A hollowed-out self-centering lock seam anti-seismic wall brick

An automatic centering and anti-seismic wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of not reducing the labor intensity of wall-building efficiency, uneven seam width, poor appearance quality, and uneven wall brick seams, etc., to achieve Improve the efficiency of wall building, convenient and fast construction, and good integration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

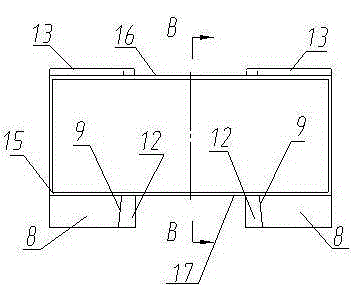

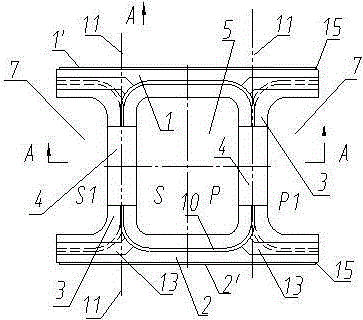

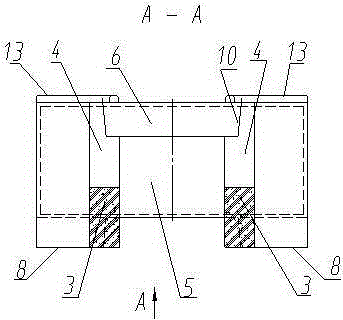

[0031] Such as Figure 1-17 As shown, a hollowed-out self-centering lock seam anti-seismic wall brick includes an inner wall panel 1, an outer wall panel 2 and two partitions 3 connected with the inner wall panel 1 and the outer wall panel 2, and the two partitions 3 has a concave gap 4 in the upper part, the upper surface 16 of the inner wall panel 1, the outer wall panel 2 and the partition 3 is on the same plane, and the lower surface 17 of the inner wall panel 1, the outer wall panel 2 and the partition 3 is on the same plane. On the same plane, there is an equal distance between the outer surfaces 1' and 2' of the inner wall panel 1 and the outer wall panel 2, and the through hole 5 surrounded by the inner wall panel 1, the outer wall panel 2 and the two partitions 3 The upper end is provided with an inverted cone counterbore 6 parallel to the inner side of the through hole, and the lower surfaces 17 of the two "U"-shaped openings 7 surrounded by the inner wall panel 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com