Tooth head structure used for waste treatment

A tooth head and waste product technology, which is applied in the field of tooth head structure for waste product treatment, can solve problems such as unreasonable structural design, easy damage to the tooth head structure, and damage to the tooth head structure, and achieve reasonable structure, extended service life, and firmness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

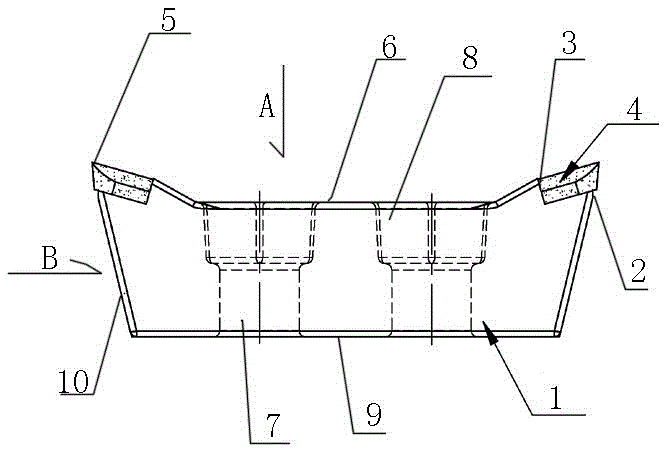

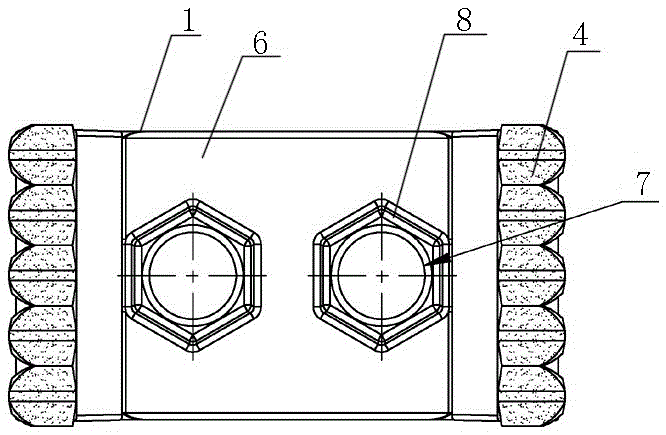

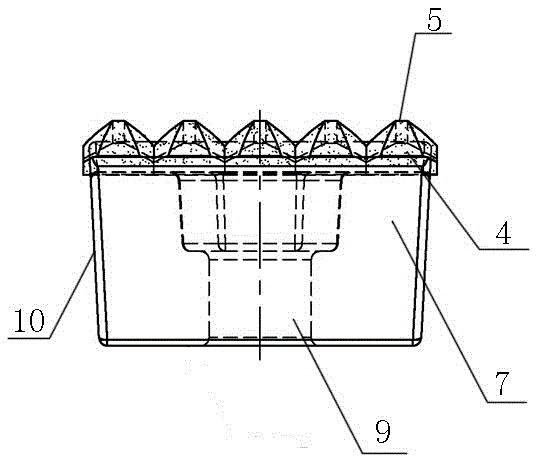

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a tooth head structure for waste product treatment according to the present invention includes a rectangular block body 1, and the upper two symmetrical long end sides of the block body 1 are respectively provided with upturned The tooth end 2 is provided with a vertically elongated notch 3 from top to bottom on the tooth end 2, and at least four cemented carbide blocks 4 arranged side by side are welded in sequence in the notch 3, and each block The head ends of the tungsten carbide block 4 are each in a slightly upturned pointed shape 5; the top of the briquetting body 1 is a working plane 6, and the middle position of the working plane 6 is provided with two positioning channels evenly distributed along the center line. hole 7, and two hexagonal nut holes 8 on the same hole center line as the respective positioning through holes 7 are arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com