Coaxial electric cable connector for sylphon bellowss

A coaxial cable and connector technology, applied in the direction of conductive connection, connection, two-component connection device, etc., can solve the problems of increasing manufacturing cost, easy to fall and lose, etc., and achieve simple and convenient use and installation, avoid difficult disassembly, and secure clamping holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

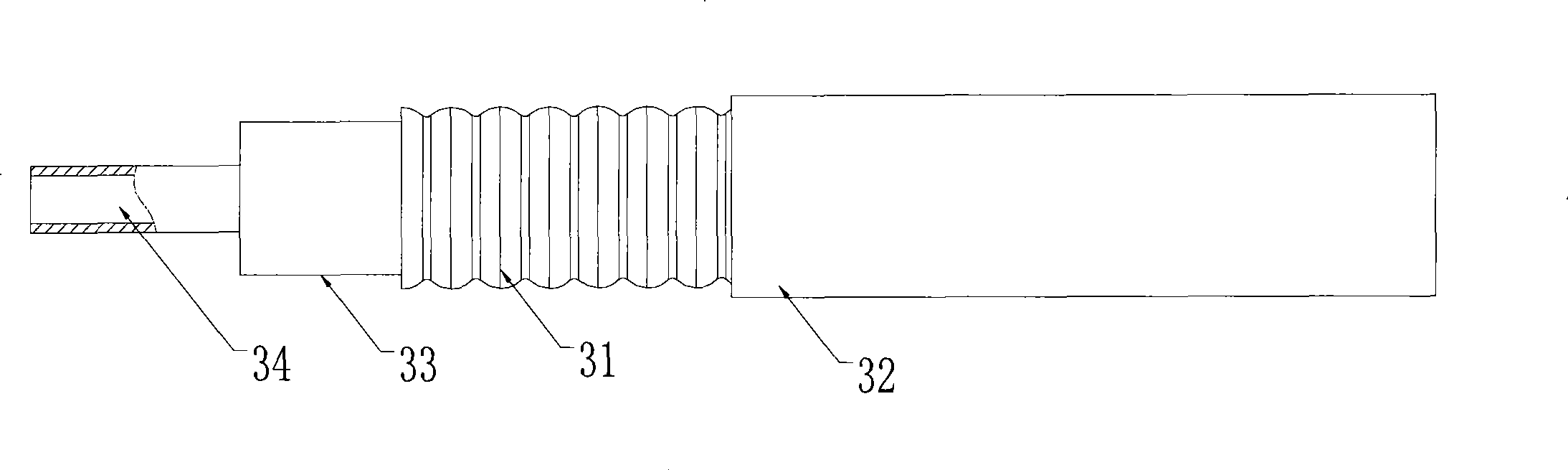

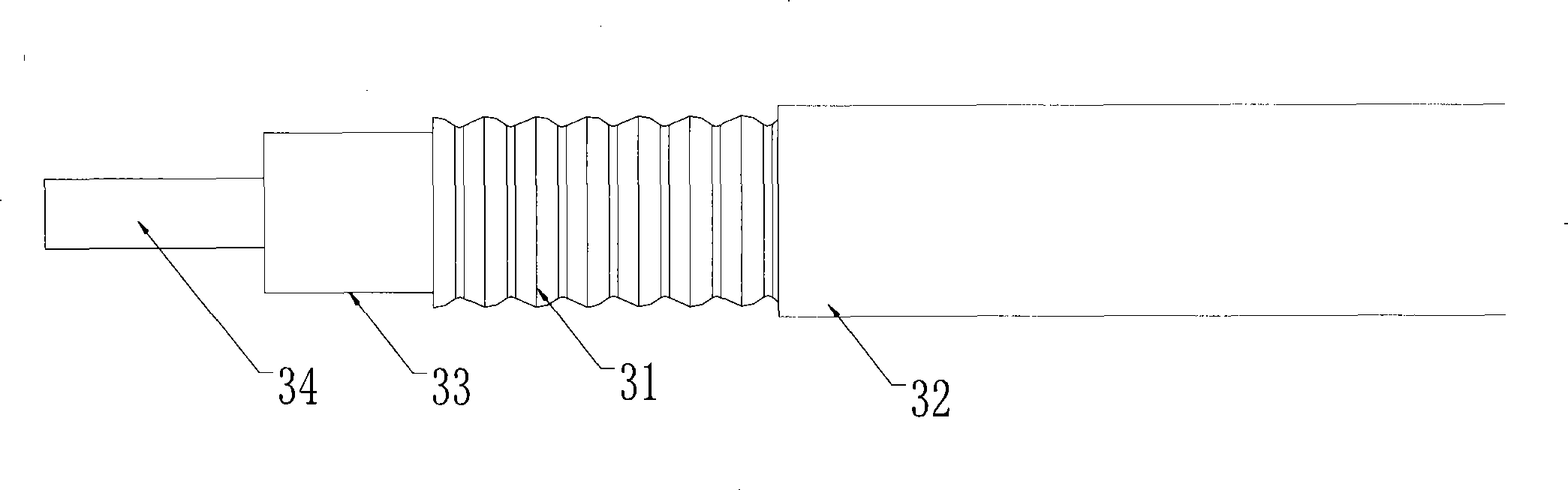

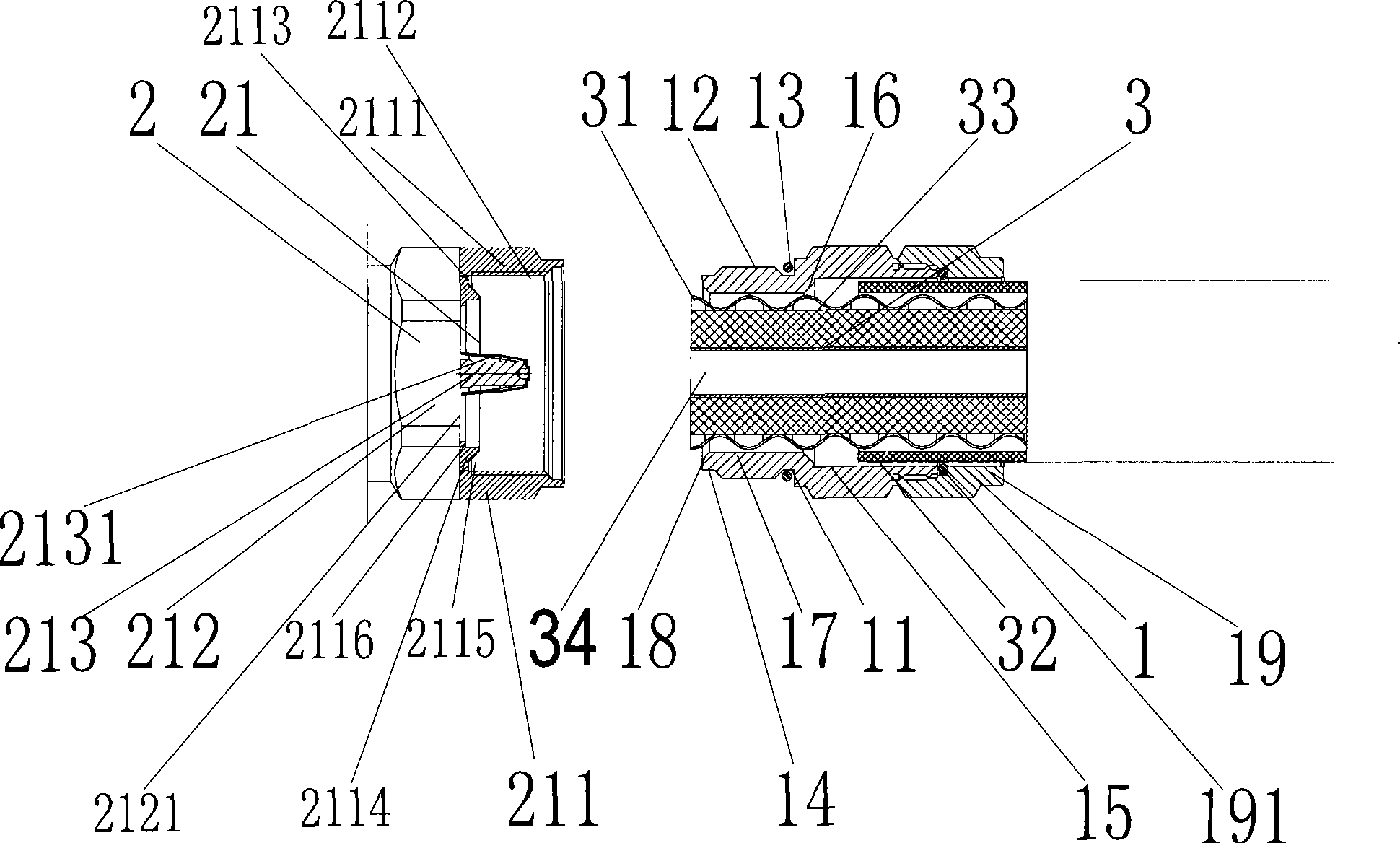

[0024] Please see figure 2 , which is a partial cross-sectional schematic diagram of a corrugated tube coaxial cable connector provided by an embodiment of the present invention. The coaxial cable 3 is also drawn in the diagram to illustrate the use of the connector. For the convenience of description, one side of the coaxial cable is taken as the rear end, and the end face connected with another corrugated coaxial cable connector is taken as the front end.

[0025] Such as figure 2 As shown, the corrugated tube coaxial cable includes two parts: a sleeve coil 1 and a terminal part 2 . figure 2 Among them, the sleeve coil 1 is sleeved on the outer conductor 31 of the coaxial cable 3 .

[0026] The sleeve coil 1 is in the shape of a thin-walled barrel. On its outer diameter surface, the front section has a smaller outer diameter and the rear section has a larger outer diameter, and a third step 11 transitions between the two. A section of external thread 12 is provided on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com