Insulating concrete material and preparation technology

A technology for concrete and cementitious materials, applied in the field of special performance building materials and their preparation, can solve the problems of high humidity, high cost, low resistivity, etc., and achieve the effects of simple preparation process, reliable insulation performance, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for an insulating concrete material, comprising the steps of:

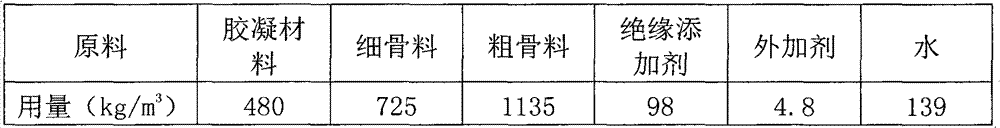

[0030] 1) Take raw materials according to Table 1:

[0031] Table 1 Embodiment 1 raw material proportioning

[0032]

[0033] The cementitious material is: 70% cement + 30% fly ash

[0034] Fine aggregate is: river sand

[0035] Coarse aggregate is: crushed stone

[0036] The insulation additive is: 98% ethylene-vinyl acetate copolymer emulsion + 2% silane waterproofing agent

[0037] The admixture is: polycarboxylate high-efficiency water reducer

[0038] (2) Mix and stir the cementitious material, fine aggregate and coarse aggregate together for 2 minutes, then add insulating additives, admixtures and water, continue stirring for 3 minutes, and then mold it;

[0039] (3) After the concrete is hardened and removed from the mold, it is first cured in an environment with a relative humidity of 95% for 7 days, and then cured in an environment with a relative humidity of 20% for 28...

Embodiment 2

[0041] A preparation method for an insulating concrete material, comprising the steps of:

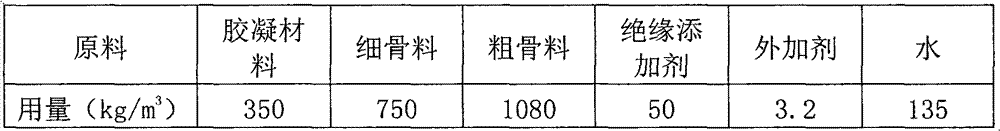

[0042] 1) Take raw materials according to Table 2:

[0043] Table 2 Embodiment 2 raw material proportioning

[0044]

[0045] The cementitious material is: 100% cement

[0046] Fine aggregate is: machine-made sand

[0047] Coarse aggregate is: crushed stone

[0048] Insulation additives: 80% vinyl acetate and higher fatty acid vinyl ester copolymer powder + 20% penetrating crystalline waterproofing agent

[0049] Admixture: 95% naphthalene superplasticizer + 5% defoamer

[0050] (2) Mix and stir the cementitious material, fine aggregate and coarse aggregate together for 1 minute, then add insulation additives, admixtures and water, and continue stirring for 5 minutes before molding into a mold;

[0051] (3) After the concrete is hardened and demoulded, it is cured for 14 days in an environment with a relative humidity of 100%, and then cured for 56 days in an environment with a re...

Embodiment 3

[0053] A preparation method for an insulating concrete material, comprising the steps of:

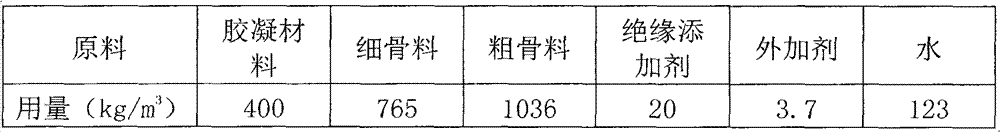

[0054] 1) Take raw materials according to Table 3:

[0055] Table 3 Embodiment 3 raw material proportioning

[0056]

[0057] The cementitious material is: 60% cement + 35% fly ash + 5% silica fume

[0058] Fine aggregate is: river sand

[0059] Coarse aggregate is: crushed stone

[0060] Insulation additives: 90% silane waterproofing agent + 10% styrene and butadiene copolymer powder

[0061] The admixture is: 99% melamine-based superplasticizer + 1% air-entraining agent

[0062] (2) Mix and stir the cementitious material, fine aggregate and coarse aggregate together for 3 minutes, then add insulation additives, admixtures and water, continue stirring for 2 minutes, and then mold it;

[0063] (3) After the concrete is hardened and removed from the mold, it is first cured in an environment with a relative humidity of 85% for 3 days, and then cured in an environment with a relati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com