Mechanical tooth used for crushing materials

A technology of mechanical teeth and crushed materials, which is applied in the direction of grain processing, etc., can solve problems such as unreasonable structural design, easily damaged tooth head structure, and damaged tooth head structure, and achieve reasonable structure, good firmness, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

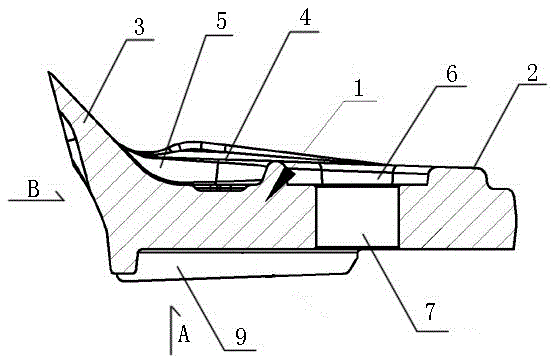

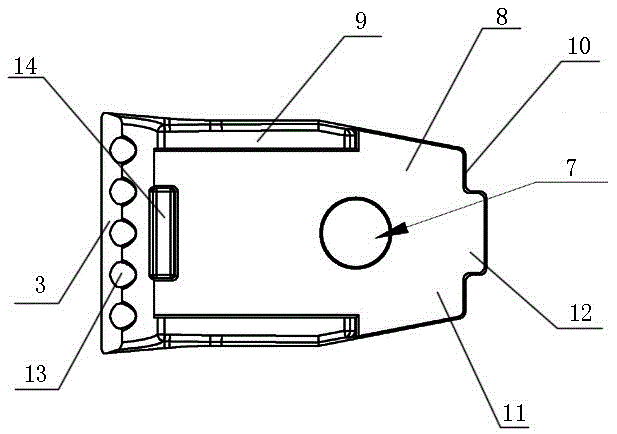

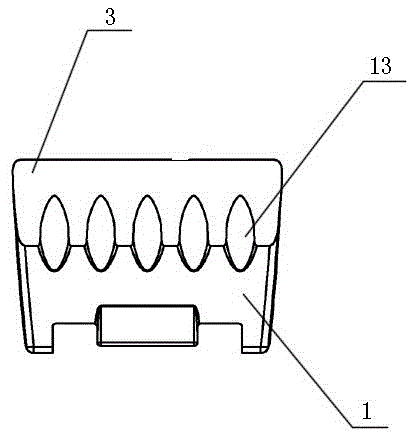

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-3 As shown, a mechanical tooth for crushing according to the present invention includes a square-shaped flat tooth head body 1 matched with the tooth seat in the crushing machine. The upper surface of the tooth head body 1 is a working surface 2, One end side of this working face 2 is provided with the obliquely upward pointed angle shape cutter angle body 3, the both sides of working surface 2, from the sharp angle shape cutter angle body 3 to the other end respectively extend a section of upper convex frame 4, and on both sides On the working surface 2 between the convex frames 4, a semicircular groove surface 5 is formed from the sharp-angled knife corner body 3 to the other end; on the working surface 2 adjacent to the semicircular groove surface 5 There is a hexagonal nut hole 6, and a positioning circular hole 7 is arranged vertically downward in the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com