Crusher tooth head of stone crusher

A stone crusher and tooth head technology, which is applied in the field of ore machinery and equipment, can solve problems such as affecting work efficiency, damage to machine tooth structure, and easy damage to machine tooth structure, so as to achieve convenient use and installation, reduce use cost, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

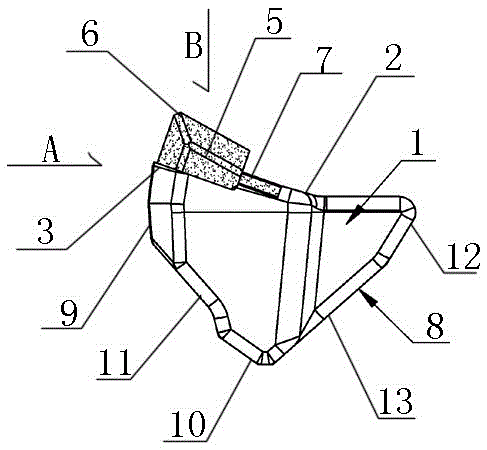

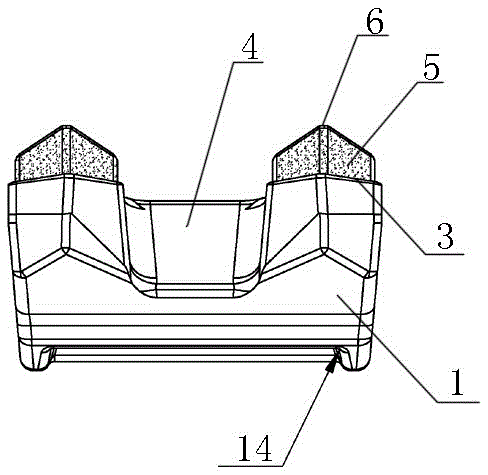

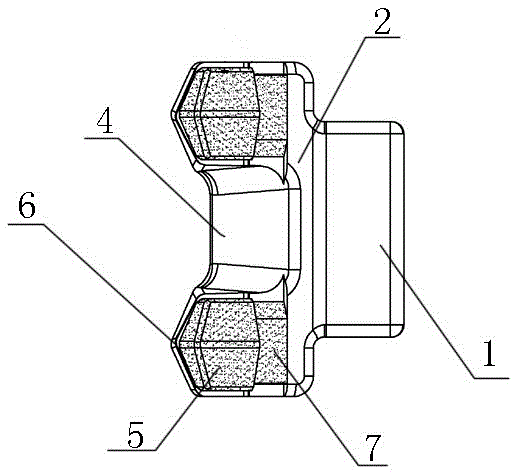

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a machine tooth head of a rock crusher according to the present invention includes a block-shaped tooth head body 1 that looks like an equilateral triangle when viewed from one side, and the upper surface of the tooth head body 1 is a working surface 2. The surface 2 is located at the front end and is provided with a pointed tooth head 3, and the two sides of the tooth head body 1 are respectively provided with an integrated outer bump 3 that is bounded downward from the upper working surface 2 and is larger than half of the area. The front end of the working surface 2 on the outer convex block 3 is a tooth head 3, and the middle of the tooth head 3 is arranged obliquely downward from the middle position of the working surface with a width greater than one-third of the entire width of the tooth head 3. The inclined-plane notch groove 4, and the tooth h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com