Electric pulse treatment method for lowering fatigue crack spreading rate of steel materials

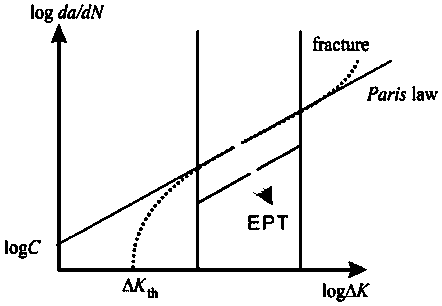

A technology for fatigue crack growth and steel materials, which is applied in the field of fatigue life of high-strength steel materials, can solve the problems of easily changing the microstructure and mechanical properties of materials, and achieve the effect of prolonging fatigue life and reducing the expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

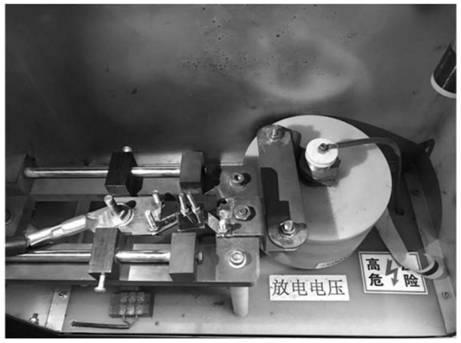

[0022] The present invention is described in detail below in conjunction with accompanying drawing.

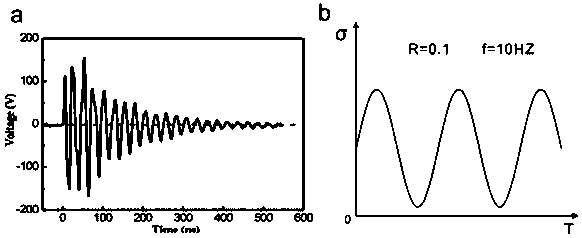

[0023] The present invention utilizes high-energy pulse current equipment to pass the compact tensile (CT) sample ( figure 1 ), to stop the crack, reduce the crack growth rate, and achieve the purpose of crack healing to a certain extent. The electric pulse technology can be used for research and engineering applications such as crack arrest and crack repair of high-strength steel materials and their components.

[0024] Using the above-mentioned device to conduct electric pulse treatment on the compact tensile sample (AISI 4340 steel), and compare and analyze the effect with the sample without electric pulse treatment (AISI 4340 steel), the specific process is as follows:

[0025] (a) Prepare compact tensile (CT) specimens of AISI 4340 steel with dimensions such as figure 2 shown.

[0026] (b) Prefabricate cracks on compact tension-CT specimens by means of tension-tension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com