Bottom guard plate structure of front bumper

A front bumper and plate structure technology, applied in the direction of bumpers, vehicle parts, vehicle safety arrangements, etc., can solve problems such as vibration durability failure, chatter, modal deviation, etc., and achieve good overall connection stiffness and structural firmness , Conducive to the effect of reliable and durable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

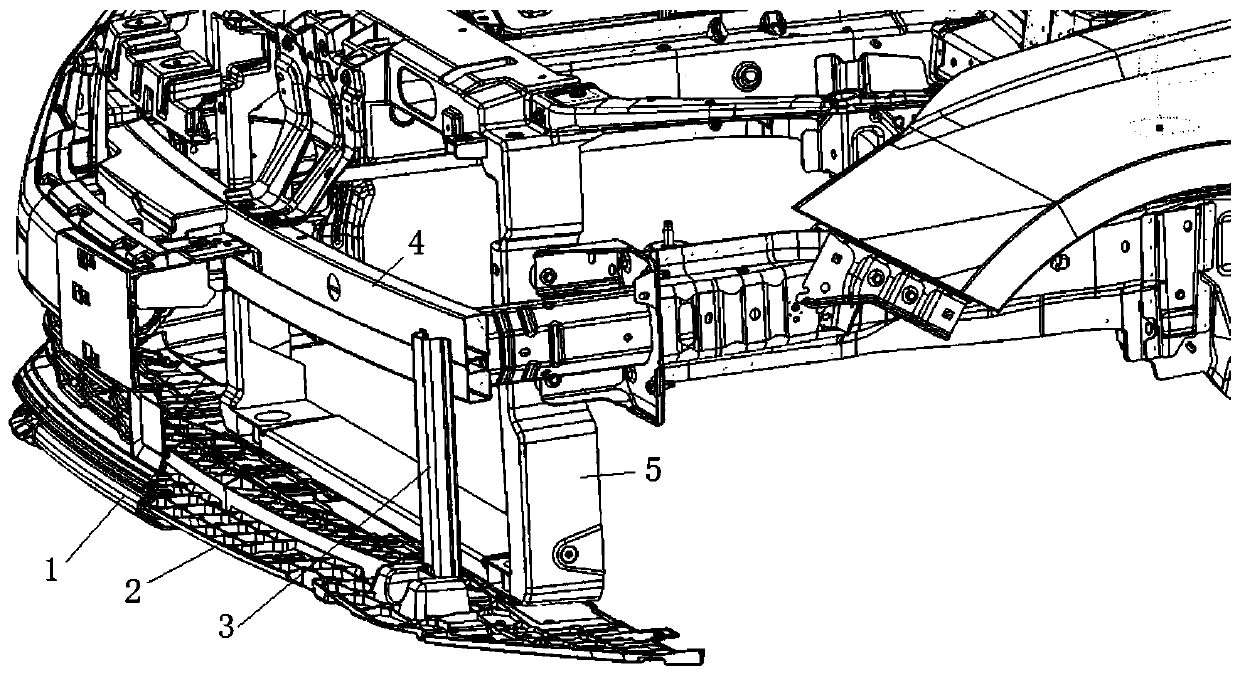

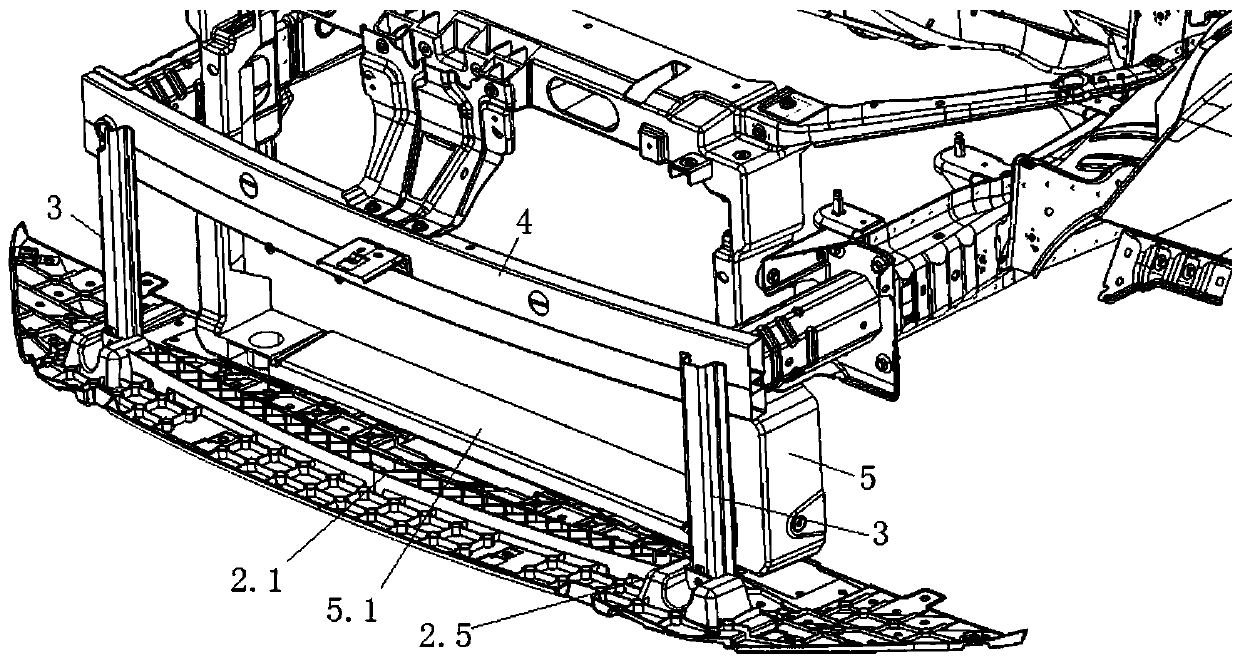

[0016] Such as Figure 1-5 As shown, a front bumper bottom guard structure of the present invention includes a bottom guard body 2, the bottom guard body 2 is installed between the front frame 5 and the front bumper 1, the front end of the bottom guard body 2 is connected to the front bumper The bar 1 is overlapped, the rear end is fixedly connected with the lower beam 5.1 of the front-end frame 5, and the bottom guard body 2 closes the gap between the front bumper 1 and the front-end frame 5, so as to improve the wind resistance of the vehicle and the heat dissipation performance of the cabin.

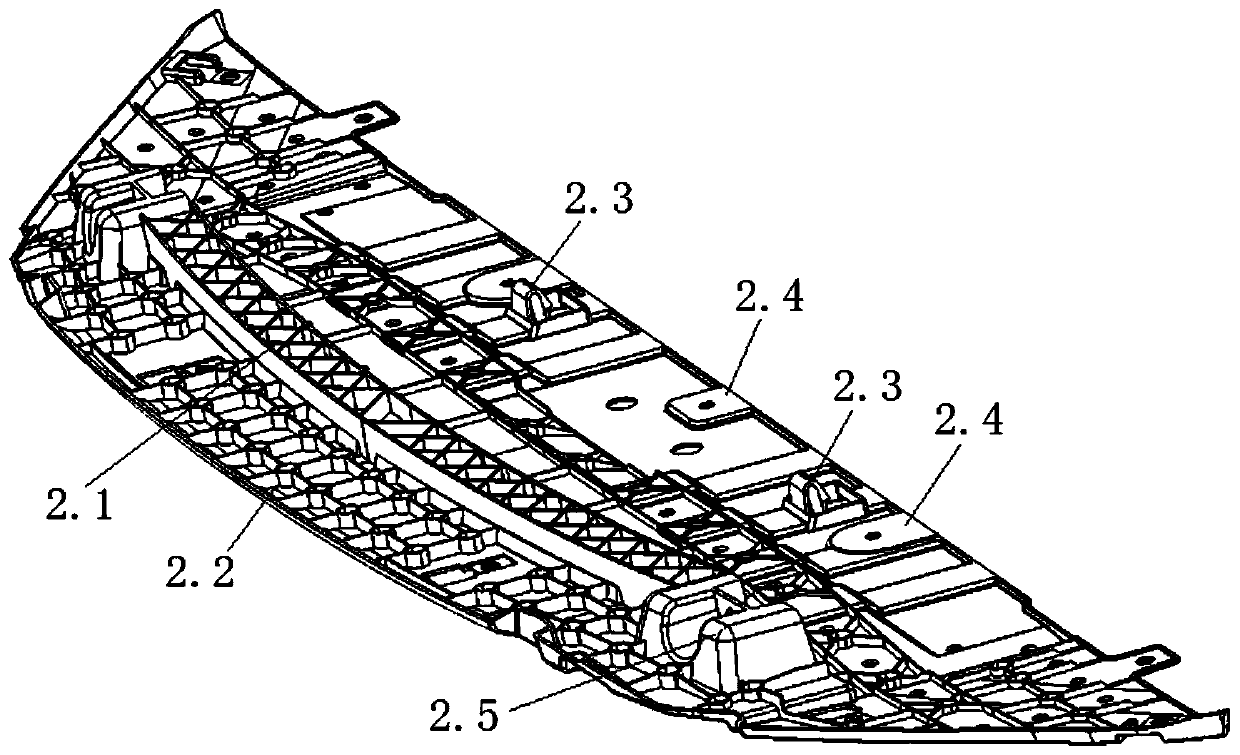

[0017] The bottom guard body 2 is provided with calf support beams 2.1 and horizontal and vertical grid ribs 2.2, and the horizontal and vertical grid ribs 2.2 are arranged in the overlapping area between the bottom guard body 2 and the front bumper 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com