Patents

Literature

55results about How to "Good structural firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

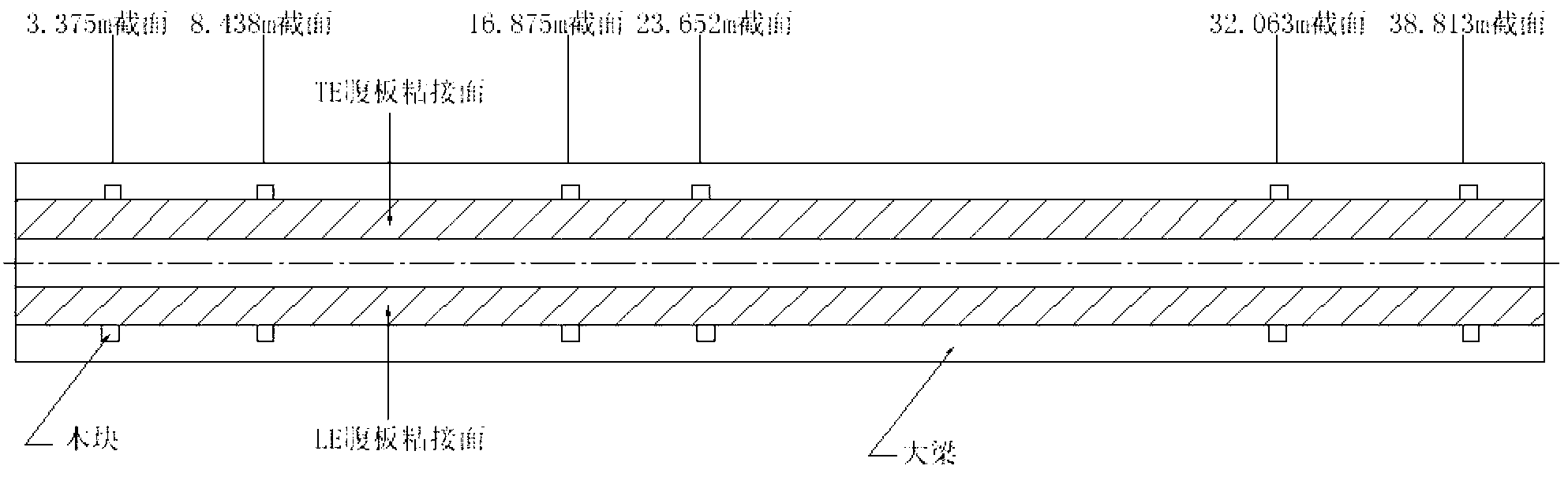

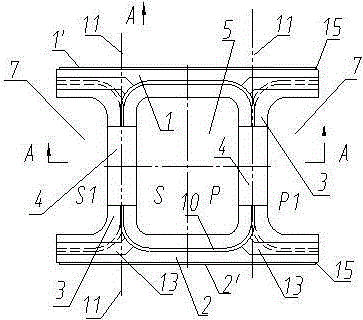

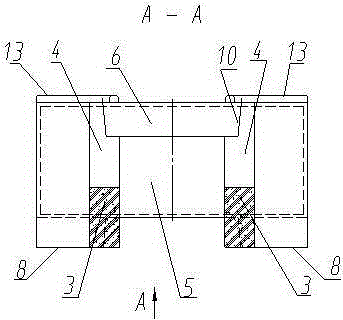

Method for positioning and bonding megawatt wind power blade web

ActiveCN103074001AReduce weightGuaranteed total weightAdhesive processes with surface pretreatmentEpoxy resin adhesivesElectricityEngineering

The invention discloses a method for positioning and bonding a megawatt wind power blade web. The method comprises the steps as follows: firstly, positioning the web on a big beam of an SS (suction surface) shell and a big beam of a PS (pressure surface) shell, and setting the position of the web by positioning blocks; secondly, applying a mixed bonding agent into a bonding area, lifting the web onto the SS shell by a crane, slightly placing the web onto the scraped bonding agent, just clamping in a gap between the positioning blocks for the trial closing operation, and extruding the web by the weight of the PS shell to bond the web with the SS shell in a fixing way; thirdly, removing the bonding agent from the web bonding area and the front and rear edges of the PS shell; and finally, closing, curing the bonding agent and integrating the PS shell, the SS shell and the web. Through the arrangement of the positioning blocks, the web can be accurately positioned on the shells, and a bonder thickness control piece is arranged in the bonding area to control the thickness of the bonding agent so as to save the usage amount of the bonding agent in the blade closing process and avoid shortage or excessiveness of the bonding agent in the local area in the closing process.

Owner:甘肃重通成飞新材料有限公司

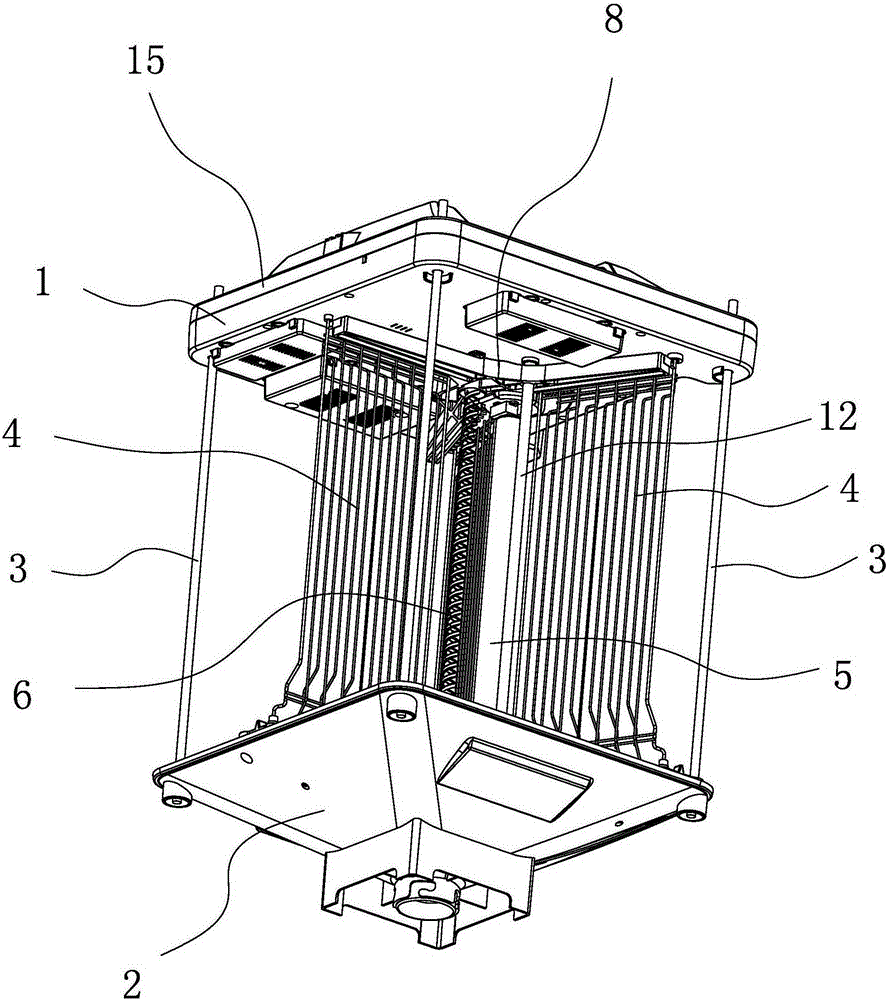

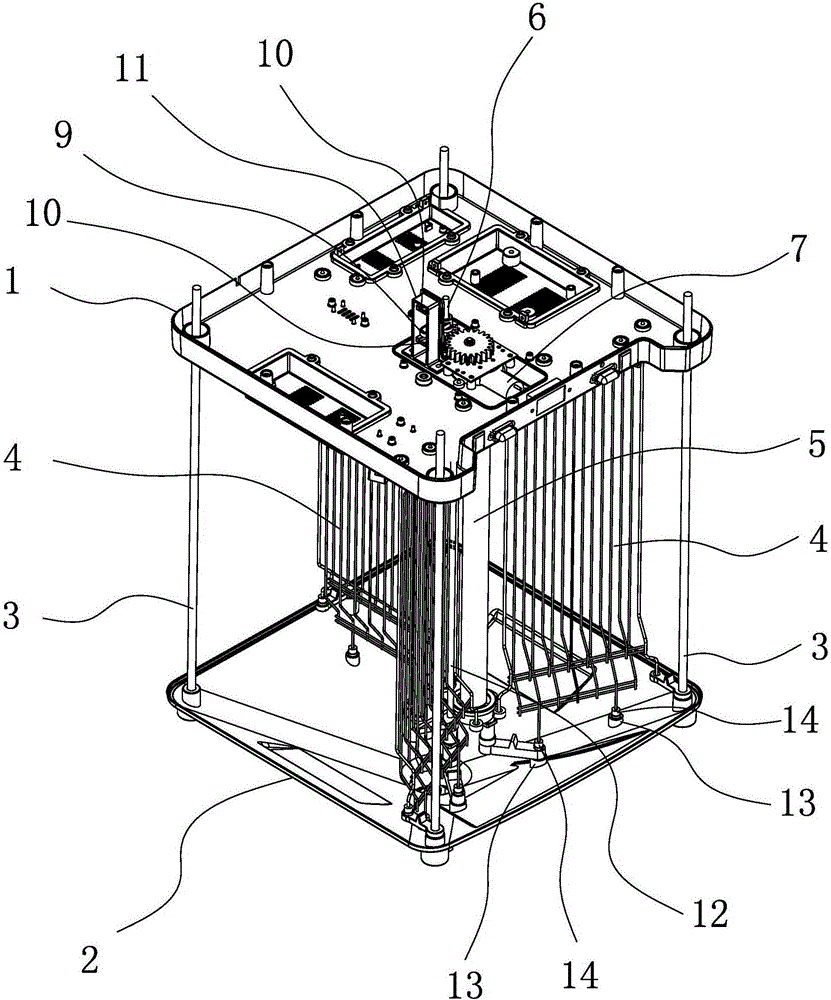

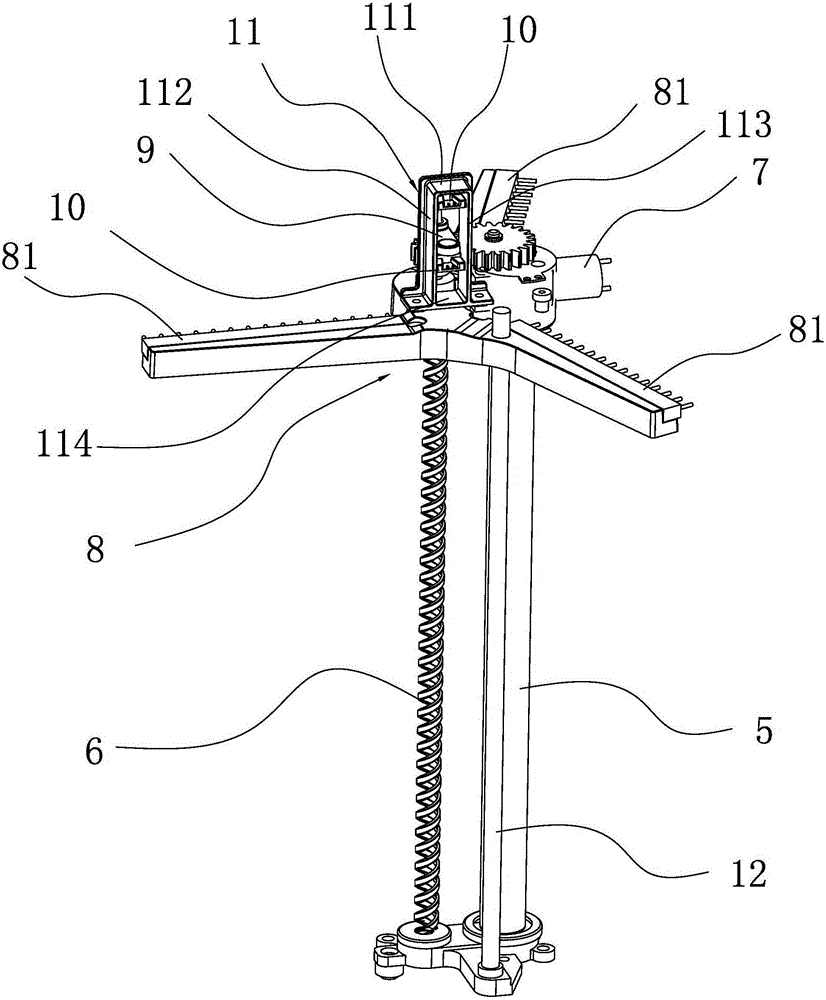

Automatic insect eliminating and killing lamp

ActiveCN105211028ANot easy to shiftInsect removal effect is goodInsect catchers and killersPaleontologyWire brush

The invention provides an automatic insect eliminating and killing lamp which belongs to the technical field of insect killing equipment. The automatic insect eliminating and killing lamp settles problems of low insect eliminating effect of an existing insect killing lamp and easy damage of an induction switch of the insect killing lamp. The automatic insect eliminating and killing lamp comprises an upper lamp cap, an insect collecting plate, a top cover, a lead screw, an insect eliminating wire brush bracket, a position induction rod, a position induction switch and a motor which is used for driving the lead screw to rotate. The lead screw is arranged on the upper lamp cap in a penetrating manner and furthermore the top of the lead screw upwards penetrates through the upper lamp cap. The insect eliminating wire brush bracket and the position induction rod are connected with the lead screw in a leadscrew-nut transmission manner. The position induction rod is arranged between the upper lamp cap and the top cover. The position induction switch is used for detecting the position of the position induction rod and makes the motor perform clockwise rotation or counter-clockwise rotation according to the position of the position induction rod. According to the automatic insect eliminating and killing lamp, automatic lifting of the insect eliminating wire brush bracket is realized; the position induction rod and the position induction switch are arranged in an inner chamber which is formed by the top cover and the upper lamp cap, thereby preventing influences of sunlight, rainwater, dust and insect bodies.

Owner:徐昌春

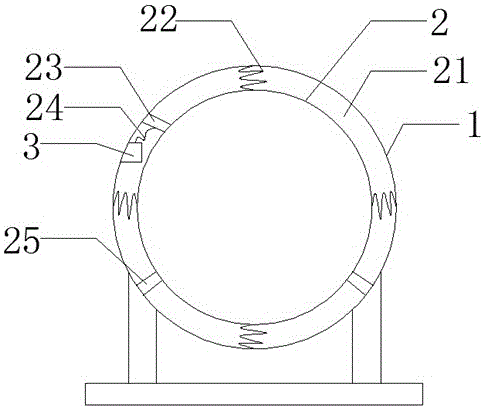

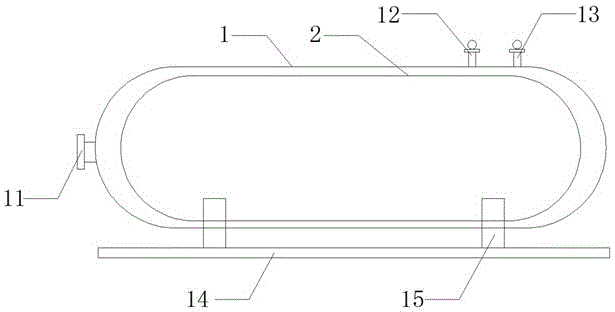

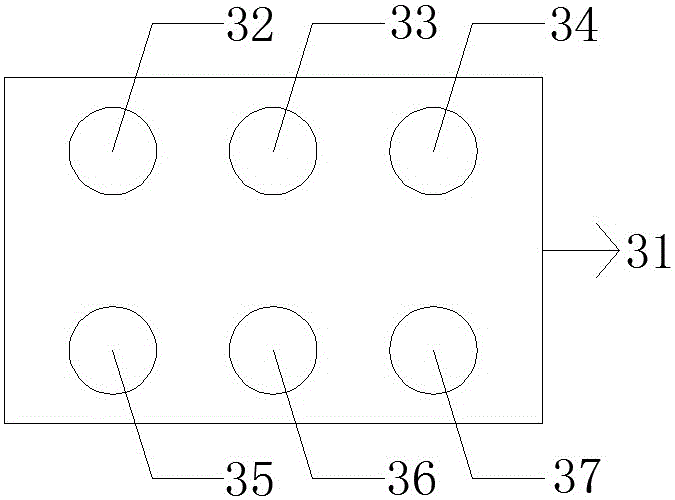

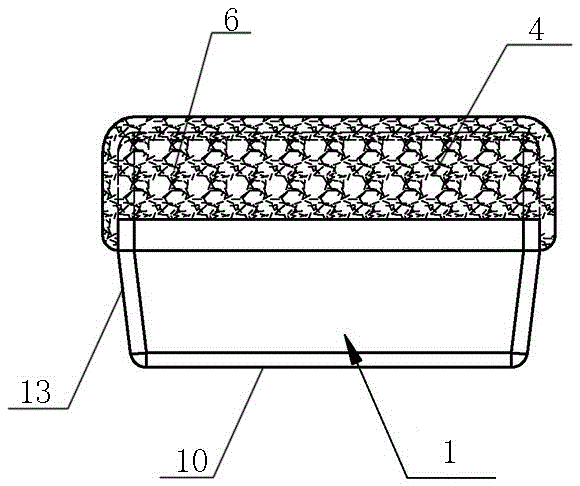

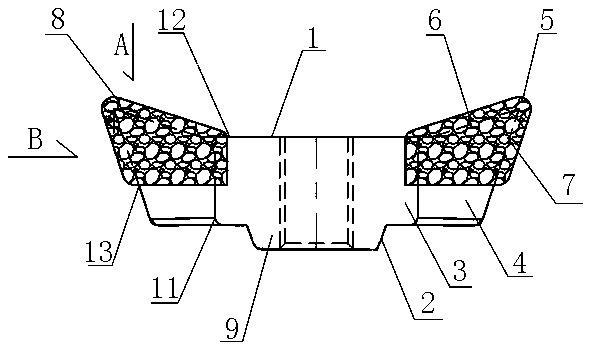

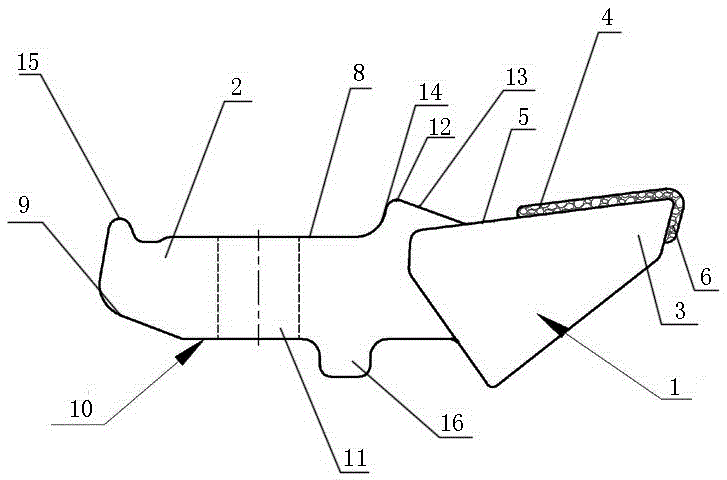

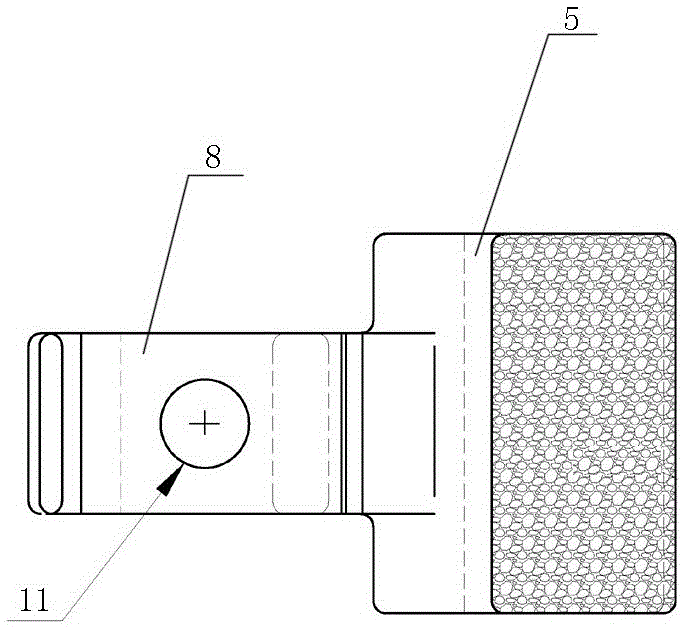

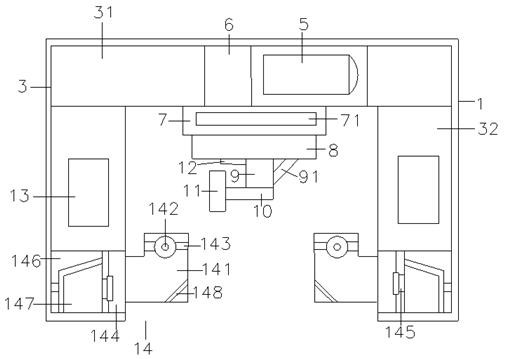

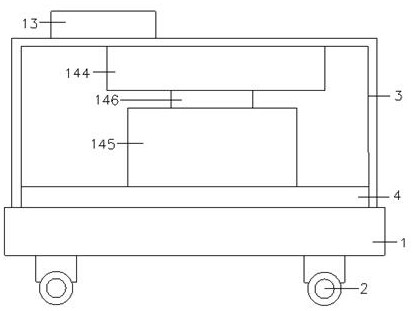

Hybrid electric vehicle gas cylinder for capable of potentiometer type detecting relative displacement in potentiometer type

ActiveCN105835693AGood structural firmnessGood connection strengthUsing electrical meansFuel supplyPotentiometerRelative displacement

The invention provides a hybrid electric vehicle gas cylinder for capable of potentiometer type detecting relative displacement in a potentiometer type. The hybrid electric vehicle gas cylinder for potentiometer type detecting relative displacement comprises an outer shell, an inner shell, a controller and a display terminal, wherein a cavity is formed between the outer shell and the inner shell; the cavity is filled with buffer fillers are filled in the cavity; the outer shell is connected with the inner shell through a buffer spring; a relative displacement sensor and the controller are also arranged in the cavity. Compared with the prior art, the hybrid electric vehicle gas cylinder has the following beneficial effects that through arranging the outer shell and the inner shell, the structure firmness is good, and the connection strength is good; with the buffer fillers and the buffer spring, the impact force can be effectively absorbed, and the damage of rigid impact on the inner shell is avoided; through arranging the relative displacement sensor, the displacement situation of the inner shell inside the outer shell can be detected, and workers can detect whether the buffer fillers and the buffer spring work normally or not according to the displacement information and then judges whether the buffer fillers and the buffer spring need to be replaced or not, so that the personal safety of passengers in an vehicle is further ensured.

Owner:滁州一银丰新材料有限公司

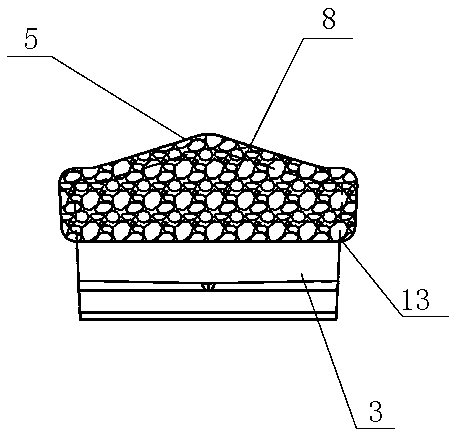

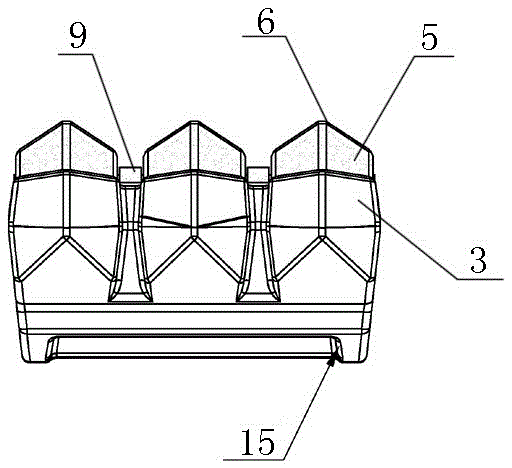

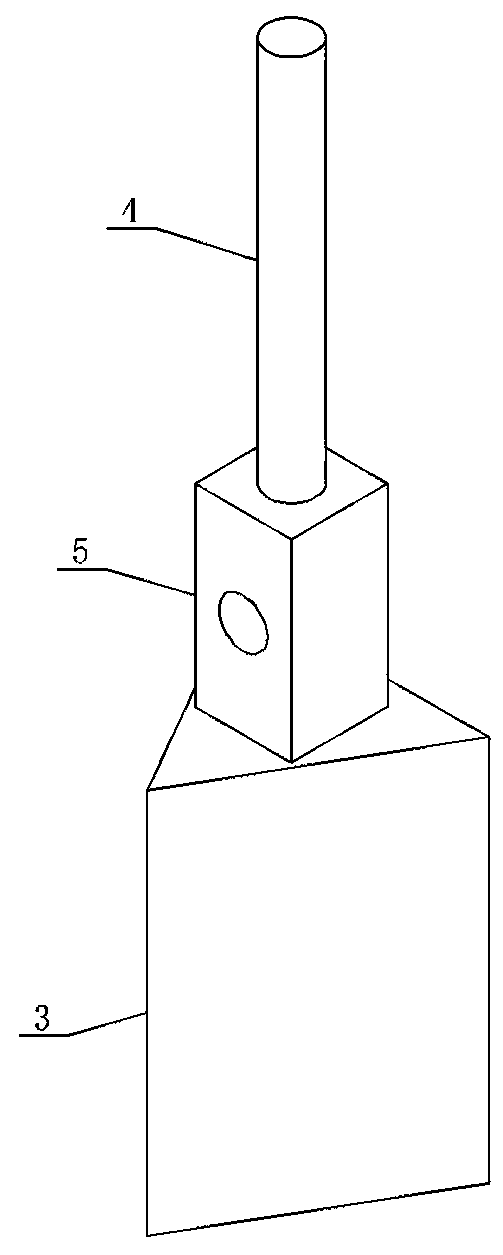

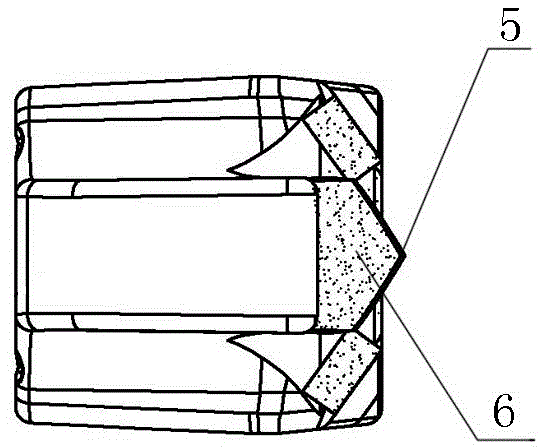

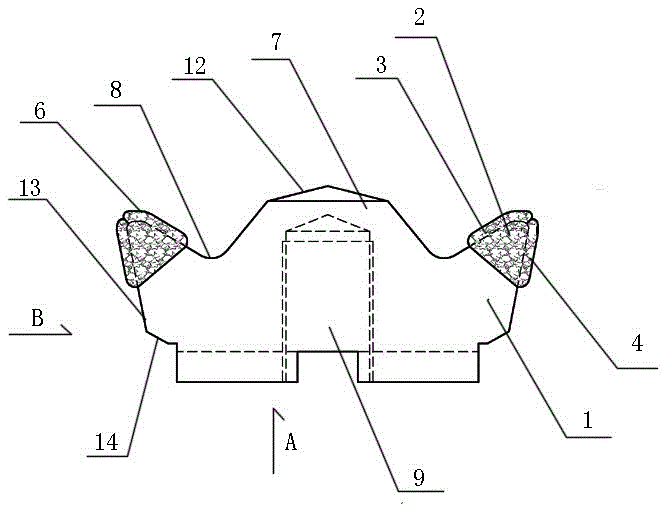

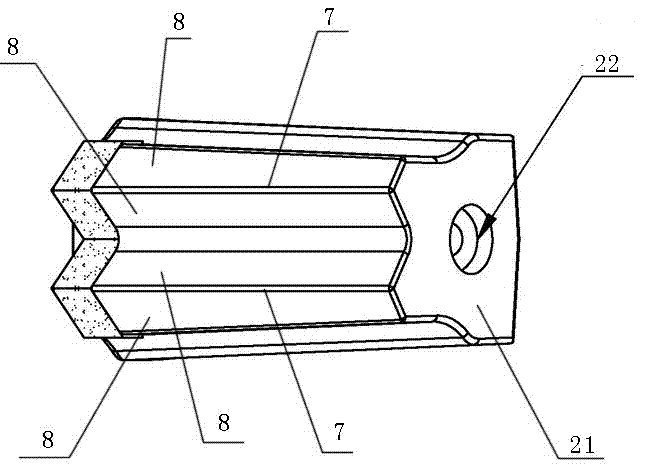

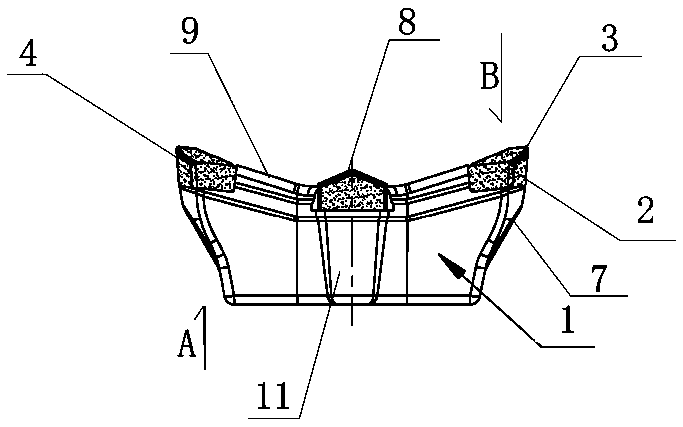

Crusher tooth head of stone crusher

A crusher tooth head of a stone crusher comprises a blocky tooth head body with the side-looking shape being similar to a regular triangle. The upper surface of the tooth head body is a working surface, and sharp-corner type tooth head parts are arranged at the front end of the working surface. Integrated outwards-protruding blocks are arranged on the two side faces of the tooth head body correspondingly, the working surface on the upper side downwards divides the outwards-protruding blocks, and the area of the outwards-protruding blocks is larger than half of the area of the working surface. The tooth head parts are arranged at the front ends of upper working surfaces of the outwards-protruding blocks. An oblique-plane notch groove with the width larger than one third of the whole width of each tooth head part is obliquely downwards formed in the middle of the tooth head part from the middle position of the corresponding working surface. Two large blocky hard alloy blocks are arranged on the portions, located on the two sides of the oblique-plane notch groove, of each tooth head part correspondingly. The sharp-tip end face tilting upwards is arranged at the front end of each large blocky hard alloy block. Each tooth head part composed of the large blocky hard alloy blocks is higher than the corresponding working surface. A small blocky hard alloy block located on the same horizontal plane with each working surface is embedded into the portion, located on the inner side of the corresponding large blocky hard alloy block, of the corresponding working surface. The crusher tooth head of the stone crusher has the characteristics that the structure is reasonable, using and mounting are convenient, the whole tooth head is good in structural firmness and resistant to abrasion, and thus the using cost is lowered, and work efficiency is improved.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

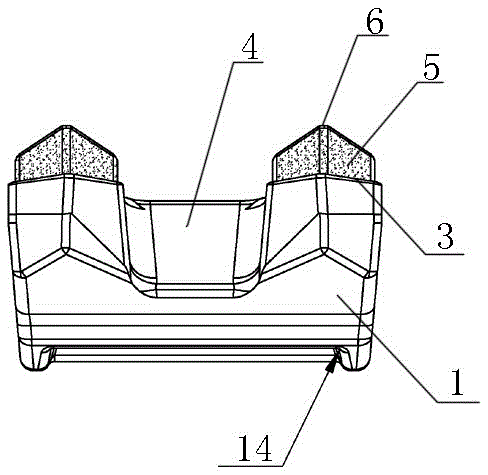

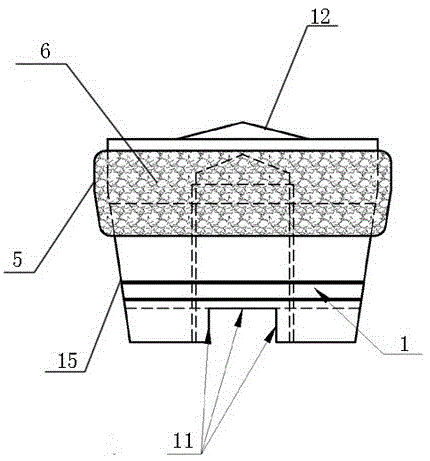

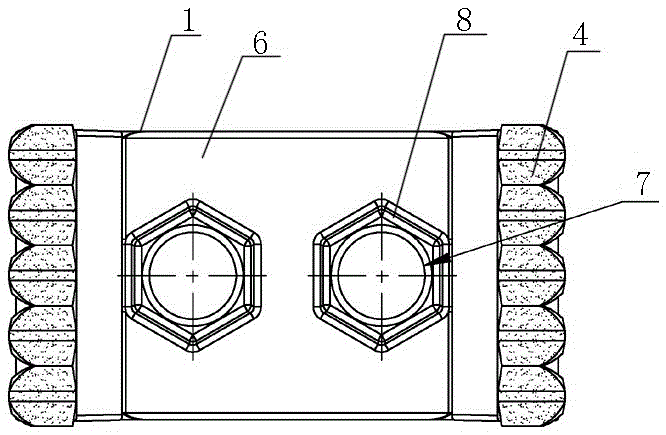

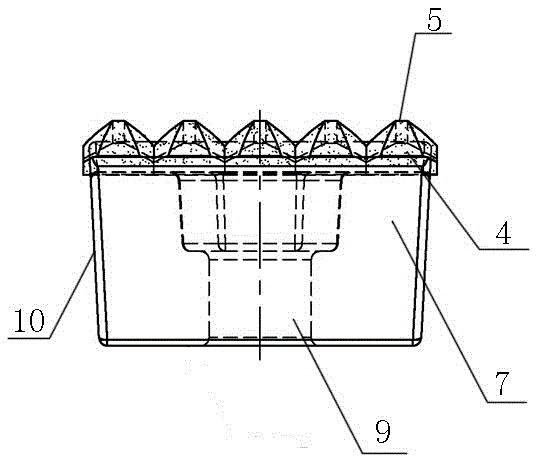

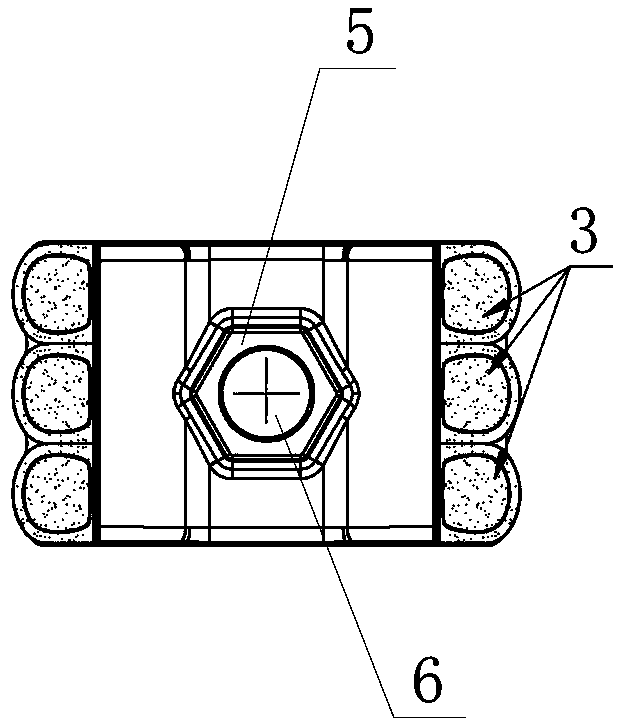

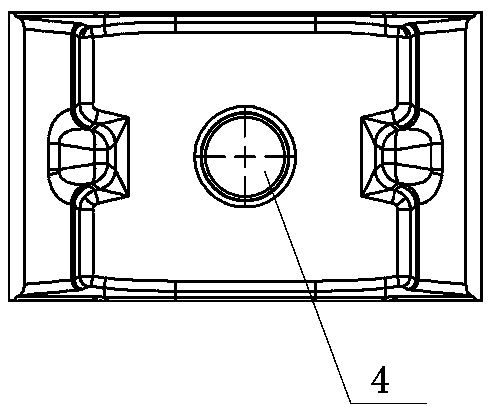

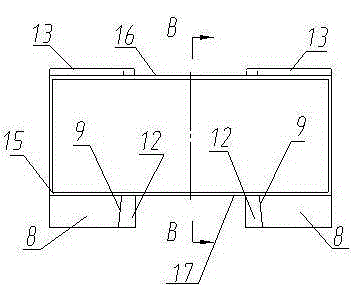

Crushing toothed head structure for waste treatment

InactiveCN106238148AGood structural firmnessReasonable structureGrain treatmentsAlloyWaste treatment

A crushing toothed head structure for waste treatment comprises a pressing block body in a cuboid shape. The side portions of the two symmetrical long ends on the upper face of the pressing block body are each provided with a tooth end portion which is warped upwards. Hard crushing alloy weld layers are welded to the upper surface of each tooth end portion, the side face of each outer ends of the tooth end portions and the respective two side faces of each tooth end portion in an overlaid manner. The upper face of the pressing block body is a work plane. Two locating through holes are evenly distributed in the middle of the work plane along the center line. The work plane is also provided with two hexagon nut holes, wherein each hexagon nut hole is located on the same hole center line with the corresponding locating through hole. The lower face of the pressing block body is an assembly plane. The crushing toothed head structure for waste treatment has the advantages that the structure is reasonable, use and installation are convenient, the whole toothed head structure is good in firmness and resistant to abrasion, so that the use cost is lowered, and the work efficiency is improved.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

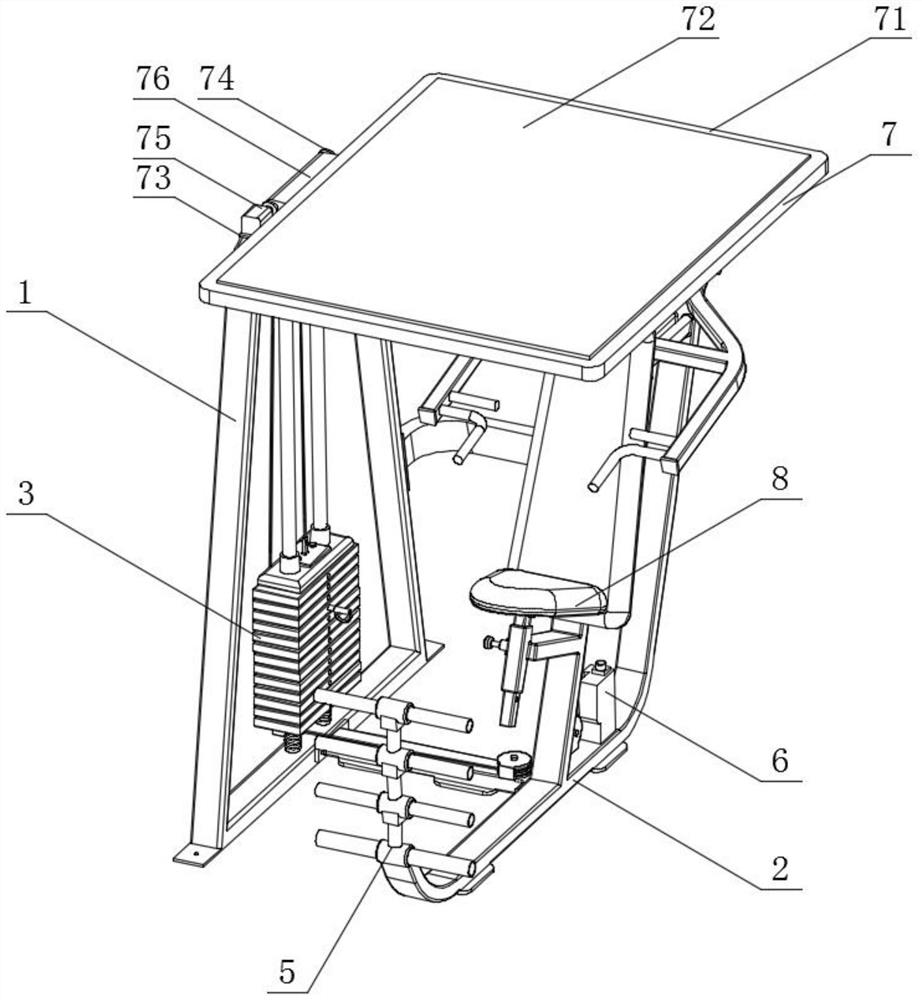

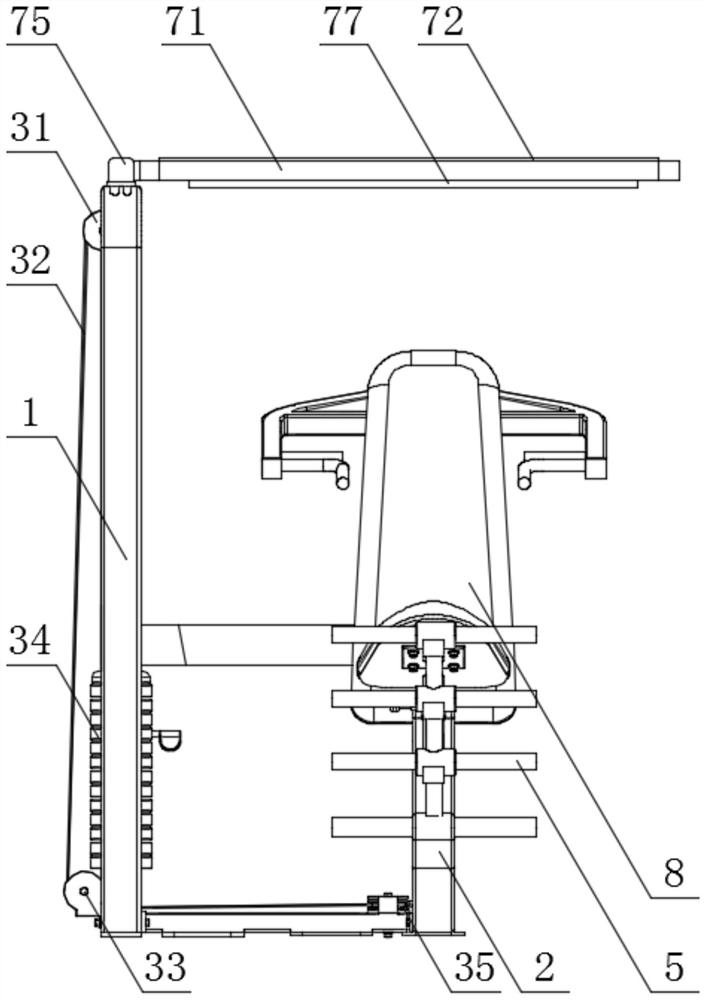

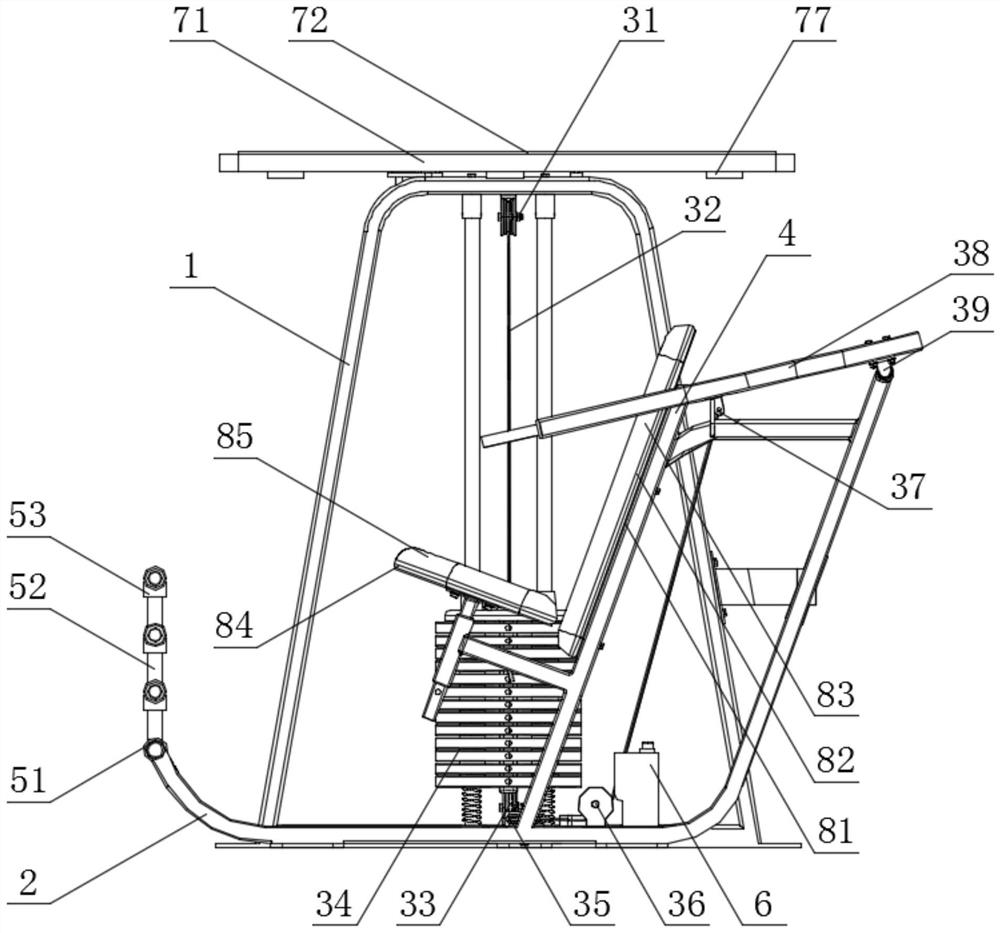

Physical training device for athletes

The invention discloses a physical training device for athletes. The device comprises a stretching frame, a bearing bottom frame, a stretching assembly, a supporting frame, a foot supporting assembly, a lubricating box, a dust blocking assembly and a warm keeping assembly, the dust blocking assembly is installed on one side of the top end face of the stretching frame, and the bearing bottom frame is fixedly installed on the end face of one side of the stretching frame through bolts; the supporting frame is fixedly installed in the center of the top of the bearing bottom frame through bolts, the warm keeping assembly is installed on the outer side of the supporting frame, the foot supporting assembly is installed on the top of one side of the bearing bottom frame, and the stretching assembly is installed on the end face of the top of the bearing bottom frame. A motor support is fixedly installed on one side of the top end face of the stretching frame through bolts. The physical training device for athletes is firm in structure and can facilitate the physical training of the athletes in use; and meanwhile, good warm-keeping and heating functions and dust-blocking and sun-shading effects are achieved, and therefore outdoor use is facilitated.

Owner:郑州大学体育学院

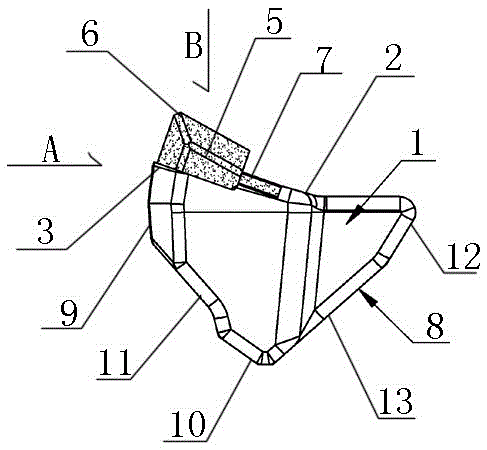

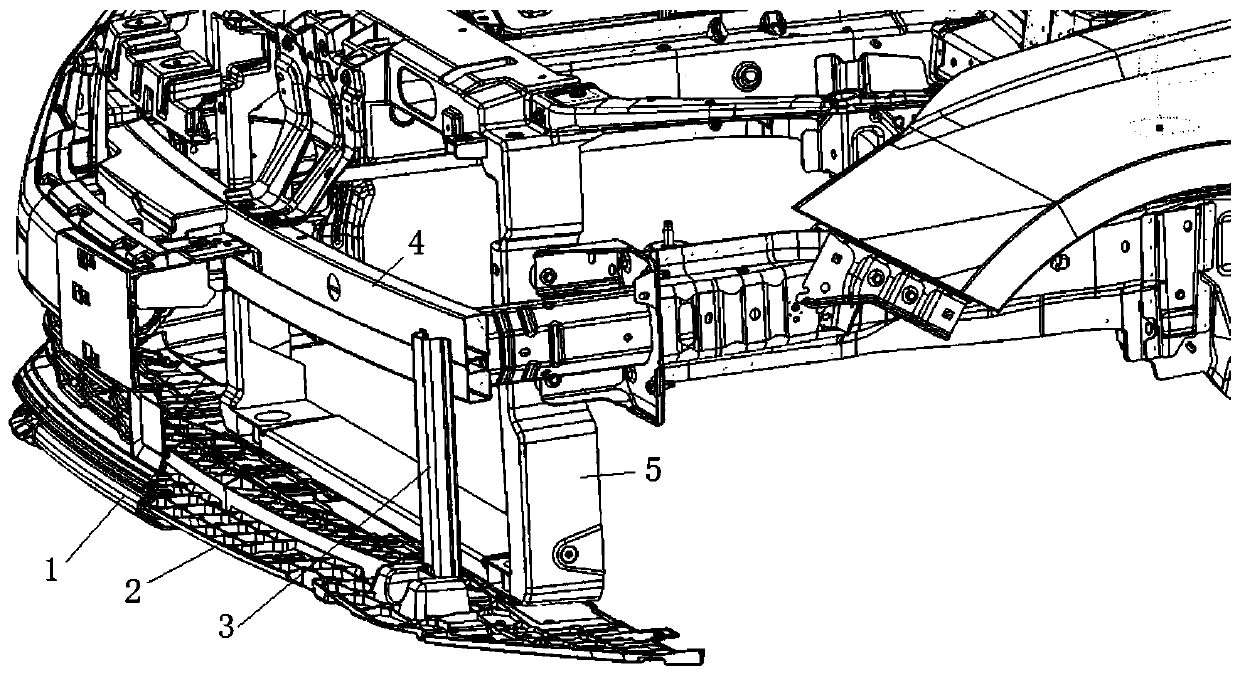

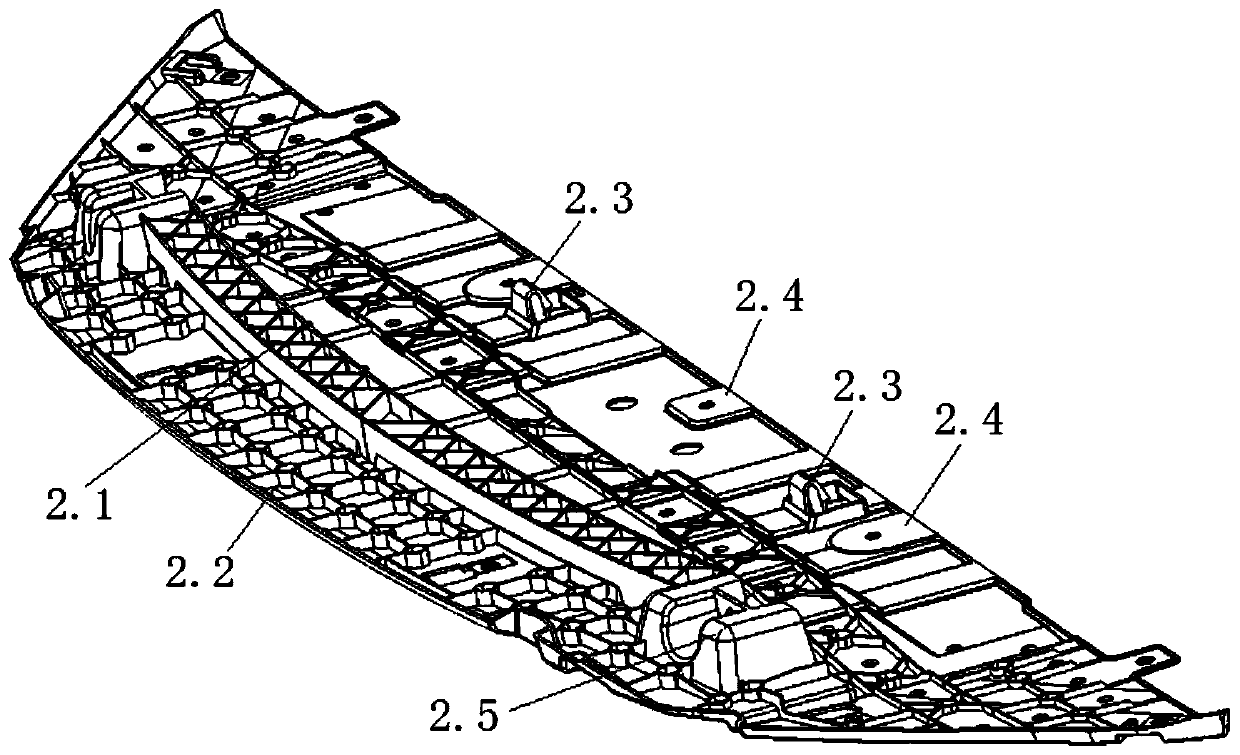

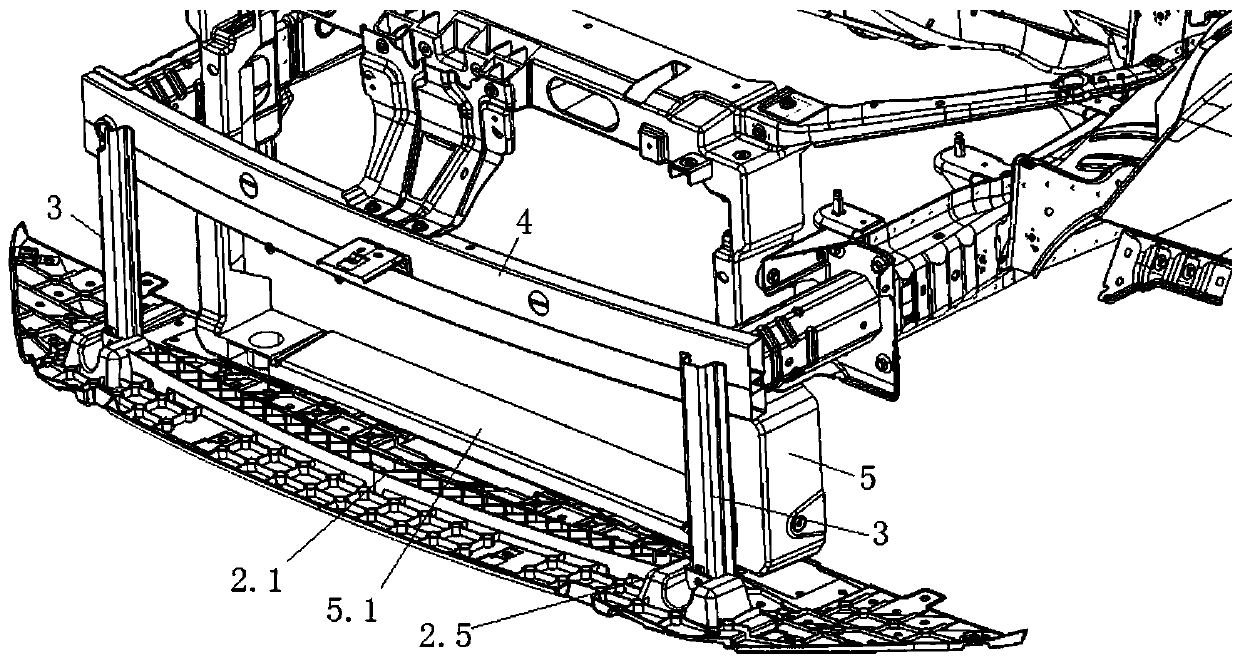

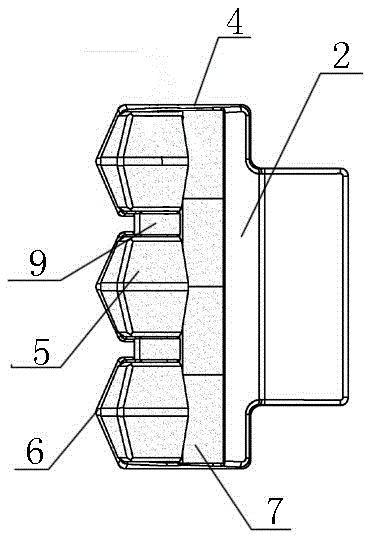

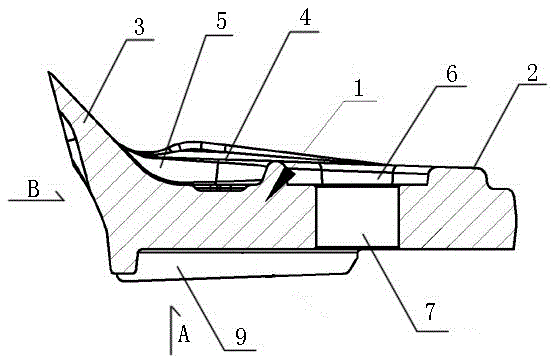

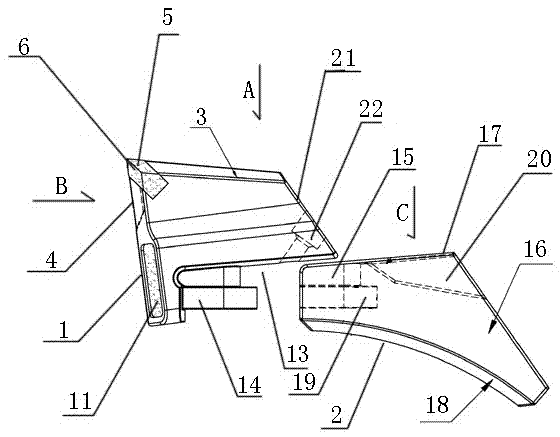

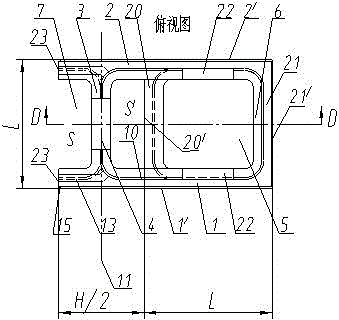

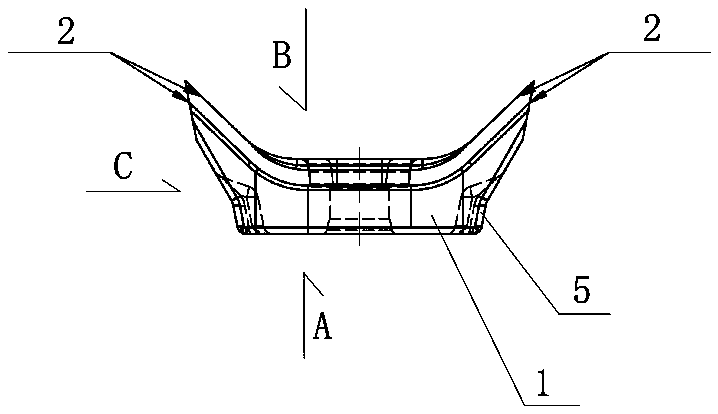

Bottom guard plate structure of front bumper

InactiveCN111516626ADurable and reliablePlay a supporting rolePedestrian/occupant safety arrangementBumpersEnergy absorptionLap joint

The invention relates to a bottom guard plate structure of a front bumper. The structure comprises a bottom protection plate body, the bottom protection plate body is installed between a front end frame and the front bumper, the front end of the bottom protection plate body is in lap joint with the front bumper, the rear end of the bottom protection plate body is fixedly connected with a lower cross beam of the front end frame, and a gap between the front bumper and the front end frame is sealed to achieve the effect of improving the whole vehicle wind resistance and the cabin heat dissipationperformance; and a shank supporting cross beam and transverse and vertical grid ribs are arranged on the bottom protection plate body, the transverse and vertical grid ribs are arranged in the lap joint area of the bottom protection plate body and the front bumper, and the shank supporting cross beam is arranged at the rear portions of the transverse and vertical grid ribs. When a pedestrian collides, the transverse and vertical grid ribs play a role in preliminary buffering and energy absorption, and the shank supporting cross beam behind the transverse and vertical grid ribs plays a role inmain energy absorption and supporting. In pedestrian protection leg type collision, the integrated shank supporting cross beam absorbs collision energy, so that light weight is achieved, and impact energy on the lower portion of the shank of a pedestrian can be effectively absorbed.

Owner:DONGFENG MOTOR CORP HUBEI

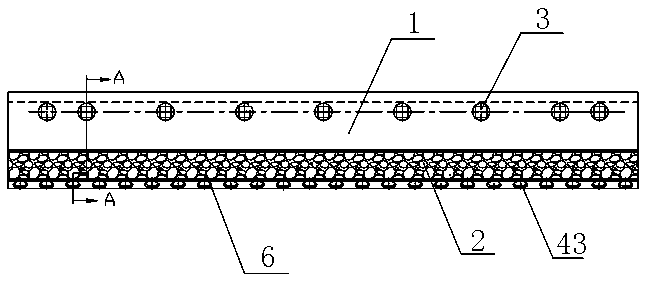

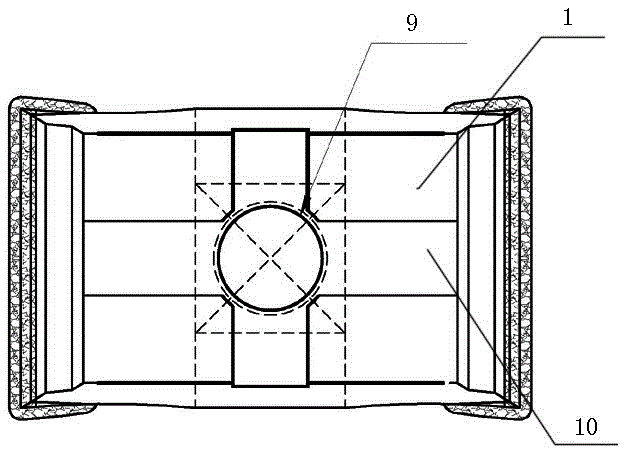

Mechanical tooth for crusher and waste product treatment

InactiveCN108236990AGood structural firmnessReasonable structureGrain treatmentsWaste productEngineering

The invention relates to a mechanical tooth for a crusher and waste product treatment. The mechanical tooth comprises a block-shaped body with an upper part as a working surface and a lower part as anassembling surface. Symmetrical triangular working blocks are externally and integrally connected to two corresponding side edges of the block-shaped body. The outer tip part of each triangular working block is obliquely and upwardly bulged to form a sharp corner part. At least one granular hard alloy welding layer is welded to the upper oblique and upward surface and the outer side surfaces of the two oblique edges of each triangular working block. A square convex block with a conical surface is arranged on the lower part of the block-shaped body. A vertically-upward positioning threaded hole is formed in the middle of the bottom of the square convex block. Transitional arc-shaped step surfaces are arranged on the portions, connected with the symmetrical triangular working blocks, of thetwo sides of the lower part of the block-shaped body, and a second-order assembly surface with the middle positioning threaded hole as the center and the two sides symmetrical is formed. The mechanical tooth has the beneficial effects that the mechanical tooth is reasonable in structure, convenient to use and mount, good in overall structure firmness and resistant to wear, so that the use cost islowered, and the working efficiency is improved.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

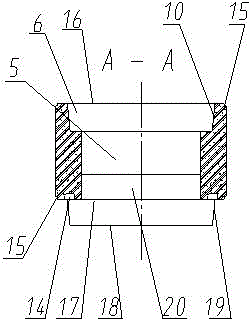

Snow sweeper and land leveler tool apron structure

InactiveCN108301374AGood structural firmnessReasonable structureSoil-shifting machines/dredgersSnow cleaningCarbideAlloy

A snow sweeper and land leveler tool apron structure is mainly formed by connecting an integrally-machined rectangular plate body with an integrally-machined strip-shaped steel plate body. Bolt assembly holes used for fixing installation and evenly distributed are formed in the rectangular plate body. The strip-shaped steel plate body with the length equal to that of the rectangular plate body iswelded to the connecting long edge of one side of the rectangular plate body. A bent connecting side face with the angle ranging from 40 degrees to 50 degrees is formed on the side of a working surface of the strip-shaped steel plate body. A working surface on the middle upper portion of the strip-shaped steel plate body is flush with a working surface of the rectangular plate body. A row of multiple tool bit installation holes perpendicular to an oblique working surface are formed in the oblique working surface on the lower portion of the strip-shaped steel plate body. A strip-shaped granularcemented carbide welding layer or a hard welding rod wear-resisting layer along the connecting long edge of the rectangular plate body is additionally arranged in the connecting position of the working surface on the upper portion of the strip-shaped steel plate body and the working surface of the rectangular plate body. The snow sweeper and land leveler tool apron structure has the beneficial effects of being reasonable, convenient to use and install, good in whole tooth head structure firmness, resistant to wear and capable of reducing use cost and improving work efficiency.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

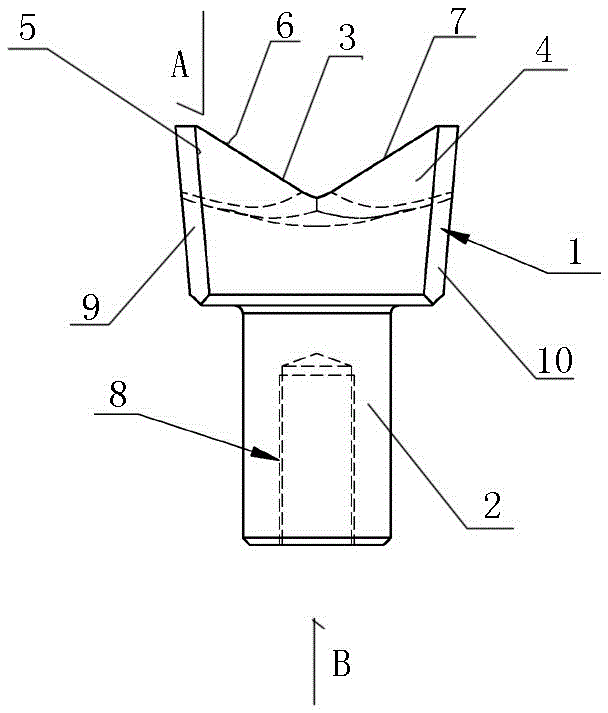

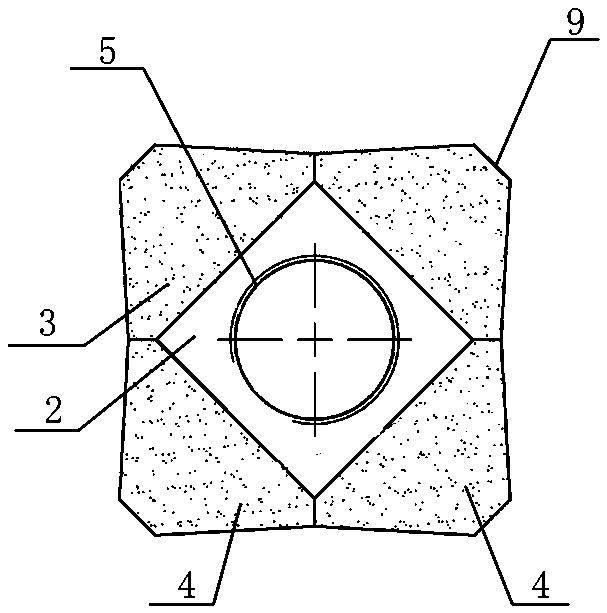

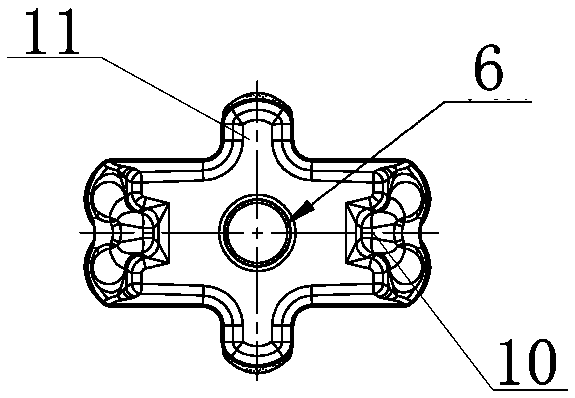

Branch crusher tooth

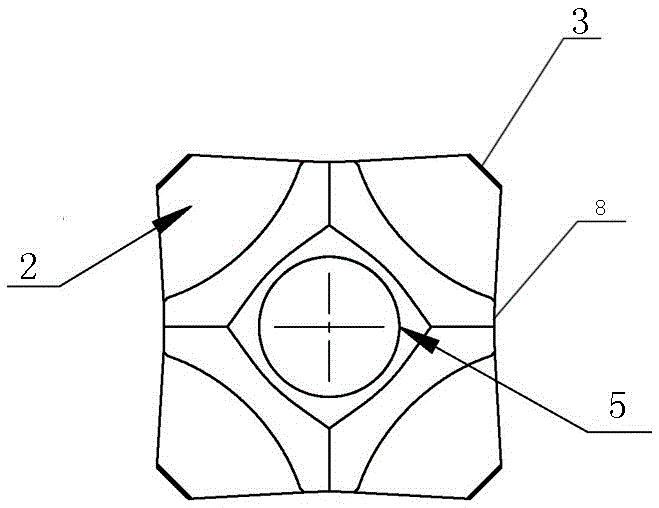

InactiveCN106216026AReasonable structureEasy to use and installGrain treatmentsEngineeringMachine tool

The invention discloses a branch crusher tooth. The branch crusher tooth comprises a square block-shaped machine tool body; the middle of the lower end surface of the machine tooth body is connected with a downward vertical connecting column; the upper end surface of the machine tooth body is a working surface; integrally molded triangular block tooth head ends are respectively arranged at four corner parts of the working surface; respective outer corner parts of all the tooth head ends are upwards projected to form sharp corners; the sharp corners at the outer ends are downwards transited to the working surface by inner inclined surfaces or arc surfaces to form four side surfaces; V-shaped groove gaps are formed in the upper surfaces of the four side surfaces; the cylindrical surface of the connecting column is an assembly surface; and a middle axial thread hole is formed in the lower end surface of the connecting column. The branch crusher tooth has such characteristics as reasonable structure, convenience for use and installation, good firmness of the whole tooth head structure, wear resistance, reduction of the use cost and improvement of the working efficiency.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

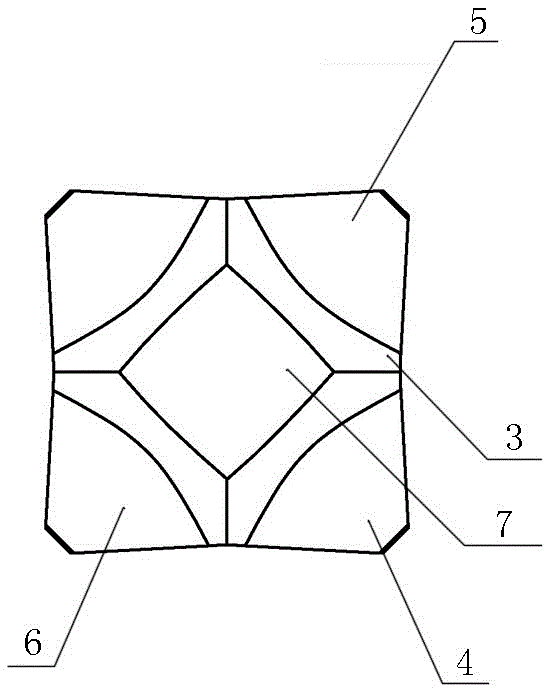

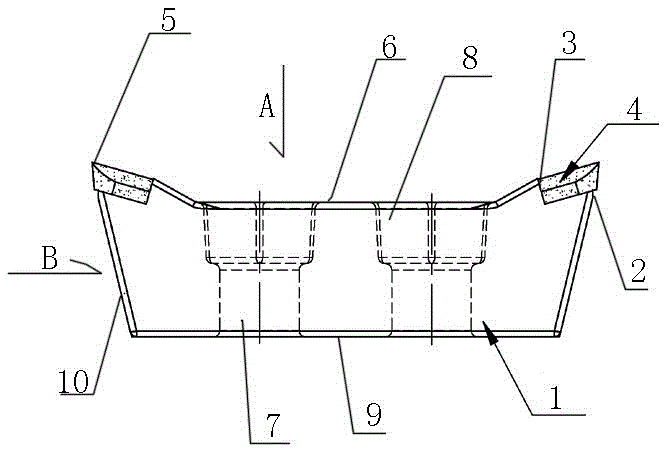

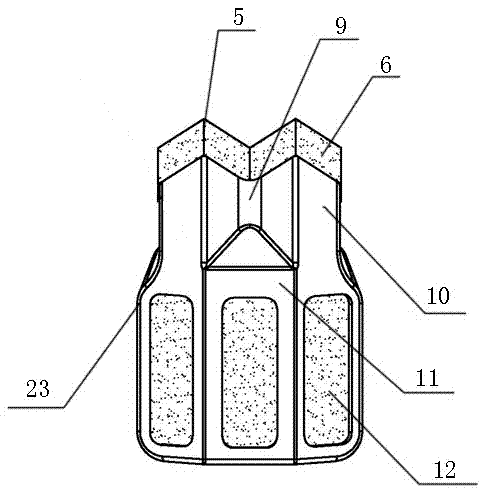

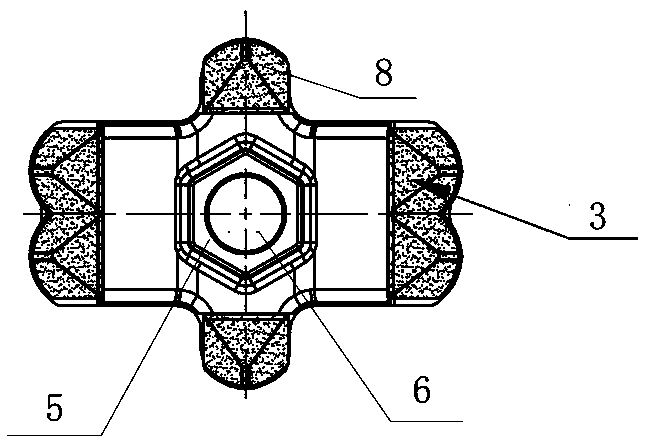

Tooth head structure of stone crusher

InactiveCN106216023AGood structural firmnessImprove wear resistanceGrain treatmentsEngineeringSharp angle

The invention discloses a tooth head structure of a stone crusher. The tooth head structure comprises a block-shaped tooth head body in the shape like a regular triangle from the lateral view. The upper face of the tooth head body is a work face. The front end portion of the work face is provided with a sharp-angle-shaped tooth head part. Outer protruding blocks are arranged on the two side faces of the tooth head body correspondingly, wherein the outer protruding blocks are integrated, the upper face work face serves as the boundary in a downward manner, and the area of the outer protruding blocks is larger than that of half of an end face. The tooth head part is arranged at the front end portion of the upper face work face of the outer protruding blocks. The tooth head part is mainly formed by connecting three large-block-shaped hard alloy blocks in parallel, wherein the three large-block-shaped hard alloy blocks are arranged in the front row. The front end portion of each large-block-shaped hard alloy is provided with an upwards-tilted sharp-angle-shaped end face. The upper face of the tooth head part composed of the large-block-shaped hard alloy blocks is higher than the work face. A whole-strip-shaped hard alloy block which is transversely arranged and is located on the same horizontal plane with the work face is further inlaid in the position, on the inner sides of the large-block-shaped hard alloy blocks, on the work face. The tooth head structure of the stone crusher has the beneficial effects of being reasonable in structure, convenient to use and install, good in overall tooth head structure firmness, high in wear resistance, capable of improving the work efficiency and the like.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

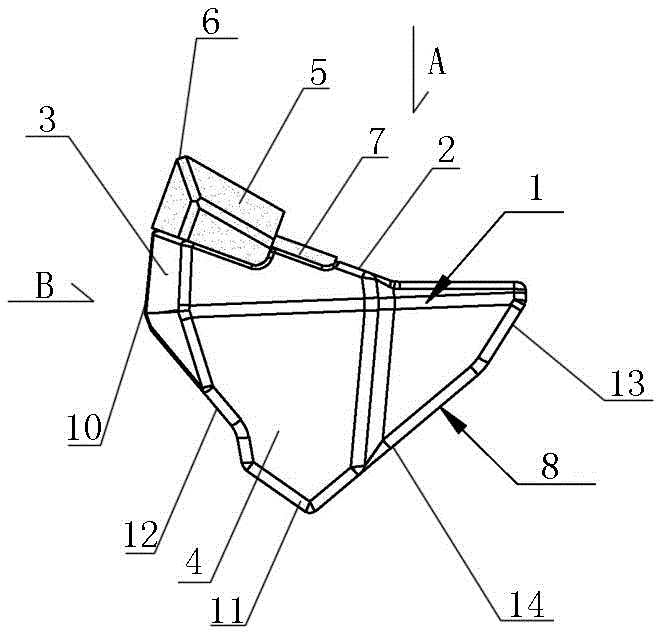

Mechanical tooth for waste treatment

InactiveCN106423410AGood structural firmnessReasonable structureGrain treatmentsWaste productEngineering

The invention discloses a mechanical tooth for waste treatment. The mechanical tooth consists of a block-shaped body with a front part with a triangular cross section and a connection grip part transversely connected to the middle position of the angle shape of the rear end of the block-shaped body, wherein hard broken alloy welding layers for covering angular end part are respectively arranged on two side surfaces of the angle shape of the front end of the block-shaped body; the upper plane between the angle shape of the rear end and the angle shape of the front end is a working plane; the hard broken alloy welding layers cover at least half or above of the whole working plane; the angle wrapping surface below the other front side and a lower slope form a small-inclination-angle slope with the angle less than 180 degrees; the hard broken alloy welding layers are arranged on the small-inclination-angle slope; the connection grip part is a cuboid grip part integrally formed on the block-shaped body; a sunken mounting plane is arranged on the upper plane of the cuboid grip part; an inwards retracted slope is arranged on the outer side of the lower surface and forms an assembling surface with the lower surface; and a locating hole perpendicular to the sunken plane is formed in the middle of the cuboid grip part. The mechanical tooth for waste treatment has the characteristics of reasonable structure, convenience for use and mounting, high overall structural firmness of a tooth head, wear resistance, capability of reducing the use and improving the working efficiency and the like.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

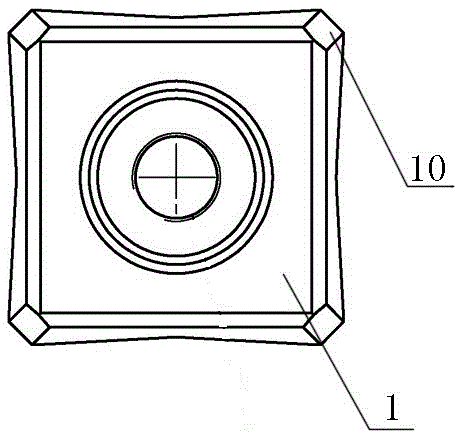

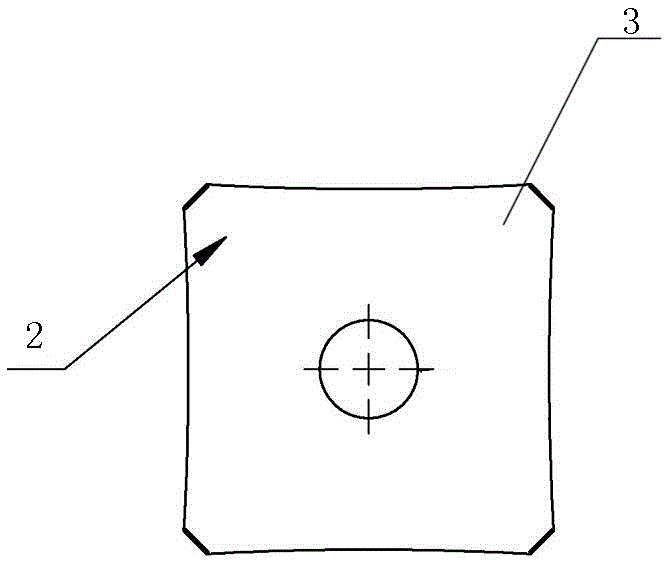

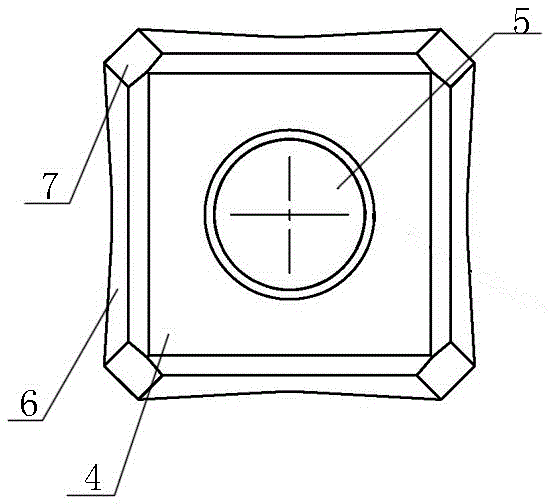

Wood chipper tooth head

InactiveCN106238150AGood structural firmnessReasonable structureGrain treatmentsEngineeringCounterbore

The invention discloses a wood chipper tooth head. The wood chipper tooth head comprises a square block-shaped tooth head body. The upper end face of the tooth head body is a working plane. The working plane consists of an arc-shaped end face which is formed in the way that a spherical body is tangent to the upper end face of the tooth head body, and convex sharp knife corners are formed at the four corners of the working plane. The lower end face of the tooth head body is an assembling plane. A counterbore hole is formed in the middle of the assembling plane, and a positioning threaded through hole is vertically formed in the middle of the counterbore hole in an upward mode. The four side faces of the tooth head body are all provided with oblique planes which are shrunken inwards from top to bottom, and accordingly a rectangular pyramid with the upper area being larger than the lower area is formed. Chamfer transition edges are arranged at the four corner edges of the four side faces. The wood chipper tooth head has the characteristics that the structure is reasonable, using and installing are convenient, the overall tooth head structure is good in firmness, abrasion resistance is achieved, and therefore the using cost is reduced, and the working efficiency is improved.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

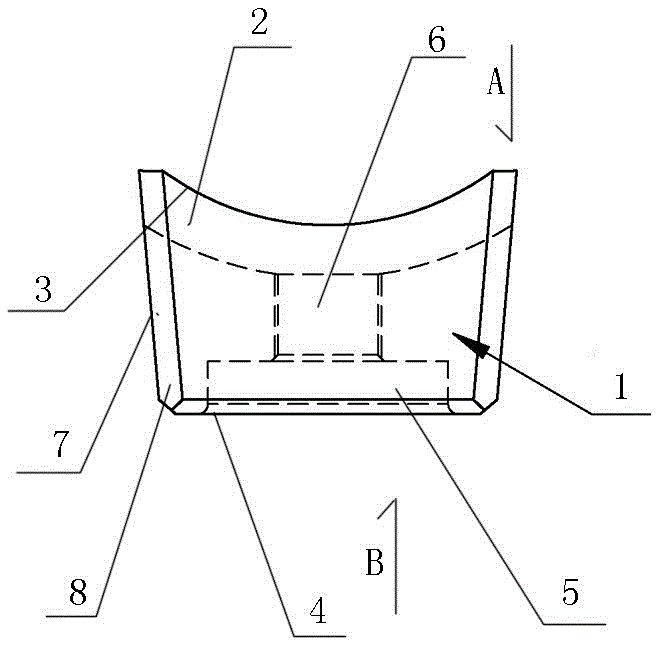

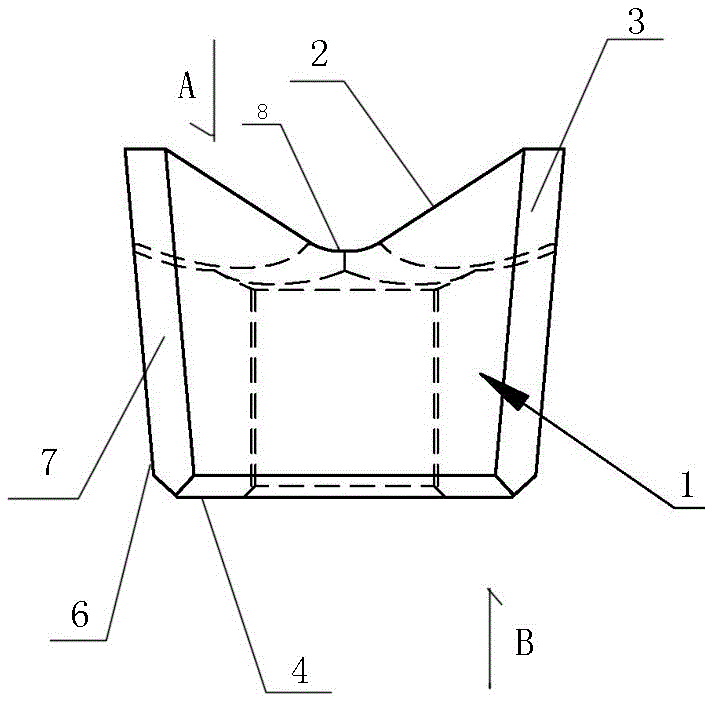

Branch crusher tooth head structure

The invention discloses a branch crusher tooth head structure. The branch crusher tooth head structure comprises a square block-shaped tooth head body; the upper end surface of the tooth head body is a working surface; the working surface is formed by four corner parts symmetrically and aslant downwards connected to an inclined surface with a square end surface or an inclined arc surface in middle; the four corner parts form sharp knife corners upwards projected; the lower end surface of the tooth head body is an assembly surface; a positioning thread through hole is vertically and upwards formed in middle of the assembly surface; four side surfaces of the tooth head body are inclined surfaces inwards shrunk from top to bottom to form a four-cone body with an upper area larger than a lower area; and chamfering transition edges are respectively arranged at four corner edges among the four side surfaces. The branch crusher tooth head structure has such characteristics as reasonable structure, convenience for use and installation, good firmness of the whole tooth head structure, wear resistance, reduction of the use cost and improvement of the working efficiency.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

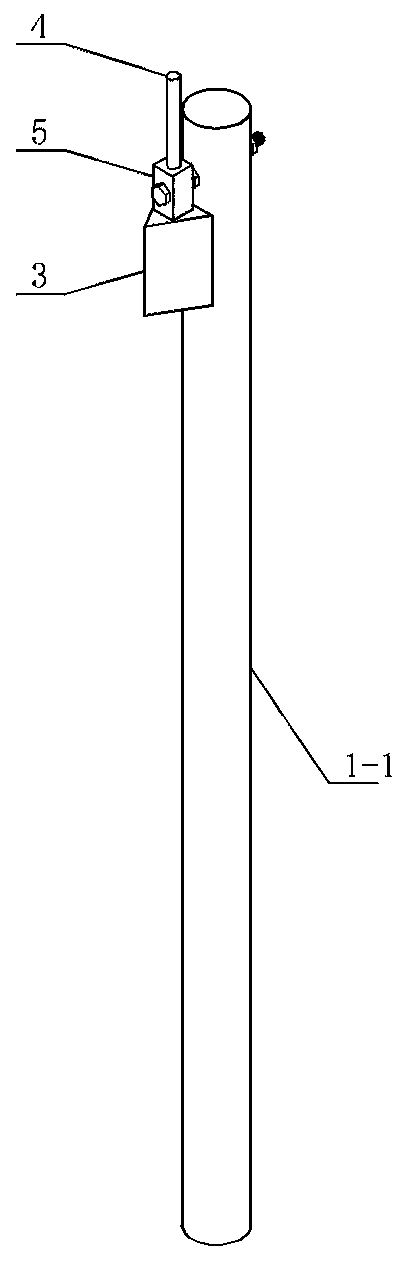

Power braking rod capable of realizing post switch five-protection interlocking

The present invention discloses a power braking rod capable of realizing post switch five-protection interlocking, pertaining to the technical field of electric power fittings. The rod comprises a rodbody, a first poking rod and a second poking rod arranged on the rod body. The first poking rod is movably connected with the rod body, and the first poking rod stretches from the rod body. The second poking rod is movably connected with the rod body, and the second poking rod stretches from the rod body. When the rod is used, the first poking rod or the second poking rod stretches from the rod body. According to the rod, the accuracy of operation is improved via the rod body, the first poking rod and the second poking rod.

Owner:STATE GRID CORP OF CHINA +1

Mechanical tooth matched with pulverizer and used for waste disposal

InactiveCN107755014AReasonable structureEasy to use and installGrain treatmentsPulverizerSquare Shape

A mechanical tooth matched to a pulverizer and waste treatment, which includes a block-shaped tooth head body, and the upper surface of the tooth head body is a working surface, which is composed of a square concave plane in the middle and four corners It consists of a four-corner bevel formed from the outside to the inside and obliquely downward to the sides of the square concave plane. A hard alloy layer is welded firmly on the four corners of the plane; the middle of the square concave plane is vertically The bottom is provided with a positioning threaded through hole; the four side walls of the tooth head body are respectively tapered surfaces expanding obliquely from bottom to top, forming a tapered square block body with a large upper part and a smaller lower part; the four An embedded cylindrical cemented carbide block is arranged on the middle upper part of the side wall and below the junction of two adjacent sloped cemented carbide layers; the bottom surface of the tooth head body is a plane and forms an assembly surface with the four side walls; It has the characteristics of reasonable structure, convenient use and installation, good overall structure firmness, wear resistance, good fastness to the tooth seat, and reasonable structure combined with each other, thereby improving work efficiency and so on.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

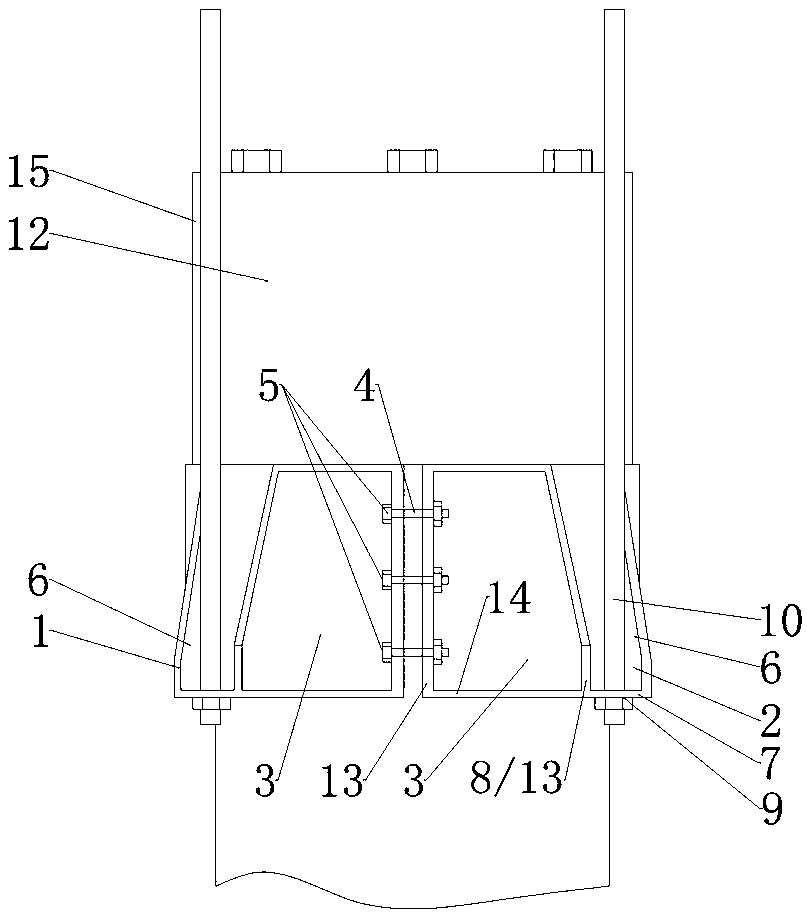

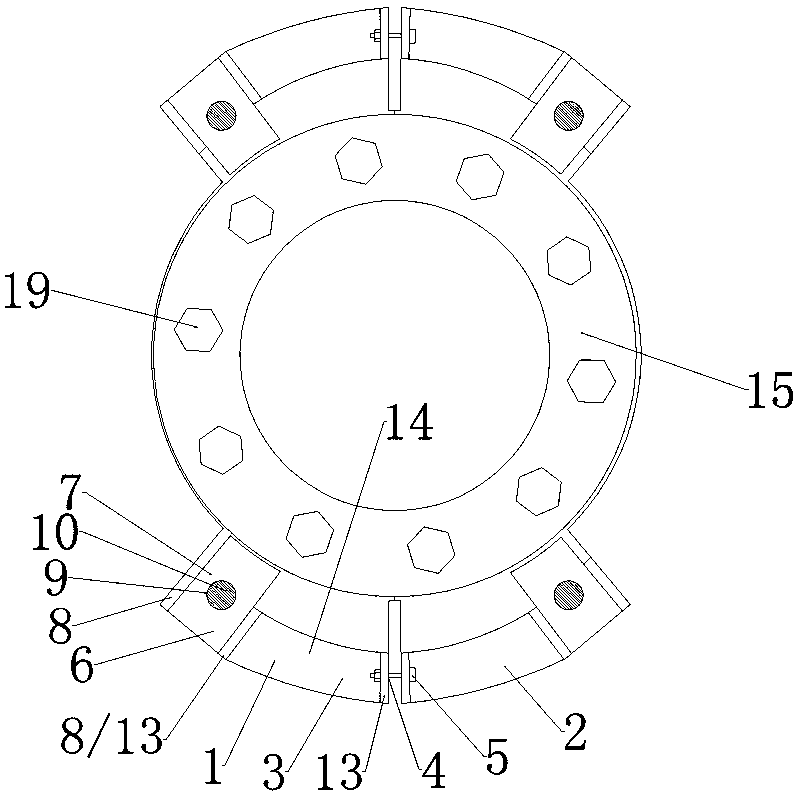

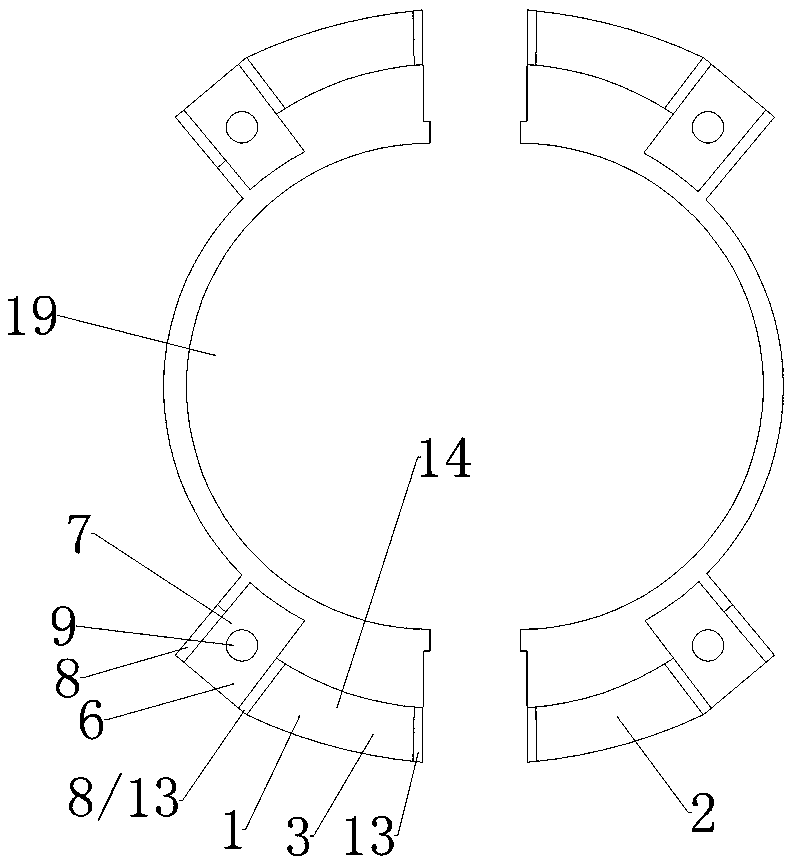

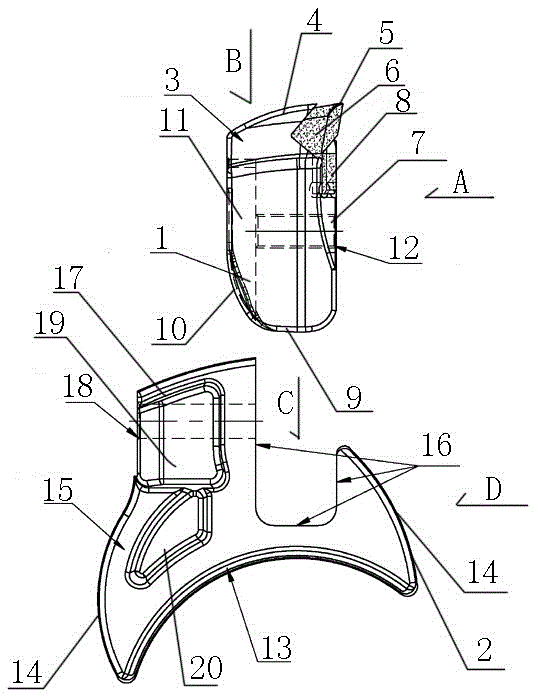

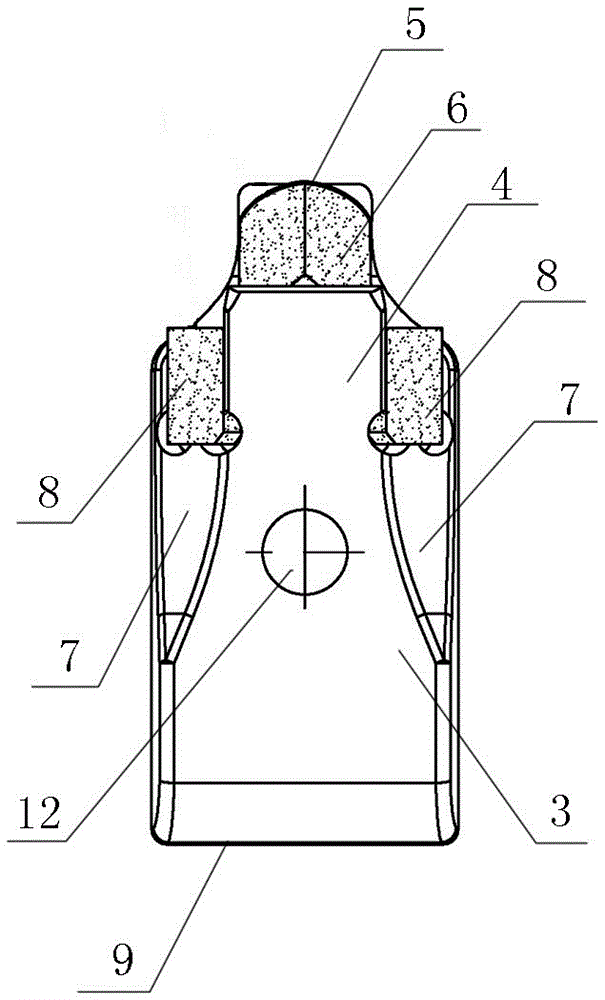

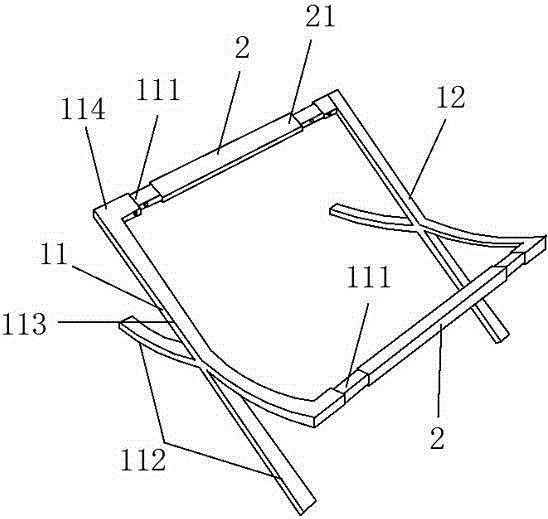

Novel prestressed pipe pile pull-out test device

PendingCN110485480AImprove structural stabilityUniform tensionFoundation testingSquare ShapeEngineering

The invention discloses a novel prestressed pipe pile pull-out test device which comprises a fixture, a fixture lifting mechanism, a pull force measurement mechanism and a displacement measurement mechanism. The fixture comprises split left fixture and right fixture; square-shaped metal frames with outward openings are arranged on the outer sides of the clamping ends of the left fixture and the right fixture; bolt connecting holes are formed in adjacent side walls of the square-shaped metal frames relatively arranged on the left fixture and the right fixture; bolts penetrate through the two bolt connecting holes so as to clamp the left fixture and the right fixture onto a pile head; connecting frames are arranged on the positions, close to the square-shaped metal frames, on the left fixture and the right fixture; each connecting frame is provided with a bottom plate and side plates located at two side ends of the bottom plate; the bottom plate and the two side plates of each connectingframe are fixed onto the outer side wall of the left fixture or the right fixture; through holes are formed in the bottom plates; pull rods with external threads at the end parts penetrate through the through holes so as to be in threaded connection with nuts; and the four pull rods are jointly and symmetrically arranged on the left fixture and the right fixture. According to the device, the fixtures are firm in structure, a pull force applied to a pile body is uniform, and the fixtures are convenient to clamp.

Owner:ZHEJIANG YUANBEN TESTING TECH SERVICE

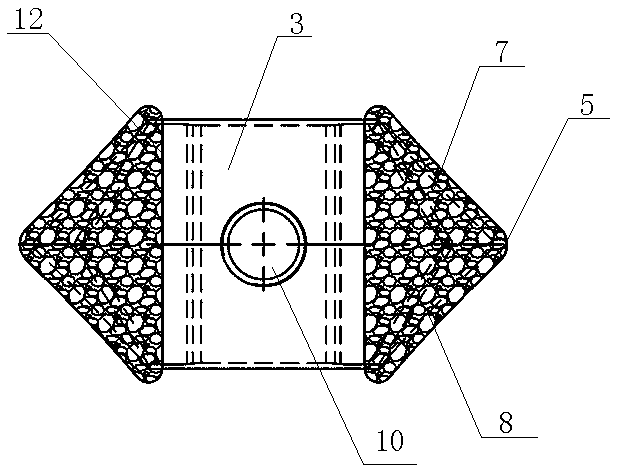

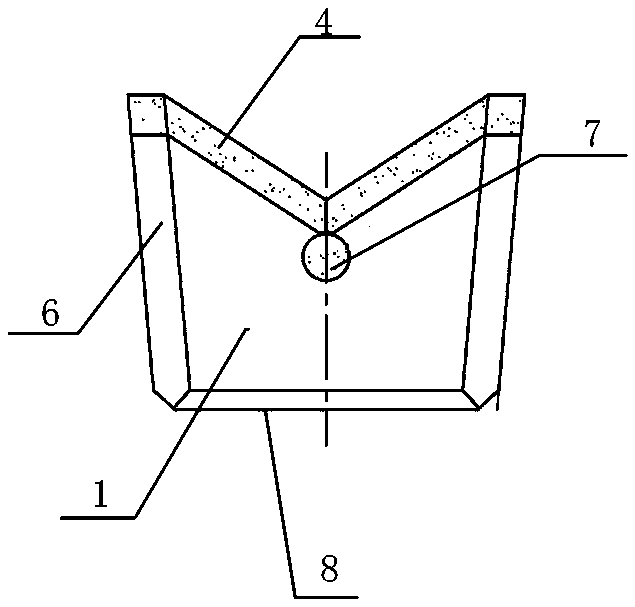

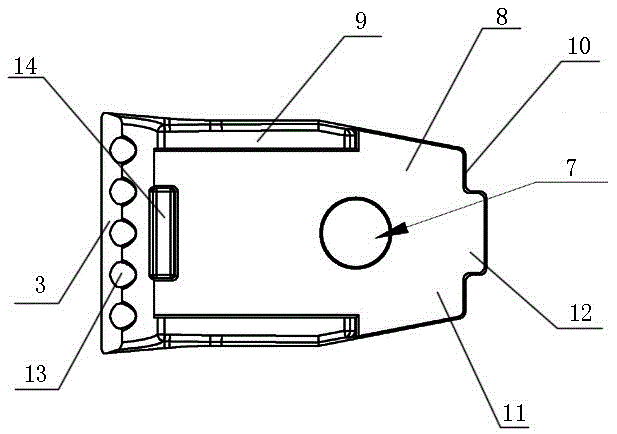

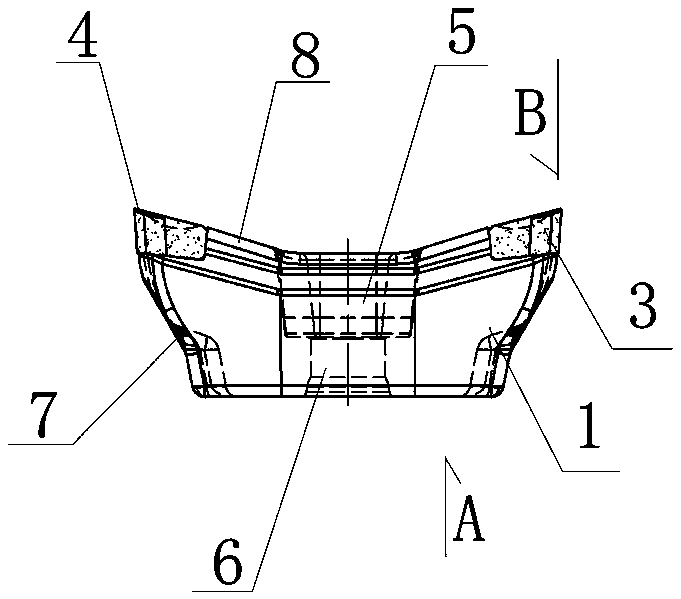

Combined material breaking tooth structure for waste treatment

ActiveCN106238153AGood structural firmnessGood combination fastnessGrain treatmentsWaste productEngineering

The invention discloses a combined material breaking tooth structure for waste treatment. The combined material breaking tooth structure is formed by combining a tooth head and a tooth seat, wherein the tooth head comprises a cuboid block-shaped body; two sides of the upper part of the block-shaped body are inwards retracted to form a working head part; a whole large hard alloy block with a forwards upwarp head sharp corner is inwards embedded into the sharp end part of the upper part of the working surface in the front in a tilting manner; slopes facing the outside of two sides of the middle part of the front surface of the block-shaped body are respectively arranged on the two sides, and cuboid hard alloy blocks are respectively embedded into the slopes; an arc-shaped transitional edge which extends into the block-shaped body in a tilting manner to the bottom is arranged at the lower part of the back surface of the block-shaped body; a downwards square groove is further formed in the back surface; a circular assembling through hole is formed in the middle of the square groove; the tooth seat is a tooth head base with an inwards sunken arc-shaped welding surface formed on the bottom surface and externally protruded arc-shaped surfaces formed on the front and rear sides; based on a middle line serving as a boundary on the upper surface of the tooth head base, a perpendicular concave gap where the tooth head is inserted is formed in one side, and an upwards protruded assembling pillar is integrally arranged on the other side; and a locating through hole located on the same central line with the circular assembling through hole is transversely formed in the assembling pillar. The combined material breaking tooth structure for waste treatment has the characteristics of reasonable structure and convenience for use and mounting, and the characteristics that the whole tooth head structure is high in firmness and wear resistance, so that the use cost is reduced, and the working efficiency is improved, and the like.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

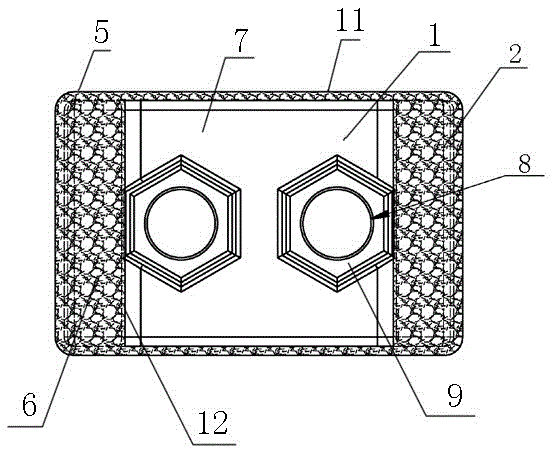

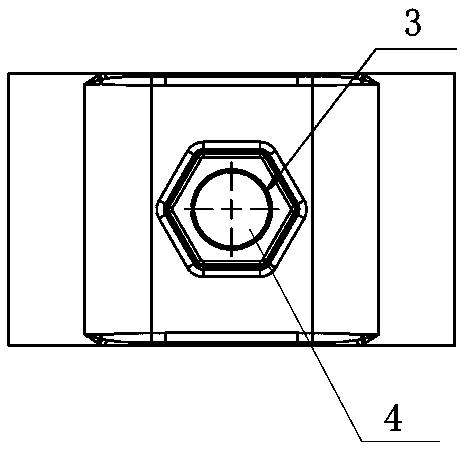

Mechanical tooth used for crushing materials

The invention discloses a mechanical tooth used for crushing materials. The mechanical tooth comprises a square flat tooth head body, wherein an upper surface of the tooth head body is a working surface; an oblique upward sharp corner-shaped tool angle body is arranged on one end side of the working surface; an upwards-convex framework extends from the sharp corner-shaped tool angle body to the other end on each of two sides of the working surface; a semi-circular groove surface extends from the sharp corner-shaped tool angle body outwards to the other end on the working surface between the two upwards-convex frameworks; a hexagon nut hole is formed in the working surface adjacent to the semicircular groove surface, and a positioning round hole is vertically formed in the center of the hexagon nut hole; the lower surface of the tooth head body is an assembly surface; and two sides of the assembly surface are correspondingly provided with downwards-convex positioning frameworks corresponding to the upwards-convex frameworks. The mechanical tooth has the characteristics that structure is reasonable; use and assembly are convenient; an integral tooth head structure is good in firmness and is abrasion-resistant, so that use cost is lowered, working efficiency is improved; and the like.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

Gold-ingot-shaped tooth for waste treatment

InactiveCN106238149AReasonable structureEasy to use and installGrain treatmentsWaste treatmentEngineering

A gold-ingot-shaped tooth for waste treatment comprises a gold-ingot-shaped pressing block. Hard crushed alloy welding layers are respectively arranged on the upper and lower oblique faces and two lateral sides of the upward pointed ends at two ends of the pressing block through build up welding to allow the pointed ends to form shapes wrapped with the hard crushed alloy welding layers. An upwardly-convex end plane is formed on the upper surface of the pressing block. The two sides of the end plane are connected with the upper oblique faces of the pointed ends at two ends through downward transition arcs. A vertically-upward threaded positioning hole is formed in the middle of the lower surface of the pressing block. A cross positioning groove using the central line of the threaded positioning hole as the center is formed in the lower surface of the pressing block. The bottom and lateral sides of the cross positioning groove are used as assembling faces. The gold-ingot-shaped tooth is reasonable in structure, convenient to use and mount, good in overall tooth head structural firmness, resistant to wear, capable of lowering use cost and increasing work efficiency, and the like.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

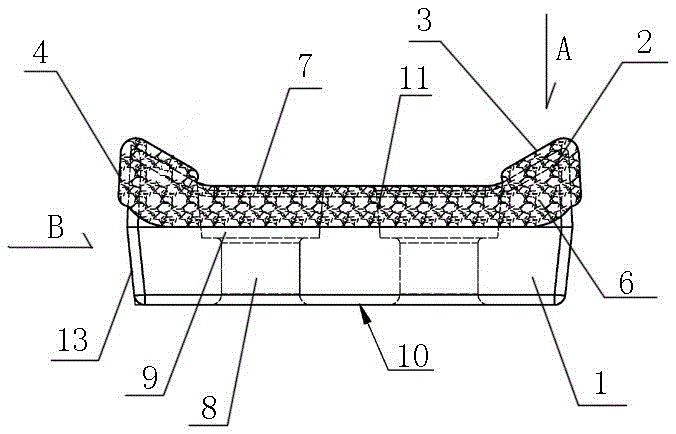

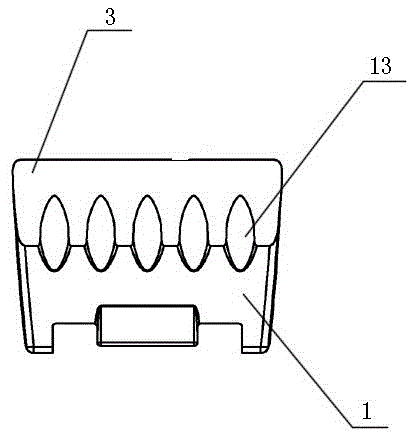

Tooth head structure used for waste treatment

InactiveCN106238173AGood structural firmnessImprove wear resistanceGrain treatmentsEngineeringCemented carbide

The invention discloses a tooth head structure used for waste treatment. The tooth head structure comprises a cuboid-shaped pressing block body. Tooth end parts warped upwards are arranged on the two symmetrical long end sides of the upper face of the pressing block body correspondingly, and a transverse rectangular notch is formed in each tooth end part from top to bottom. At least four cemented carbide blocks arranged side by side are sequentially connected into each notch in a welded mode, and the head end of each cemented carbide block is in a sharp corner shape which is warped upwards slightly. The upper surface of the pressing block body is a working plane. Two positioning through holes evenly distributed along the center line are formed in the middle position of the working plane. The working plane is further provided with two hexagonal nut holes with the respective positioning through holes located in the same hole center line. An assembling plane is arranged on the lower surface of the pressing block body. The area of the upper surface of the pressing block body is larger than that of the lower surface of the pressing block body. Oblique side edges which are shrunken inwards from top to bottom are formed on the four side edges of the pressing block body correspondingly, so that a positioning assembly shape is formed. The tooth head structure has the characteristics that the structure is reasonable, using and installing are convenient, the whole tooth head structure is good in firmness, abrasion resistance is high, and therefore the working efficiency is improved, and the service life is prolonged.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

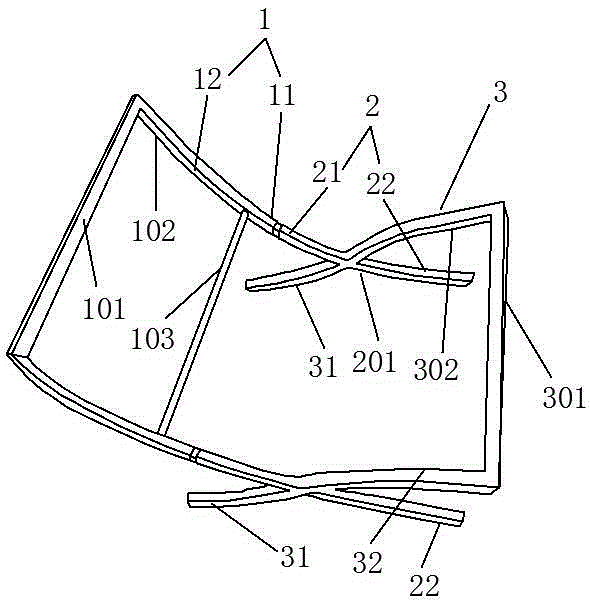

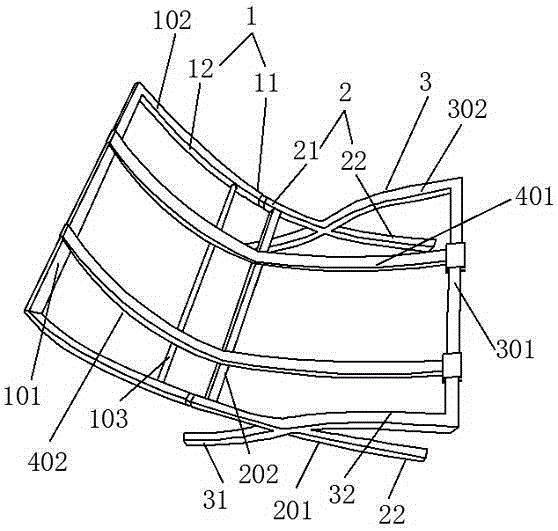

Detachable sofa support

InactiveCN105380436AReduce handling costsSimple structureStoolsChairsSoftware engineeringMechanical engineering

The invention relates to a detachable sofa support. The detachable sofa support comprises a first support, a second support and a third support. The first support is provided with a first connection part and a rear support part for supporting a sofa backrest. The second support is provided with a second connection part connected to the first connection part. The second support comprises a support part. The third support is provided with a second support part, wherein the second support part and the support part of the second support support the sofa backrest together, and also is provided with a front support part for supporting a sofa seat. The detachable sofa support has a simple structure, can be assembled conveniently, is convenient for transport, has good structure firmness, greatly reduces a sofa carrying cost and is suitable for large scope promotion.

Owner:王剑

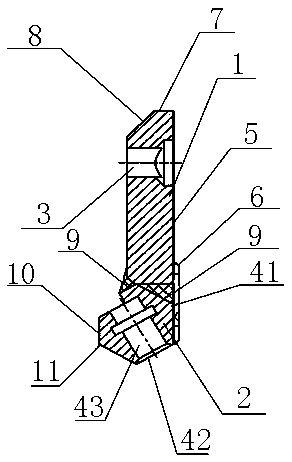

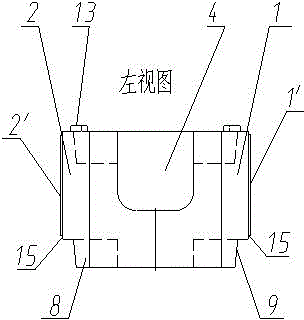

Combination scrap tooth structure for waste treatment

ActiveCN106216054BGood structural firmnessGood combination fastnessGrain treatmentsVertical planeWaste product

A combined material crushing tooth structure used for waste processing is formed by combining a tooth head with a tooth holder. The tooth head comprises a blocky body with one side face shaped like a flag. The front face of the blocky body is a working face. Two hard alloy blocks which are connected in parallel and are each provided with a head sharp corner are obliquely embedded in the sharp end portion of the upper portion of the working face. Vertical inclined faces aligned with the outer lateral sides of the two head sharp corners correspondingly are arranged on the two outer sides of the front face of the blocky body. Long-strip-shaped hard alloy strips are embedded in the vertical inclined faces on the two outer sides and a vertical plane in the middle correspondingly. An inner concave part matched with the tooth holder and connected with the tooth holder in an inserted manner is arranged on the lower face of the blocky body. The tooth holder comprises a tooth base, wherein a connection end portion matched with the inner concave part of the blocky body is arranged on the front end portion of the tooth base, the rear end portion of the tooth base is in a conical shape, an outwards-protruding triangular part is formed in the middle of the upper portion of the tooth holder, and an arc-shaped welding face is arranged on the lower face of the connection end portion and the lower face of the tooth base. The combined material crushing tooth structure has the beneficial effects that the structure is reasonable, use and installation are convenient, the whole tooth head is good in structure firmness, wear resistance is achieved, the binding strength of the tooth head and the tooth holder is good, the mutually-combined structure is reasonable, and therefore the use cost is reduced, and the work efficiency is improved.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

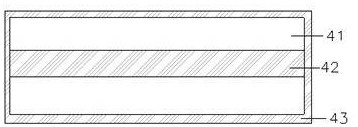

Corner brick for hollowed-out, self-centering, lock-jointed, anti-seismic wall bricks

The invention relates to a quoin brick of a hollowed automatic centering seam-locking shock-resistant wall brick. The quoin brick comprises an inner wall panel, an outer wall panel and a clapboard connected with the inner wall panel and the outer wall panel, wherein a concave gap is formed in the middle-upper part of the clapboard. The quoin brick is characterized by also comprising an end panel and an auxiliary clapboard, wherein the distance between the outer surface of the end panel and the outer side surface of the auxiliary clapboard is equal to that between the outer surfaces of the inner and outer wall panels; the part encircled by the outer side surface of the auxiliary clapboard and the end surfaces of the inner and outer wall panels is structurally a half of the wall brick; an inverted frustum counter bored hole parallel to the inner edge surface of a through hole is formed in the upper part of the through hole which is encircled by the inner and outer wall panels, the clapboard and the end panel; a U-shaped inverted frustum is grown on the lower surface of a U-shaped opening encircled by the inner and outer wall panels and the clapboard; a square inverted frustum ring is grown on the lower surface of a square ring encircled by the end panel, the auxiliary clapboard and the inner and outer wall panels. By using the quoin brick disclosed by the invention to build a wall, the labor intensity is low, the efficiency is high, and the built wall is firm, has a good shock-resistant effect and can be butted with the wall brick.

Owner:湖南园艺建筑集团有限公司

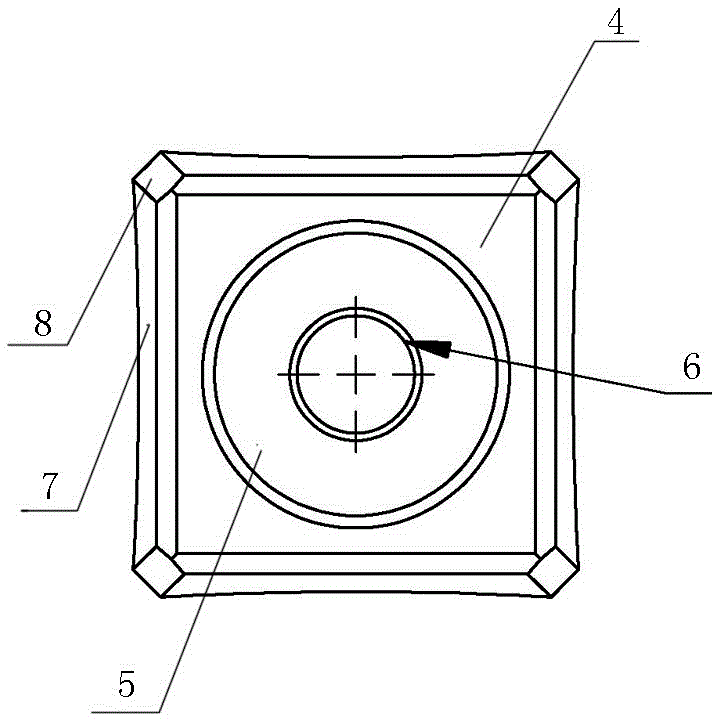

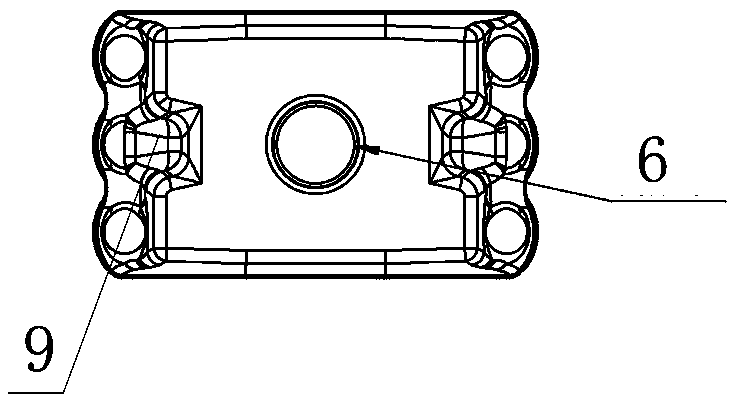

Pulverizer and mechanical tooth for waste treatment

The invention discloses a pulverizer and a mechanical tooth for waste treatment. A blocky pressing block body is included. Downward strip-shaped concave gaps are arranged on the two symmetric sides ofthe upper face of the pressing block body, at least three hard alloy shoes which are connected side by side to form a whole are embedded and welded to the gaps, the head ends of the hard alloy shoesform sharp-corner-shaped head tip parts which is outwards and slightly cocked up, a hexagonal positioning single hole is formed in the middle of the upper face of the pressing block body, an assembling through hole is formed in the middle of the hexagonal positioning single hole, inclined downward inwards-shrunk surfaces are arranged on the two symmetric side faces, that is the outer sides of thehard alloy shoes, of the pressing block body, and the pressing block body forms a shoe-shaped gold ingot shape. The pulverizer and the mechanical tooth have the beneficial effects that use and mounting are convenient, the whole structure firmness is good, wear resistance is achieved, the combination of the tooth and a tooth holder is good in firmness, the combination structure is reasonable, and work efficiency is improved.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

A special sawing device for wood block processing

ActiveCN109352491BSimple structureEasy to useGrinding carriagesGrinding machinesTemperature controlInsulation layer

The invention relates to a special sawing device for wood block processing, which includes a shell, the top of the shell is provided with a feed port, the feed port is provided with a one-way valve, and the right side of the feed port is connected to a temperature controller. The temperature controller is connected to the heating device on the inner cavity of the shell, an insulation layer is provided between the inner cavity and the shell, the heating device is connected to a blowing device, and the blowing device is fixed on the inner wall of the inner cavity, and through the fixing piece Fixed, the fixed plate provided at the bottom of the inner cavity, the fixed plate and the bottom of the inner cavity are at 5-8 degrees, the top of the fixed plate is provided with a shock-absorbing layer, and the slightly lower end of the fixed plate is connected to the discharge port. The discharge port is provided with a stop valve, the discharge port is provided with a protective cover, the outer wall of the housing is provided with a motor, and the motor is provided with a control panel. In the present invention, the heating speed is fast, the application range is wide, and the work efficiency and precision are effectively improved. The blowing device accelerates the uniform distribution of heat, improves the drying rate and uniform performance, has low cost, and improves comprehensive economic benefits.

Owner:济宁麟鼎信息科技有限公司

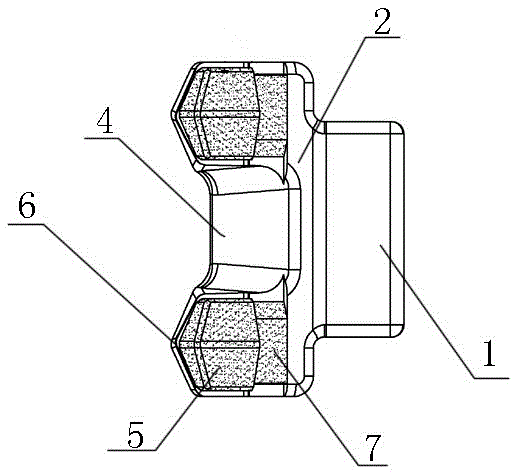

Mechanical tooth for pulverizer and waste treatment

InactiveCN109046607AReasonable structureEasy to use and installGrain treatmentsSingle holePulverizer

The invention discloses a mechanical tooth for a pulverizer and a waste treatment, comprising a block-shaped pressing block body. The mechanical tooth is characterized in that sharp tool angle workingends which are obliquely upward and cone-shaped are arranged on the two symmetrical side portions on the top surface the pressing block body; a hexagonal positioning single hole is formed in the middle position on the top surface of the pressing block body; a mounting through hole is formed in the middle position on the top surface of the hexagonal positioning single hole; a step surface which isinclined downward and inner tapered is arranged on the two symmetrical sides surfaces of the pressing block body, i.e., the outer side surfaces of the working ends, so that the pressing block body forms into a treasure shape. The mechanical tooth for the pulverizer and the waste treatment is characterized in that the tooth is reasonable in structure, convenient to use and mount, good in overall structure firmness, is wear-resisting, good in bonding firmness with a tooth base, and reasonable in a combined structure, thereby improving the work efficiency.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

Footstool frame

The invention relates to a footstool frame, which comprises two support frames and connecting bodies, wherein the support frames are oppositely arranged and a flat footrest plane is formed on the upper parts of the support frames, and the connecting bodies are used for connecting the support frames; each of the support frames comprises a first support body and a second support body; both the first and the second support bodies comprise connecting parts, supporting parts and transition parts which are used for connecting the connecting parts with the supporting parts; the first and second support bodies are connected by virtue of respective transition parts; matching parts are arranged at two ends of the connecting body; and the support frames and the connecting body are detachably connected by virtue of the connecting parts and the matching parts. The footstool frame disclosed by the invention is simple in structure, convenient to assemble, convenient to transport and good in structure firmness; the footstool frame is capable of greatly reducing sofa carrying cost; and the footstool frame is suitable for popularization in a large scope.

Owner:王剑

Mechanical tooth head for pulverizer and waste disposal

The invention discloses a mechanical tooth head structure for a pulverizer and waste disposal. The mechanical tooth head structure comprises a block-shaped lock block body, wherein upwardly protrudinggranular cemented carbide welding layers are welded on the upper two symmetrical side portions of the lock block body. Outer protruding blocks integrated with the lock block body are arranged at themiddle positions of the two symmetrical sides of the lock block body, wherein the thickness of the outer protruding blocks is equal to the thickness of the lock block body. A hexagonal positioning single hole is formed in the upper middle position of the lock block body, and an assembly through hole is formed in the middle of the hexagonal positioning single hole. Surfaces inclined downwards and retracted inwards are arranged on the two symmetrical side surfaces of the lock block body, that is, the outer side surfaces of the granular cemented carbide welding layers. The mechanical tooth head structure has the characteristics of reasonable structure, convenient use and installation, good firmness of the overall structure, abrasion resistance, good binding strength with a tooth holder, reasonable combined structure, improved work efficiency and the like.

Owner:ZHEJIANG PACIFIC MACHINERY CO LTD

A hollowed-out self-centering lock seam anti-seismic wall brick

The invention relates to a hollow automatic-centering stitch-locking anti-seismic wall body brick in the field of building materials. The hollow automatic-centering stitch-locking anti-seismic wall brick comprises an inner wall panel, an outside wall panel and two partition boards, wherein concave notches are formed in the middle upper parts of the two partition boards; the wall body brick is characterized in that inverted frustum counter bores parallel to inner edge surfaces of through holes formed by the inner wall panel, the outside wall panel and the two partition boards in a surrounding manner are formed in the upper parts of the through holes; a U-shaped inverted frustum is formed in each of the lower surfaces of two U-shaped openings formed by the inner wall panel, the outside wall panel and the two partition boards in a surrounding manner; conical surfaces of the U-shaped inverted frustums are matched with half of conical surfaces of the inverted frustum counter bores which are formed in the upper parts and corresponding to the U-shaped inverted frustums; U-shaped inverted frustums formed in the lower surfaces of U-shaped openings of two adjacent wall bricks form a sealed inverted frustum ring matched with one inverted frustum counter bore in the upper part. The wall brick provided by the invention has the advantages that the construction is convenient and fast, the labor intensity is greatly reduced, the walling efficiency is improved, the structural firmness and the unity of a built wall body are good, and an anti-seismic effect is good.

Owner:广州市尺道室内装饰设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com