Method for positioning and bonding megawatt wind power blade web

A wind turbine blade and bonding method technology, applied in bonding methods, surface pretreatment bonding methods, adhesives, etc., can solve the problems of web slippage, inaccurate web positioning, waste of adhesives, etc. Increased firmness, fast installation, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

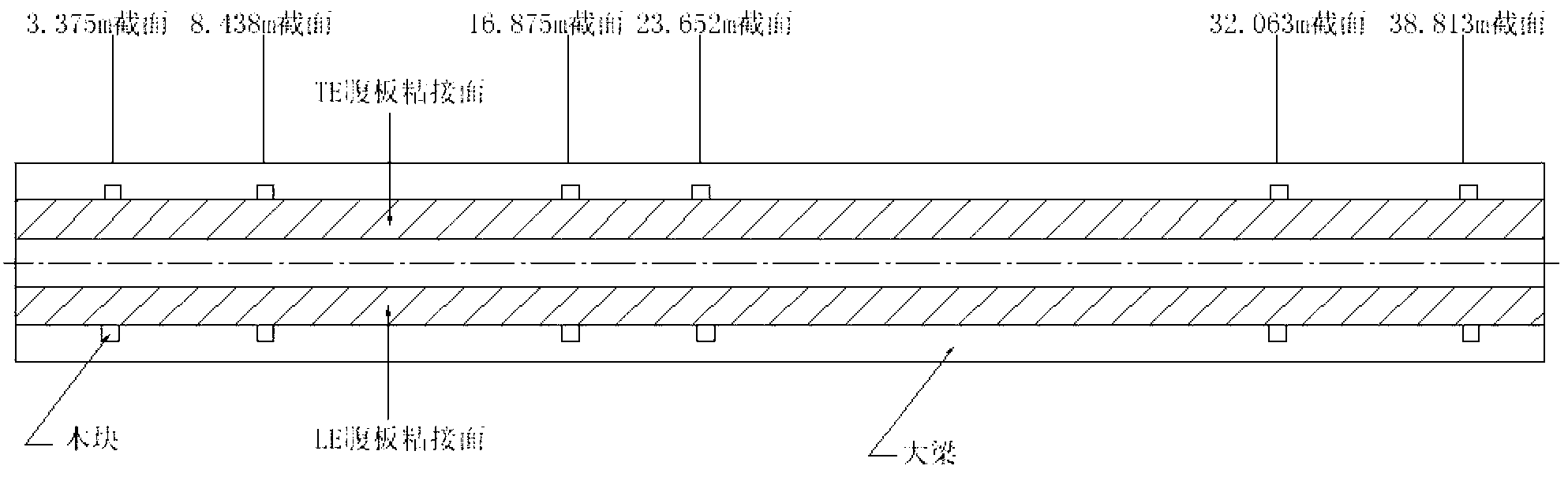

[0037] Example: such as figure 1 As shown, a method for positioning and bonding a megawatt wind turbine blade web, the method includes the following steps:

[0038] (1) Locate the position of the web on the girder of the SS shell and the girder of the PS shell: In order to protect the cleanliness of the bonding area of the web, select the 3.375m cross-section, 8.438m on the girder of the SS shell and the PS shell The m section, 16.875m section, 23.652m section, 32.063m section and 38.813m section are positioning sections, (the sections on the SS shell and PS shell are when making the girder of the SS shell and the girder of the PS shell, Based on the leaf root end faces of the girders of the SS shell and the PS shell, measure and mark the section along the length direction of the girders of the SS shell and the PS shell girder, for example, the 3.375m section is the distance between the leaves on the girder Root end surface 3.375m section), tear off the release cloth at the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com