Patents

Literature

204 results about "Step edges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

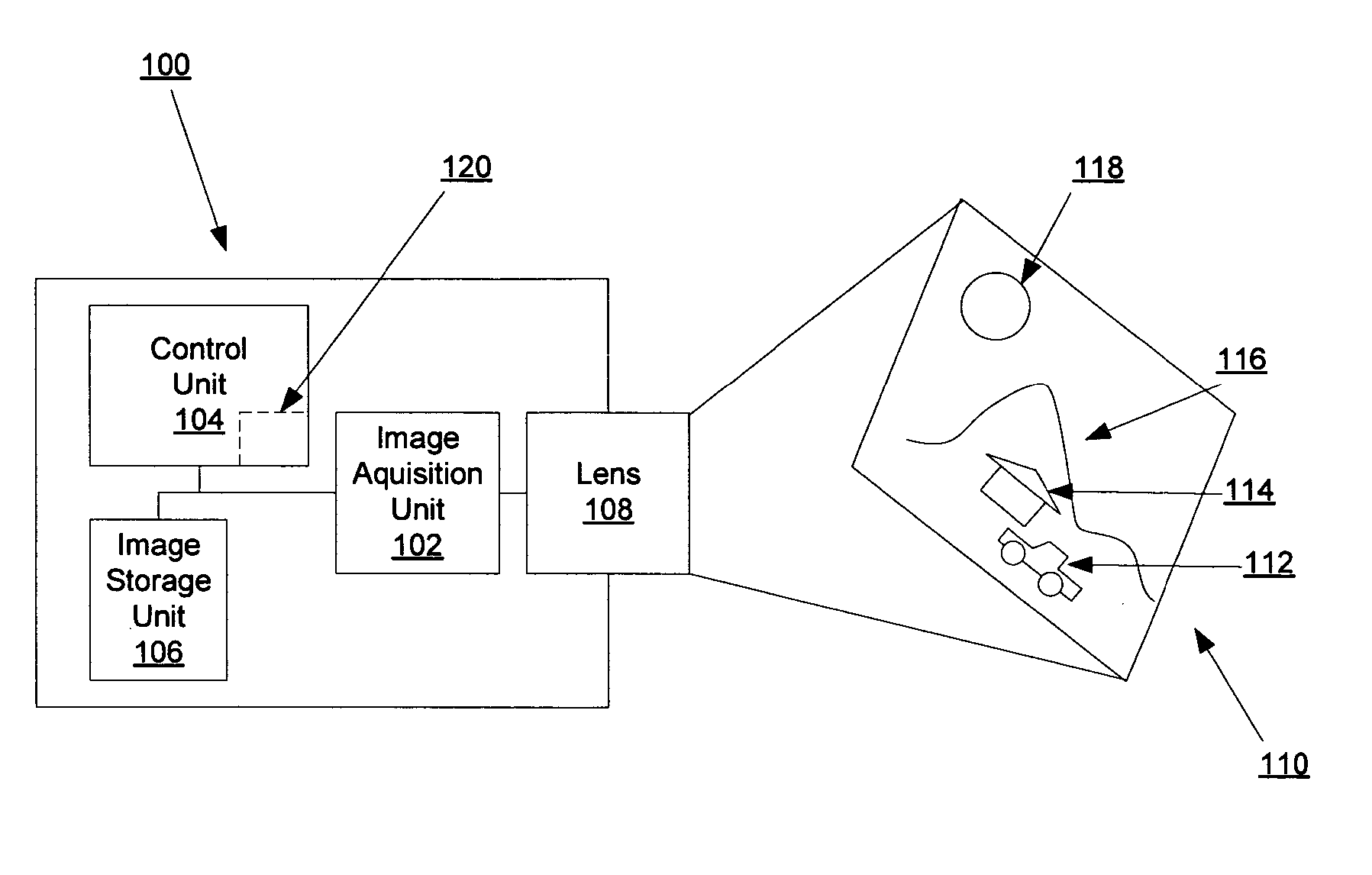

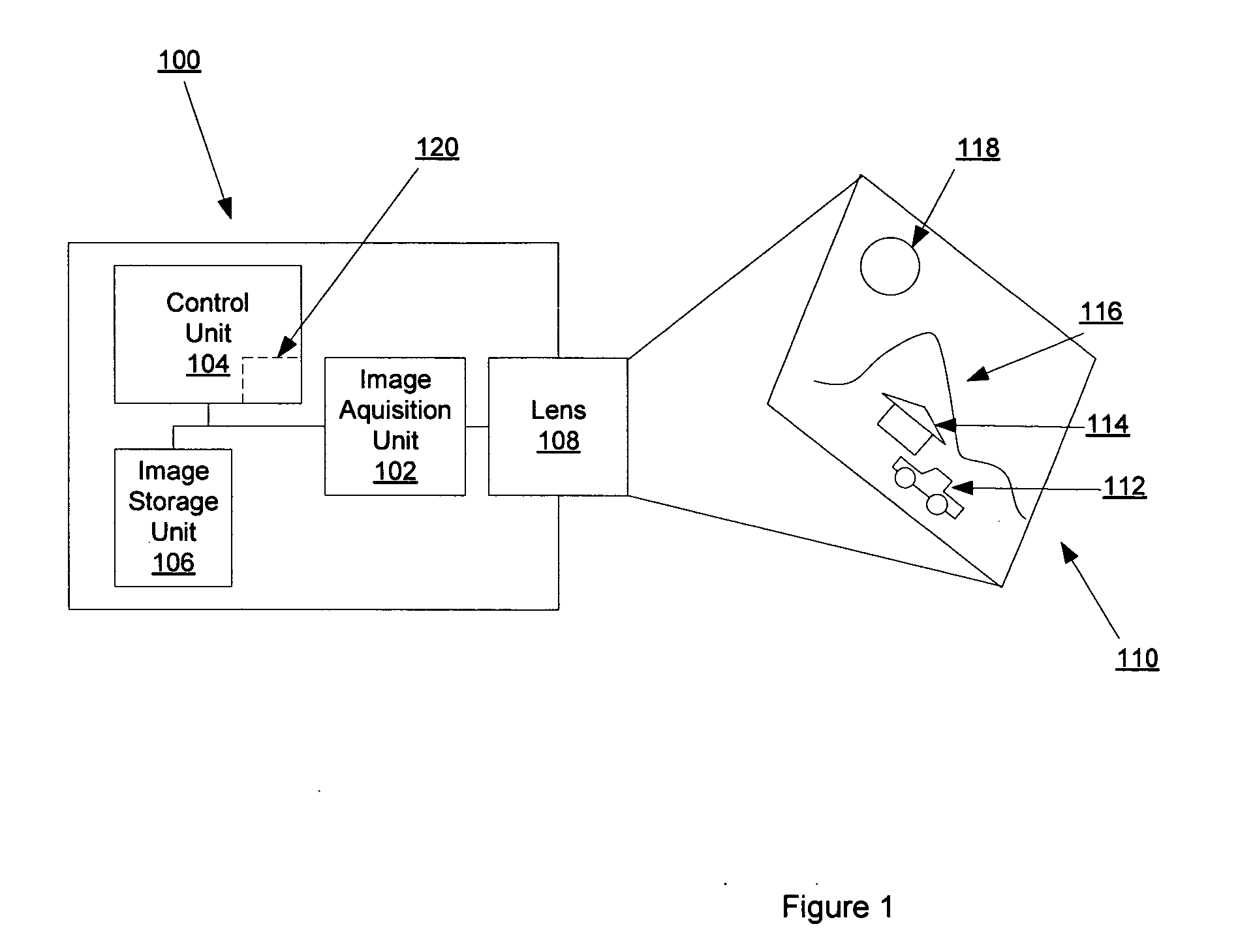

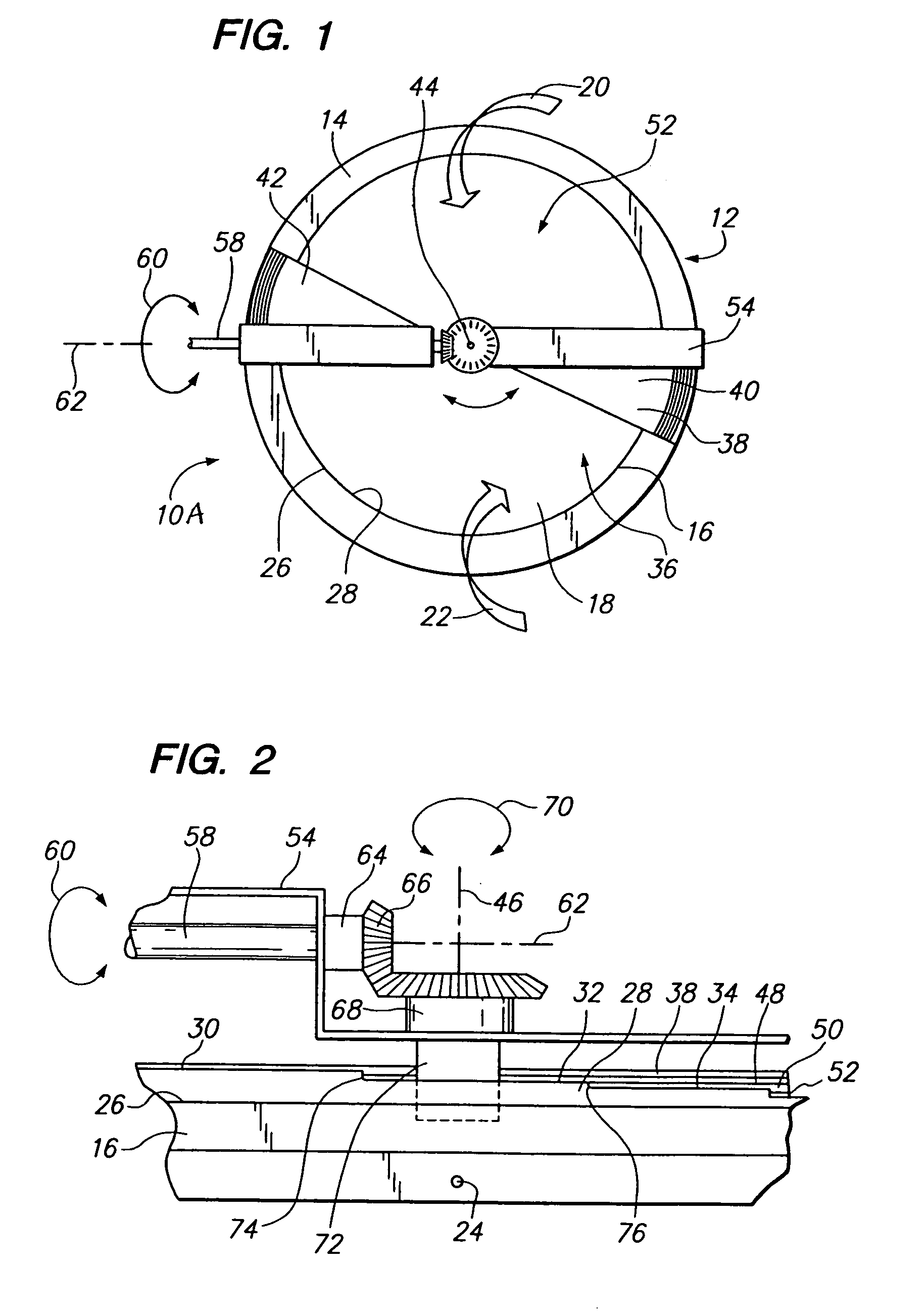

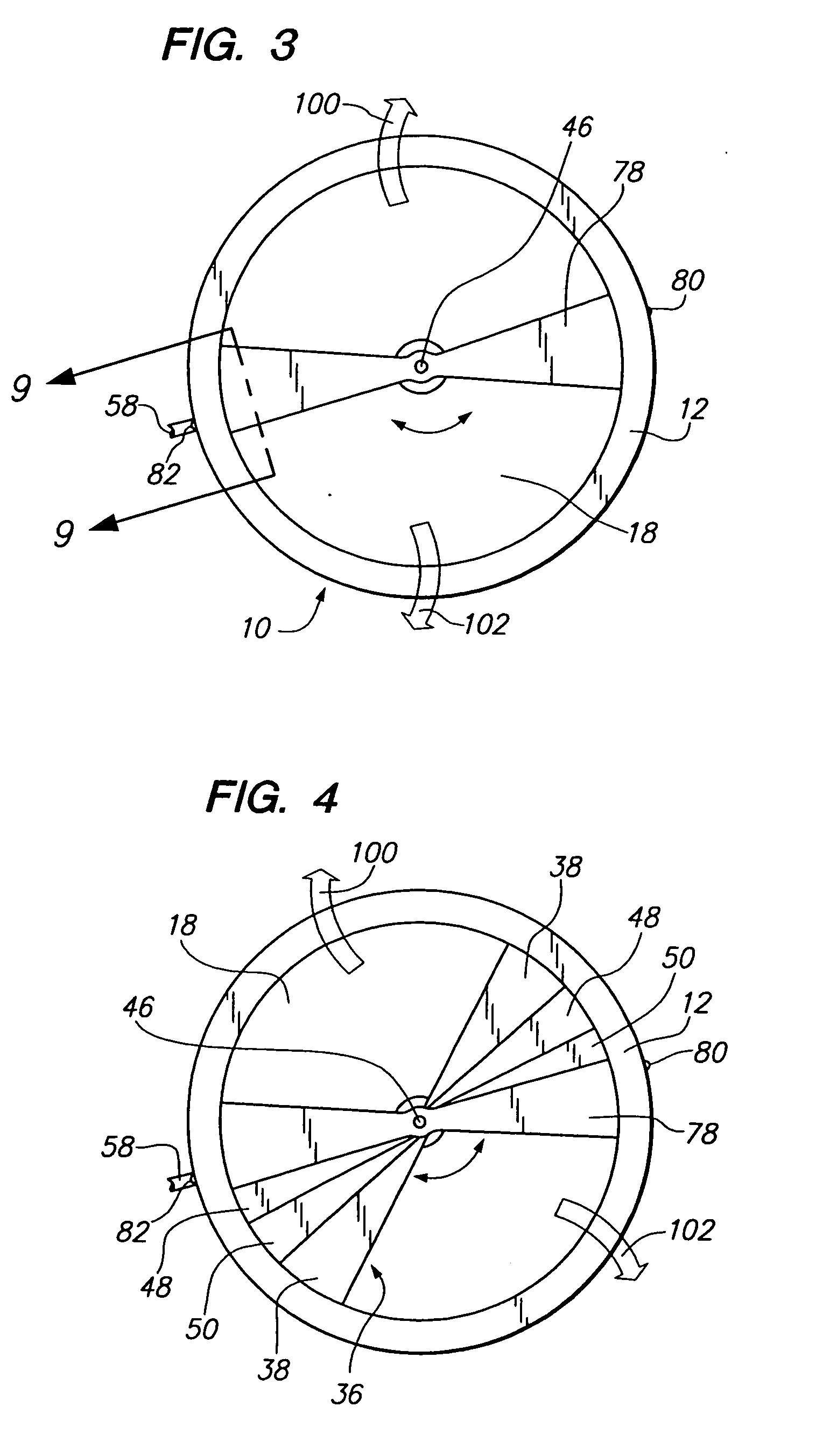

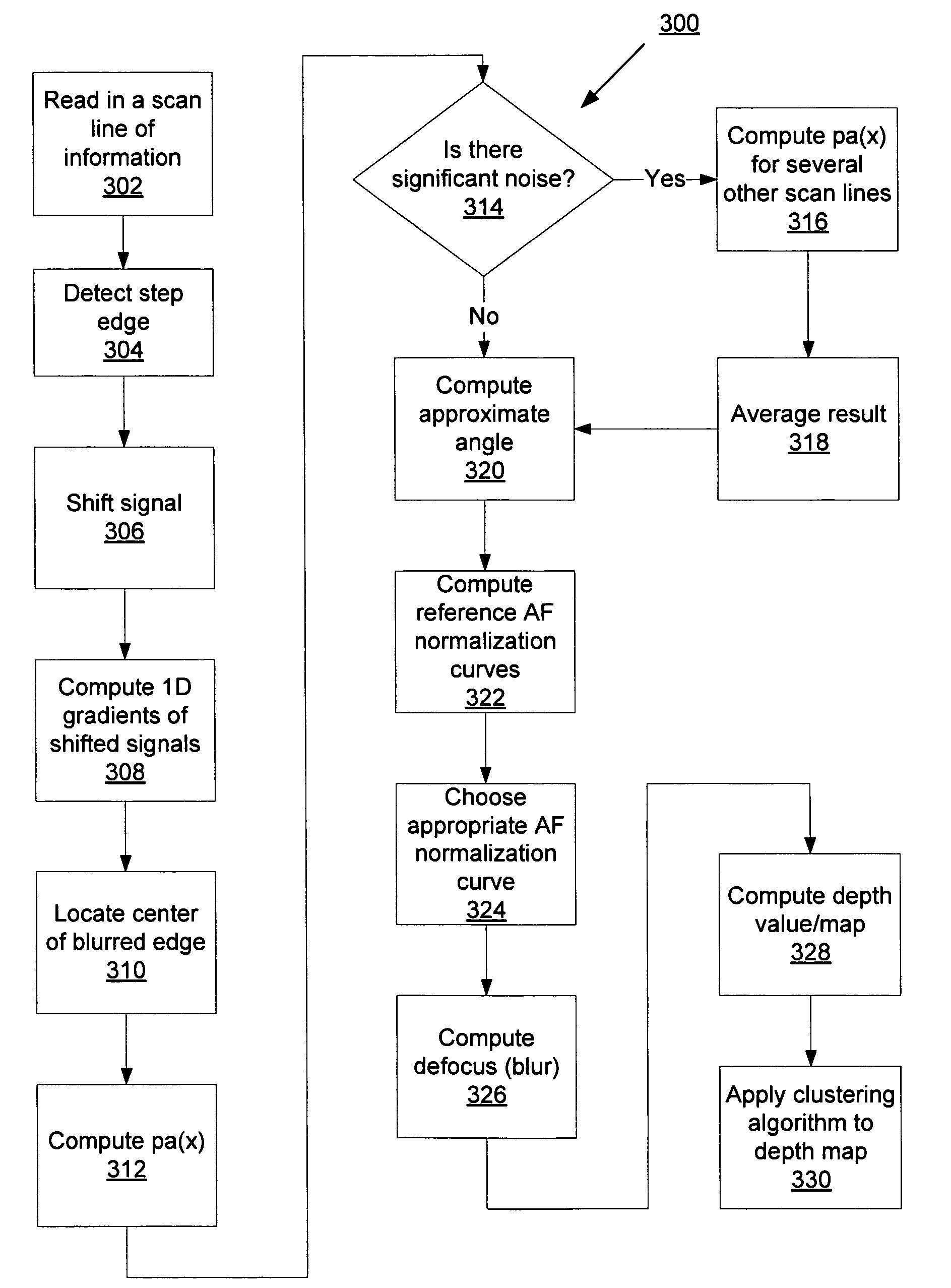

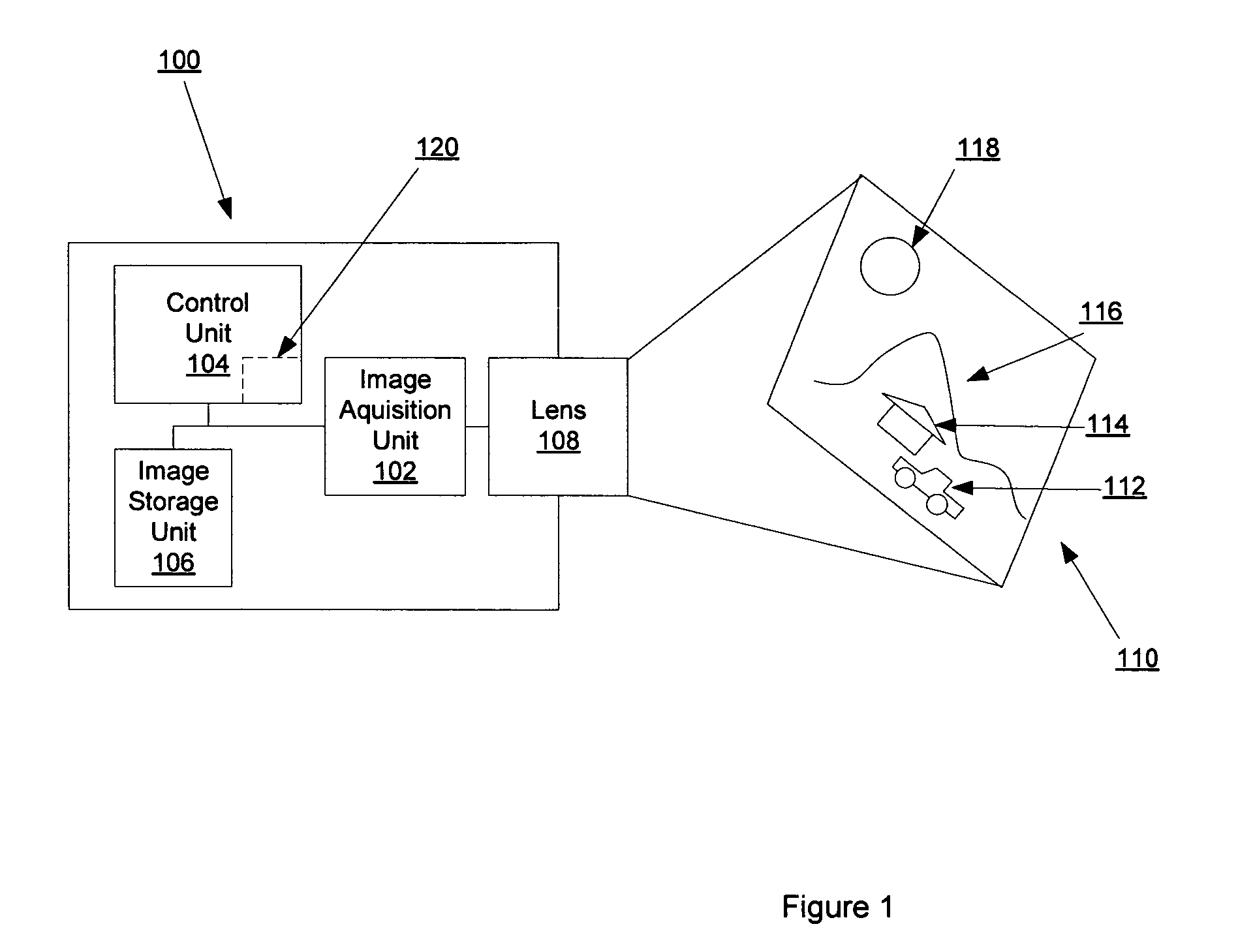

Simple method for calculating camera defocus from an image scene

ActiveUS20070216765A1Television system detailsProjector focusing arrangementThree-dimensional spaceAutofocus

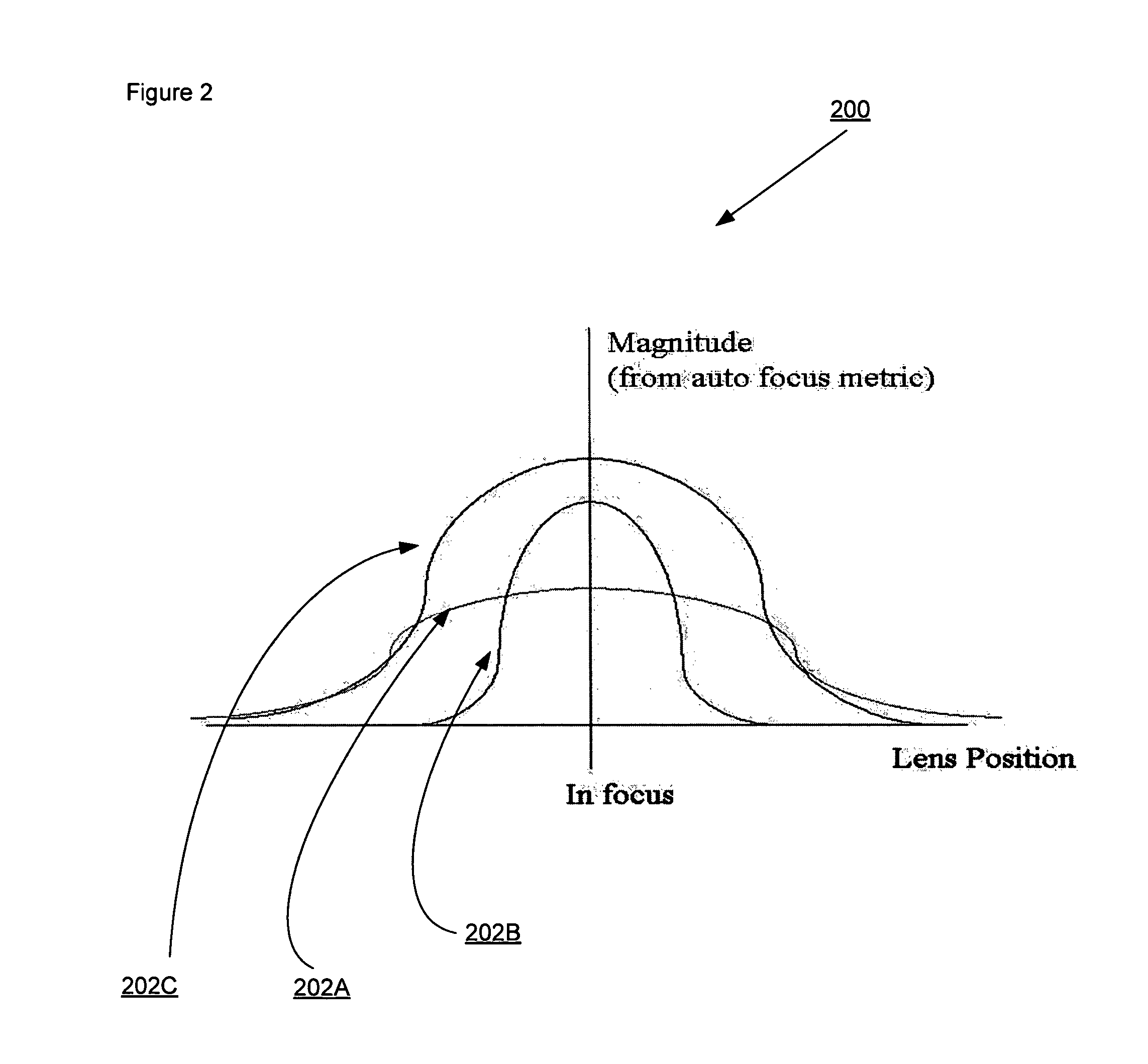

An imaging acquisition system that generates a picture depth from an auto focus curve generated from picture of a three dimensional spatial scene is described. The auto focus curve comprises a step edge. The system generates the depth based on the step edge and a reference auto focus normalization curve.

Owner:SONY CORP +1

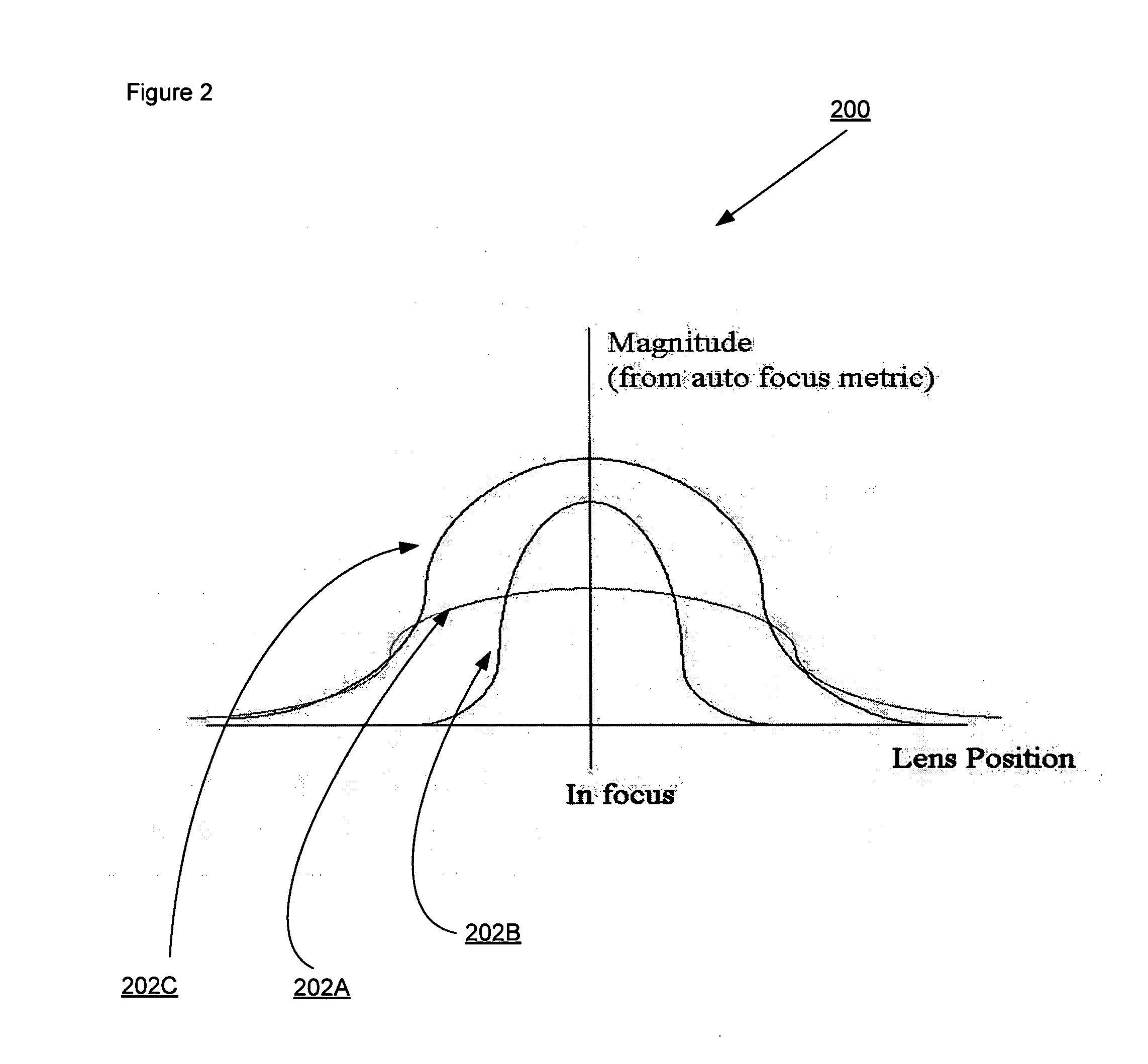

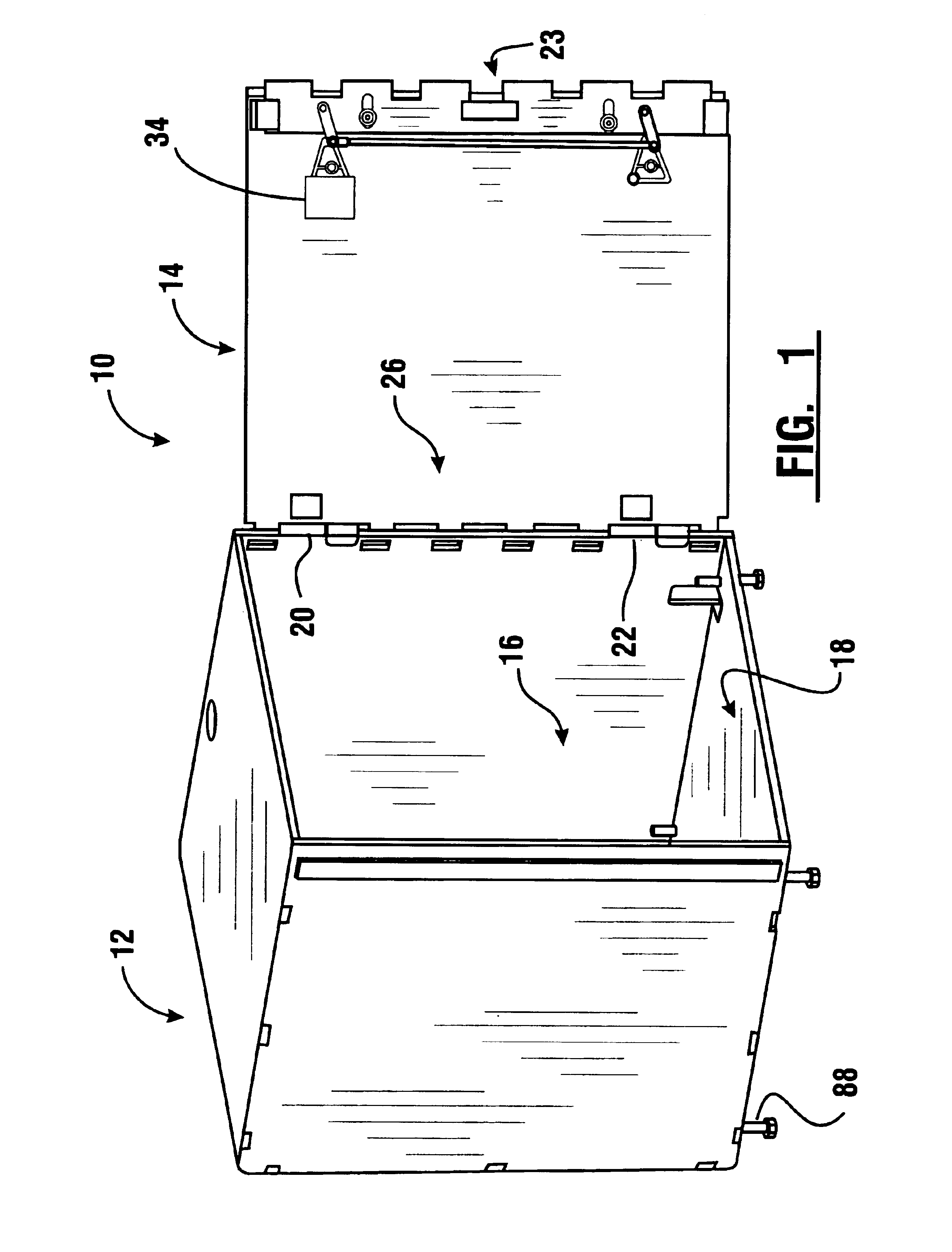

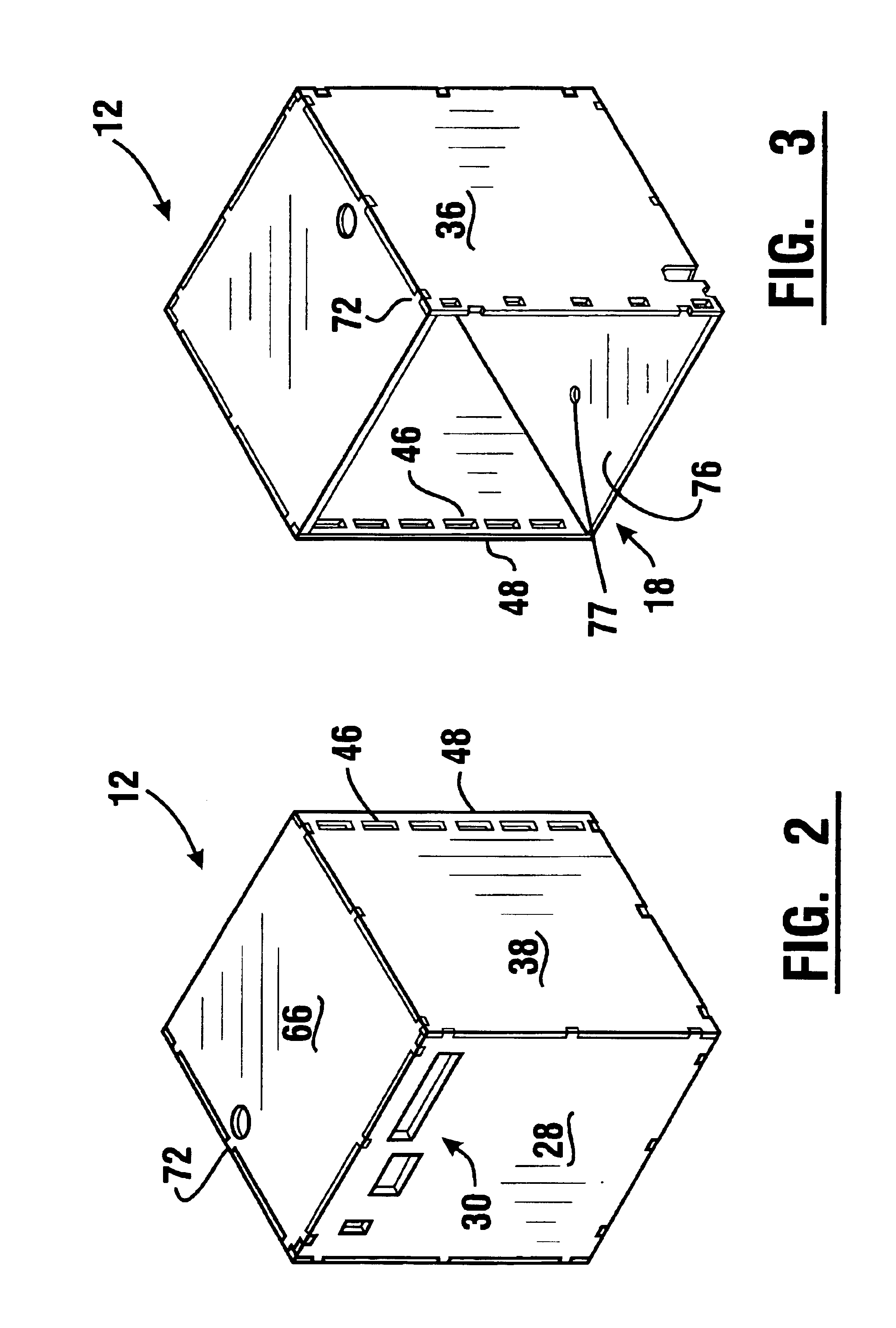

Container with tamper resistant lid

InactiveUS6899245B1Improve sealingEasy to disassembleCapsClosure using stoppersDetentElectrical and Electronics engineering

A container lid having a tamper evident and tamper resistant band formed of a plurality of equally spaced tabs having spurs that engage the rim of a container with latches formed on the spurs. In one embodiment the tamper evident band is unique because it hinges up instead of down and has a plurality of spurs with a stepped edge forming latches with the spurs engaging slots around the periphery of the lid. The reverse action makes the step edges on the spurs on the inside of tabs formed on the tamper resistant strip pull tighter when any attempt is made to pry or remove the lid from a container or cup. The lid also includes an annulus having interior surfaces that provide an excellent seal both inside and outside of the cup when the tamper resistant band is removed. In a second embodiment a tamper resistant band is formed with a curved surface to engage the exterior surface of the cup and has a plurality of spurs with a detent forming a latch to engage the lower edge of the skirt around the periphery of the lid. Each tab on the tamper resistant and tamper evident band has preferably two spurs.

Owner:NELSON JAMES L

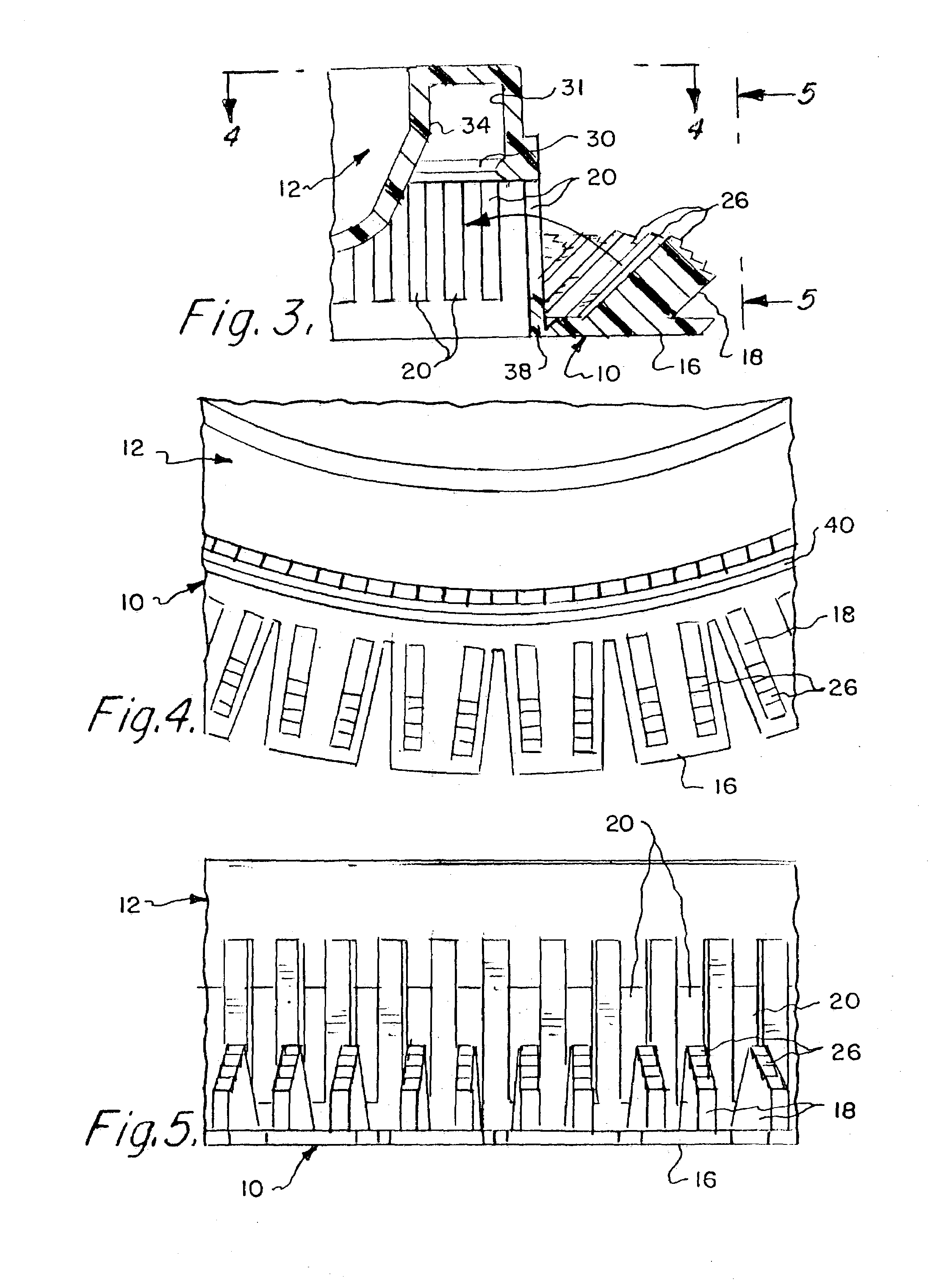

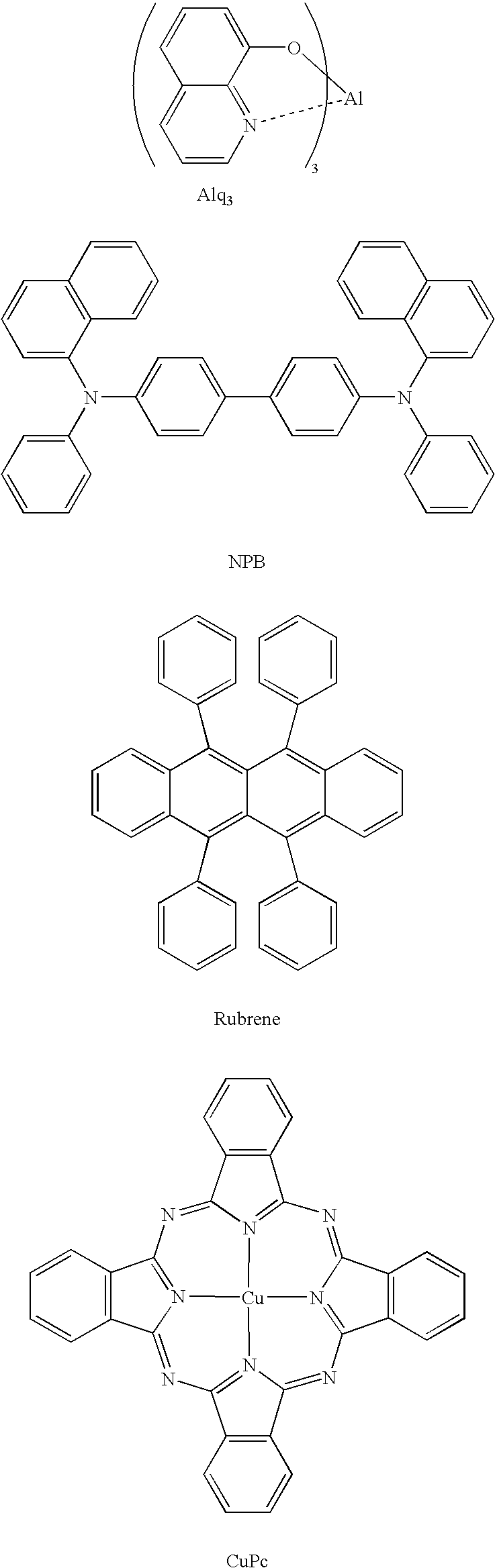

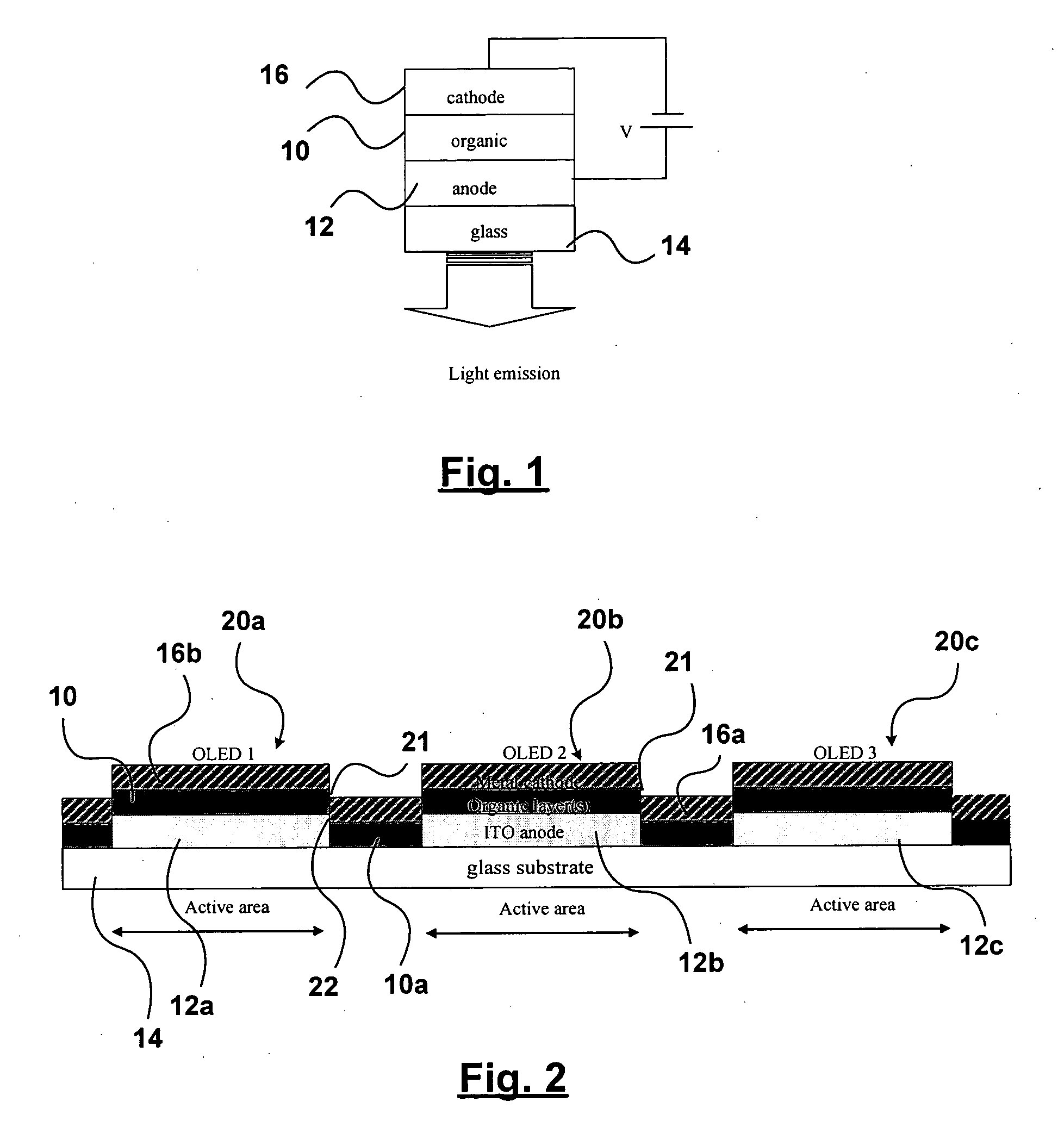

Photoresist mask/smoothing layer ensuring the field homogeneity and better step-coverage in OLED displays

InactiveUS20040075385A1Discharge tube luminescnet screensElectroluminescent light sourcesOrganic light emitting deviceComputational physics

A method of making an organic light emitting device (OLED) is disclosed wherein an inert insulating conformal smoothing layer is deposited over a protruding structure. The smoothing layer is patterned to expose portions of the structure underlying the smoothing layer and defining active regions of the device. The inert smoothing layer is treated, preferably by heat reflow, to taper the layer over the stepped edges of the structure on the exposed portions. Additional layers are then deposited over the smoothing layer and the exposed portions of the structure. The smoothing layer blunts all underlying layer edges and provides sloped edges wherever a step occurs from one layer to another. This effect results in a homogeneous field across the pixel and the continuity in the layers deposited after the photoresist layer.

Owner:NAT RES COUNCIL OF CANADA

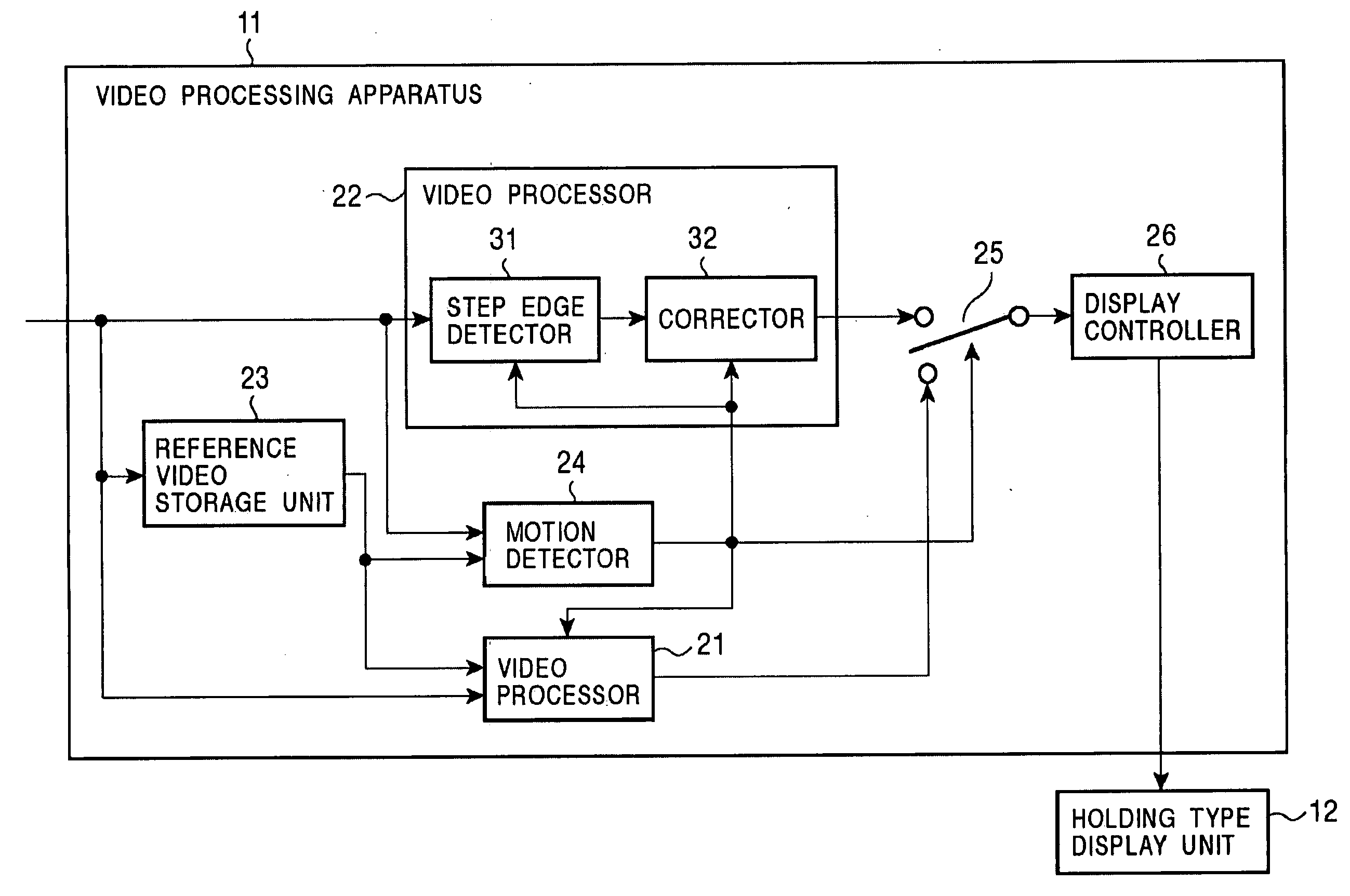

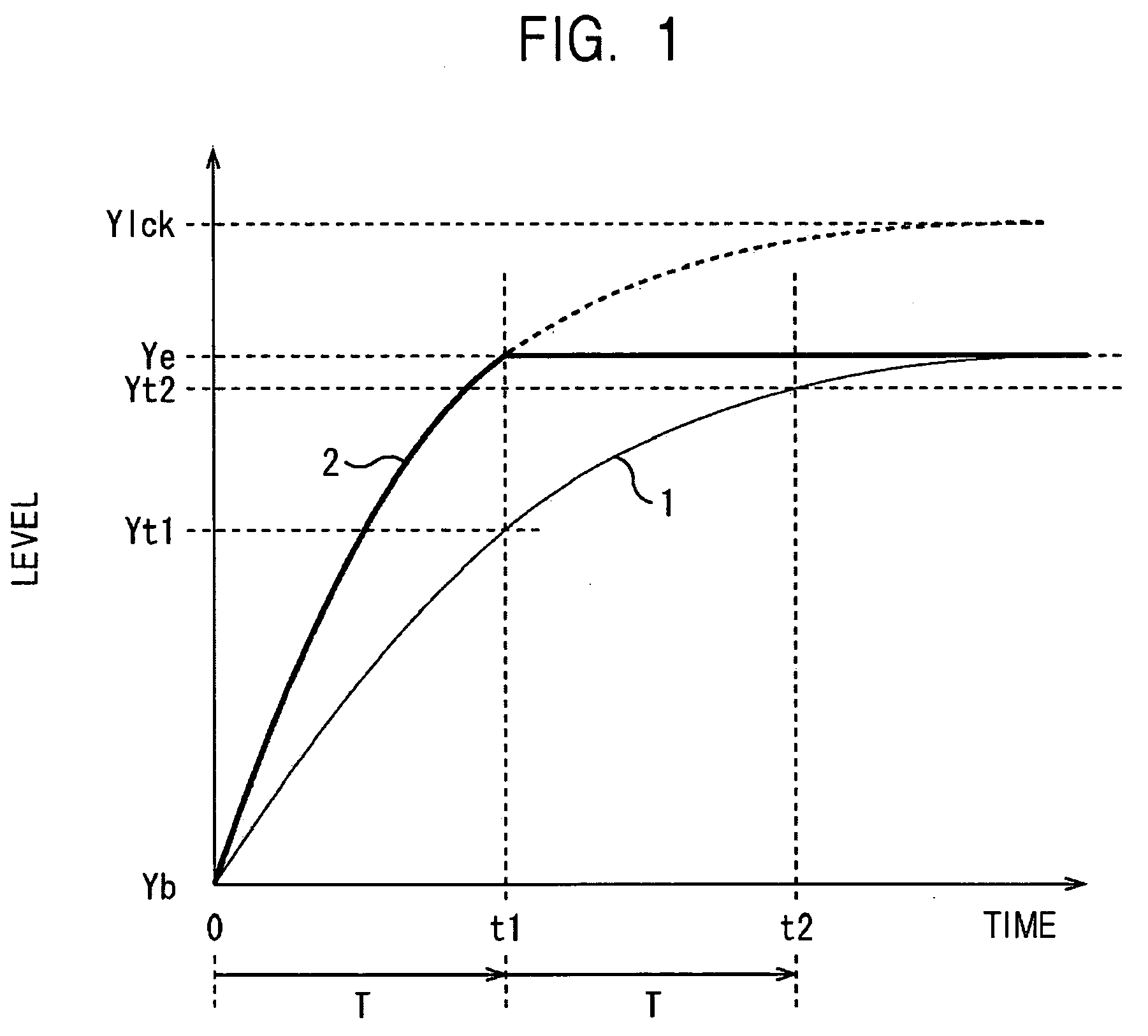

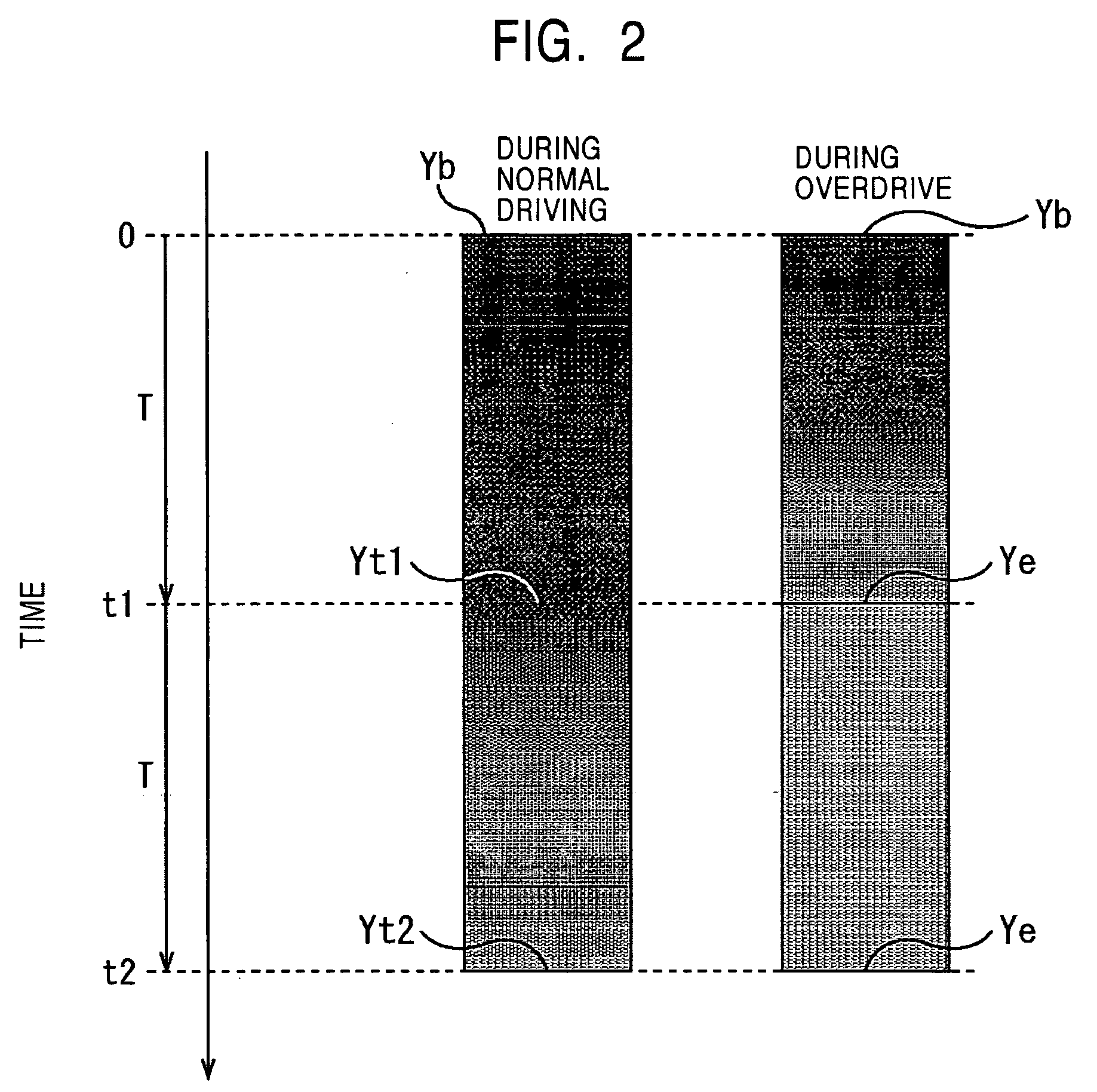

Video processing apparatus, video processing method, and computer program

A holding type display such as a liquid-crystal display for controlling motion blur is disclosed. A step edge detector detects an edge portion of a moving step edge in video data in an input frame or an input field. A corrector corrects a pixel value of a pixel at the edge portion of the step edge detected by the step edge detector, based on a spatial amount of motion of the corresponding pixel supplied by a motion detector.

Owner:SONY CORP

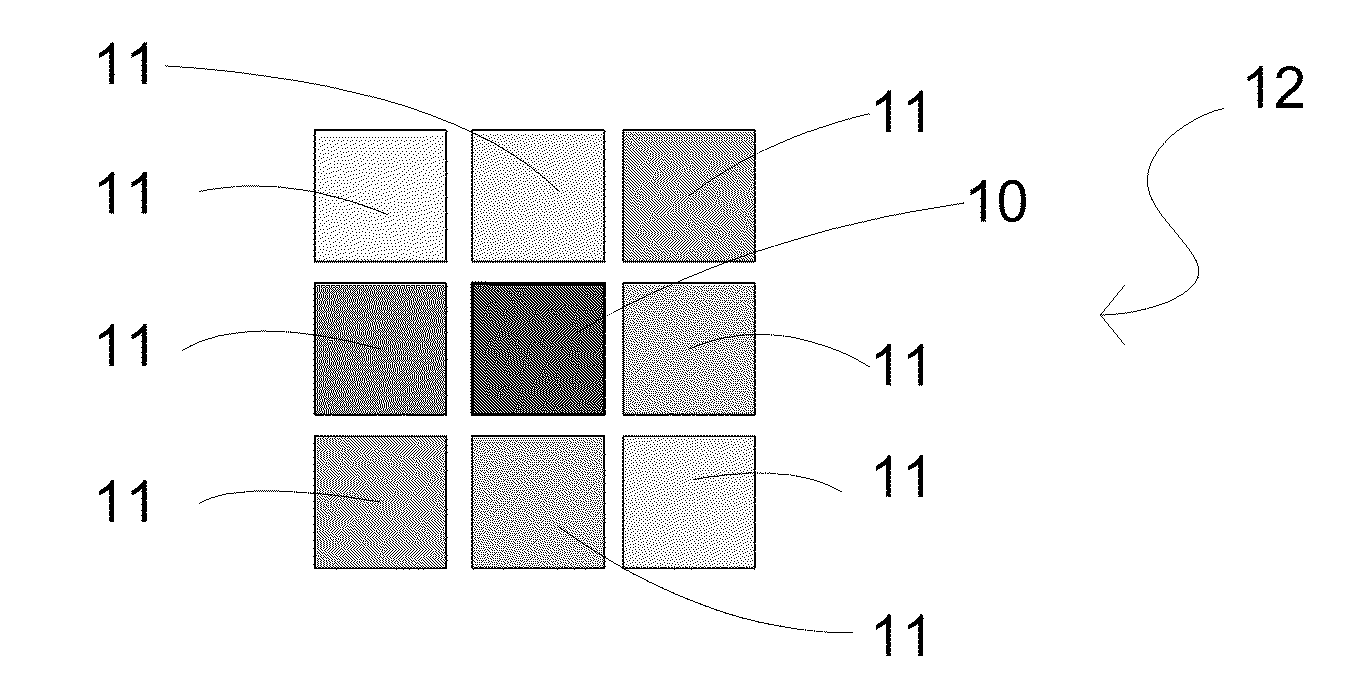

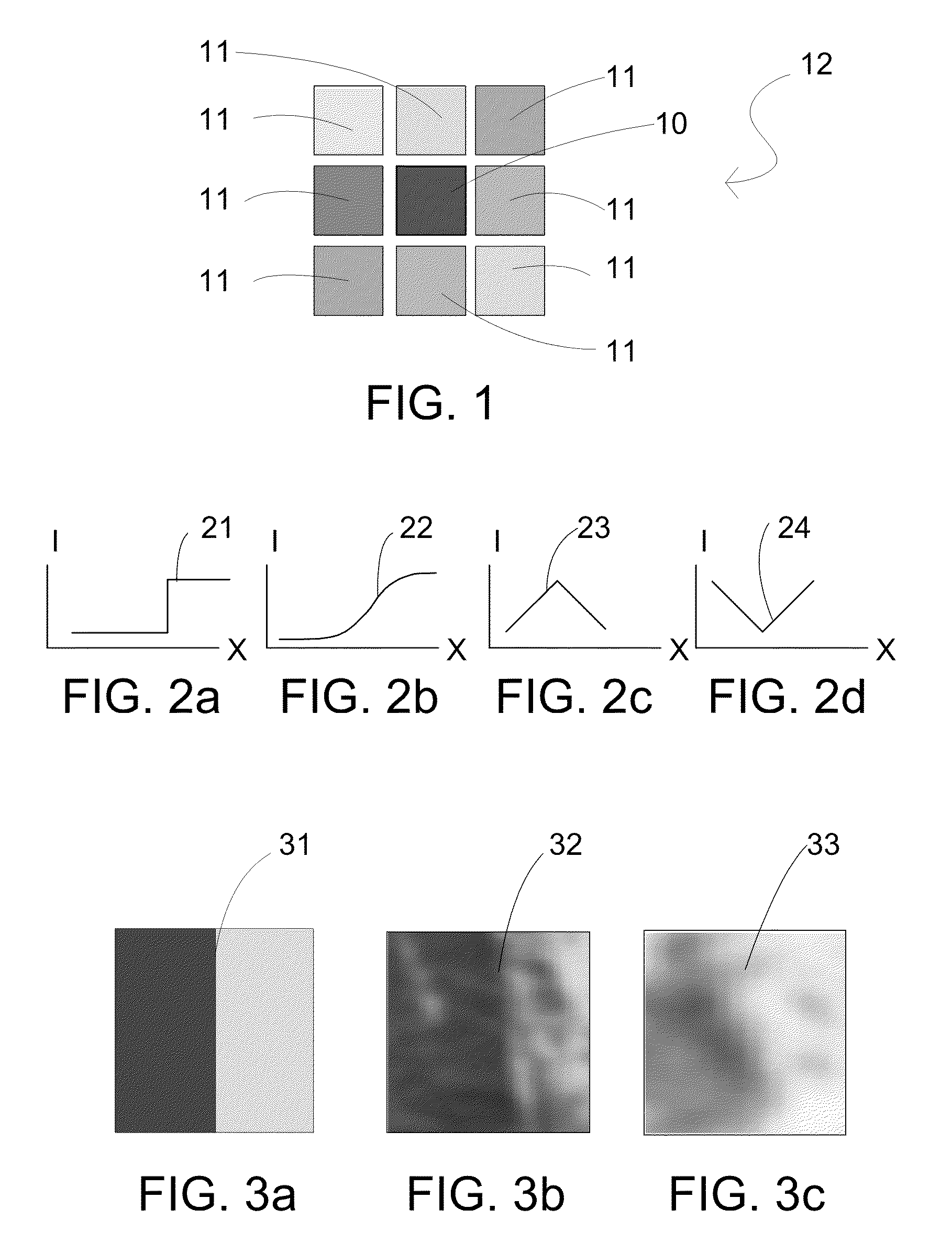

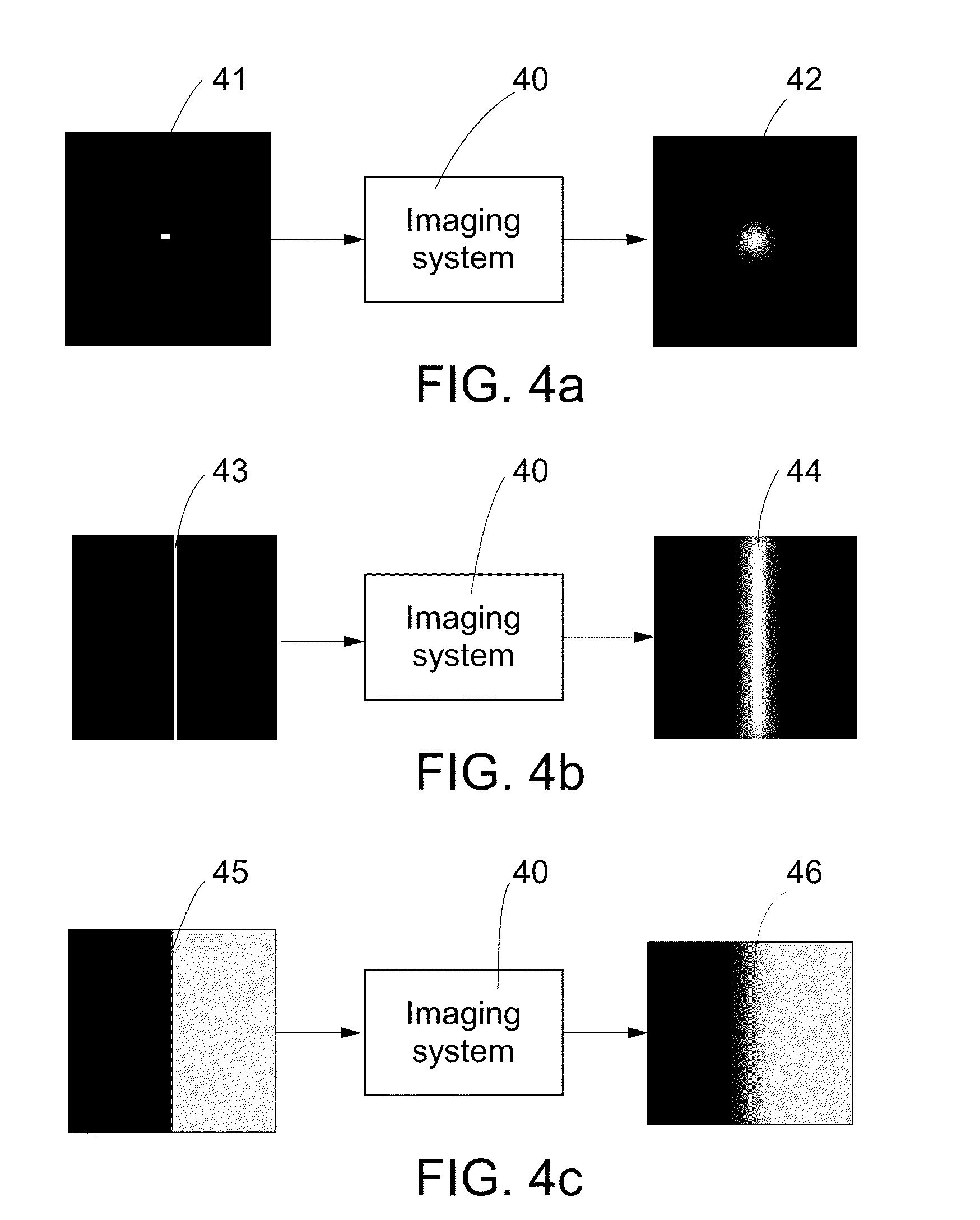

Blind restoration of images degraded by isotropic blur

ActiveUS20100080487A1Reduce noise artifactBetter signal to noise ratioImage enhancementImage analysisDigital imageComputer science

A system and a method for automatic restoration of isotropic degradations of a digital image, based on receiving a blurred image by an image capture assembly, automatically finding proper step edge, calculating the PSF from the step edge, and restoring the blurred image by means of a processor, and with the option to display the resorted image by means of an output assembly.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

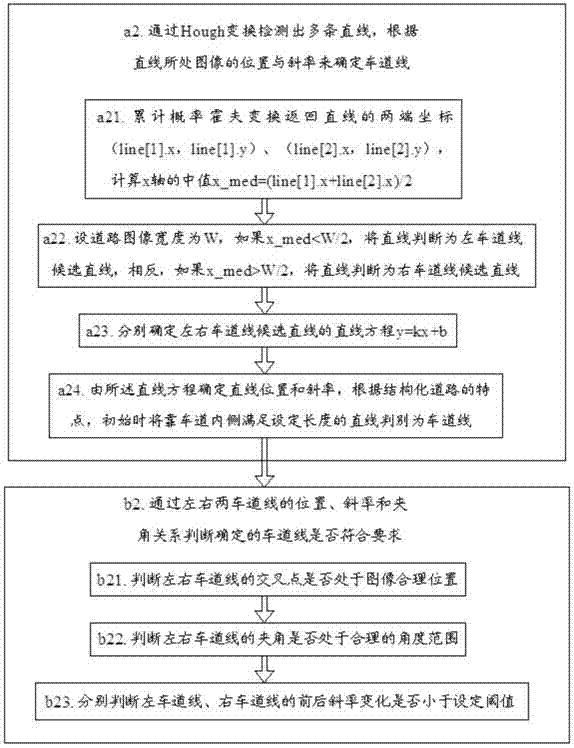

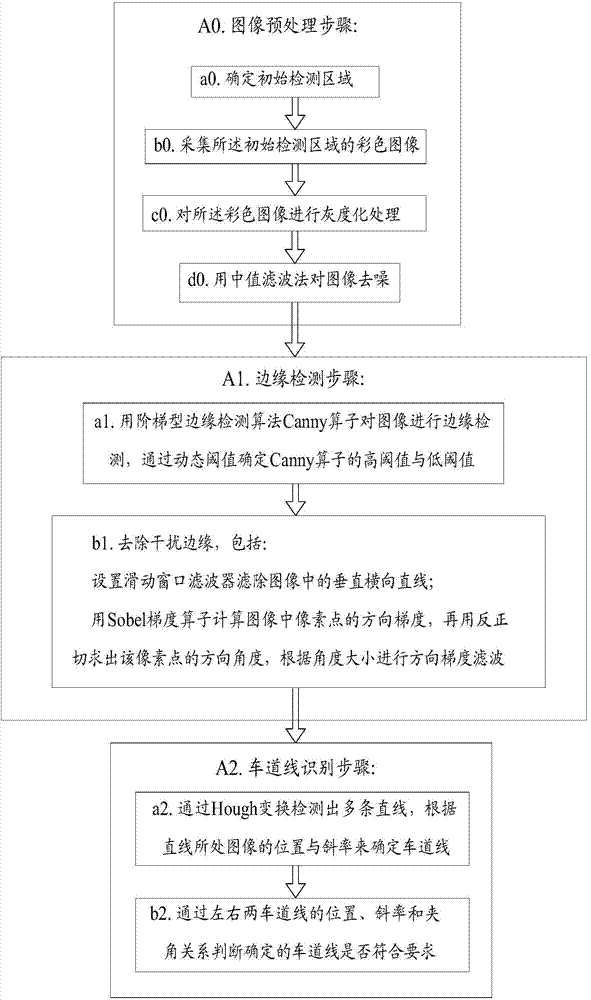

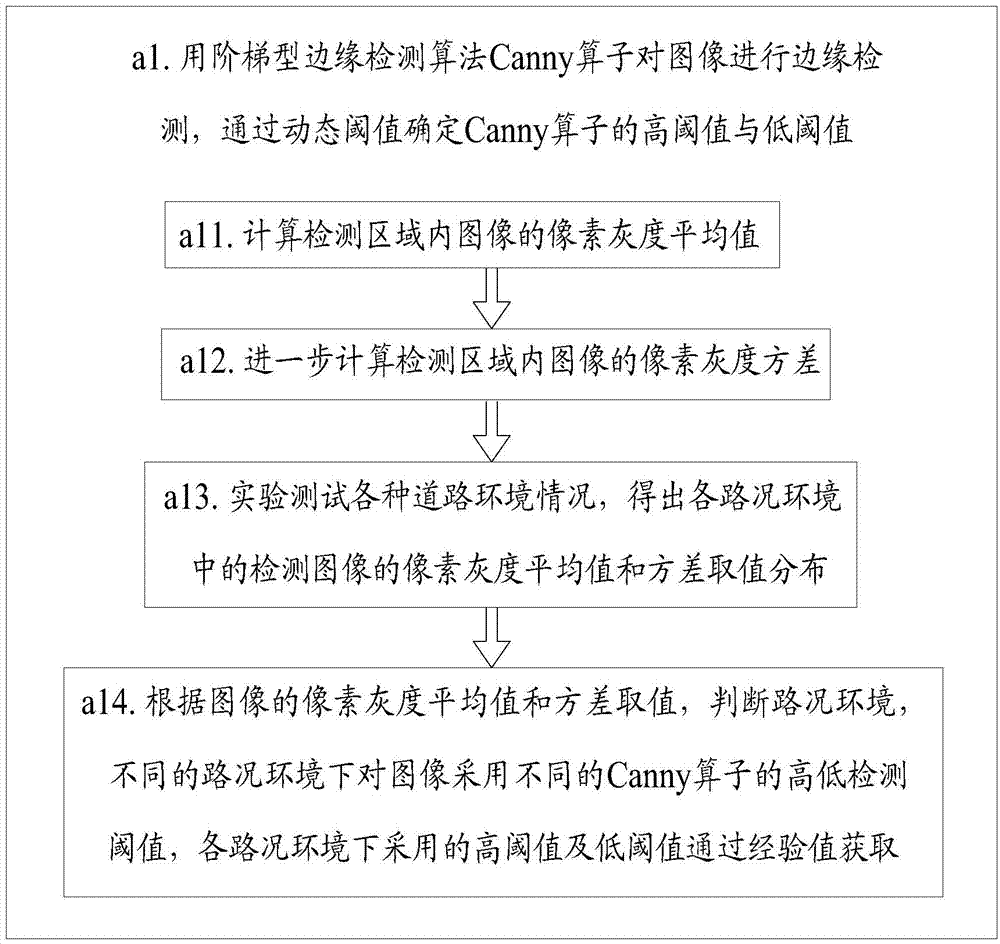

Lane line detection method for lane departure early warning

ActiveCN103593649AImprove noiseImprove anti-interference abilityImage analysisCharacter and pattern recognitionGradient operatorsSlide window

The invention provides a lane line detection method for lane departure early warning. The method includes the edge detection step and the lane line recognition step. In the edge detection step, edge detection is conducted on images through a stepped edge detection algorithm Canny operator, and the high threshold value and the low threshold value of the Canny operator are determined through a dynamic threshold value; interference edges are removed, namely, a sliding window filter is arranged to filter perpendicular and transverse straight lines in the images, a Sobel gradient operator is utilized to calculate the direction gradient of pixel points in the images, the direction angle of the pixel points is acquired through arc tangent, and then direction gradient filtering is conducted according to the size of the angle. In the lane line recognition step, a plurality of straight lines are detected through Hough transformation, and lane lines are determined according to the positions, where the straight lines are located, of the images and the slope; whether the determined lane lines meet requirements or not is judged according to the relations of the positions and the slope of the left lane line and the right lane line and the included angle between the left lane line and the right lane line. According to the method, lane departure warning anti-noise and anti-interference capacity is improved, high robustness is achieved, and detection efficiency is improved.

Owner:FORYOU GENERAL ELECTRONICS

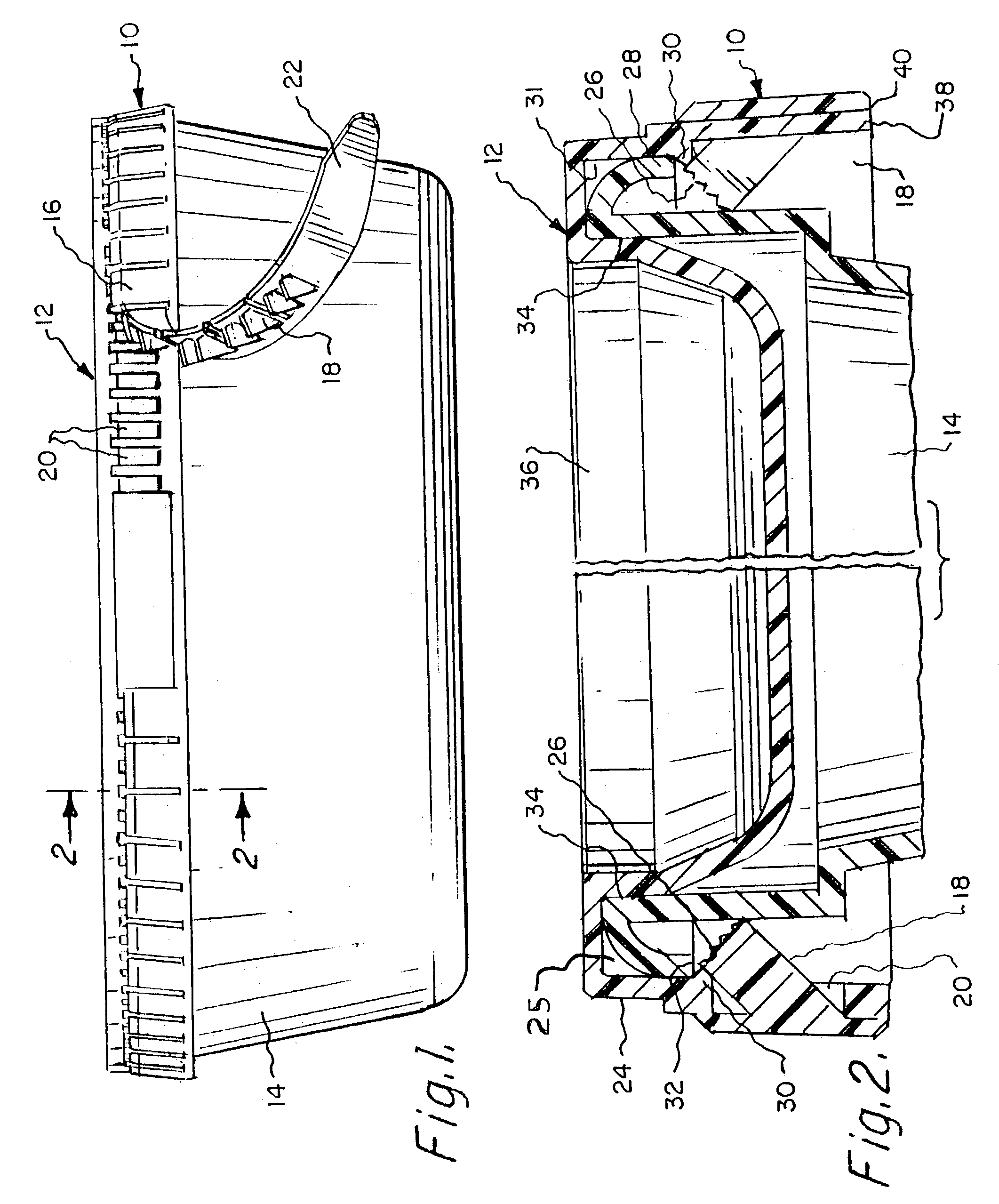

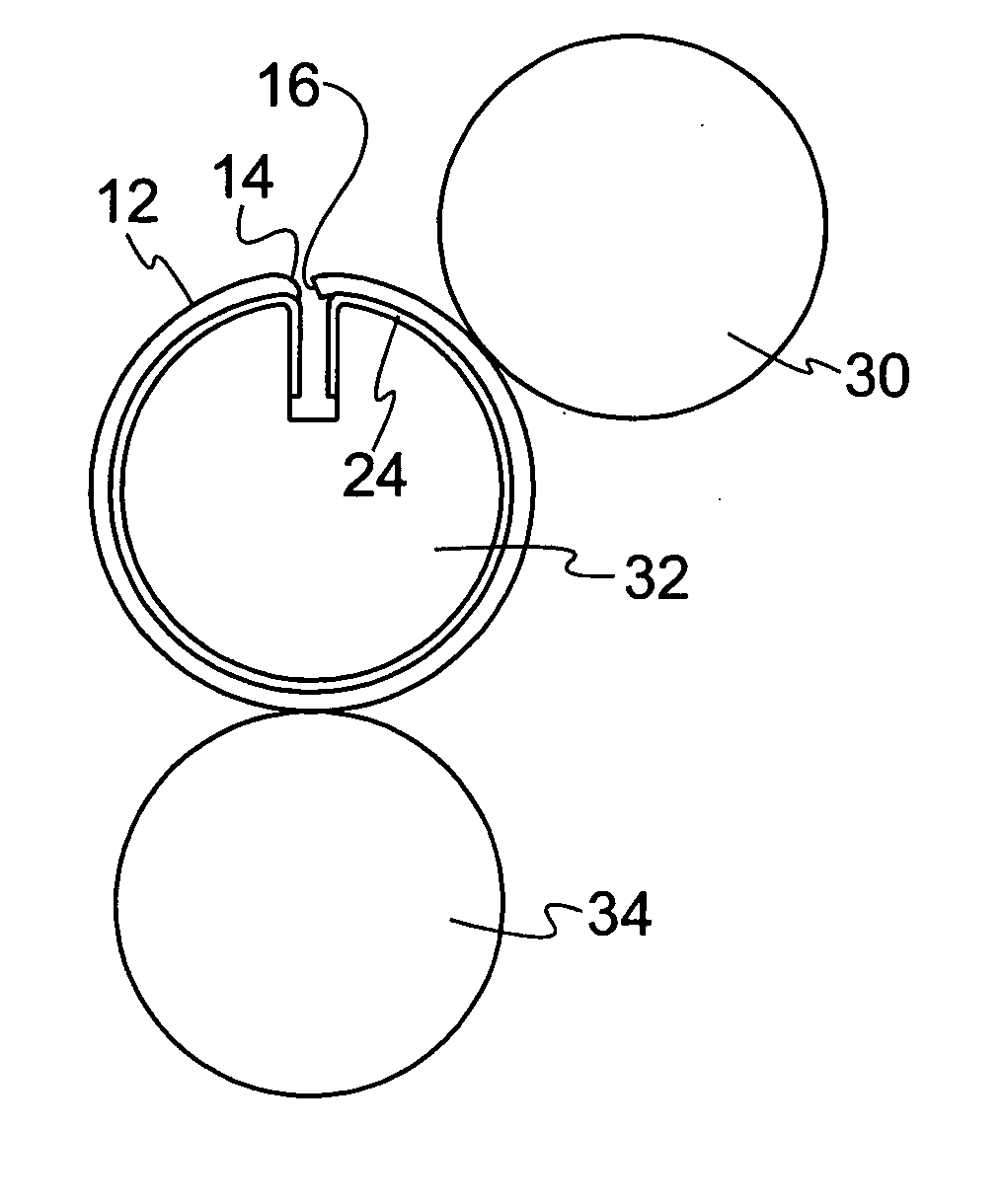

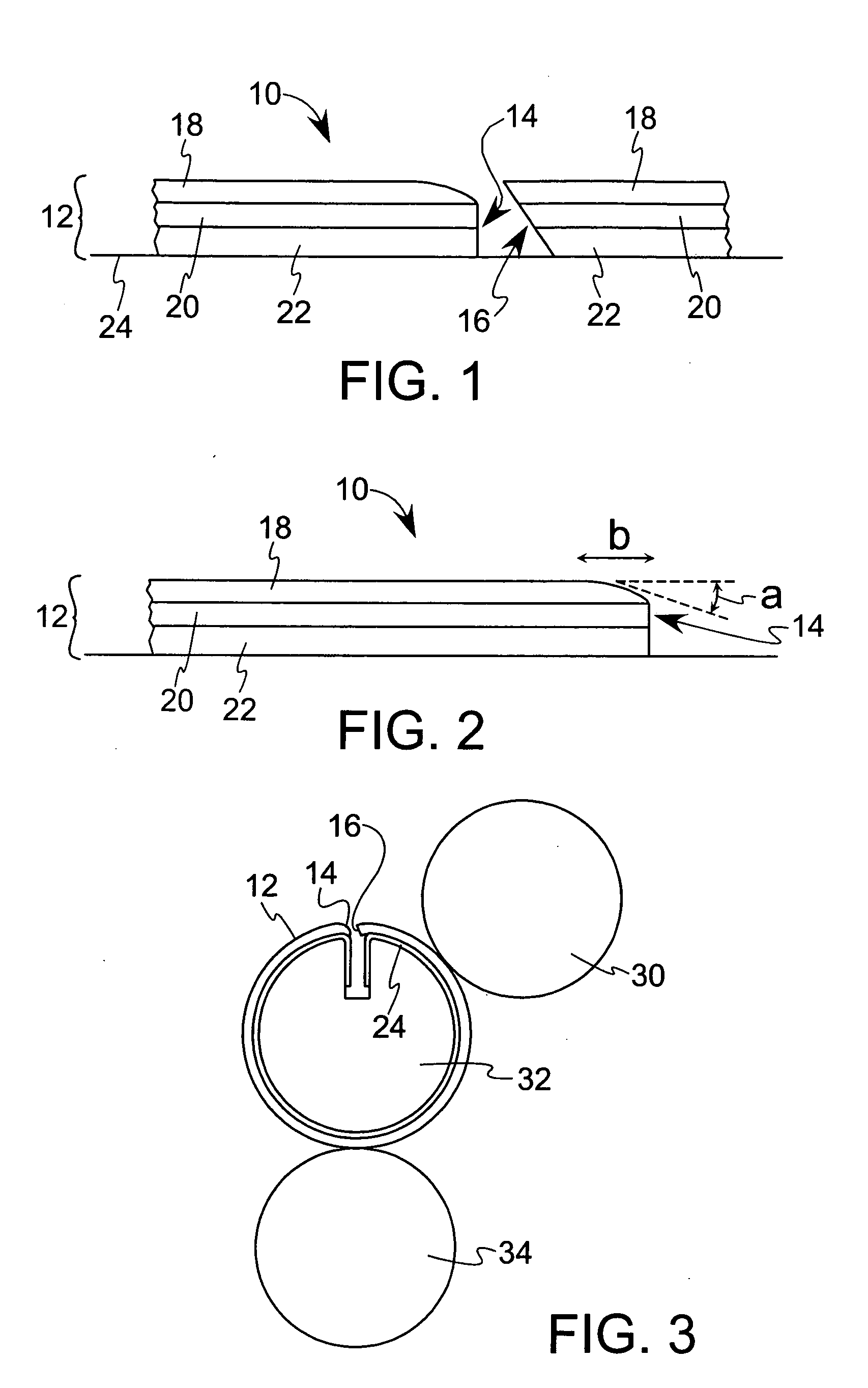

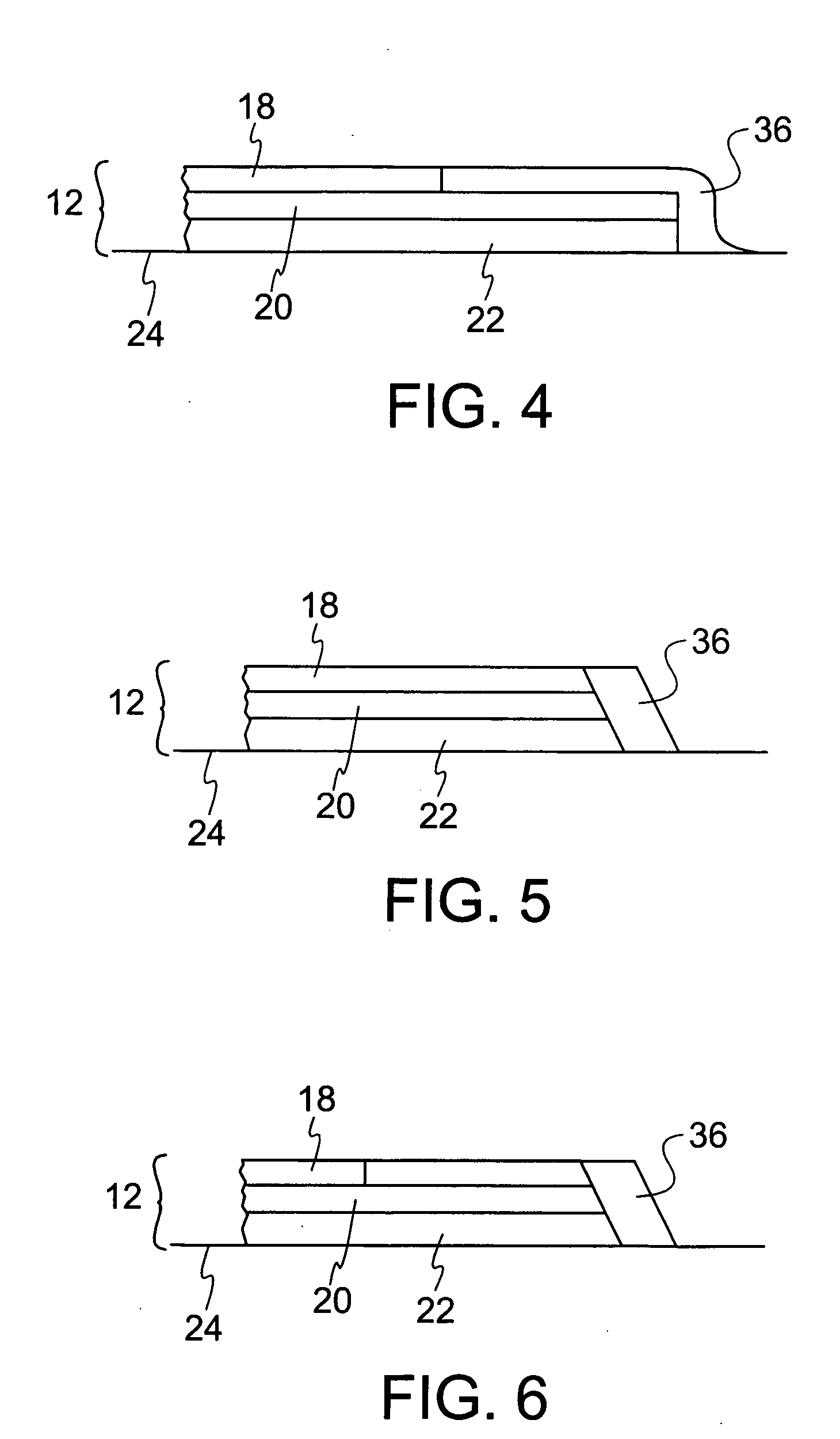

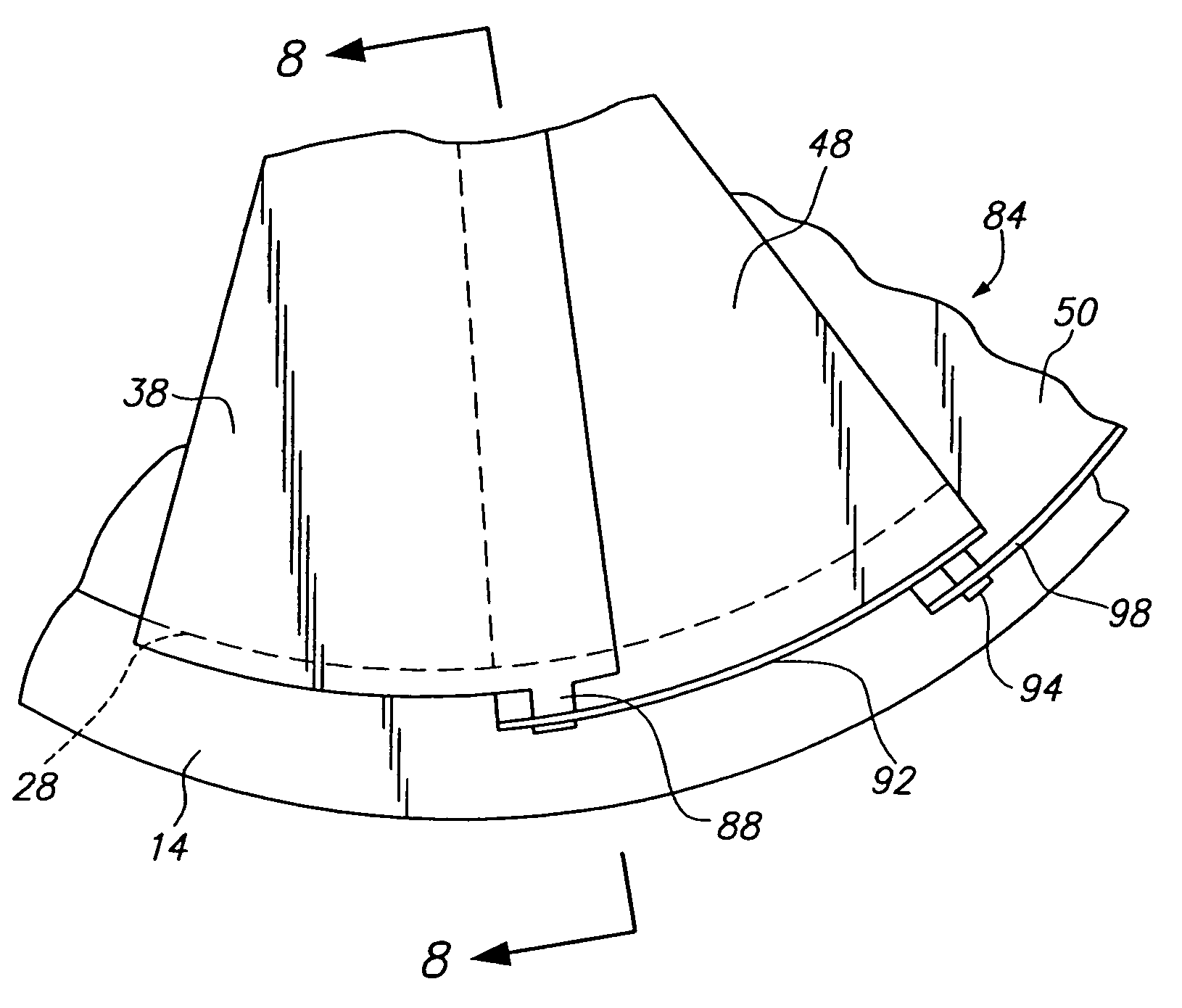

Printing blanket construction and method of making

ActiveUS20050098051A1Reduce shock effectsIncrease surface areaPrinting blanketsRotary lithographic machinesLeading edgeEngineering

An improved printing blanket construction is provided which includes at least a top ply, a bottom ply, and a non-extensible backing ply. The blanket includes leading and trailing edges which are secured directly to the backing ply, where at least a portion of the leading edge forms a contoured edge, a stair-stepped edge, a beveled edge, or a combination thereof. The printing blanket construction having such a shaped leading edge reduces printing gap, reduces the impact forces on the leading edge of the blanket, and protects the blanket from the penetration of ink, solvents, moisture and the like into the blanket plies during use.

Owner:DAY INT

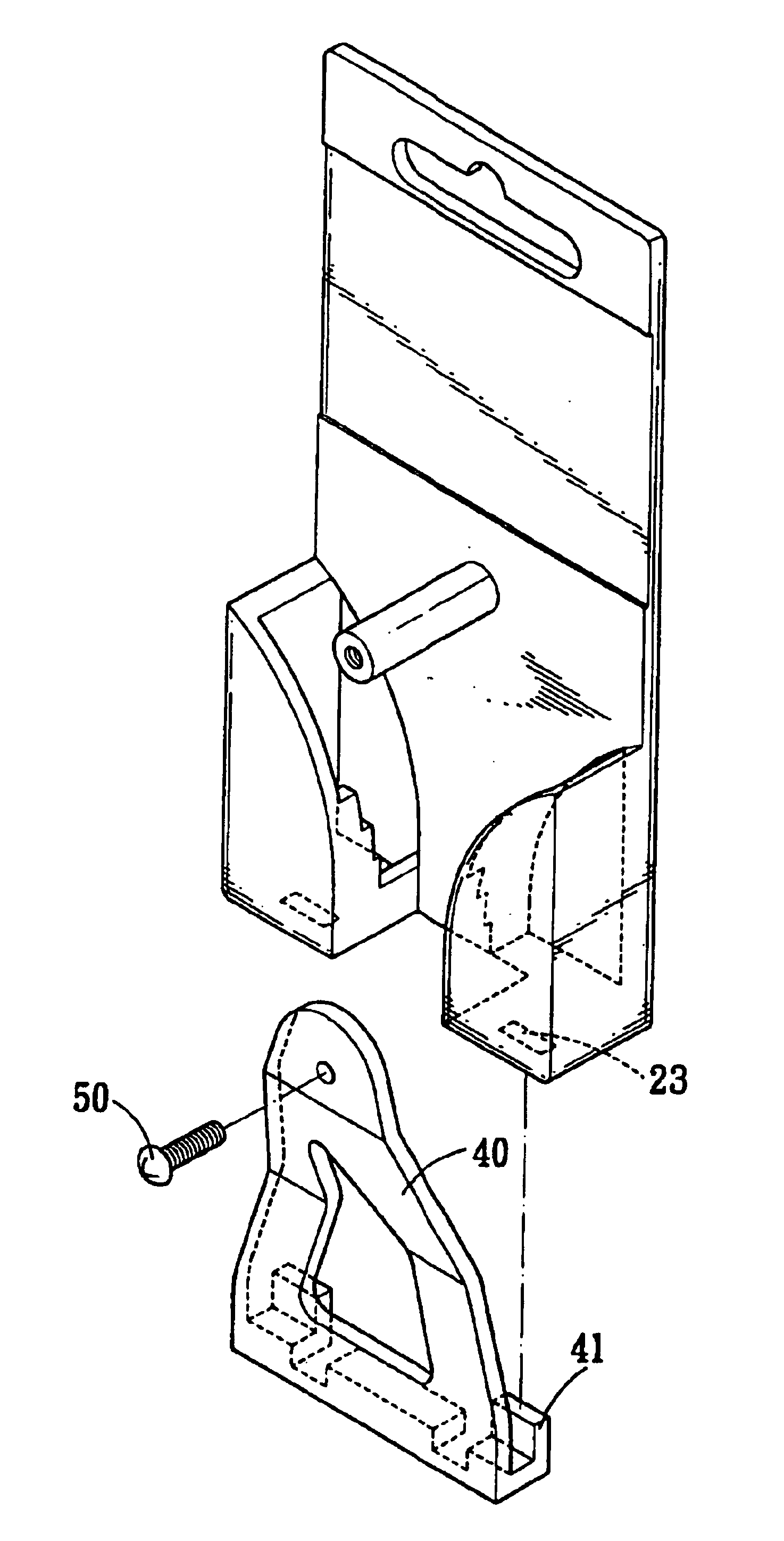

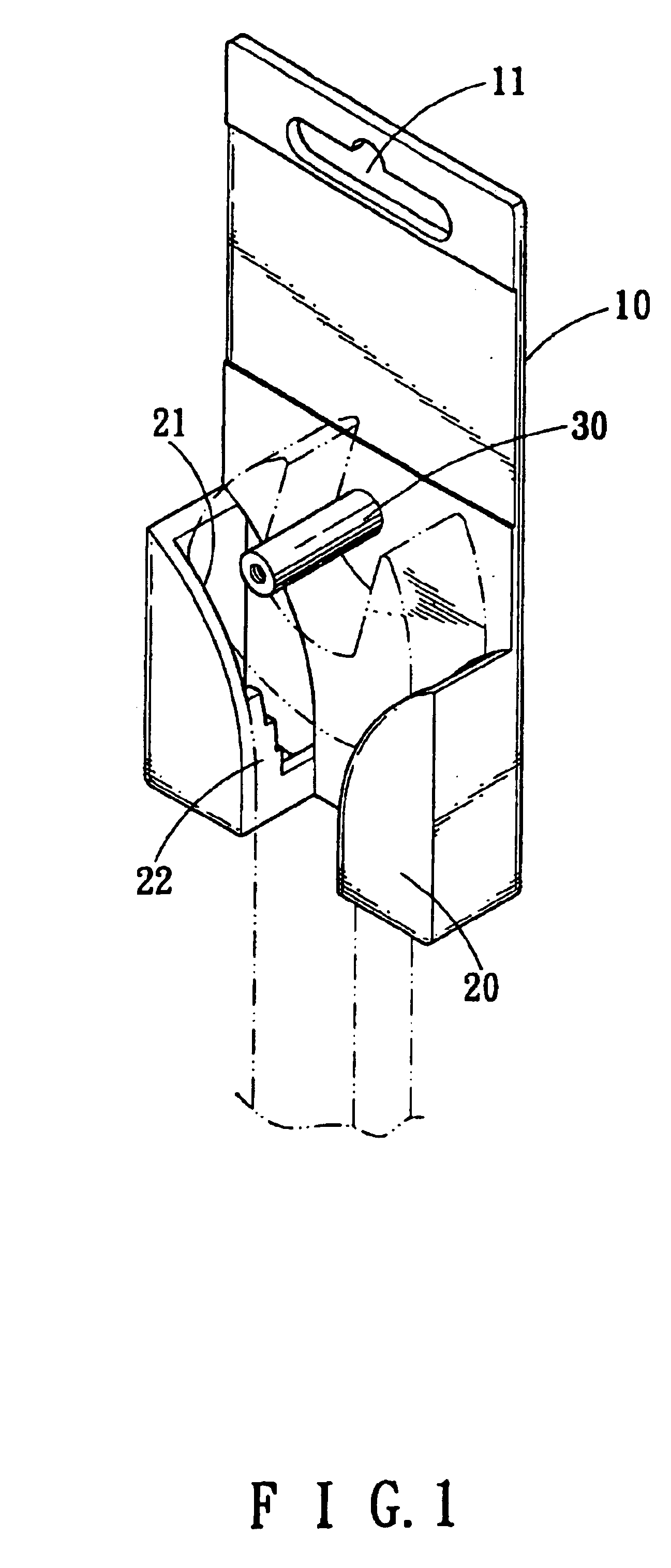

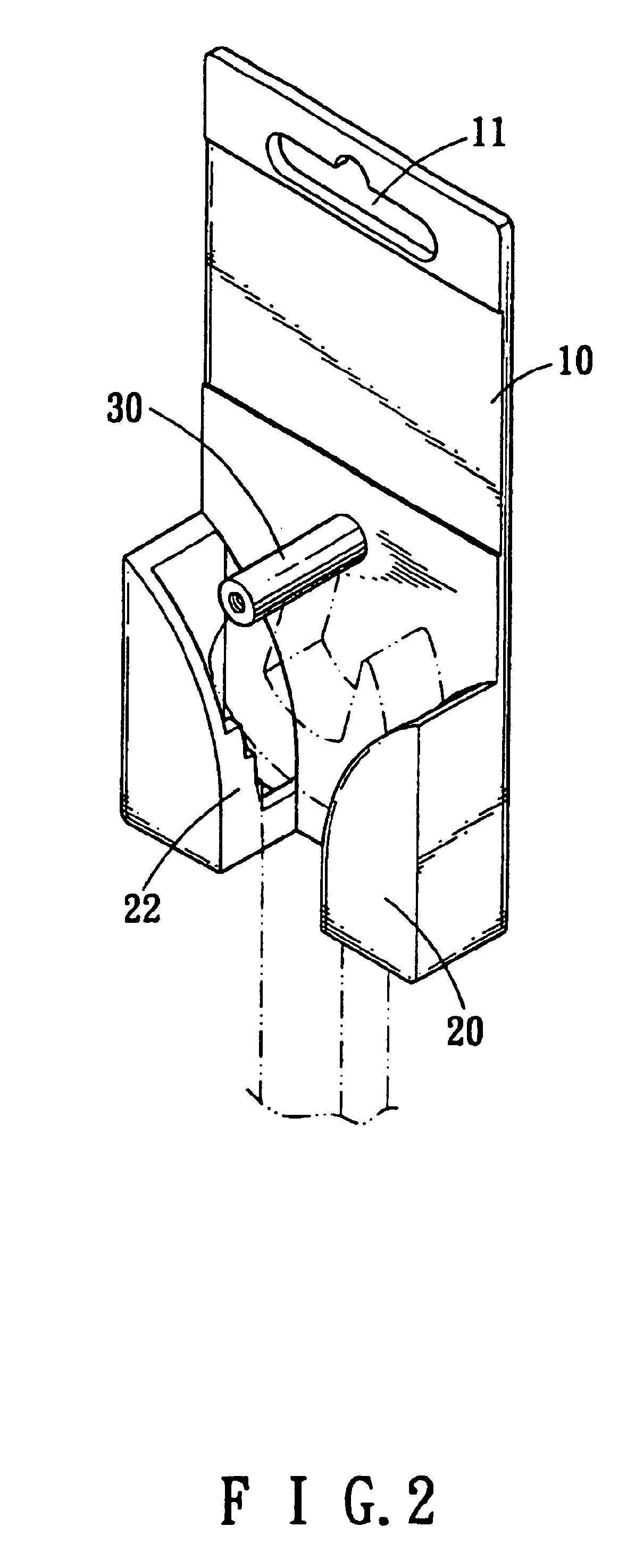

Tool display member

A tool display member includes a board and two side pieces are connected to a first side of the board. A gap is defined between the two side pieces and each side piece has an opening defined in an inside thereof. A protrusion extends from an inside of each of the opening and includes a stepped edge so that a tool can be supported and clamped between the stepped edges. A locking plate is fixed to the board and connected between the two side pieces.

Owner:LEE DANIEL

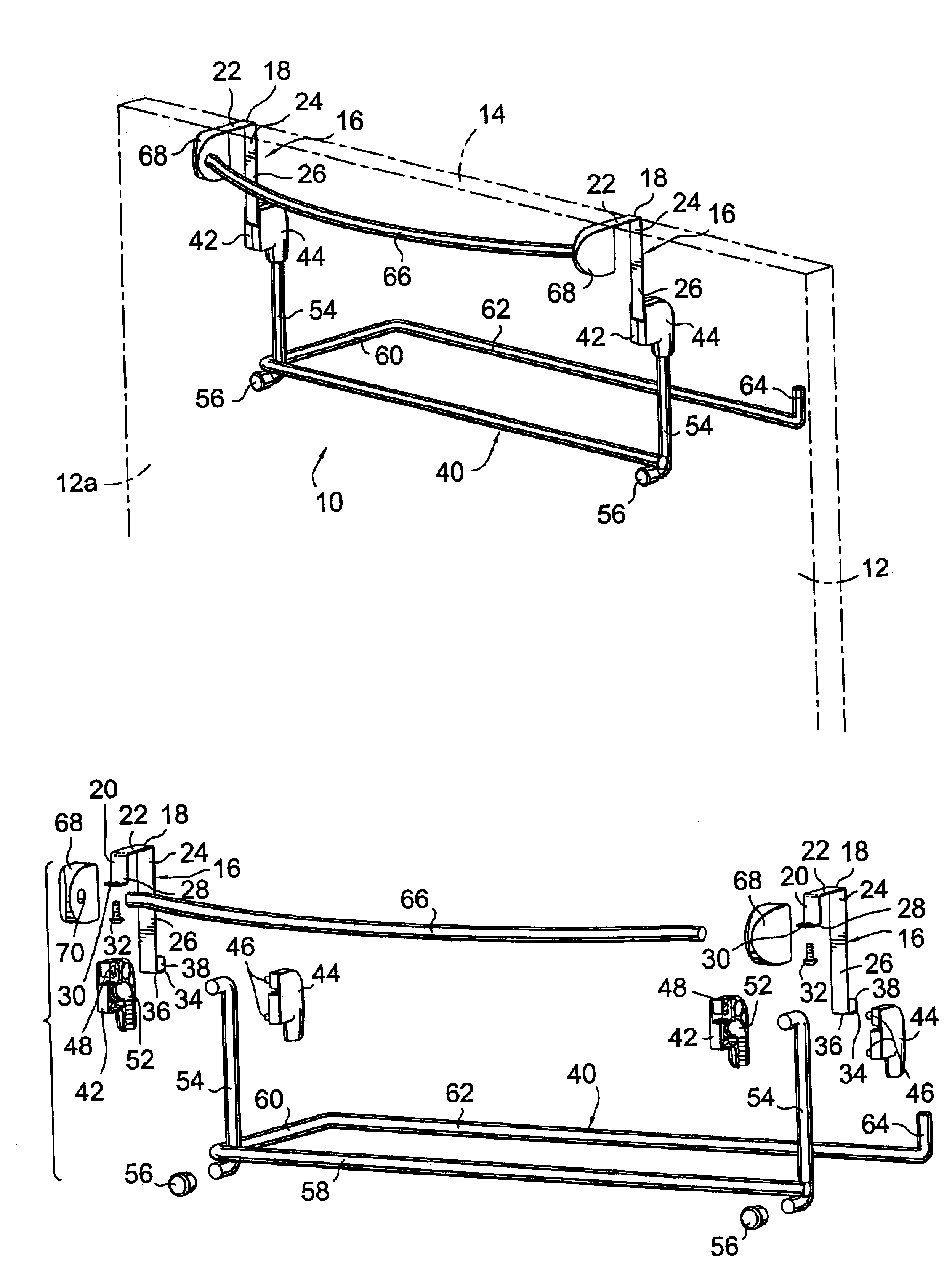

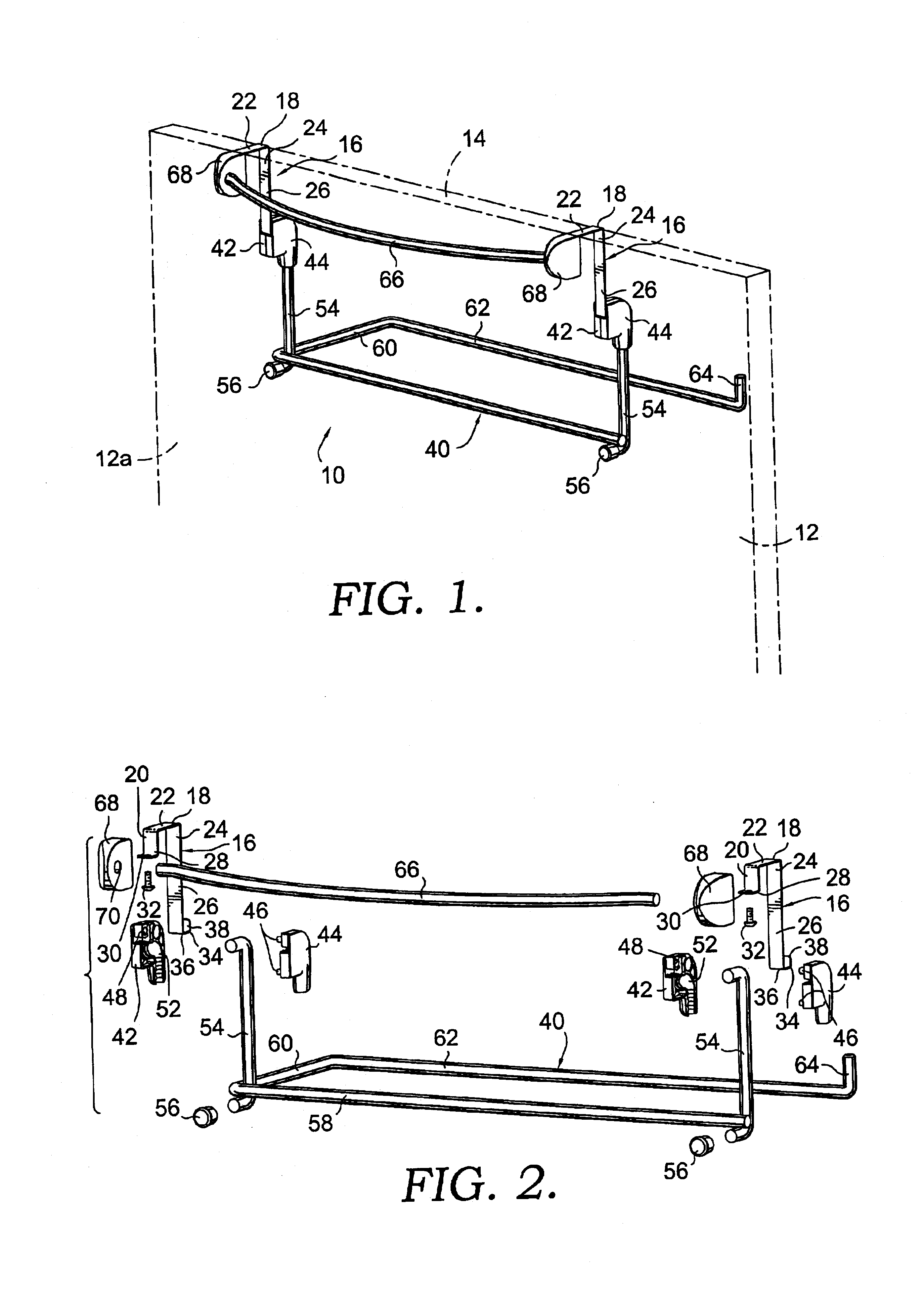

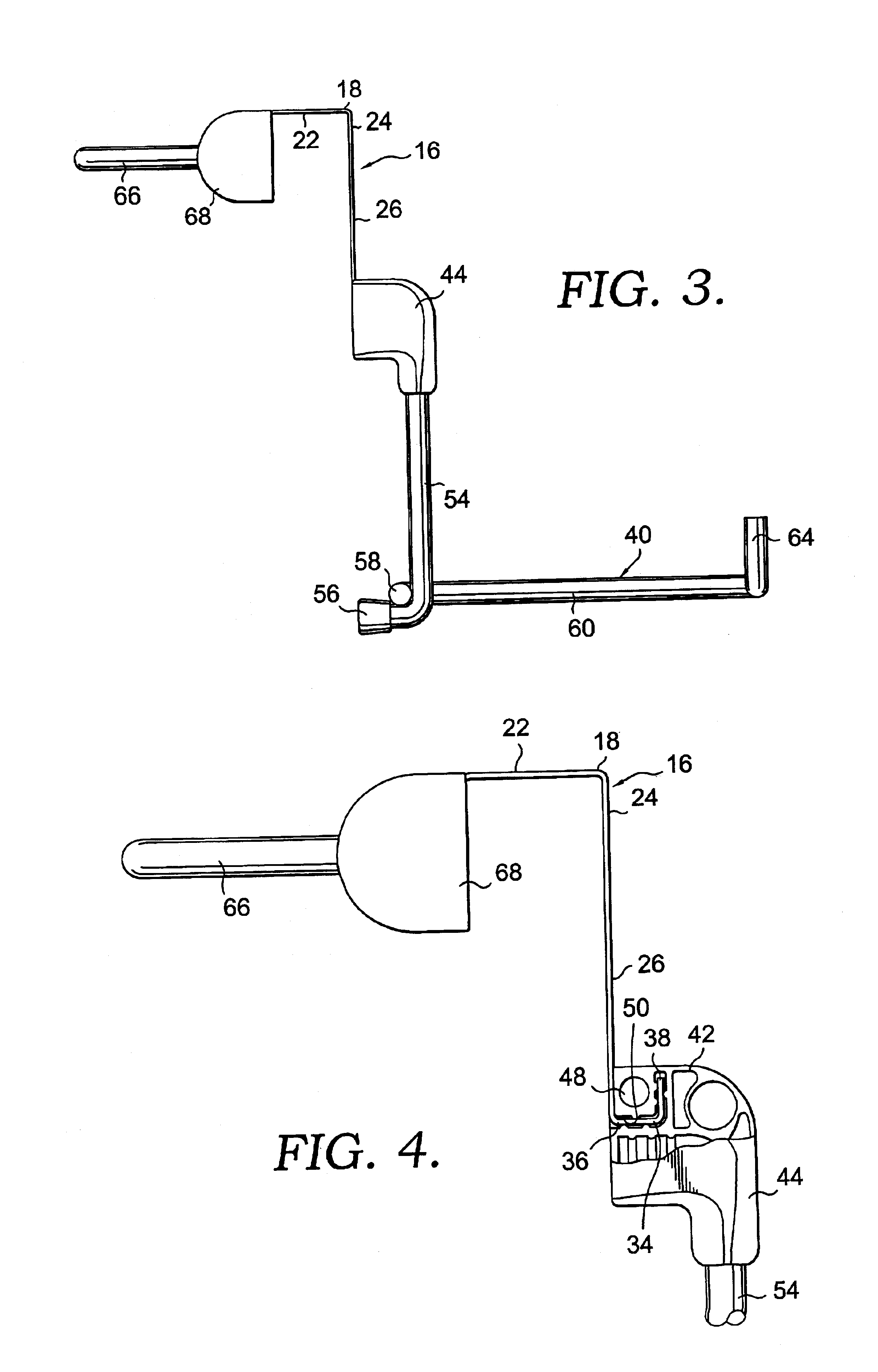

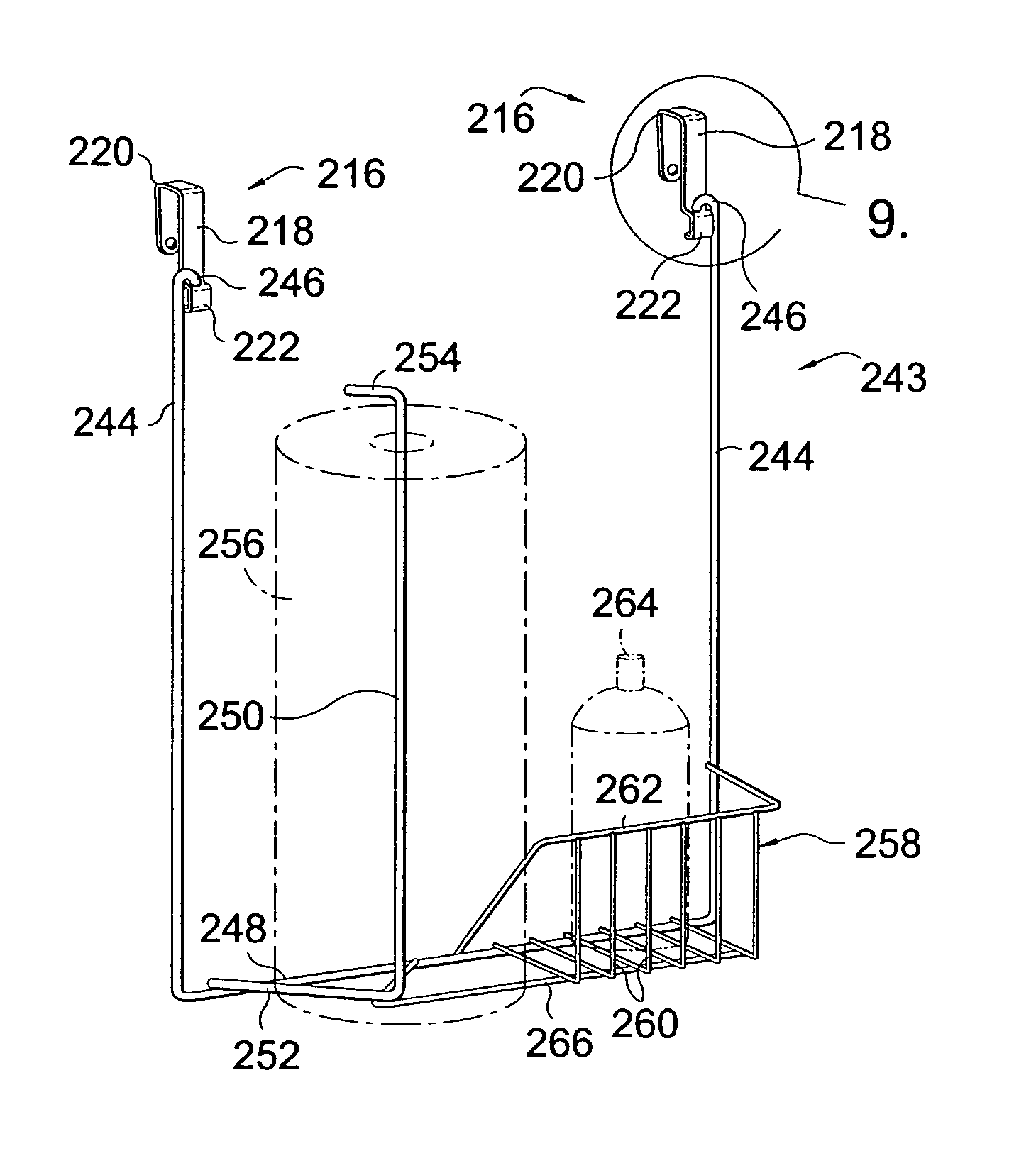

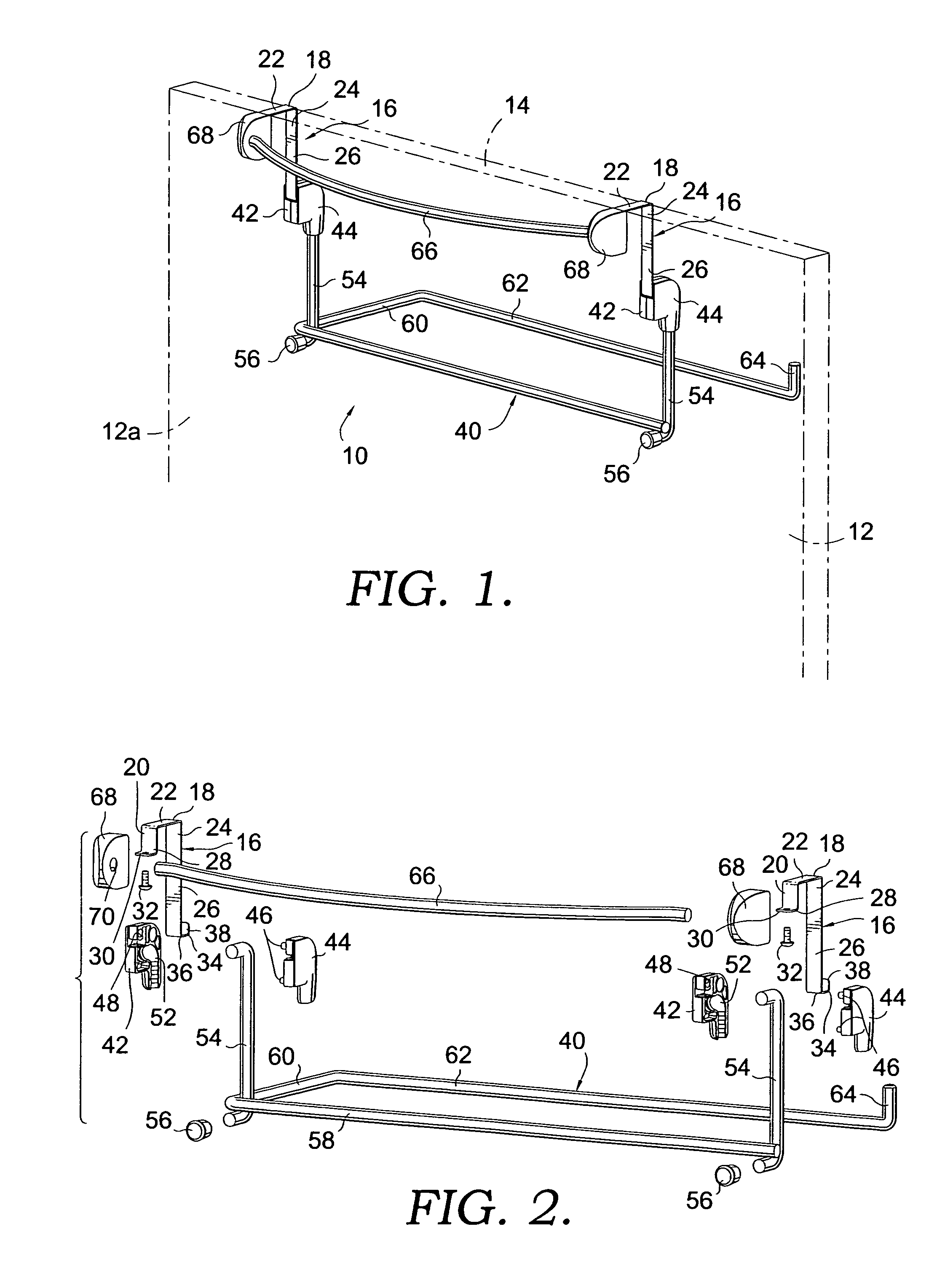

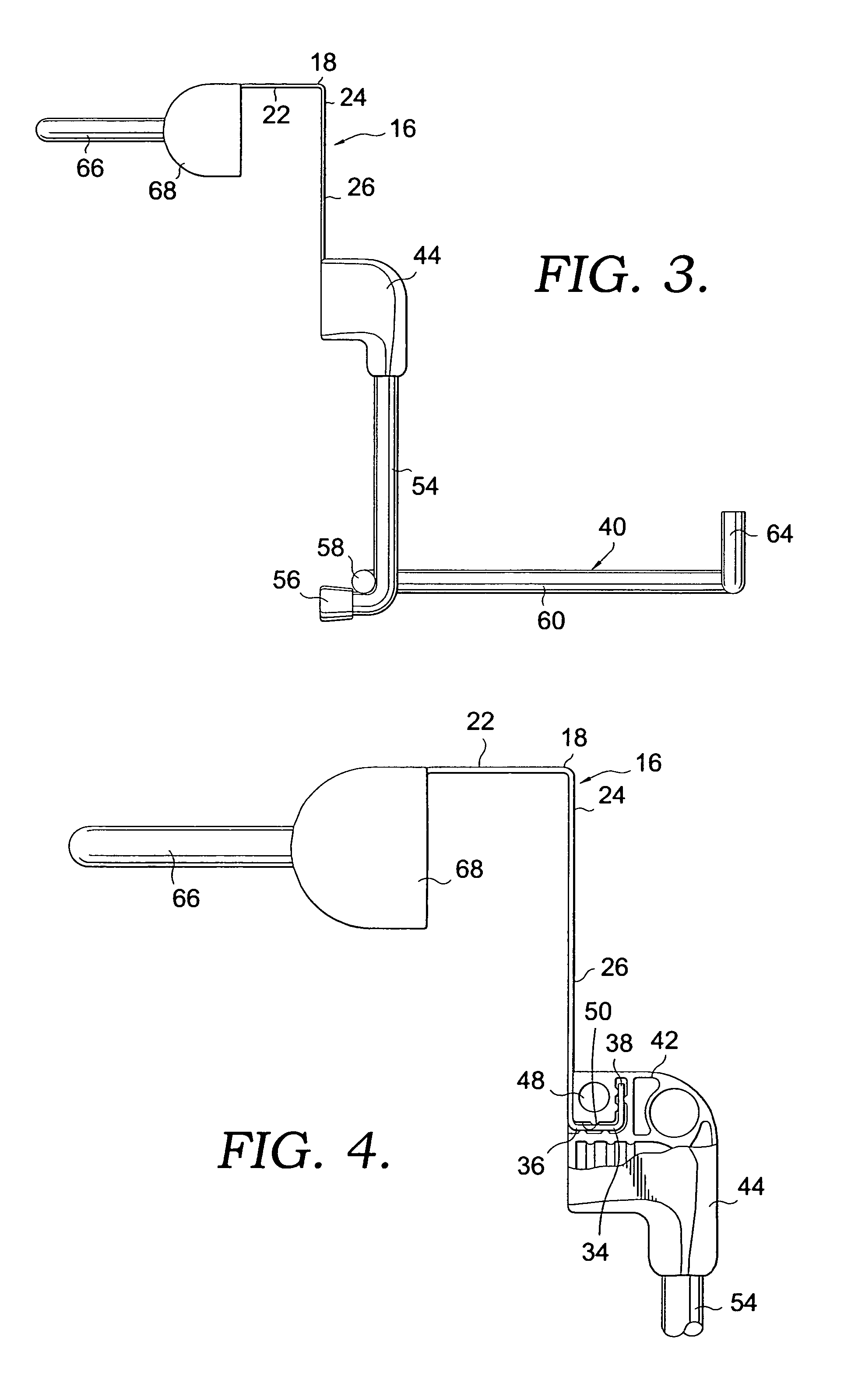

Over door storage rack for base cabinet doors

A storage rack which hangs on the upper edge of a base cabinet door. A pair of hanger brackets fit closely on the door edge and are constructed to accommodate the plain edge of a flush mounted door or the stepped edge of a recessed cabinet door. Hooks on the inside parts of the brackets receive mounting fixtures used to attach storage devices such as baskets, trays, shelves, paper towel holders, food wrap dispensers, towel hooks or towel bars. Tabs on the outside parts of the hanger brackets allow a towel bar or other device to be mounted on the outside surface of the base cabinet door.

Owner:LYNK

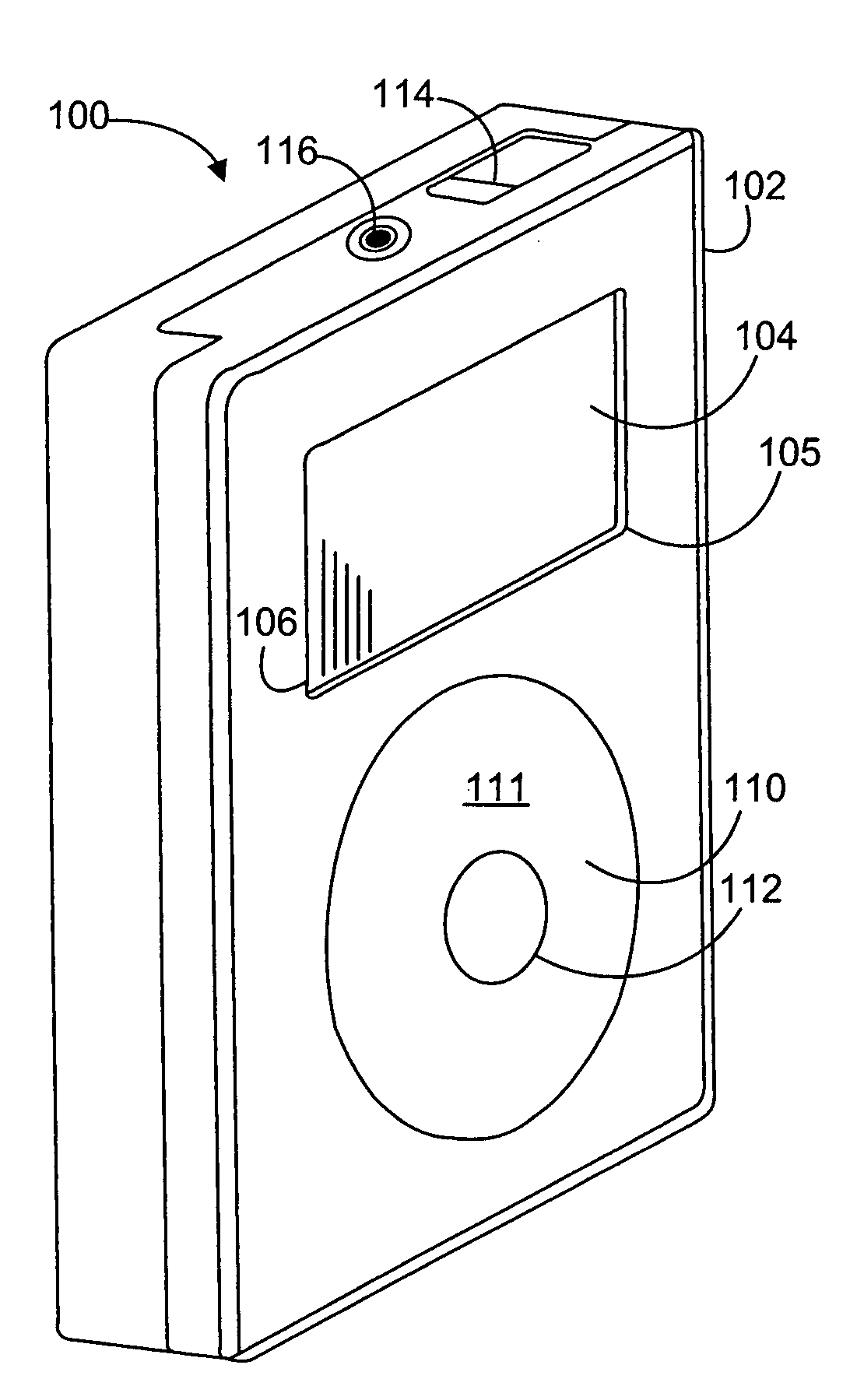

Machined window undercut

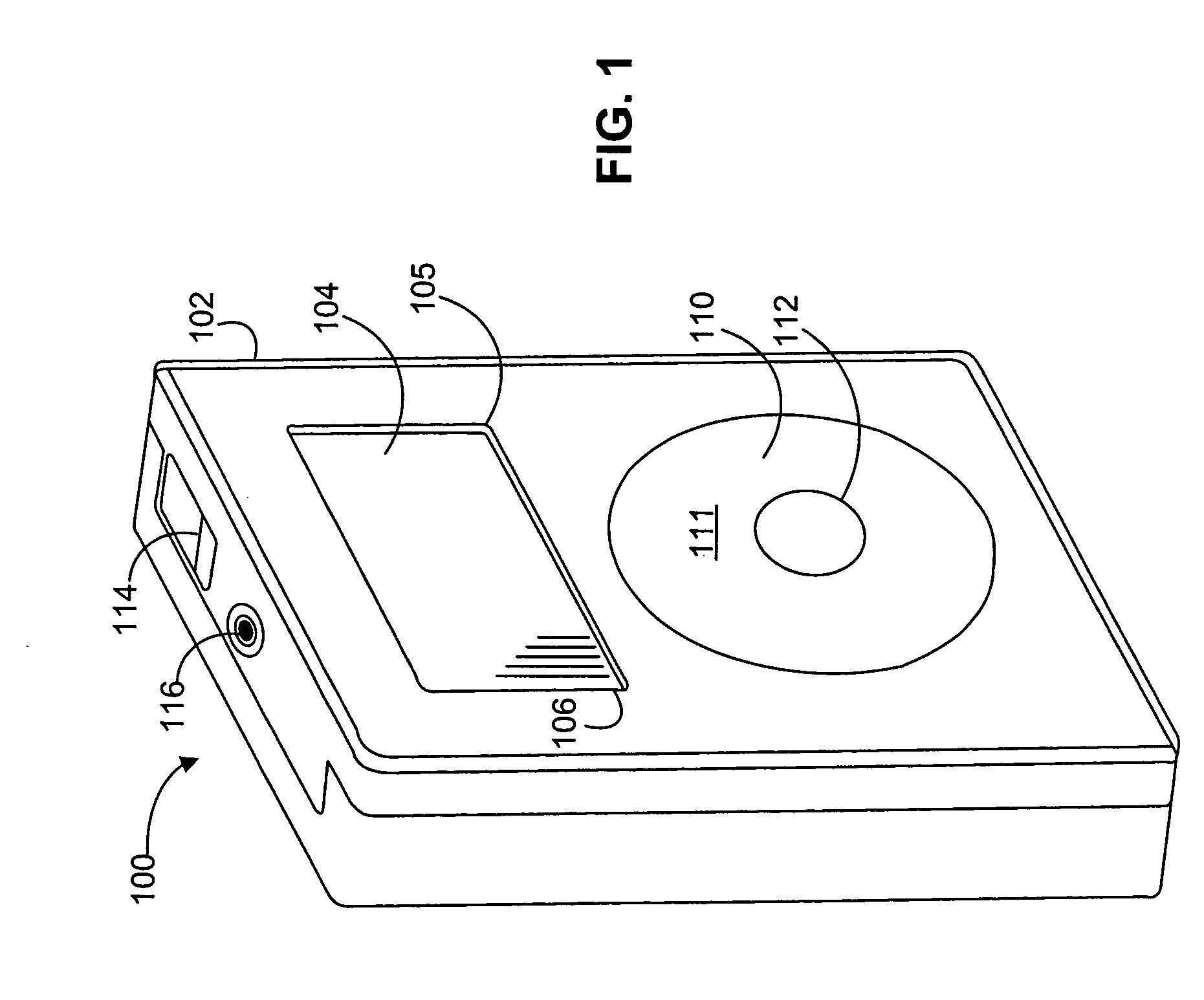

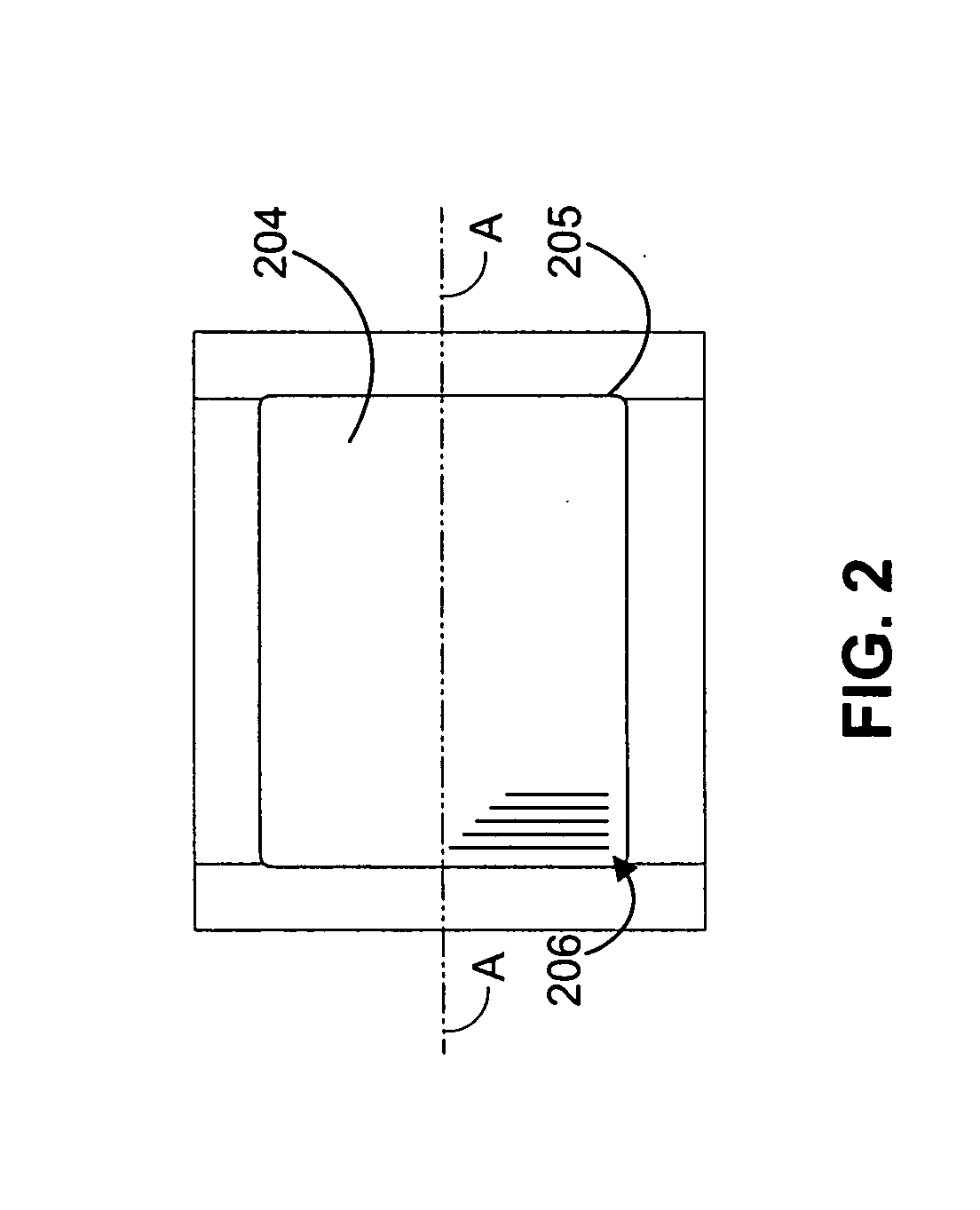

InactiveUS20080063218A1Small sizeReduce weightDigital data processing detailsCasings/cabinets/drawers detailsAdhesiveEngineering

A media player comprising a display screen is provided. The media player can include a housing having an opening and an area of reduced thickness around the opening. The media player can also include a transparent wall having a flange. Alternatively, the transparent wall may not require a flange but rather can be a flat, substantially transparent piece of material such as plexiglass or glass. The flange can be adhered to a surface of the area of reduced thickness in order to form a transparent protective cover for the display screen. In another embodiment of the invention, a method is provided. The method can include forming a transparent wall having a stepped edge for placing in an opening of a media player. The method can also include adhering an adhesive to at least one surface of the stepped edge of the transparent wall. The method can include as well using the cutting tool to cut away a portion of the underside of a housing that surrounds an opening in a media player. The method can also include adhering the transparent wall to the housing using the adhesive.

Owner:APPLE INC

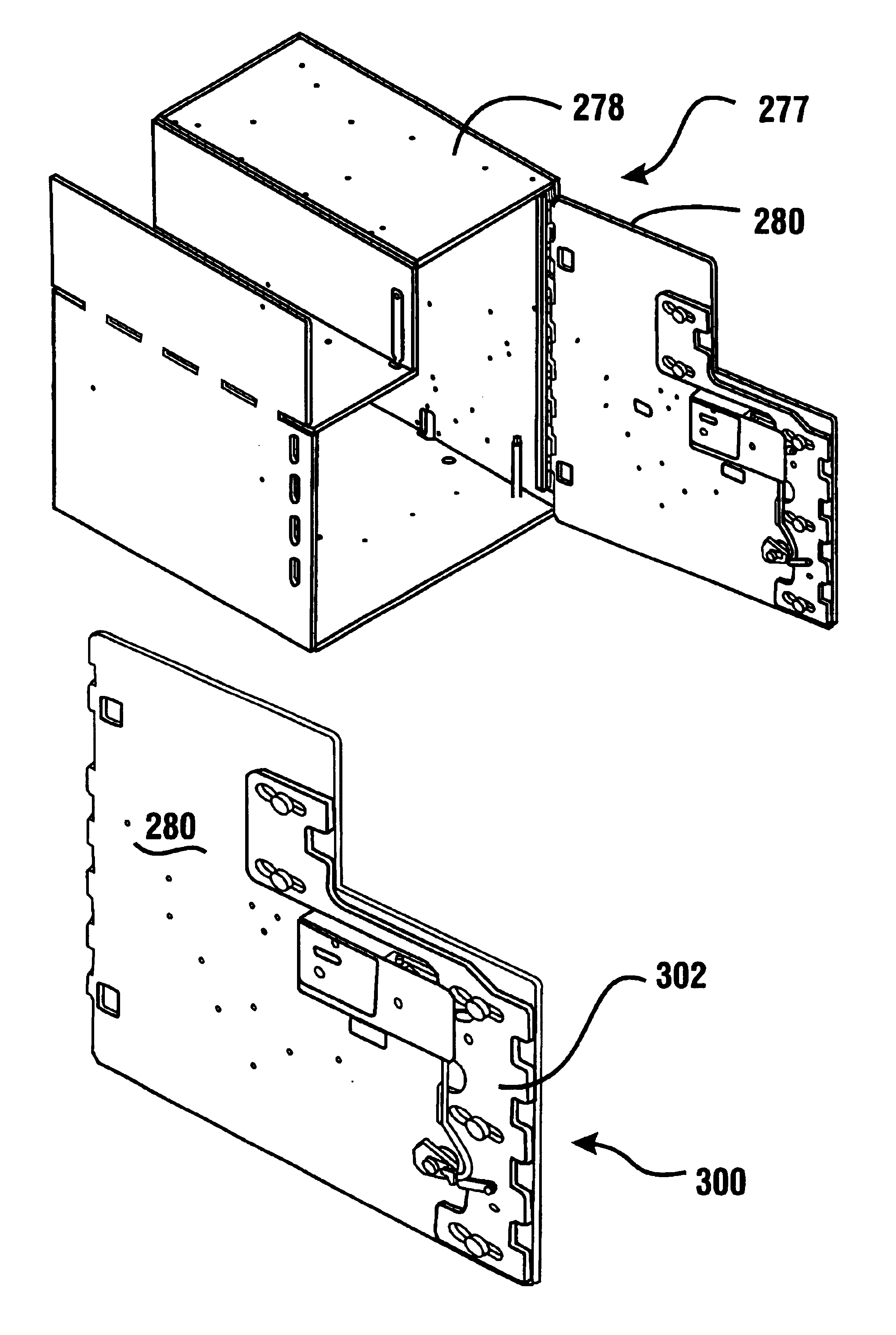

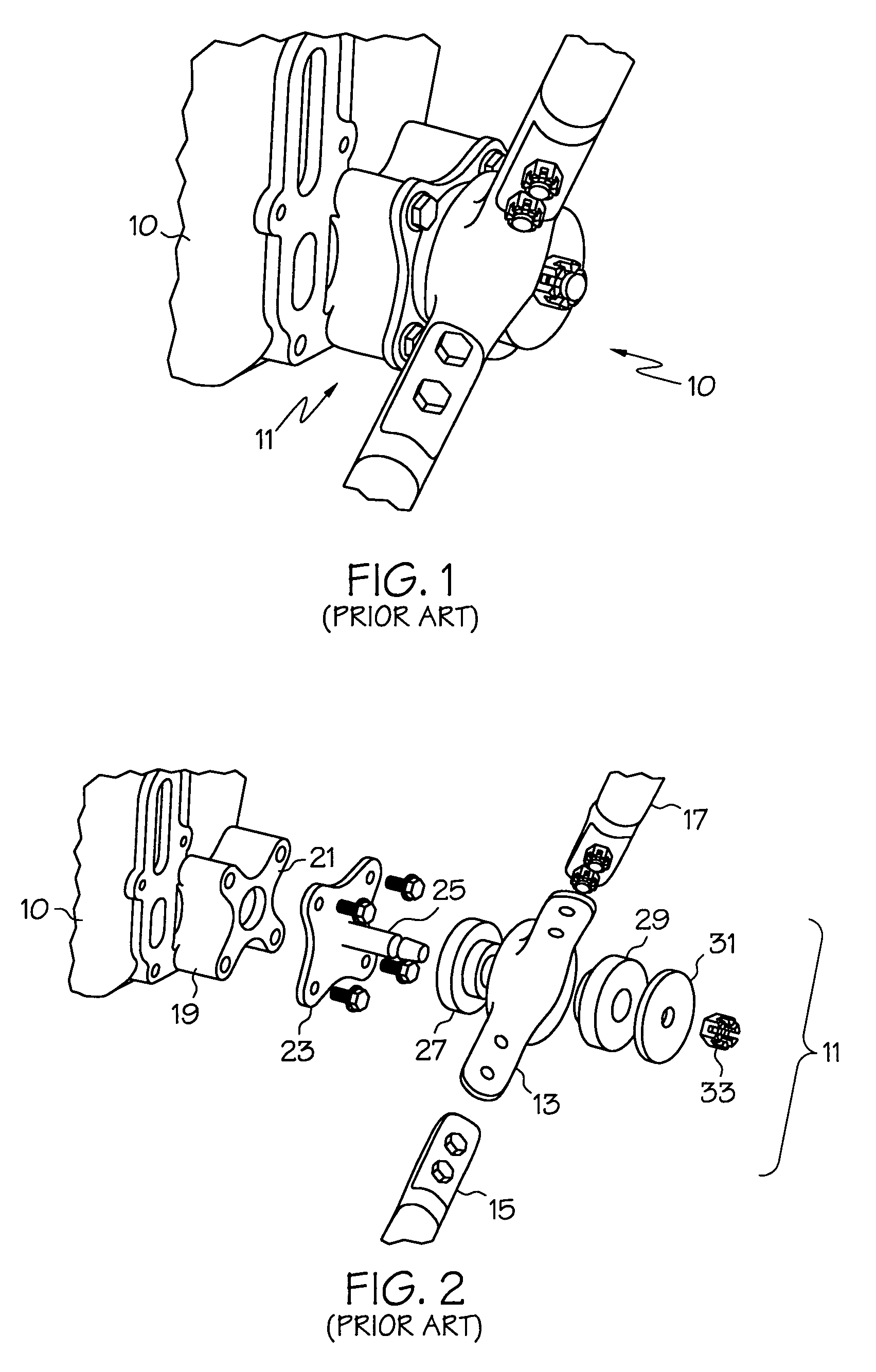

Locking bolt work apparatus for automated banking machine

ActiveUS7000830B2Economical and reliableImprove securityComplete banking machinesFinanceCamMechanical engineering

A secure enclosure for an automated banking machine includes a chest portion and a moveable door. The door has mounted thereon a locking bolt work mechanism which is operable to secure the door in a closed position. The bolt work mechanism includes a drive cam that is connected to an idler cam by a cam link. The drive cam is further connected to a locking bolt by a drive bolt link. The idler cam is connected to the locking bolt by an idler bolt link. Movement of the drive cam enables movement of the locking bolt between extended and retracted positions. The locking bolt can have a stepped edge configuration to provide stepped engagement in securing a door having a similar stepped edge configuration.

Owner:DIEBOLD SELF SERVICE SYST DIV OF DIEBOLD NIXDORF INC

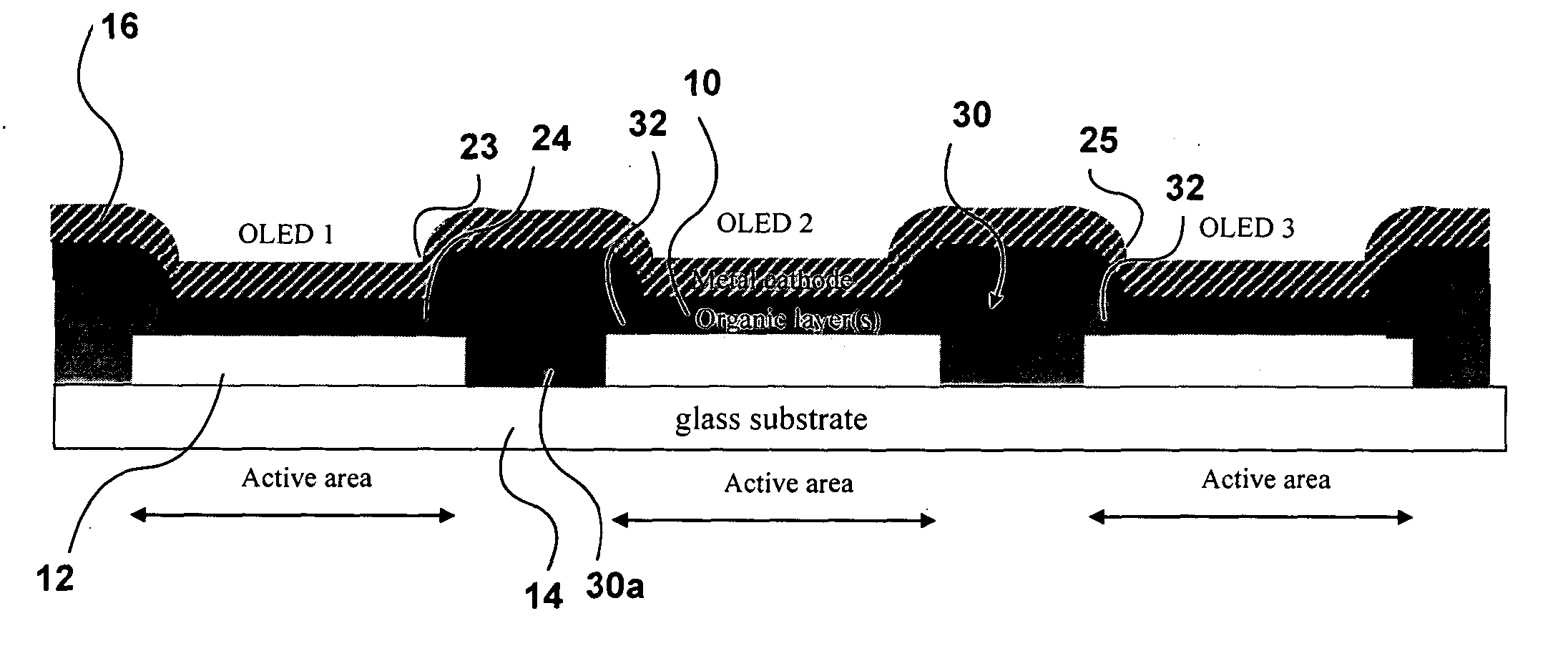

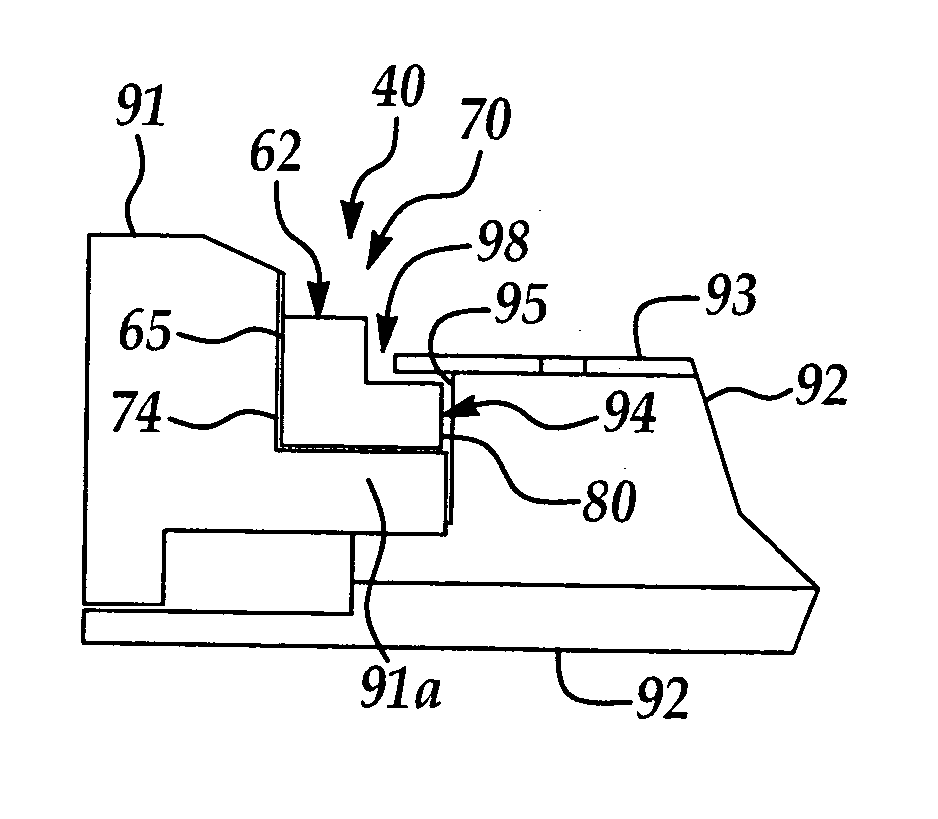

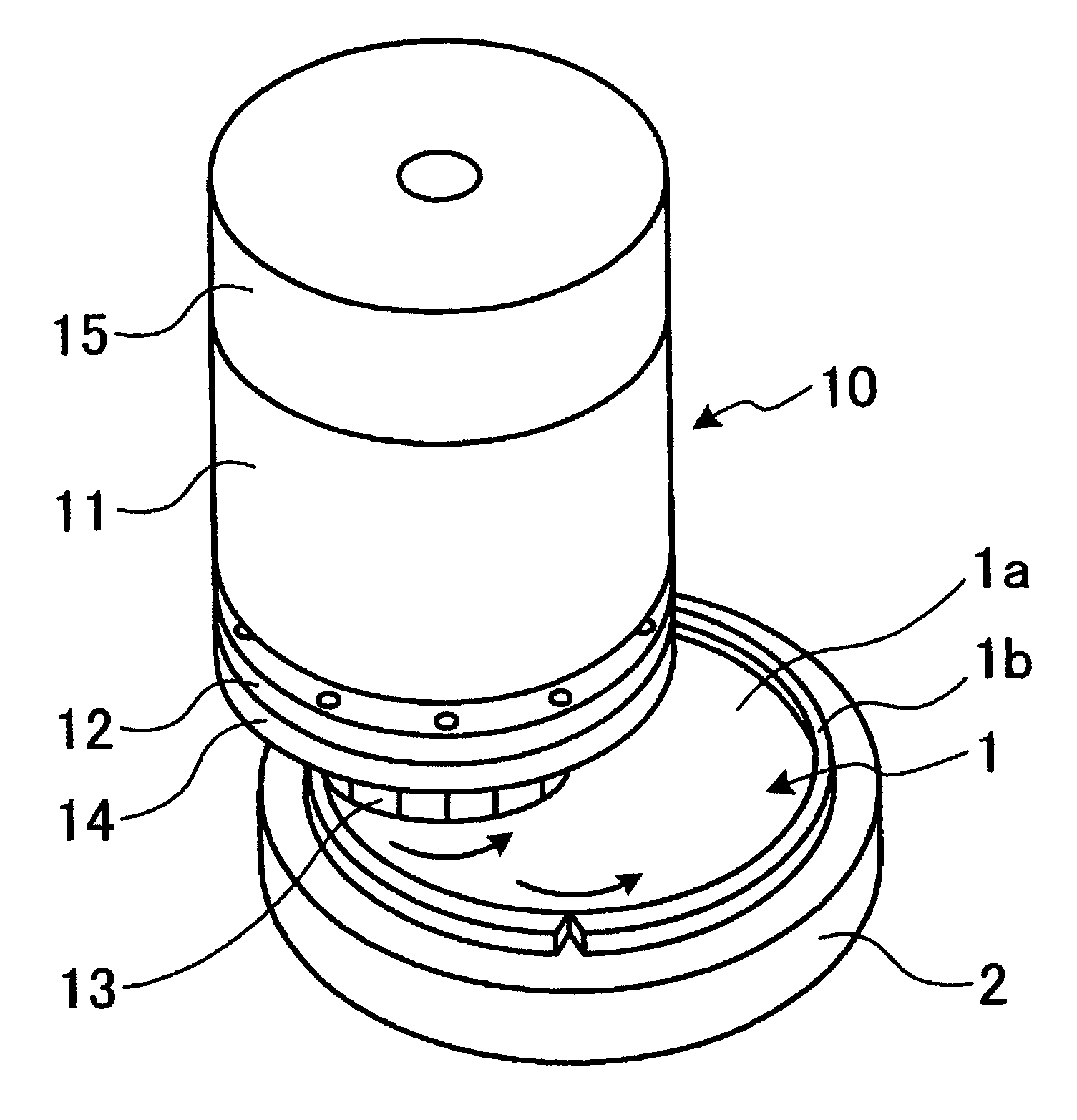

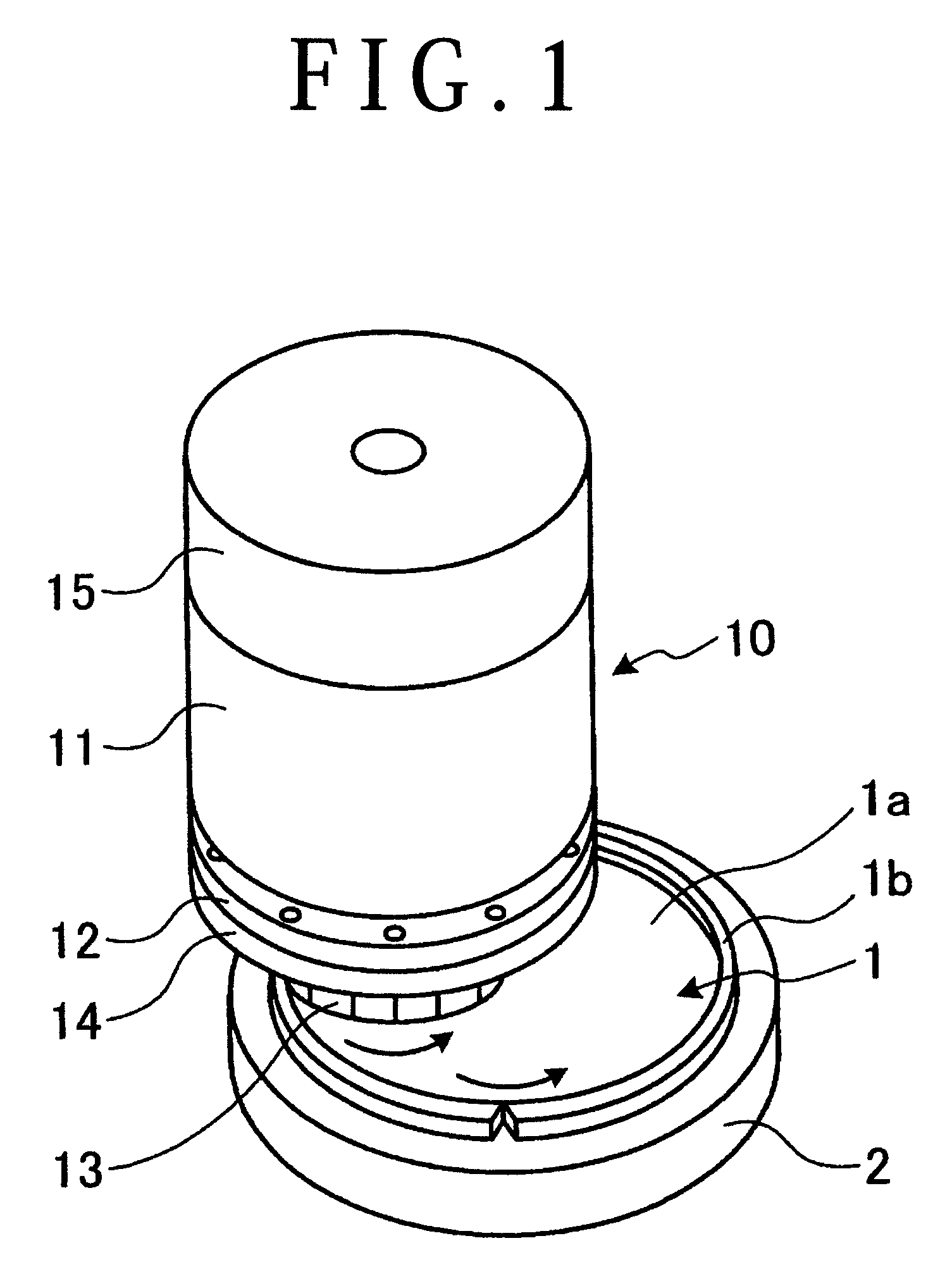

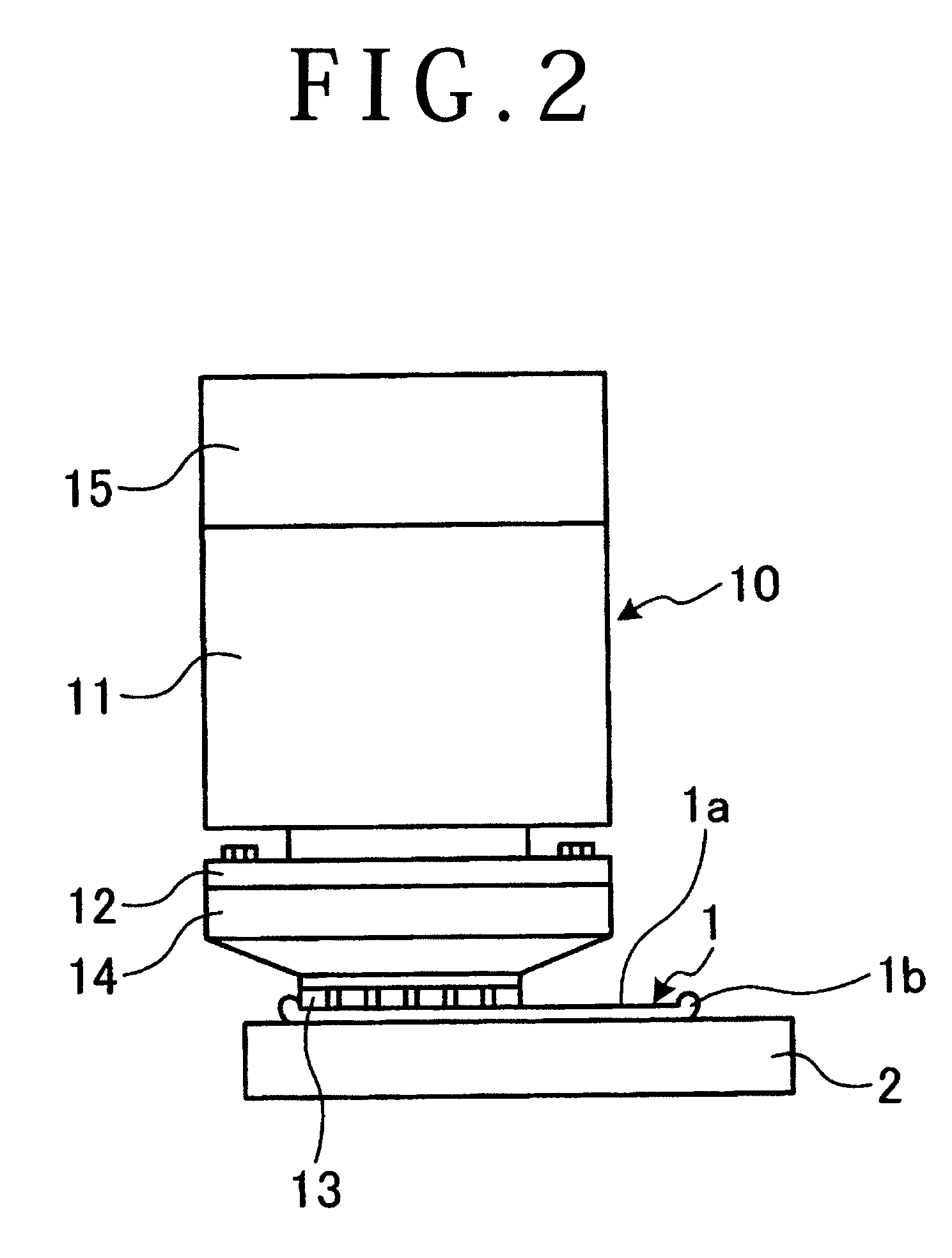

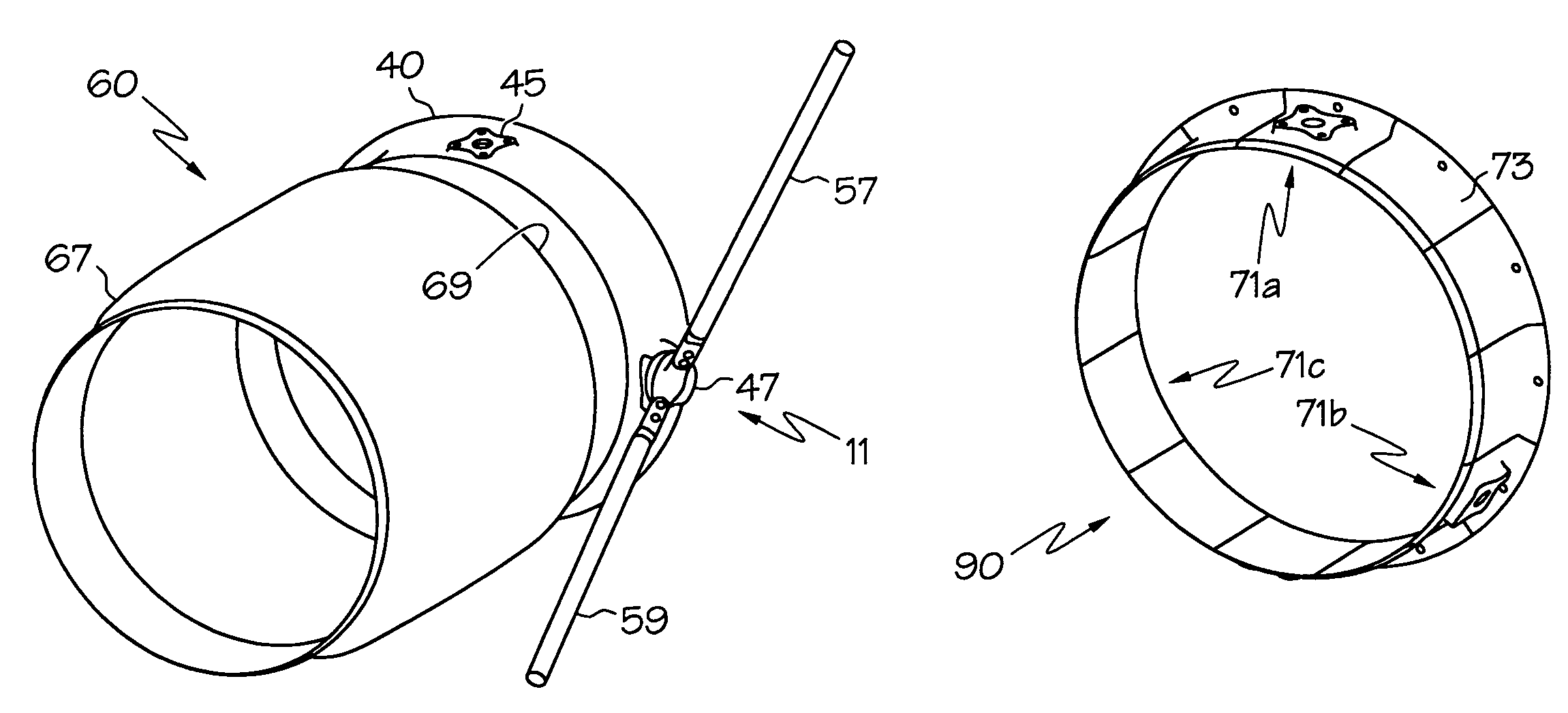

Step edge insert ring for etch chamber

InactiveUS20050155718A1Reduce flakingOperating processElectric discharge tubesDecorative surface effectsEngineeringMechanical engineering

An insert ring for a wafer support inside a processing chamber for the processing, particularly dry etching, of semiconductor wafer substrates. The insert ring has a generally step-shaped cross-sectional configuration which defines a perpendicular gap or flow space between the insert ring and the wafer support. In the etching of substrates on the wafer support, the perpendicular gap or flow space defines a perpendicular flow path for plasma species. Consequently, flow of heavy plasma species against the outer wall of the wafer support is substantially hindered or reduced to reduce accumulation of polymer material on the inner surface of the insert ring and / or the outer wall of the wafer support.

Owner:TAIWAN SEMICON MFG CO LTD

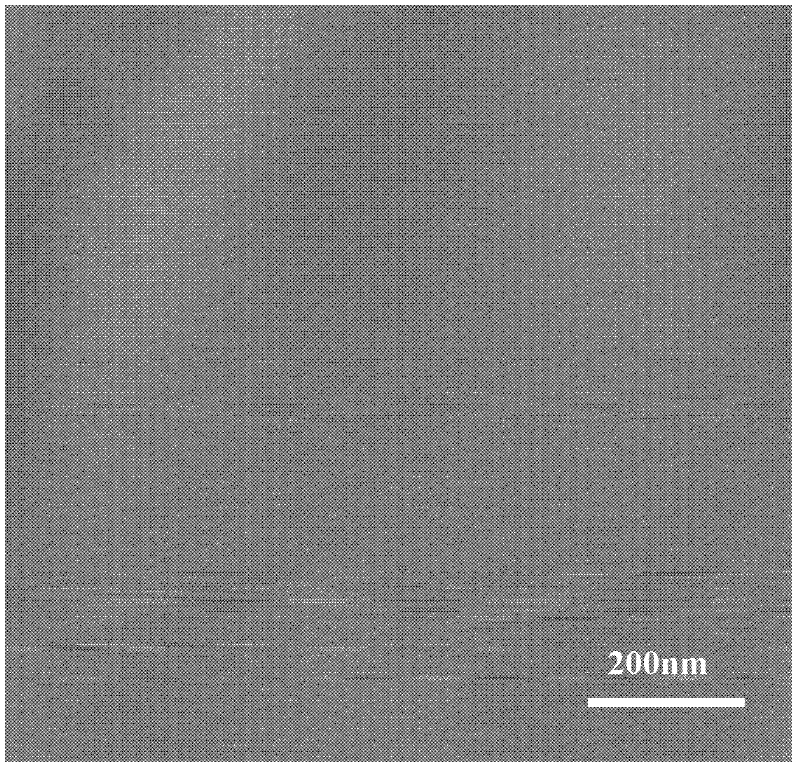

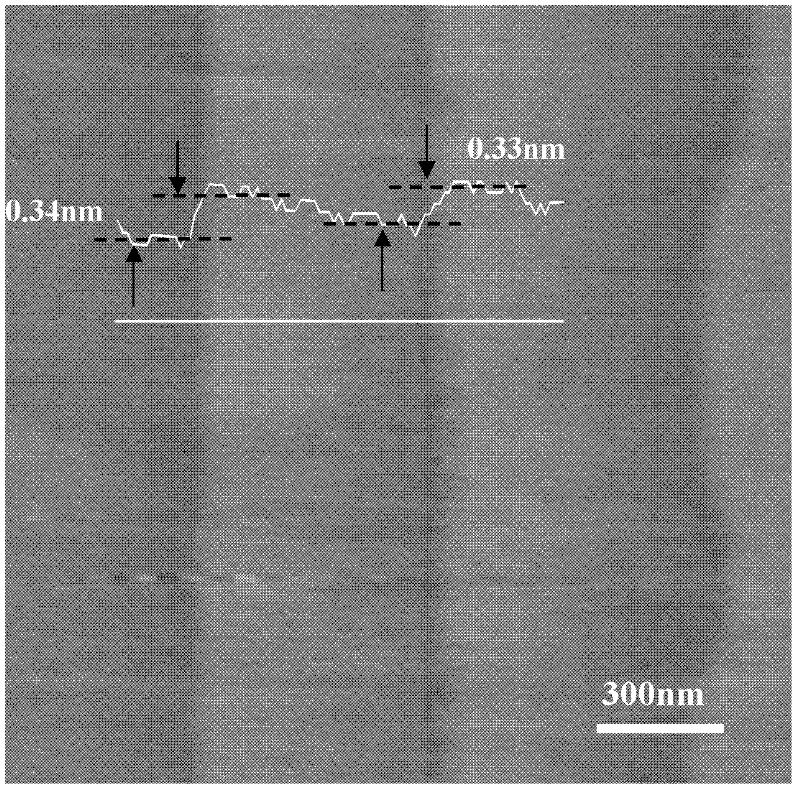

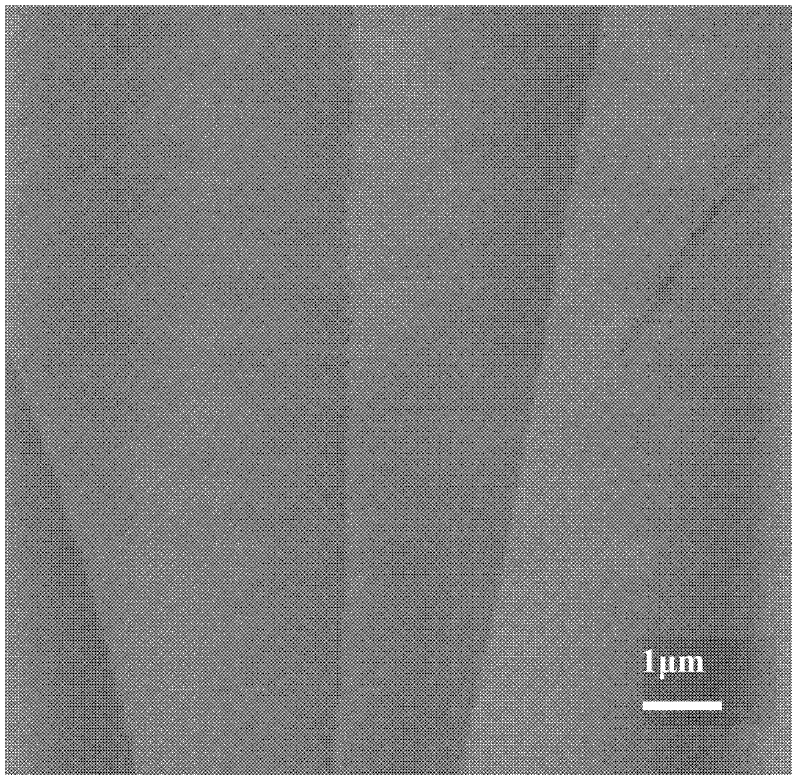

Method for preparing graphene nanoribbon on insulating substrate

ActiveCN102392225AGrow up toAvoid diversionMaterial nanotechnologyGrapheneGraphene nanoribbonsNucleation

The invention provides a method for growing a graphene nanoribbon on an insulating substrate of a cleavage surface with atomic scale smoothness, belonging to the field of low-dimensional materials and novel materials. The method comprises the following steps of: firstly, splitting the insulating substrate to obtain a cleavage surface with atomic scale smoothness, and preparing a monoatomic layer step; and secondly, directly growing the graphene nanoribbon by using the insulating substrate with the regular monoatomic layer step. With the adoption of the characteristics of different nucleation powers of the graphene on the atomic step and the smooth cleavage surface, the graphene is ensured to grow into the graphene nanoribbon with adjustable size only along step edges through regulating conditions, such as temperature, pressure intensity, active carbon atom supersaturation degree and the like. The method for preparing the graphene nanoribbon on the insulating substrate is mainly applied to the field of novel graphene photoelectric devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Over door storage rack for cabinet doors

A storage rack which hangs on the upper edge of a base cabinet door. A pair of hanger brackets fit closely on the door edge and are constructed to accommodate the plain edge of a flush mounted door or the stepped edge of a recessed cabinet door. Hooks on the inside parts of the brackets receive mounting fixtures used to attach storage devices such as baskets, trays, shelves, paper towel holders, food wrap dispensers, towel hooks or towel bars. Tabs on the outside parts of the hanger brackets allow a towel bar or other device to be mounted on the outside surface of the base cabinet door. Alternative embodiments provide a single bracket which can be applied to both flush and recessed doors and which accommodates different types of storage devices that may be hooked or otherwise connected to the brackets. The connections between the brackets and storage devices can be made in various ways, including hooks fitting through openings and threaded connections.

Owner:LYNK

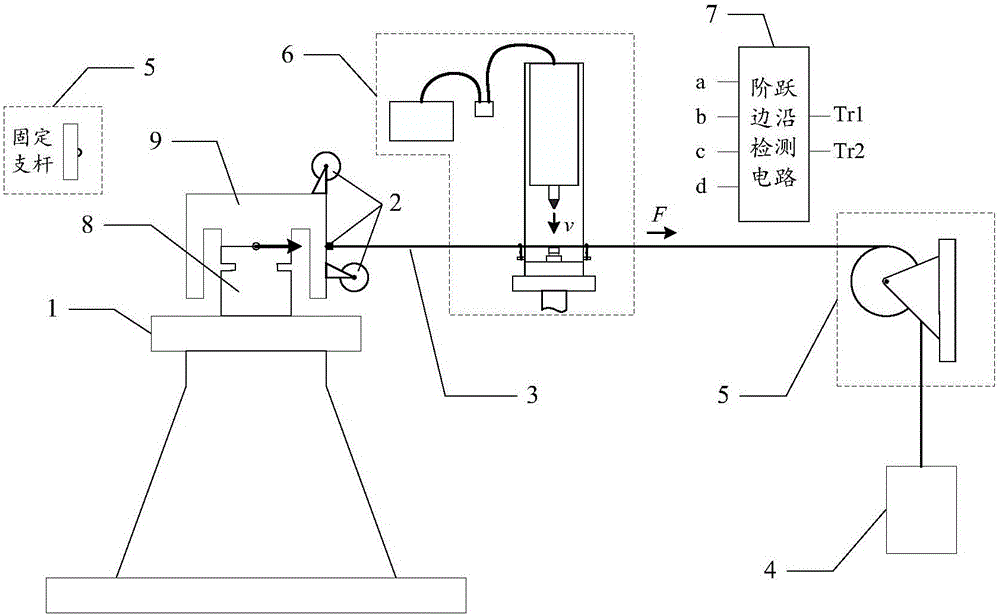

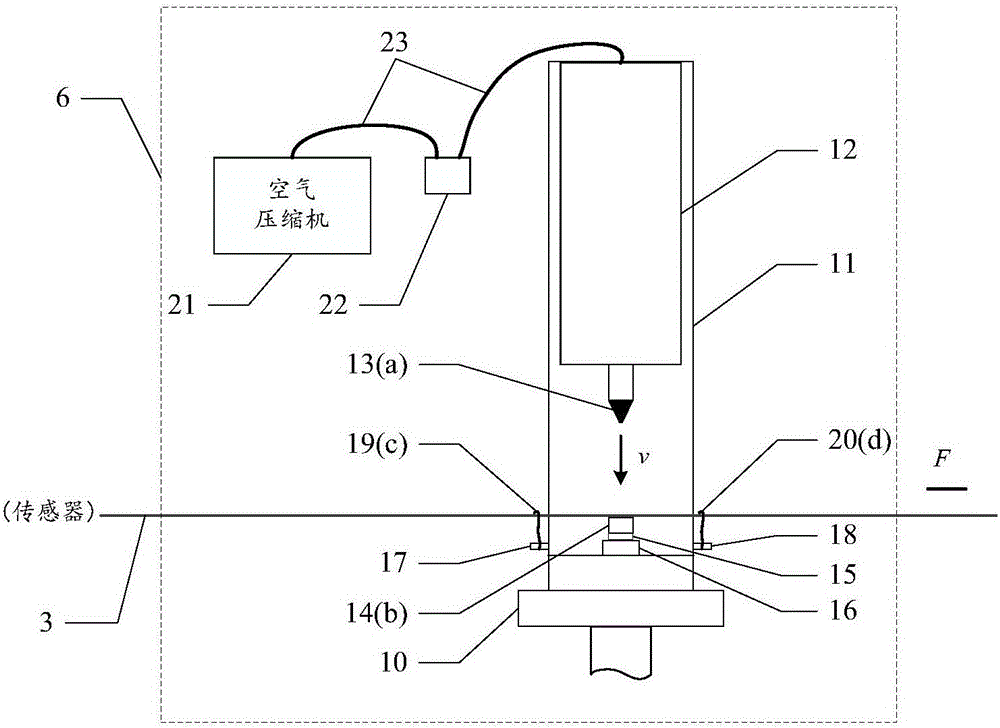

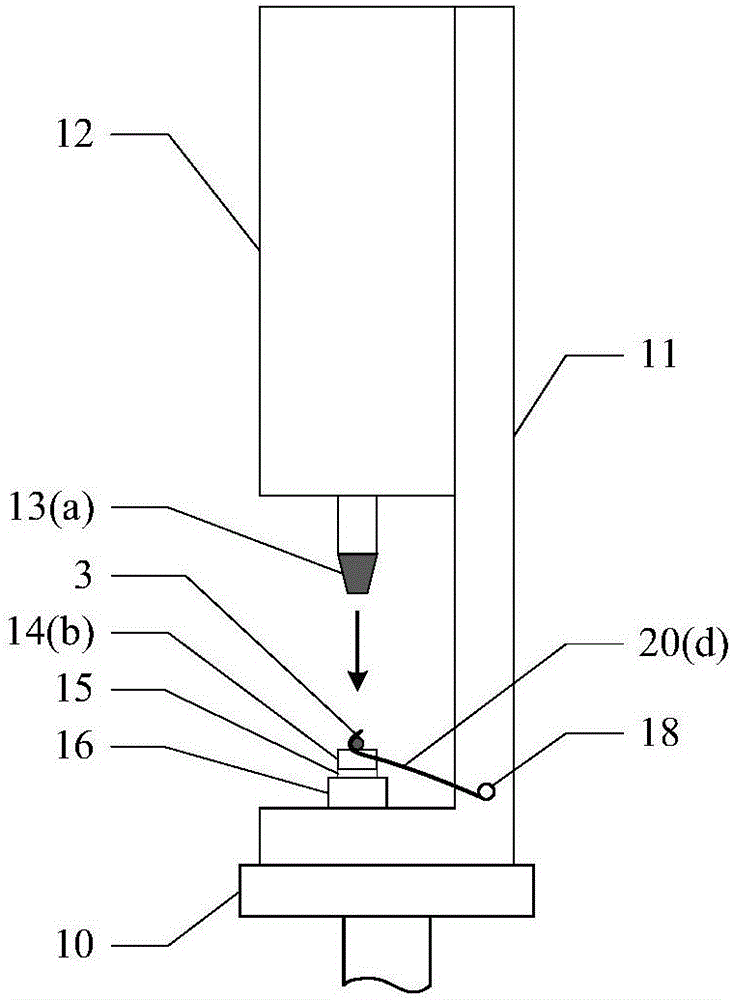

Step force generating device for dynamic calibration of force sensor

ActiveCN106706207AAchieving Negative Step ForceAchieving Negative Step TorqueApparatus for force/torque/work measurementForce/torque/work measurement apparatus calibration/testingContact timeEngineering

The invention provides a step force generating device for dynamic calibration of a force sensor, wherein the step force generating device is suitable for dynamic calibration experiment of a force sensor having an irregular tool structure of a load terminal or needing to carry out loading of a plurality of directive forces / torques. The step force generating device comprises a calibration table, a directional loading assembly, a steel force transmission wire, a force source, a pulley suspension system, an impact shearing device and a step edge detection circuit. A stable load is applied to a force sensor by using the directional loading assembly based on steel wire force transmission; and the steel force transmission wire is impacted and sheared suddenly to carry out step unloading on the force sensor to realize negative step excitation on the force sensor. The impact shearing device uses a high-speed and large-impact-force impact cylinder as an impact execution mechanism to extend a dynamic calibration frequency and a load range of the force sensor. With cooperation of an impact gasket block, the disturbance during the impact shearing process can be suppressed, so that the dynamic calibration precision can be improved. The step edge detection circuit obtains step edge time based on starting steel force transmission wire contact time by a detection impact head and a steel force transmission wire shearing time.

Owner:HEFEI UNIV OF TECH

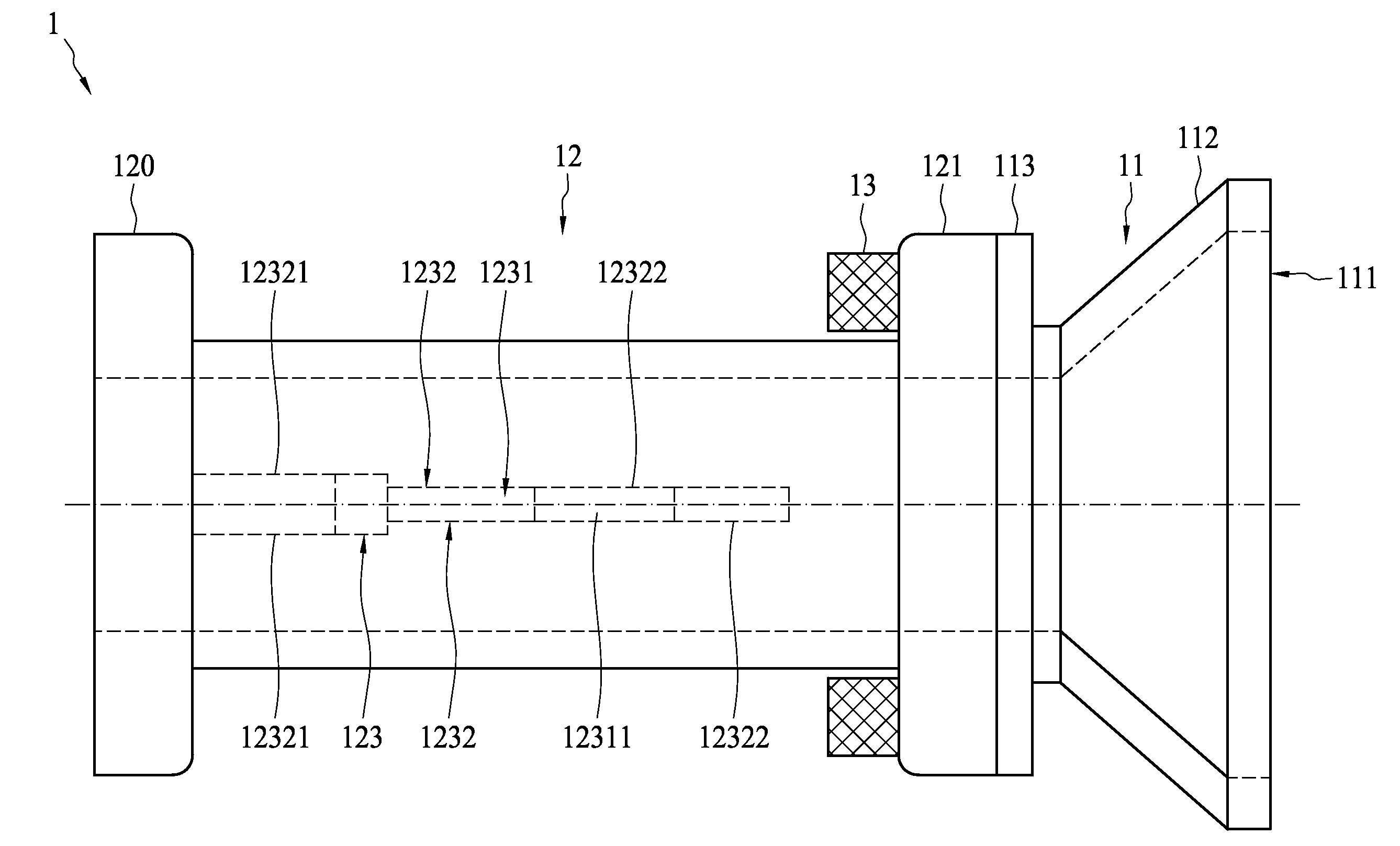

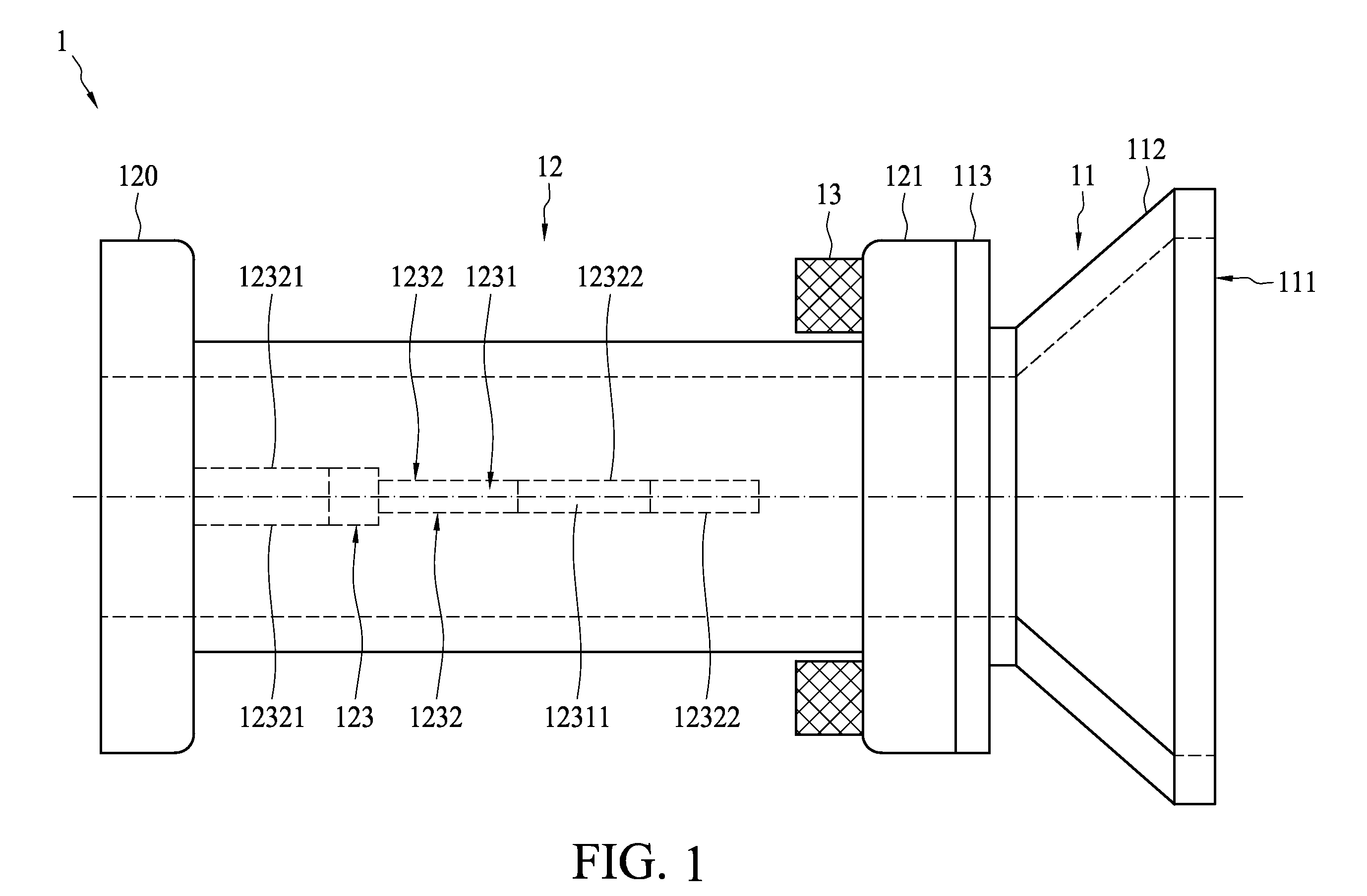

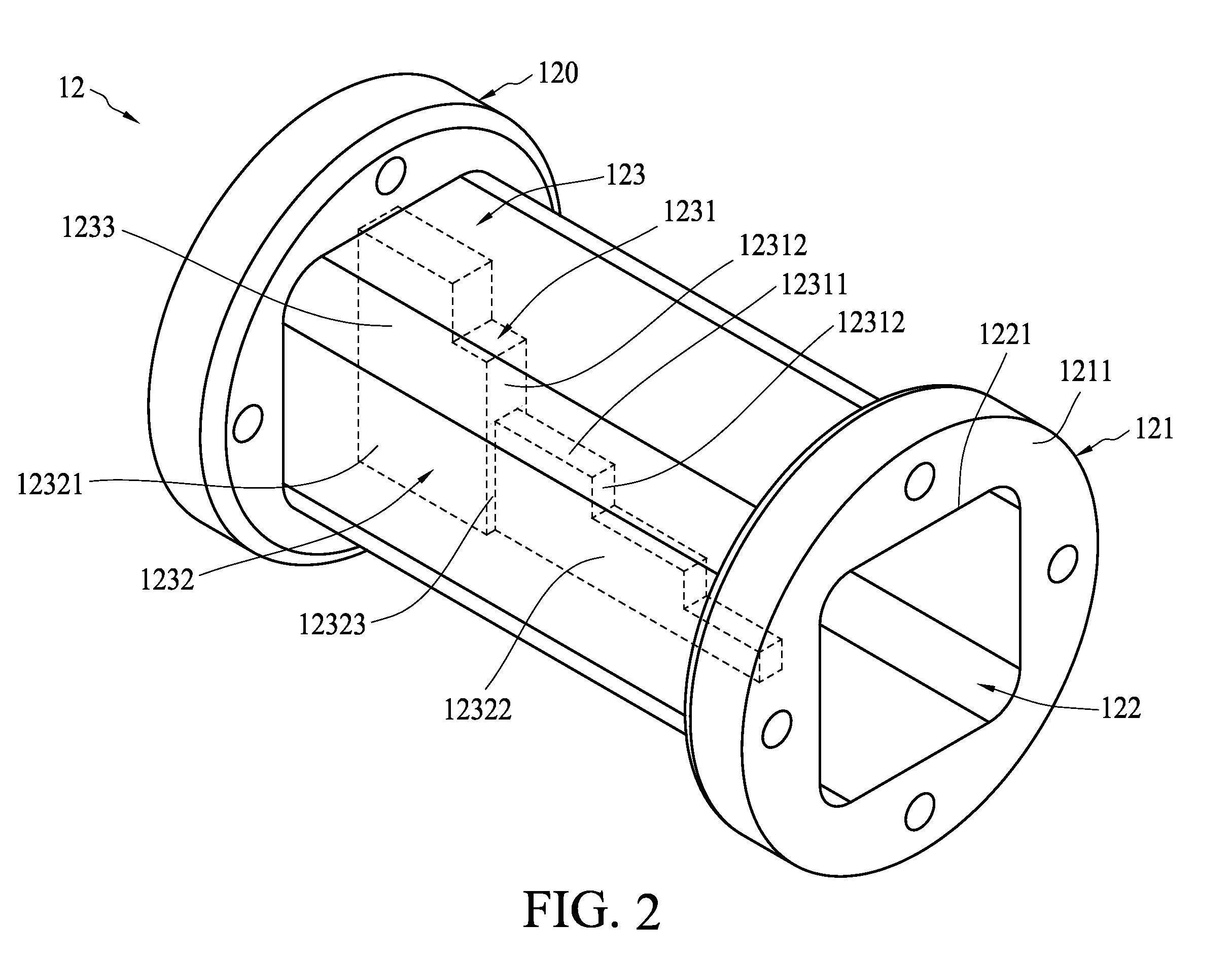

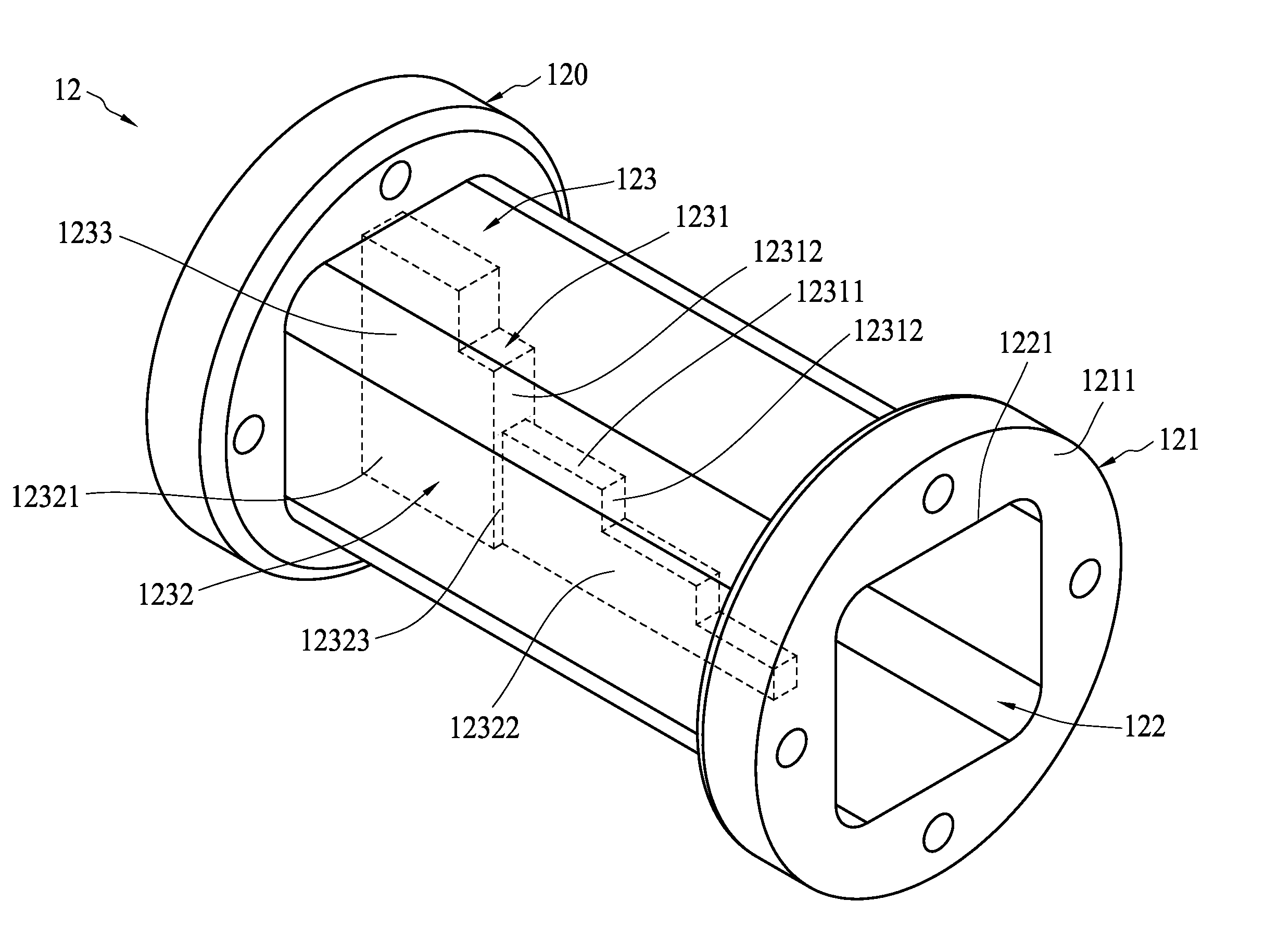

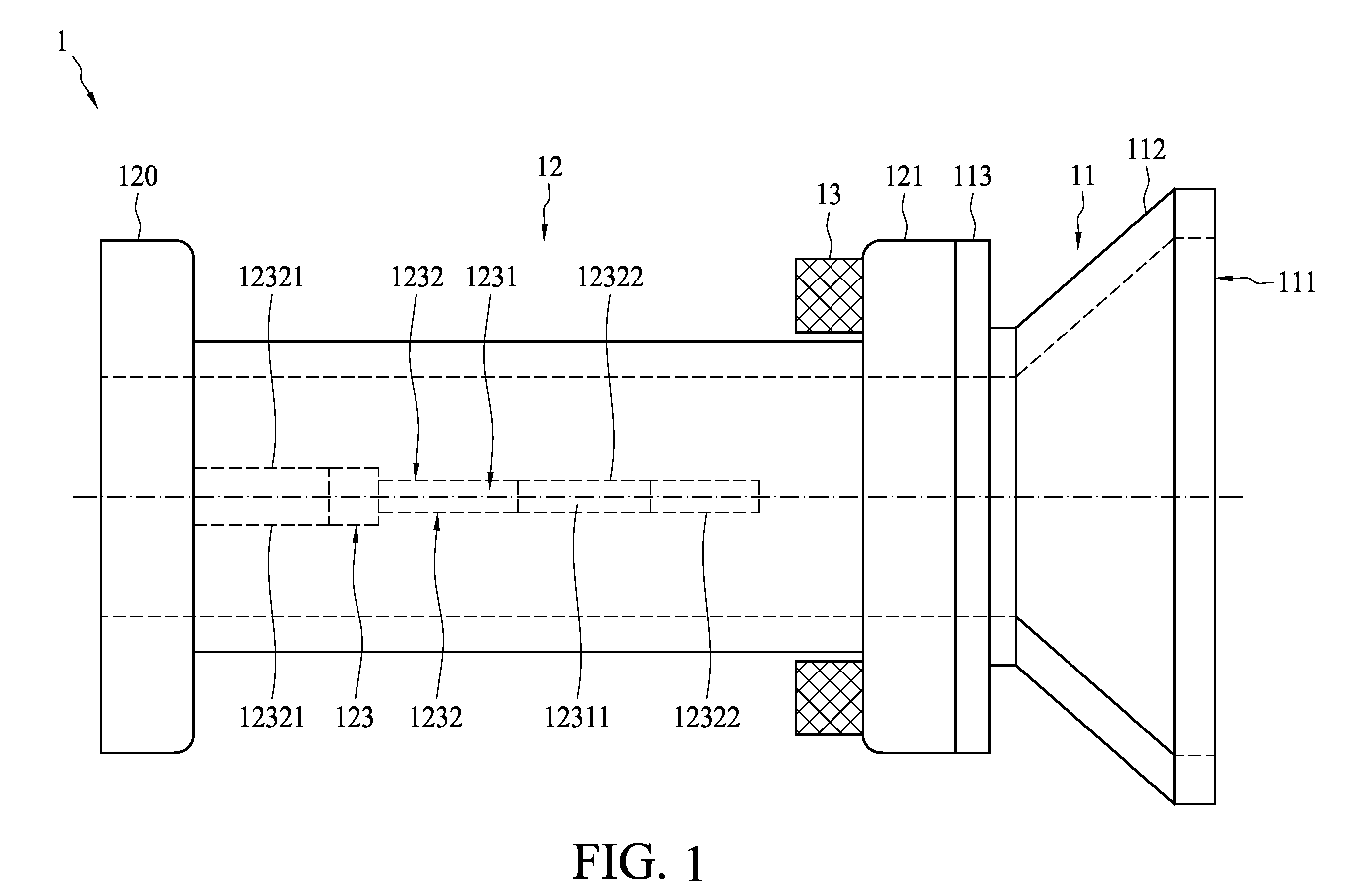

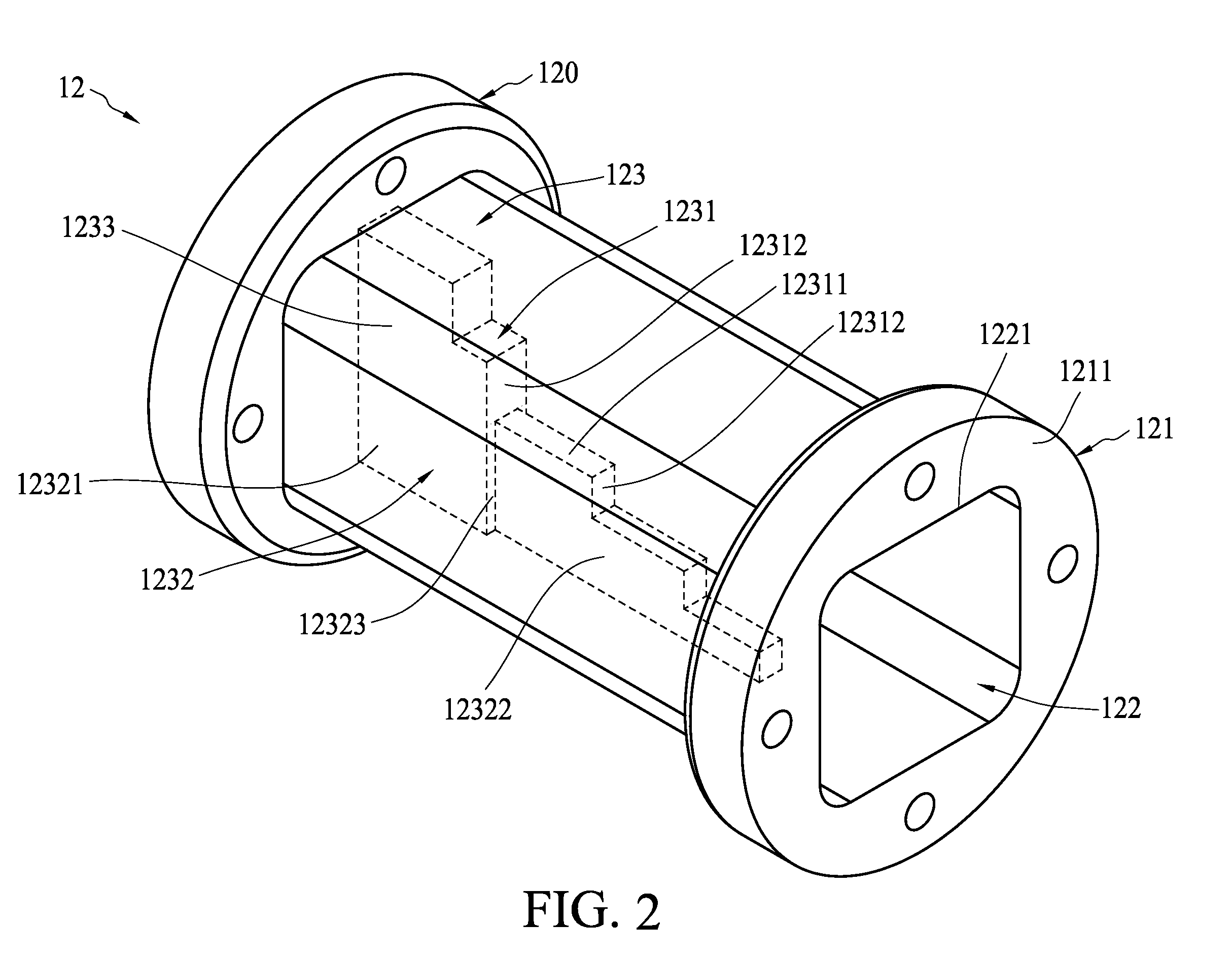

Polarizer and Waveguide Antenna Apparatus Using the Same

A polarizer includes a waveguide channel having a substantially square cross section and a septum disposed within the waveguide channel. The septum includes a stepped edge and two opposite stepped surfaces. The stepped surfaces are sectionally recessed toward each other along the direction pointing toward the interior of the waveguide channel, wherein the number of the steps of the stepped surface is greater than two, but smaller than the number of the steps of the stepped edge. In one embodiment, the square cross section may include a plurality of rounded corners and a plurality of edges extending correspondingly between the rounded corners, wherein the ratio of the radius of the rounded corner to the distance between two opposite edges is in a range of from 0.05 to 0.3.

Owner:MICROELECTRONICS TECH INC

Wafer processing method

ActiveUS20090186563A1Without impairing productivityAvoid it happening againSemiconductor/solid-state device manufacturingLapping machinesEngineeringStep edges

In a wafer processing method, rough grinding using a first grinding stone is divided into first and second steps. In the first step, a wafer is processed into a concave shape at a first transfer rate with a reinforcing rib area slightly left. Thereafter, as primary rough grinding in the second step, the grinding stone is positioned slightly on the inner circumferential side and the wafer is further processed into the concave portion at a second transfer rate faster than the first transfer rate. Since the first transfer rate is suppressed to a rate not to cause a burst chipping, a burst chipping resulting from the second step fast in the processing rate to ensure productivity will occur at the stepped edge portion on the inside of the reinforcing rib area surface. Thus, the flatness of the reinforcing rib area can be ensured.

Owner:DISCO CORP

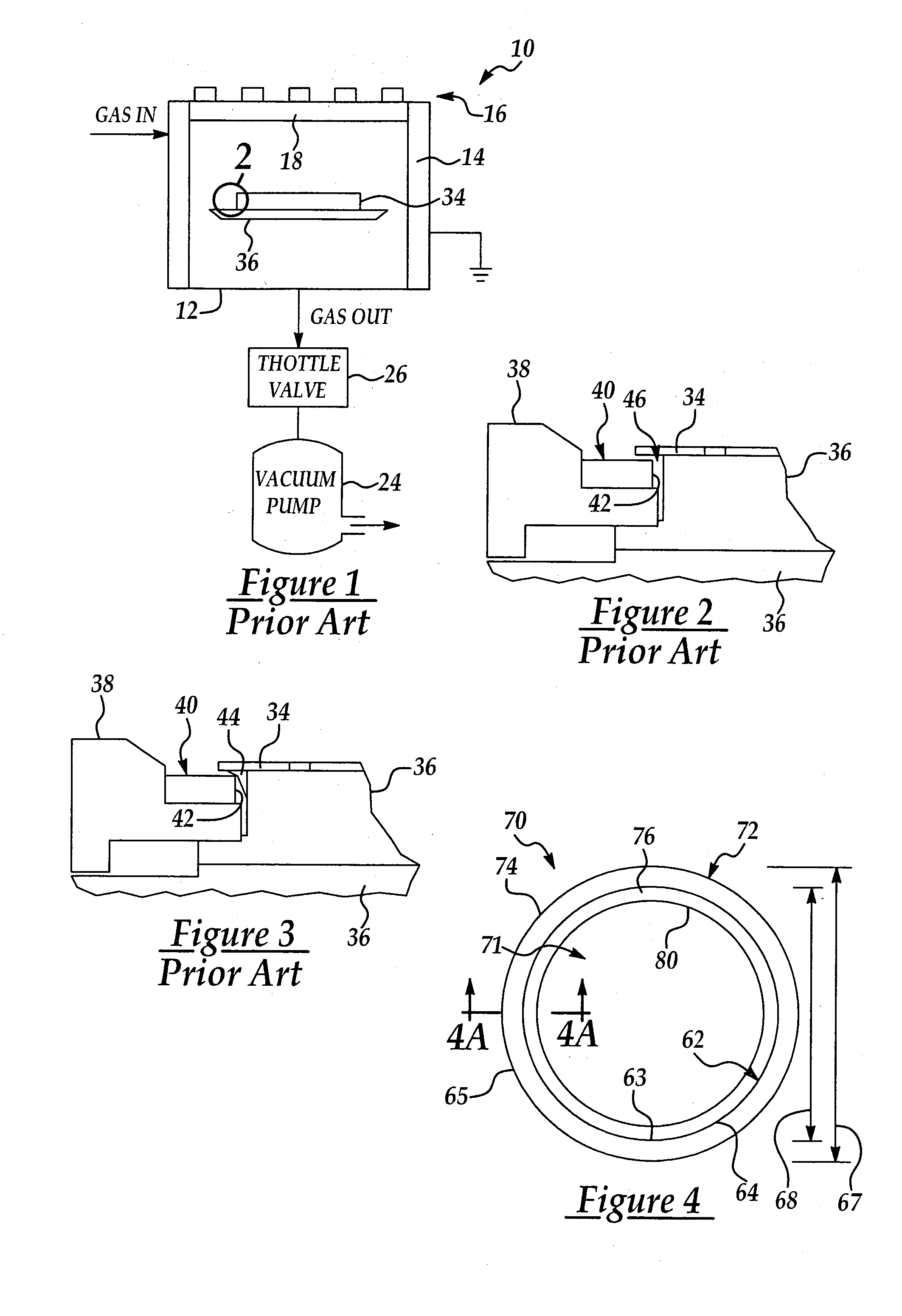

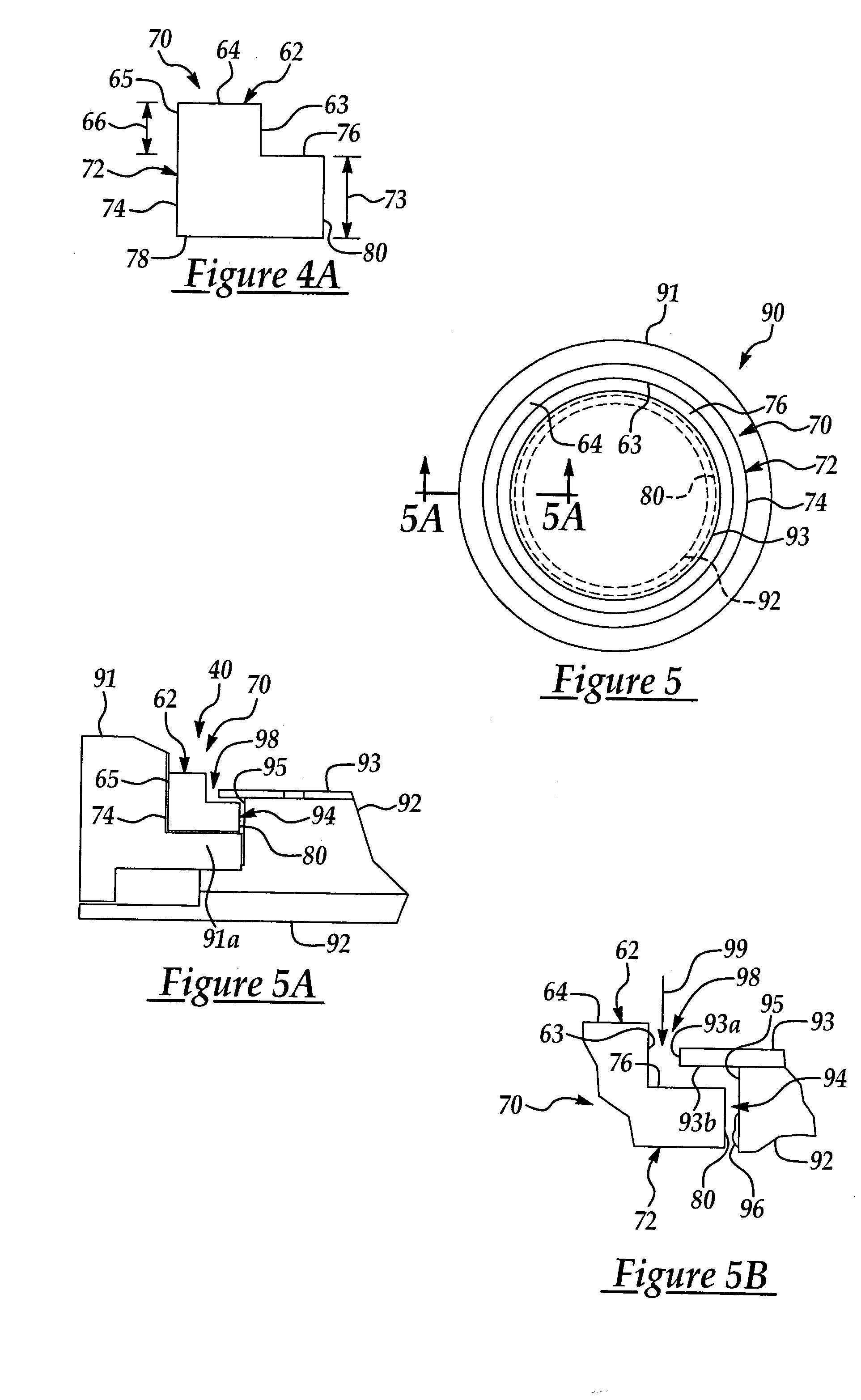

Fluid damper

InactiveUS6971631B1Easy to controlEasy to installOperating means/releasing devices for valvesFlow control without auxillary powerEngineeringShock absorber

A damper utilizing a frame having a base and a wall portion extending outwardly from the same. The wall portion supports a stepped edge which is positioned to at least partially circumvent and aperture formed by the frame. A plurality of flanges are positioned in overlying relationship and slidably move relative to one another by a mechanical mechanism. A plurality of flanges ride on a stepped edge portion to cause fanning of the flanges across the aperture to selectively occlude the aperture or a portion thereof.

Owner:NAUGHTON BART

Simple method for calculating camera defocus from an image scene

ActiveUS7616254B2Television system detailsProjector focusing arrangementThree-dimensional spaceAutofocus

An imaging acquisition system that generates a picture depth from an auto focus curve generated from picture of a three dimensional spatial scene is described. The auto focus curve comprises a step edge. The system generates the depth based on the step edge and a reference auto focus normalization curve.

Owner:SONY CORP +1

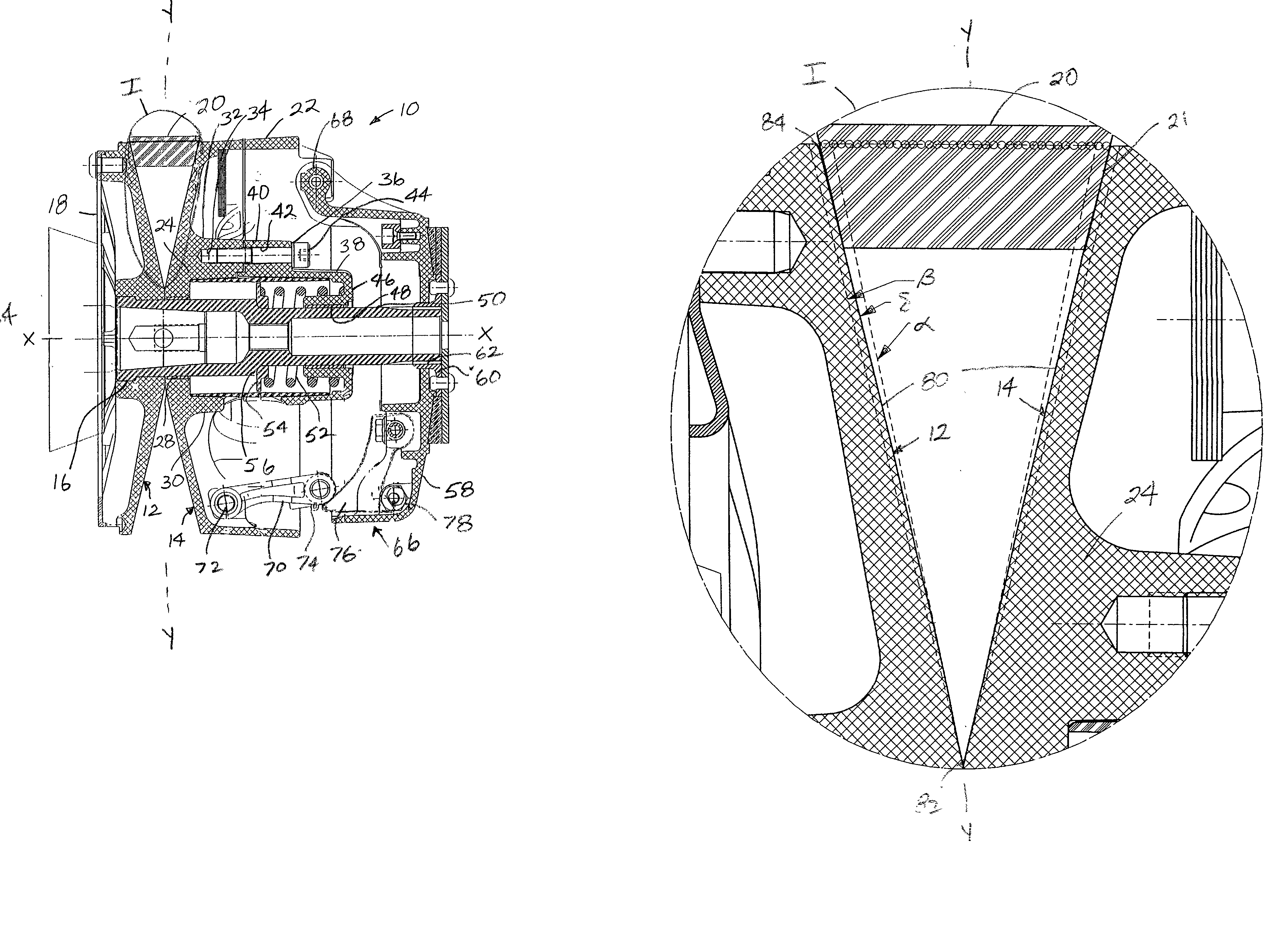

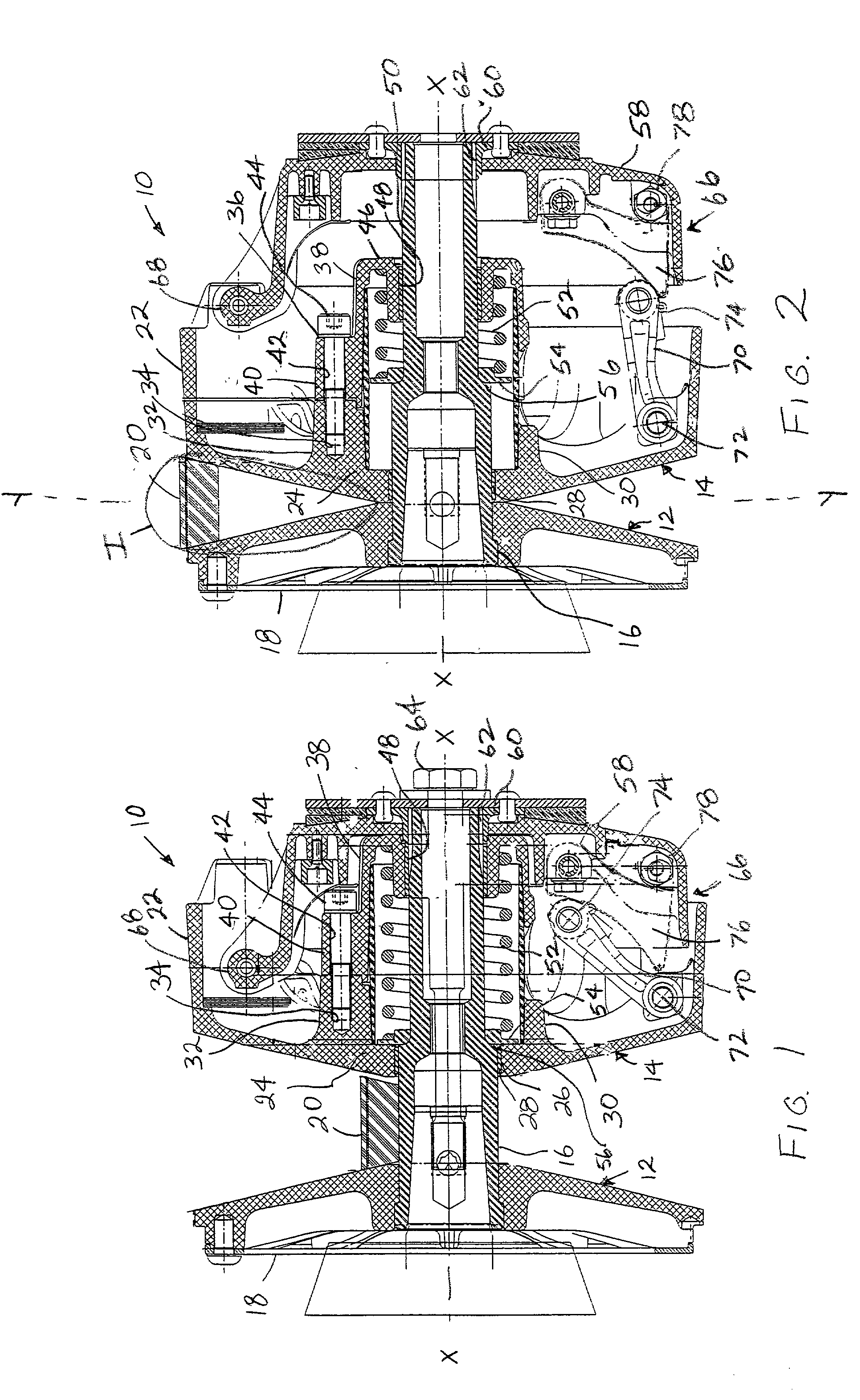

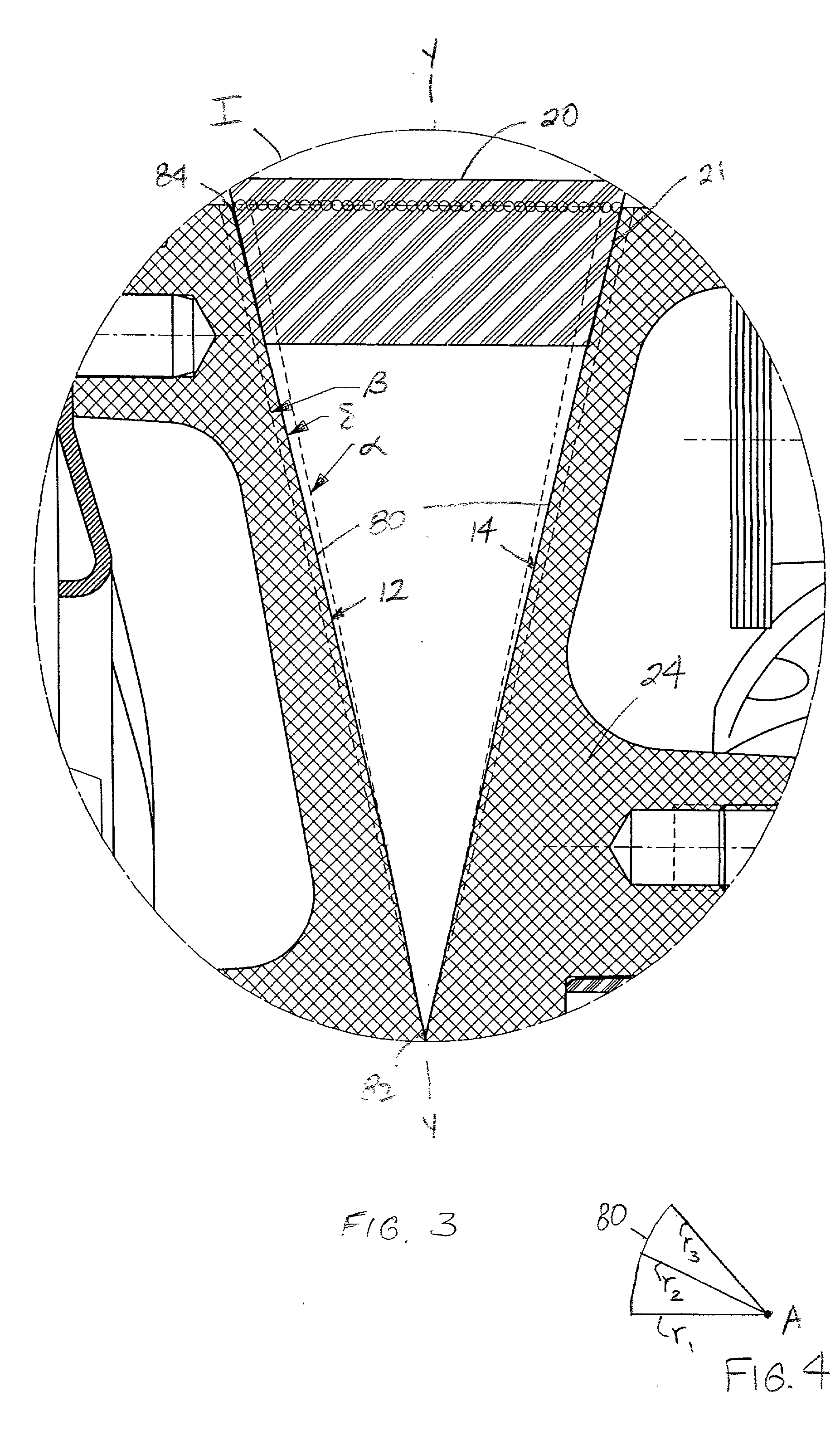

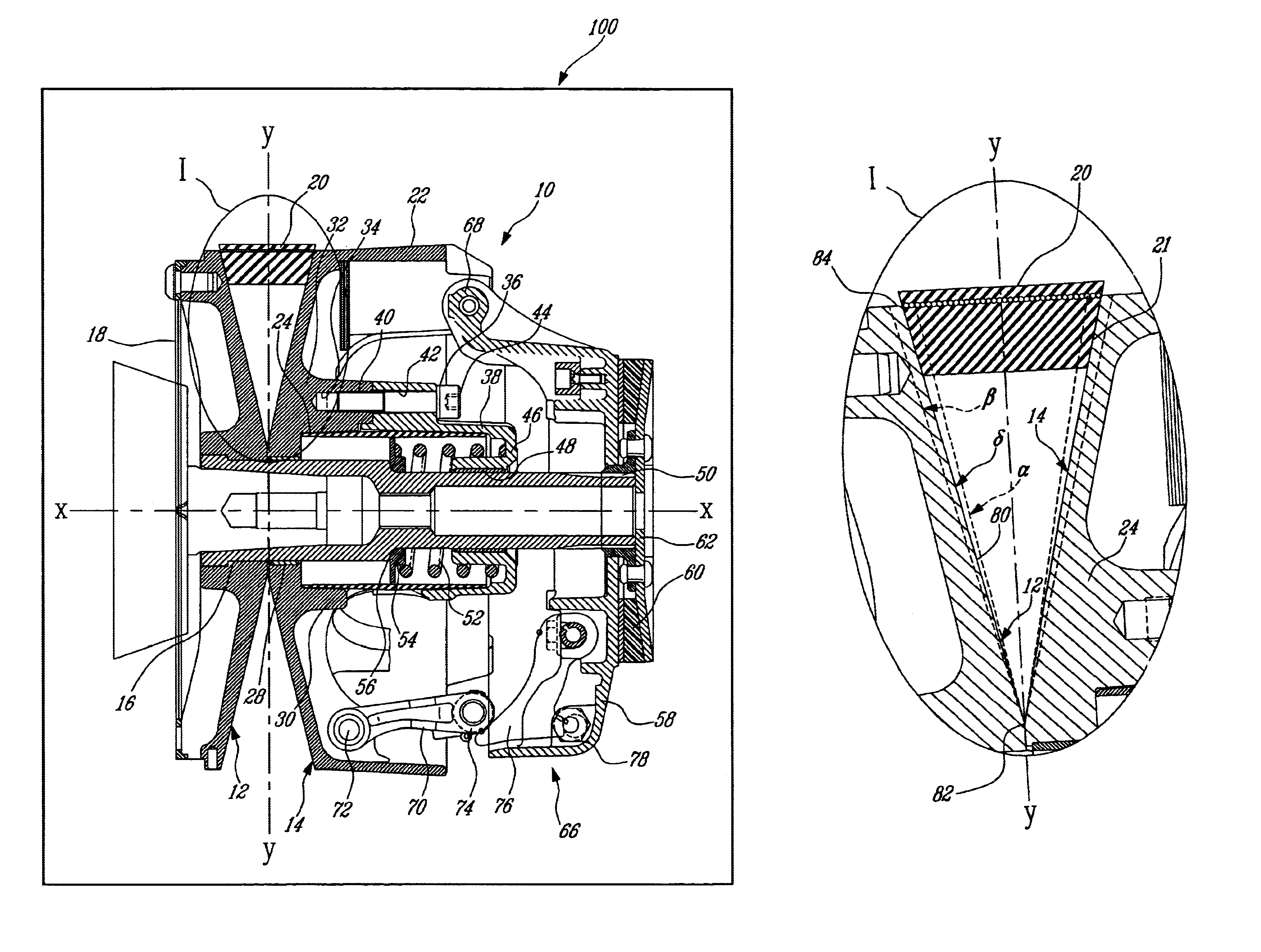

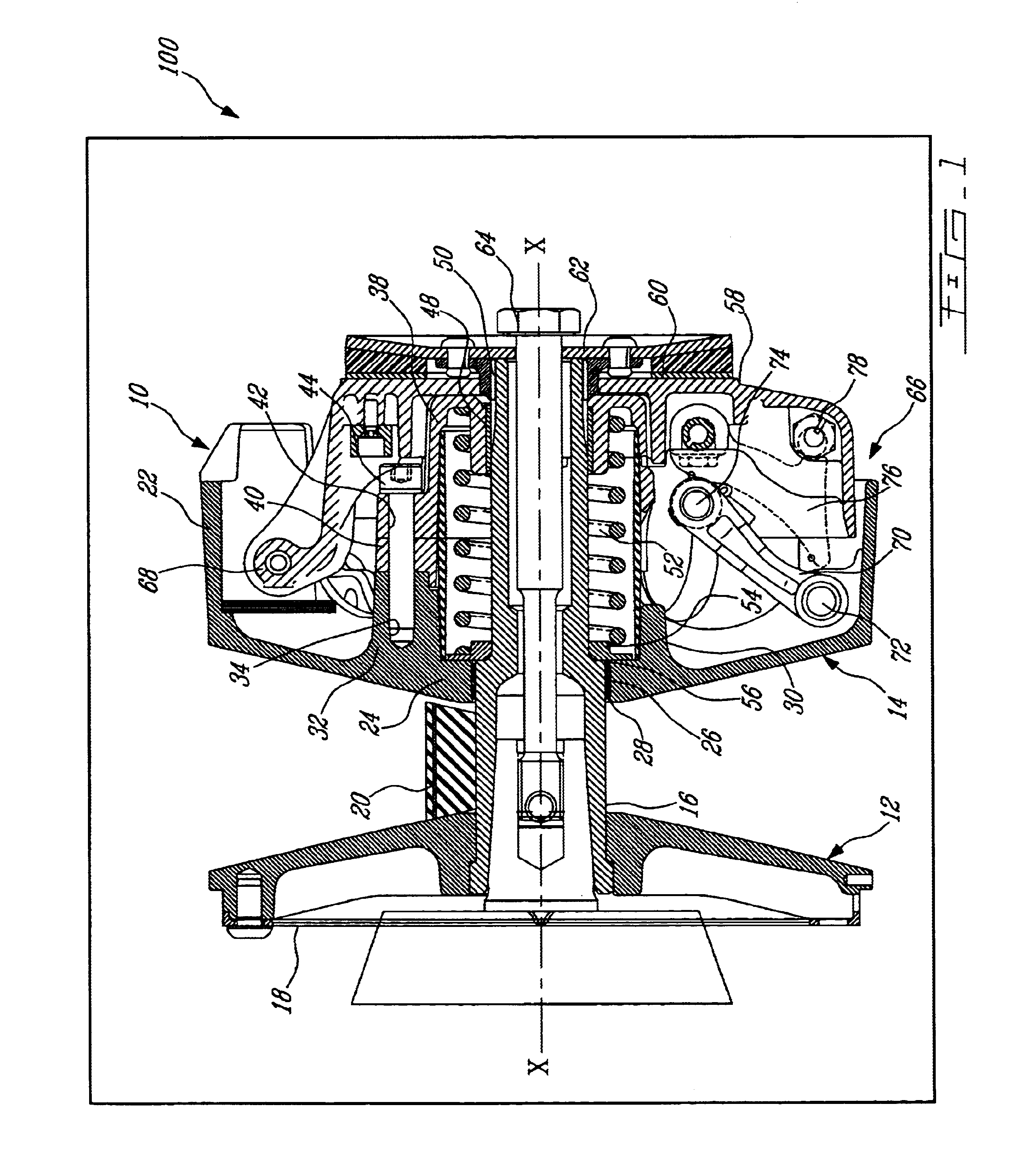

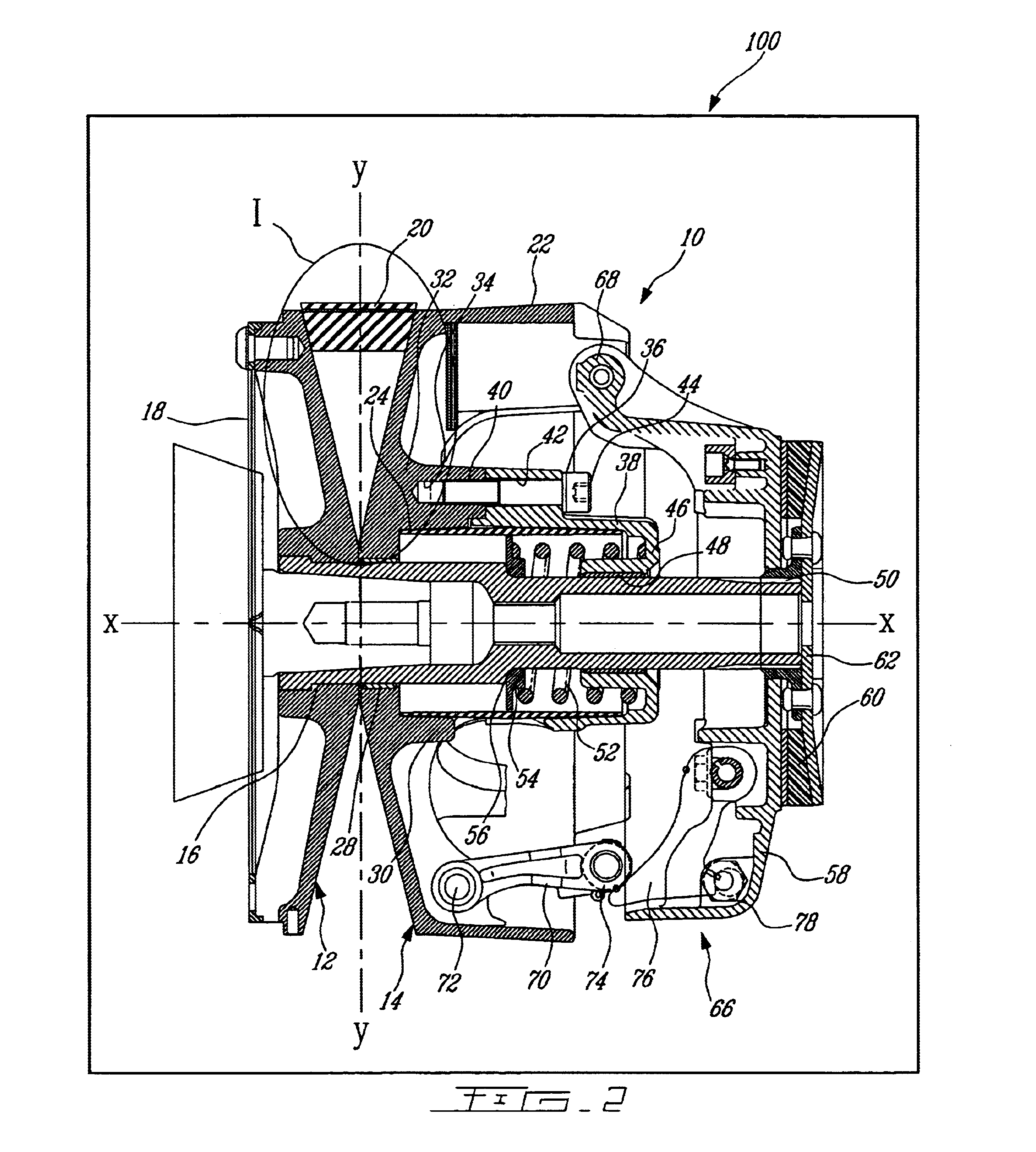

Pulley having progressively variable sheave angle

InactiveUS20020042313A1Constant powerReduce power lossV-beltsRopes and cables for vehicles/pulleyVariable angleFlange

A pulley system for use in a constant variable transmission includes a pair of pulley sheaves or flanges mechanically linked by a belt so that the outer surfaces of the belt interact with the inner surfaces of the flanges. At least one of the pulley flanges has an inclined inner surface disposed at an angle that changes progressively based on a curve have a variable radius. For example, the sheave angle can change progressively from 9 degrees to 12 degrees or from 12 degrees to 14 degrees, with no sharp or stepped edges. The belt can have a complementary angled surface also. The progressively variable angle allows the flange surface to more closely match the side surface of the belt, which can increase the belt life be reducing stress experienced by the belt. The pulley system is useable in a transmission for a vehicle, for example a snowmobile or an all terrain vehicle.

Owner:BOMBARDIER RECREATIONAL PROD INC

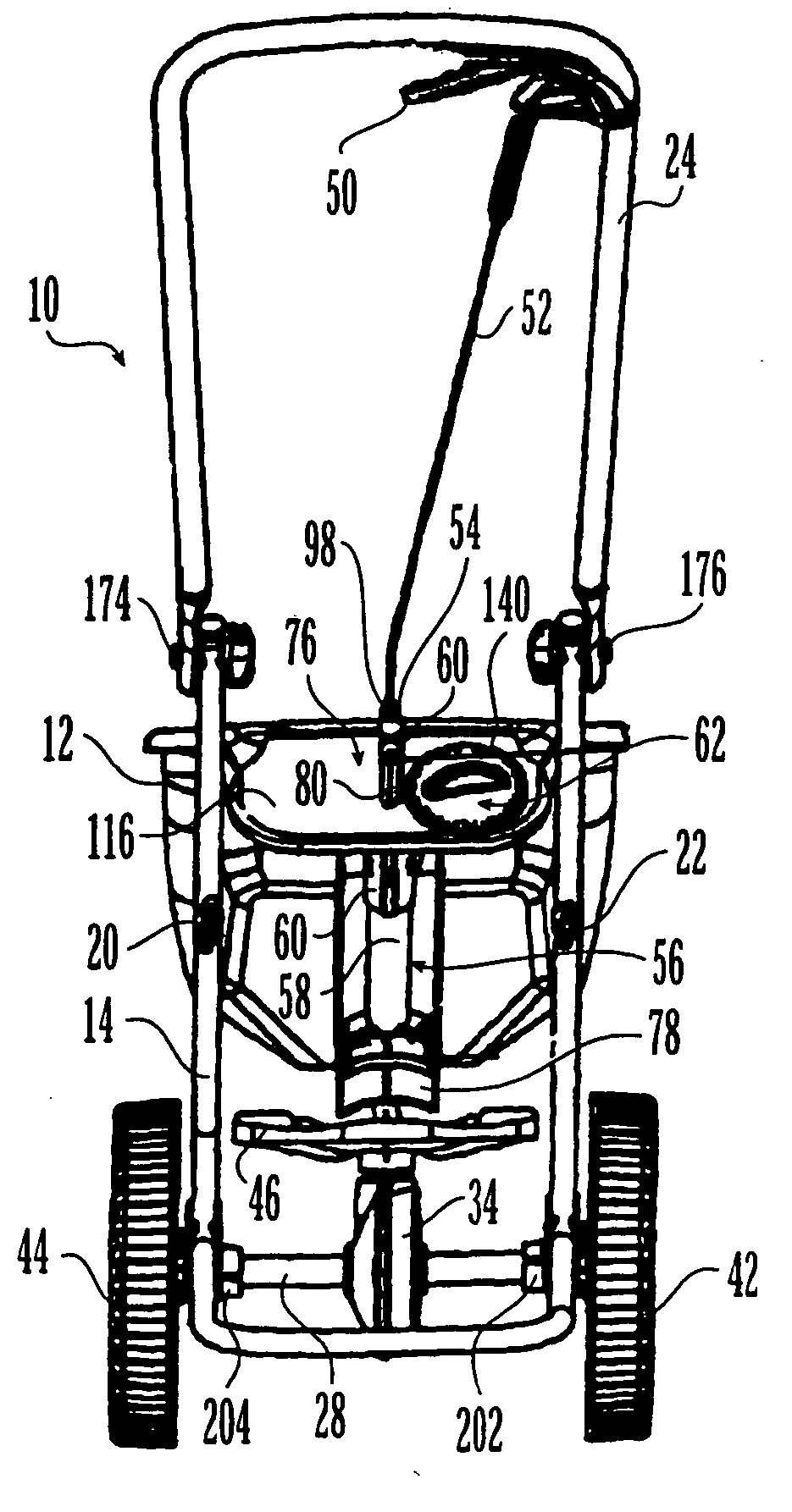

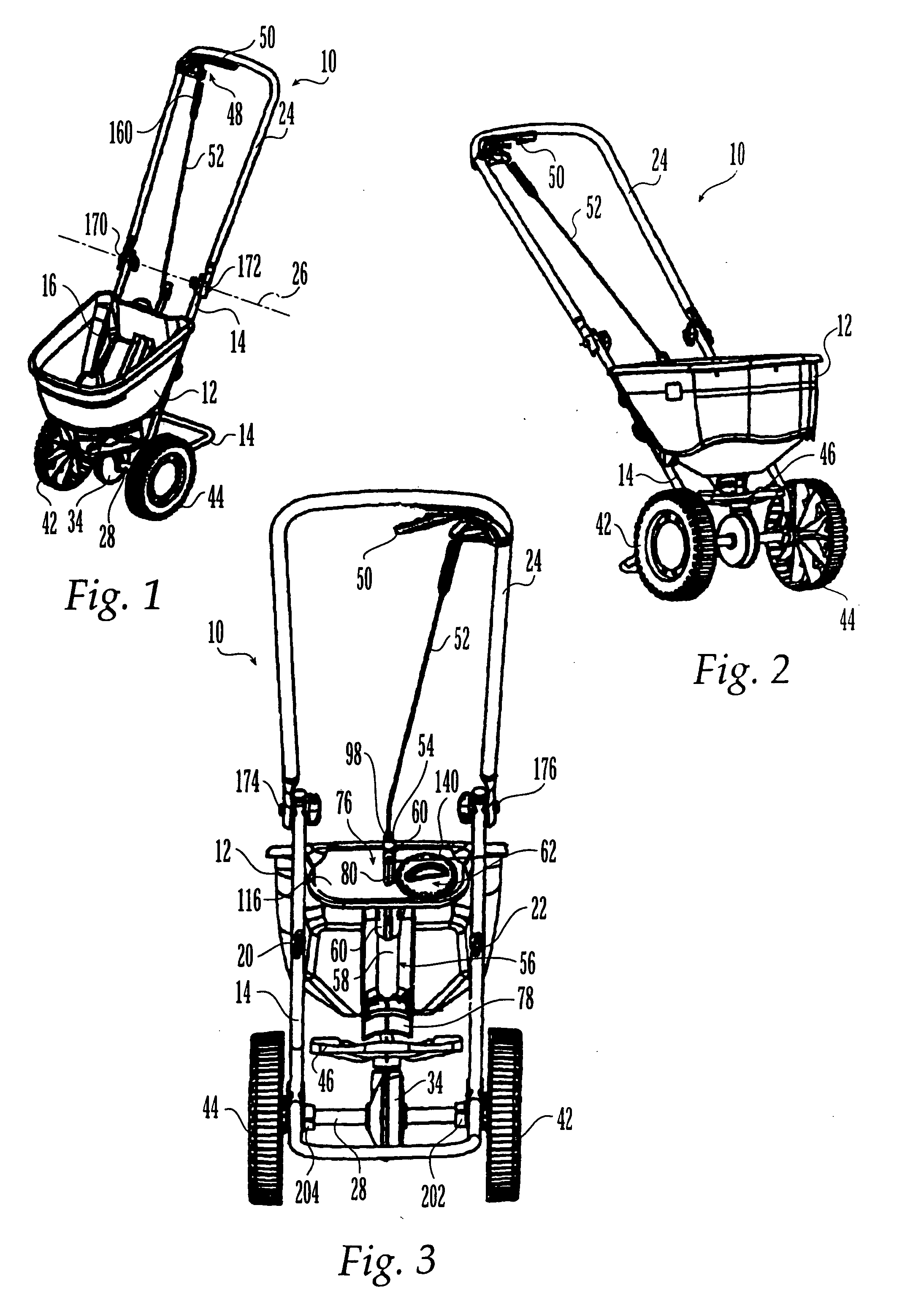

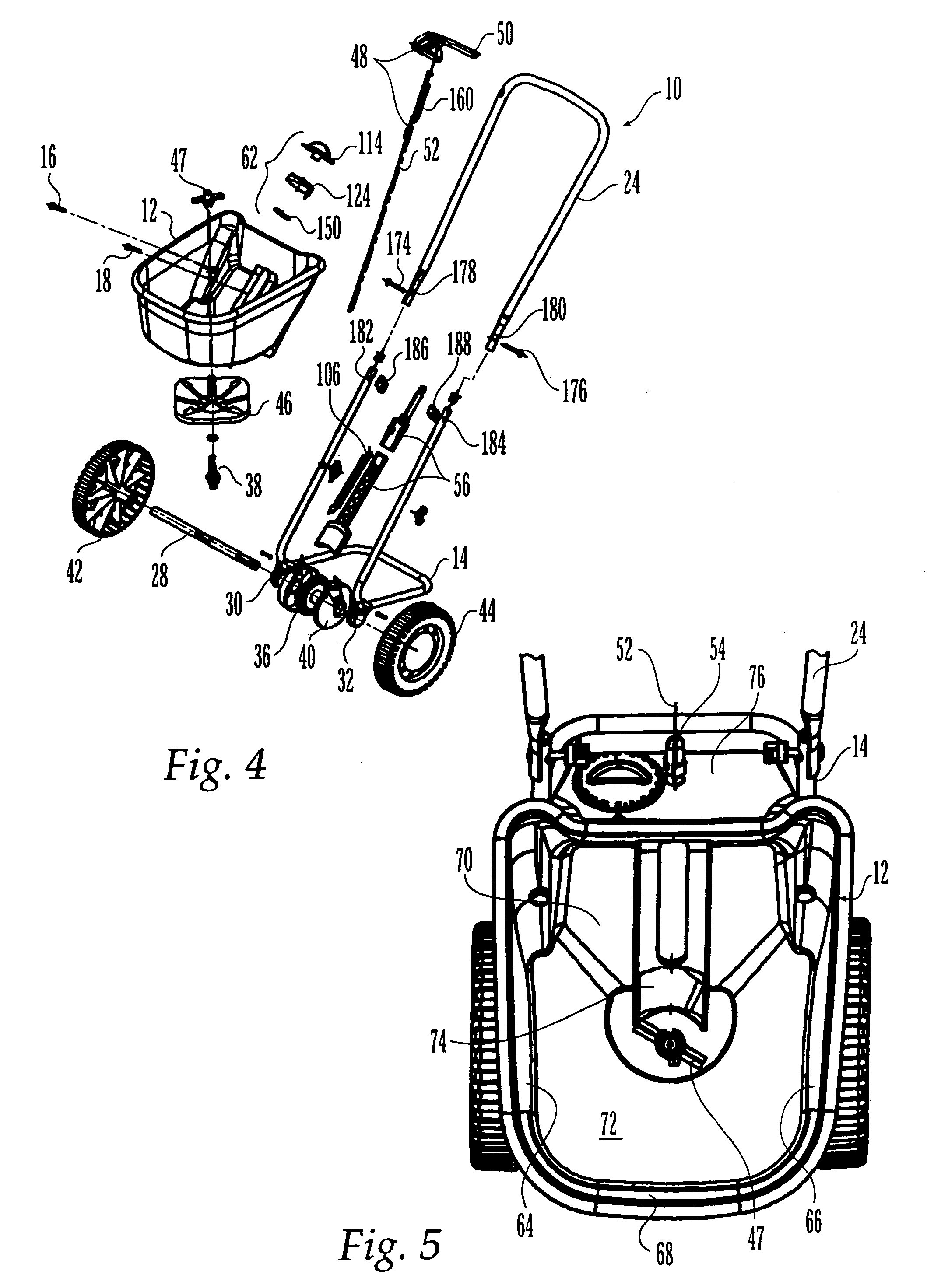

Collapsible spreader

ActiveUS20060157518A1Easy constructionEasy to assembleFertiliser distributersCentrifugal wheel fertilisersMechanical engineeringSpread rate

An improved collapsible spreader with a spread rate selection mechanism including a knob and a rotatable cup-shaped structure. The cup-shaped structure includes an elongated setting tab and a thirty-six step edge corresponding to thirty-six spread rate settings on the knob. Operatively engaged with the cup-shaped structure is an abutment tab that is part of a closure structure for blocking and selectively unblocking a hopper opening. The tab engages the setting tab to define the adjustable length of the closure structure. Thereafter, abutment rate selection is a function of the rotatable position of the cup-shaped structure. Engagement of the abutment tab and a step defines the size of the hopper opening and thus the amount of product released from the hopper during operation. The spreader also includes a dual spring arrangement to bias the closure structure to a closed position and to prevent breakage. The disclosed spreader also features a one piece wheel to reduce parts and assembly costs.

Owner:OMS INVESTMENTS INC

Pulley having progressively variable sheave angle

InactiveUS6656068B2Constant powerReduce power lossV-beltsRopes and cables for vehicles/pulleyEngineeringVariable angle

A pulley system for use in a constant variable transmission includes a pair of pulley sheaves or flanges mechanically linked by a belt so that the outer surfaces of the belt interact with the inner surfaces of the flanges. At least one of the pulley flanges has an inclined inner surface disposed at an angle that changes progressively based on a curve have a variable radius. For example, the sheave angle can change progressively from 9 degrees to 12 degrees or from 12 degrees to 14 degrees, with no sharp or stepped edges. The belt can have a complementary angled surface also. The progressively variable angle allows the flange surface to more closely match the side surface of the belt, which can increase the belt life be reducing stress experienced by the belt. The pulley system is useable in a transmission for a vehicle, for example a snowmobile or an all terrain vehicle.

Owner:BOMBARDIER RECREATIONAL PROD INC

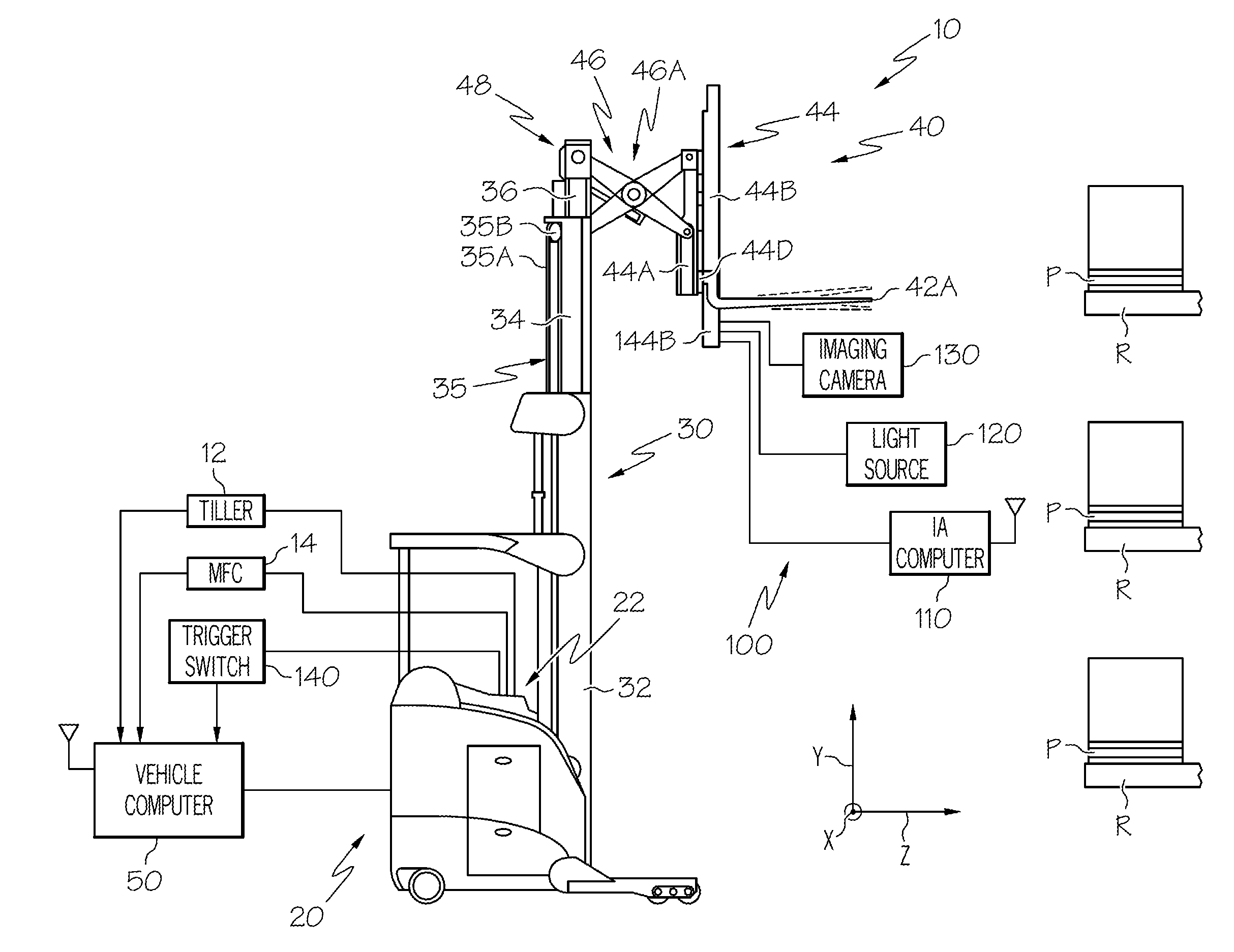

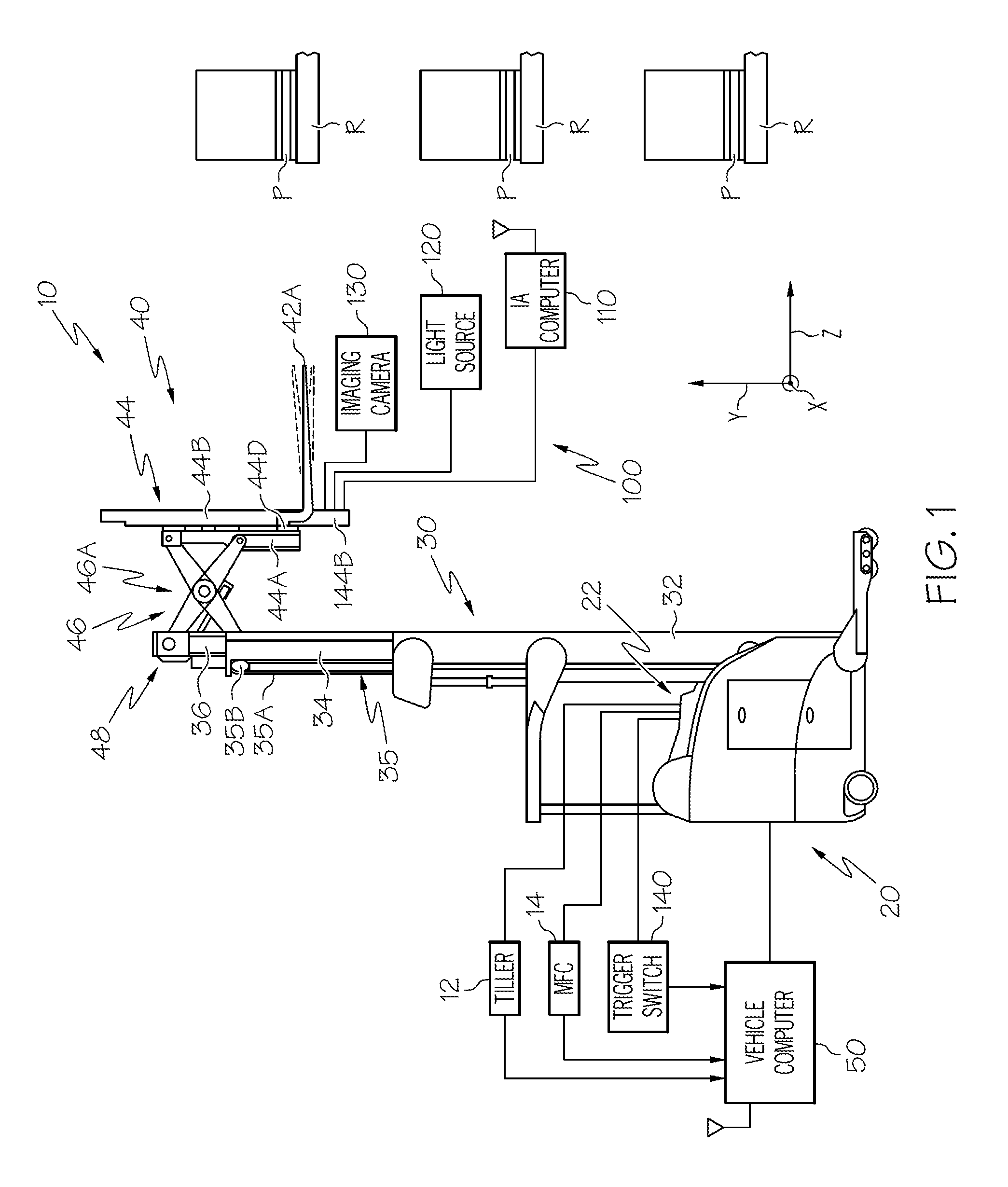

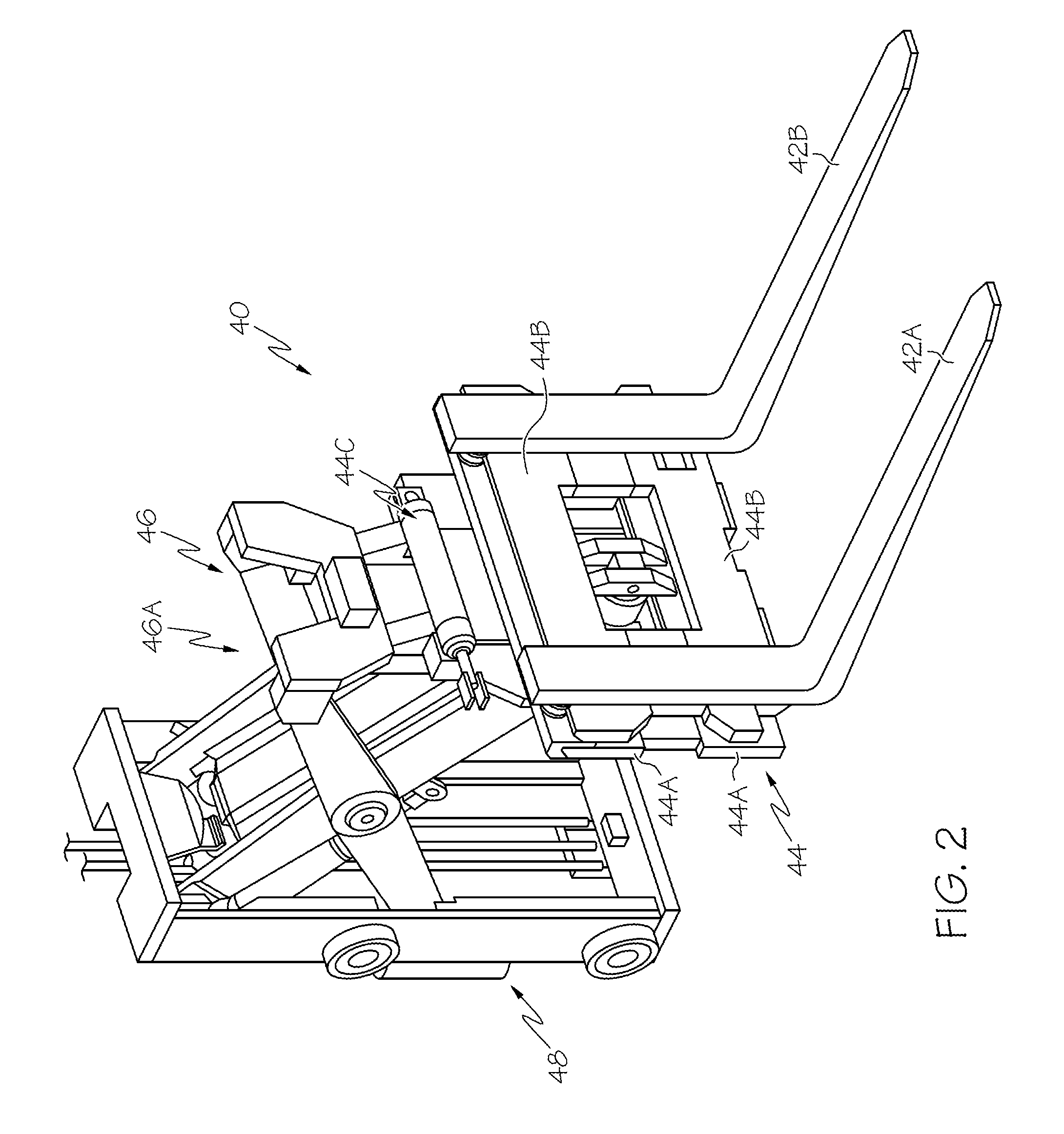

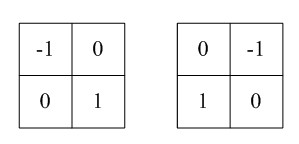

Evaluating features in an image possibly corresponding to an intersection of a pallet stringer and a pallet board

A programmable computer-implemented method is provided for finding possible corners of a pallet in an image. The method may comprise: acquiring a grey scale image including one or more pallets; determining, using a computer, horizontal cross correlations between the image and a first step-edge template to generate a set of horizontal cross correlation results; determining, using the computer, vertical cross correlations between the image and a second step-edge template to generate a set of vertical cross correlation results; and determining, using the computer, a first set of pixels, each such pixel respectively corresponding to a possible first corner of the one or more pallets, using a first corner template, the set of horizontal cross correlation results and the set of vertical cross correlation results.

Owner:CROWN EQUIP CORP

Polarizer and waveguide antenna apparatus using the same

A polarizer includes a waveguide channel having a substantially square cross section and a septum disposed within the waveguide channel. The septum includes a stepped edge and two opposite stepped surfaces. The stepped surfaces are sectionally recessed toward each other along the direction pointing toward the interior of the waveguide channel, wherein the number of the steps of the stepped surface is greater than two, but smaller than the number of the steps of the stepped edge. In one embodiment, the square cross section may include a plurality of rounded corners and a plurality of edges extending correspondingly between the rounded corners, wherein the ratio of the radius of the rounded corner to the distance between two opposite edges is in a range of from 0.05 to 0.3.

Owner:MICROELECTRONICS TECH INC

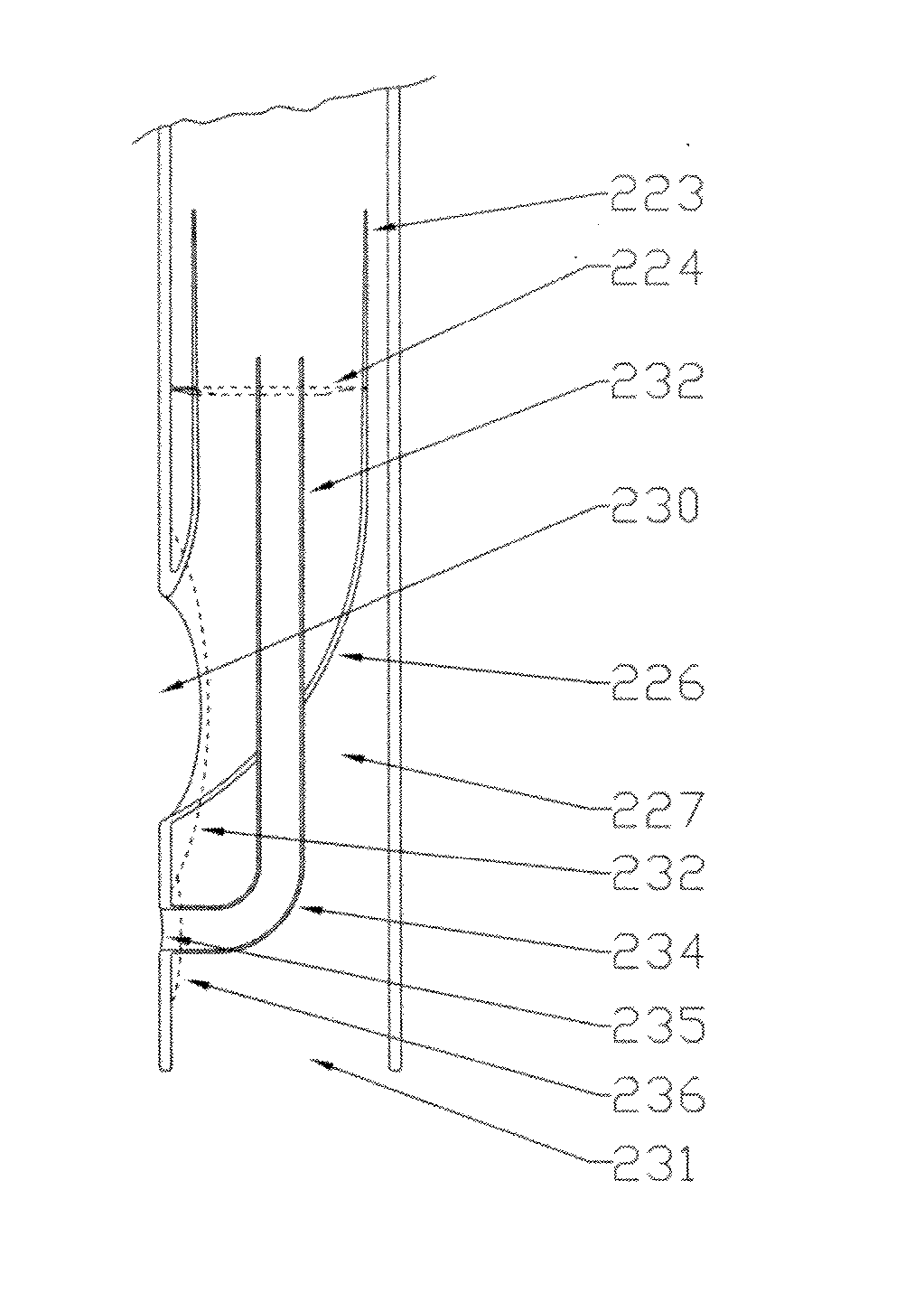

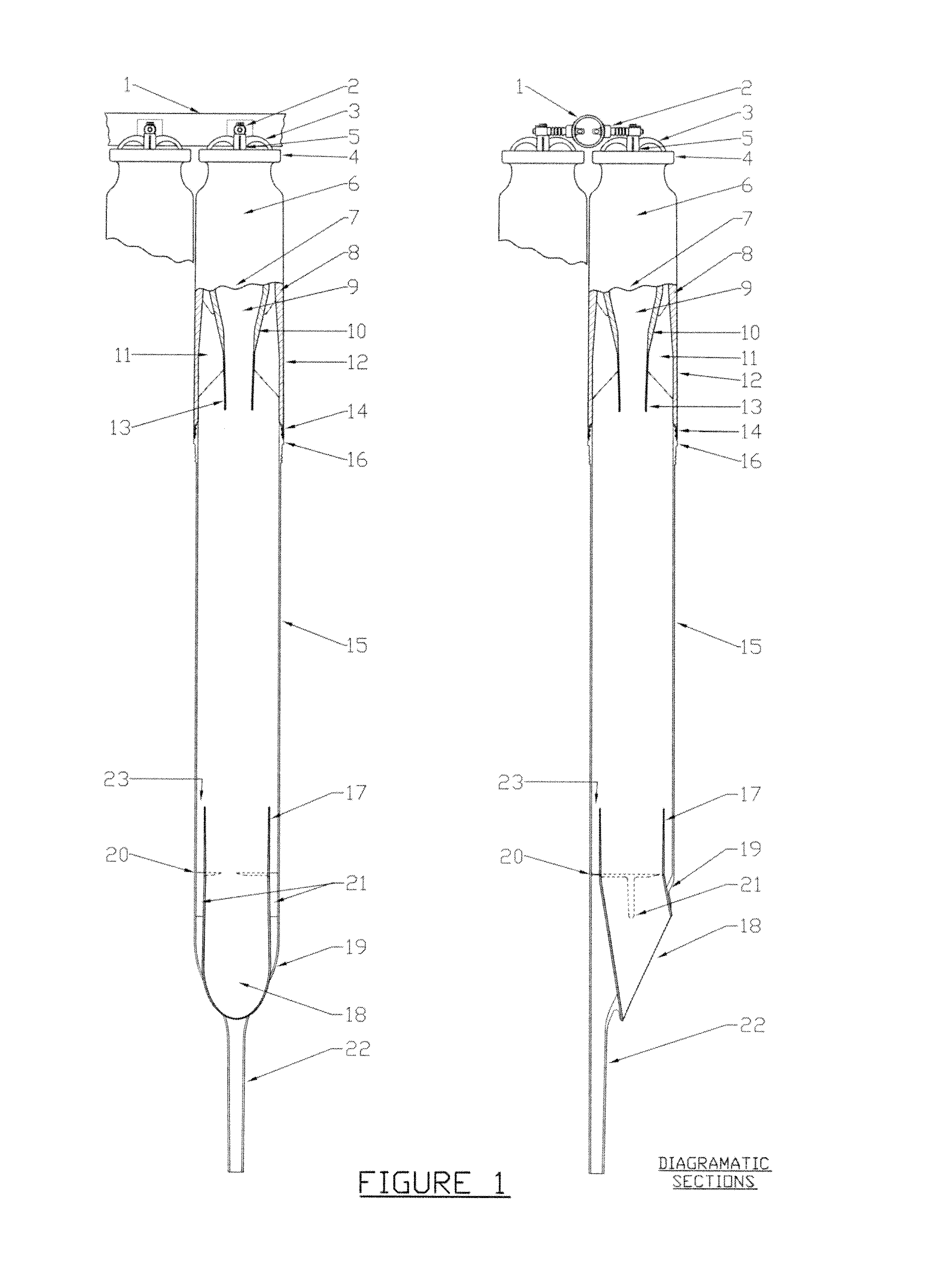

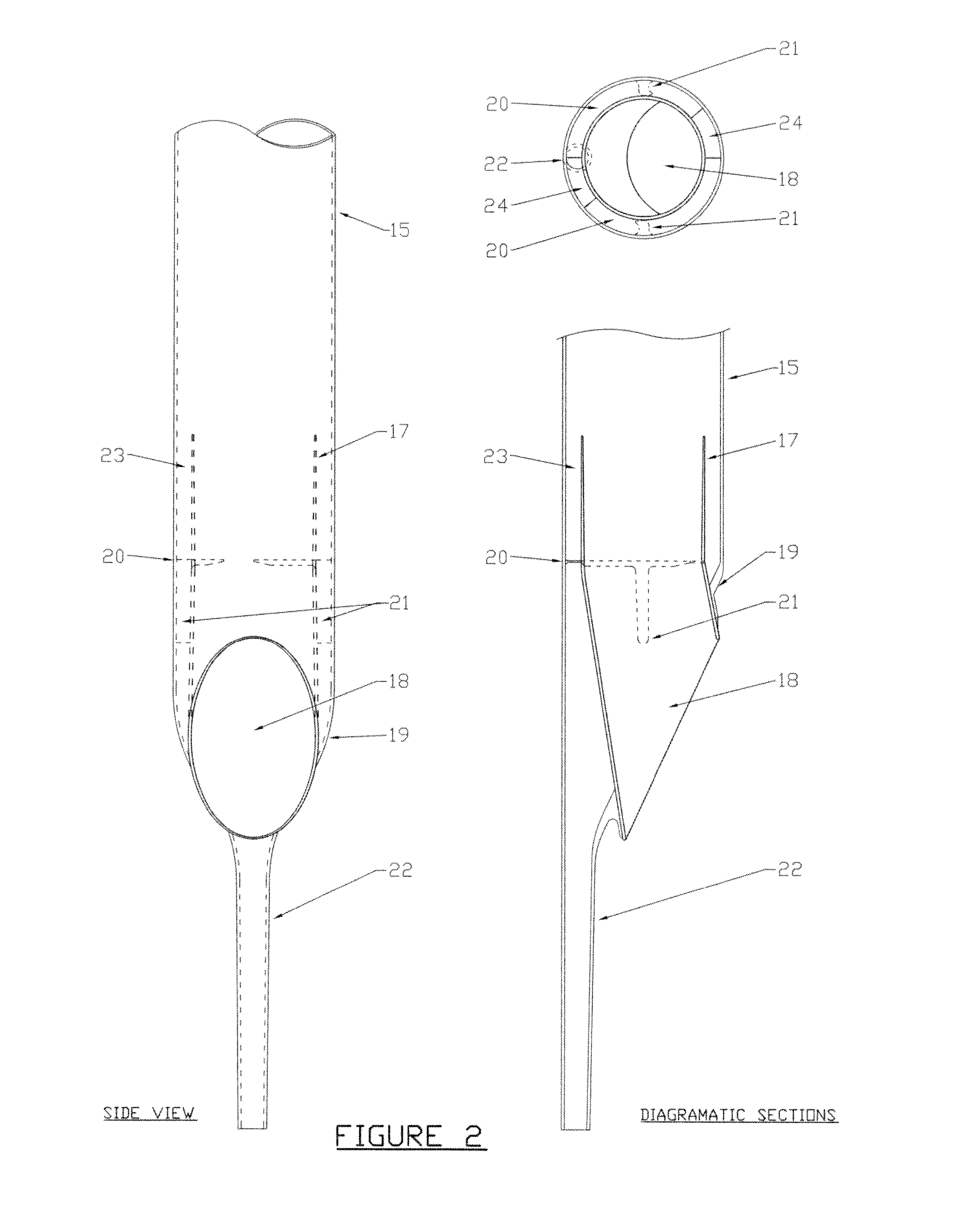

Apparatus for separation and processing of materials

ActiveUS20140225286A1Effectively frictionlessFineness is limitedLiquid degasificationReversed direction vortexCyclonic separationEngineering

This invention relates to a tubular cyclonic separation device the style of which was presented in PCT / ZA2003 / 000160 and which enables all of the inlet and outlet connections to be completely contained within a tubular profile, the diameter of which is that of the body of the cyclonic section. This disclosure adds further novel and inventive developments to the cyclonic device which enable it to be used as a separating device for systems involving all three phases (gas, liquid and solid) and where two, three or more different product streams may be separated, all within the same cylindrical profile. These further inventive developments also relate to the use of externally supplied gas and / or additional liquid phases which are injected through the walls of the cyclonic body using specifically located slots and / or holes in combination with specifically located stepped edges. These further novel and inventive developments enable the concepts of froth floatation (FF) and Dispersed Air Floatation (DAF) to be exploited within an enhanced gravitational field together with the options for washing the separated froth and / or the separated heavier fractions, all within the same cyclonic unit. As part of the novel and inventive introduction of the stepped edges, means are provided whereby gas bubbles smaller than 30 microns can be created on a large scale and with a reduced energy input relative to typical conventional equipment. Also the size of the gas bubbles may be controlled together with the intensity of any particle on particle interactions that may be created. This latter has many potential applications within FF and / or DAF processes, including applications within oil and tar separation from solid surfaces and within many ore preparation and ore leaching processes. The tubular profile enables processing and separation to be achieved “within the pipe line” or for very closely packed arrangements to be assembled within carrier vessels.

Owner:CYDAF TECH

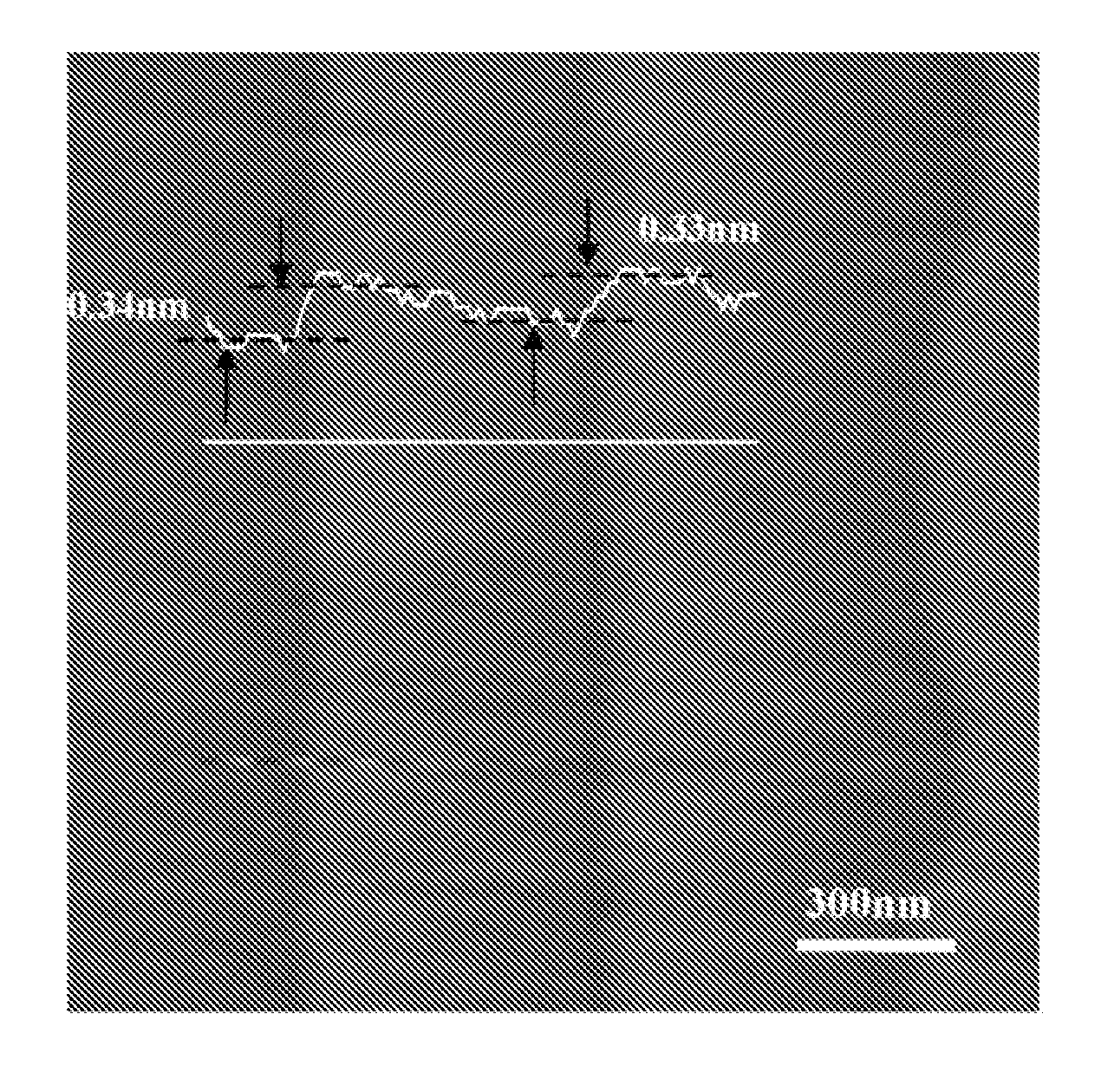

Method for preparing graphene nanoribbon on insulating substrate

ActiveUS20130022813A1Inhibit transferEnsure performanceMaterial nanotechnologyLayered productsActivated carbonGraphene nanoribbons

A method for growing a graphene nanoribbon on an insulating substrate having a cleavage plane with atomic level flatness is provided, and belongs to the field of low-dimensional materials and new materials. The method includes the following steps. Step 1: Cleave an insulating substrate to obtain a cleavage plane with atomic level flatness, and prepare a single atomic layer step. Step 2: Directly grow a graphene nanoribbon on the insulating substrate having regular single atomic steps. In the method, a characteristic that nucleation energy of graphene on the atomic step is different from that on the flat cleavage plane is used, and conditions, such as the temperature, intensity of pressure and supersaturation degree of activated carbon atoms, are adjusted, so that the graphene grows only along a step edge into a graphene nanoribbon of an adjustable size. The method is mainly applied to the field of new-type graphene optoelectronic devices.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

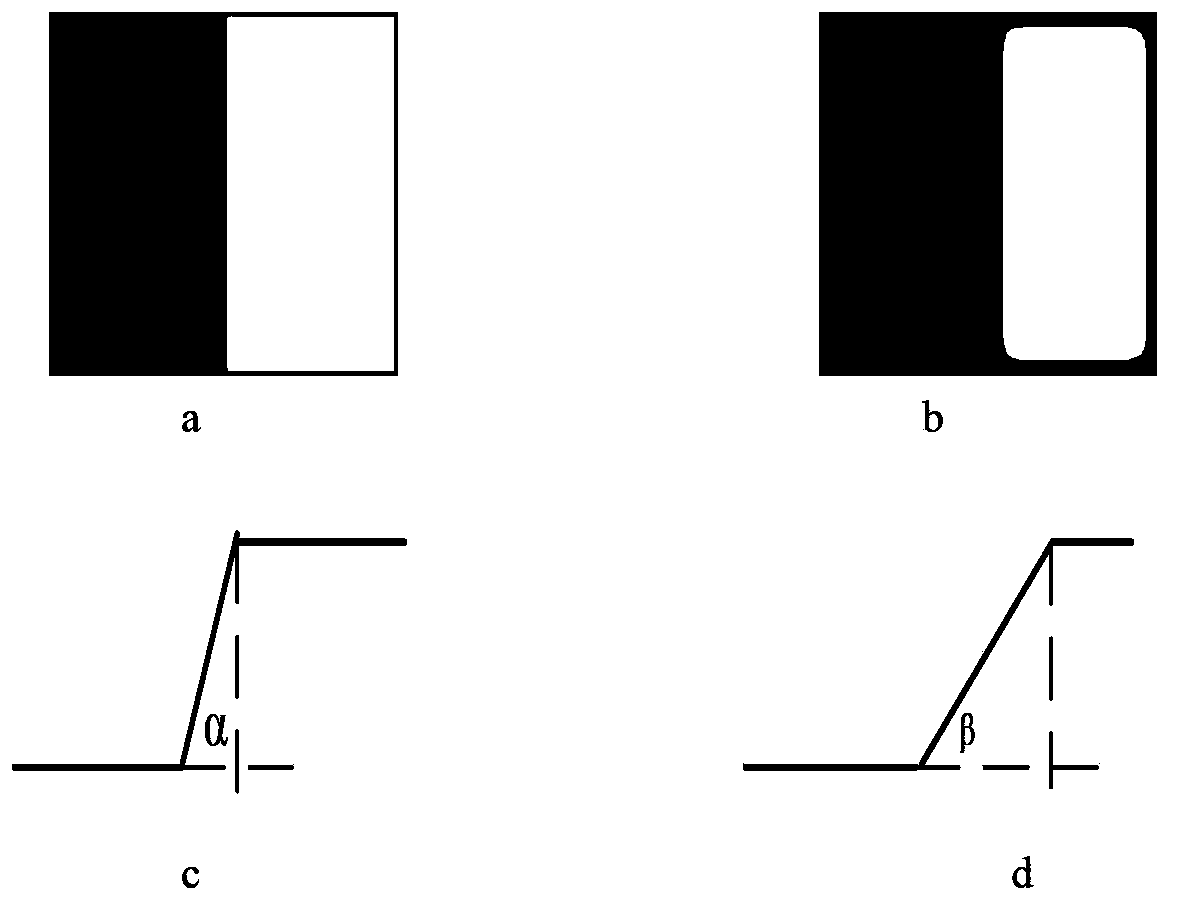

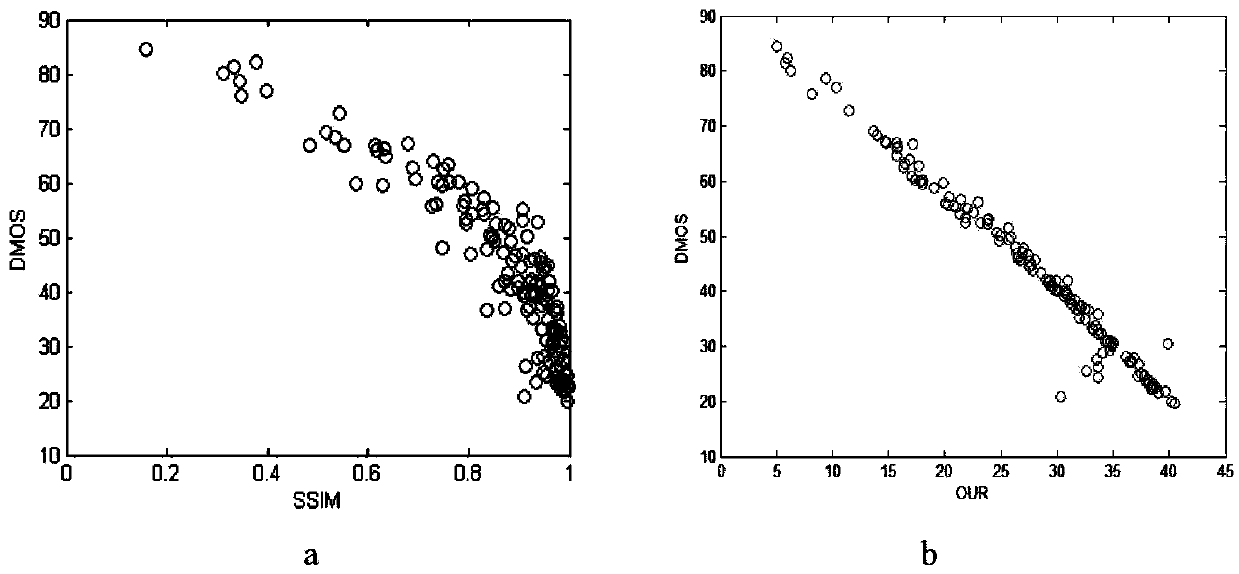

No-reference blurred image quality evaluation method

The invention discloses a no-reference blurred image quality evaluation method, and belongs to the image processing technical field. A characteristic that compared with a sharp image, edge features of a blurred image change greatly is utilized; all step edges of the image is sought; appropriate portion edges based on contrast ratio and pixel distance is selected; and the sharpness degree of the edges is calculated and taken as the evaluation basis for image blurriness. The method provided in the invention highlights the influence of human eye-sensitive edge information portion of the image on the image quality, so that images of the blur types, such as Gaussian blur, defocus blur, motion blur and the like can be well evaluated, structural dependence of subjective evaluation is high, and the characteristic of a human eye vision system is accorded with.

Owner:HOHAI UNIV CHANGZHOU

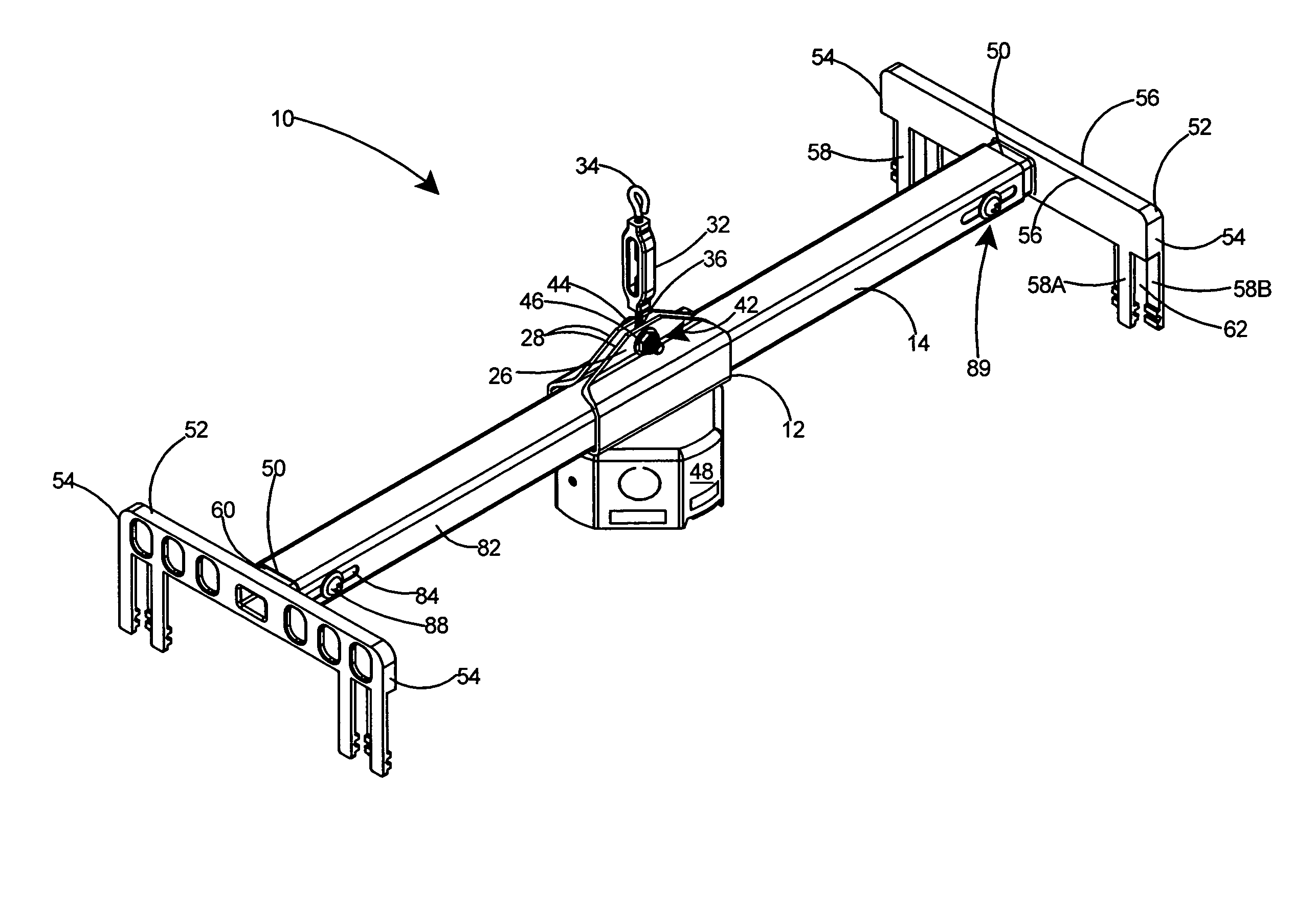

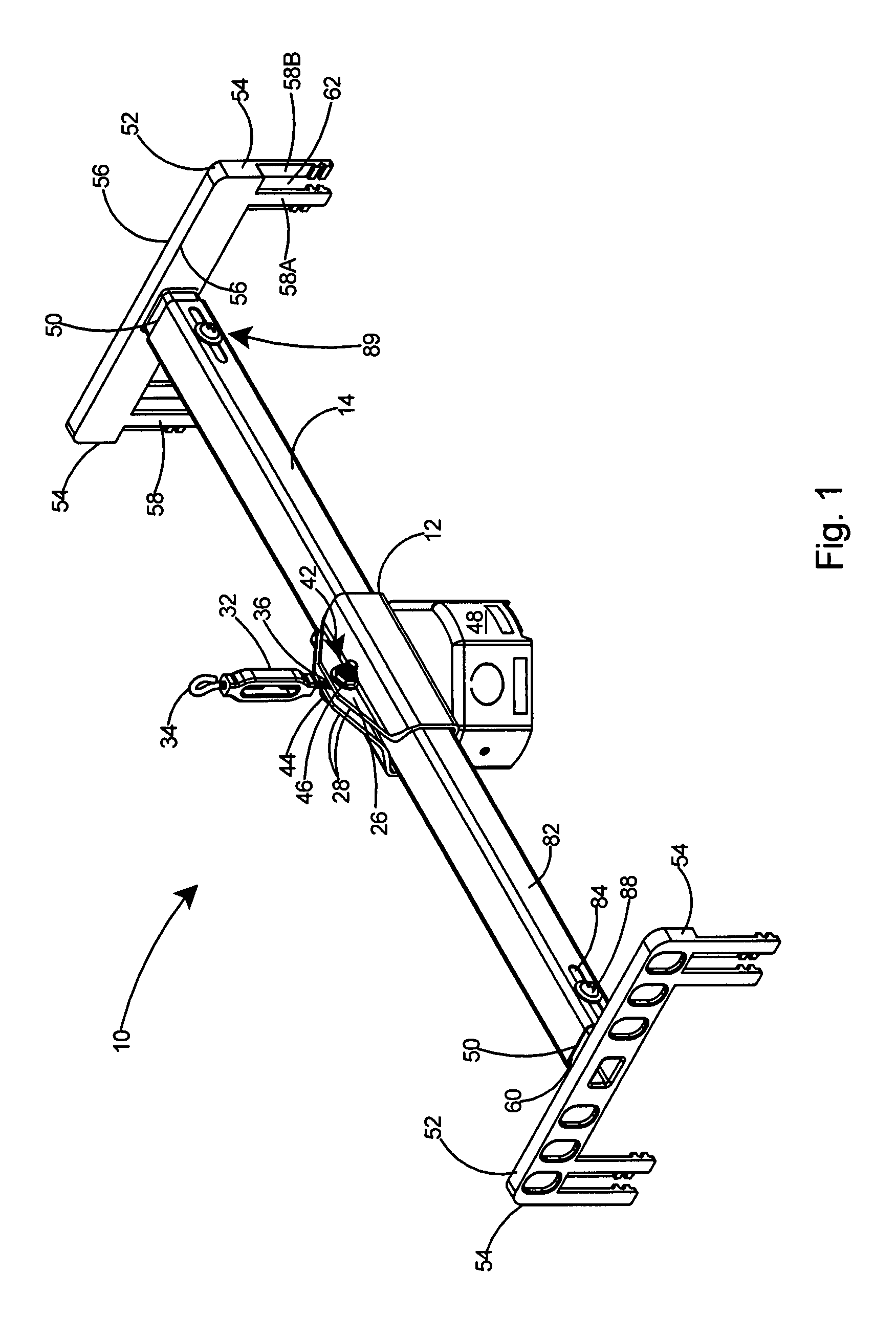

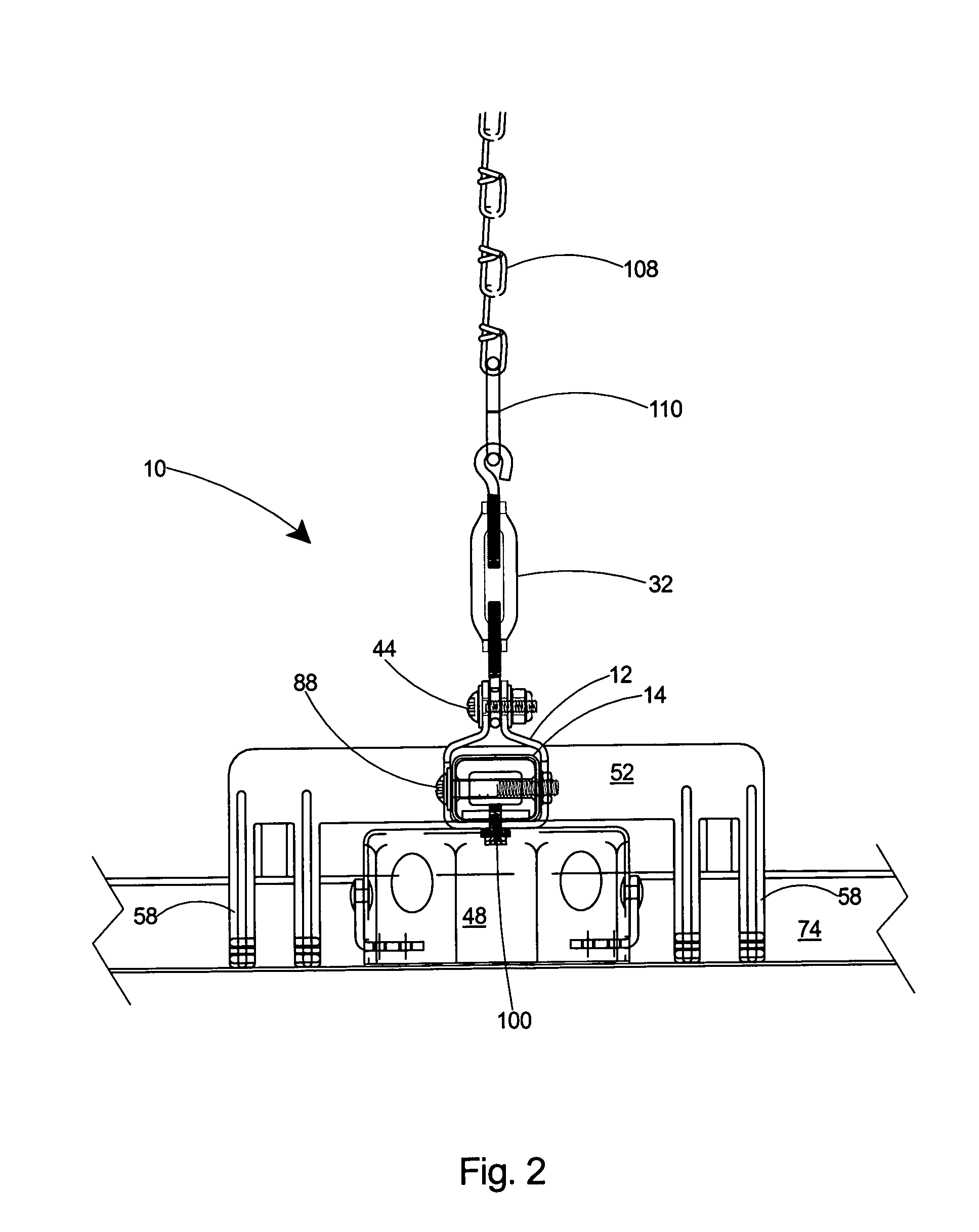

Adjustable mounting bracket for suspended ceiling

ActiveUS8087631B1Easy to installSimple taskCeilingsLighting support devicesEngineeringDropped ceiling

A load bearing assembly for supporting a lighting or fan fixture on a drop ceiling having a grid supporting structure. The assembly includes a single center bar, two end brackets with widely spaced support legs, and an electrical box. The support legs include removable portions that allow rapid modification to accommodate ceiling tiles of uniform thickness or ceiling tiles having a stepped edge. By adjusting the length of the legs, the lower surface of the tiles is leveled with the lower edge of the electrical box for either tiles of uniform thickness or those having stepped edges. A fastening arrangement enables adjustment of the end brackets with respect to the center bar, thereby allowing rapid fitting to adjacent T-rails. A locking arrangement enables easy adjustment of the location of the electrical box along the length of the center bar, thereby allowing the assembly to be rapidly fitted to a desired location on a drop ceiling.

Owner:ARLINGTON INDS

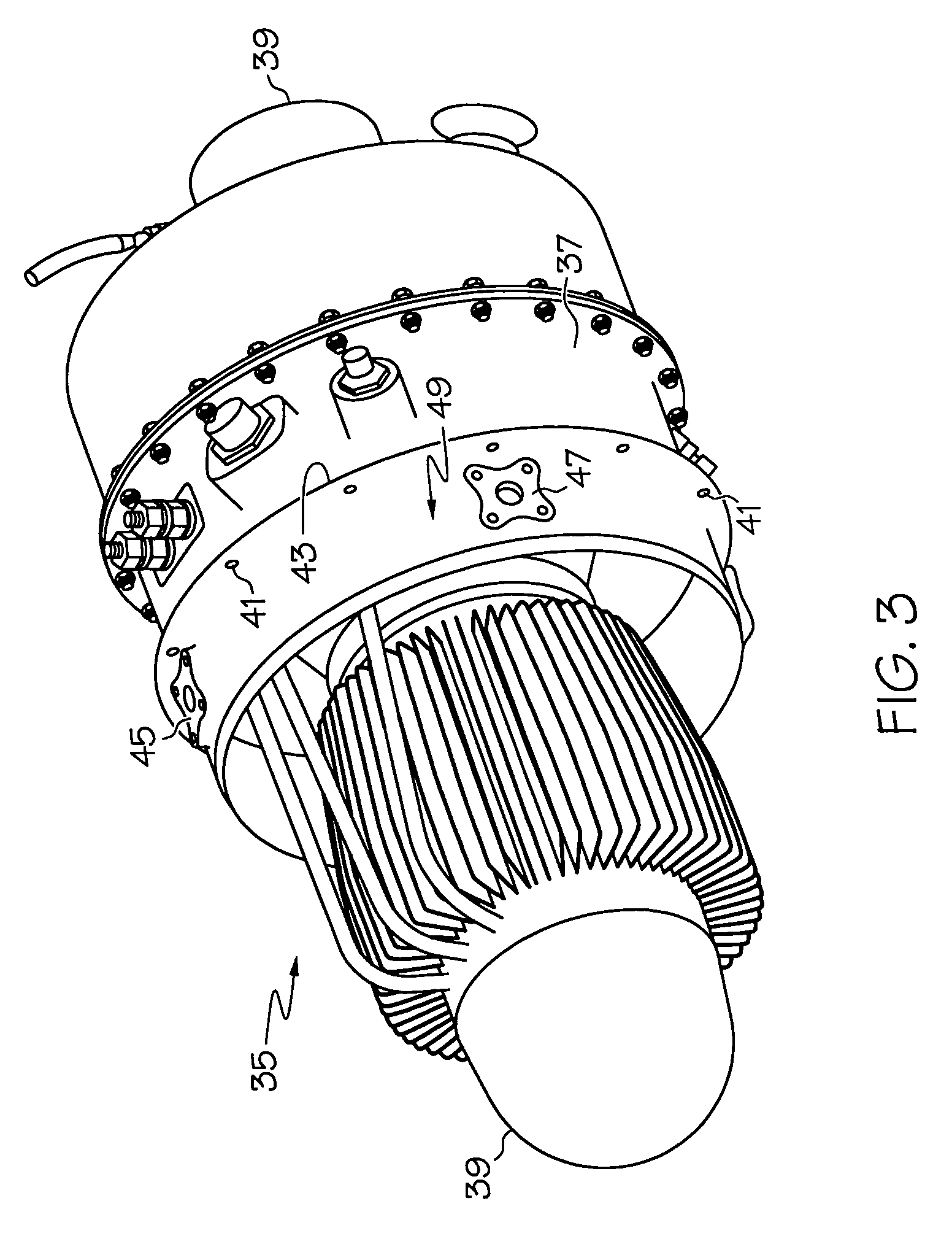

Integrated mount duct for use with airborne auxiliary power units and other turbomachines

InactiveUS7419121B2Power plant arrangements/mountingAircraft power plant componentsFlight vehicleEngineering

Owner:HONEYWELL INT INC

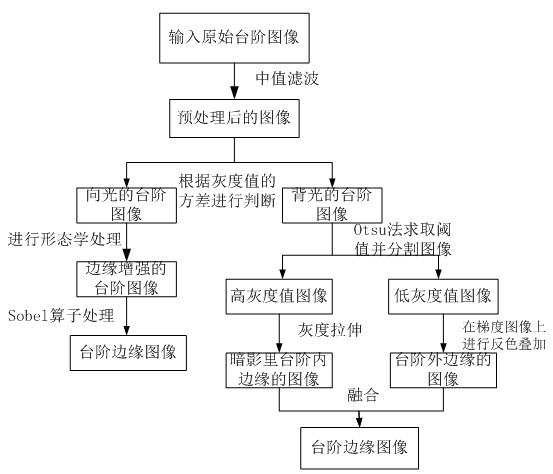

Step edge detection method oriented to humanoid robot

InactiveCN102324099ATimelinessAccuracy requirements metImage analysisMorphological processingHumanoid robot

The invention relates to a step edge detection method oriented to a humanoid robot, which comprises the following steps of: 1) preprocessing an image to the detected; 2) judging the image; 3) conducting morphological processing to the image; 4) processing the image to obtain the edges of phototropic steps; 5) seeking threshold values and converting the image into a binary image to obtain the edges of apheliotropic steps; 6) using edge lines at the step 5 to segment the image at the step 2 and conducting gray stretching to parts with high gray values to obtain a new image; 7) conducting gradient transform according to the new image obtained at the step 6 to obtain a gradient image; 8) conducting invert color transform according to the new image obtained at the step 6 and then conducting gradient transform to obtain another gradient image; 9) adding the corresponding pixel points of the two gradient images respectively obtained at the step 7 and the step 8 to obtain the edges of the image; and 10) fusing the edges obtained at the step 5 and the edges obtained at the step 9 into one image. The edge detection method provided by the invention can satisfy the requirements on the timeliness and the accuracy of the vision of the robot.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com