient to install and more stable and more durable accordingly.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

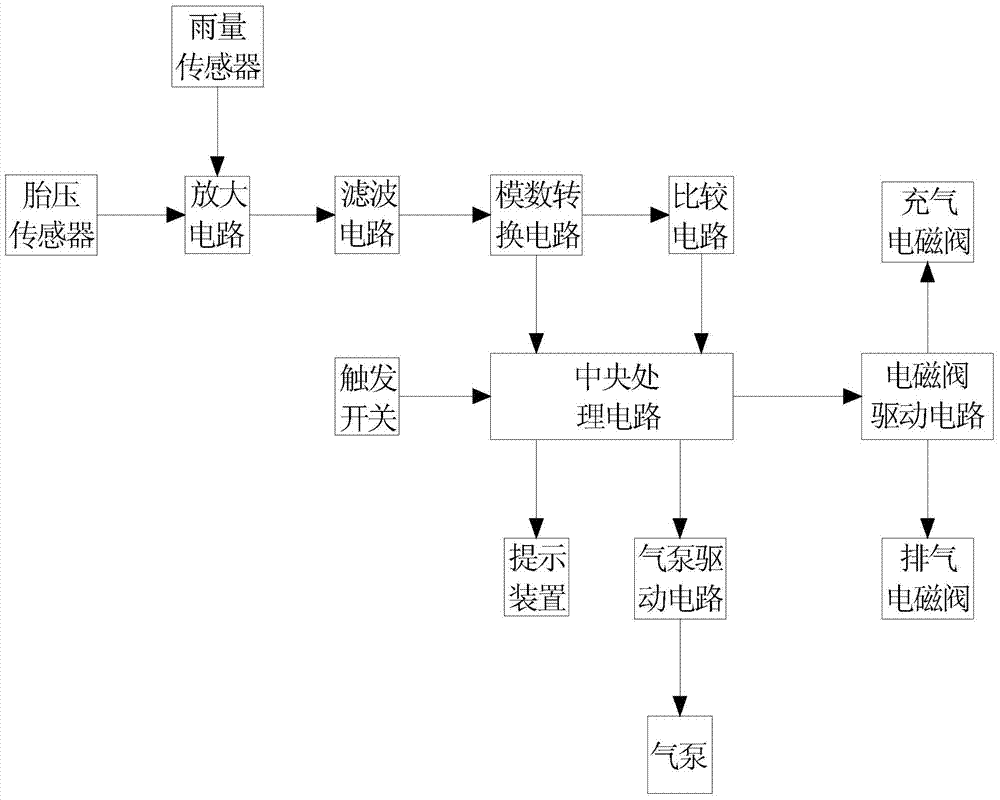

Multifunctional automobile wheel

ActiveCN104742643AStrong gripImprove stabilityTyre measurementsMultiple wheel assemblyDriving safetyEngineering

The invention provides a multifunctional automobile wheel which comprises a hub, a tire for rainy days and a tire for sunny days. The tire for the rainy days and the tire for the sunny days are coaxially arranged on the hub in parallel. The wheel further comprises a control unit used for controlling switching of the tire for the rainy days and the tire for the sunny days. The wheel can keep good road holding force when a vehicle runs on a slippery road surface, improves operation stability, can reduce tire abrasion when the vehicle runs on a dry road surface, can effectively prolong service life as a whole, and guarantees driving safety.

Owner:CHONGQING JIAOTONG UNIVERSITY

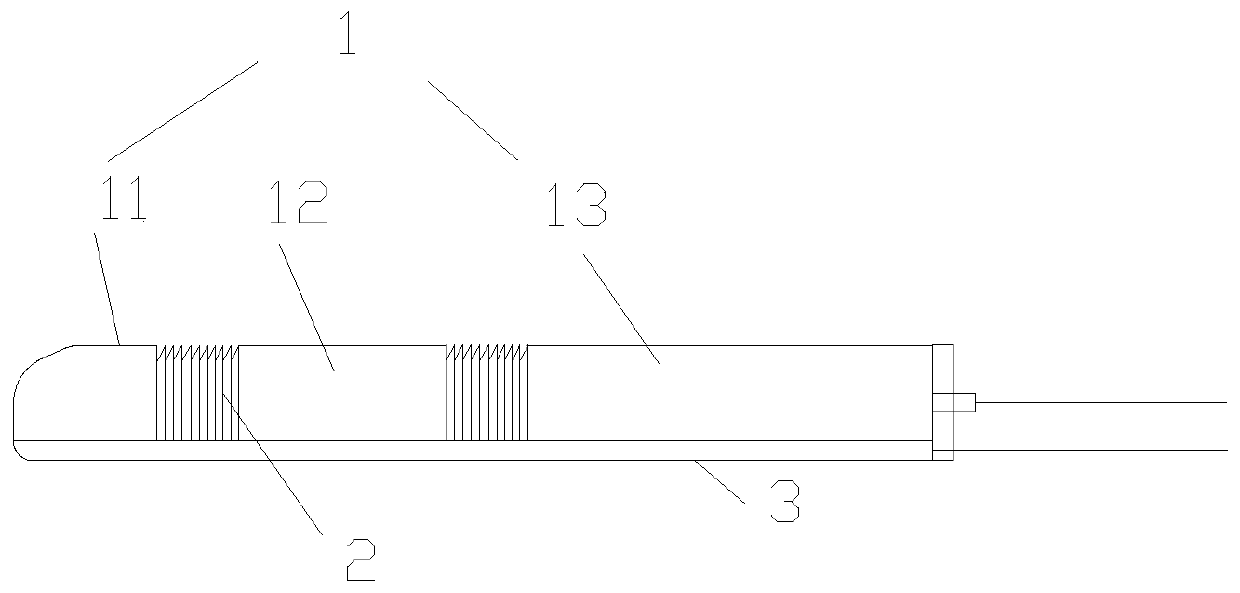

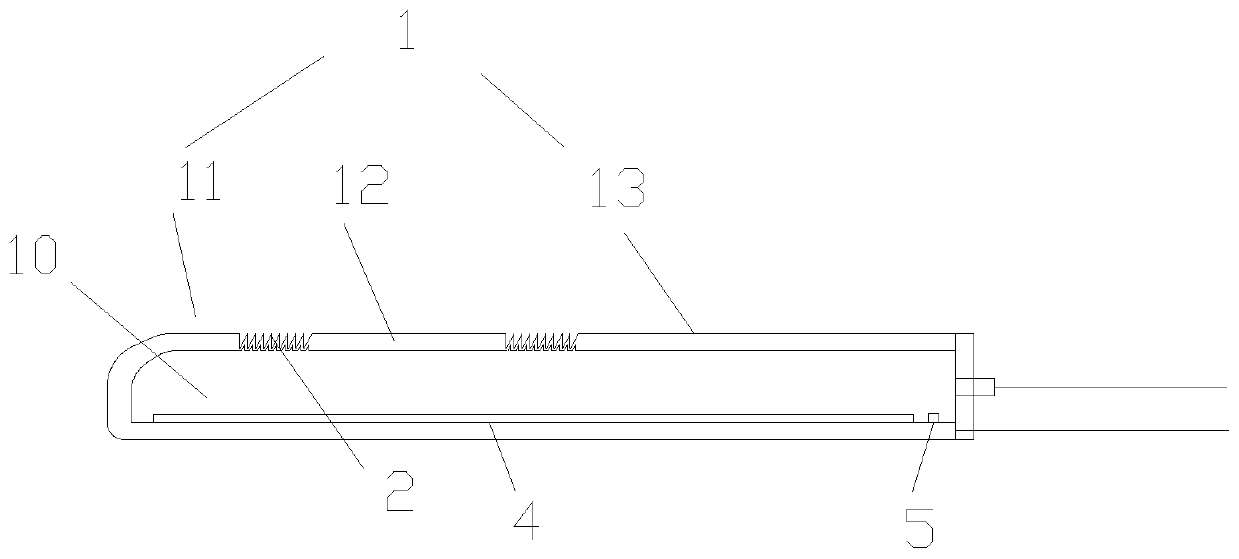

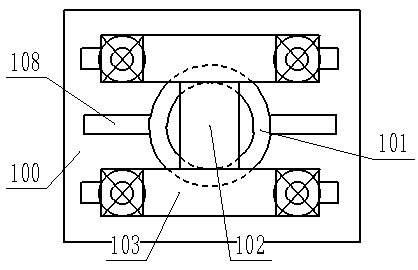

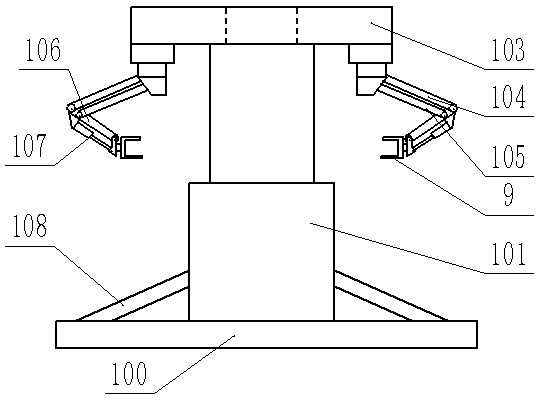

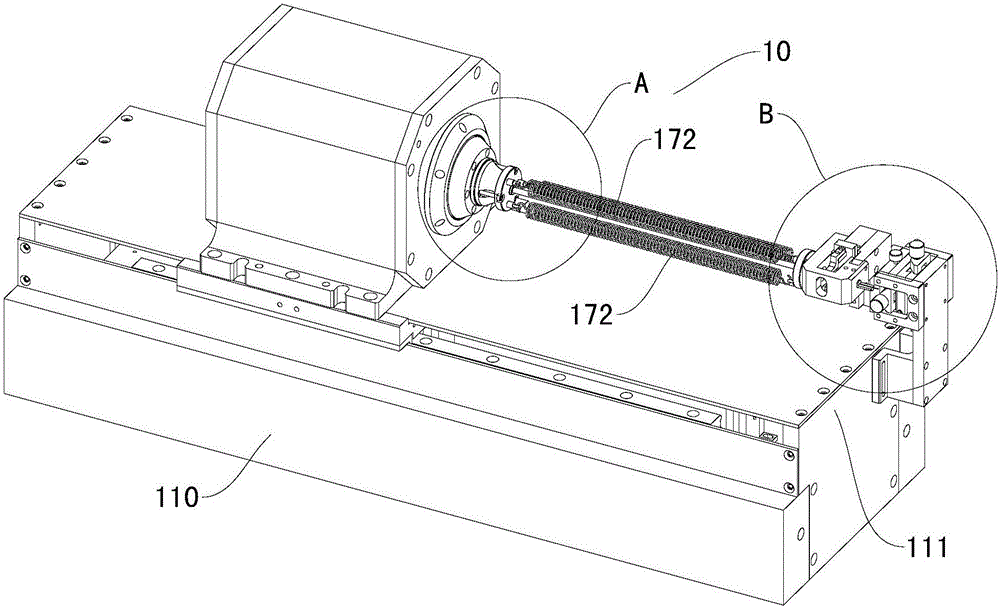

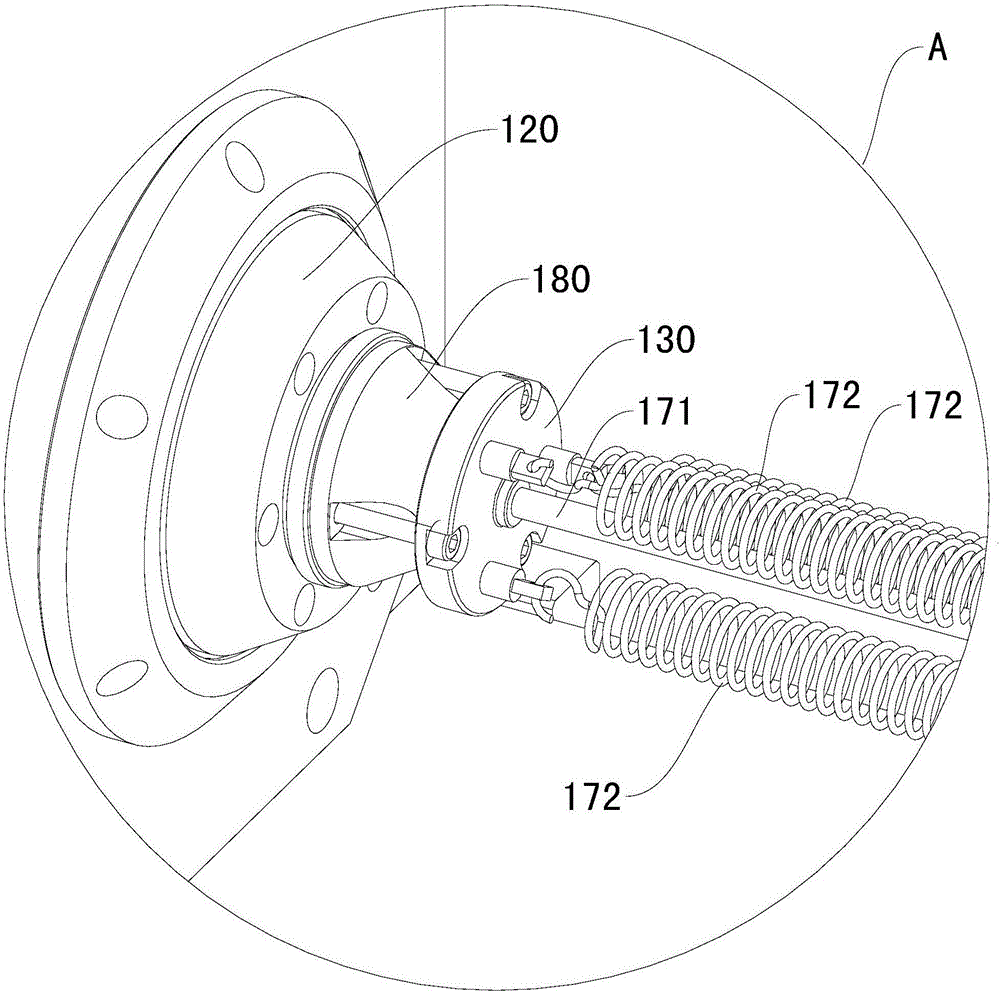

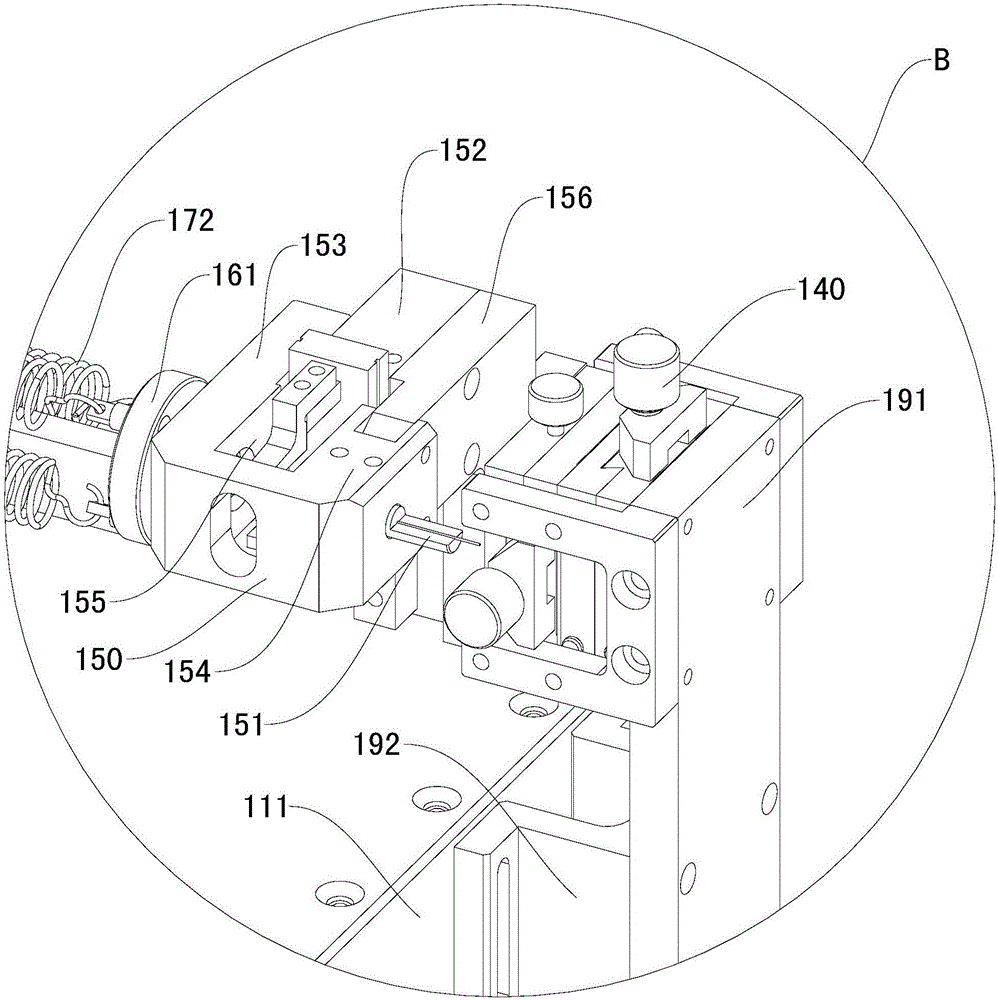

Machine tool and clamping jig thereof

ActiveCN106808092APrecise positioningStrong gripLaser beam welding apparatusDislocationRotational axis

The invention discloses a machine tool and a clamping jig thereof. The machine tool comprises a lathe bed, a rotary shaft, a transition base, a two-dimensional adjusting device, a mounting seat, a rotary connecting seat, a hollow elastic pipe and a plurality of elastic parts. An X-axis motion platform is arranged on the lathe bed. The rotary shaft is arranged on the X-axis motion platform in the direction X in the manner of being capable of doing reciprocating motion. The transition base is arranged on the rotary shaft. The two-dimensional adjusting device is arranged on the X-axis motion platform. The mounting seat is arranged on the two-dimensional adjusting device. The rotary connecting seat is rotationally arranged on the mounting seat. The first end of the hollow elastic pipe is arranged on the transition base, and the second end of the hollow elastic pipe is arranged on the rotary connecting seat. The multiple elastic parts are arranged around the hollow elastic pipe, the first end of each elastic part is arranged on the transition base, and the second end of each elastic part is arranged on the rotary connecting seat. The machine tool has the beneficial effects of being firm in clamping, accurate in locating, stable, reliable and the like, and the defects that when an existing machine tool jig clamps thin and long workpieces, the middles of the workpieces are concave, and butt joint dislocation happens during continuous machining are completely avoided.

Owner:KUNSHAN YUNCO PRECISION IND TECH

Shower nozzle fixing device

The invention belongs to the field of machinery, and particularly relates to a shower nozzle fixing device which comprises a movable plate and a fixed plate fixed to a wall. One end of the fixed plate is hinged to the movable plate, and the other end of the fixed plate is provided with a spherical rod. The other end of the movable plate is provided with a spherical hole. The spherical hole can just penetrate through the spherical part of the spherical rod so that the movable plate can be hung on the spherical part of the spherical rod to form clamping together with the fixed plate. An arc-shaped groove I is formed in the fixed plate. An arc-shaped groove II is formed in the position, corresponding to the arc-shaped groove I, of the movable plate. A clamping part of a shower nozzle is formed between the arc-shaped groove I and the arc-shaped groove II. The shower nozzle fixing device is simple in structure and convenient to use, the service life of the shower nozzle fixing device is prolonged, and the use cost of consumers is reduced.

Owner:CHENGDU LYUDI TECH

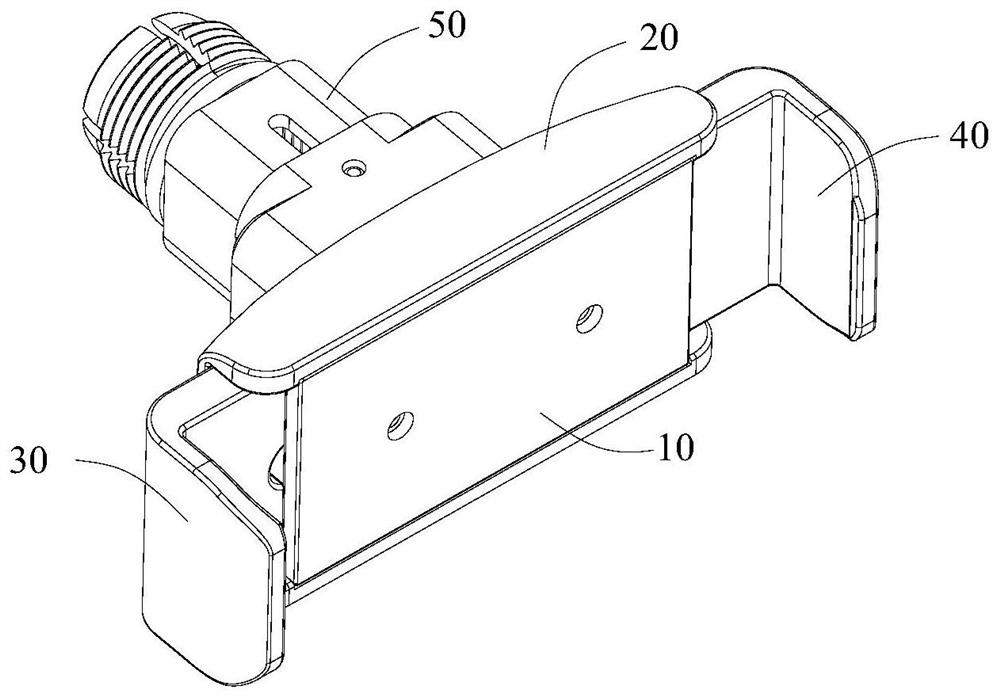

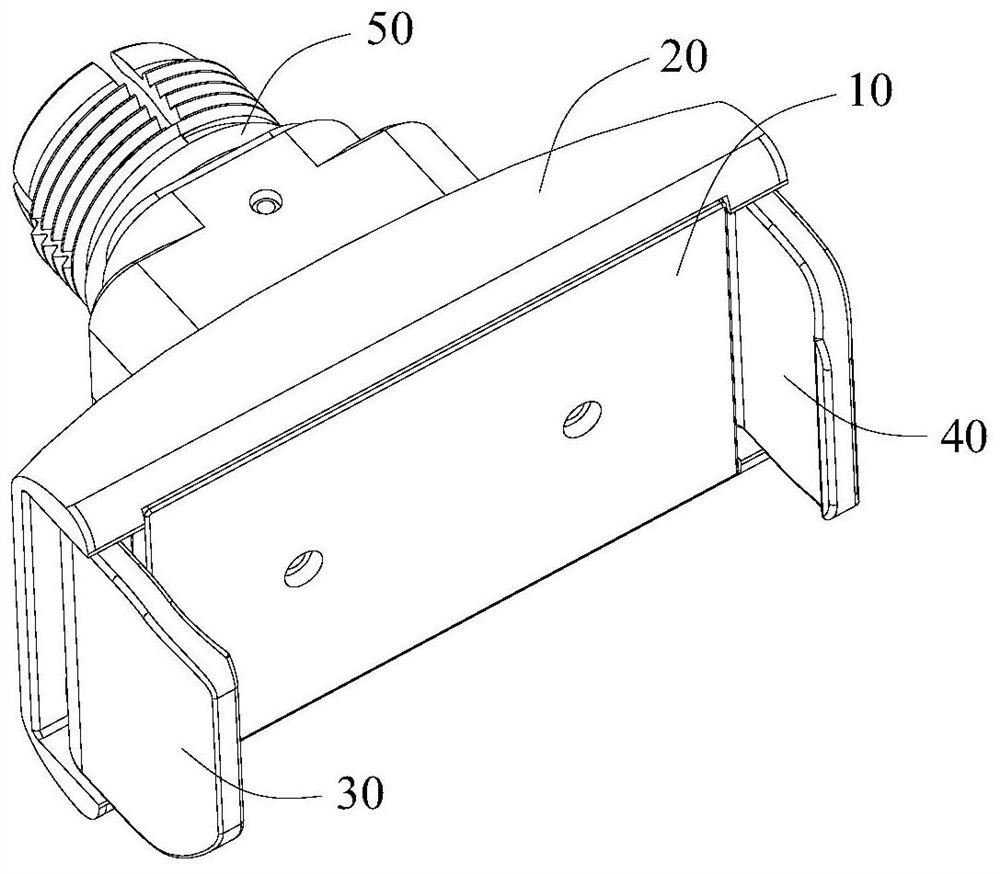

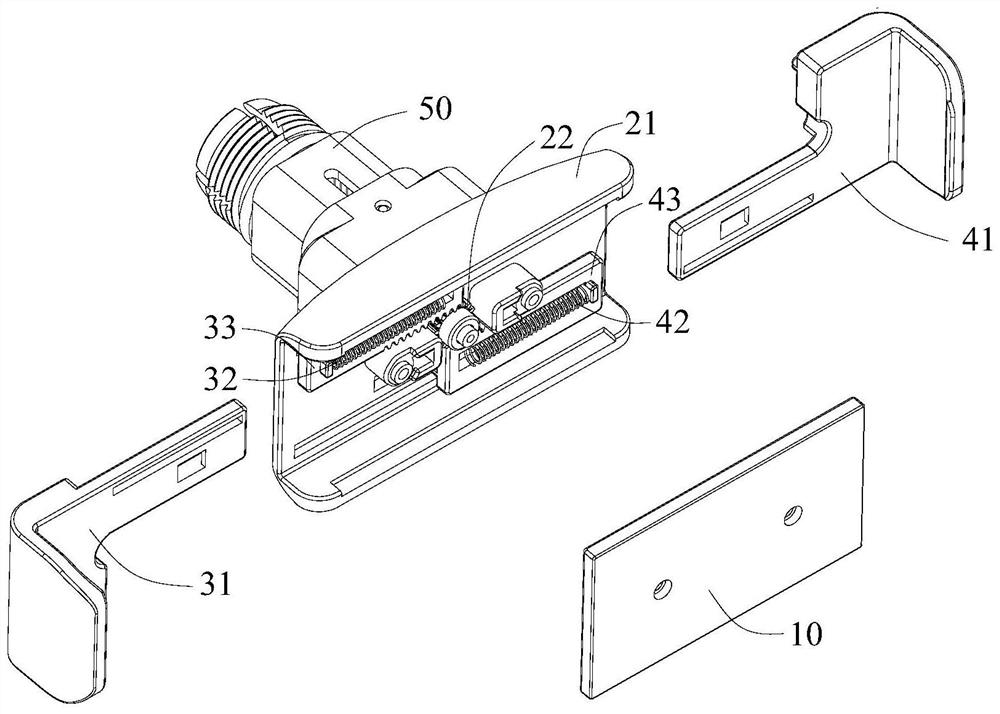

Clamping support capable of being automatically locked and mobile terminal support

InactiveCN111677988AStrong gripGood user experienceStands/trestlesTelephone set constructionsPull forceExternal pressure

The invention provides a clamping support capable of being automatically locked and a mobile terminal support. The clamping support comprises a bearing seat, a first clamping arm, a second clamping arm and a supporting seat, wherein a driving gear and a tension spring are arranged in the supporting seat, the driving gear is engaged with a supporting seat rack part arranged in the supporting seat in the front-back direction, one end of the tension spring is connected to the bearing seat, the other end of the tension spring is eccentrically connected to the driving gear, the first clamping arm is provided with a first rack part in the clamping direction, the first rack part is engaged with the driving gear, when external pressure or pulling force acts on the bearing seat, the bearing seat slides in the front-back direction relative to the supporting seat, the driving gear rotates to drive the first rack part to slide in the clamping direction, and therefore relative clamping or looseningof the first clamping arm and the second clamping arm is achieved. According to the clamping support capable of being automatically locked, the tension spring and the driving gear can be in a self-locking state through tension of the tension spring, firmer and more reliable clamping is provided, and better user experience can be obtained.

Owner:SHENZHEN LANHE TECH CO LTD

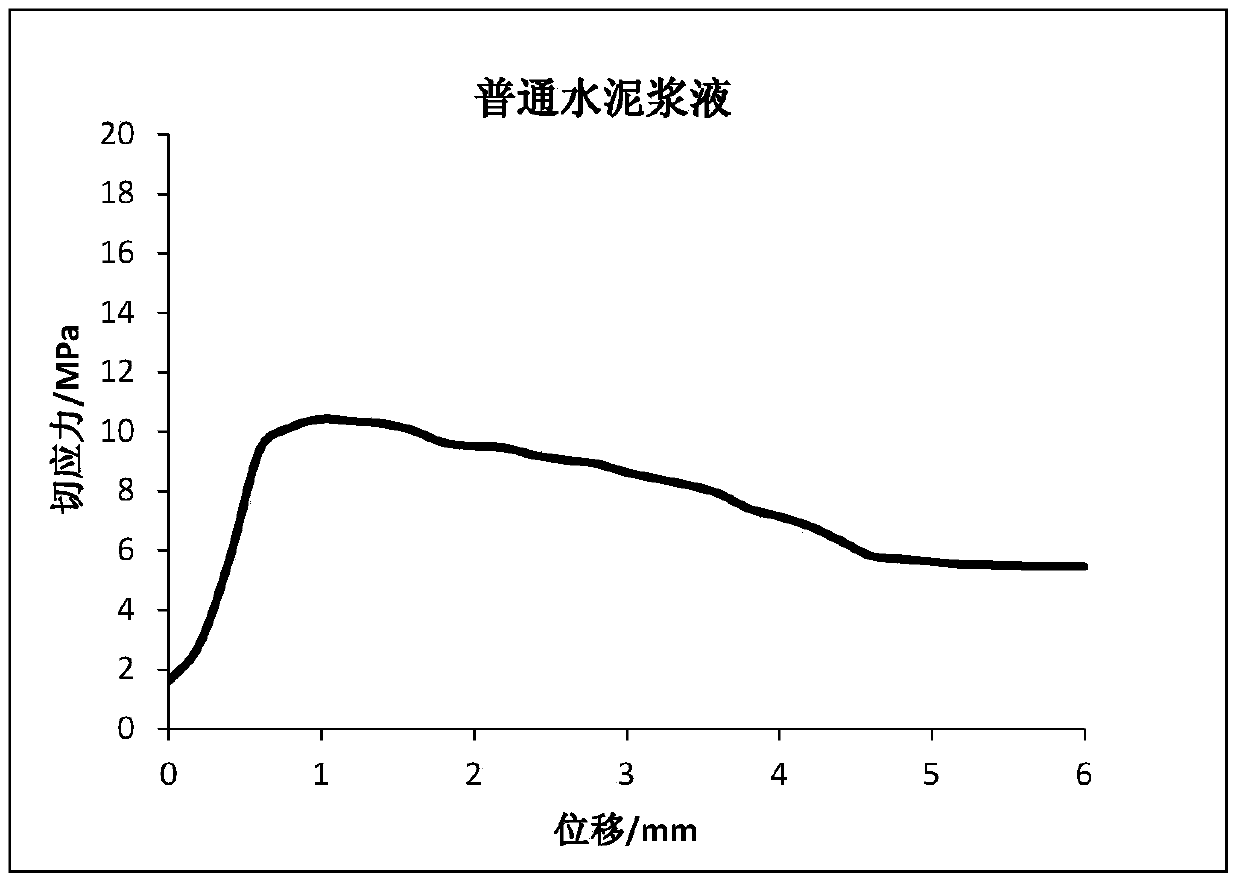

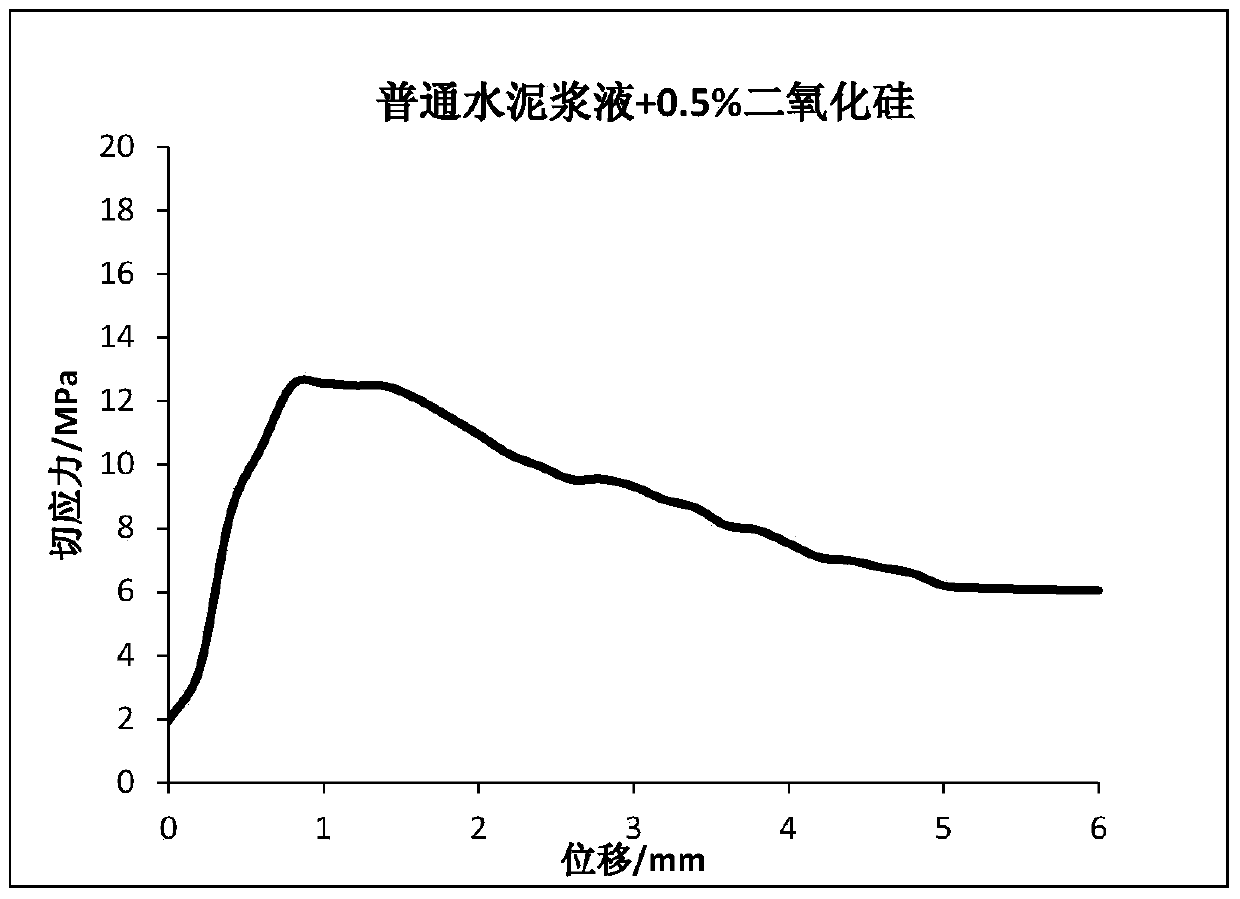

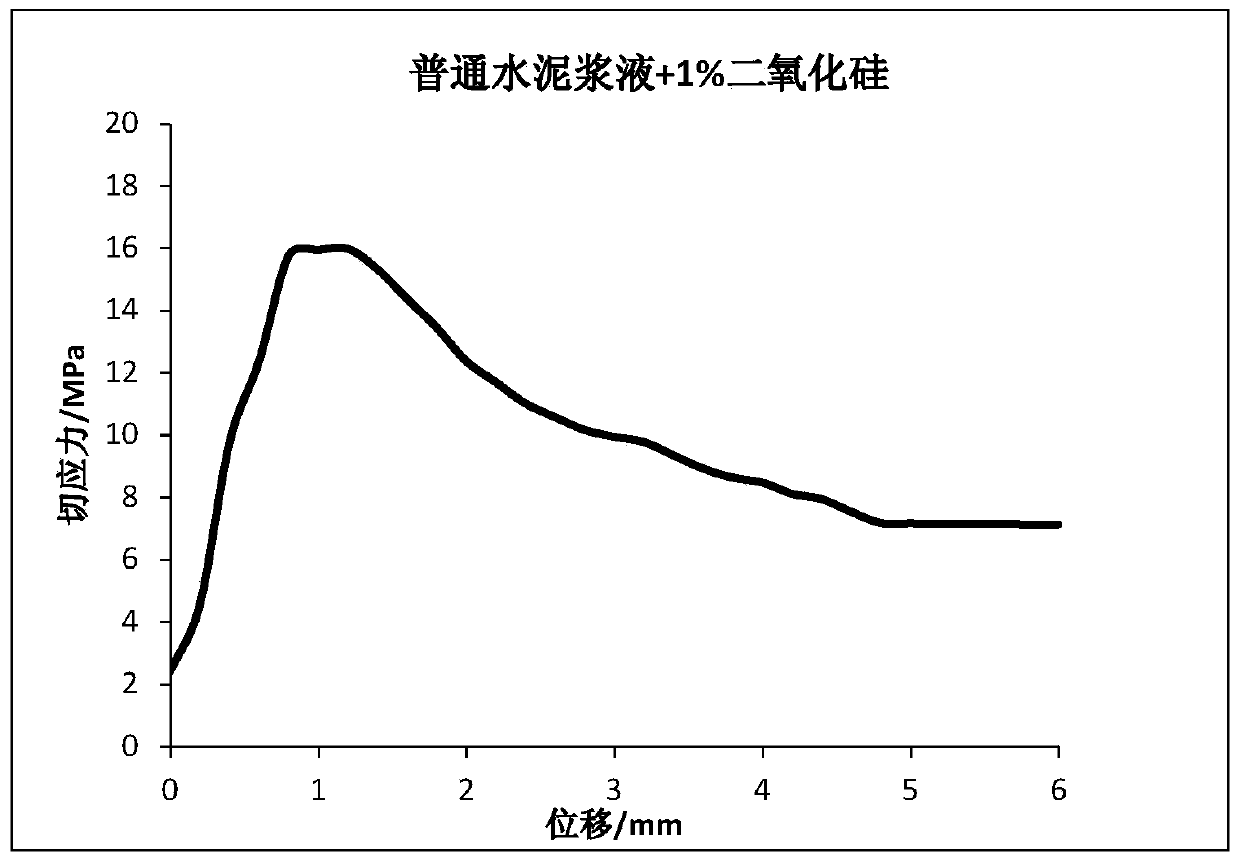

Nanometer cement grout and application thereof

The invention belongs to the technical field of slope reinforcement engineering material, and in particular relates to a nanometer cement grout and application thereof. The nanometer cement grout is composed of the following components: normal silicate cement grout, hydrophilic nano-silicon dioxide accounting for 0.5-1.5% of the mass of the normal silicate cement grout, and UNF-5 type naphthalene water reducer accounting for 0.2-3% of the mass of the normal silicate cement grout. The nanometer cement grout provided by the invention is used for anchoring an anchor rod or an anchor cable, and has higher grip force to reinforcing steel bars than portland cement grout, and is more compact than the portland cement grout.

Owner:BEIJING JIAOTONG UNIV

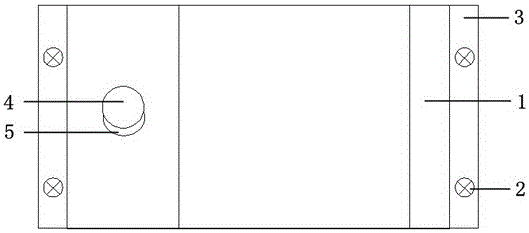

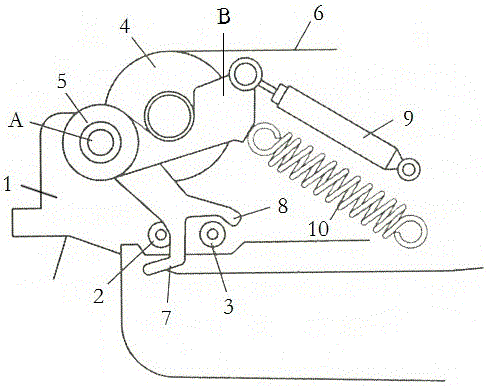

Warp tension detection mechanism

The invention discloses a warp tension detection mechanism. The warp tension detection mechanism comprises a rack and a rear beam arranged on the rack, the rear beam is provided with a swing rod, and the swing rod comprises an end A and an end B. The warp tension detection mechanism is characterized by further comprising a damper; one end of the damper is arranged on the rack, the other end of the damper is debatably arranged at the end B of the swing rod, one end of a tension spring is arranged on the rack, the other end of the tension spring is arranged at the end B of the swing rod, a first proximity switch and a second proximity switch are further arranged on the rack, a first detection body and a second detection body are arranged at the end A of the swing rod, the first detection body can induct the first proximity switch and the second proximity switch, and the second detection body can induct the second proximity switch. The warp tension detection mechanism is more flexible to use and capable of improving the accuracy of warp tension adjustment.

Owner:WUJIANG JINYE WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com