Method for determining spreading rate of paper-process reconstituted tobacco finished products

A technology of reconstituted tobacco leaves and papermaking method is applied in the field of measuring the coating rate of finished tobacco leaves of reconstituted tobacco leaves by the papermaking method, and the effect of the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 1. Experimental materials

[0018] Papermaking method reconstituted tobacco leaf products, sheet base, and coating solution (prepared according to conventional production formula).

[0019] 2 Experimental Instruments

[0020] BUCHI cable extractor, BINDER WTC constant temperature and humidity box, Mettler Toledo AG204 electronic balance, QS-I shredding machine, electric blast drying oven, and silica gel dryer are purchased in the market.

[0021] 3 Sample preparation

[0022] Cut the reconstituted tobacco leaves and base samples by the papermaking method into shreds with a width of 0.85mm, and place them in a constant temperature and humidity box for 48 hours to balance. The temperature of the constant temperature and humidity box is set at 22°C and the humidity is 60%.

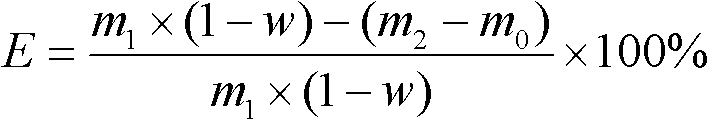

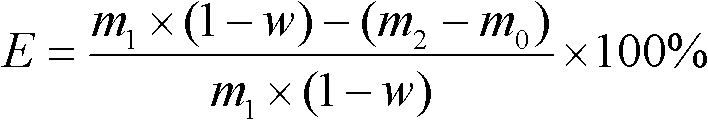

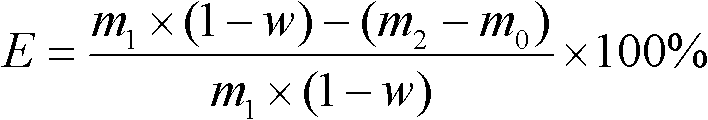

[0023] 4. Determination of spreading rate

[0024] Weigh a certain amount of reconstituted tobacco shredded tobacco sample m 1 Place in the solvent cup of the Soxhlet extractor, add distilled water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com