Mechanical tooth for waste treatment

A technology of mechanical teeth and waste products, which is applied in the field of scrap machinery and equipment for waste treatment, can solve problems such as unreasonable structural design, easy damage to the tooth head structure, and increased use costs, and achieve reasonable structure, good firmness, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

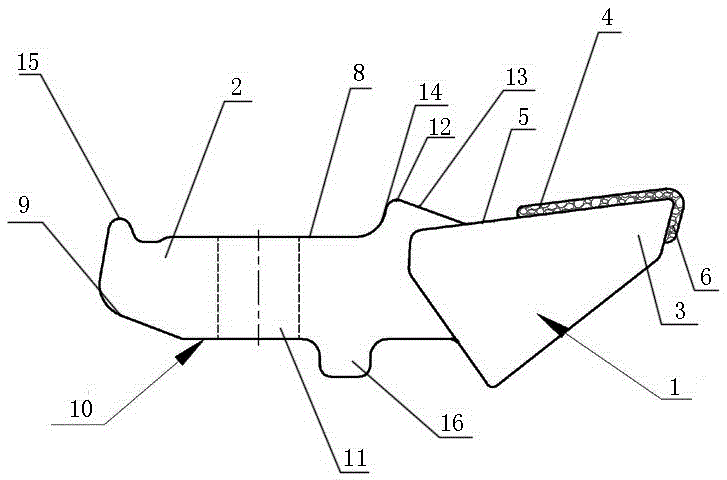

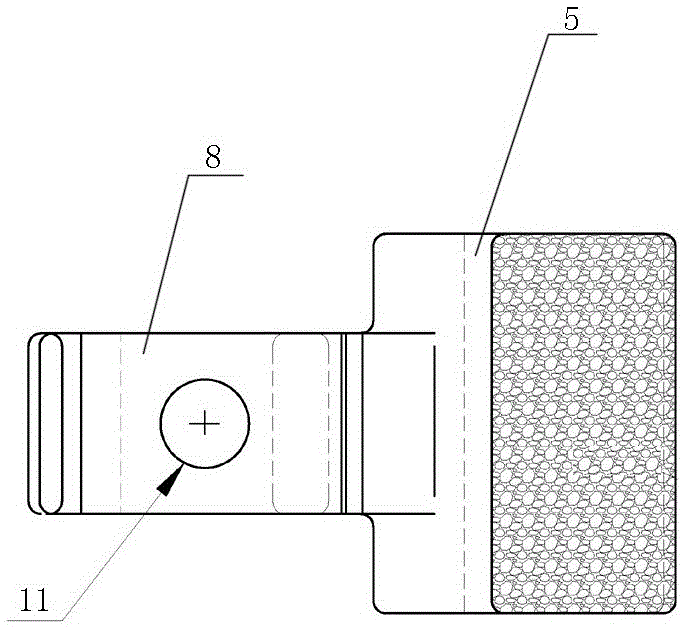

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, a mechanical tooth for waste disposal according to the present invention is composed of a block body 1 with a triangular cross-section at the front and a connecting handle 2 transversely connected to the middle of the block body 1-rear end angular shape, The two sides of the front end angle of the block body 1 are respectively provided with a hard alloy welding layer 4 enclosing the angle end 3, and the upper plane between the rear end angle and the front end angle is a working surface 5, wherein the hard The shattered alloy welding layer 4 covers at least half of the entire working surface 5, and the angled surface 6 and the lower slope 7 on the other front side form a small angled slope less than 180°. The small angled slope is provided with the angled surface Carbide crushed alloy welding layer 4; the connecting handle 2 is a cuboid handle integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com