Alumina type high-temperature resistant corrosion resisting high strength alloy steel and preparation method thereof

A technology of aluminum oxide and high temperature resistance, which is applied in the field of austenitic alloy steel, can solve problems such as heat exchanger tube explosion accidents, difficult substrate steel protection, and easy failure, so as to prevent oxidation and corrosion, improve high temperature resistance, and good The effect of welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

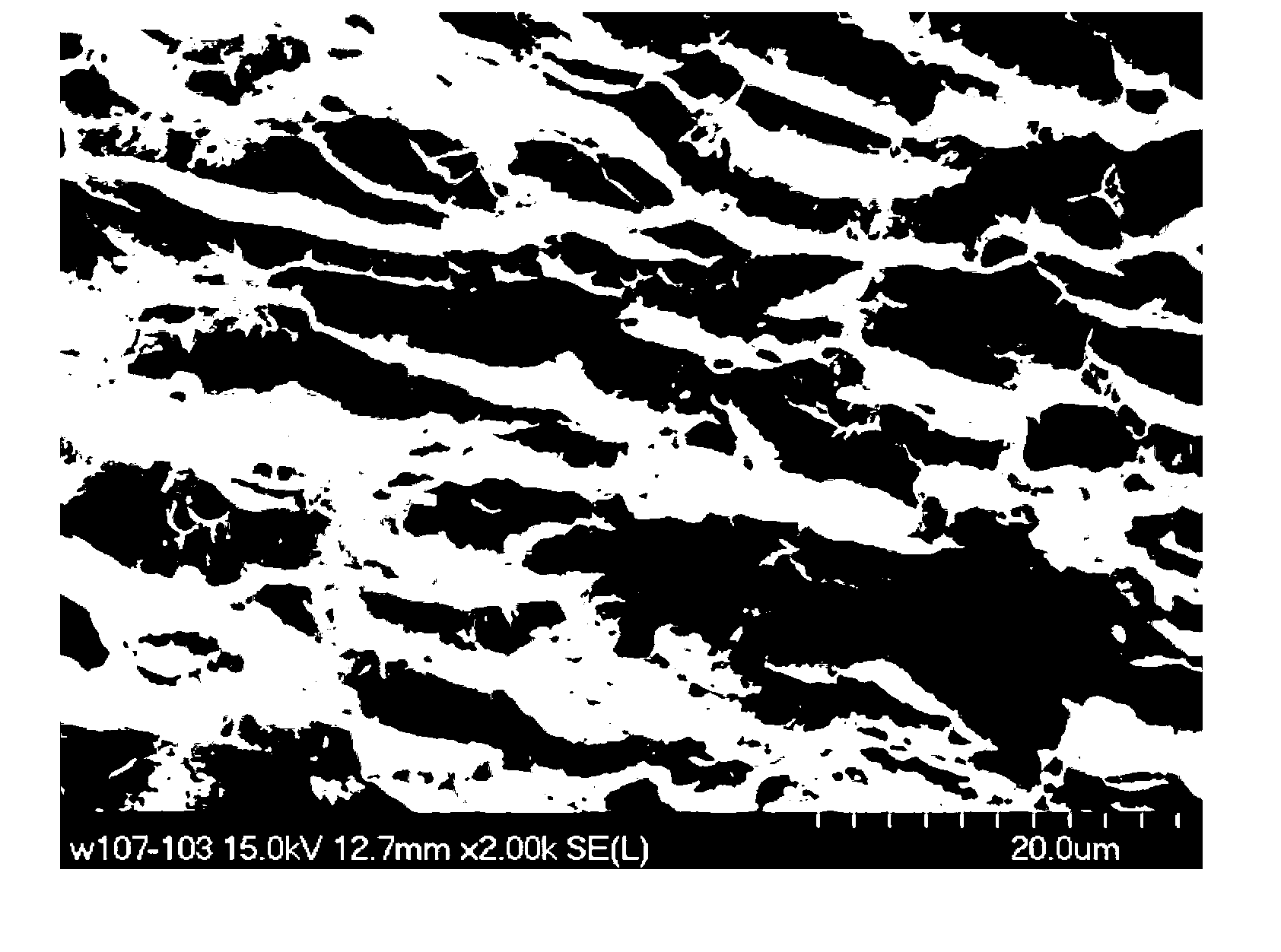

Image

Examples

specific Embodiment approach 1

[0022] 1. According to the weight ratio of the elements in the product, the composition is C0.03-0.08%, Cr18-24%, Ni8-16%, Mn0.5-1%, Mo1-2%, W1-5%, Co0.05-0.5 %, Al3-8%, Nd0.1-2%, S≤0.007%, P≤0.02% and the balance of Fe are ready for alloying elements.

[0023] 2. Carry out chemical analysis of each element before smelting to ensure the accuracy of element content.

[0024] 3. Put the selected charge into the electric arc furnace for smelting, and wait for 10 minutes when the temperature of the furnace rises to 1680. Then transfer to ladle refining furnace (LF furnace) + vacuum argon-oxygen decarburization refining furnace (VOD furnace) for further refining, and complete the decarburization and degassing of alloy steel in this process. to obtain a clean slab.

[0025] The production process of the present invention adopts an electric arc furnace + a ladle refining furnace (LF furnace) + a vacuum argon-oxygen decarburization refining furnace (VOD furnace), and realizes the fo...

specific Embodiment approach 2

[0028] 1. According to the weight ratio of the elements in the product, the composition is C0.05-0.06%, Cr20-22%, Ni10-14%, Mn0.7-0.9%, Mo1.2-1.8%, W2-4%, Co0.1 The ratio of -0.4%, Al5-7%, Nd0.5-1.5%, S≤0.007%, P≤0.02% and the balance of Fe is ready for alloying elements.

[0029] 2. Carry out chemical analysis of each element before smelting to ensure the accuracy of element content.

[0030] 3. Put the selected charge into the electric arc furnace for smelting, and wait for 10 minutes when the temperature of the furnace rises to 1680. Then transfer to the ladle refining furnace (LF furnace) + vacuum argon oxygen decarburization refining furnace (VOD furnace) for further refining and then tap the steel.

specific Embodiment approach 3

[0031] 1. According to the weight ratio of the elements in the product, the composition is C0.06%, Cr21%, Ni12%, Mn0.8%, Mo1.6%, W3%, Co0.3%, Al7%, Nd1.2%, S≤ The ratio of 0.007%, P≤0.02% and the balance of Fe is ready for alloying elements.

[0032] 2. Carry out chemical analysis of each element before smelting to ensure the accuracy of element content.

[0033] 3. Put the selected charge into the electric arc furnace for smelting, and wait for 10 minutes when the temperature of the furnace rises to 1680. Then transfer to the ladle refining furnace (LF furnace) + vacuum argon oxygen decarburization refining furnace (VOD furnace) for further refining and then tap the steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com