Corner brick for hollowed-out, self-centering, lock-jointed, anti-seismic wall bricks

An automatic centering and anti-seismic wall technology, which is applied in the field of wall bricks and corner bricks, can solve the problem of affecting the integrity of the wall and the earthquake resistance, the upper and lower bricks cannot be automatically centered and the main alignment, and the upper and lower bricks cannot extend each other In order to improve the efficiency of wall-building, strengthen the strength, and facilitate the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

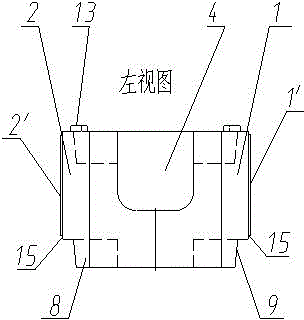

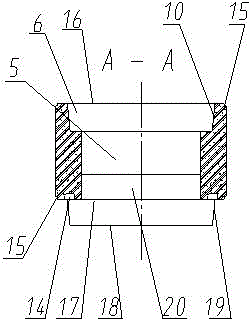

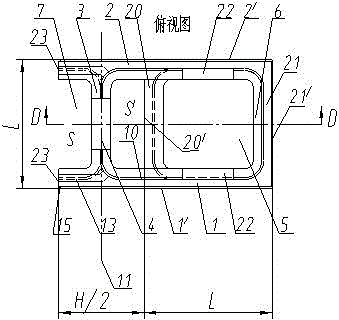

[0021] Such as Figure 1-9 As shown, a corner brick of a hollowed-out, self-centering, lock-seam seismic wall brick includes an inner wall panel 1, an outer wall panel 2, and a partition 3 connected to the inner wall panel 1 and the outer wall panel 2, and the partition 3 has a concave gap 4 in the upper part, the upper surface 16 of the inner wall panel 1, the outer wall panel 2 and the partition 3 is on the same plane, and the lower surface 17 of the inner wall panel 1, the outer wall panel 2 and the partition 3 is on the same plane. On the same plane, the outer surface 1' of the inner wall panel and the outer surface 2' of the outer wall panel are parallel to each other, which is characterized in that there is a terminal panel 21 and an auxiliary partition 20, and the end panel 21 and the auxiliary partition 20 and the partition 3 are parallel to each other and are connected with the inner wall panel 1 and the outer wall panel 2; The lower surface 17 is on the same plane, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com