Combined material breaking tooth structure for waste treatment

A technology for scrap and waste products, applied in the field of combined scrap tooth structure for waste treatment, can solve the problems of unreasonable structural design, easy damage to the tooth head structure, increased use cost, etc. Efficient, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

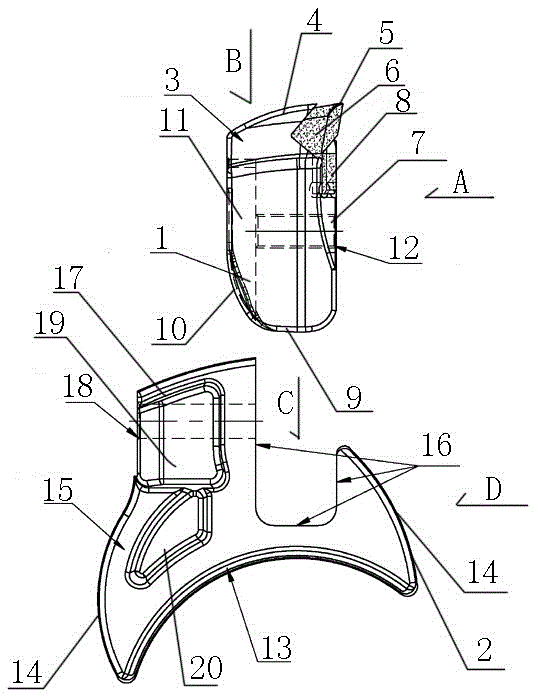

[0013] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a combined scrap tooth structure for waste treatment according to the present invention is composed of a tooth head 1 and a tooth seat 2.

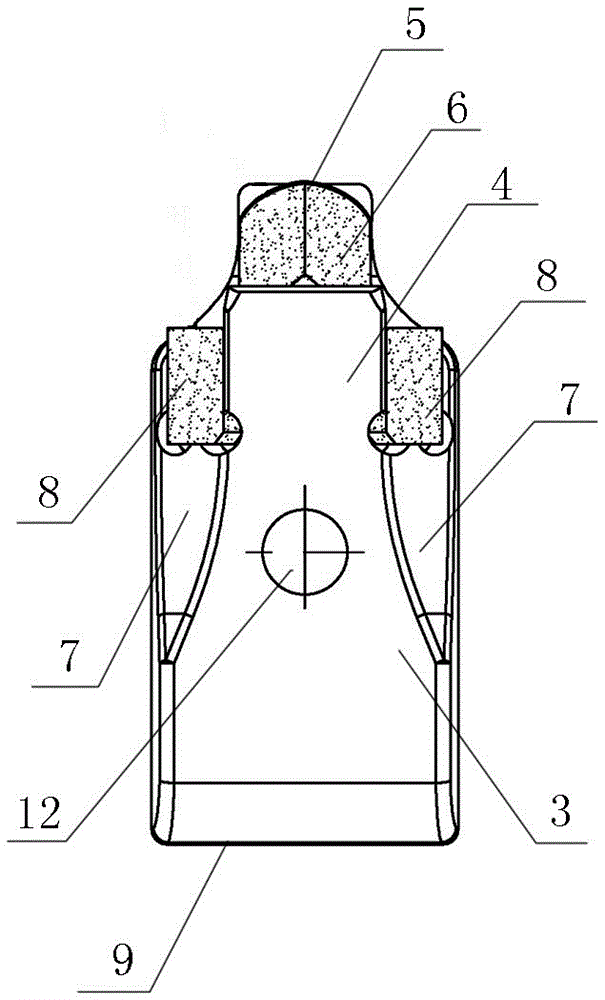

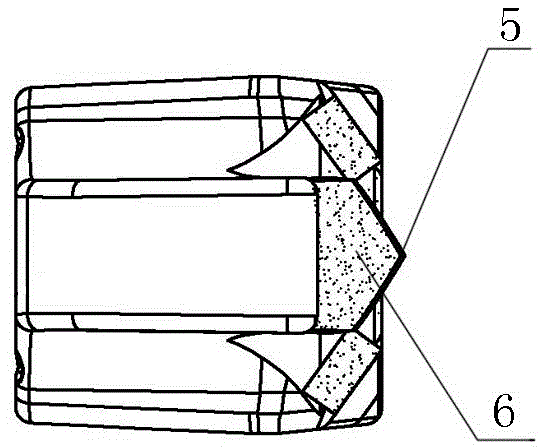

[0014] combine figure 2 , 3 As shown, the tooth head 1 according to the present invention includes a cuboid block body 3, the two sides of the upper part of the block body 3 are retracted into a working head 4, and the upper tip of the front working surface is obliquely embedded. There is a whole block of large cemented carbide block 6 with pointed corners 5 facing upwards. The two sides of the middle part of the front of the block body 3 are respectively provided with slopes 7 facing the sides, and cuboids are inlaid on the slopes 7 respectively. Carbide block 8; the lower part of the back of the block body 3 is provided with an arc-shaped transition edge 10 obliquely inward to the bottom 9, and an inward and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com