Gold-ingot-shaped tooth for waste treatment

A waste product and ingot technology, which is applied in the field of ingot-shaped waste product processing teeth, can solve problems such as unreasonable structural design, easy damage to the tooth head structure, and damage to the tooth head structure, achieving reasonable structure, good firmness, and improved work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

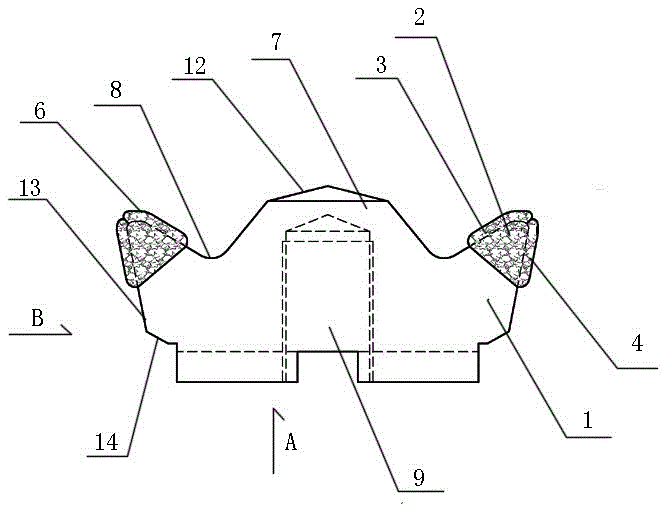

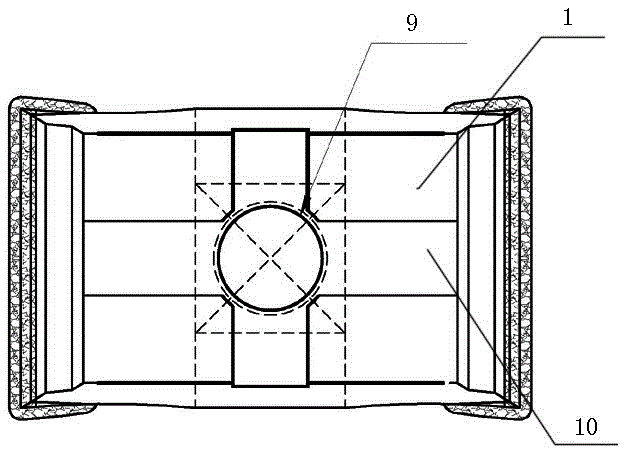

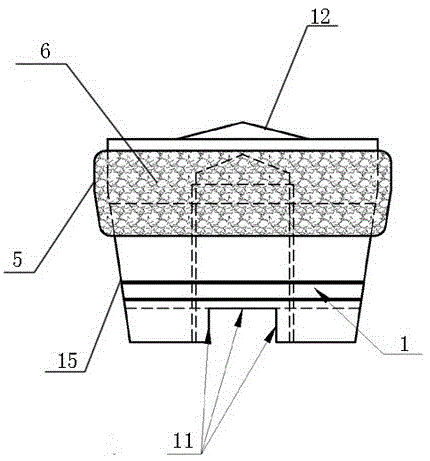

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a kind of ingot-shaped waste product treatment tooth according to the present invention includes an ingot-shaped briquetting body 1, an upward tip 2 provided on both ends of the briquetting body 1, upper and lower slopes 3, 4 and two side surfaces 5 respectively surfacing with hard crushed alloy welding layer 6, so that the tip part 2 forms a wrapped shape of hard crushed alloy weld layer, and the upper surface of the briquetting body 1 forms an upwardly convex end plane 7, and the upwardly convex end plane 7 The two sides are respectively connected to the upper slope 3 of the tip part 2 on both ends by a downward transition arc 8; A cross positioning groove 10 centered on the center line of the threaded positioning hole 9 is provided, and the bottom and sides of the cross positioning groove 10 are used as the mounting surface 11 .

[0011] As shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com