Rapid determining method for spreading rate of paper-making method reconstituted tobacco production

A technology for rapid determination of reconstituted tobacco leaves, applied in the direction of using material absorption and weighing, etc., can solve the problems that the test results are easily interfered by moisture and the investment in testing equipment is large, and achieve high reproducibility of measurement results, short detection cycle, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

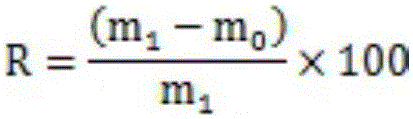

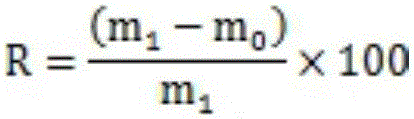

[0019] During the stable production period of a certain type of reconstituted tobacco leaf product by papermaking method, the feed sheet and the finished product (about 25cm×100cm, 2 pieces each) of the coating machine were torn off respectively; the sheet sample to be tested, Finished sample to be tested (0.01m 2 , a group of 5 sheets, a total of 2 × 2 groups); set the heating gear of the flat sheet dryer at 120±1°C, and the oven gear at 105±2°C; take the prepared sheet base to be tested and the product to be tested Each group of samples was laid flat on a flat-plate dryer for 2 minutes and placed in an oven for 2 hours; the dried samples were taken out from the flat-plate dryer and the oven respectively, and the mass was weighed quickly and accurate to 0.001g ;Dry the film substrate to be tested and the quality of the finished product to be tested by the flat plate dryer that is basically dry, and mark it as m 0 、m 1 , the mass of the oven-dried base and finished samples t...

Embodiment 2

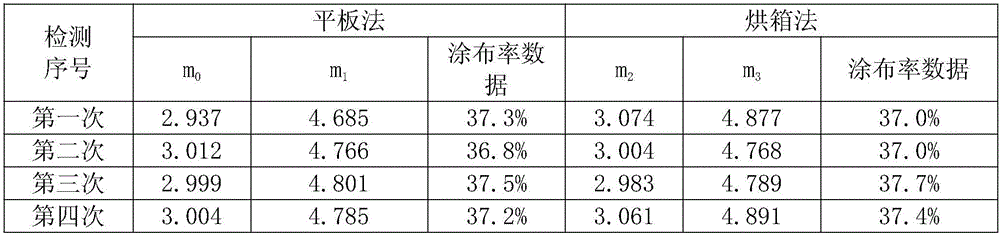

[0024] In order to monitor the finished product coating rate situation of continuous production, carry out the coating rate measurement of certain papermaking method reconstituted tobacco leaf product by the step shown in embodiment 1, difference is to only use the plate drying method of the present invention's design, and the sampling cycle is 30 every minute.

[0025] The following table shows the measurement results:

[0026] Sampling order

Embodiment 3

[0028] In order to shorten the parameter setting period of the coating machine after changing the coating roller, after the coating machine is running, tear off the feed film base and the finished product (size about 25cm×100cm, 1 piece each) of the coating machine; The paper quantitative sampler prepares the film base to be tested and the finished product to be tested (0.01m 2 , 5 sheets in one group, 2 groups in each); set the heating gear of the flat sheet dryer at 120±1°C; take a group of prepared sheet bases and product samples to be tested, and lay them flat in the flat sheet dryer for drying Dry for 2 minutes; take out the dried film base and finished product to be tested and quickly weigh the mass, the data is marked as m 0 、m 1 , the exact value is 0.001g; the obtained data is calculated with the calculation formula of the present invention to calculate the coating rate of the finished reconstituted tobacco leaf.

[0029] In this embodiment, 2 paper sheet flat dryer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com