Patents

Literature

94 results about "Spread rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of Rate Spread. Rate Spread means the positive difference, if any, between (a) the Extension Contract Rate then in effect during the Interest Period in which the conversion of the Extension Contract Rate takes place and (b) the Federal Funds Rate on the day that is two (2) Business Days prior to the first day of such Interest Period.

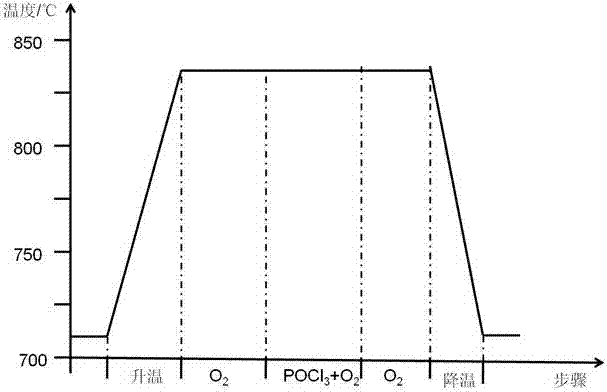

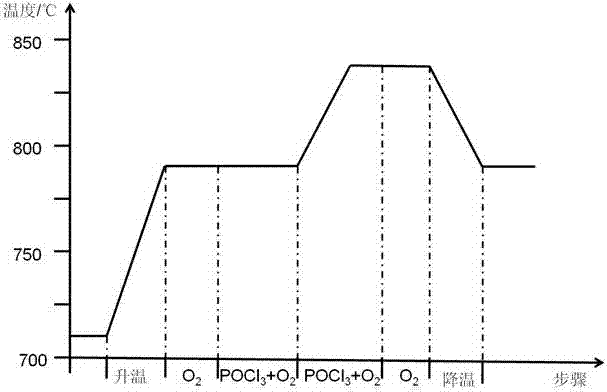

Spread method of polycrystalline silicon solar cell

InactiveCN102820383AImprove square resistance uniformityUniform concentration distributionFinal product manufactureDiffusion/dopingPre depositionSilicon chip

The invention relates to a spread method of a polycrystalline silicon solar cell. The spread method is characterized in that the spread method comprises the following processing steps of entering a boat, warming, oxidizing, spreading, redistributing, cooling and going out the boat, wherein the spreading step comprises low temperature pre-deposition and then high temperature spreading. Reaction between a phosphorus source and a silicon wafer cannot be completed under low temperature, so that the low temperature pre-deposition is carried out on low temperature source communication at a first step of spreading, the phosphorus source cannot spread (or conduct spreading with low rate) inside a silicon wafer, the phosphorus source only accumulates on the surface of the silicon wafer, and a phosphorus film with certain thickness is formed on the surface of the silicon wafer after source communication for certain time; and the high temperature spreading is carried out on high temperature source communication at a second step, phosphorus on the surface of an original silicon wafer is reacted with the silicon wafer and spreads to the inside of the silicon wafer, and spreading rates of the center point and the periphery of the silicon wafer are same. Therefore, spreading uniformity is good, concentration distribution of impurities on the surface of the silicon wafer and inside the silicon wafer body is even, sheet resistance uniformity is improved, and final photoelectric conversion efficiency of a cell sheet is improved accordingly.

Owner:JIANGYIN XINHUI SOLAR ENERGY

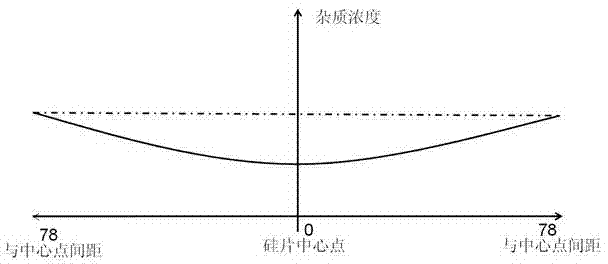

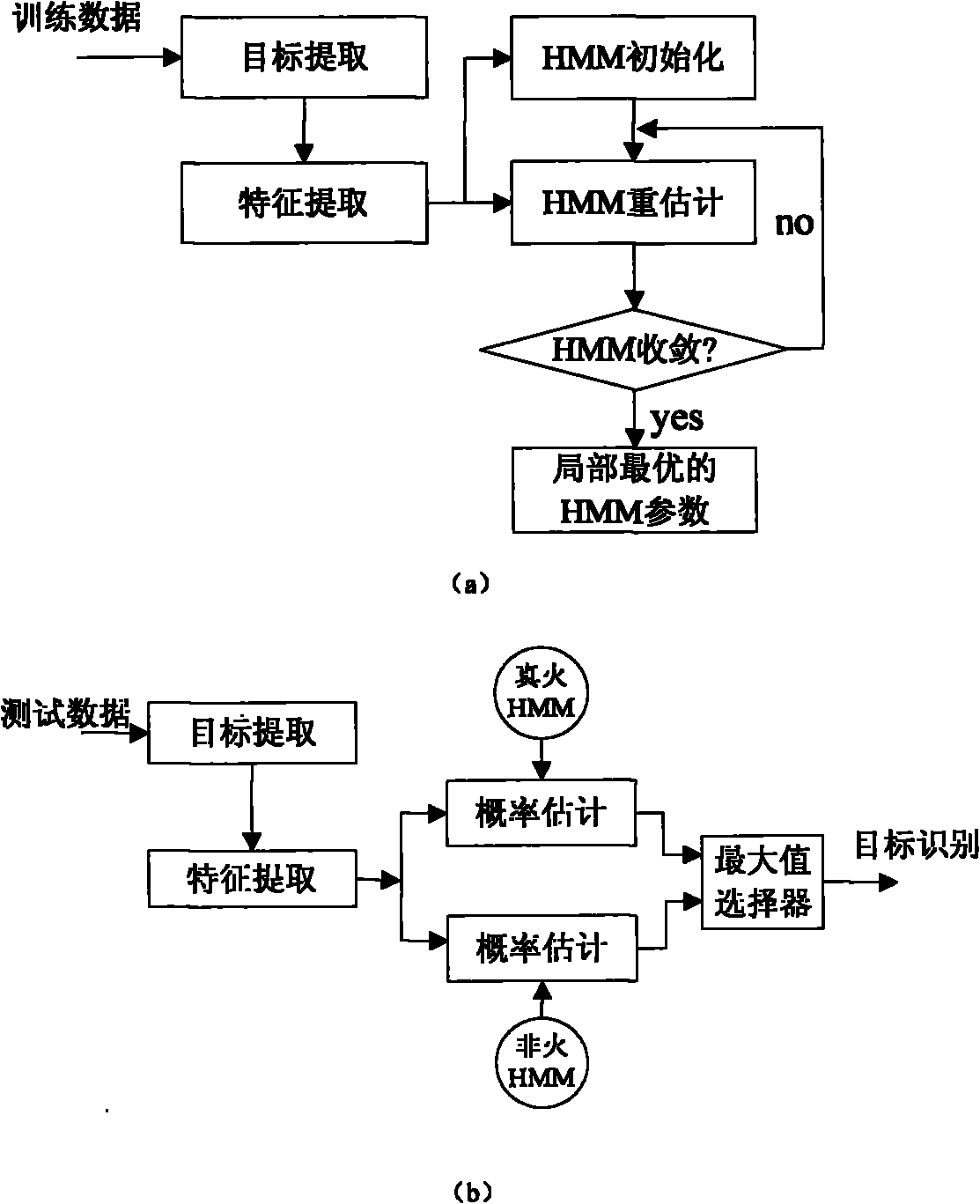

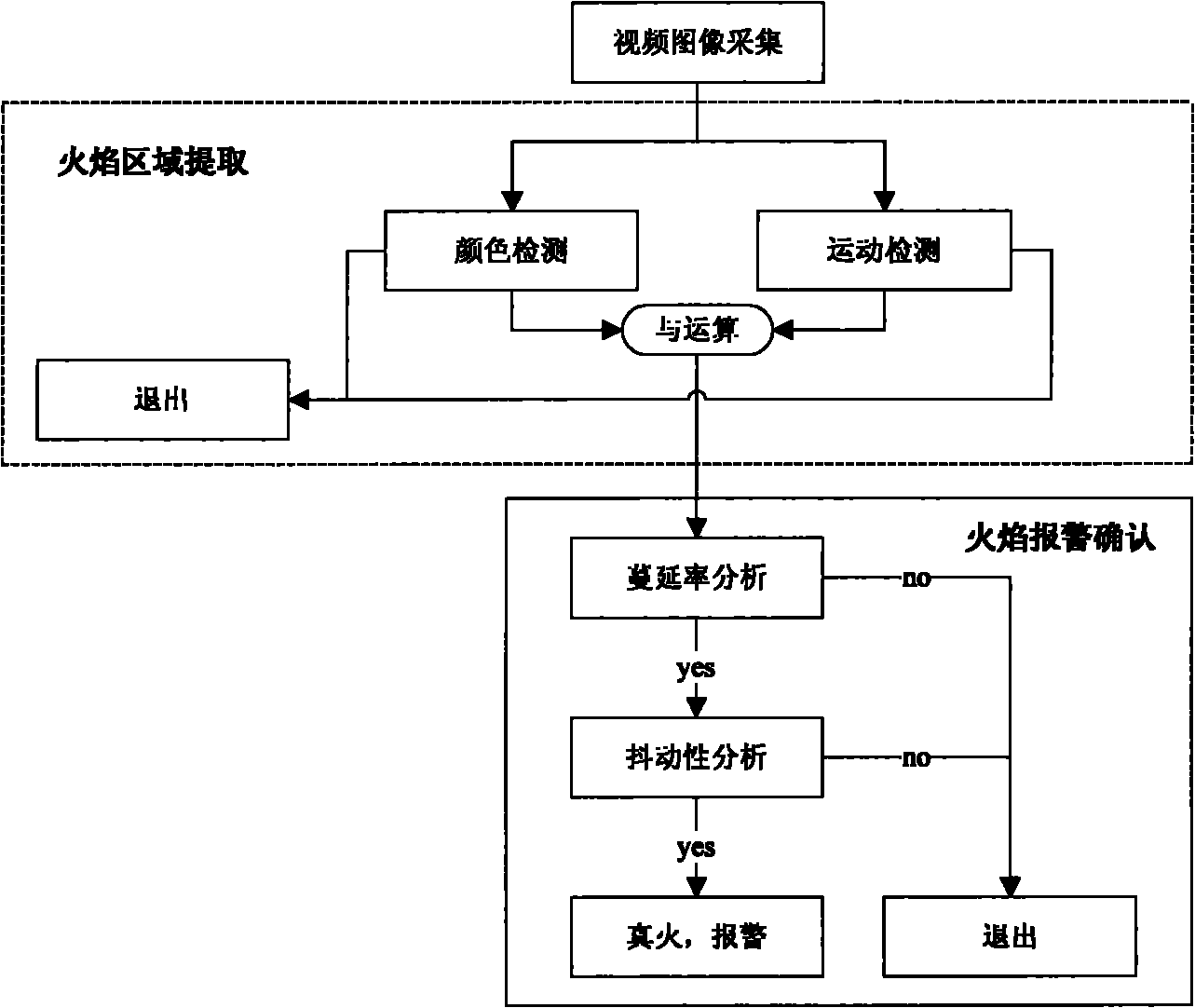

Flame detection method based on video image

InactiveCN101840571AAccurate detectionAccurate automatic tracking alarmImage analysisTime domainFlame detection

The invention relates to a flame detection method based on a video image and solves the defects of the existing fire monitoring method. The method comprises the following steps that: the video image is acquired first, color detection is conducted to the video image according to the spatial domain features of a flame, a flame color region in the video image is extracted, and motion detection is conducted to the acquired video image according to the spatial domain features of the flame to realize the extraction of a motion region in the video image; pixel-by-pixel AND operation is conducted to the obtained flame color region and the video motion region, and spread rate analysis is conducted to exclude the interference of flame analogues and to obtain a final flame pixel region; and shake analysis is conducted to the final flame pixel region and finally the alarm confirmation of the flame is conducted. From the spatial domain and the time domain, in combination with the flame color detection method and the motion detection method to obtain a suspect fire region, the method realizes the accurate detection and extraction and the automatic tracking and alarm of the flame, and provides strong method supports for the intelligentization of fire monitoring devices.

Owner:南通升环木业有限公司

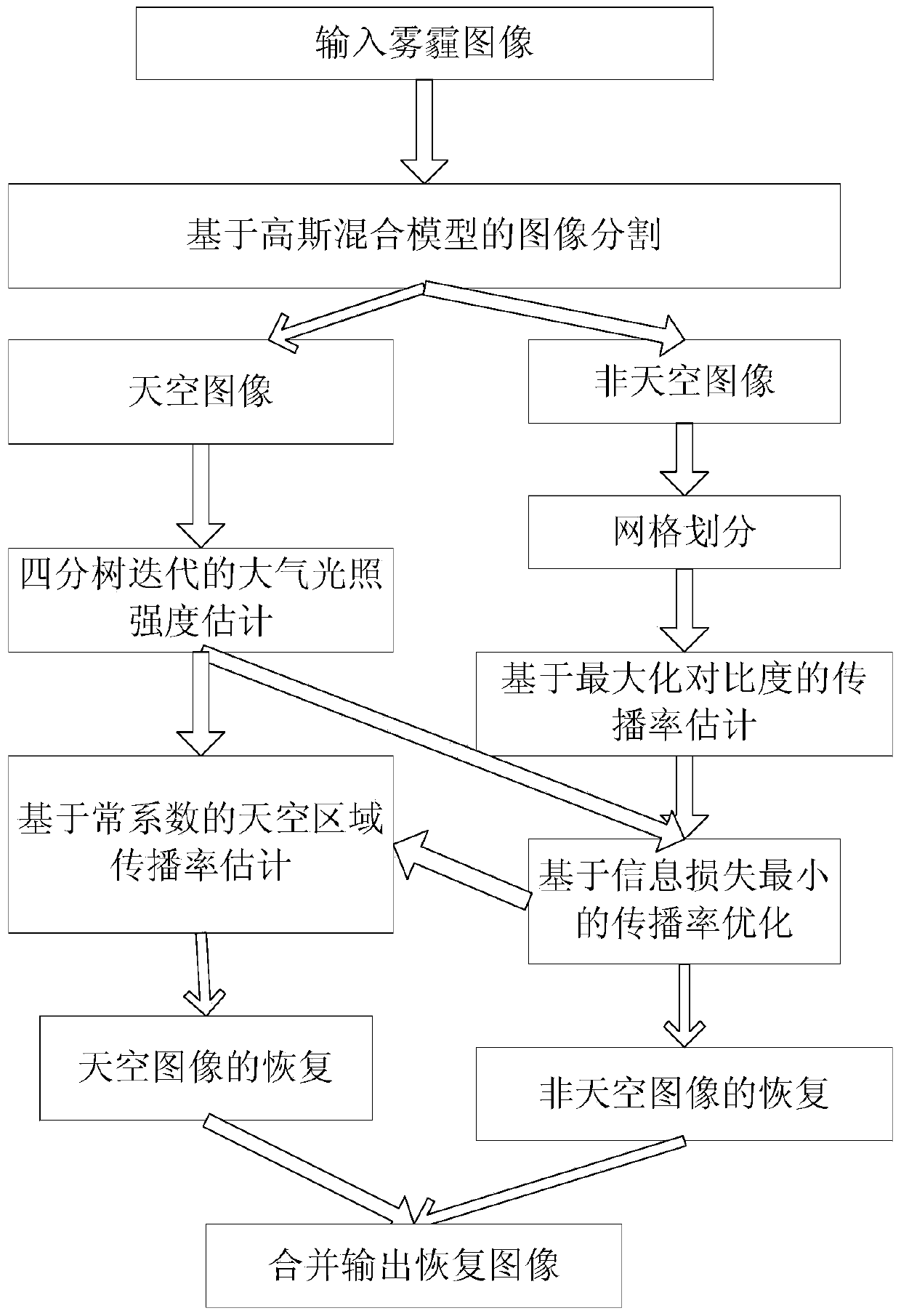

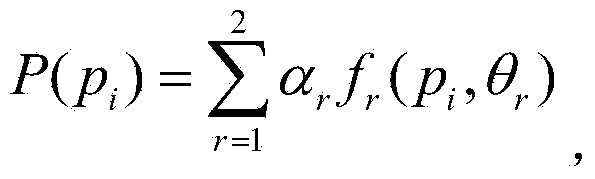

Image defogging method with optimal contrast ratio and minimal information loss

The invention relates to an image defogging method with optimal contrast ratio and minimal information loss. The image defogging method is characterized in that through the adoption of functions including the Gauss mixed model, the quadtree, the maximal contrast ratio and the minimal information loss, the image defogging method is realized. The image defogging method comprises the following steps: firstly, based on the Gauss mixed model and the expected value maximal algorithm, images are segmented into two categories, namely, a sky region and a non-sky region; secondly, the quadtree iteration method is adopted in the sky region of the images to estimate the atmospheric illumination intensity of an atmospheric scattering model; then, the grid partition method is adopted to partition the non-sky region of the images and the functions of the maximal contrast ratio and the minimal information loss are adopted to calculate the spreading rate of an atmospheric lighting model of each grid unit; based on the constant coefficient and the optimal spreading rate of the non-sky region, the spreading rate of the sky region is estimated; finally, the recovery images of the sky region and the non-sky region are merged and output.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

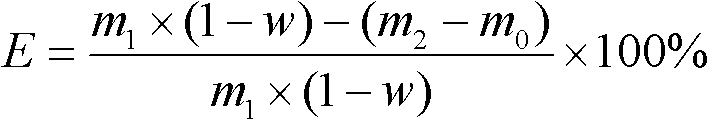

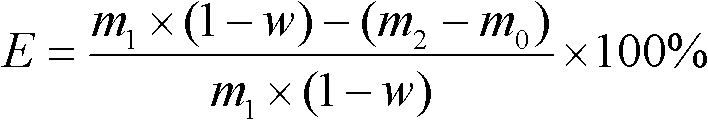

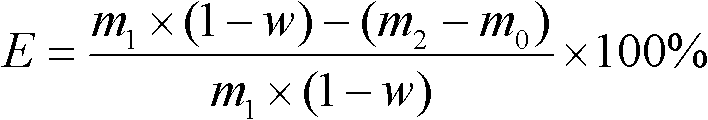

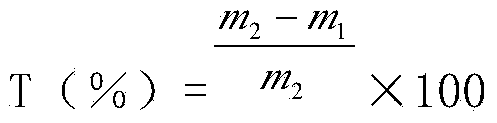

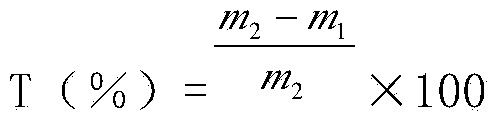

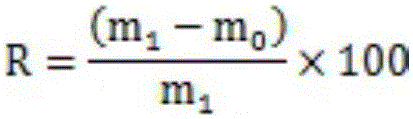

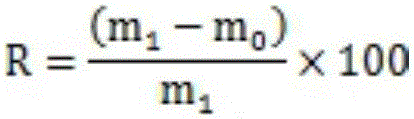

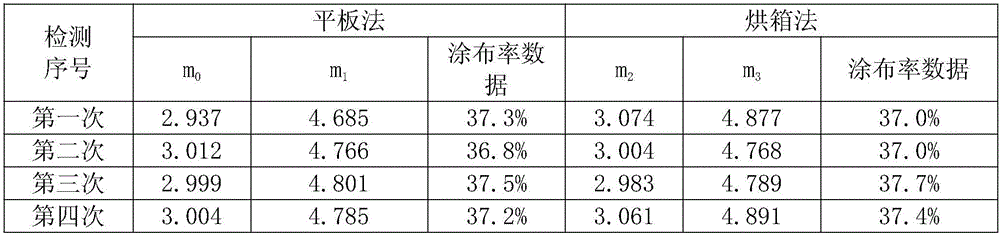

Method for determining spreading rate of paper-process reconstituted tobacco finished products

The invention relates to a method for determining the spreading rate of paper-process reconstituted tobacco finished products, which belongs to the technical field of reconstituted tobacco. The method includes steps: a, taking a certain quantity of paper-process reconstituted tobacco and a sheet base to be shredded, and the placing the tobacco shreds into a constant-temperature and constant-humidity box with the temperature of 22 DEG C and the humidity of 60% to balance for 48 hours; b, weighing a certain quantity of reconstituted tobacco shred samples m1 to be placed in a solvent cup of a Soxhlet extractor, adding distilled water according to feed to liquid ratio of 1:30, and setting the circulation times of the Soxhlet extractor to be 10 times, and the extracting temperature to be 19-level and the temperature of a condensing circulation pump to be 2 DEG C to extract; c, taking out the samples after extraction is finished, transferring the samples into an aluminum box reaching the constant weight of m0, placing the aluminum box into a drying oven, drying the samples at the temperature of 100+ / -1 DEG C so that the constant weight of the aluminum box is m2, realizing the precision of the constant weight to be 0.001g, determining moisture content w of the samples, and extracting the sheet base of the reconstituted tobacco by the same method; and d, calculating the spreading rate according to a formula. The method has the advantages that the method is simple, and is applicable to determining the spreading rate of the paper-process reconstituted tobacco finished products.

Owner:YUNNAN RES INST OF TOBACCO SCI

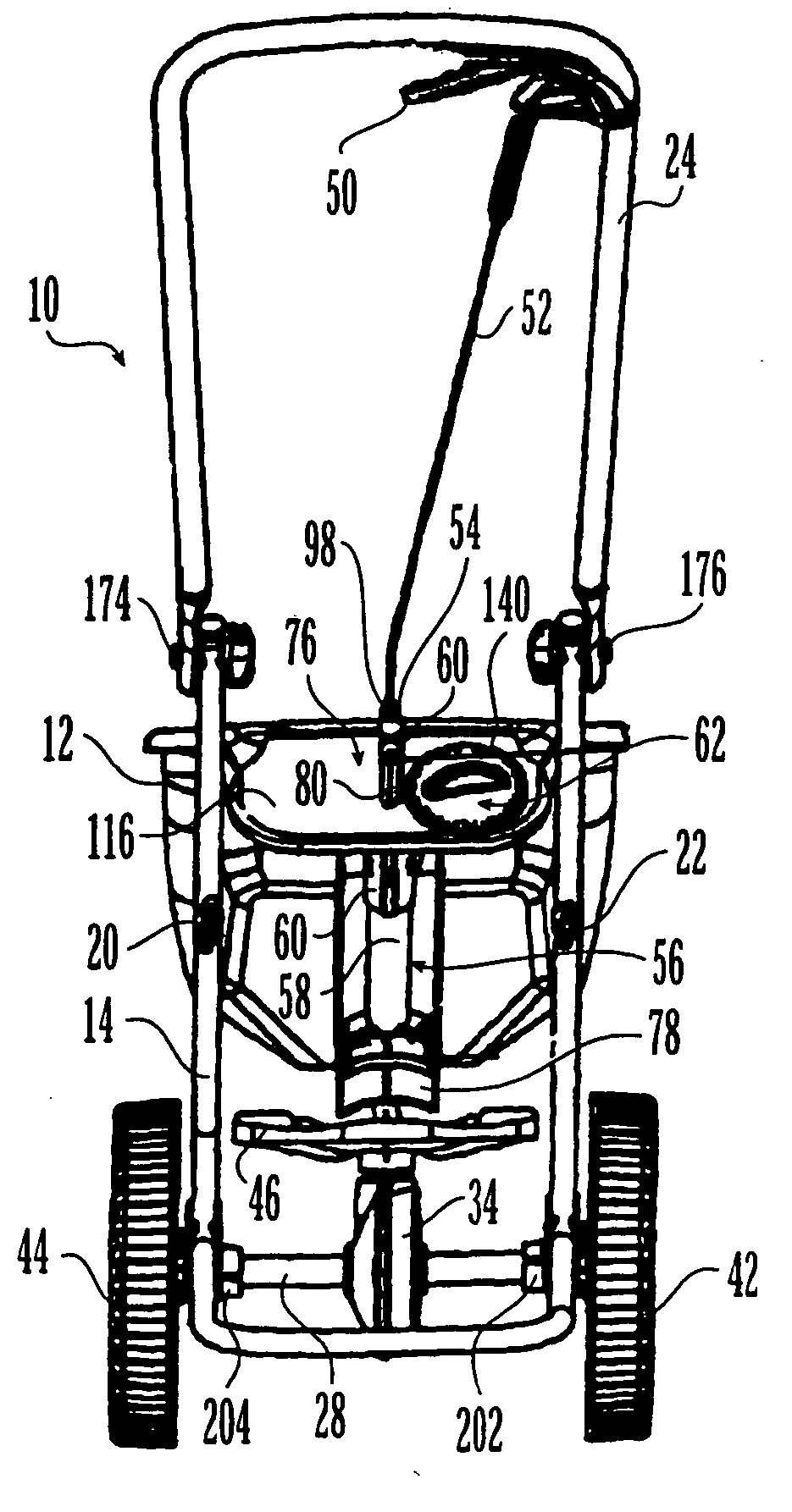

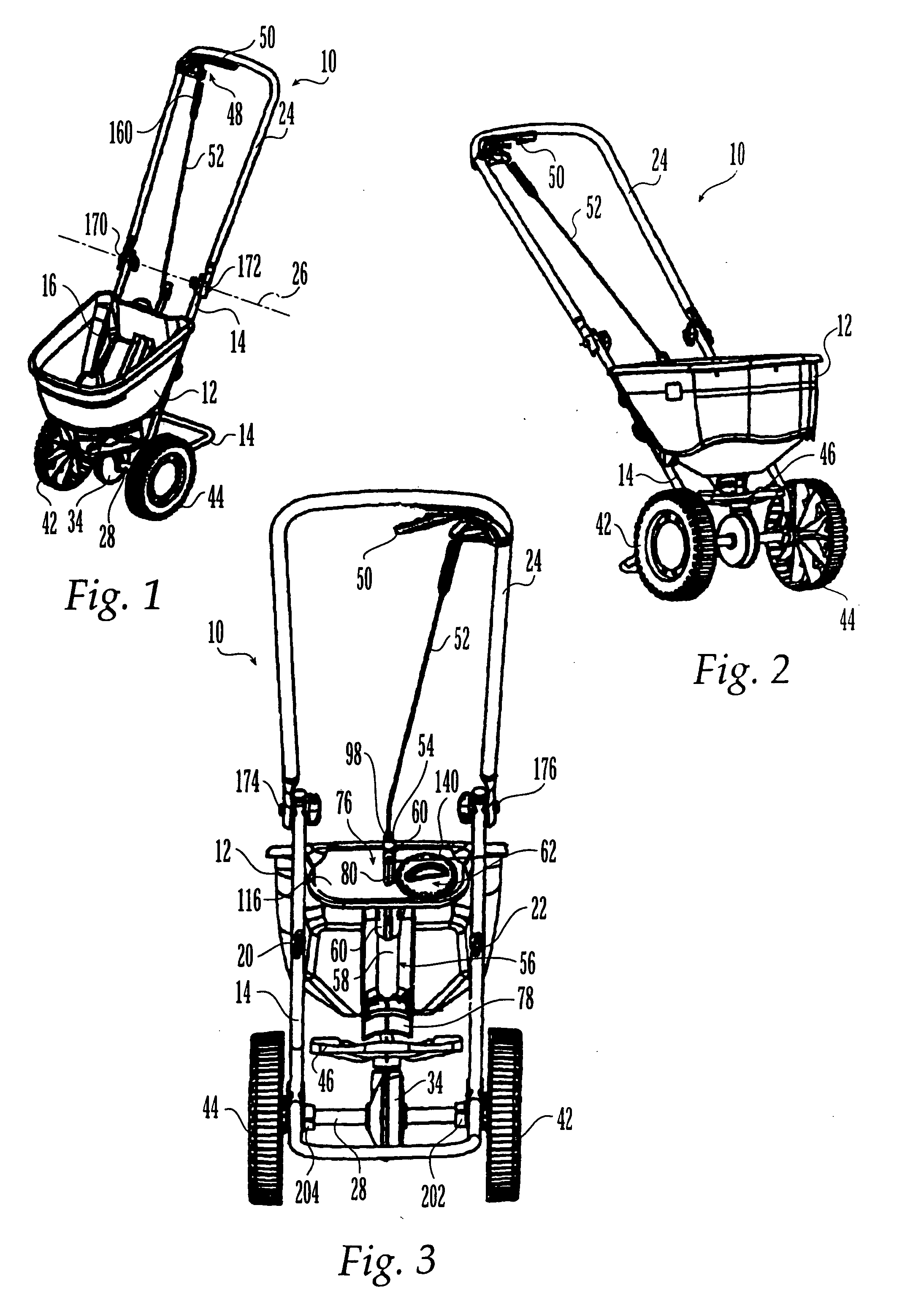

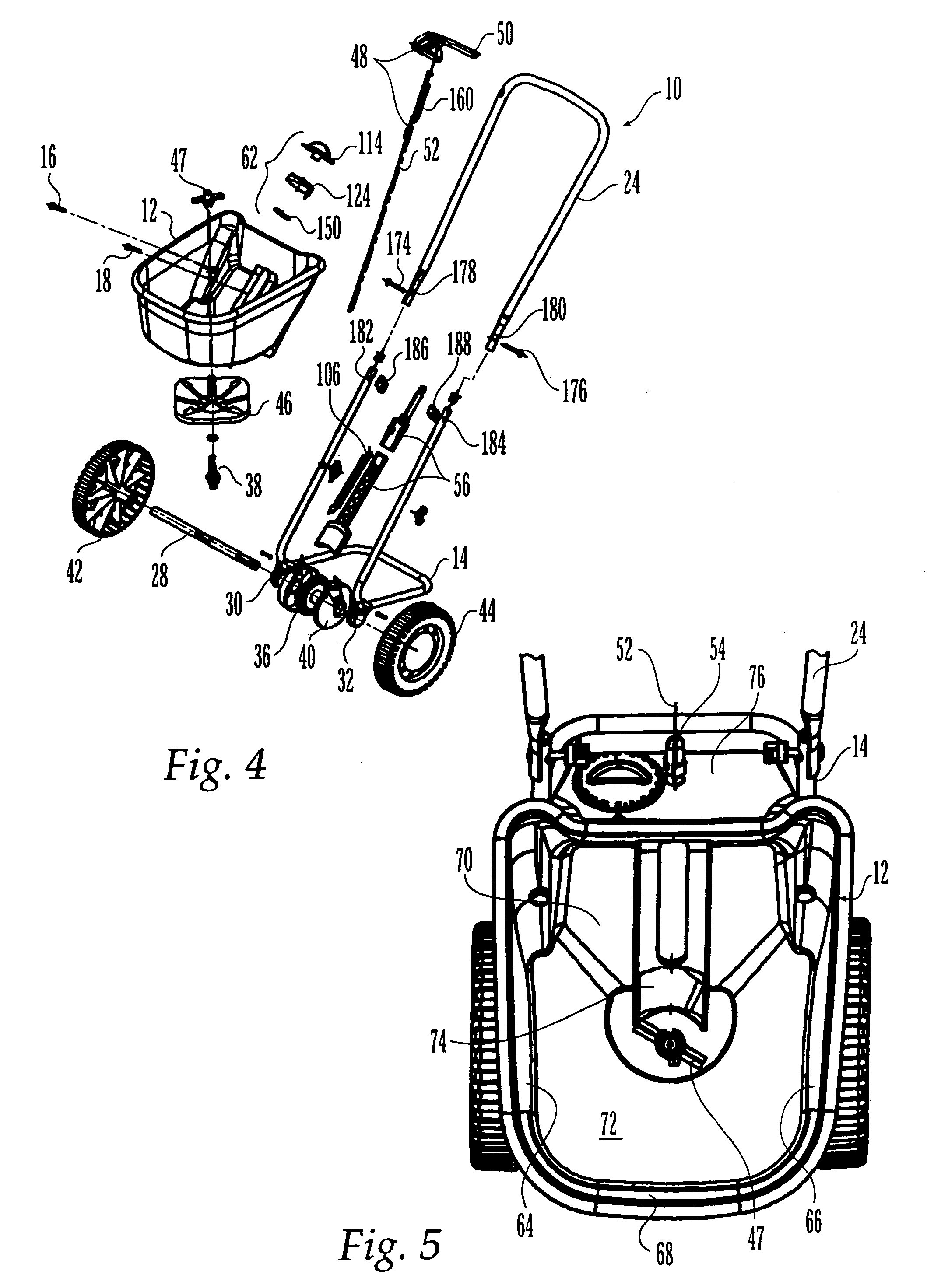

Collapsible spreader

ActiveUS20060157518A1Easy constructionEasy to assembleFertiliser distributersCentrifugal wheel fertilisersMechanical engineeringSpread rate

An improved collapsible spreader with a spread rate selection mechanism including a knob and a rotatable cup-shaped structure. The cup-shaped structure includes an elongated setting tab and a thirty-six step edge corresponding to thirty-six spread rate settings on the knob. Operatively engaged with the cup-shaped structure is an abutment tab that is part of a closure structure for blocking and selectively unblocking a hopper opening. The tab engages the setting tab to define the adjustable length of the closure structure. Thereafter, abutment rate selection is a function of the rotatable position of the cup-shaped structure. Engagement of the abutment tab and a step defines the size of the hopper opening and thus the amount of product released from the hopper during operation. The spreader also includes a dual spring arrangement to bias the closure structure to a closed position and to prevent breakage. The disclosed spreader also features a one piece wheel to reduce parts and assembly costs.

Owner:OMS INVESTMENTS INC

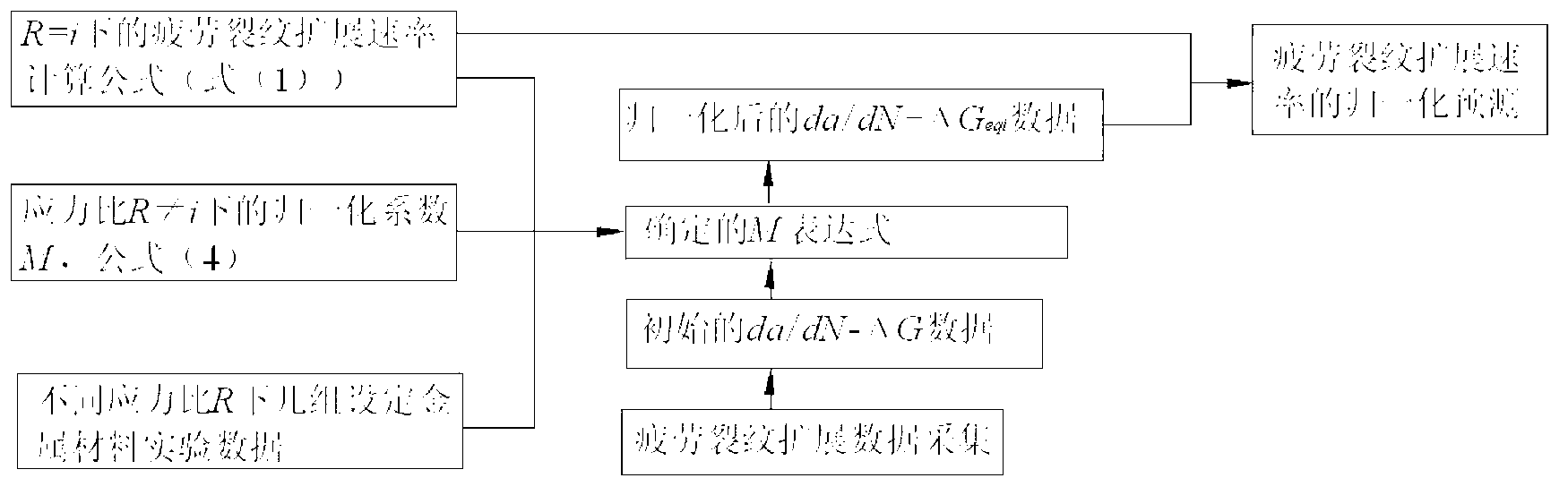

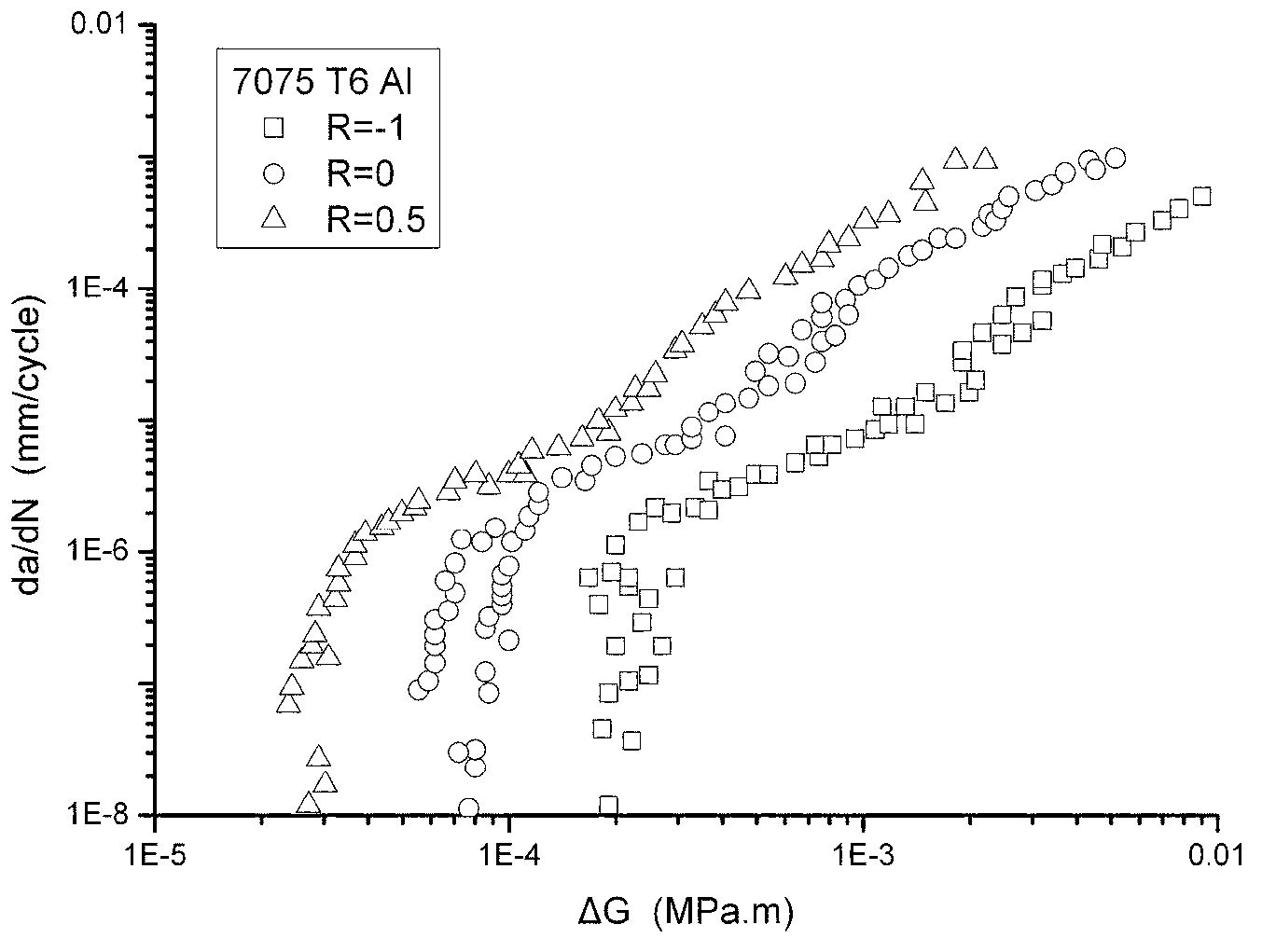

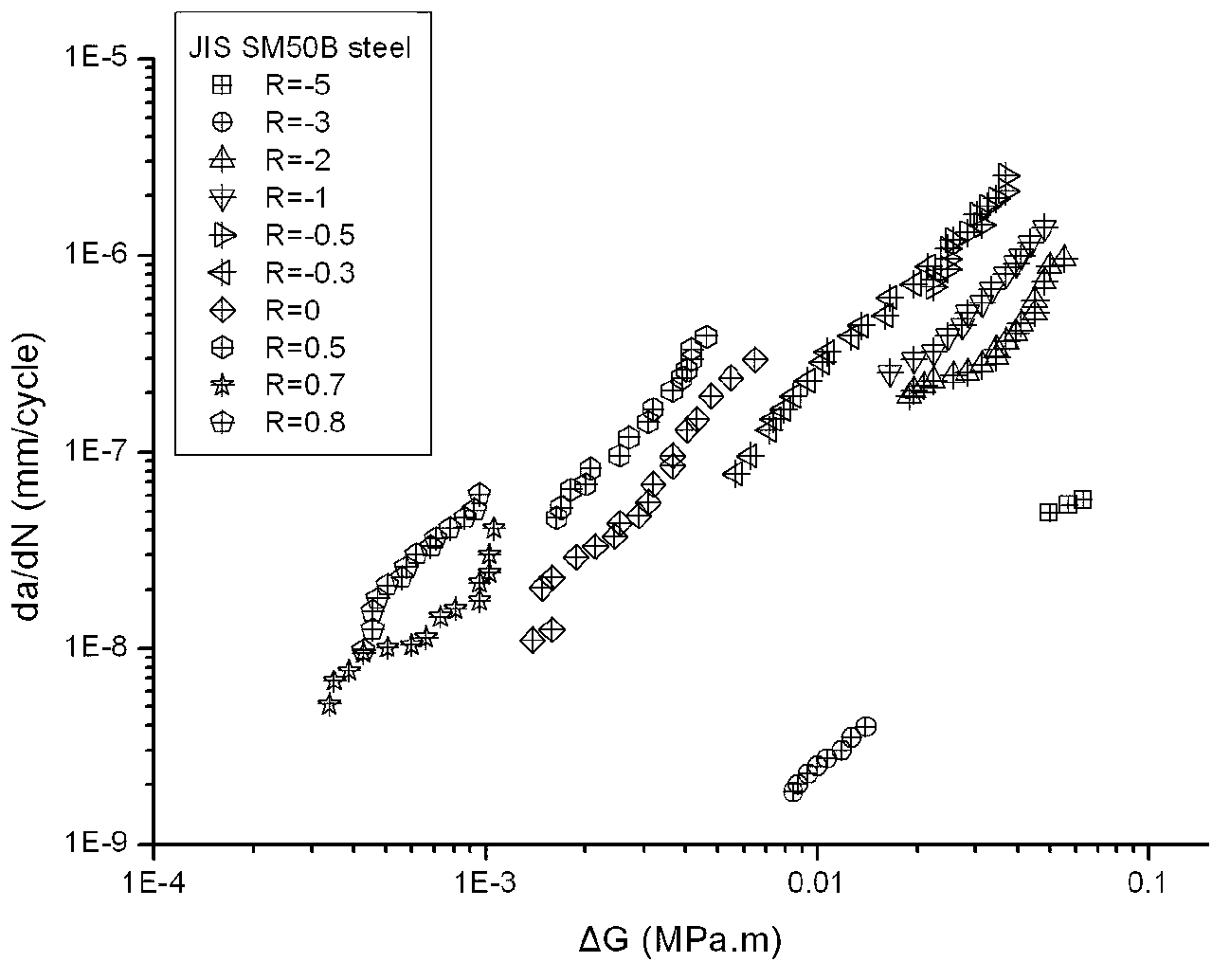

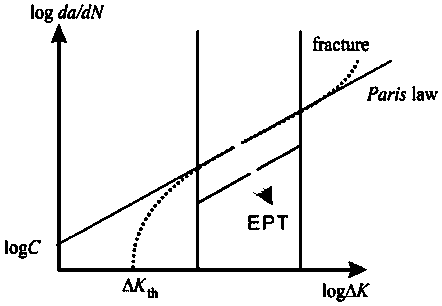

Fatigue crack spreading rate normalization forecasting method

ActiveCN103308381ASimple methodWell formedSpecial data processing applicationsStrength propertiesApplicability domainStress ratio

The invention relates to the field of forecast of a fatigue crack spreading rate of a material, and in particular relates to a fatigue crack spreading rate normalization forecasting method based on the energy release rate. The method comprises the following steps of: drawing a data map for setting a metal material to be under different stress ratios; constructing a fatigue crack spreading rate calculation formula for the metal material under the stress ratio of R:i of 1:1, FORMULA, and expressing the formula as a function; determining experiment constants and curves of the expression under the stress ratio of R:i of 1:1; constructing normalization method expressions of experiment data under different stress ratios that R is not equal to i, and obtaining the normalization method expressions, FORMULA; determining the value Alpha and a math expression Alpha=f(R), and determining an expression of a stress ratio normalization coefficient M and an expression of a data normalization method; and forecasting normalized data through the fatigue crack spreading rate formula under the determined stress ratio of R:i of 1:1. The method has the characteristics of simplicity, wide application range and the like and is favorable for engineering application.

Owner:HEFEI GENERAL MACHINERY RES INST

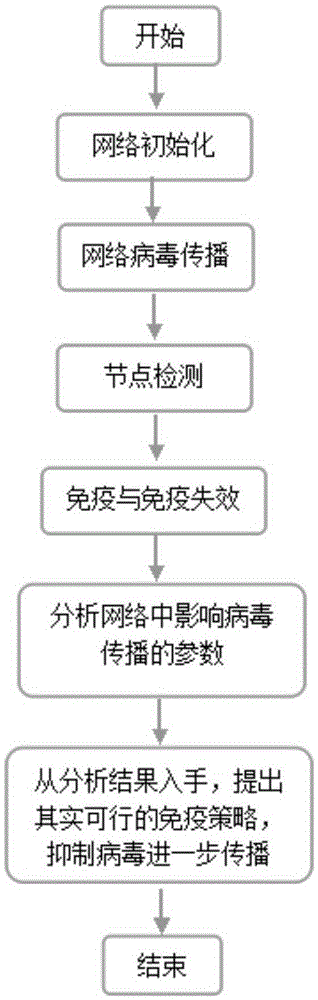

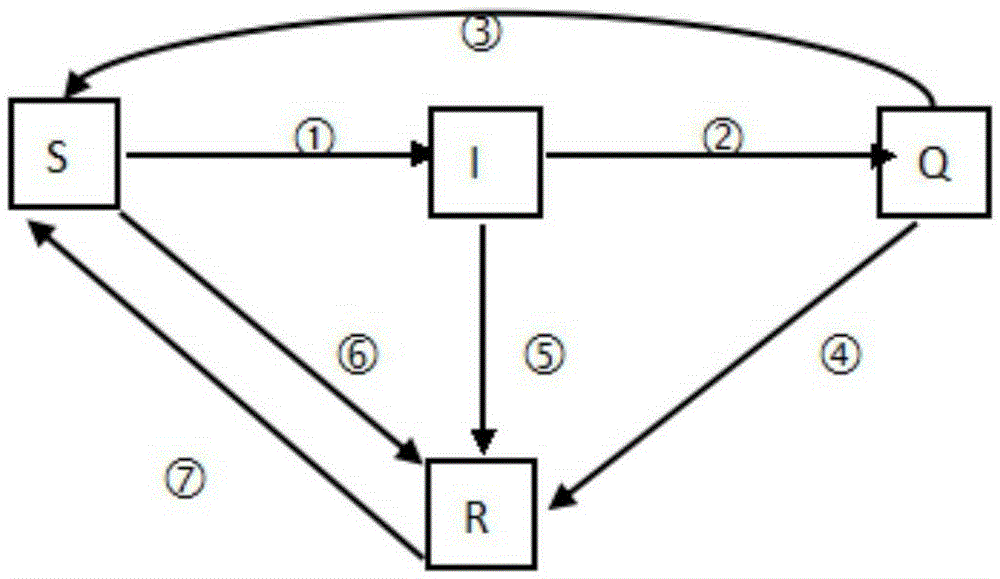

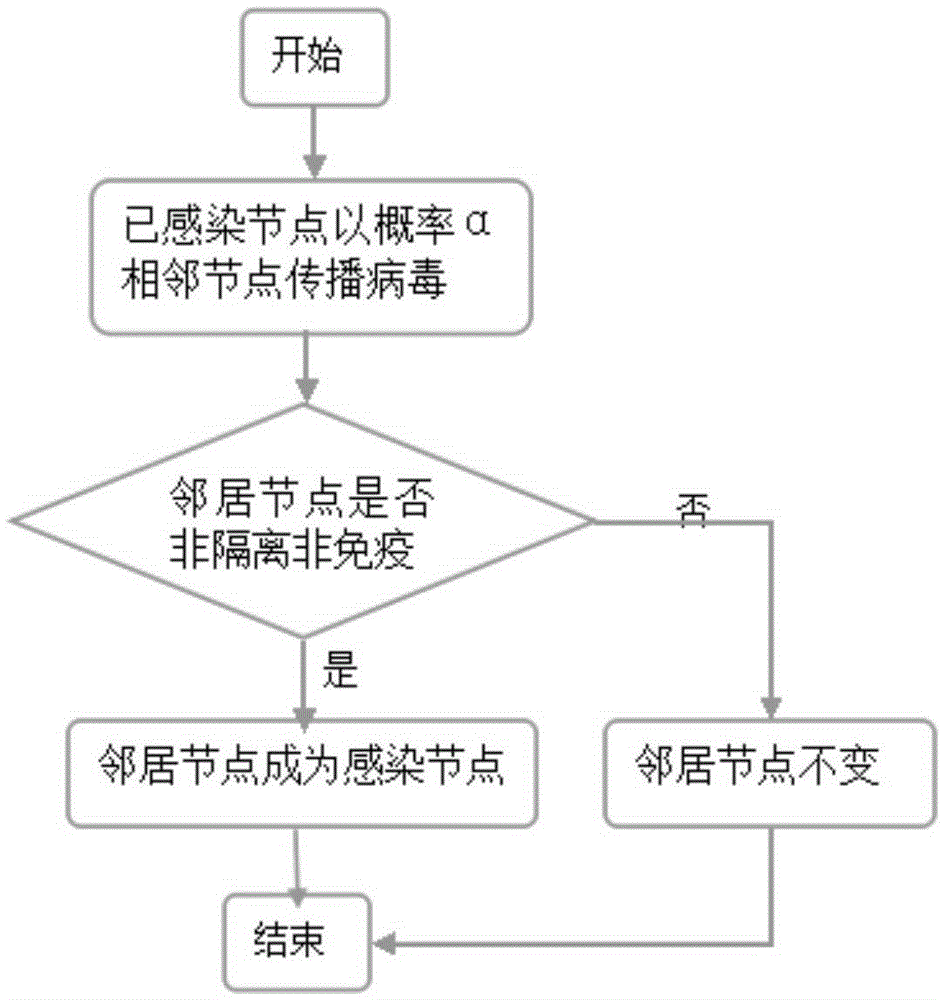

Network virus transmission behavior modeling method

The invention discloses a network virus transmission behavior modeling method. The method comprises a network initialization process, a virus transmission process, a node detection process, an immunization and immunization failure process, a model evaluation process and an immunization strategy proposing process. When a model runs, an infected state (I) node transmits a virus to a neighbor node at certain probability; an infectious state (S) node is infected into the infected state (I) node by the virus at the certain probability; meanwhile, the infected state (I) node is isolated at the certain probability, and becomes an isolated state (Q) node which does not have the virus transmission capacity and cannot be infected; and an immune state (R) node which cannot be infected by the virus appears in the model through treatment on the isolated state (Q) node and immunization on all nodes. The factors affecting virus transmission in the SIOR model include total node number n, average node degree <k>, initially infected node number n<0>, virus transmission rate alpha, isolating treatment rate beta and isolating recovery rate lambda; and the cured node has immune efficacy probability mu, vaccine injection rate gamma and vaccine failure rate eta. An achievable immunization strategy is proposed on the basis of these factors.

Owner:HOHAI UNIV

Dry powder extinguishing agent using expansible graphite as main material

InactiveCN102921139AImprove the disadvantage of poor re-ignition resistanceReduce heat radiation powerFire extinguisherAnticaking agentFire - disasters

The invention provides a dry powder extinguishing agent using expansible graphite as a main material; the dry powder extinguishing agent comprises the main material and additives, wherein the main material is graphite which is expansible when being heated; and the additives are anti-blocking agent, inert adding component and so on. According to the invention, the heat insulating efficiency and anti-burnback performance of the dry powder extinguishing agent during extinguishing large-area pool fire and flowing fire can be enhanced, and spread rate and scale of a fire disaster mainly caused by thermal radiation are effectively reduced.

Owner:CHINESE PEOPLES ARMED POLICE FORCE ACAD

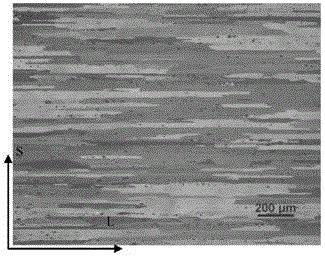

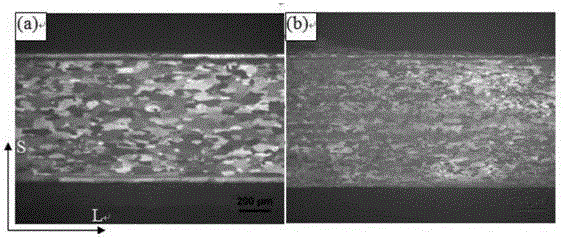

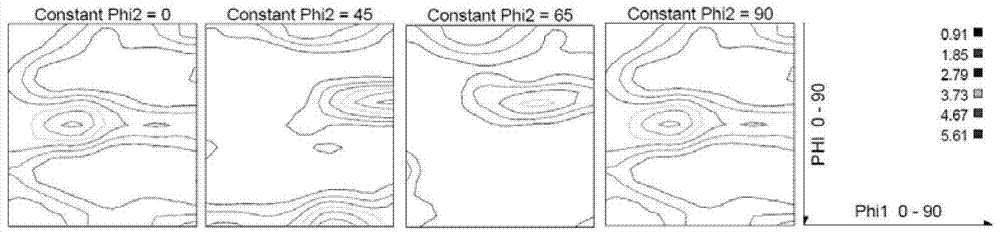

Machining technology for improving fatigue damage resisting performance of 2xxx aluminum alloy plate

ActiveCN105483579AImproved resistance to fatigue damageImprove resistance to fatigue damageAviationFatigue damage

The invention relates to a machining technology for improving the fatigue damage resisting performance of a 2xxx aluminum alloy plate. The machining technology comprises the following steps that 1, alloy is subjected to burdening smelting and is cast into an ingot casting; 2, the ingot casting is sequentially subjected to homogenization treatment, surface milling and aluminum cladding, preheating is carried out, and a hot rough-rolled plate is manufactured; 3, the hot rough-rolled plate is subjected to hot finishing and cold rolling deformation to the thickness of the finished plate; 4, recrystallization pre-annealing treatment is carried out, temperature is raised to 300-450 DEG C at the average speed of 10-300 DEG C / h or within 1.0-45 h, and heat preservation is carried out for 1-20 h; 5, solid solution hardening treatment is carried out, the solid solution temperature is 480-505 DEG C, and heat preservation time is 3-60 min; and 6, the plate is straightened, and natural ageing is carried out to the stable state. According to the machining technology, recrystallization pre-annealing treatment is added so that the L-ST section grain average equivalent diameter and grain length-width ratio of the plate can be effectively controlled, and the tensile mechanical property and fatigue crack spreading rate of the plate can both meet the AMS 4296 aviation standard requirement.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD +1

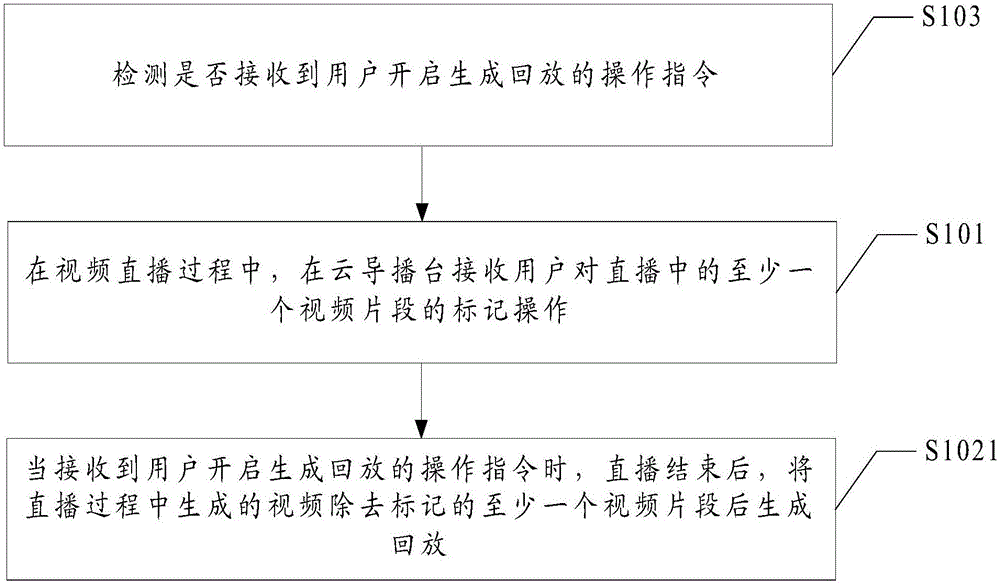

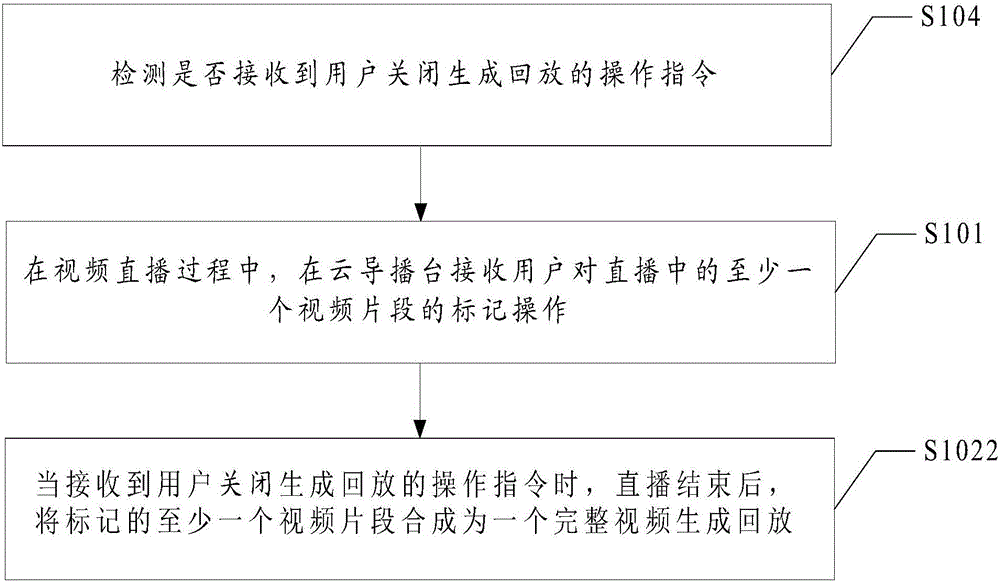

Live streaming playback method and device

The disclosure relates to a live streaming playback method and device. The method includes the steps of receiving marking operations of a user of at least one video fragment during live streaming on a cloud director platform during a video live streaming process, and after live streaming ends, generating playback on the basis of the at least one video fragment marked during live streaming. Playback is generated selectively according to the marked video fragments when the live streaming process is too long. Therefore, live streaming can be edited quickly and conveniently, playback can be generated, wonderful moments of live streaming activities can be effectively recorded, and the secondary spreading rate of playback can be increased.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

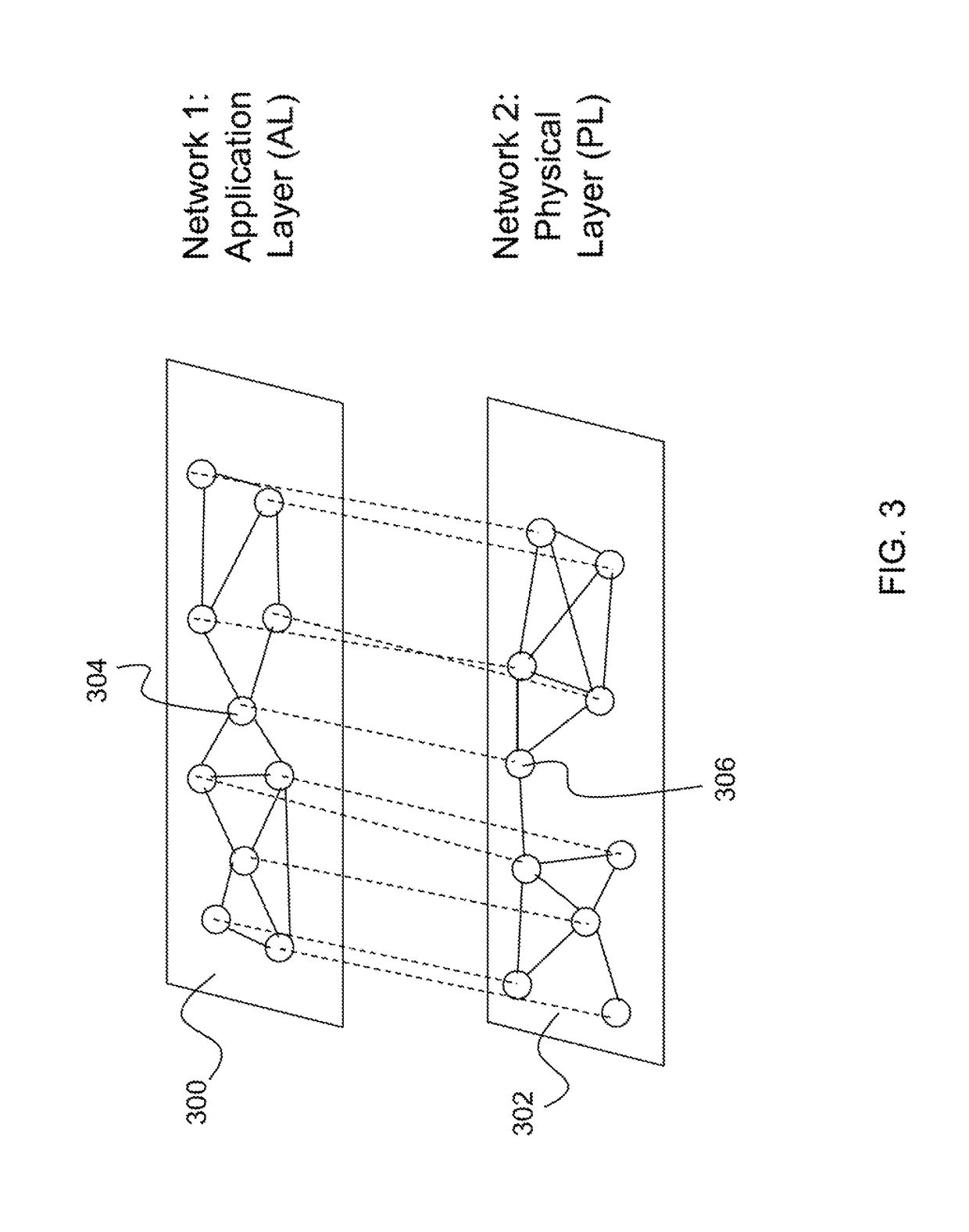

Method for determining contagion dynamics on a multilayer network

Described is a system for predicting temporal evolution of contagions on multilayer networks. The system determines a functional epidemic threshold for disappearance of a contagion on a multilayer network model according to a score value s=λβ / δ, where λ corresponds to an adjacency matrix of the first layer of the multilayer network model, β represents a spread rate of the contagion, and δ represents a recovery rate. A prediction of future behavior of the contagion on the multilayer network model using the functional epidemic threshold is output and utilized to inform decisions regarding connectivity within a multilayer network in order to prevent spread of the contagion on a multilayer network.

Owner:HRL LAB

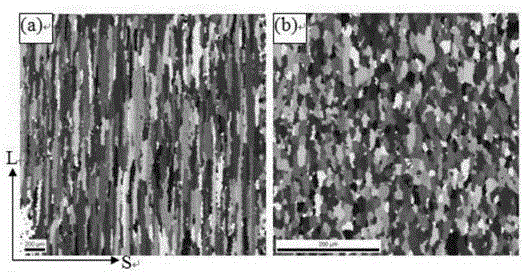

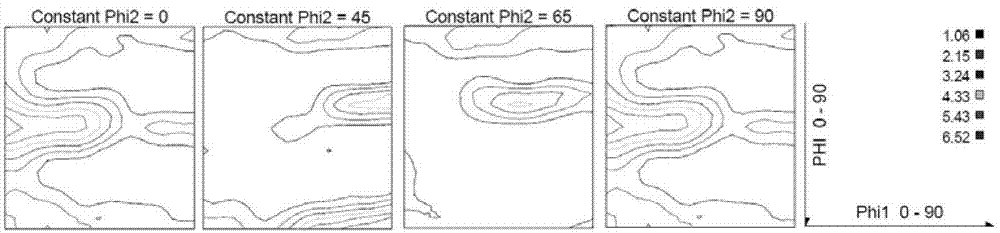

Heat treatment method capable of improving anti-fatigue performance of aluminum alloy

ActiveCN103045976AEliminate entangled dislocation configurationsStress reliefRoom temperatureCorrosion fatigue

The invention relates to a heat treatment method capable of improving the anti-fatigue performance of Al-Cu-Mg alloy. The method comprises the following steps: performing intermediate annealing on a cold-rolled plate at the temperature of between 300 and 440 DEG C for 20 to 120 minutes; performing solution hardening treatment at the temperature of between 475 and 505 DEG C for 10 to 120 minutes; and naturally ageing at room temperature for at least 100 hours. The Al-Cu-Mg alloy comprises the following components: Cu, Mg, Mn, Ti and Al. The process method is simple and reasonable. By the intermediate annealing heat treatment process, the Gauss texture score of the alloy is increased, and orientation of most of crystal faces {111} of crystal grains of the cold-rolled Al-Cu-Mg alloy is positioned or close to the direction of the maximum external shearing stress, so that reciprocating sliding dislocated under the action of alternating stress is promoted, the closed effect of fatigue crack is improved, the spreading rate of the fatigue crack is reduced, and the alloy has excellent stress corrosion resistance and anti-stripping corrosion fatigue performance and is suitable for industrialized application.

Owner:CENT SOUTH UNIV

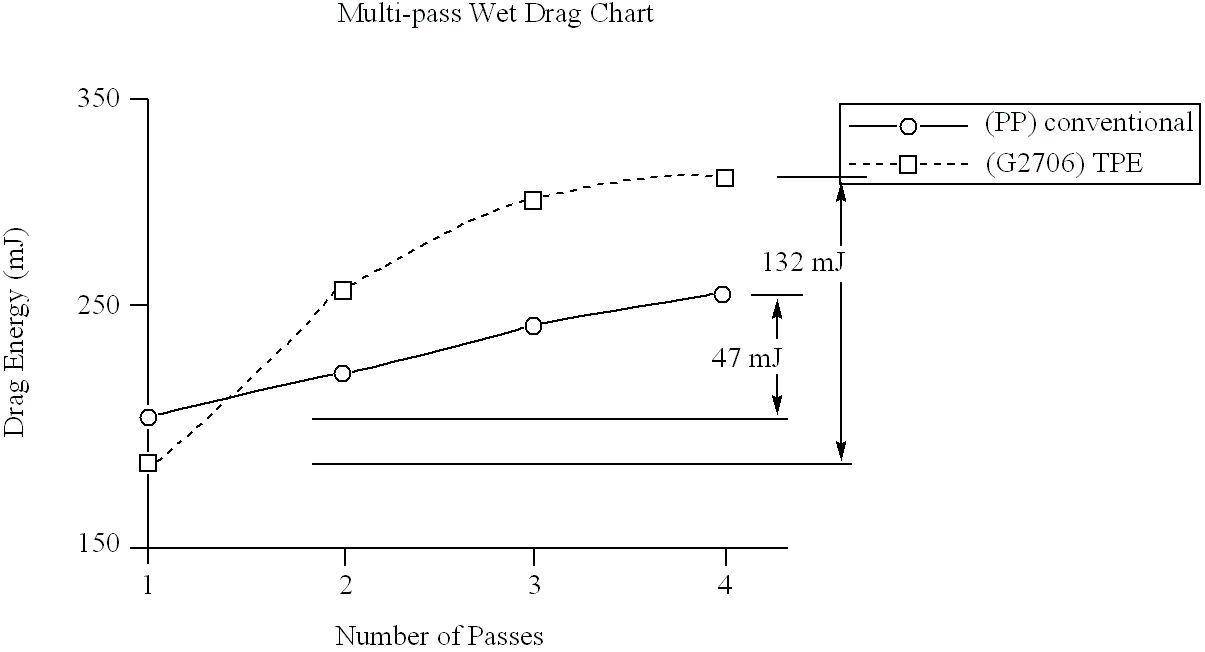

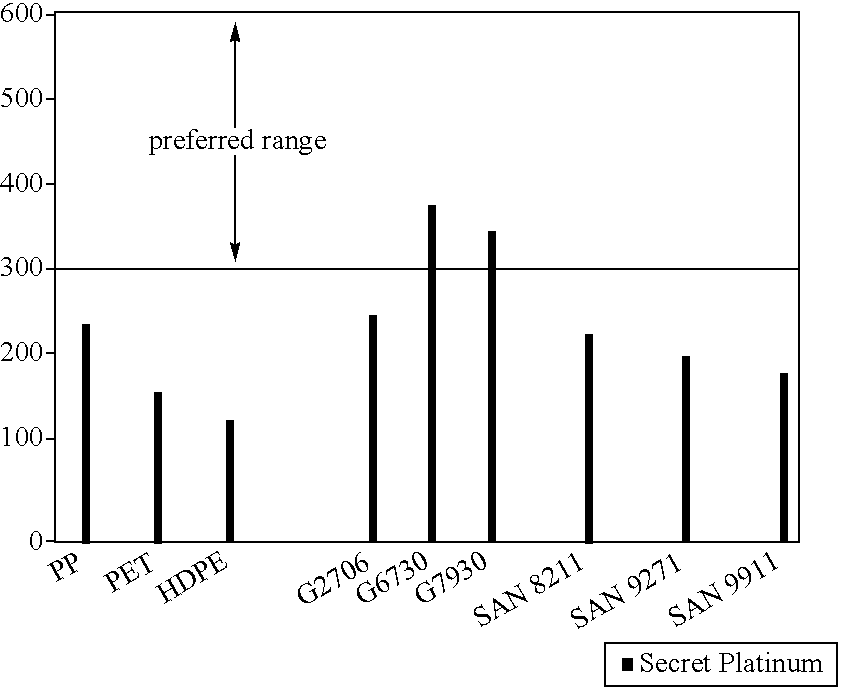

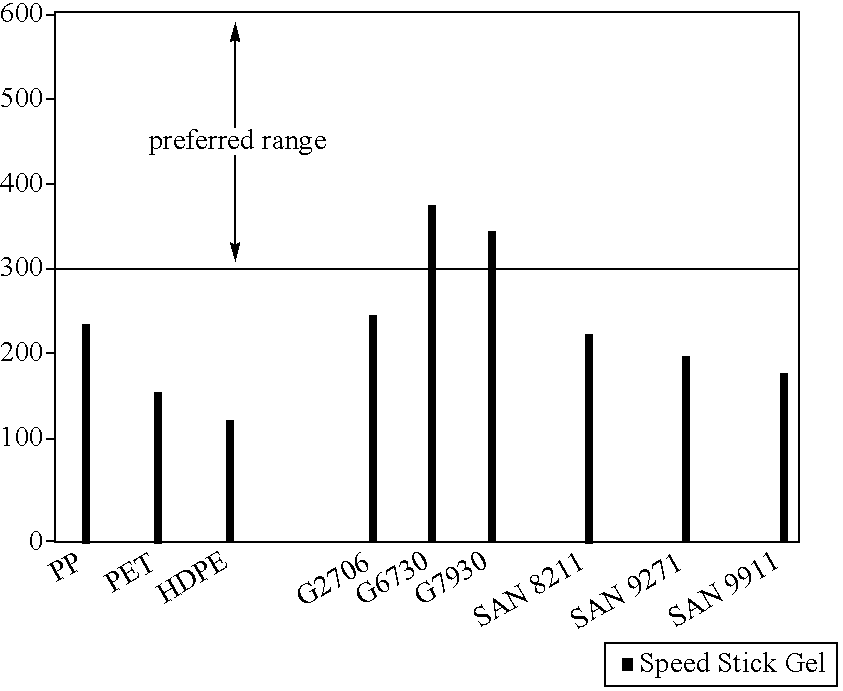

Soft applicator dome

InactiveUS20020048483A1Liquid surface applicatorsPropelling pencilsThermoplastic elastomerBiomedical engineering

An applicator being constructed to include a thermoplastic elastomer. In another embodiment, an applicator dome has a first material and a second material, wherein, the first material is made of a thermoplastic elastomer and the second material is made of a material having more rigidity than the first material. The second material provides structural support for the first material. In yet another embodiment, an applicator dome has a first material and a second material, wherein, the first material has a Dimethicone Droplet Spread Rate value from about 200 mm2 to about 900 mm2. In yet another embodiment, an applicator dome has an inward-deflection value of at least 0.17 mm2. This embodiment may also include an outward-deflection value ranging from 0.000 mm to about 0.40 mm. In yet another embodiment, an applicator dome has a wet-drag value ranging from about 300 mJ to about 600 mJ. In yet another embodiment, an applicator dome has a dry-drag value ranging from about 500 mJ to about 3000 mJ. In yet another embodiment, an applicator dome has an increase in wet-drag value of at least 150 mJ after four product application strokes onto an application surface.

Owner:THE PROCTER & GAMBLE COMPANY

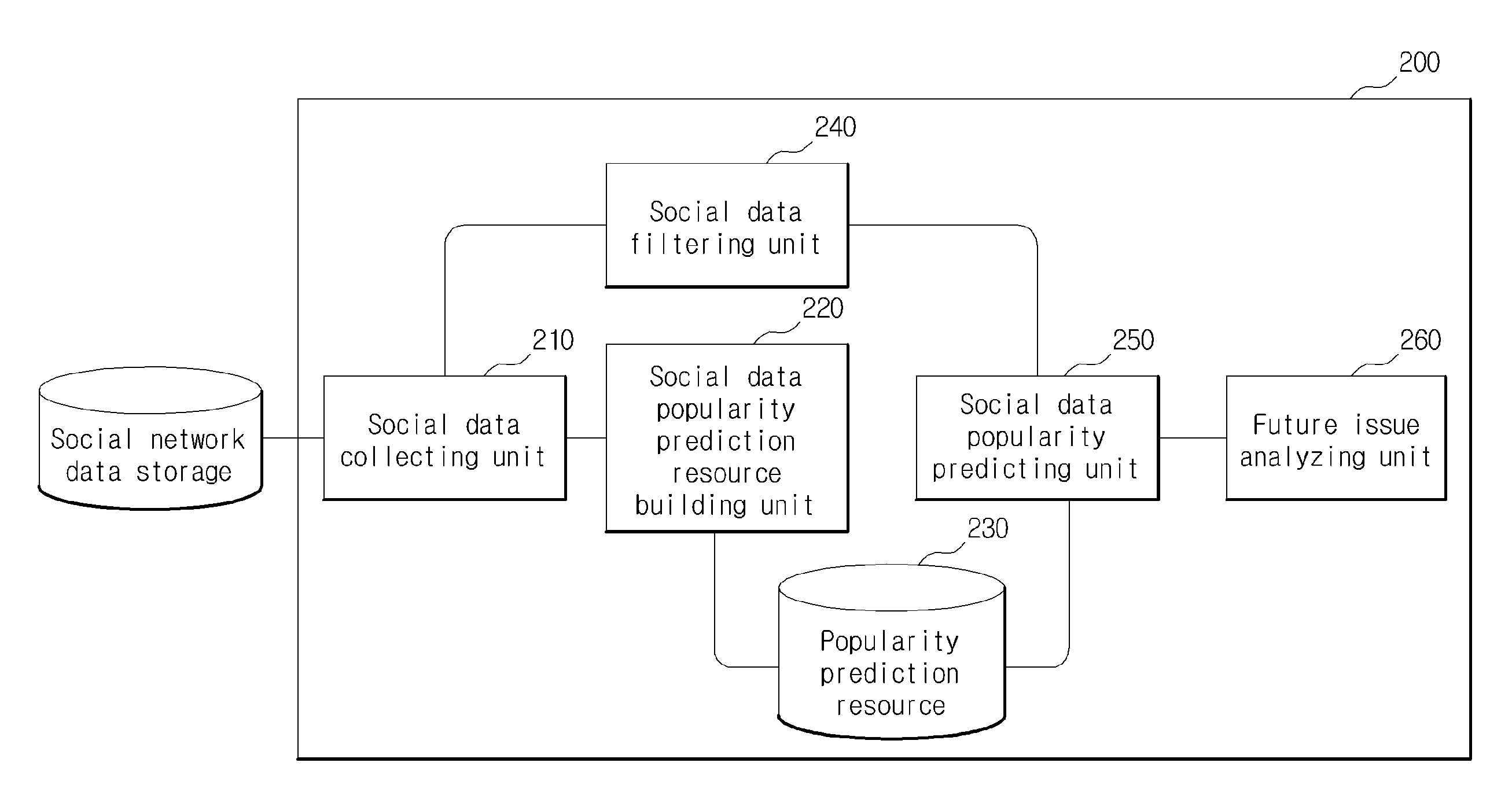

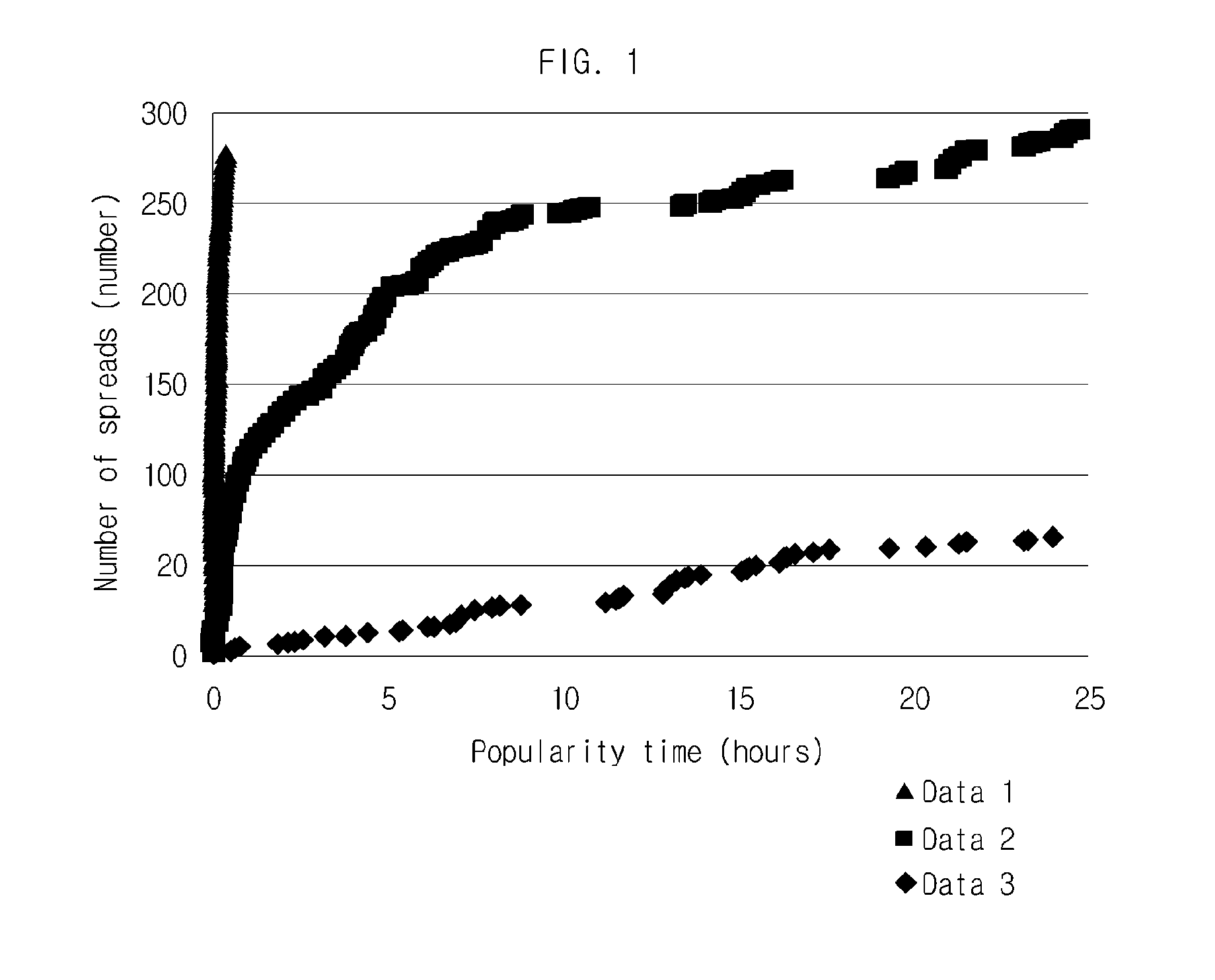

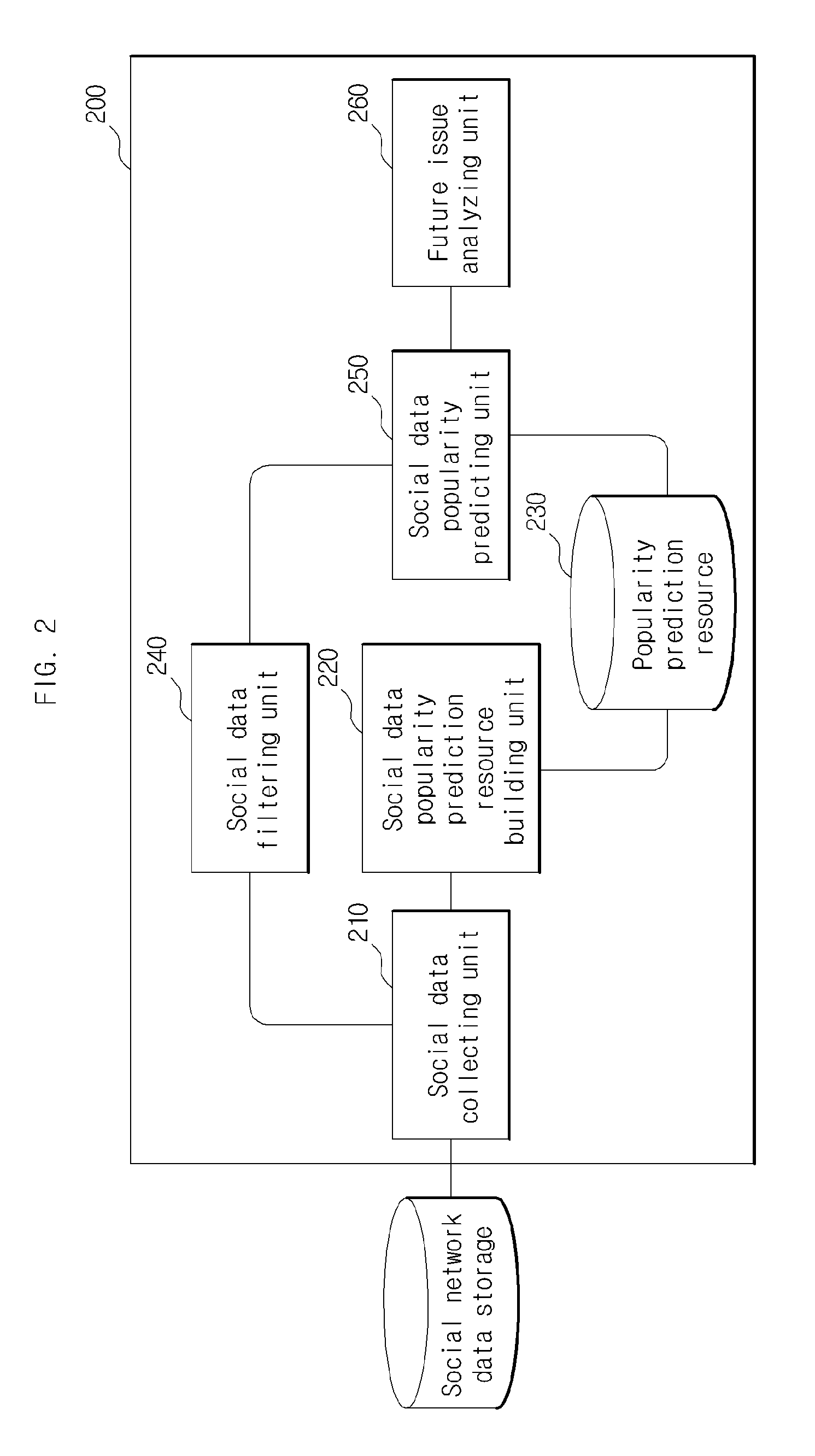

Device and method for predicting popularity of social data

InactiveUS20150161517A1Quick shareShort timeData processing applicationsDigital computer detailsData informationData memory

A method and device for predicting popularity by setting various criteria of popularity of social data spread over a social network service (SNS) including: a data collecting unit to collect previous data created during a predetermined time and created in real time from data storage associated with an SNS, a data popularity prediction resource building unit to extract user information and data information from the previous data created during the predetermined time and build a social data popularity prediction resource using the extracted user information and data information, and a popularity predicting unit to predict popularity of the social data created in real time using the data information and the user information extracted from the data created in real time and the built popularity prediction resource, in which the predicted popularity includes predicted values of at least two items among a spread amount, a popularity time, and a spread rate.

Owner:ELECTRONICS & TELECOMM RES INST

Measuring method for spreading rate in paper-making reconstituted tobacco production process

ActiveCN103439466AObjective accuracyMeet process technology control needsMaterial analysisFlow chemistryChemistry

The invention relates to a measuring method for a spreading rate in a paper-making reconstituted tobacco production process, belonging to the technical field of paper-making reconstituted tobacco production. The measuring method for the spraying rate in the paper-making reconstituted tobacco production process comprises the following steps: (1) measuring chlorine content c1 of approached stock in the production process by adopting a flow chemical analyzer; (2) measuring the chlorine content c2 in coating liquor in the production process by adopting the flow chemical analyzer; (3) measuring the chlorine content c3 of a reconstituted tobacco finished product by adopting the flow chemical analyzer; (4) calculating the spreading rate x of paper-making reconstituted tobacco according to the following formula: x=(c3-c1) / (c2-c1)*100%. The measuring method for the spreading rate in the paper-making reconstituted tobacco is higher in degree of accuracy and capable of objectively representing the spreading rate of the paper-making reconstituted tobacco.

Owner:FUJIAN JINMIN RECONSTITUTED TOBACCO DEV

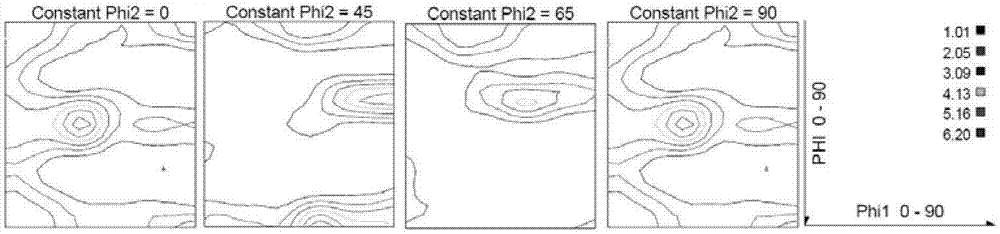

Heat treatment method for improving fatigue resistance of Al-Cu-Mg alloy

ActiveCN103526140AReduce the expansion rateImprove resistance to fatigue damageRoom temperatureNatural aging

A heat treatment method for improving fatigue resistance of Al-Cu-Mg alloy comprises: performing high-temperature short-time (505-535 DEG C / 1-25 min) solution hardening treatment on cold-rolled sheets, then performing natural aging at room temperature for 96 h or more. The aluminium alloy capable of being treated by the heat treatment method comprise the components: Cu, Mg, Ti and Al. The technology is simple and reasonable; and through high-temperature short-time solution hardening treatment, the alloy obtains relatively high goss texture components. Because most of crystal faces {111} of crystal grains in the alloy with high goss texture is positioned or close to the direction of the maximum external shearing stress, the reciprocating sliding of dislocation is promoted and a persistent slip band is easy to generate in the alloy, and thus the plasticity induction closure effect of fatigue crack is enhanced and the damage accumulation is reduced, also the crack deflection is promoted, and thus the fatigue crack spreading rate of the alloy is reduced and the fatigue resistance of the alloy is improved.

Owner:CENT SOUTH UNIV

Method for reducing tar and harm of papermaking reconstituted tobacco

InactiveCN102068034AExcellent focus and harm reduction effectImprove suction qualityTobacco preparationReflux extractionAlcohol

The invention discloses a method for reducing tar and harm of papermaking reconstituted tobacco, which comprises the following steps of: crushing lucid ganoderma into fine particles of 10 to 100 meshes, heating and performing reflux extraction by using water in an amount which is 4 to 10 times the weight of the fine particles or 40 to 80 percent alcohol and controlling the extraction temperature to be between 50 and 95 DEG C and the extraction time to be between 30 and 120 minutes; cooling the obtained product to 25 DEG C after the extraction, and filtering to obtain a filtrate A; extracting residue once again according to the requirement to obtain a filtrate B; mixing the two filtrates, standing for sedimentation, and evaporating and concentrating a supernatant to the density d2020 (equal to 1.180) to obtain lucid ganoderma cream; and adding the prepared lucid ganoderma cream in an amount which is 0.1 to 1.0 percent of the weight of a coating fluid into the coating fluid for reconstituted tobacco, uniformly mixing the obtained solution, heating to 60 DEG C, spreading the obtained solution on a film base, controlling the spreading rate to be 55+ / -1 percent, and drying the film base at the temperature of between 100 and 150 DEG C to obtain the reconstituted tobacco. The method can improve the efficacy of the reconstituted tobacco in reduction of tar and harm.

Owner:CHINA TOBACCO GUIZHOU IND

Processing method of alloy surface micro-cracks

InactiveCN102642177AExtended peening timeReduce processing timeAbrasion apparatusSurface finishHardness

The invention relates to a processing method of alloy surface micro-cracks. The aimed micro-crack size range is that the depth is smaller than 0.8 mm, the width is smaller than 0.2 mm, and the length is smaller than 2 mm. A compressive stress layer is formed on the periphery of the alloy surface cracks by using liquid shot-peening repair method, so that micro-cracks with lower depth are eliminated directly, the size of cracks with deeper depth become small, closure effects are produced, spreading rate of the surface micro-cracks is effectively reduced, the surface rigidity and toughness are increased, and components serve continuously; and deformation of alloy after processing is small, and the surface fineness is high. The method is applied in the repair of alloy surface micro-cracks, the operation of the device is flexible, and the process is simple; and limits to workpiece size, operation site and space are small, the processing efficiency is high, energy is saved, and the method is clean and pollution-free.

Owner:DALIAN UNIV OF TECH

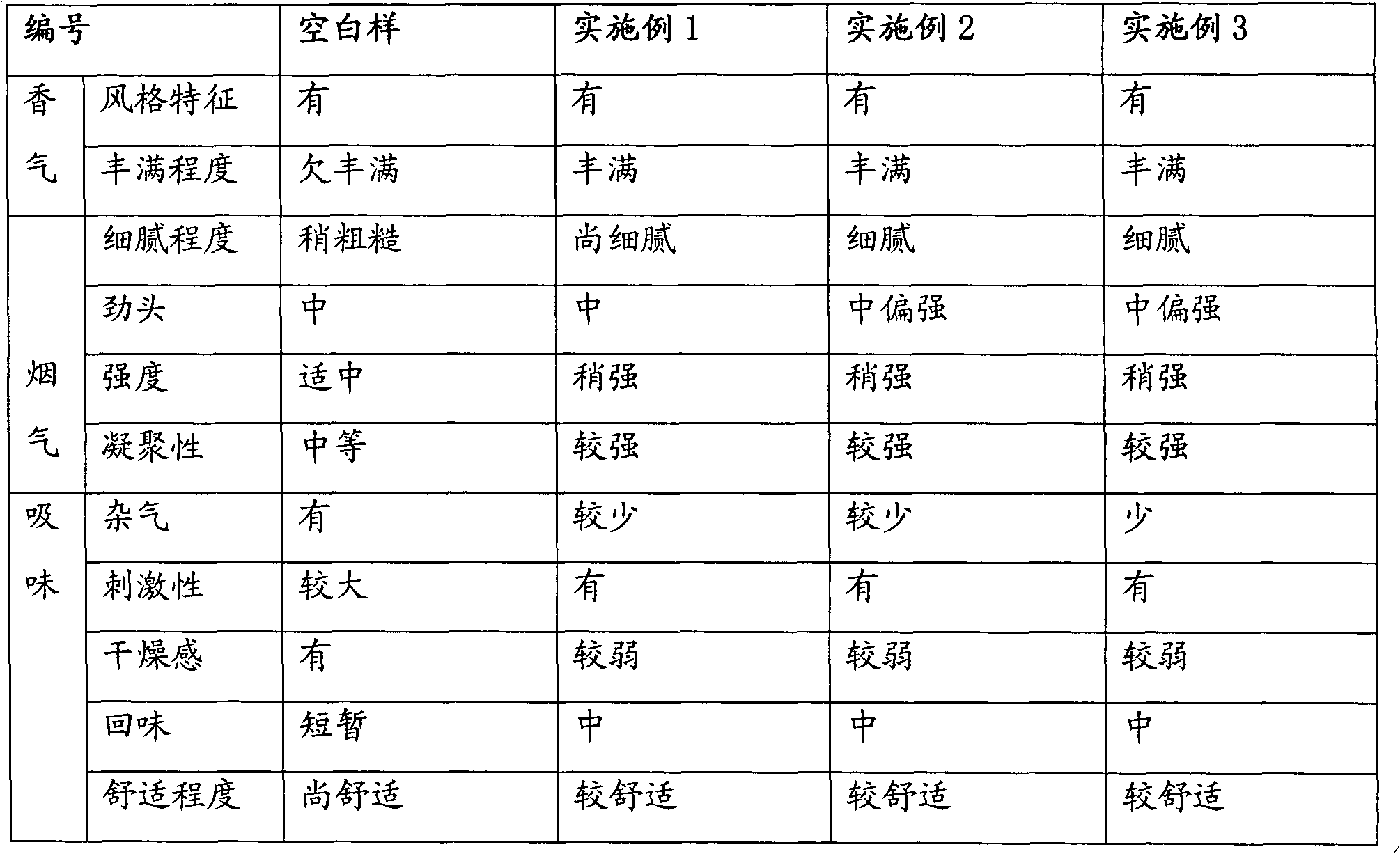

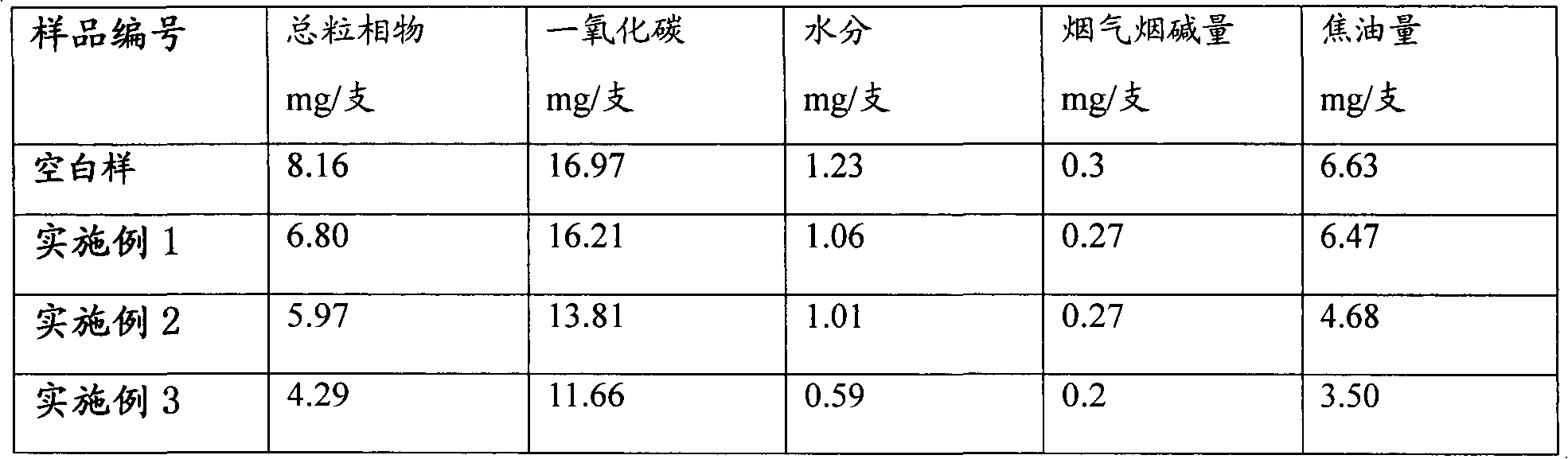

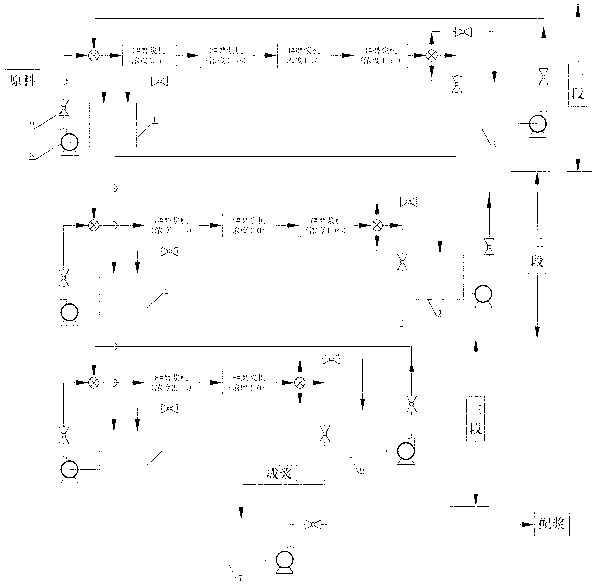

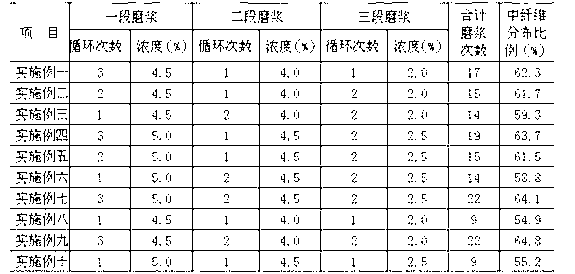

Papermaking tobacco sheet pulp grinding process

The invention discloses a papermaking tobacco sheet pulp grinding process. Specifically speaking, under the light beating condition, three-stage light beating flexible pulp grinding is adopted, each stage needs at least two pulp grinding machines, pulp concentration is decreased gradually, and size circulation process is controlled. In prepared size, fibers with the length of 0.5-1.25mm reach more than 63%, bulk degrees of base tabs reach 2.8-3.0cm <3> / g, spreading rates, filling values, burning velocity of finished sheets are improved greatly, tar contents and carbon oxide contents are reduced greatly, and the bulk degrees of the finished sheets reach 2.3-2.5cm<3> / g. The number of pulp grinding machines arranged in the first stage, the second stage and the third stage in a serial connection mode is respectively 4, 3 and 2. The pulp grinding concentration in the first stage, the second stage and the third stage are respectively set to be 4.5-5.0%, 4.0-4.5% and 2.0-2.5%. Times of self-circulation of the size in the first stage, the second stage and the third stage are respectively 1-3 times, 1-2 times and 1-2 times. The times for which mixed size prepared in different components passes through the pulp grinding machines in the whole process are 9-22 times actually, and all nine pulp grinding machines allow constant power regulation independently.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

Method of predicting fertilizer performance

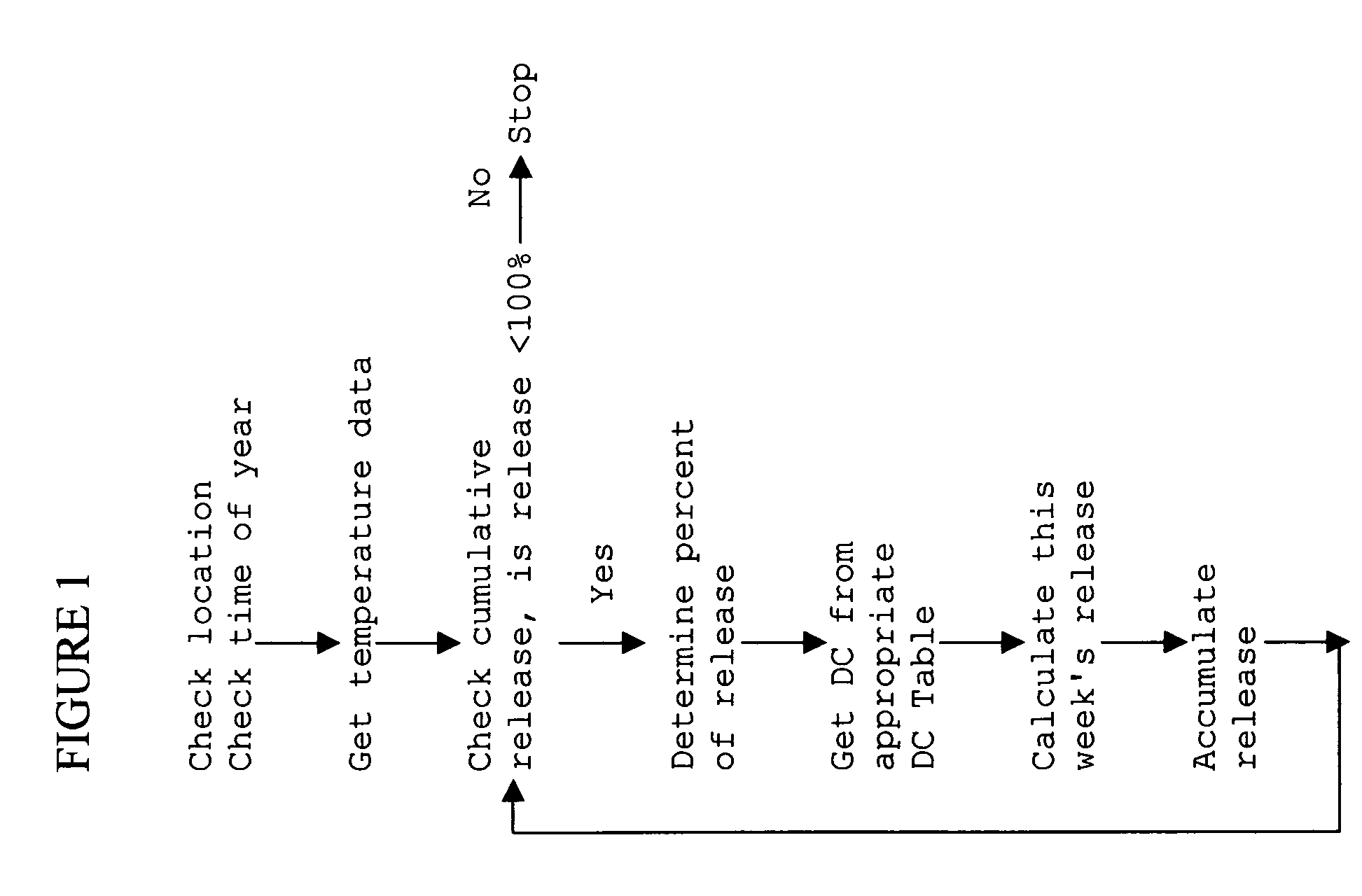

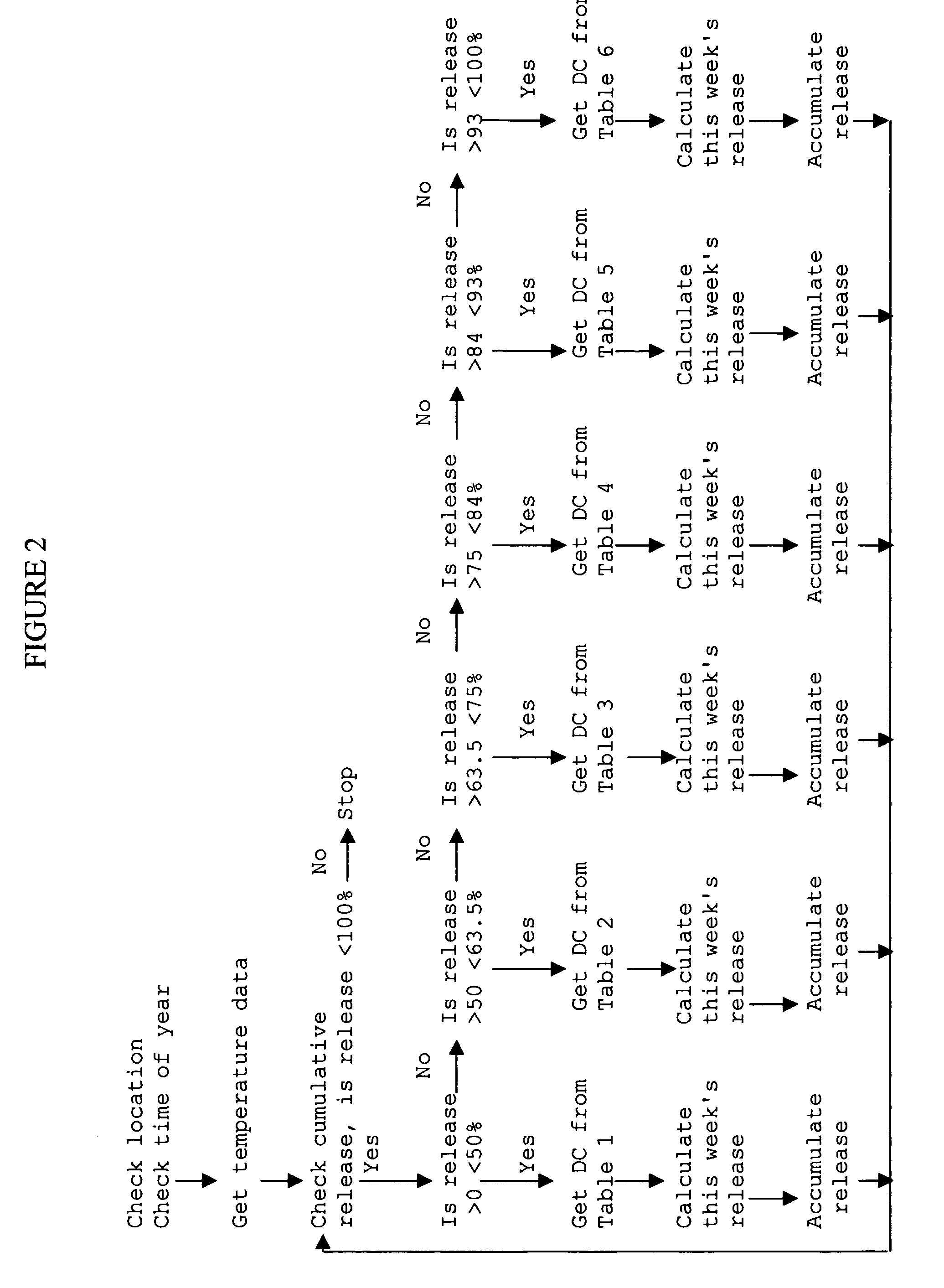

InactiveUS20050246066A1Simple methodEfficient use ofSampled-variable control systemsForecastingFast releaseThe Internet

A method of predicting fertilizer performance for optimum efficiency of a fertilizer is described. The method of conducting a computerized fertilizer performance analysis is based upon a request including a plurality of parameter requirements entered on a client computer. A routine is then performed to analyze the plurality of parameter requirements. The routine may be performed by a software program, such as on a provider computer via the Internet, on a CD-ROM inserted into the client computer or downloaded onto the client computer. Upon completion, the fertilizer performance analysis results are received by the client computer and preferably include re-application time, nutrient release indicator, amount of nutrients released, fertilizer nutrient release rate, suggested fertilizer application rate, percent quick release, average nutrient release per time interval, cumulative nutrient release, nutrient longevity, fertilizer spread rate, total amount of fertilizer required or any combination thereof.

Owner:AGRIUM ADVANCED TECH U S

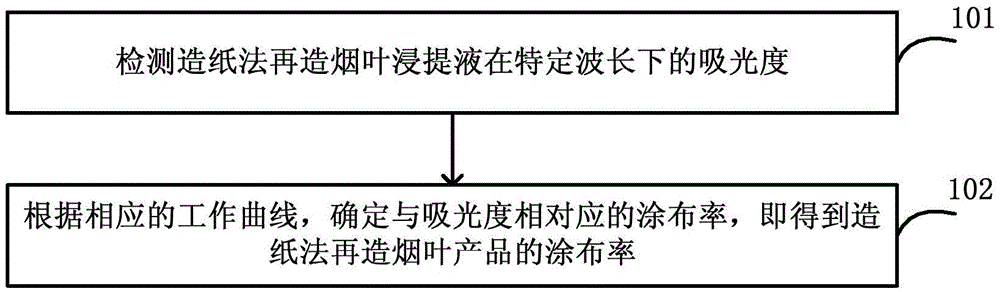

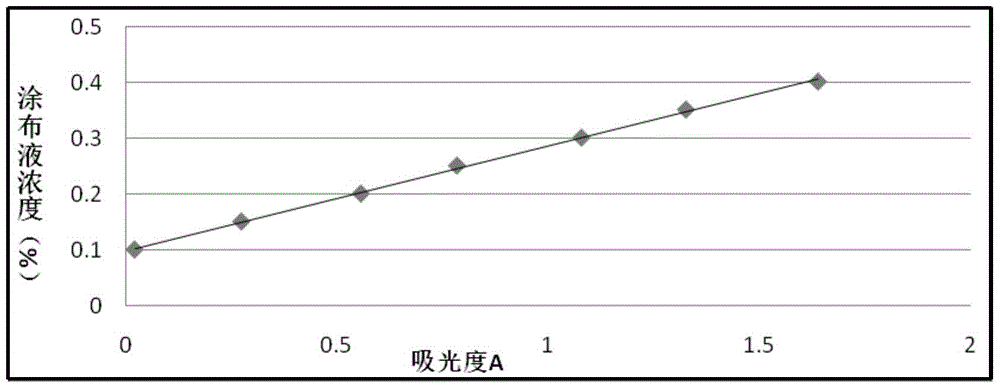

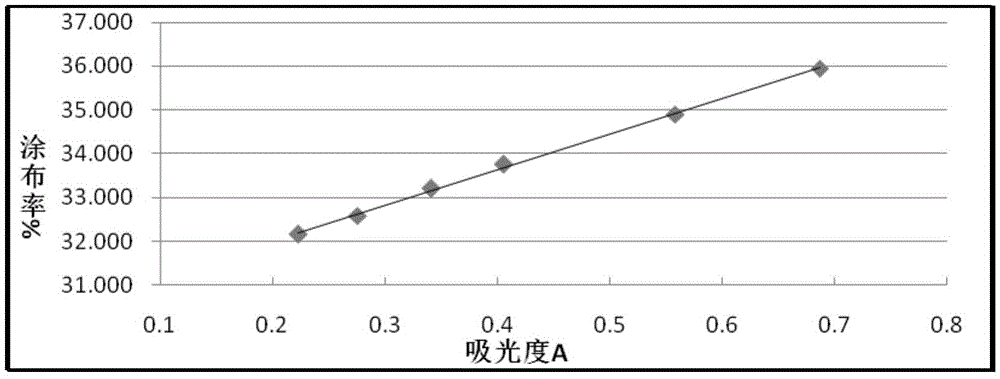

Method and device for detecting spreading rate of papermaking-method reconstituted tobacco product

The invention discloses a method and device for detecting the spreading rate of a papermaking-method reconstituted tobacco product and relates to the field of reconstituted tobaccos.According to the method for detecting the spreading rate of the papermaking-method reconstituted tobacco product, and the spreading rate corresponding to the absorbance is determined according to a corresponding working curve by detecting the absorbance of a papermaking-method reconstituted tobacco product leaching liquor under specific wave length, namely the spreading rate of the papermaking-method reconstituted tobacco product is obtained.Due to the fact that the absorbance of the papermaking-method reconstituted tobacco product leaching liquor under the specific wave length and the spreading rate corresponding to the absorbance have linear relation, the spreading rate of the product can be conveniently, quickly and accurately obtained by detecting the absorbance of the product leaching liquor, and accordingly the method facilitates the production process monitoring of papermaking-method reconstituted tobaccos and determination of the spreading rate of a finished papermaking-method reconstituted tobacco product.

Owner:CHINA TOBACCO FUJIAN IND

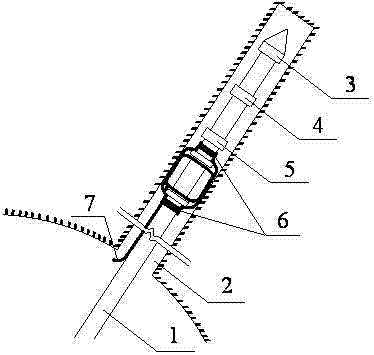

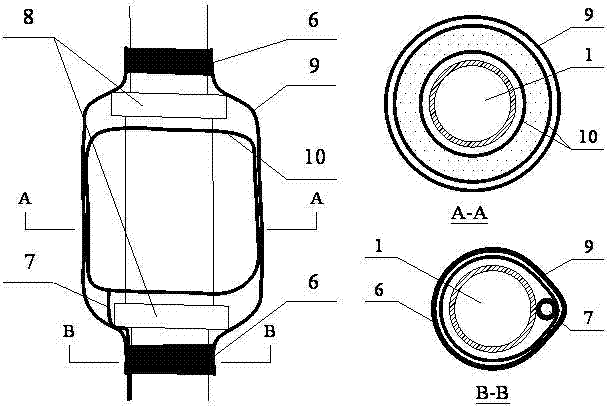

Inside-hole water shutoff device used in detection of wall rock damage range in upward hole by means of sonic approach

InactiveCN103161479APrevent outflowReduce the amount of diffused waterUnderground chambersTunnel liningCouplingAcoustic wave

The invention discloses an inside-hole water shutoff device used in detection of the wall rock damage range in an upward hole by means of a sonic approach. The inside-hole water shutoff device prevents coupling water from flowing out along a drilling hole, simultaneously limits the water spreading range of the coupling water along cracks within the drilling hole with a specific length and effectively controls the spreading rate of the coupling water inside the drilling hole. The inside-hole water shutoff device is characterized by being composed of a rubber air bag (10), an air bag protection sleeve (9) and a ring-shaped ferrule (8), and the air bag protection sleeve is tied to a steel tube close to the outer side of the ring-shaped ferrule through adhesive tape (6). The inside-hole water shutoff device mainly has the advantages that the rubber air bag with good expansibility and toughness can fully fill a gap between the steel tube and the hole wall, the air bag protection sleeve can protect the rubber air bag from being damaged due to abrasion and can effectively restore an original shape after air is exhausted, the ring-shaped ferrule and the adhesive tape can effectively fix positions of the air bag protection sleeve and the rubber air bag and prevents the air bag protection sleeve and the rubber air bag from being pressed and overlapped together due to the fact that the steel tube is put in or pulled out.

Owner:蒲成志

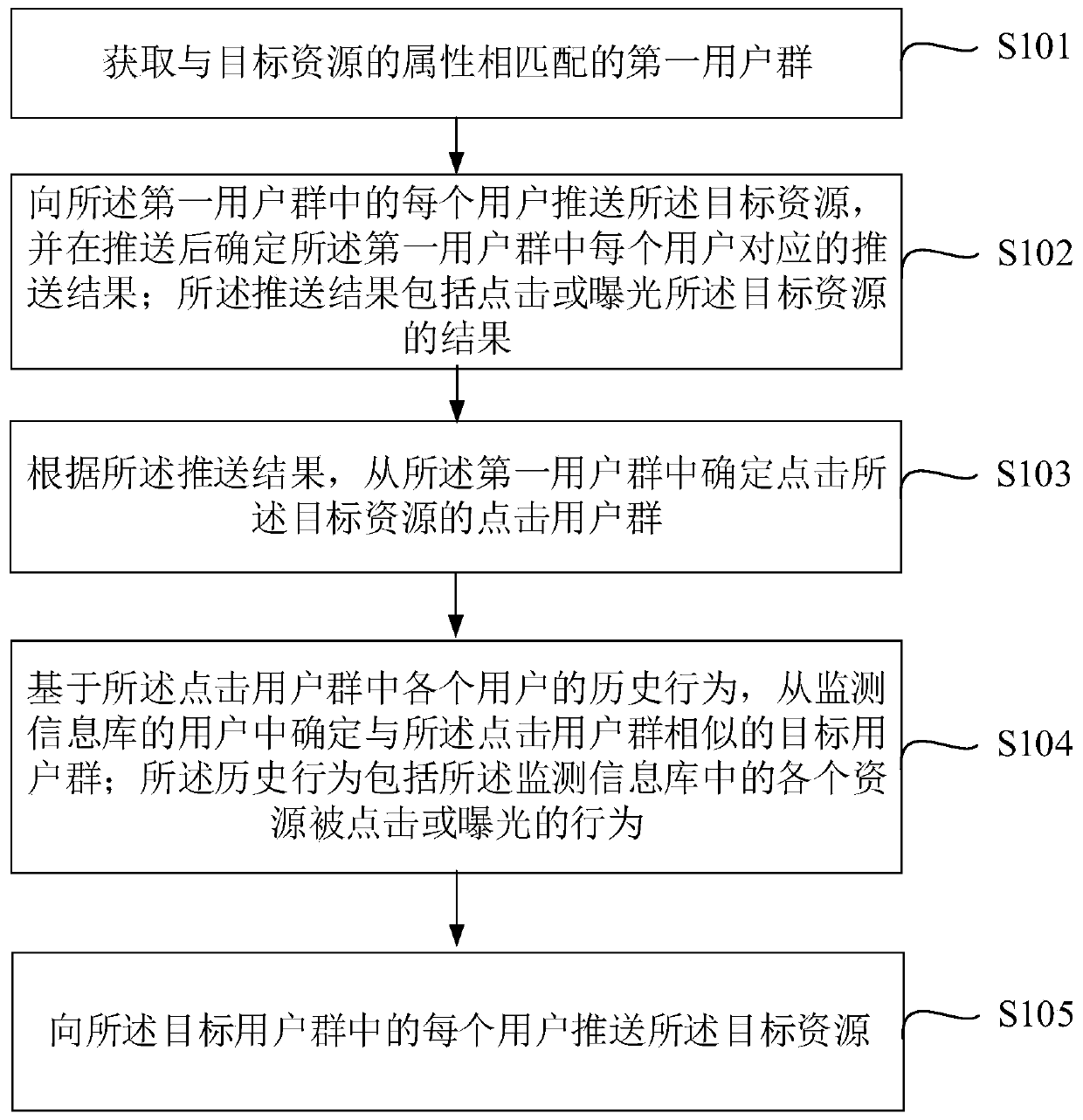

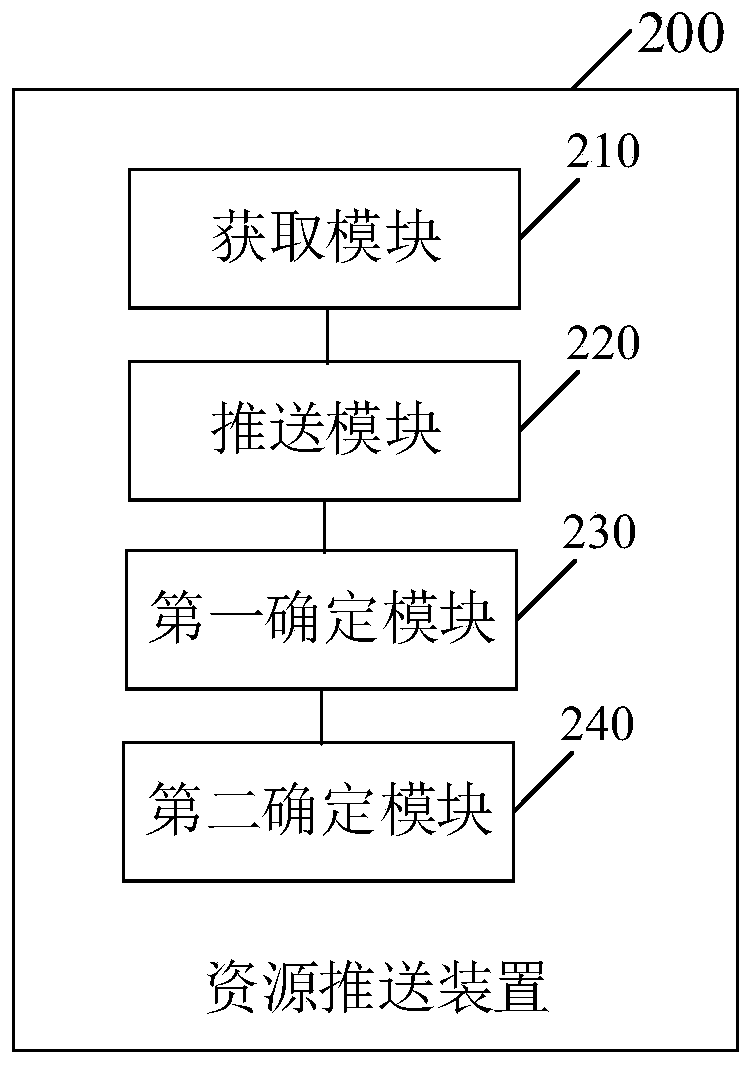

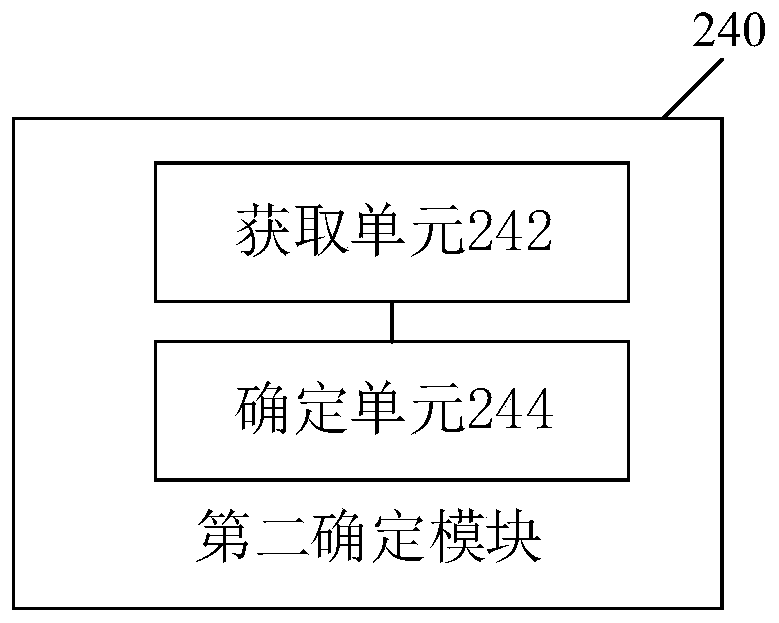

Resource pushing method and device, electronic equipment and readable storage medium

ActiveCN110472154AImprove accuracyDigital data information retrievalSpecial data processing applicationsPush technologyInformation repository

The invention provides a resource pushing method and device, electronic equipment and a readable storage medium, and relates to the technical field of resource pushing. According to the embodiment ofthe invention, the method comprises the steps: the target resource is pushed to the obtained first user group matched with the attribute of the target resource; the pushing result pushed to the firstuser group can be determined after pushing; and according to a pushing result of the first user group, the click user group which is actually interested in the target resource can be determined from the first user group; further, the monitoring information is sent to users in the monitoring information base; the target user group similar to the historical behavior of the click user group is determined according to the historical behavior of the click user group, i.e., more people interested in the target resource are expanded by clicking the user group, and the target resource is pushed to thetarget user group, so that the pushing accuracy of the target resource can be improved while the pushing spreading rate of the target resource is improved.

Owner:MIAOZHEN INFORMATION TECH CO LTD

Traditional Chinese medicinal prescription for treating acute conjunctivitis and preparation method thereof

ActiveCN103536707AImprove immunityQuick resultsAntibacterial agentsSenses disorderPhysical well beingAdemetionine

The invention relates to a traditional Chinese medicinal prescription for treating acute conjunctivitis and a preparation method thereof, and belongs to the technical field of medicines. The invention provides a traditional Chinese medicinal prescription for treating acute conjunctivitis. The prescription consists of the following raw materials in parts by weight: 10-15 parts of senecio scandens, 10-15 parts of common scouring rush herb, 5-10 parts of cassia seed, 6-10 parts of fructus viticis, 5-10 parts of chrysanthemum, 8-14 parts of mulberry leaf, 8-15 parts of self heal, 3-5 parts of golden thread, 5-9 parts of dandelion, 5-10 parts of Chinese violet, and 5-9 parts of folium isatidis. The traditional Chinese medicinal prescription for treating acute conjunctivitis is prepared by scientific compatibility according to pathogenesis, has the functions of clearing heat and removing toxicity, diminishing inflammation and removing internal fire, cooling and activating blood and the like, and is quick in response, short in course of treatment and high in cure rate, so that the patient immunity can be improved, patients can be quickly recovered to normal work and life, the spreading rate is reduced, and the body health of surrounding people can be guaranteed.

Owner:海门市创豪工业设计有限公司

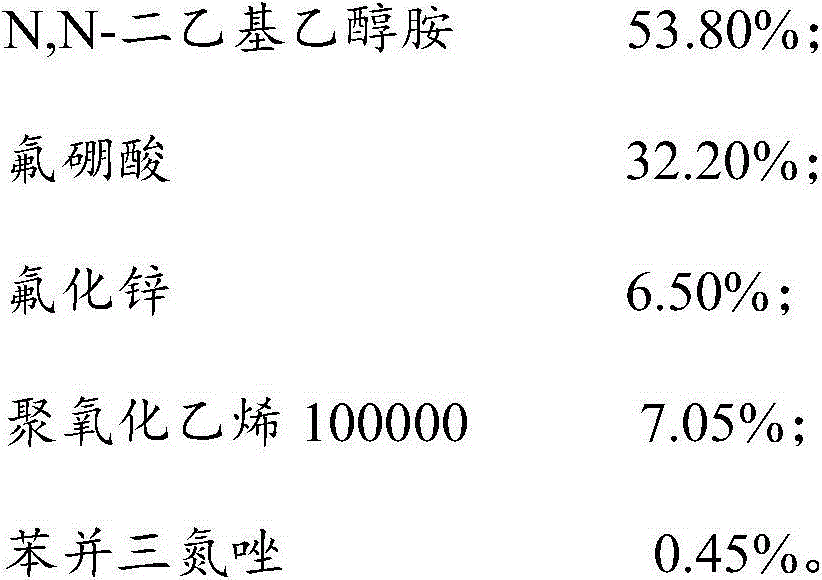

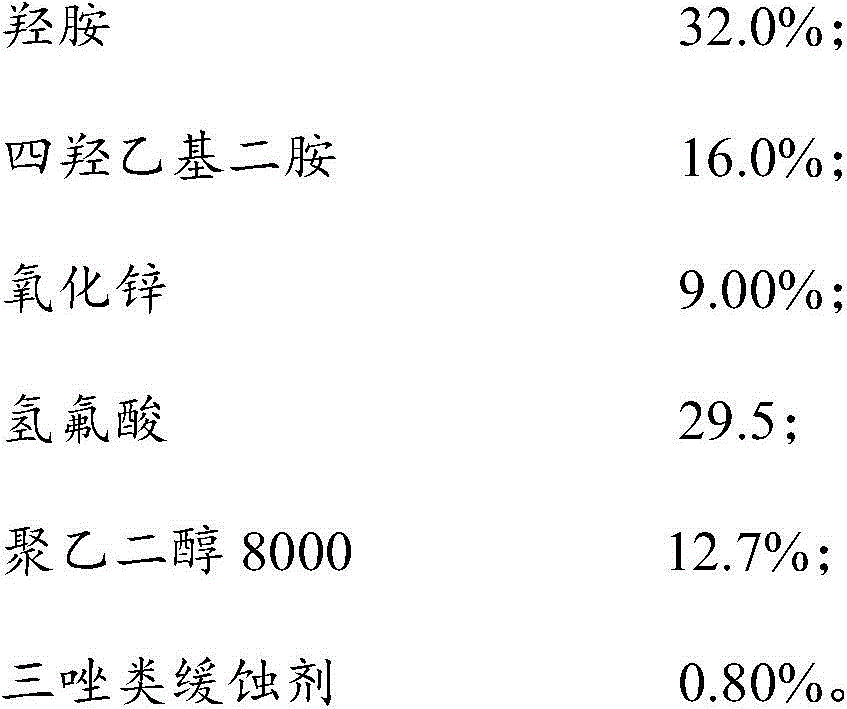

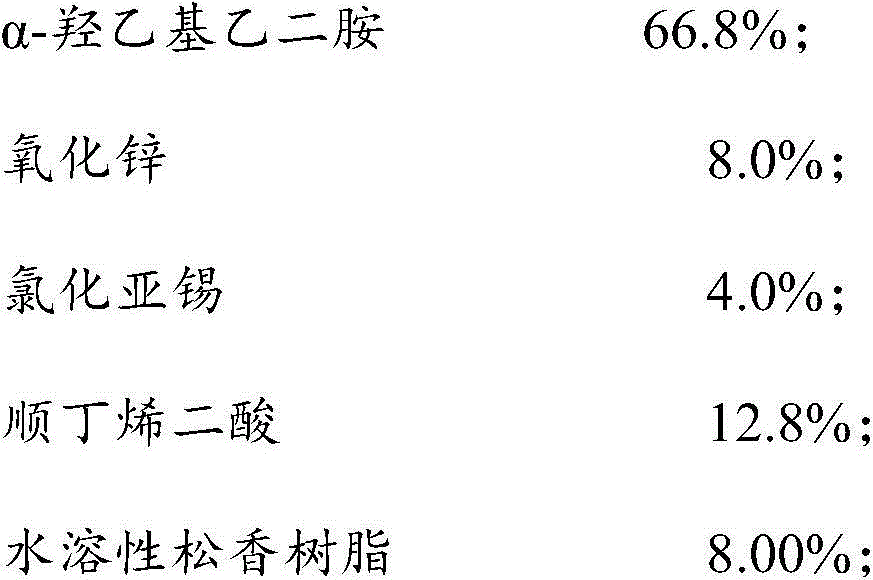

Solid state scaling powder for stainless steel soldering and preparing method

ActiveCN104942480AHigh expansion rateNot corrosiveWelding/cutting media/materialsSoldering mediaActive agentSoldering

The invention discloses solid state scaling powder for stainless steel soldering and a preparing method. The solid state scaling powder comprises 0-68.5% of organic cosolvent, 0-19.8% of a metal active agent, 0-39.8% of an acids active agent, 0.1-0.8% of inhibiter and the balance is an organic vehicle. The preparing method comprises the steps that firstly, according to the weight ratio, the organic cosolvent and the metal active agent are mixed and stirred; secondly, the acids active agent is added into a solution disposed in the first step, standing is carried out on the solution for 24 hours. The solid state scaling powder for stainless steel soldering and the preparing method can be applied to the field of scaling powder, the problem that the welding performance is unstable can be effectively solved, and the problems that the spreading condition of soldering materials is poor, and the spreading rate is low can be effectively solved.

Owner:THOUSAND ISLAND METAL FOIL

Method for paper-making process reconstituted tobacco coating with high spreading rate

InactiveCN107874316AImprove suction qualityImprove sensory qualityTobacco preparationFlavorDip-coating

A method for paper-making process reconstituted tobacco coating with a high spreading rate includes the steps of mixing stem paste, leaf paste and tobacco flavors and fragrances at a mass ratio of 30:65:5 into a coating liquid with the solid content of 40%-46%; preparing the stem paste and the leaf paste at a mass ratio of 25:75, or preparing a single leaf paste or a single stem paste to a spraying liquid with the solid content of 20%-35%; adopting a roller painting and dip-coating process to coat the paper-making process reconstituted tobacco with the coating liquid, and using the spraying liquid to perform spraying 2-3 times. Through coating many times, the spreading rate of the paper-making process reconstituted tobacco is improved, and the suction quality of the paper-making process reconstituted tobacco is improved.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

Disinfectant liquid

InactiveCN101390523AGood antibacterial effectLong-acting antibacterialBiocideDisinfectantsDiseaseDisinfectant

The invention discloses a disinfection solution, which is characterized in that the solution has the following components based on weight proportion: 50-100PPM of nano-silver ions, 1-5% of polyvinylpyrrolidone, 1-5% of polyethylene glycol, and the remaining water. As the anti-bacterial rate is up to 99.99%, the invention can effectively kill, resist and inhibit Staphyloccocus aureus Rosenbach, Escherichia coli and other 650 kinds of bacteria and viruses to reduce the spreading rate of disease, and can be used in the disinfection of various environments.

Owner:陈汉洲

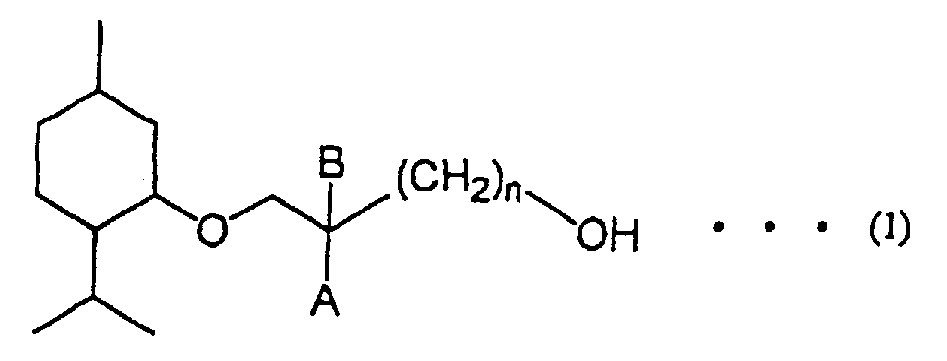

Increasing agent for fregrance spreading rate and lasting property and increasing method thereof

A fragrance composition having an excellent diffusivity and long-lasting property of fragrance and a cosmetic, toiletry, bath composition, food and drink and pharmaceutical having an excellent diffusivity and long-lasting property of fragrance by using a novel fixative. A compound represented by the following general formula (1) is incorporated in a fragrance composition or the foregoing products. The amount of the compound of the general formula (1) to be incorporated in the fragrance composition is preferably from 0.01 to 90% by weight. The amount of the compound of the general formula (1) to be incorporated directly in the foregoing products is preferably from 0.0001 to 2.0 times (by weight) the weight of the aroma composition and / or composition to be incorporated therein. In this arrangement, a fragrance composition or products having an enhanced diffusivity and long-lasting property of fragrance can be obtained without causing any safety problem on human being. Wherein A represents H or OH group; B represents H or methyl group; and n represents an integer of from 0 to 2.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Rapid determining method for spreading rate of paper-making method reconstituted tobacco production

InactiveCN105806734ASimple and fast operationShort detection cycleWeighing by absorbing componentEngineeringRepeatability

Disclosed is a rapid determining method for the spreading rate of paper-making method reconstituted tobacco production.A front part coating base and a rear finished product coating sample of a coating machine for paper-making method reconstituted tobacco production are taken respectively and dried at the same time through a paper sheet panel drier, the dried samples are taken out and weighed, and the spreading rate of reconstituted tobacco is calculated.According to the method, detection equipment can be placed near the coating machine for rapid detection, operation is easy and convenient, the detection period is short, and the measuring result is high in repeatability.

Owner:CHINA TOBACCO YUNNAN REMFG TOBACCO CO LTD

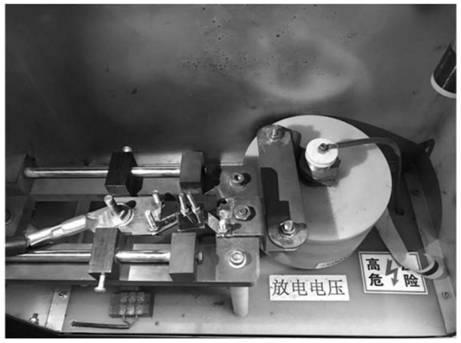

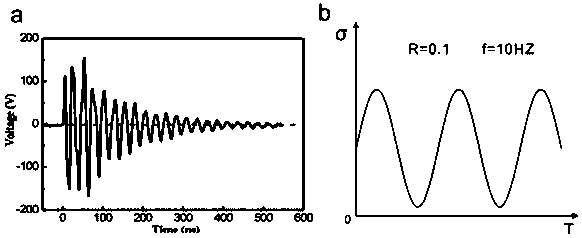

Electric pulse treatment method for lowering fatigue crack spreading rate of steel materials

InactiveCN109338093AReach arrestTo achieve the purpose of crack healingFatigue damageElectrical impulse

The invention discloses an electric pulse treatment method for lowering the fatigue crack spreading rate of steel materials, and belongs to the technical field of fatigue life of high-strength steel materials. Through the method, the steel materials with fatigue cracks are subjected to electric pulse treatment, the fatigue crack spreading rate of the steel materials is lowered, and thus the fatigue life of the materials is prolonged. In the electric pulse treatment process, the electric pulse discharge waveform is in a damped waveform, the discharge period is 400 ns, treatment is conducted twice, the first treatment working voltage is 9-10 kV, and the second treatment working voltage is 10.5-12 kV. The method can be used for research and engineering application of crack arresting, crack healing and fatigue damage repair and fatigue life prolonging of the high-strength steel materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com