Method and device for detecting spreading rate of papermaking-method reconstituted tobacco product

A technology of reconstituted tobacco leaves and coating rate, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems that the substrate cannot be completely matched, the error of the detection result is large, and the time is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

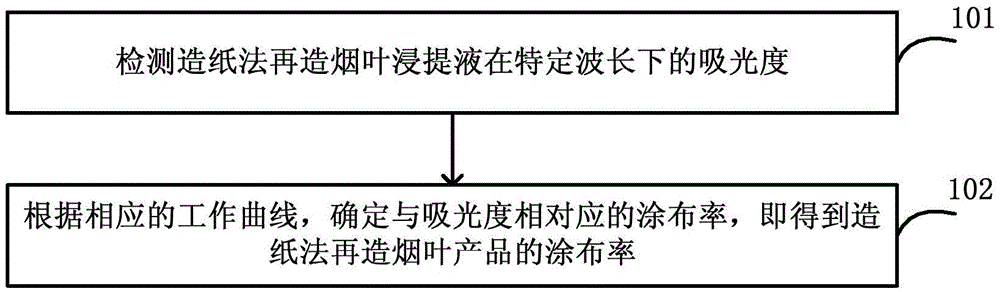

Image

Examples

Embodiment 1

[0057] The coating solution, substrate and finished products of different brands of the same brand are diluted or leached, and the full spectrum is scanned by UV.

[0058] Through the experimental results, it can be found that for the products of the same brand, the fluctuation of the UV full spectrum scan curve of the coating solution and the paper-making reconstituted tobacco product extract is consistent, and the UV full spectrum scan curve of the substrate extract is obviously different, especially Between the wavelength of 200.0nm-400.0nm, the absorbance of the substrate extract is 0.0000, while the absorbance of the coating solution and the paper-making reconstituted tobacco product extract has obvious characteristic peaks.

[0059] For products of different brands, it can be seen that there are three characteristic peaks in the leaching solution of different brands between 200.0nm and 400.0nm, and the absorbance of the substrate leaching solution is 0.0000.

[0060] What needs...

Embodiment 2

[0062] First, take a certain amount of coating solution (the coating solution is prepared according to the product formula requirements) and place it in an evaporating dish, and bake it in an oven at 100°C until it is absolutely dry, and then take out the absolutely dry sample and grind it into powder and prepare at least five Gradient standard concentration solution. Using distilled water as a reference, the absorbance was measured by ultraviolet spectrophotometry. The test results are shown in Table 1.

[0063]

[0064] Table 1

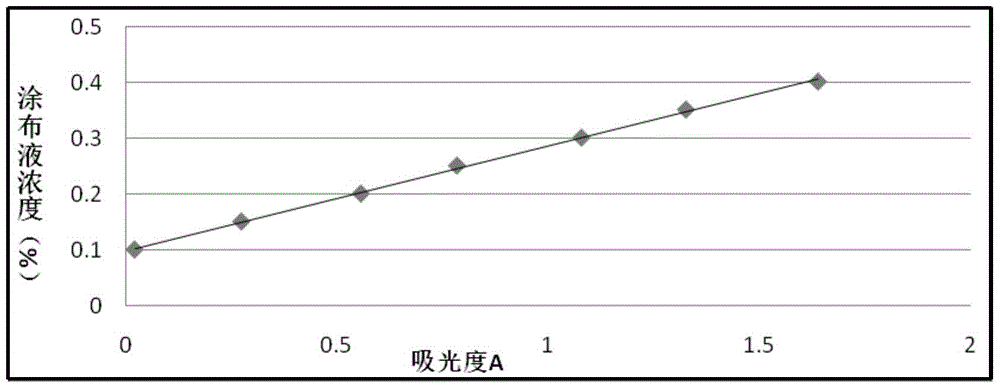

[0065] Fit the obtained results to get the corresponding working curve, such as figure 2 Shown. Among them, the linear equation of the corresponding working curve is:

[0066] y=0.187x+0.098

[0067] Here x is the absorbance and y is the concentration of the coating solution. Due to the goodness of fit R 2 It can reach 0.999, indicating a significant linear relationship between absorbance and coating solution concentration.

[0068] Then the sample to be...

Embodiment 3

[0074] First, prepare the test sample: Weigh a certain mass m of the absolutely dry substrate and coat it with the prepared coating solution, then place the coated sample in an oven at 100°C until it is absolutely dry, and call its mass M. Calculate the true value of the coating rate T (it is required that the finished product has at least five gradients of coating rate after coating).

[0075] T=(M-m) / M×100%

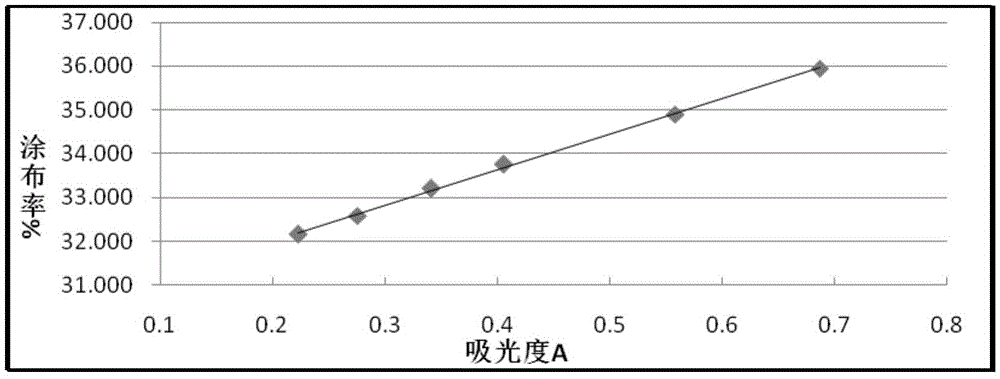

[0076] Then, make a standard working curve: place the coated product in a beaker, then measure distilled water with a certain temperature, stir and extract for a certain period of time, then transfer to a volumetric flask for constant volume, and transfer a small amount of extract with qualitative filter paper Filter and measure the absorbance A at a specific wavelength. The test results are shown in Table 3.

[0077] Coating rate (%)

32.168

32.594

33.210

33.760

34.899

36.143

0.2226

0.2755

0.3410

0.4058

0.5584

0.6866

[0078] table 3

[0079] Fit the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com