Method for reducing tar and harm of papermaking reconstituted tobacco

A technology for reconstituted tobacco leaves, tar reduction and harm reduction, applied in the fields of tobacco, tobacco preparation, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

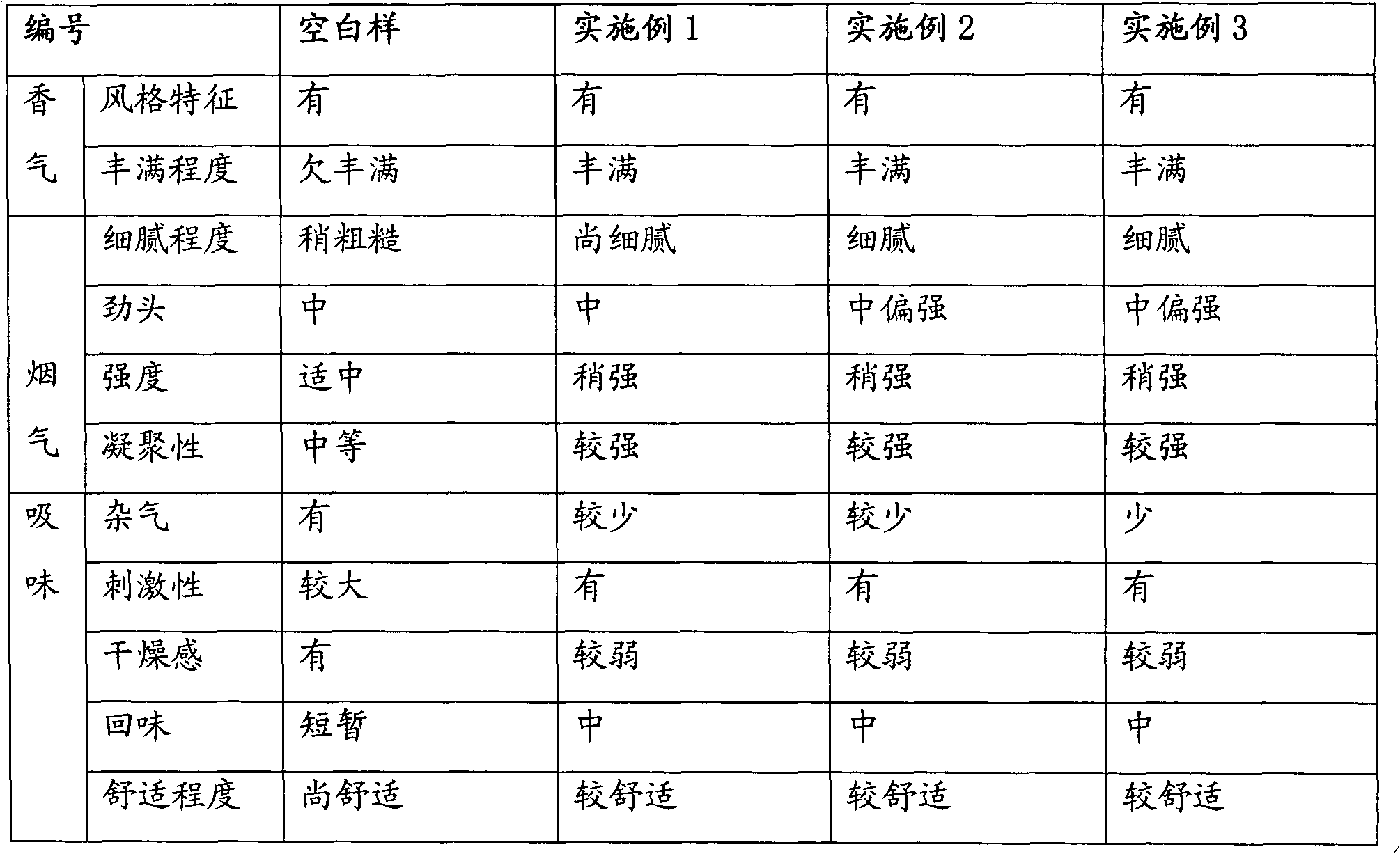

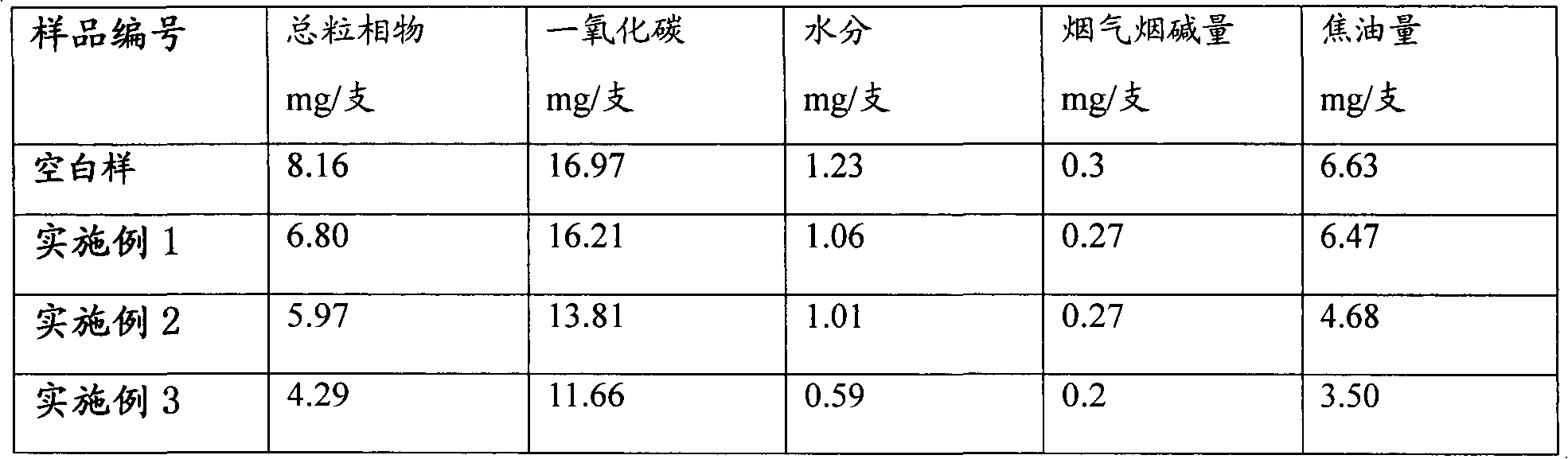

Embodiment 1

[0011] (1) Take 50 grams of pulverized Ganoderma lucidum powder of 10 to 100 mesh, add 500 grams of water and heat and reflux extraction in a 2000 ml round bottom flask. The extraction temperature is controlled at 95 ° C, the extraction time is 120 minutes, and cooled to 25 °C, filter to obtain filtrate A, extract the residue once more according to the above requirements, cool to 25 °C after extraction, and filter to obtain filtrate B, combine the two filtrates, set aside to settle, and take the supernatant to evaporate and concentrate to a density of d 20 20 =1.180, obtain Ganoderma lucidum paste, yield is 56.7%;

[0012] (2) Add the Ganoderma lucidum paste prepared above to the coating solution for reconstituted tobacco leaves by 0.1% of the weight of the coating solution (the coating solution obtained from China Tobacco Kunchuan Ruisheng Company), fully stir and mix, and heat to 60°C, apply it on the film base (taken from the film base of China Tobacco Kunchuan Ruisheng Co...

Embodiment 2

[0017] (1) Take 50 grams of pulverized Ganoderma lucidum powder of 10-100 mesh, add 200 grams of alcohol with a weight concentration of 80% in a 2000-ml round-bottomed flask, heat and reflux for extraction, control the extraction temperature at 65°C, and extract for 60 minutes , cooled to 25°C after extraction, filtered to obtain filtrate A; the residue was extracted once more according to the above requirements to obtain filtrate B; the two filtrates were combined, left to settle, and the supernatant was evaporated and concentrated to a density of d 20 20 =1.180, obtain Ganoderma lucidum paste, yield is 49.4%;

[0018] (2) Add the ganoderma lucidum paste prepared above into the coating solution for reconstituted tobacco leaves (from the coating solution of China Tobacco Kunchuan Ruisheng Co., Ltd.) by 0.3% of the coating solution weight, fully stir and mix, and heat to 60°C, apply it on the film base (taken from the film base of China Tobacco Kunchuan Ruisheng Company in Yun...

Embodiment 3

[0022] (1) Take 500 grams of ganoderma lucidum powder, add 4000 grams of alcohol with a weight concentration of 40%, heat and reflux extraction in a 5000 ml round bottom flask, control the extraction temperature to 50 ° C, stir and extract for 30 minutes, and cool to 25 ° C after extraction , filtered to obtain filtrate A; the residue was extracted once more according to the above requirements to obtain filtrate B; the two filtrates were combined, left to settle, and the supernatant was evaporated and concentrated to a density of d 20 20 =1.180, obtain Ganoderma lucidum paste, yield is 54.4%;

[0023] (2) Add the Ganoderma lucidum paste prepared above into the coating solution for reconstituted tobacco leaves (from the coating solution of China Tobacco Kunchuan Ruisheng Co., Ltd.) by 1.0% of the coating solution weight, fully stir and mix, and heat to 60°C, apply it on the film base (taken from the film base of China Tobacco Kunchuan Ruisheng Company in Yunnan), control the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com