Hot spray coating anti-crack-expansion aluminum oxide ceramic composite coating material and use method thereof

A technology of alumina ceramics and composite coatings, applied in the field of ceramic wear-resistant coatings, can solve the problems of microcracks, high brittleness and low toughness of thermal spray coating materials, etc., to solve microcracks, reduce volume shrinkage, and prepare low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

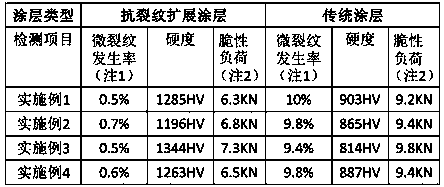

Examples

Embodiment 1

[0021] The thermal spraying anti-crack propagation alumina ceramic composite coating material is prepared from the following raw materials, 65g of strengthening agent, 30g of loosening agent, and 5g of healing agent, wherein the strengthening agent is aluminum oxide powder, the loosening agent is copper, and the healing agent is dioxide Zirconium powder.

[0022] The use method of the thermal spraying anti-crack propagation alumina ceramic composite coating material is to sieve the strengthening agent, the loosening agent and the healing agent respectively, then mix the strengthening agent and the healing agent evenly, and then send the loosening agent into two feeders respectively. In the powder machine, the powder is fed to carry out thermal spraying on the sprayed substrate, and an anti-crack propagation alumina ceramic composite coating material is obtained on the surface of the sprayed substrate.

[0023] The above method of use, the specific process is:

[0024] Step 1....

Embodiment 2

[0027] The thermal spraying anti-crack propagation alumina ceramic composite coating material is prepared from the following raw materials, 40g of strengthening agent, 40g of loosening agent, and 20g of healing agent, wherein the strengthening agent is alumina powder, the loosening agent is copper, and the healing agent is dioxide Zirconium powder.

[0028] The use method of the thermal spraying anti-crack propagation alumina ceramic composite coating material is to sieve the strengthening agent, the loosening agent and the healing agent respectively, then mix the strengthening agent and the healing agent evenly, and then send the loosening agent into two feeders respectively. In the powder machine, the powder is fed to carry out thermal spraying on the sprayed substrate, and an anti-crack propagation alumina ceramic composite coating material is obtained on the surface of the sprayed substrate.

[0029] The above method of use, the specific process is:

[0030] Step 1. Perfo...

Embodiment 3

[0033] The thermal spraying anti-crack propagation alumina ceramic composite coating material is prepared from the following raw materials, 60g of strengthening agent, 32g of loosening agent, and 8g of healing agent, wherein the strengthening agent is alumina powder, the loosening agent is NiAl, and the healing agent is dioxide Zirconium powder.

[0034] The use method of the thermal spraying anti-crack propagation alumina ceramic composite coating material is to sieve the strengthening agent, the loosening agent and the healing agent respectively, then mix the strengthening agent and the healing agent evenly, and then send the loosening agent into two feeders respectively. In the powder machine, powder-feeding thermal spraying is carried out on the surface of the substrate in step 1 to obtain an anti-crack propagation alumina ceramic composite coating material.

[0035] The above method of use, the specific process is:

[0036] Step 1. The surface of the substrate (cast iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com