Snow sweeper and land leveler tool apron structure

A technology for motor graders and snow plows, which is applied to earth moving machines/shovels, snow surface cleaning, construction, etc., can solve problems such as affecting work efficiency, collision with hard objects, encountering resistance, etc., so as to improve work efficiency, Good firmness and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

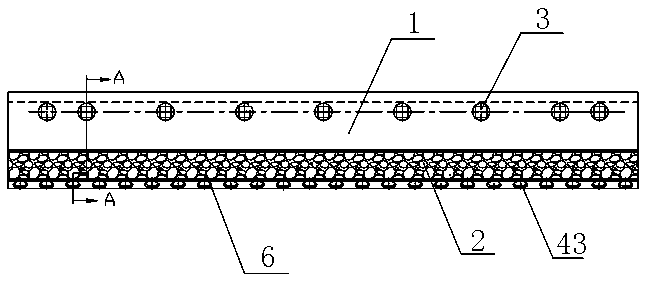

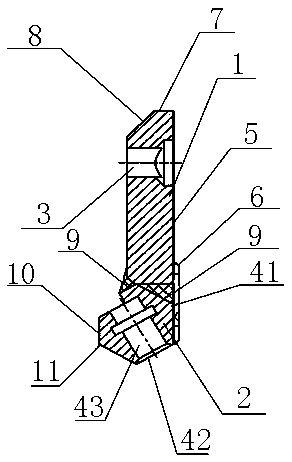

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, a kind of snowplow and flat machine tool seat structure of the present invention, it is mainly connected by a rectangular plate body 1 processed by a whole strip shape and a long strip shape steel plate body 2 processed by a whole strip shape Formed, the above-mentioned rectangular plate body 1 is provided with the bolt assembly hole 3 that is used for fixed installation, uniform distribution, and one side of this rectangular plate body 1 is welded on the long side that is connected with described equal-length strip shape. Steel plate body 2, and the working surface side of the elongated steel plate body 2 forms a 40-50° bending connection side 4, preferably 45°; wherein the upper working surface 41 is flush with the working surface 5 of the rectangular plate body 1 , the lower oblique working surface 42 is provided with a row of a plurality of cutte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com